low beam ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 79 of 1640

Engine Removal/Installatio n

Installation

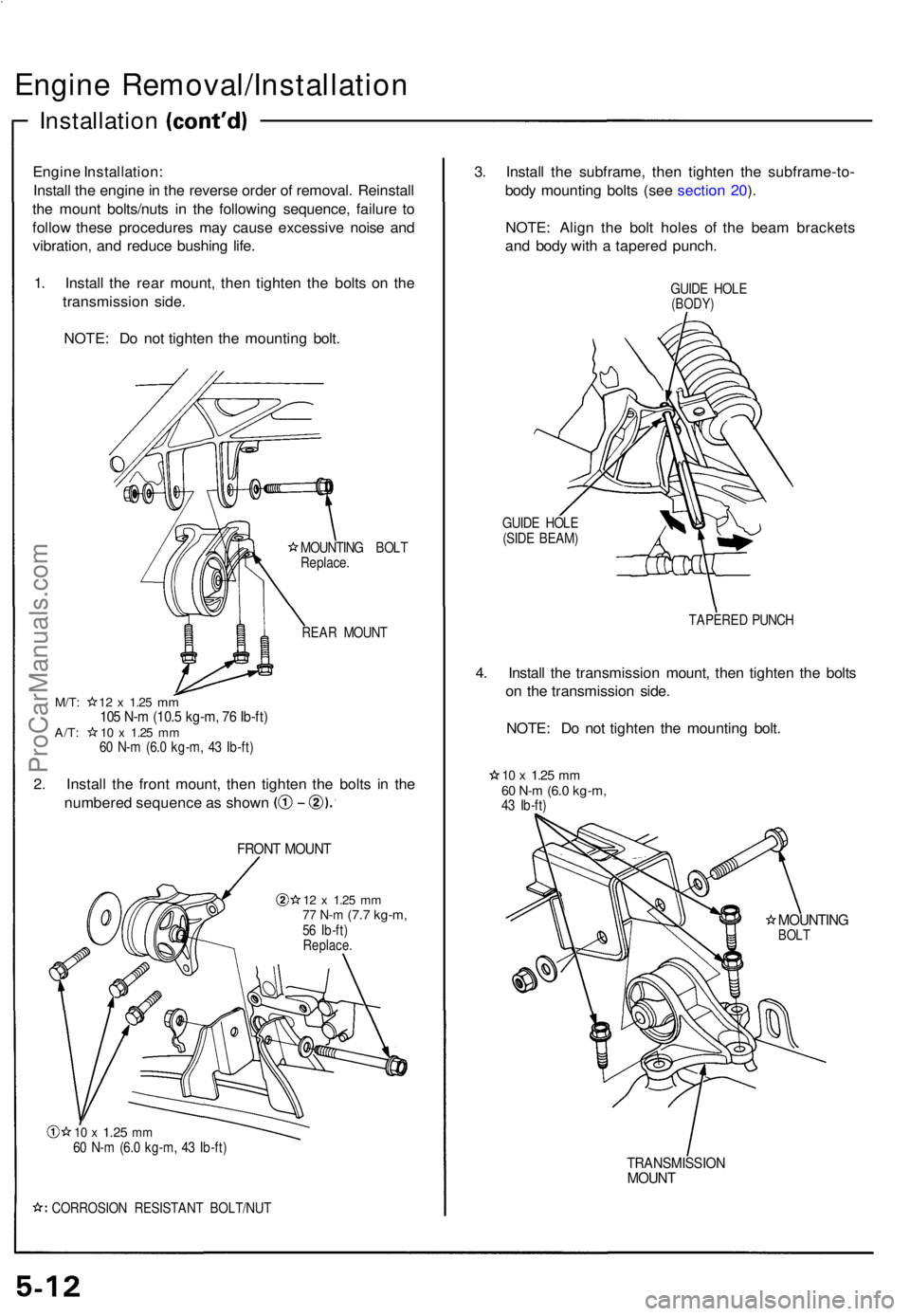

Engine Installation :

Instal l th e engin e in th e revers e orde r o f removal . Reinstal l

th e moun t bolts/nut s i n th e followin g sequence , failur e t o

follo w thes e procedure s ma y caus e excessiv e nois e an d

vibration , an d reduc e bushin g life .

1 . Instal l th e rea r mount , the n tighte n th e bolt s o n th e

transmissio n side .

NOTE : D o no t tighte n th e mountin g bolt .

MOUNTIN G BOL T

Replace .

REA R MOUN T

M/T: 1 2 x 1.2 5 mm105 N- m (10. 5 kg-m , 7 6 Ib-ft )A/T: 1 0 x 1.2 5 mm60 N- m (6. 0 kg-m , 4 3 Ib-ft )

2. Instal l th e fron t mount , the n tighte n th e bolt s i n th e

numbere d sequenc e a s show n

FRONT MOUN T

12 x 1.2 5 mm77 N- m (7. 7 kg-m ,56 Ib-ft )Replace .

10 x 1.2 5 mm60 N- m (6. 0 kg-m , 4 3 Ib-ft )

CORROSIO N RESISTAN T BOLT/NU T

3. Instal l th e subframe , the n tighte n th e subframe-to -

bod y mountin g bolt s (se e sectio n 20 ).

NOTE : Alig n th e bol t hole s o f th e bea m bracket s

an d bod y wit h a tapere d punch .

GUIDE HOL E(BODY )

GUIDE HOL E

(SID E BEAM )

TAPERED PUNC H

4. Instal l th e transmissio n mount , the n tighte n th e bolt s

o n th e transmissio n side .

NOTE : D o no t tighte n th e mountin g bolt .

10 x 1.2 5 mm60 N- m (6. 0 kg-m ,43 Ib-ft )

MOUNTIN GBOLT

TRANSMISSIO NMOUNT

ProCarManuals.com

Page 121 of 1640

Cylinder Head s

Installatio n

Rear:

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft ) REA

R PRIMAR Y

HO2S45 N- m (4. 5 kg-m ,33 Ib-ft )

B e carefu l no t t o damage .

GASKE T

Replace .

REA R EXHAUS T

MANIFOLD

EXHAUSTMANIFOL DCOVER

SELF-LOCKIN G NU T8 x 1.2 5 mm34 N- m (3. 4 kg-m ,25 Ib-ft )Replace .

