oil ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 9 of 1640

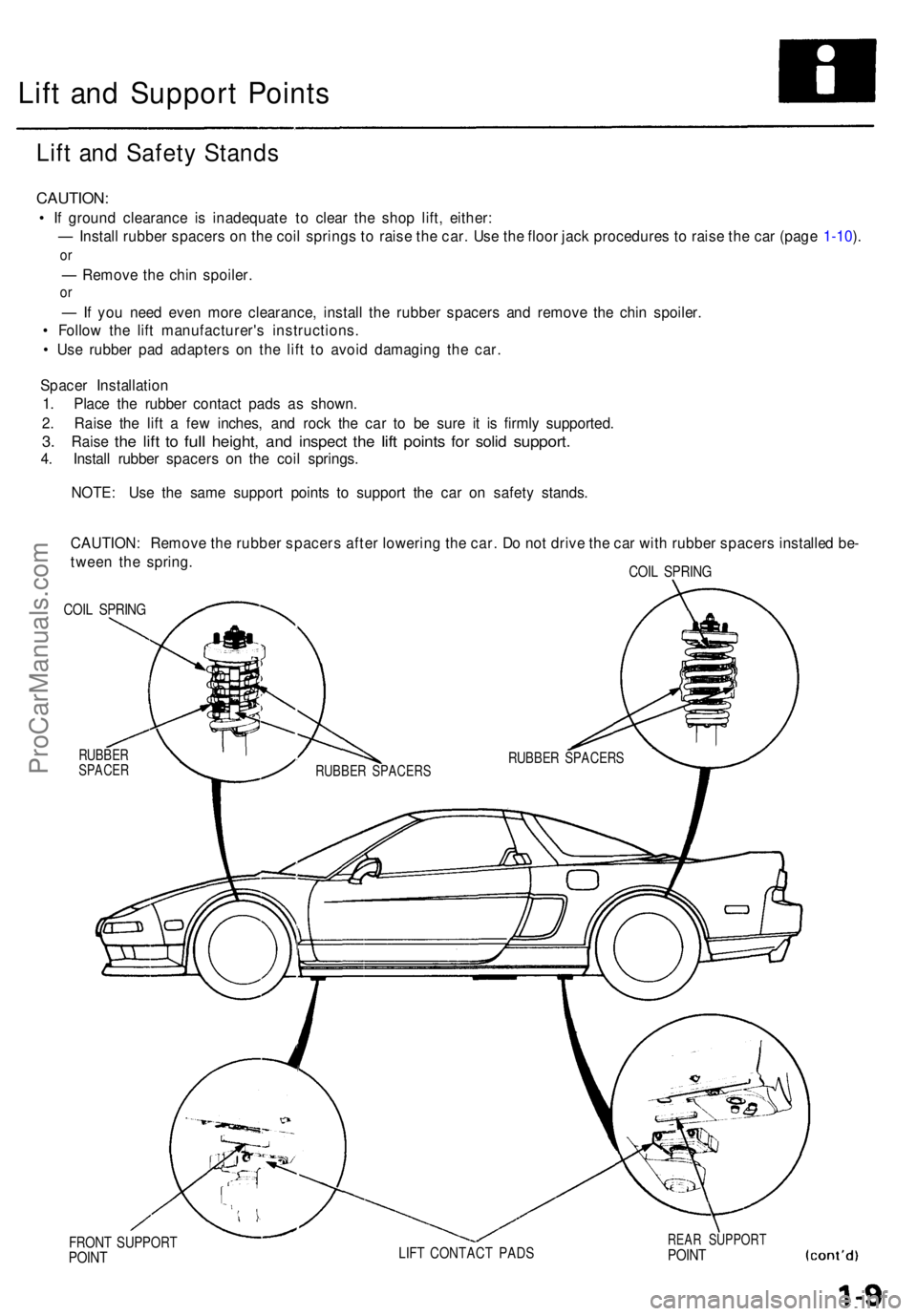

Lift an d Suppor t Point s

Lift an d Safet y Stand s

CAUTION :

• I f groun d clearanc e i s inadequat e t o clea r th e sho p lift , either :

— Instal l rubbe r spacer s o n th e coi l spring s t o rais e th e car . Us e th e floo r jac k procedure s t o rais e th e ca r (pag e 1-10 ).

o r

— Remov e th e chi n spoiler .

or

— If yo u nee d eve n mor e clearance , instal l th e rubbe r spacer s an d remov e th e chi n spoiler .

