tow ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 11 of 1640

Towing

If th e ca r need s t o b e towed , cal l a professiona l towin g

service . Neve r to w th e ca r behin d anothe r ca r wit h jus t

a rop e o r chain . I t i s ver y dangerous .

Ther e ar e thre e widel y use d method s o f towin g a car :

Flat-be d Equipmen t — Th e operato r load s th e ca r o n th e

bac k o f a truck . Thi s i s th e onl y recommende d wa y o f

towin g th e NS X & NSX-T .

Whee l Lif t Equipment— The to w truc k drive r use s tw o

pivotin g arm s whic h g o unde r th e tire s (fron t o r rear ) an d

lif t the m of f th e ground . Th e othe r tw o wheel s remai n

o n th e ground . Thi s towin g metho d i s no t recommend -

ed . Becaus e o f th e NS X & NSX-T' s lo w groun d clearance ,

th e bod y ca n b e damage d goin g ove r larg e bump s o r u p

inclines .

Sling-typ e Equipment— The tow truc k use s meta l chain s

wit h hook s o n th e ends . Thes e hook s g o aroun d part s

of th e fram e or suspensio n and th e cable s lift tha t end

of th e ca r of f th e ground . Damag e t o th e car' s suspen -

sio n an d bod y i s almos t certai n if thi s metho d o f towin g

i s attempted .

I f th e NS X & NSX- T canno t b e towe d b y flat-bed , i t

shoul d b e towe d wit h th e rea r wheel s of f th e ground .

If , du e t o damage , th e ca r mus t b e towe d wit h th e rea r

wheel s o n th e ground , d o th e following :

Manual Transmissio n

• Releas e th e parkin g brak e

• Shif t th e transmissio n t o Neutra l

Automati c Transmissio n

• Releas e th e parkin g brak e

• Star t th e engin e

• Shif t t o position , the n t o positio n

• Tur n of f th e engin e

NOTICE :

• Imprope r towin g preparatio n wil l damag e th e trans -

mission . Follo w th e abov e procedur e exactly . Th e ca r

mus t b e towe d o n a fla t be d if th e engin e wil l no t star t

o r th e transmissio n wil l no t shift .

• I t i s bes t t o to w th e ca r n o farthe r tha n 5 0 mile s (8 0

km) , an d kee p th e spee d belo w 3 5 mp h (5 5 km/h) .

• Tryin g t o lif t o r to w th e ca r b y th e bumper s wil l caus e

seriou s damage . Th e bumper s ar e no t designe d to sup -

por t th e car' s weight .

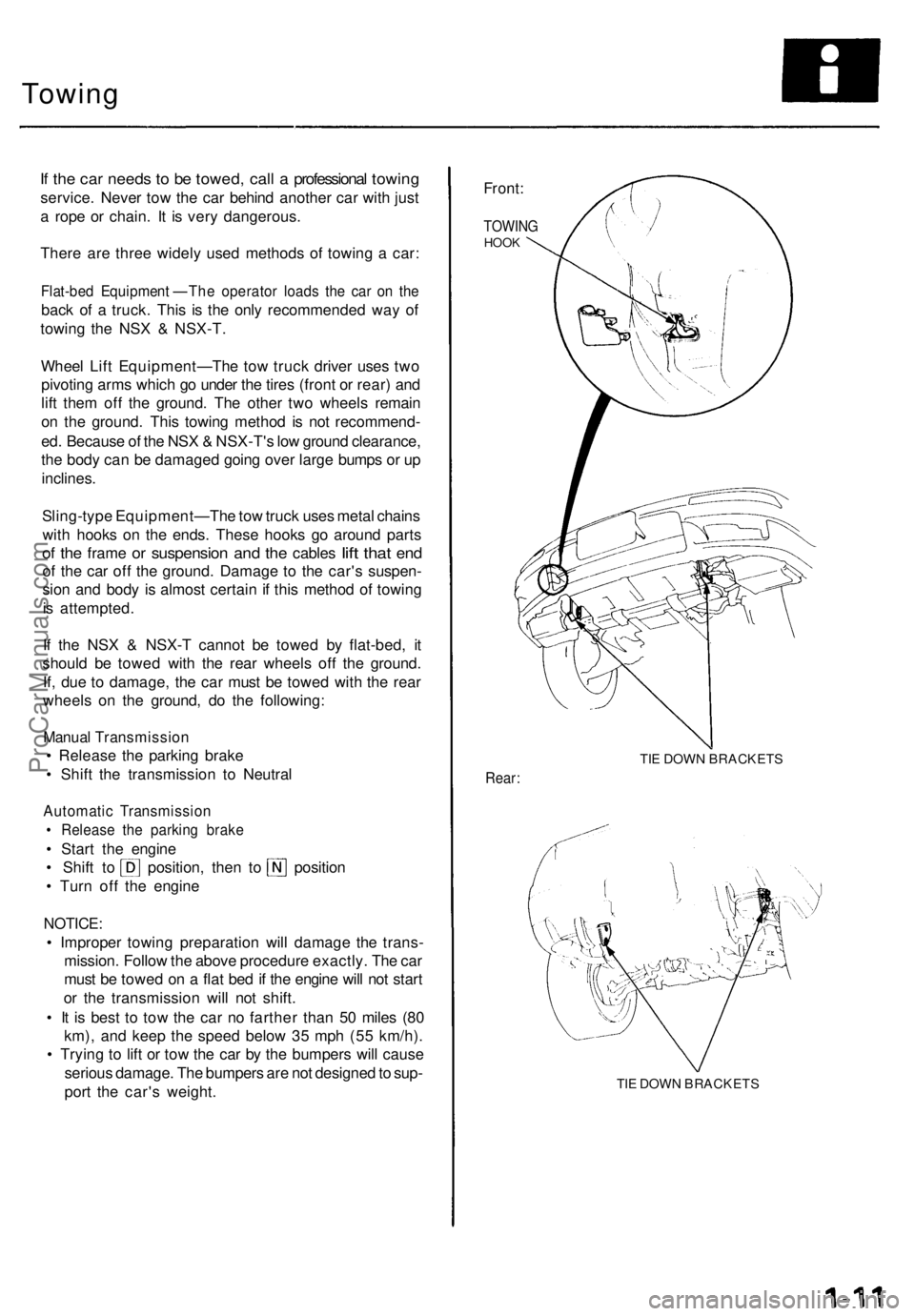

Front:

TOWIN GHOOK

TIE DOW N BRACKET S

Rear:

TIE DOW N BRACKET S

ProCarManuals.com

Page 32 of 1640

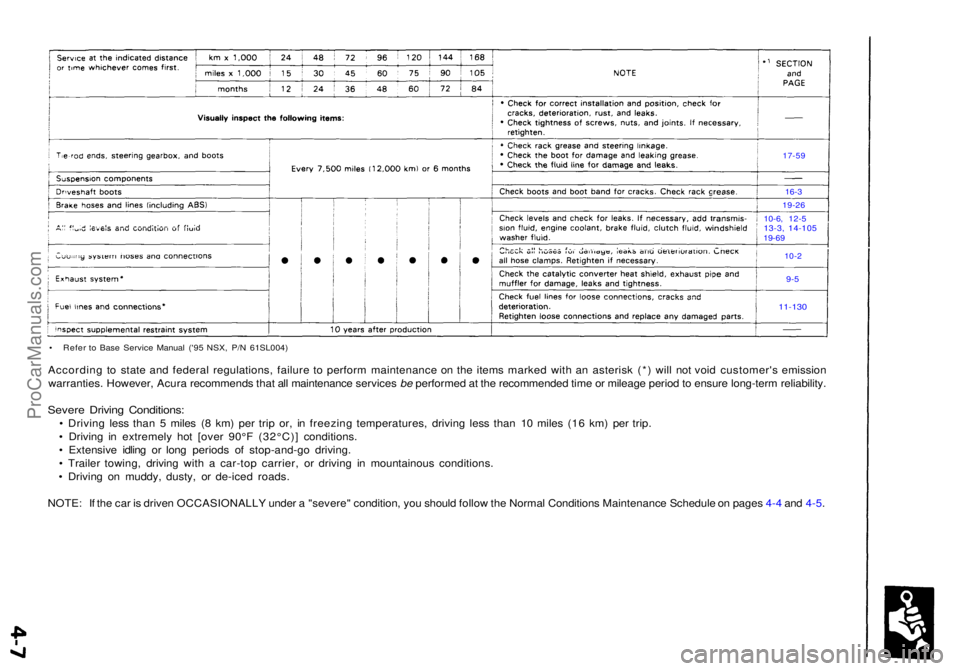

• Refe r t o Bas e Servic e Manua l ('9 5 NSX , P/ N 61SL004 )

According t o stat e an d federa l regulations , failur e t o perfor m maintenanc e o n th e item s marke d wit h a n asteris k (* ) wil l no t voi d customer' s emissio n

warranties . However , Acur a recommend s tha t al l maintenanc e service s be performe d a t th e recommende d tim e o r mileag e perio d to ensur e long-ter m reliability .

Severe Drivin g Conditions :

• Drivin g les s tha n 5 mile s ( 8 km ) pe r tri p or , i n freezin g temperatures , drivin g les s tha n 1 0 mile s (1 6 km ) pe r trip .

• Drivin g i n extremel y ho t [ove r 90° F (32°C) ] conditions .

• Extensiv e idlin g o r lon g period s o f stop-and-g o driving .

• Traile r towing , drivin g wit h a car-to p carrier , o r drivin g i n mountainou s conditions .

• Drivin g o n muddy , dusty , o r de-ice d roads .

NOTE : I f th e ca r i s drive n OCCASIONALL Y unde r a "severe " condition , yo u shoul d follo w th e Norma l Condition s Maintenanc e Schedul e o n page s 4- 4 an d 4-5 .

17-5 9

16-3

19-2 6

10-6 , 12- 5

13-3, 14-10 519-69

10-2

9-5

11-13 0

ProCarManuals.com

Page 44 of 1640

Towing

If th e ca r need s t o b e towed , cal l a professiona l towin g

service . Neve r to w th e ca r behin d anothe r ca r wit h jus t

a rop e o r chain . I t i s ver y dangerous .

Ther e ar e thre e widel y use d method s o f towin g a car :

Flat-be d Equipment—Th e operato r load s th e ca r o n th e

bac k o f a truck . This is th e onl y recommende d wa y o f

towin g th e NS X & NSX-T .

Whee l Lif t Equipment—Th e to w truc k drive r use s tw o

pivotin g arm s whic h g o unde r th e tire s (fron t o r rear ) an d

lif t the m of f th e ground . Th e othe r tw o wheel s remai n

o n th e ground . Thi s towin g metho d i s no t recommend -

ed . Becaus e o f th e NS X & NSX-T' s lo w groun d clearance ,

th e bod y ca n b e damage d goin g ove r larg e bump s o r u p

inclines .

Sling-typ e Equipment—Th e to w truc k use s meta l chain s

wit h hooks on th e ends . Thes e hook s g o aroun d part s

o f th e fram e o r suspensio n an d th e cable s lif t tha t en d

o f th e ca r of f th e ground . Damag e t o th e car' s suspen -

sio n an d bod y i s almos t certai n if thi s metho d o f towin g

i s attempted .

I f th e NS X & NSX- T canno t b e towe d b y flat-bed , i t

shoul d b e towe d wit h th e rea r wheel s of f th e ground .

If , du e t o damage , th e ca r mus t b e towe d wit h th e rea r

wheel s o n th e ground , d o th e following :

Manual Transmissio n

Release th e parkin g brak e

Shift th e transmissio n t o Neutra l

Automati c Transmissio n

Releas e th e parkin g brak e

Star t th e engin e

Shift t o position , the n t o positio n

Tur n of f th e engin e

NOTICE :

Improper towin g preparatio n wil l damag e th e trans -

mission . Follo w th e abov e procedur e exactly . Th e ca r

mus t b e towe d o n a fla t be d if th e engin e wil l no t star t

or th e transmissio n wil l no t shift .

It i s bes t t o to w th e ca r n o farthe r tha n 5 0 mile s (8 0

km) , an d kee p th e spee d belo w 3 5 mp h (5 5 km/h) .

Tryin g t o lif t o r to w th e ca r b y th e bumper s wil l caus e

seriou s damage . Th e bumper s ar e no t designe d to sup -

por t th e car' s weight .