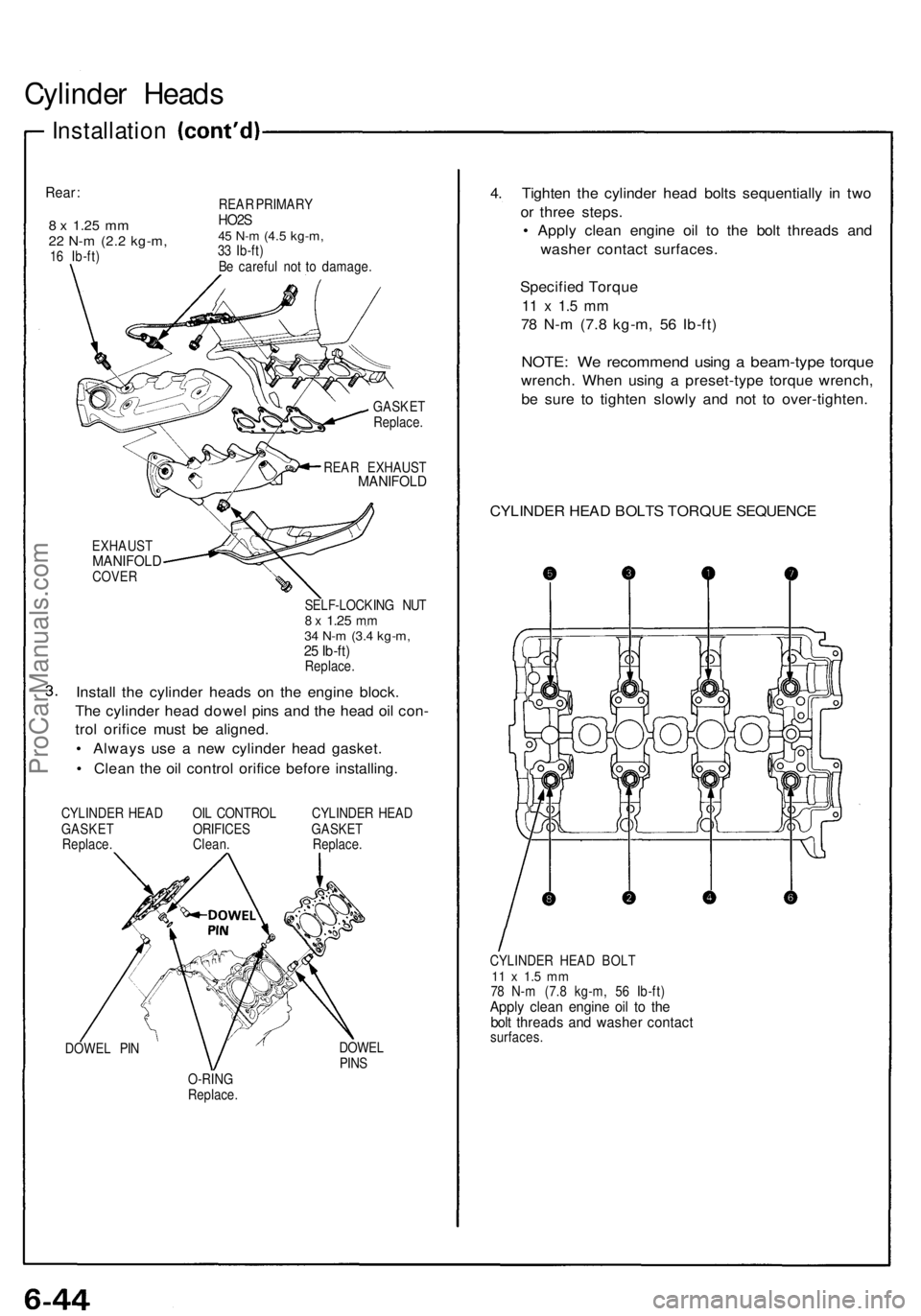

Install th e cylinde r head s o n th e engin e block .

Th e cylinde r hea d dowe l pin s an d th e hea d oi l con -

tro l orific e mus t b e aligned .

• Alway s us e a ne w cylinde r hea d gasket .

• Clea n th e oi l contro l orific e befor e installing .

CYLINDE R HEA D OI L CONTRO L CYLINDE R HEA D

GASKE T ORIFICE S GASKE T

Replace . Clean . Replace .

DOWE L PI N DOWE

L

PIN S

O-RIN G

Replace .

4. Tighte n th e cylinde r hea d bolt s sequentiall y i n tw o

o r thre e steps .

• Appl y clea n engin e oi l t o th e bol t thread s an d

washe r contac t surfaces .

Specifie d Torqu e

11 x 1. 5 m m

78 N- m (7. 8 kg-m , 5 6 Ib-ft )

NOTE : W e recommen d usin g a beam-typ e torqu e

wrench . Whe n usin g a preset-typ e torqu e wrench ,

b e sur e t o tighte n slowl y an d no t t o over-tighten .

CYLINDE R HEA D BOLT S TORQU E SEQUENC E

CYLINDER HEA D BOL T11 x 1. 5 m m78 N- m (7. 8 kg-m , 5 6 Ib-ft )Apply clea n engin e oi l t o th ebolt thread s an d washe r contac tsurfaces .