• Follo w th e lif t manufacturer' s instructions .

• Us e rubbe r pa d adapter s o n th e lif t t o avoi d damagin g th e car .

Space r Installatio n

1 . Plac e th e rubbe r contac t pad s a s shown .

2 . Rais e th e lif t a fe w inches , an d roc k th e ca r t o b e sur e i t i s firml y supported .

3. Rais e the lift to ful l height , and inspec t the lift point s for soli d support .

4. Instal l rubbe r spacer s o n th e coi l springs .

NOTE : Us e th e sam e suppor t point s t o suppor t th e ca r o n safet y stands .

CAUTION : Remov e th e rubbe r spacer s afte r lowerin g th e car . D o no t driv e th e ca r wit h rubbe r spacer s installe d be -

twee n th e spring .

COIL SPRIN G

COIL SPRIN G

RUBBE RSPACE R

FRONT SUPPOR TPOINTLIFT CONTAC T PAD SREAR SUPPOR TPOINT

RUBBE R SPACER SRUBBER SPACER S

ProCarManuals.com

Page 27 of 1640

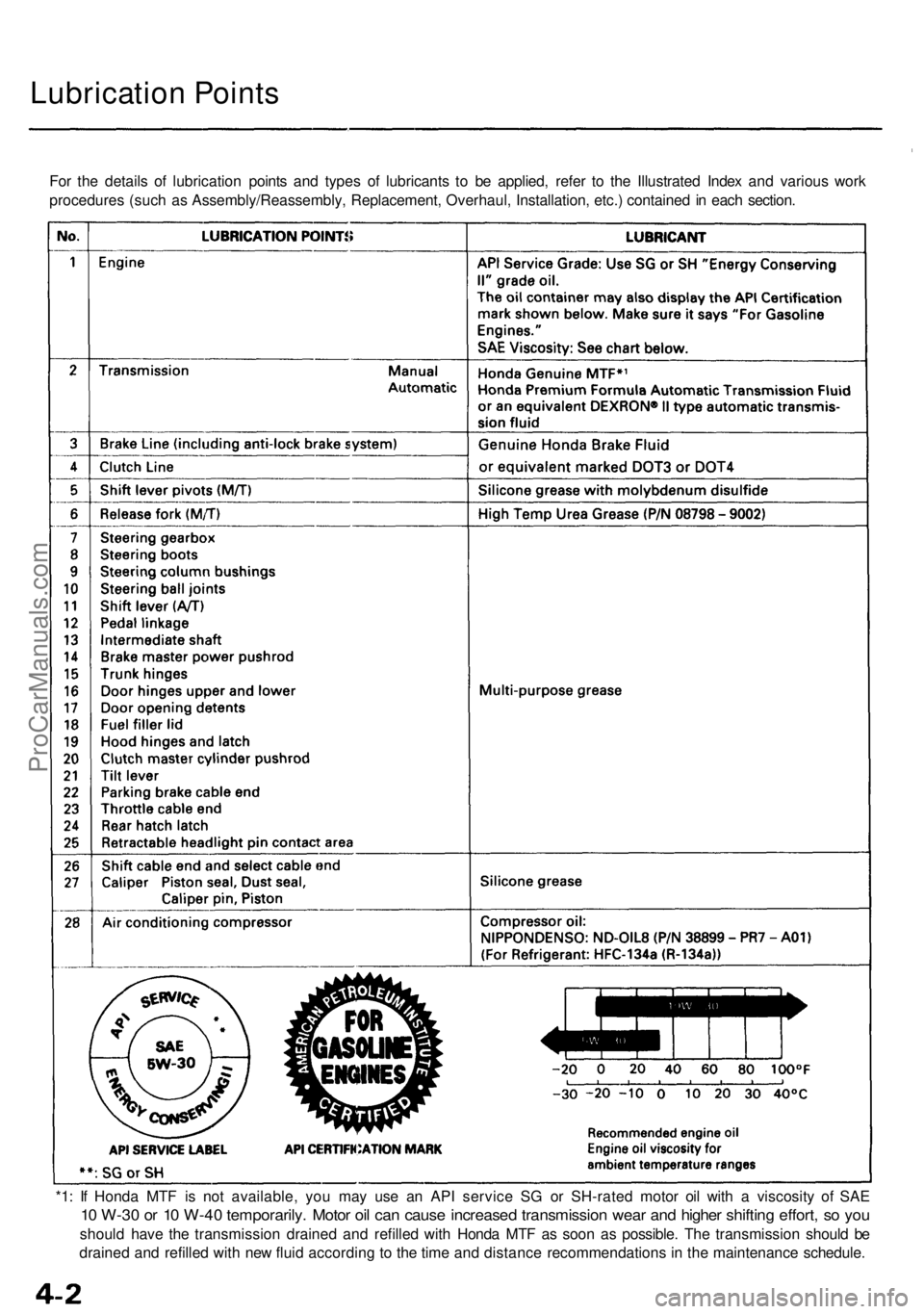

Lubrication Points

For the details of lubrication points and types of lubricants to be applied, refer to the Illustrated Index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

*1: If Honda MTF is not available, you may use an API service SG or SH-rated motor oil with a viscosity of SAE

10 W-30 or 10 W-40 temporarily. Motor oil can cause increased transmission wear and higher shifting effort, so you

should have the transmission drained and refilled with Honda MTF as soon as possible. The transmission should be

drained and refilled with new fluid according to the time and distance recommendations in the maintenance schedule.ProCarManuals.com