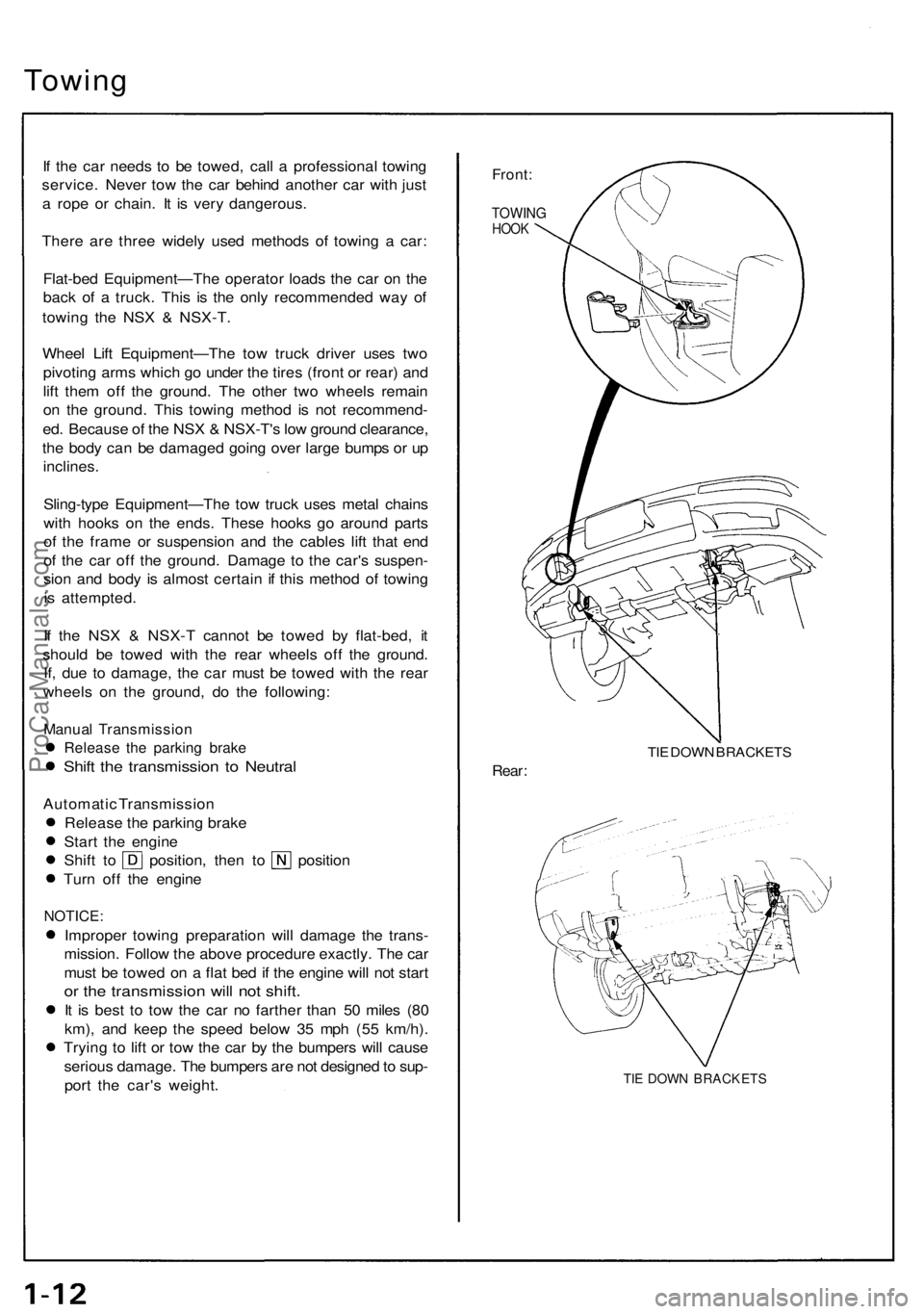

Front:

TOWIN GHOOK

TIE DOW N BRACKET S

Rear:

TIE DOW N BRACKET S

ProCarManuals.com

Page 68 of 1640

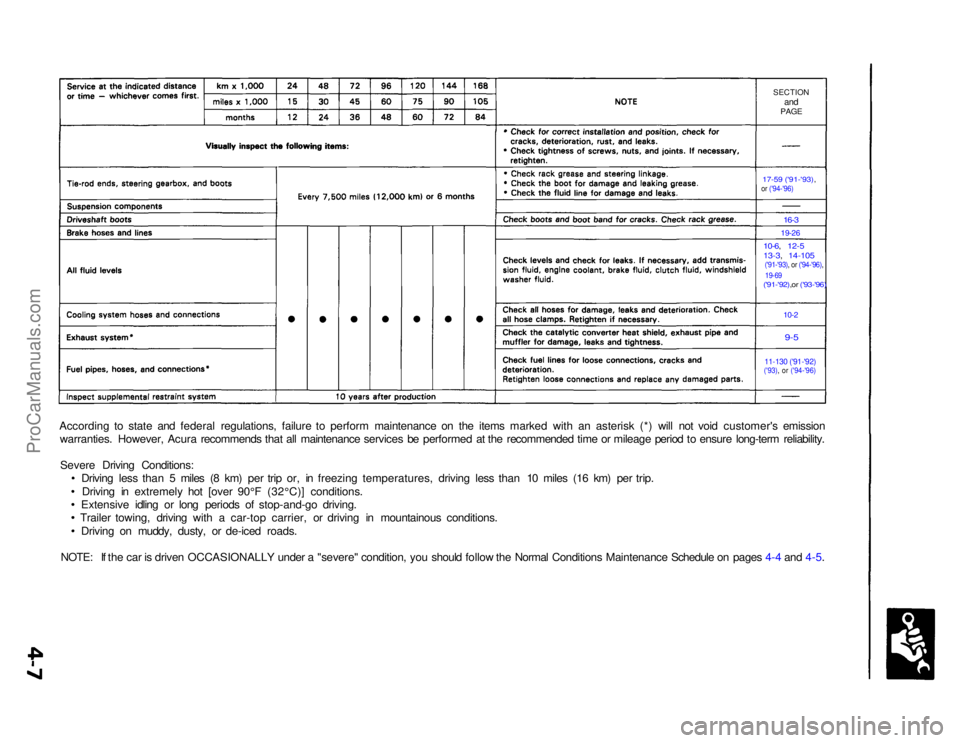

SECTION

and

PAGE

17-59 ('91-'93),

or ('94-'96)

16-3

19-26

10-6, 12-5

13-3, 14-105

('91-'93), or ('94-'96), 19-69

('91-'92),or ('93-'96)

10-2

9-5

11-130 ('91-'92)('93), or ('94-'96)

According to state and federal regulations, failure to perform maintenance on the items marked with an asterisk (*) will not void customer's emission

warranties. However, Acura recommends that all maintenance services be performed at the recommended time or mileage period to ensure long-term reliability.

Severe Driving Conditions: Driving less than 5 miles (8 km) per trip or, in freezing temperatures, driving less than 10 miles (16 km) per trip.

Driving in extremely hot [over 90°F (32°C)] conditions.

Extensive idling or long periods of stop-and-go driving.

Trailer towing, driving with a car-top carrier, or driving in mountainous conditions.

Driving on muddy, dusty, or de-iced roads.