ProCarManuals.com

Page 306 of 1640

Transmission Assembly

Removal

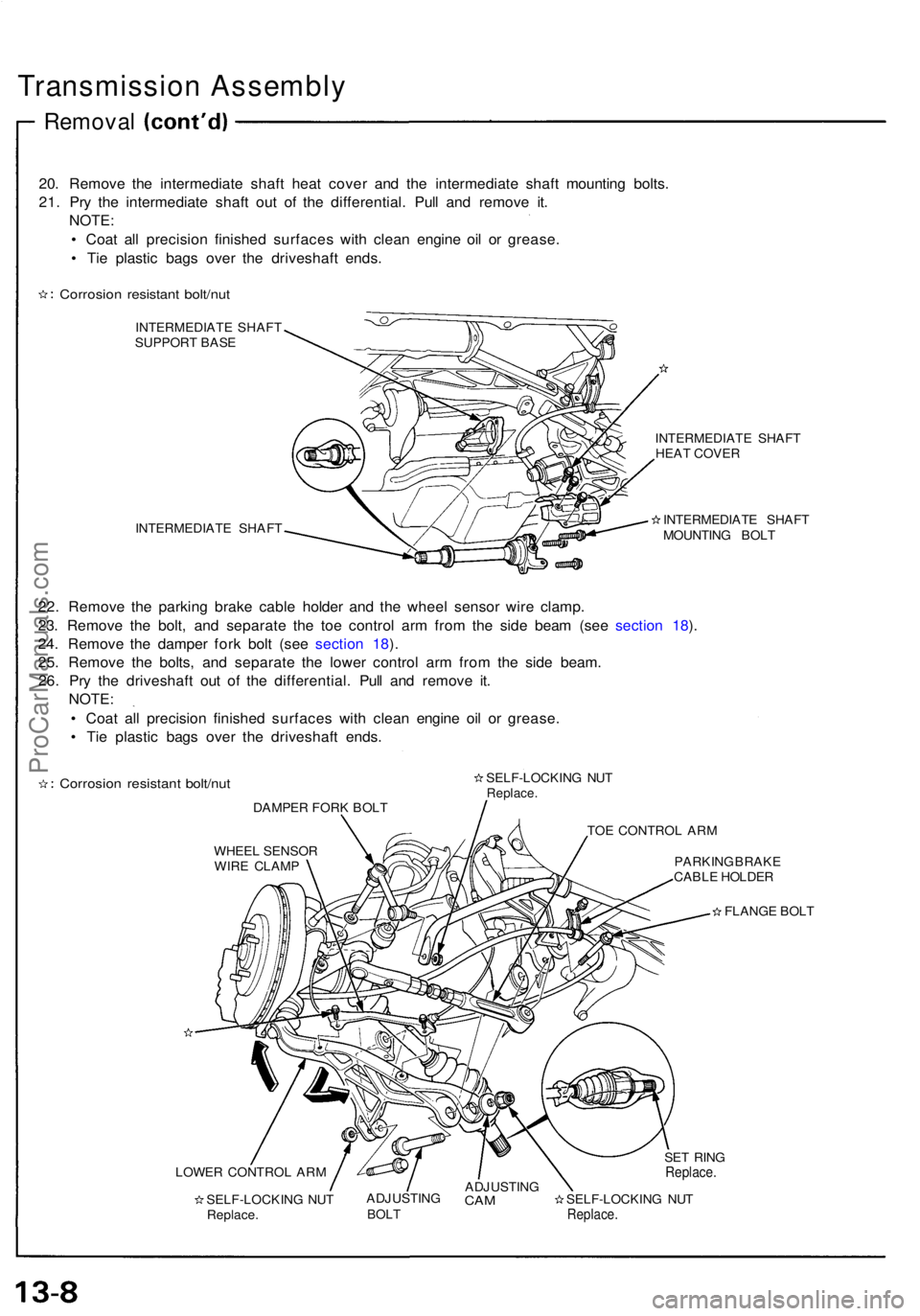

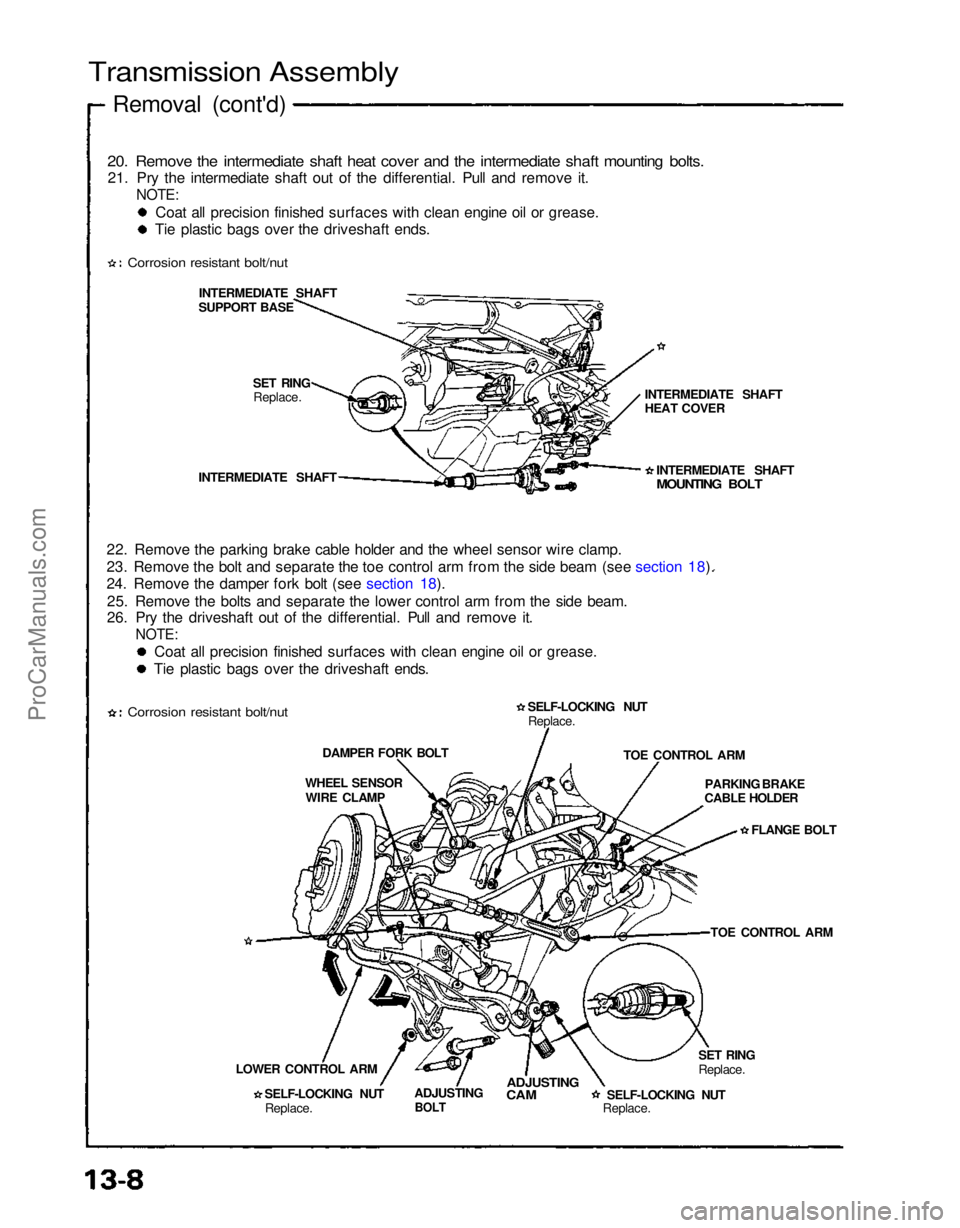

20. Remove the intermediate shaft heat cover and the intermediate shaft mounting bolts.

21. Pry the intermediate shaft out of the differential. Pull and remove it. NOTE:

• Coat all precision finished surfaces with clean engine oil or grease.

• Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

INTERMEDIATE SHAFT

SUPPORT BASE

INTERMEDIATE SHAFT INTERMEDIATE SHAFT

HEAT COVER

INTERMEDIATE SHAFT

MOUNTING BOLT

22. Remove the parking brake cable holder and the wheel sensor wire clamp.

23. Remove the bolt, and separate the toe control arm from the side beam (see section 18).

24. Remove the damper fork bolt (see section 18).

25. Remove the bolts, and separate the lower control arm from the side beam. 26. Pry the driveshaft out of the differential. Pull and remove it. NOTE:

• Coat all precision finished surfaces with clean engine oil or grease.

• Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

DAMPER FORK BOLT SELF-LOCKING NUT

Replace.

TOE CONTROL ARM

WHEEL SENSOR WIRE CLAMP PARKING BRAKE

CABLE HOLDER

FLANGE BOLT

LOWER CONTROL ARM SELF-LOCKING NUTReplace. ADJUSTING

BOLT

ADJUSTING

CAM

SELF-LOCKING NUT

Replace.