Page 33 of 1640

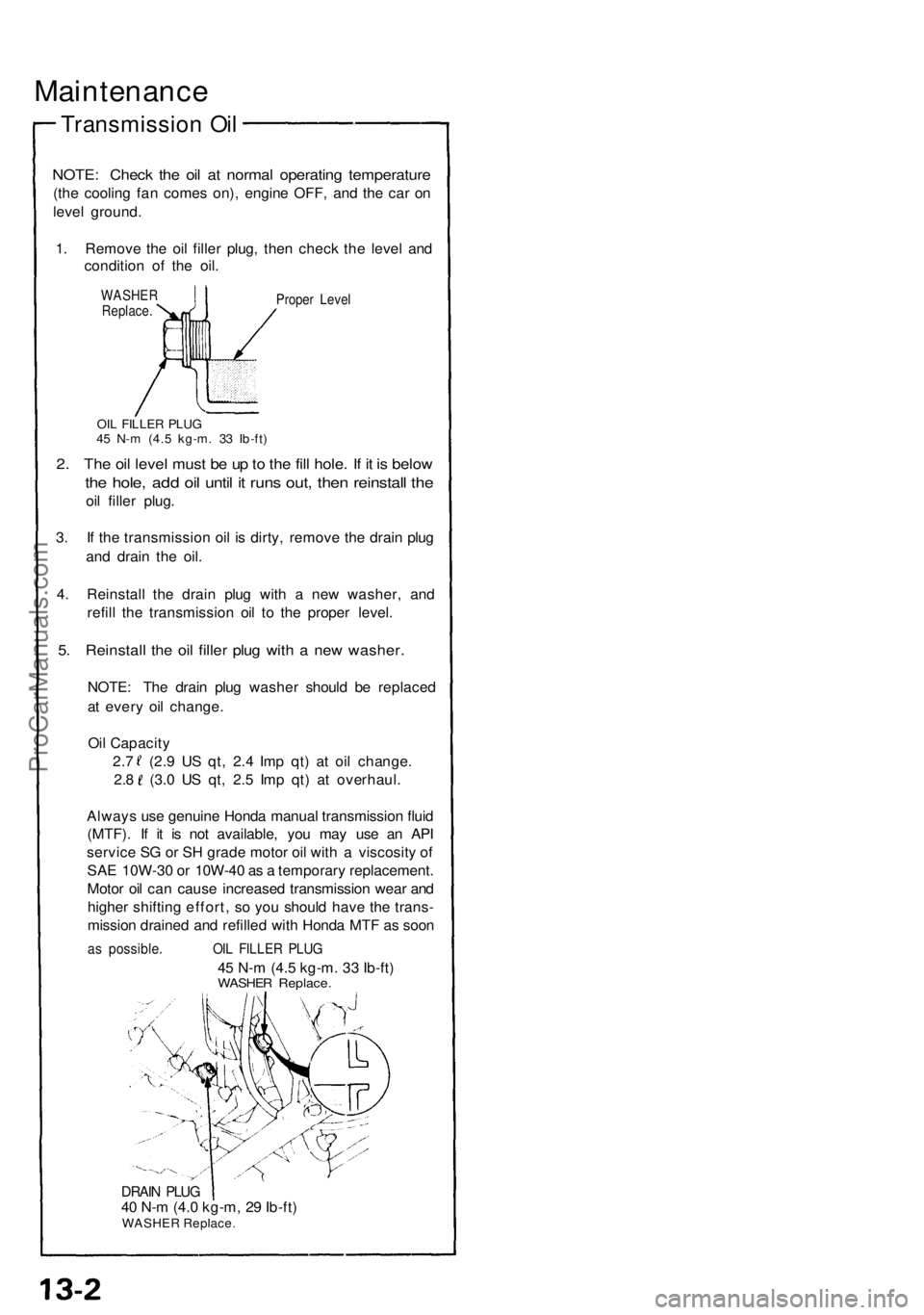

Maintenance

Transmissio n Oi l

NOTE : Chec k th e oi l a t norma l operatin g temperatur e

(the coolin g fa n come s on) , engin e OFF , an d th e ca r o n

leve l ground .

1 . Remov e th e oi l fille r plug , the n chec k th e leve l an d

conditio n o f th e oil .

WASHE RReplace .Proper Leve l

OIL FILLE R PLU G45 N- m (4. 5 kg-m . 3 3 Ib-ft )

2. Th e oi l leve l mus t b e u p to th e fil l hole . I f i t i s belo w

the hole , ad d oi l unti l i t run s out , the n reinstal l th e

oil fille r plug .

3 . I f th e transmissio n oi l i s dirty , remov e th e drai n plu g

an d drai n th e oil .

4 . Reinstal l th e drai n plu g wit h a ne w washer , an d

refil l th e transmissio n oi l t o th e prope r level .

5. Reinstal l th e oi l fille r plu g wit h a ne w washer .

NOTE: Th e drai n plu g washe r shoul d b e replace d

a t ever y oi l change .

Oi l Capacit y

2. 7 ( 2.9 U S qt , 2. 4 Im p qt ) a t oi l change .

2.8 (3. 0 U S qt , 2. 5 Im p qt ) a t overhaul .

Alway s us e genuin e Hond a manua l transmissio n flui d

(MTF) . I f i t i s no t available , yo u ma y us e a n AP I

servic e S G o r S H grad e moto r oi l wit h a viscosit y o f

SA E 10W-3 0 o r 10W-4 0 a s a temporar y replacement .