NOTE: If the car is driven OCCASIONALLY under a "severe" condition, you should follow the Normal Conditions Maintenance Schedule on pages 4-4 and 4-5.ProCarManuals.com

Page 83 of 1640

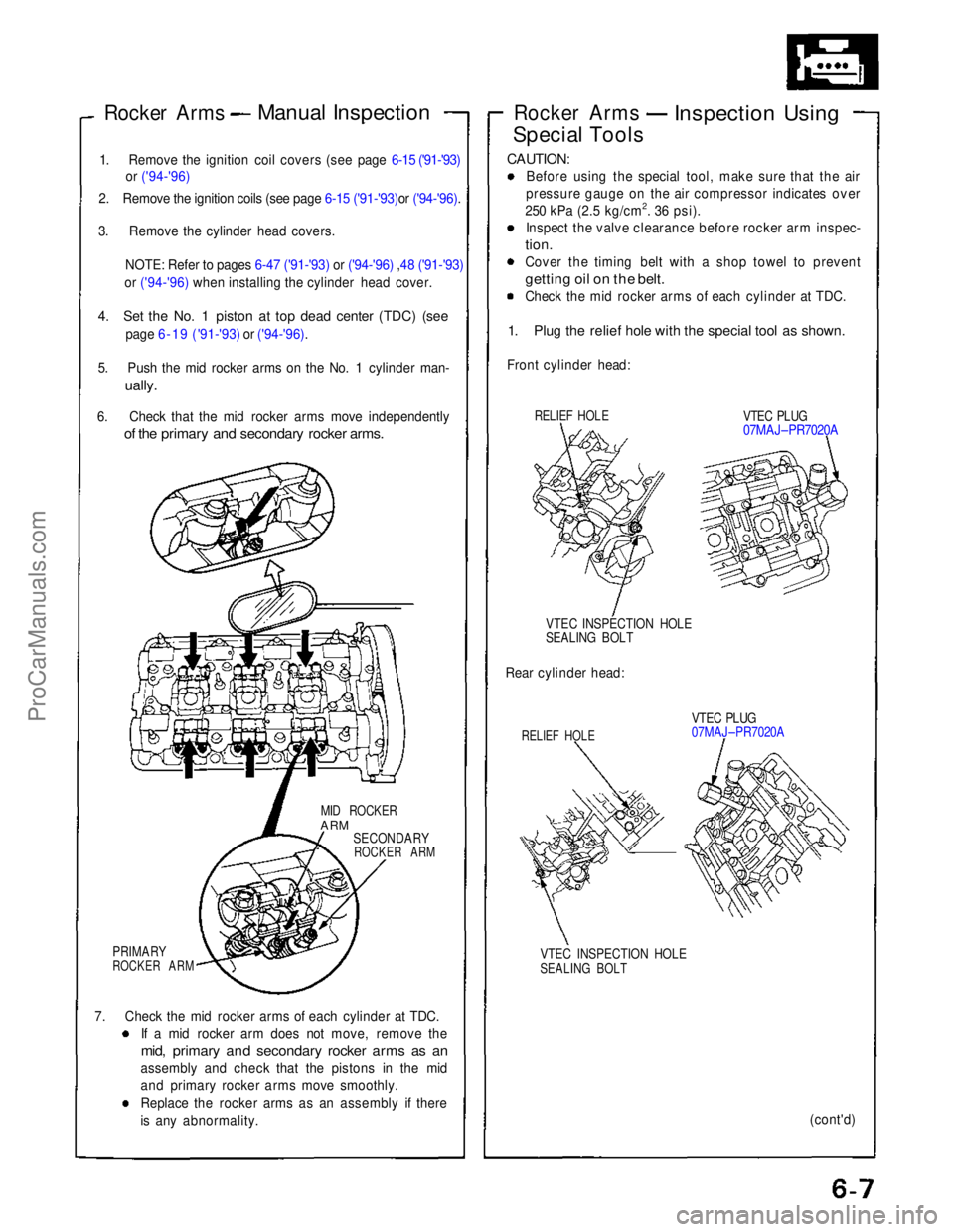

Rocker Arms

Manual Inspection

1. Remove the ignition coil covers (see page 6-15 ('91-'93) or ('94-'96)

2. Remove the ignition coils (see page 6-15 ('91-'93)or ('94-'96).

3. Remove the cylinder head covers.

NOTE: Refer to pages 6-47 ('91-'93)

or ('94-'96) ,48 ('91-'93)

or ('94-'96) when installing the cylinder head cover.

4. Set the No. 1 piston at top dead center (TDC) (see

page 6-19 ('91-'93)

or ('94-'96).

5. Push the mid rocker arms on the No. 1 cylinder man-

ually.

6. Check that the mid rocker arms move independently

of the primary and secondary rocker arms.

MID ROCKER

ARM

SECONDARY

ROCKER ARM

PRIMARY

ROCKER ARM

7. Check the mid rocker arms of each cylinder at TDC. If a mid rocker arm does not move, remove the

mid, primary and secondary rocker arms as an

assembly and check that the pistons in the mid

and primary rocker arms move smoothly.

Replace the rocker arms as an assembly if there

is any abnormality. Rocker Arms

Inspection Using

Special Tools

CAUTION:

Before using the special tool, make sure that the air

pressure gauge on the air compressor indicates over

250 kPa (2.5 kg/cm2. 36 psi). Inspect the valve clearance before rocker arm inspec-

tion.

Cover the timing belt with a shop towel to prevent

getting oil on the belt.

Check the mid rocker arms of each cylinder at TDC.

1. Plug the relief hole with the special tool as shown.

Front cylinder head:

RELIEF HOLE

VTEC PLUG

07MAJ–PR7020A

VTEC INSPECTION HOLE

SEALING BOLT

Rear cylinder head:

RELIEF HOLE

VTEC PLUG

07MAJ–PR7020A

VTEC INSPECTION HOLE

SEALING BOLT

(cont'd)ProCarManuals.com

Page 100 of 1640

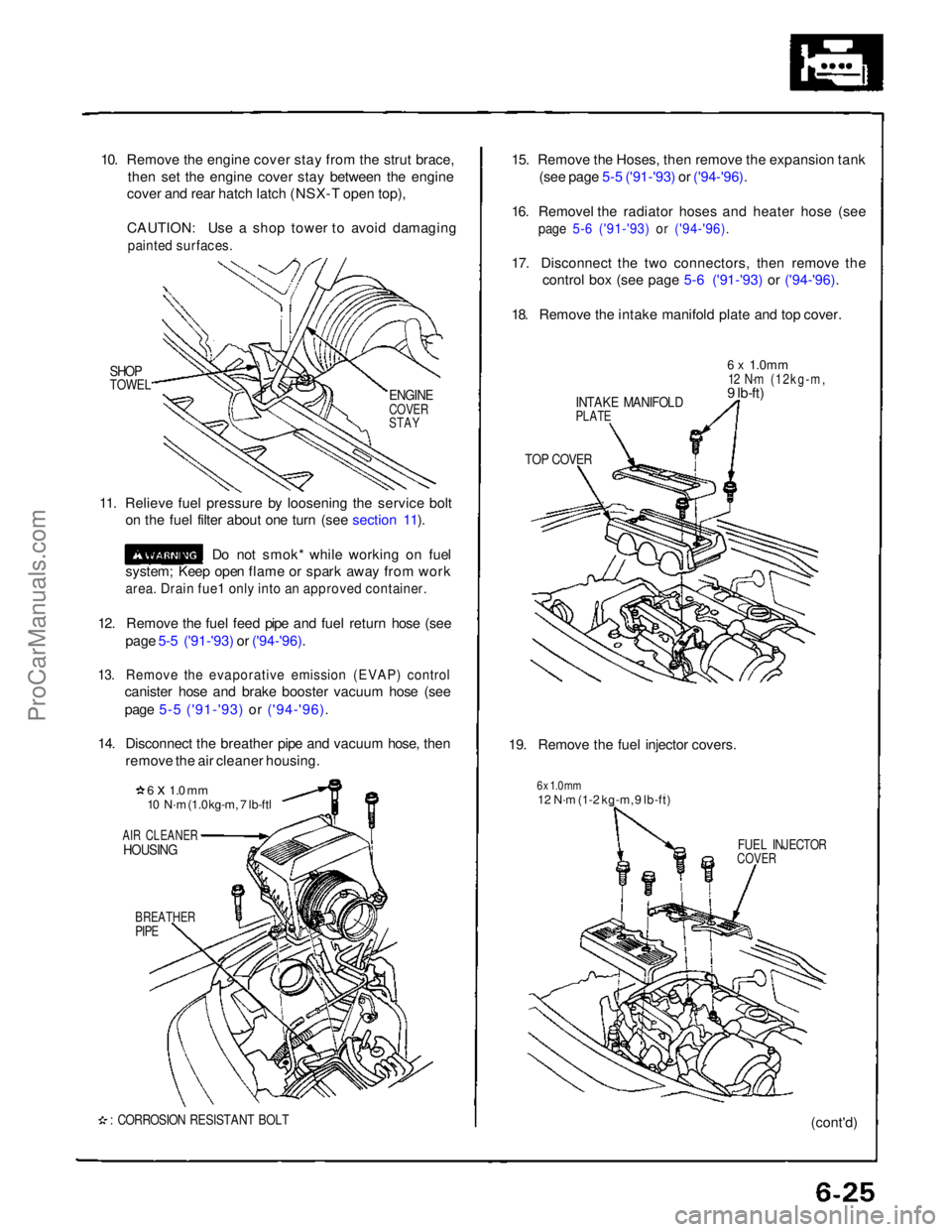

10. Remove the engine cover stay from the strut brace,

then set the engine cover stay between the engine

cover and rear hatch latch (NSX-T open top),

CAUTION: Use a shop tower to avoid damaging

painted surfaces.

SHOP

TOWEL

11. Relieve fuel pressure by loosening the service bolt on the fuel filter about one turn (see section 11).

Do not smok* while working on fuel

system; Keep open flame or spark away from work

area. Drain fue1 only into an approved container.

12. Remove the fuel feed pipe and fuel return hose (see page 5-5 ('91-'93) or ('94-'96).

13. Remove the evaporative emission (EVAP) control

canister hose and brake booster vacuum hose (see

page 5-5 ('91-'93) or ('94-'96).

14. Disconnect the breather pipe and vacuum hose, then remove the air cleaner housing.

6 x 1.0 mm

10 N·m (1.0 kg-m, 7 lb-ftl

AIR CLEANER

HOUSING

BREATHER

PIPE

: CORROSION RESISTANT BOLT

15. Remove the Hoses, then remove the expansion tank

(see page 5-5 ('91-'93) or ('94-'96).

16. Removel the radiator hoses and heater hose (see

page 5-6 ('91-'93) or ('94-'96).

17. Disconnect the two connectors, then remove the

control box (see page 5-6 ('91-'93) or ('94-'96).

18. Remove the intake manifold plate and top cover.

INTAKE MANIFOLD

PLATE

6 x

1.0mm

12 N·m (12kg-m,

9 lb-ft)

TOP COVER

19. Remove the fuel injector covers.

6 x 1.0 mm

12 N·m (1-2 kg-m, 9 lb-ft)

FUEL INJECTOR

COVER

(cont'd)