SET RING

Replace.ProCarManuals.com

Page 439 of 1640

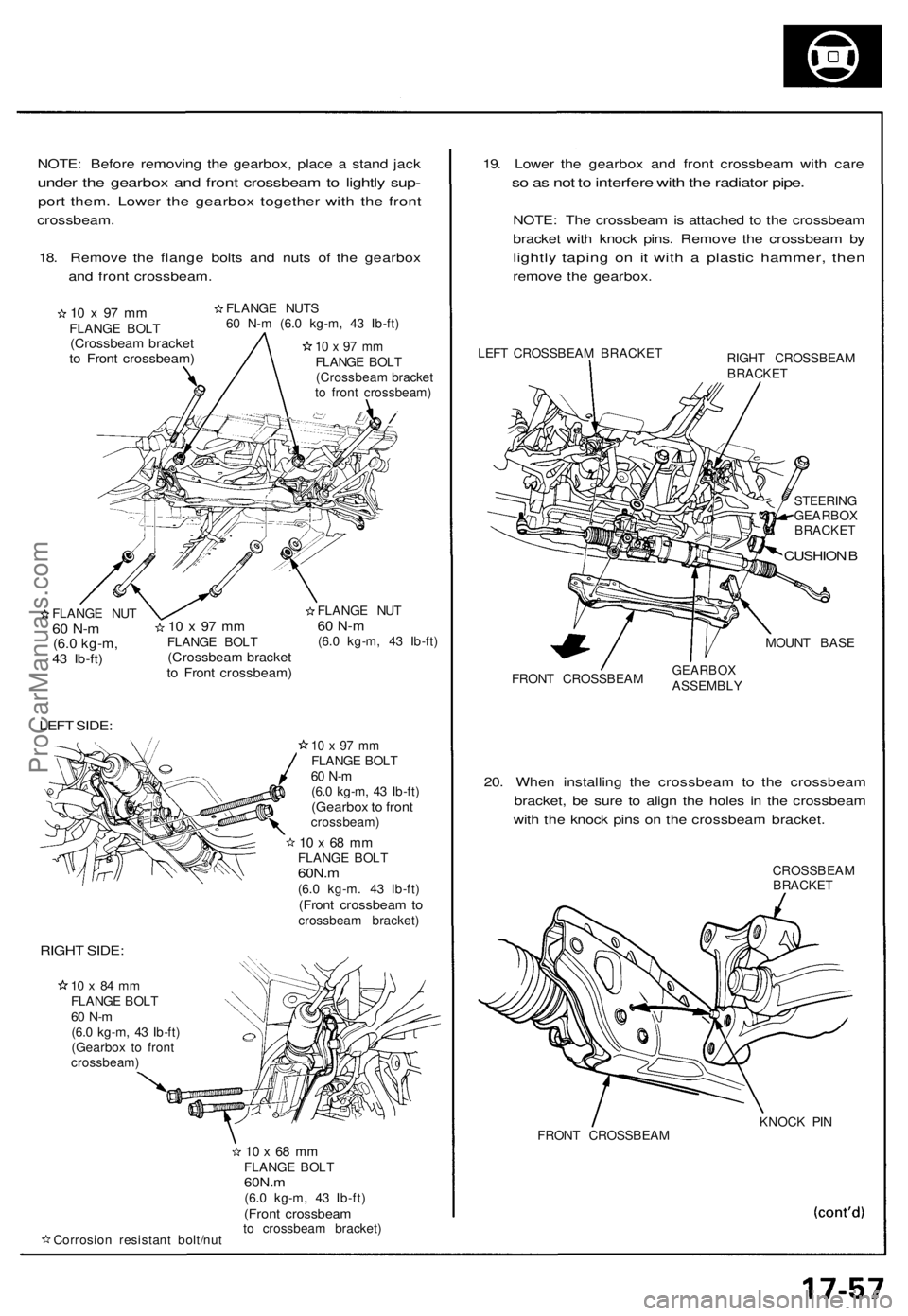

NOTE: Before removing the gearbox, place a stand jack

under the gearbox and front crossbeam to lightly sup-

port them. Lower the gearbox together with the front

crossbeam.

18. Remove the flange bolts and nuts of the gearbox

and front crossbeam.

10 x 97 mm

FLANGE BOLT

(Crossbeam bracket

to Front crossbeam)

FLANGE NUTS

60 N-m (6.0 kg-m, 43 Ib-ft)

10 x 97 mm

FLANGE BOLT

(Crossbeam bracket

to front crossbeam)

/

FLANGE NUT

60 N-m

(6.0 kg-m,

43 Ib-ft)

LEFT SIDE:

10 x 97 mm

FLANGE BOLT

(Crossbeam bracket

to Front crossbeam)

FLANGE NUT

60 N-m

(6.0 kg-m, 43 Ib-ft)

10 x 97 mm

FLANGE BOLT

60 N-m

(6.0 kg-m, 43 Ib-ft)

(Gearbox to front

crossbeam)

10 x 68 mm

FLANGE BOLT

60N.m

(6.0 kg-m. 43 Ib-ft)

(Front crossbeam to

crossbeam bracket)

RIGHT SIDE:

10 x 84 mm

FLANGE BOLT

60 N-m

(6.0 kg-m, 43 Ib-ft)

(Gearbox to front

crossbeam)

Corrosion resistant bolt/nut

10 x 68 mm

FLANGE BOLT

60N.m

(6.0 kg-m, 43 Ib-ft)

(Front crossbeam

to crossbeam bracket)

19. Lower the gearbox and front crossbeam with care

so as not to interfere with the radiator pipe.

NOTE: The crossbeam is attached to the crossbeam

bracket with knock pins. Remove the crossbeam by

lightly taping on it with a plastic hammer, then

remove the gearbox.

LEFT CROSSBEAM BRACKET

RIGHT CROSSBEAM

BRACKET

STEERING

GEARBOX

BRACKET

CUSHION B

MOUNT BASE

FRONT CROSSBEAM

GEARBOX

ASSEMBLY

20. When installing the crossbeam to the crossbeam

bracket, be sure to align the holes in the crossbeam

with the knock pins on the crossbeam bracket.