Moto r oi l ca n caus e increase d transmissio n wea r an d

highe r shiftin g effort , s o yo u shoul d hav e th e trans -

missio n draine d an d refille d wit h Hond a MT F a s soo n

as possible . OIL FILLE R PLU G

45 N- m (4. 5 kg-m . 3 3 Ib-ft )WASHE R Replace .

DRAIN PLU G40 N- m (4. 0 kg-m , 2 9 Ib-ft )WASHE R Replac e

ProCarManuals.com

Page 41 of 1640

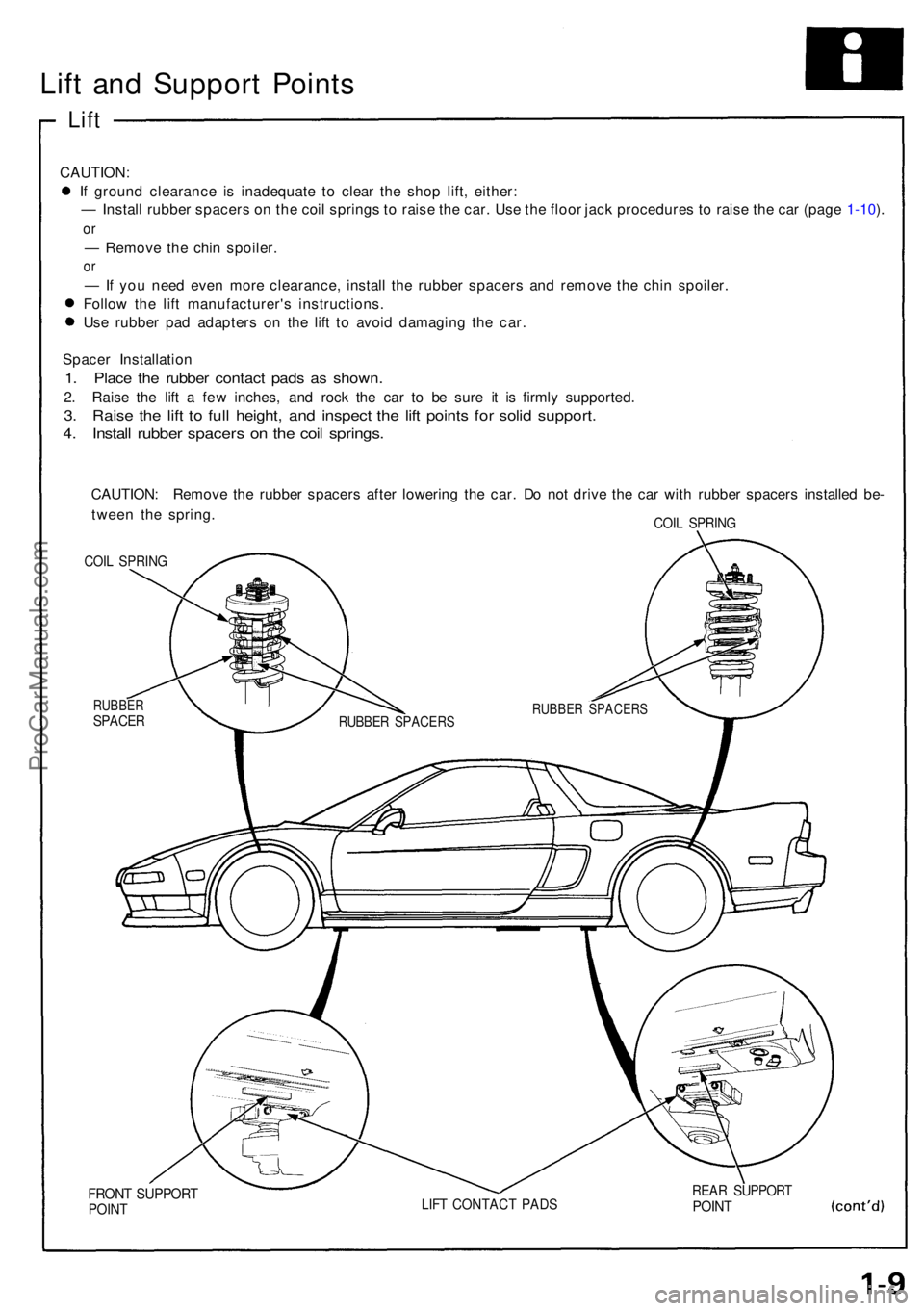

Lift an d Suppor t Point s

Lift

CAUTION :

I f groun d clearanc e i s inadequat e t o clea r th e sho p lift , either :

— Instal l rubbe r spacer s o n th e coi l spring s t o rais e th e car . Us e th e floo r jac k procedure s t o rais e th e ca r (pag e 1-10 ).

o r

— Remov e th e chi n spoiler .

or

— If yo u nee d eve n mor e clearance , instal l th e rubbe r spacer s an d remov e th e chi n spoiler .

Follo w th e lif t manufacturer' s instructions .