ENGINE

COVER

STAYProCarManuals.com

Page 105 of 1640

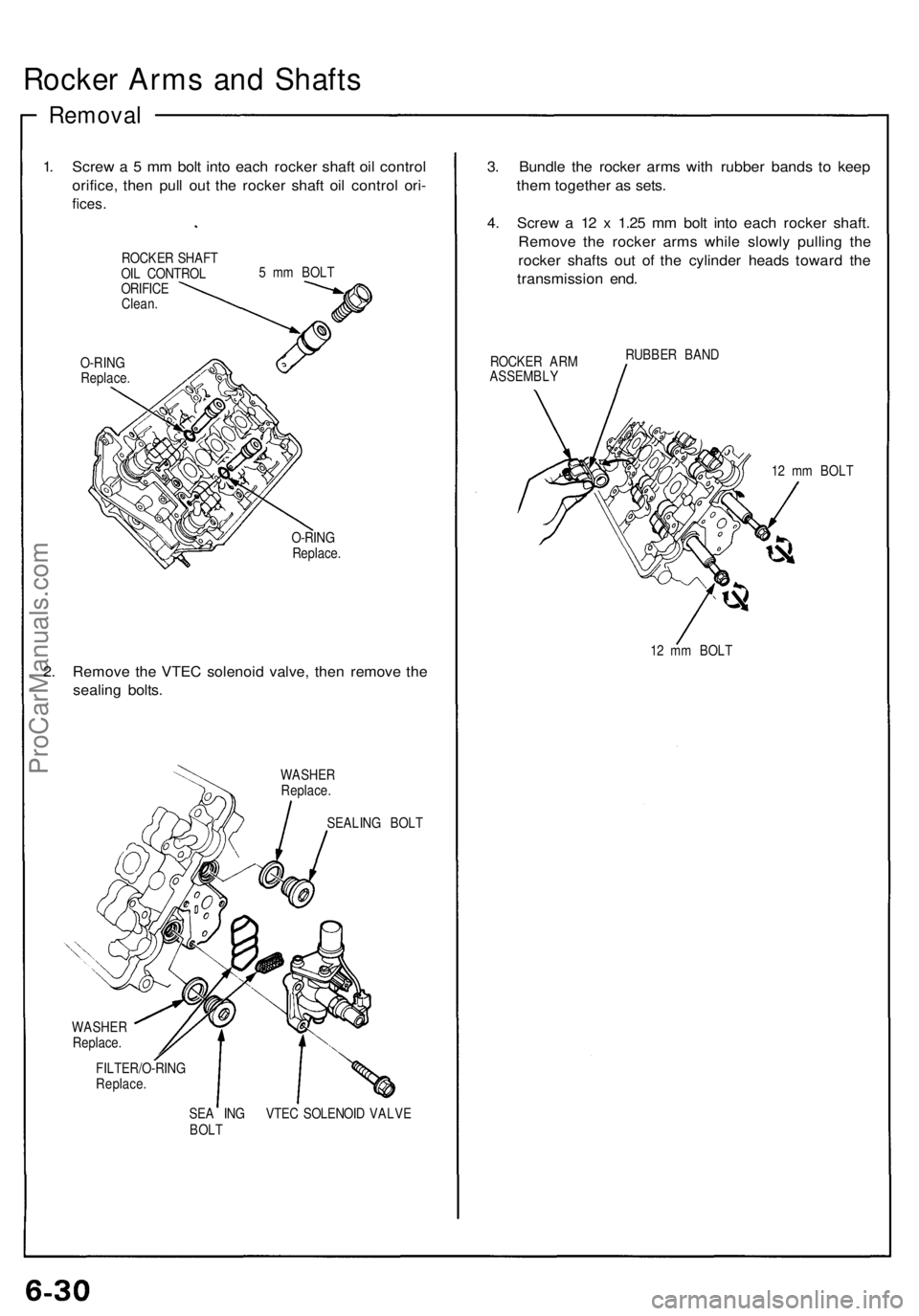

Rocker Arm s an d Shaft s

Remova l

1. Scre w a 5 m m bol t int o eac h rocke r shaf t oi l contro l

orifice , the n pul l ou t th e rocke r shaf t oi l contro l ori -

fices .

ROCKE R SHAF T

OI L CONTRO L

ORIFIC E

Clean . 5

m m BOL T

O-RIN G

Replace .

O-RING

Replace .

2. Remov e th e VTE C solenoi d valve , the n remov e th e

sealin g bolts .

WASHE R

Replace .

SEALIN G BOL T

WASHE R

Replace .

FILTER/O-RIN G

Replace .

SEA IN G VTE C SOLENOI D VALV E

BOL T

3. Bundl e th e rocke r arm s wit h rubbe r band s t o kee p

the m togethe r a s sets .

4 . Scre w a 1 2 x 1.2 5 m m bol t int o eac h rocke r shaft .

Remov e th e rocke r arm s whil e slowl y pullin g th e

rocke r shaft s ou t o f th e cylinde r head s towar d th e

transmissio n end .

ROCKE R AR M

ASSEMBL Y RUBBE

R BAN D

12 m m BOL T

1 2 m m BOL T

ProCarManuals.com

Page 109 of 1640

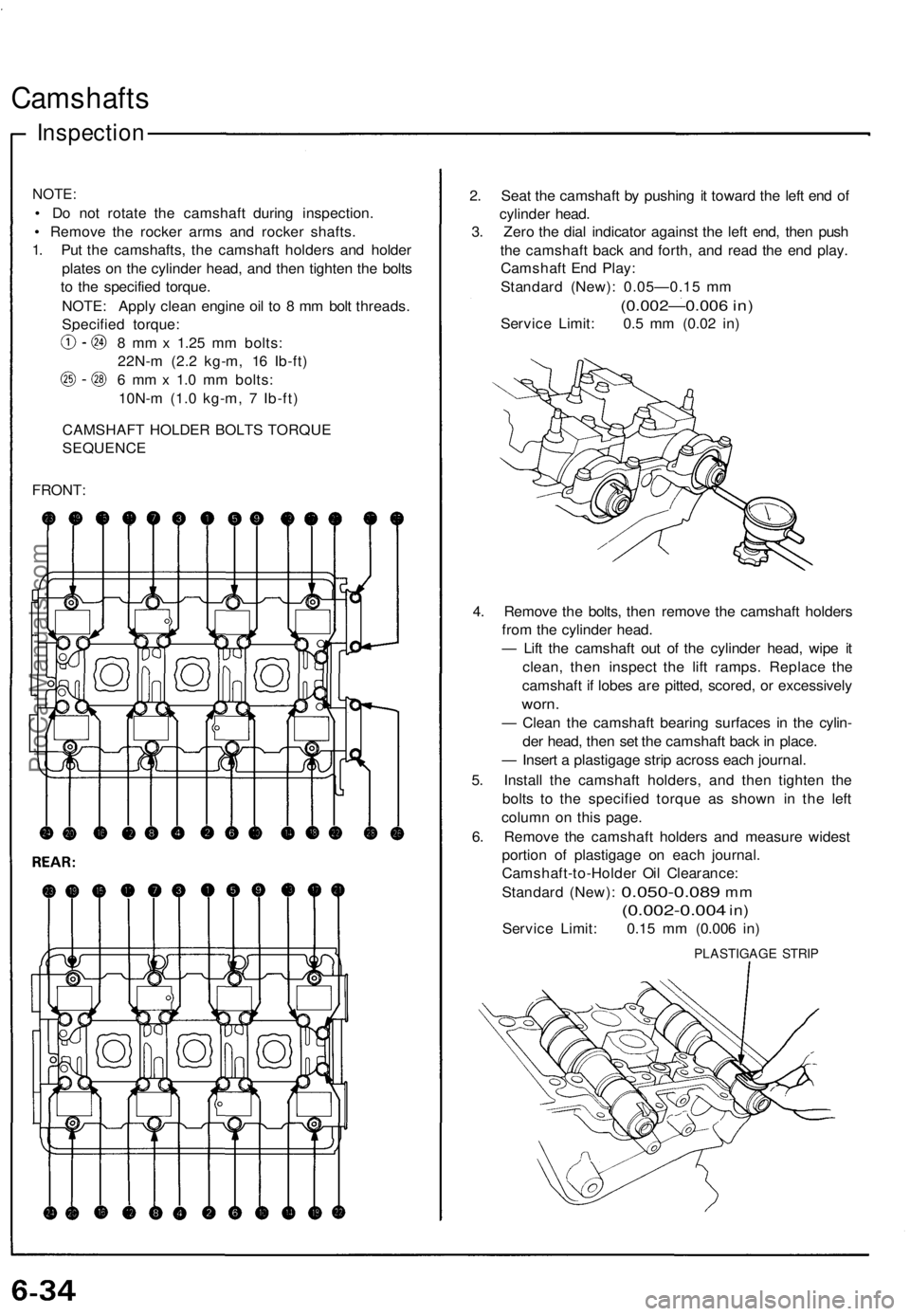

Camshafts

Inspection

NOTE:

• D o no t rotat e th e camshaf t durin g inspection .