CROSSBEAM

BRACKET

FRONT CROSSBEAM

KNOCK PINProCarManuals.com

Page 789 of 1640

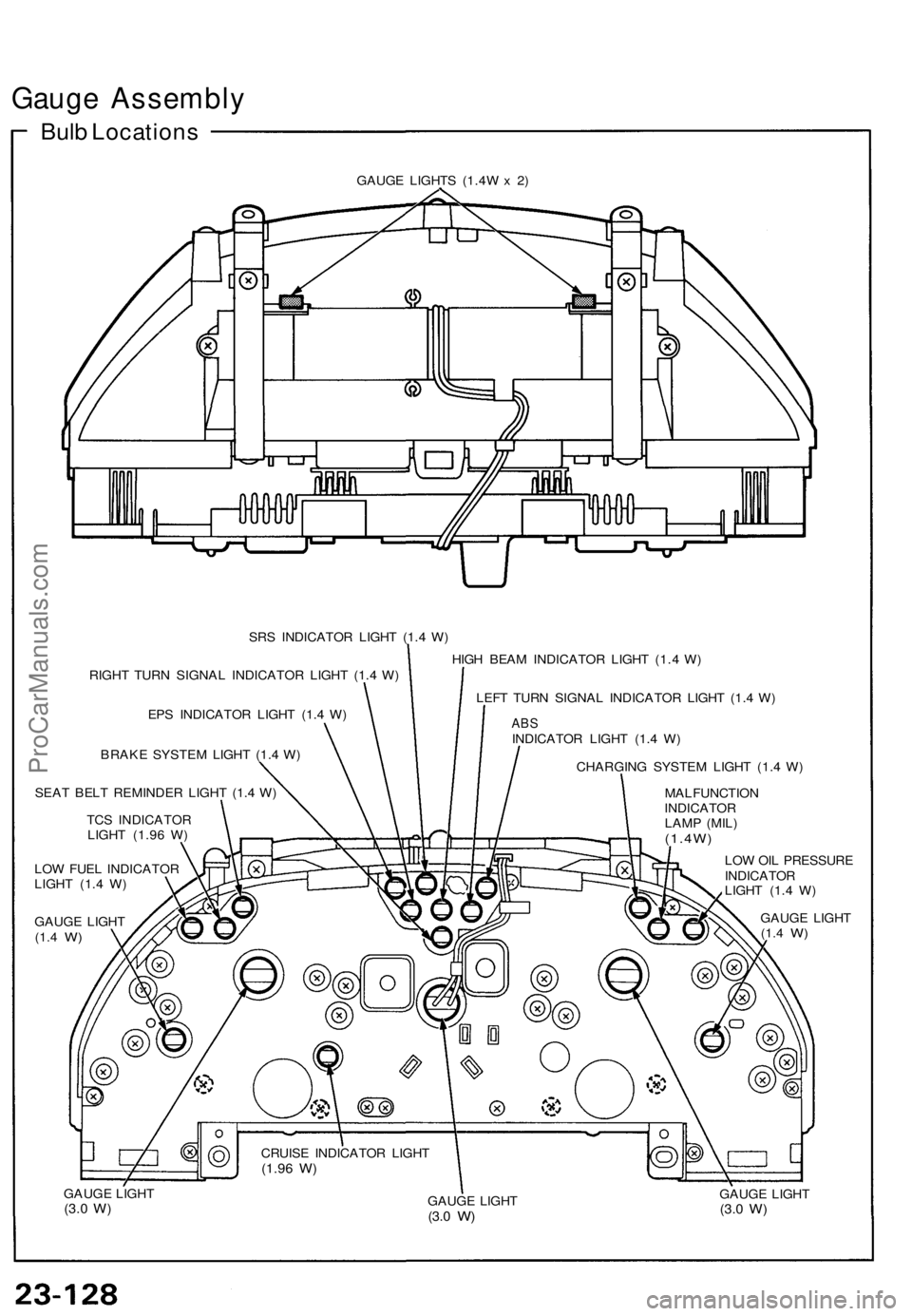

Gauge Assembly

Bulb Locations

GAUGE LIGHTS (1.4W x 2)

SRS INDICATOR LIGHT (1.4 W)

RIGHT TURN SIGNAL INDICATOR LIGHT (1.4 W)

EPS INDICATOR LIGHT (1.4 W)

BRAKE SYSTEM LIGHT (1.4 W)

SEAT BELT REMINDER LIGHT (1.4 W)

TCS INDICATOR

LIGHT (1.96 W)

LOW FUEL INDICATOR

LIGHT (1.4 W)

GAUGE LIGHT

(1.4

W)

HIGH BEAM INDICATOR LIGHT (1.4 W)

LEFT TURN SIGNAL INDICATOR LIGHT (1.4 W)

ABS

INDICATOR LIGHT (1.4 W)

CHARGING SYSTEM LIGHT (1.4 W)

MALFUNCTION

INDICATOR

LAMP (MIL)

(1.4W)

LOW OIL PRESSURE

INDICATOR

LIGHT (1.4 W)

GAUGE LIGHT

(1.4

W)

GAUGE LIGHT

(3.0

W)

GAUGE LIGHT

(3.0

W)

GAUGE LIGHT

(3.0

W)