Us e rubbe r pa d adapter s o n th e lif t t o avoi d damagin g th e car .

Space r Installatio n

1. Plac e th e rubbe r contac t pad s a s shown .

2. Rais e th e lif t a fe w inches, and roc k th e ca r t o b e sur e i t i s firml y supported .

3. Rais e th e lif t t o ful l height , an d inspec t th e lif t point s fo r soli d support .

4. Instal l rubbe r spacer s o n th e coi l springs .

CAUTION : Remov e th e rubbe r spacer s afte r lowerin g th e car . D o no t driv e th e ca r wit h rubbe r spacer s installe d be -

twee n th e spring .

COIL SPRIN G

COIL SPRIN G

RUBBE RSPACER

FRONT SUPPOR TPOINTLIFT CONTAC T PAD SREAR SUPPOR TPOINT

RUBBE R SPACER SRUBBER SPACER S

ProCarManuals.com

Page 72 of 1640

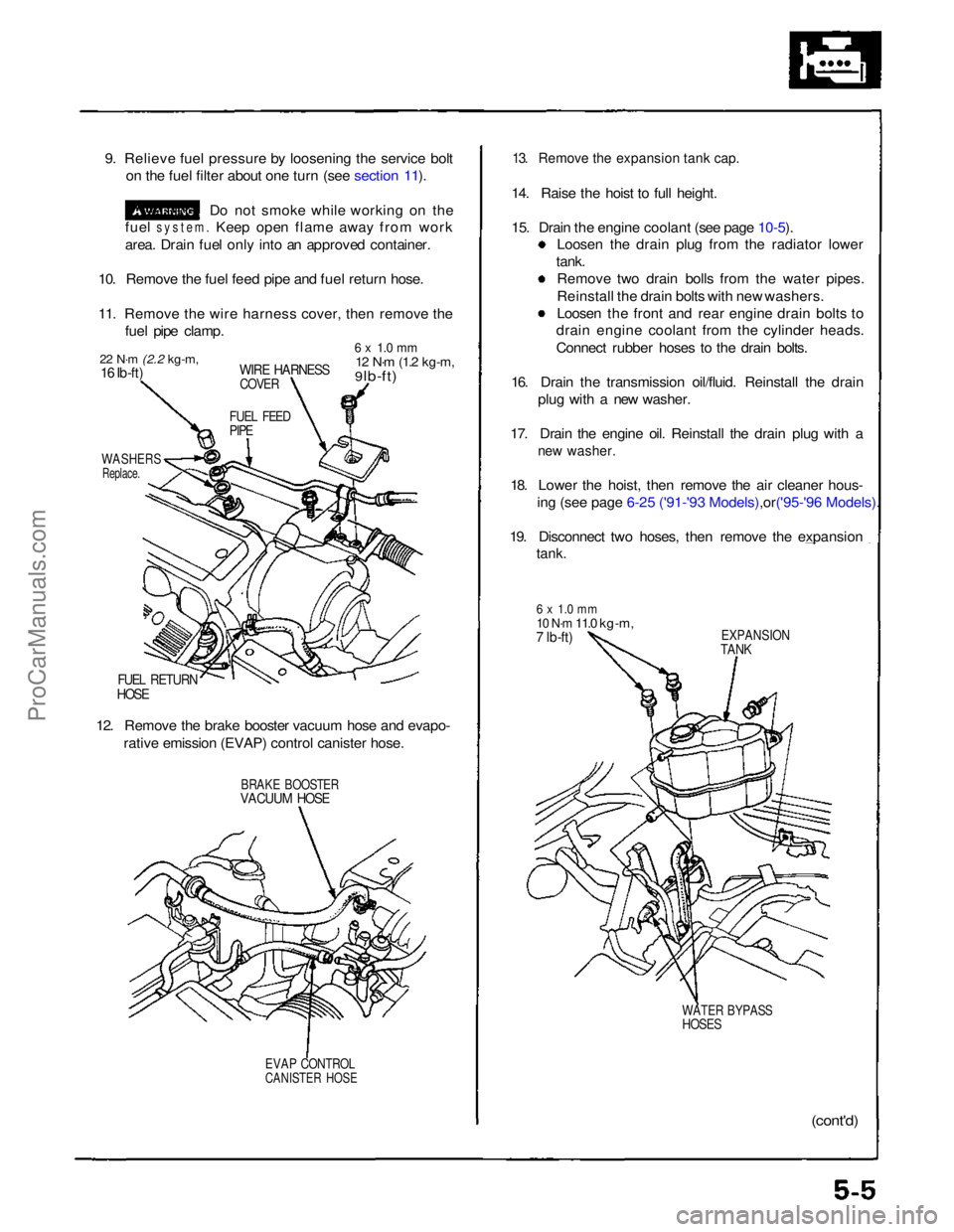

9. Relieve fuel pressure by loosening the service bolt

on the fuel filter about one turn (see section 11).

Do not smoke while working on the

fuel

system.

Keep open flame away from work

area. Drain fuel only into an approved container.

10. Remove the fuel feed pipe and fuel return hose.

11. Remove the wire harness cover, then remove the fuel pipe clamp.

22 N·m

(2.2 kg-m,

16 Ib-ft)

WIRE HARNESS

COVER

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 lb-ft)

FUEL FEED

PIPE

WASHERS

Replace.

FUEL RETURN

HOSE

12. Remove the brake booster vacuum hose and evapo- rative emission (EVAP) control canister hose.

BRAKE BOOSTER

VACUUM HOSE

EVAP CONTROL

CANISTER HOSE

13. Remove the expansion tank cap.

14. Raise the hoist to full height.

15. Drain the engine coolant (see page

10-5).

Loosen the drain plug from the radiator lower

tank. Remove two drain bolls from the water pipes.

Reinstall the drain bolts with new washers.

Loosen the front and rear engine drain bolts to

drain engine coolant from the cylinder heads.

Connect rubber hoses to the drain bolts.

16. Drain the transmission oil/fluid. Reinstall the drain plug with a new washer.

17. Drain the engine oil. Reinstall the drain plug with a

new washer.

18. Lower the hoist, then remove the air cleaner hous-

ing (see page 6-25 ('91-'93 Mode ls),or('95-'96 Models).

19. Disconnect two hoses, then remove the expansion

tank.

6 x 1.0 mm

10 N·m

11.0 kg-m,

7 lb-ft)