• Remov e th e rocke r arm s an d rocke r shafts .

1 . Pu t th e camshafts , th e camshaf t holder s an d holde r

plate s o n th e cylinde r head , an d the n tighte n th e bolt s

t o th e specifie d torque .

NOTE : Appl y clea n engin e oi l t o 8 m m bol t threads .

Specifie d torque :

8 m m x 1.2 5 m m bolts :

22N- m (2. 2 kg-m , 1 6 Ib-ft )

6 m m x 1. 0 m m bolts :

10N- m (1. 0 kg-m , 7 Ib-ft )

CAMSHAF T HOLDE R BOLT S TORQU E

SEQUENCE

FRONT :

2. Sea t th e camshaf t b y pushin g i t towar d th e lef t en d o f

cylinde r head .

3 . Zer o th e dia l indicato r agains t th e lef t end , the n pus h

th e camshaf t bac k an d forth , an d rea d th e en d play .

Camshaf t En d Play :

Standar d (New) : 0.05—0.1 5 m m

(0.002—0.006 in)

Servic e Limit : 0. 5 m m (0.0 2 in )

4 . Remov e th e bolts , the n remov e th e camshaf t holder s

fro m th e cylinde r head .

— Lif t th e camshaft out o f th e cylinde r head , wip e i t

clean , the n inspec t th e lif t ramps . Replac e th e

camshaft if lobe s ar e pitted , scored , o r excessivel y

worn.

— Clea n th e camshaf t bearin g surface s i n th e cylin -

de r head , the n se t th e camshaf t bac k in place .

— Inser t a plastigag e stri p acros s eac h journal.

5 . Instal l th e camshaf t holders , an d the n tighte n th e

bolt s t o th e specifie d torqu e a s show n i n th e lef t

colum n o n thi s page .

6 . Remov e th e camshaf t holder s an d measur e wides t

portio n o f plastigag e o n eac h journal .

Camshaft-to-Holde r Oi l Clearance :

Standar d (New) :

0.050-0.08 9 mm

(0.002-0.00 4 in)

Servic e Limit : 0.1 5 m m (0.00 6 in )

PLASTIGAG E STRI P

ProCarManuals.com

Page 116 of 1640

Valve Guide s

Replacemen t

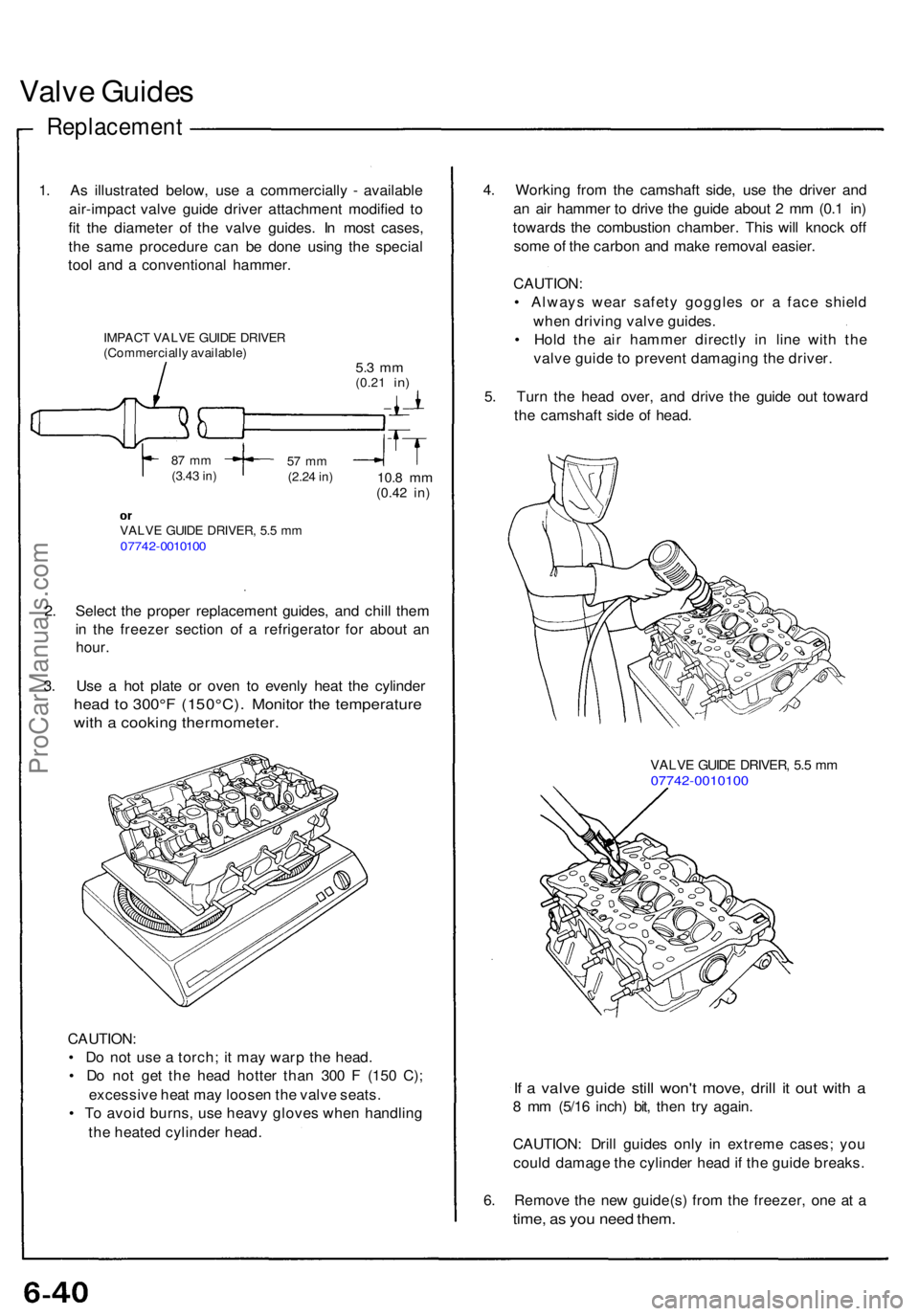

1. A s illustrate d below , us e a commerciall y - availabl e

air-impac t valv e guid e drive r attachmen t modifie d t o

fi t th e diamete r o f th e valv e guides . I n mos t cases ,

th e sam e procedur e ca n b e don e usin g th e specia l

too l an d a conventiona l hammer .