CRUISE INDICATOR LIGHT

(1.96

W)ProCarManuals.com

Page 991 of 1640

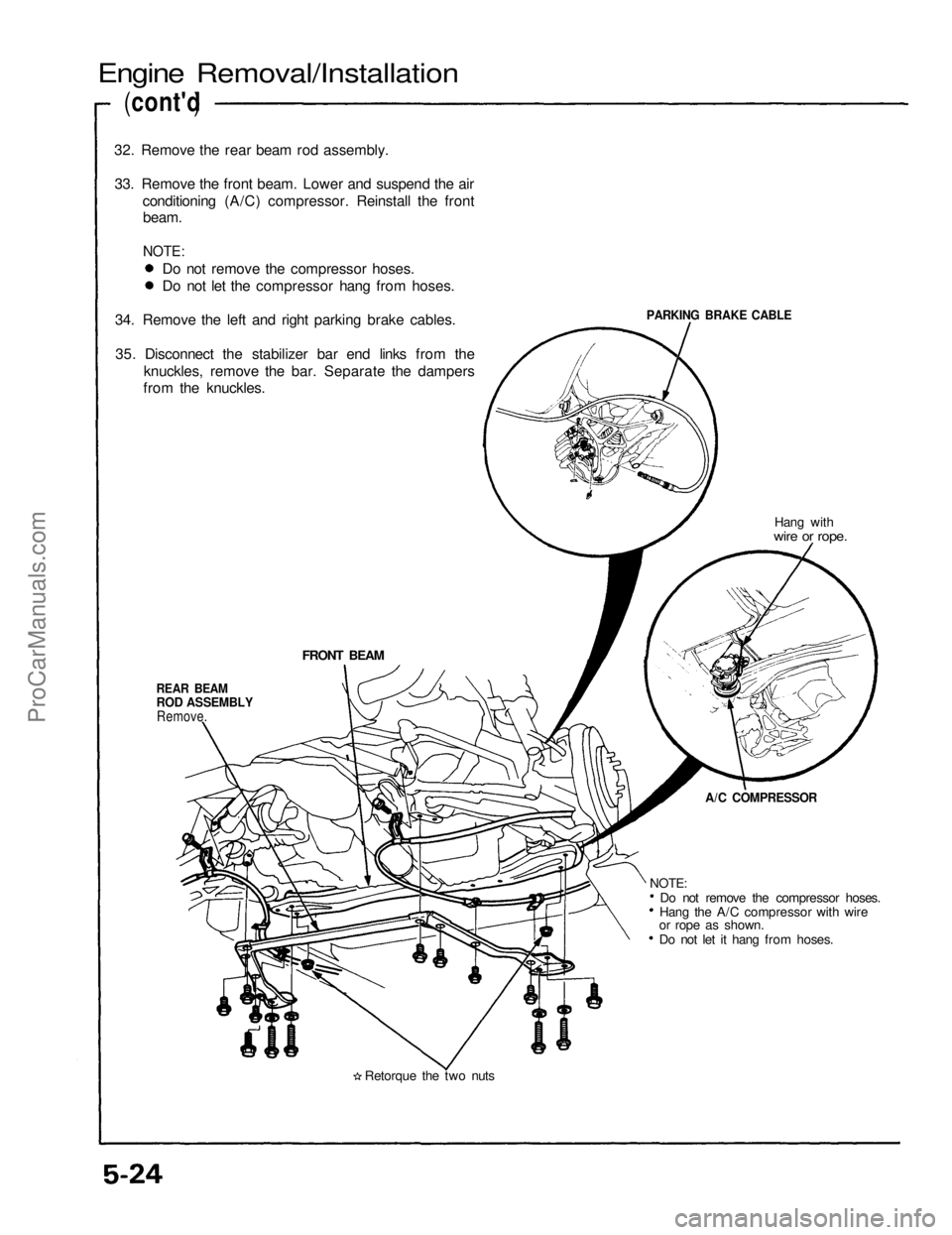

Engine Removal/Installation

(cont'd )

32. Remove the rear beam rod assembly.

33. Remove the front beam. Lower and suspend the air conditioning (A/C) compressor. Reinstall the frontbeam.

NOTE:

PARKING BRAKE CABLE

Hang with

wire or rope.

FRONT BEAM

REAR BEAM

ROD ASSEMBLY

Remove.

A/C COMPRESSOR

Do not remove the compressor hoses.

Hang the A/C compressor with wire

or rope as shown.

Do not let it hang from hoses.

Retorque the two nuts

NOTE:

Do not remove the compressor hoses.

Do not let the compressor hang from hoses.

34. Remove the left and right parking brake cables.

35. Disconnect the stabilizer bar end links from the knuckles, remove the bar. Separate the dampers

from the knuckles.ProCarManuals.com

Page 1036 of 1640

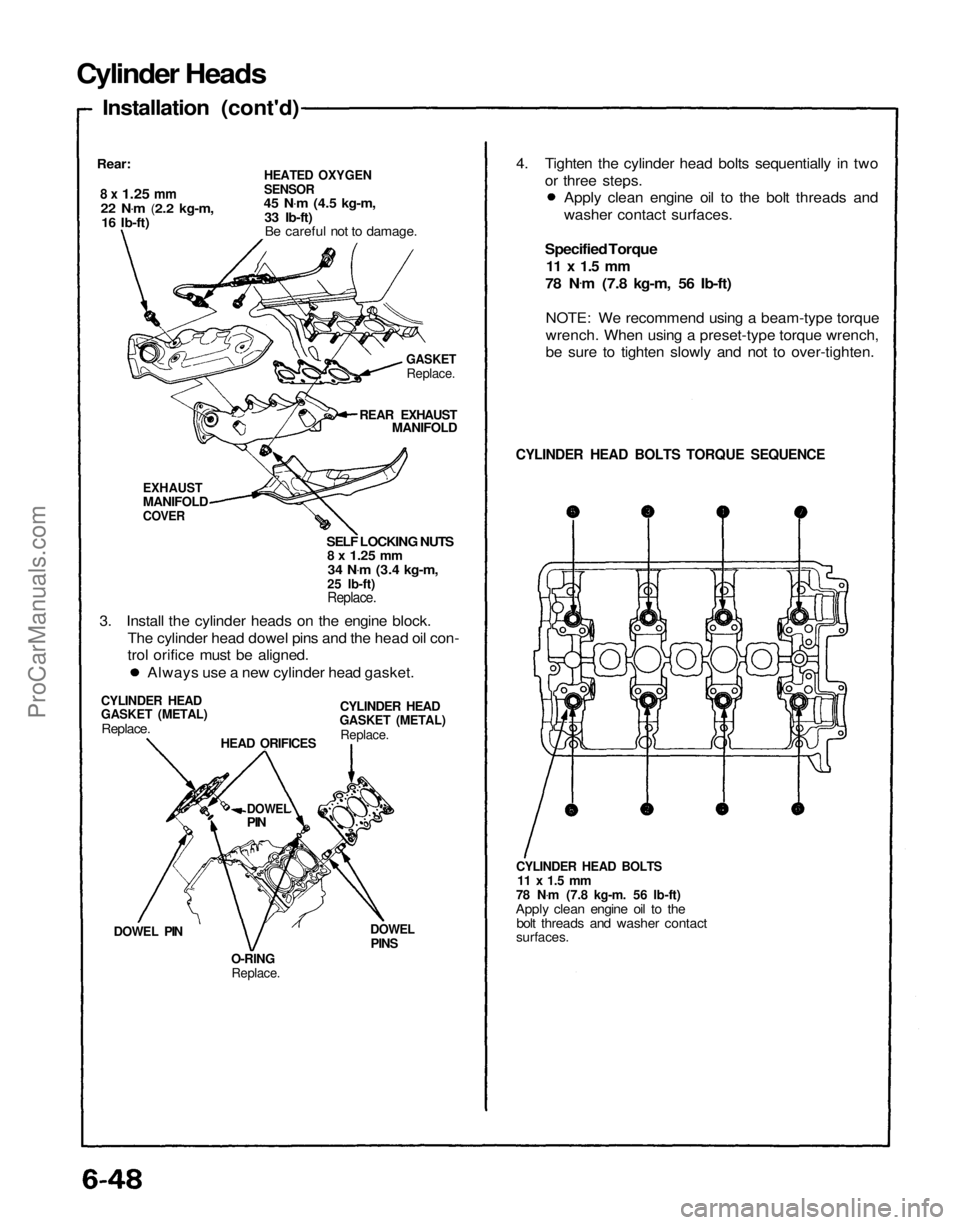

Cylinder Heads

Installation (cont'd)

Rear:

8 x

1.25

mm

22 N .

m

(2.2 kg-m,

16 Ib-ft)

HEATED OXYGEN

SENSOR

45 N .

m

(4.5 kg-m,

33 Ib-ft) Be careful not to damage.

GASKET

Replace.

REAR EXHAUST

MANIFOLD

EXHAUST

MANIFOLD

COVER

SELF LOCKING NUTS

8 x

1.25

mm

34 N .

m

(3.4 kg-m,

25 Ib-ft)

Replace.

3. Install the cylinder heads on the engine block. The cylinder head dowel pins and the head oil con-

trol orifice must be aligned.

CYLINDER HEAD

GASKET (METAL)

Replace.

CYLINDER HEAD

GASKET (METAL)

Replace.

HEAD ORIFICES

DOWEL

PIN

DOWEL PIN

O-RING

Replace.

DOWEL

PINS

CYLINDER HEAD BOLTS

11 x 1.5 mm

78 N .

m (7.8 kg-m. 56 Ib-ft)

Apply clean engine oil to the bolt threads and washer contact

surfaces.

CYLINDER HEAD BOLTS TORQUE SEQUENCE

Specified Torque

11 x 1.5 mm

78 N .

m (7.8 kg-m, 56 Ib-ft)

NOTE: We recommend using a beam-type torque

wrench. When using a preset-type torque wrench,

be sure to tighten slowly and not to over-tighten.

Always use a new cylinder head gasket. Apply clean engine oil to the bolt threads and

washer contact surfaces.

4. Tighten the cylinder head bolts sequentially in two

or three steps.ProCarManuals.com

Page 1149 of 1640

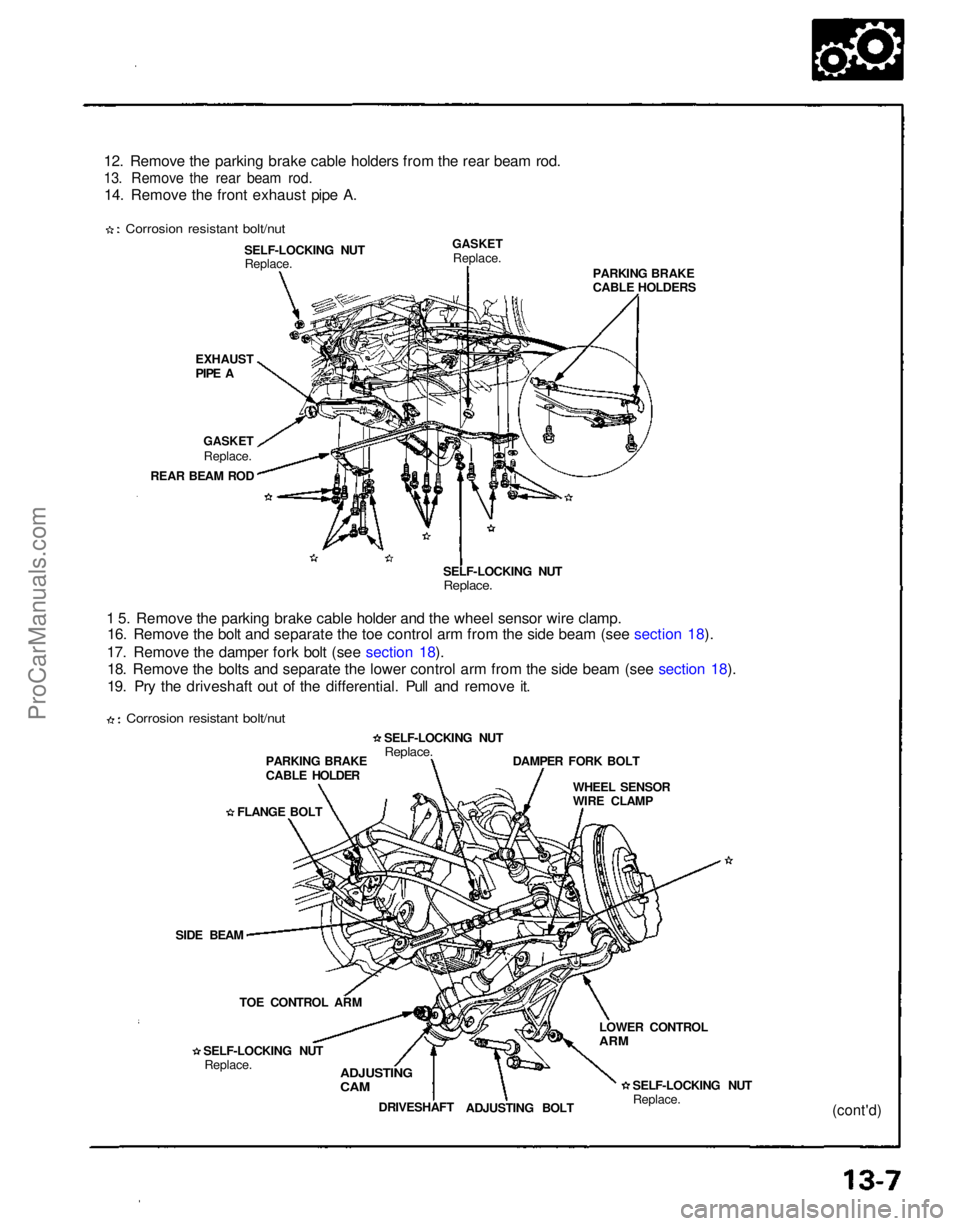

12. Remove the parking brake cable holders from the rear beam rod.

13. Remove the rear beam rod.

14. Remove the front exhaust pipe A.

Corrosion resistant bolt/nut

EXHAUST

PIPE ASELF-LOCKING NUT

Replace.

GASKET

Replace.

GASKET

Replace.

REAR BEAM ROD

1 5. Remove the parking brake cable holder and the wheel sensor wire clamp. 16. Remove the bolt and separate the toe control arm from the side beam (see section 18).

17. Remove the damper fork bolt (see section 18). 18. Remove the bolts and separate the lower control arm from the side beam (see section 18).

19. Pry the driveshaft out of the differential. Pull and remove it. SELF-LOCKING NUT

Replace.

PARKING BRAKE

CABLE HOLDERS

PARKING BRAKE

CABLE HOLDER

FLANGE BOLT

SIDE BEAM TOE CONTROL ARM

SELF-LOCKING NUT Replace. SELF-LOCKING NUT

Replace.

WHEEL SENSOR

WIRE CLAMP

DAMPER FORK BOLT

ADJUSTING

CAM

DRIVESHAFT

ADJUSTING BOLT SELF-LOCKING NUT

Replace.

LOWER CONTROL

ARM

(cont'd)

Corrosion resistant bolt/nutProCarManuals.com

Page 1150 of 1640

Transmission Assembly

Removal (cont'd)

20. Remove the intermediate shaft heat cover and the intermediate shaft mounting bolts.

21. Pry the intermediate shaft out of the differential. Pull and remove it.

NOTE:

Coat all precision finished surfaces with clean engine oil or grease.

Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

INTERMEDIATE SHAFT

SUPPORT BASE

SET RINGReplace.

INTERMEDIATE SHAFT

22. Remove the parking brake cable holder and the wheel sensor wire clamp.

23. Remove the bolt and separate the toe control arm from the side beam (see section 18).

24. Remove the damper fork bolt (see section 18). 25. Remove the bolts and separate the lower control arm from the side beam.