IMPACT VALV E GUID E DRIVE R(Commerciall y available )5.3 m m(0.2 1 in)

87 m m(3.4 3 in)57 m m(2.2 4 in)10. 8 m m(0.4 2 in)

VALV E GUID E DRIVER , 5. 5 m m0774 2-001010 0

2. Selec t th e prope r replacemen t guides , an d chil l the m

i n th e freeze r sectio n o f a refrigerato r fo r abou t a n

hour .

3. Us e a ho t plat e o r ove n t o evenl y hea t th e cylinde r

head t o 300° F ( 150°C) . Monito r th e temperatur e

with a cookin g thermometer .

CAUTION:

• D o no t us e a torch ; i t ma y war p th e head .

• D o no t ge t th e hea d hotte r tha n 30 0 F (15 0 C) ;

excessiv e hea t ma y loose n th e valv e seats .

• T o avoi d burns , us e heav y glove s whe n handlin g

th e heate d cylinde r head . 4

. Workin g fro m th e camshaf t side , us e th e drive r an d

a n ai r hamme r t o driv e th e guid e abou t 2 m m (0. 1 in )

toward s th e combustio n chamber . Thi s wil l knoc k of f

som e o f th e carbo n an d mak e remova l easier .

CAUTION :

• Alway s wea r safet y goggle s o r a fac e shiel d

whe n drivin g valv e guides .

• Hol d th e ai r hamme r directl y i n lin e wit h th e

valv e guid e t o preven t damagin g th e driver .

5 . Tur n th e hea d over , an d driv e th e guid e ou t towar d

th e camshaf t sid e o f head .

VALV E GUID E DRIVER , 5. 5 m m07742-001010 0

If a valv e guid e stil l won' t move , dril l i t ou t wit h a

8 m m (5/1 6 inch ) bit , the n tr y again .

CAUTION : Dril l guide s onl y i n extrem e cases ; yo u

coul d damag e th e cylinde r hea d if th e guid e breaks .

6 . Remov e th e ne w guide(s ) fro m th e freezer , on e a t a

time , a s yo u nee d them .

ProCarManuals.com

Page 119 of 1640

Valves, Valv e Spring s an d Valv e Seal s

Installatio n Sequenc e

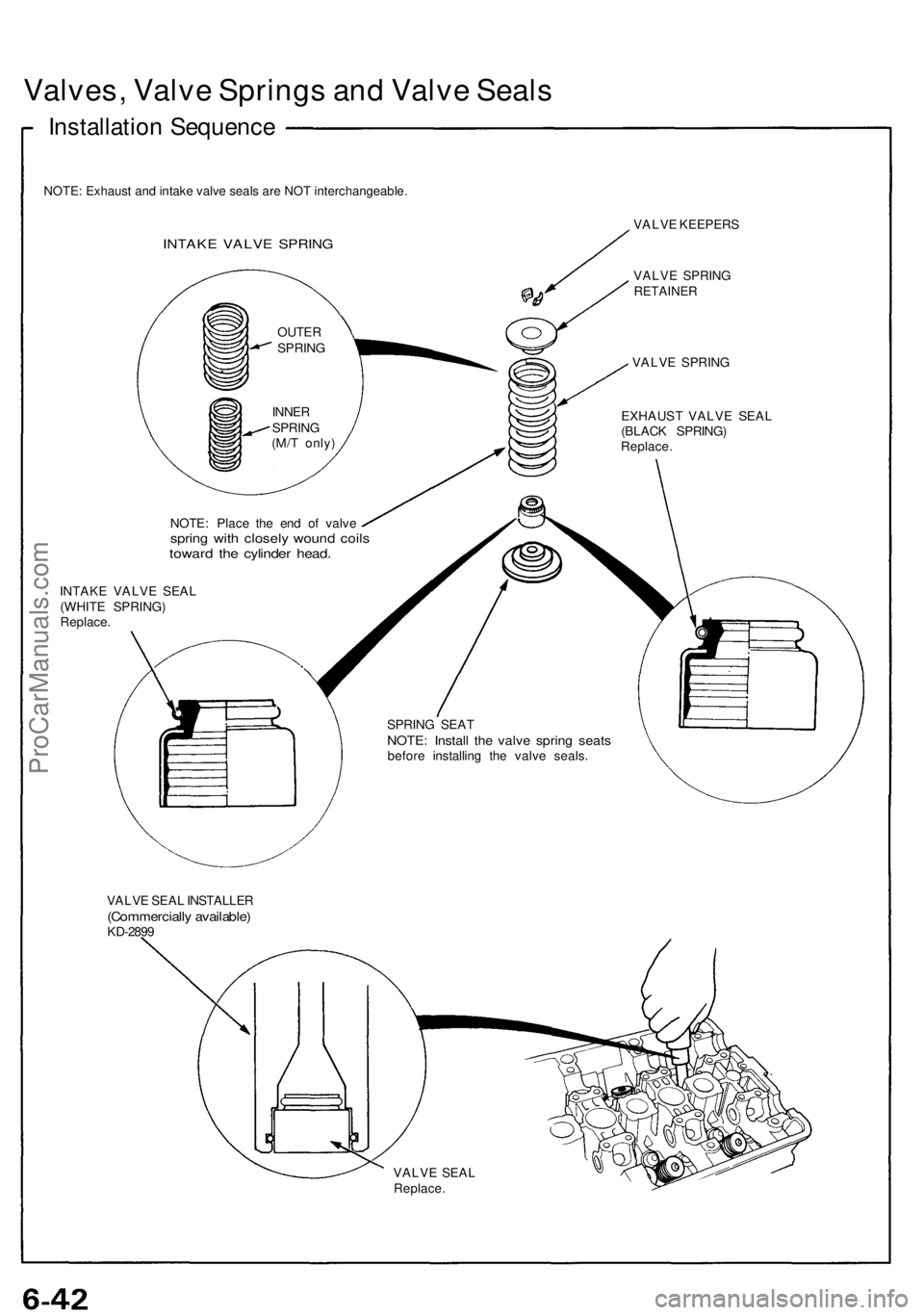

NOTE: Exhaust and intake valve seals are NOT interchangeable.

INTAKE VALV E SPRIN G

VALVE KEEPER S

VALV E SPRIN G

RETAINE R

VALVE SPRIN G

EXHAUS T VALV E SEA L

(BLAC K SPRING )

Replace.

NOTE: Plac e th e en d o f valv espring wit h closel y woun d coil stowar d th e cylinde r head .

INTAK E VALV E SEA L

(WHIT E SPRING )

Replace .

SPRING SEA T

NOTE : Instal l th e valv e sprin g seat sbefor e installin g th e valv e seals .

VALV E SEA L INSTALLE R

(Commerciall y available )KD-2899

VALVE SEA L

Replace .

OUTER

SPRIN G

INNE R

SPRIN G

(M/ T only )

ProCarManuals.com