26. Pry the driveshaft out of the differential. Pull and remove it.

NOTE:

Coat all precision finished surfaces with clean engine oil or grease.

Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

DAMPER FORK BOLT

WHEEL SENSOR WIRE CLAMP

LOWER CONTROL ARM SELF-LOCKING NUTReplace. ADJUSTING

BOLT

ADJUSTING

CAM

SELF-LOCKING NUT

Replace.SET RING

Replace.TOE CONTROL ARM

PARKING BRAKE

CABLE HOLDER

FLANGE BOLT

TOE CONTROL ARM

SELF-LOCKING NUT

Replace. INTERMEDIATE SHAFT

MOUNTING BOLT

INTERMEDIATE SHAFT

HEAT COVERProCarManuals.com

Page 1161 of 1640

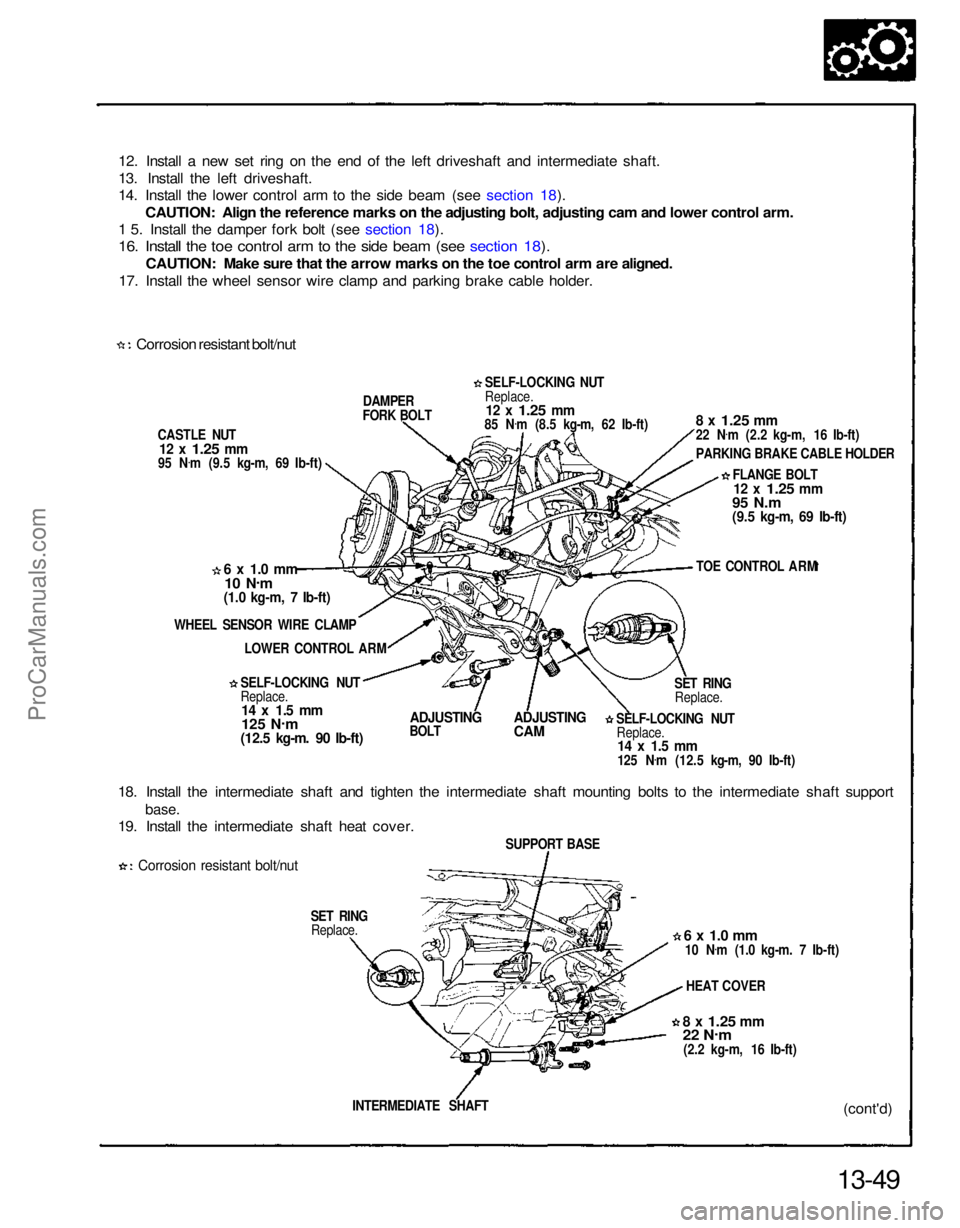

12. Install a new set ring on the end of the left driveshaft and intermediate shaft.

13. Install the left driveshaft.

14. Install the lower control arm to the side beam (see section 18).

CAUTION: Align the reference marks on the adjusting bolt, adjusting cam and lower control arm.

1 5. Install the damper fork bolt (see section 18).

16. Install the toe control arm to the side beam (see section 18).

CAUTION: Make sure that the arrow marks on the toe control arm are aligned.

17. Install the wheel sensor wire clamp and parking brake cable holder.

Corrosion resistant bolt/nut

CASTLE NUT

12 x

1.25

mm

95 N .

m (9.5 kg-m, 69 Ib-ft) DAMPER

FORK BOLT

6 x 1.0 mm

10 N .

m

(1.0 kg-m, 7 Ib-ft)

WHEEL SENSOR WIRE CLAMP LOWER CONTROL ARM

SELF-LOCKING NUT

Replace.

14 x 1.5 mm

125 N .

m

(12.5 kg-m. 90 Ib-ft)

ADJUSTING

BOLT

ADJUSTING

CAM

18. Install the intermediate shaft and tighten the intermediate shaft mounting bolts to the intermediate shaft support

base.

19. Install the intermediate shaft heat cover.

Corrosion resistant bolt/nut

SET RINGReplace.

13-49(cont'd)

INTERMEDIATE SHAFT

8 x

1.25

mm

22 N

.

m

(2.2 kg-m, 16 Ib-ft) HEAT COVER

6 x 1.0 mm

10 N .

m (1.0 kg-m. 7 Ib-ft)

SUPPORT BASE SELF-LOCKING NUT

Replace.

14 x 1.5 mm

125 N .

m (12.5 kg-m, 90 Ib-ft) SET RING

Replace. TOE CONTROL ARM

FLANGE BOLT

12 x

1.25

mm

95 N.m

(9.5 kg-m, 69 Ib-ft)

8 x

1.25

mm

22 N

.

m (2.2 kg-m, 16 Ib-ft)

PARKING BRAKE CABLE HOLDER

SELF-LOCKING NUT

Replace.

12 x

1.25

mm

85 N .

m (8.5 kg-m, 62 Ib-ft)ProCarManuals.com