EXPANSION

TANK

WATER BYPASS

HOSES

(cont'd)ProCarManuals.com

Page 77 of 1640

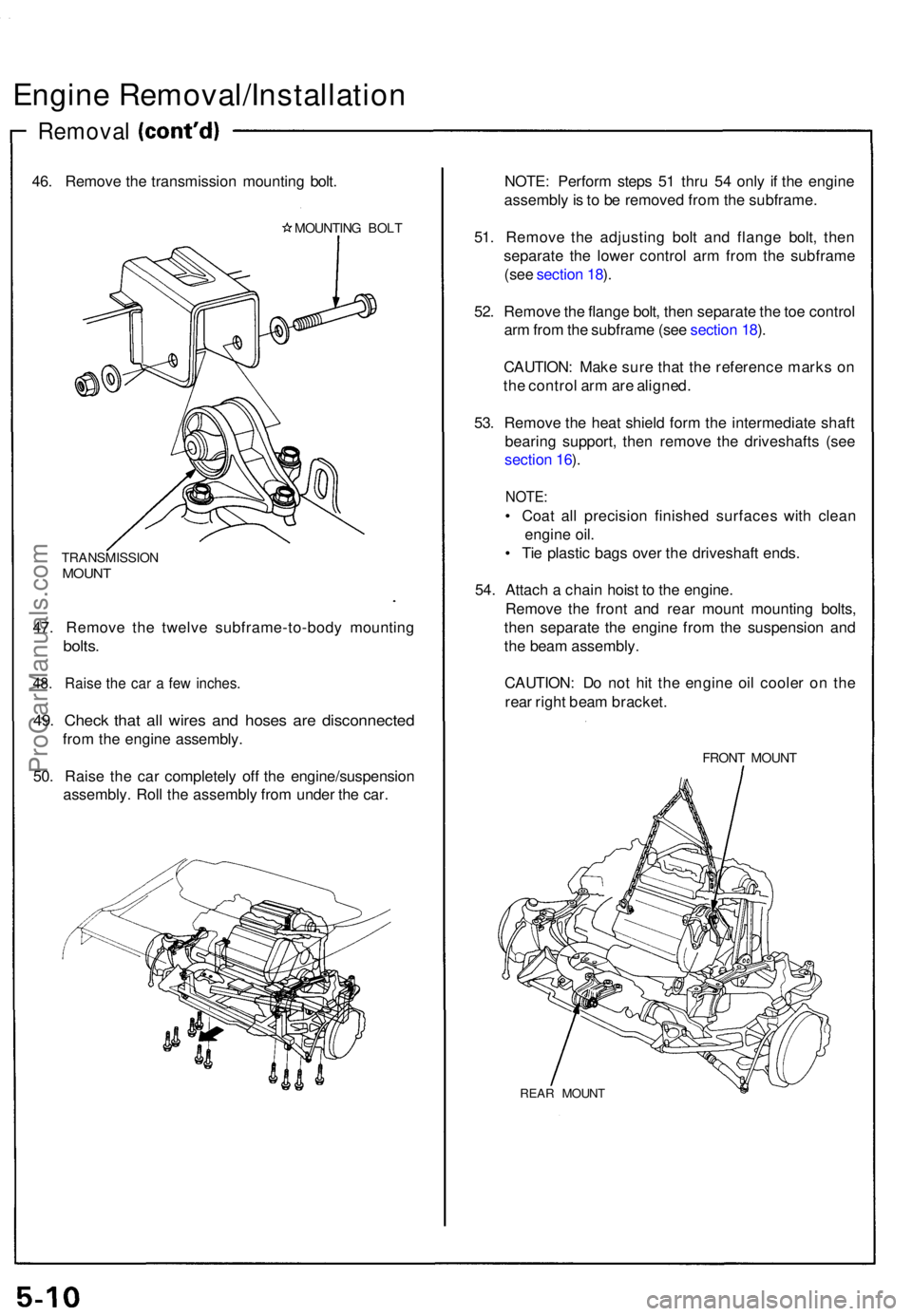

Engine Removal/Installatio n

Removal

46. Remov e th e transmissio n mountin g bolt .

MOUNTIN G BOL T

TRANSMISSIO NMOUNT

47. Remov e th e twelv e subframe-to-bod y mountin g

bolts.

48. Rais e th e ca r a fe w inches .

49. Chec k tha t al l wire s an d hose s ar e disconnecte d

from th e engin e assembly .

50 . Rais e th e ca r completel y of f th e engine/suspensio n

assembly . Rol l th e assembl y fro m unde r th e car . NOTE

: Perfor m step s 5 1 thr u 5 4 onl y i f th e engin e

assembl y is t o b e remove d fro m th e subframe .

51 . Remov e th e adjustin g bol t an d flang e bolt , the n

separat e th e lowe r contro l ar m fro m th e subfram e

(se e sectio n 18 ).

52 . Remov e th e flang e bolt , the n separat e th e to e contro l

ar m fro m th e subfram e (se e sectio n 18 ).

CAUTION : Mak e sur e tha t th e referenc e mark s o n

th e contro l ar m ar e aligned .

53 . Remov e th e hea t shiel d for m th e intermediat e shaf t

bearin g support , the n remov e th e driveshaft s (se e

sectio n 16 ).

NOTE :

• Coa t al l precisio n finishe d surface s wit h clea n

engin e oil .

• Ti e plasti c bag s ove r th e driveshaf t ends .

54 . Attac h a chai n hois t t o th e engine .

Remov e th e fron t an d rea r moun t mountin g bolts ,

the n separat e th e engine from th e suspensio n an d

th e bea m assembly .

CAUTION : D o no t hi t th e engin e oi l coole r o n th e

rea r righ t bea m bracket .

FRONT MOUN T

REAR MOUN T

ProCarManuals.com

Page 80 of 1640

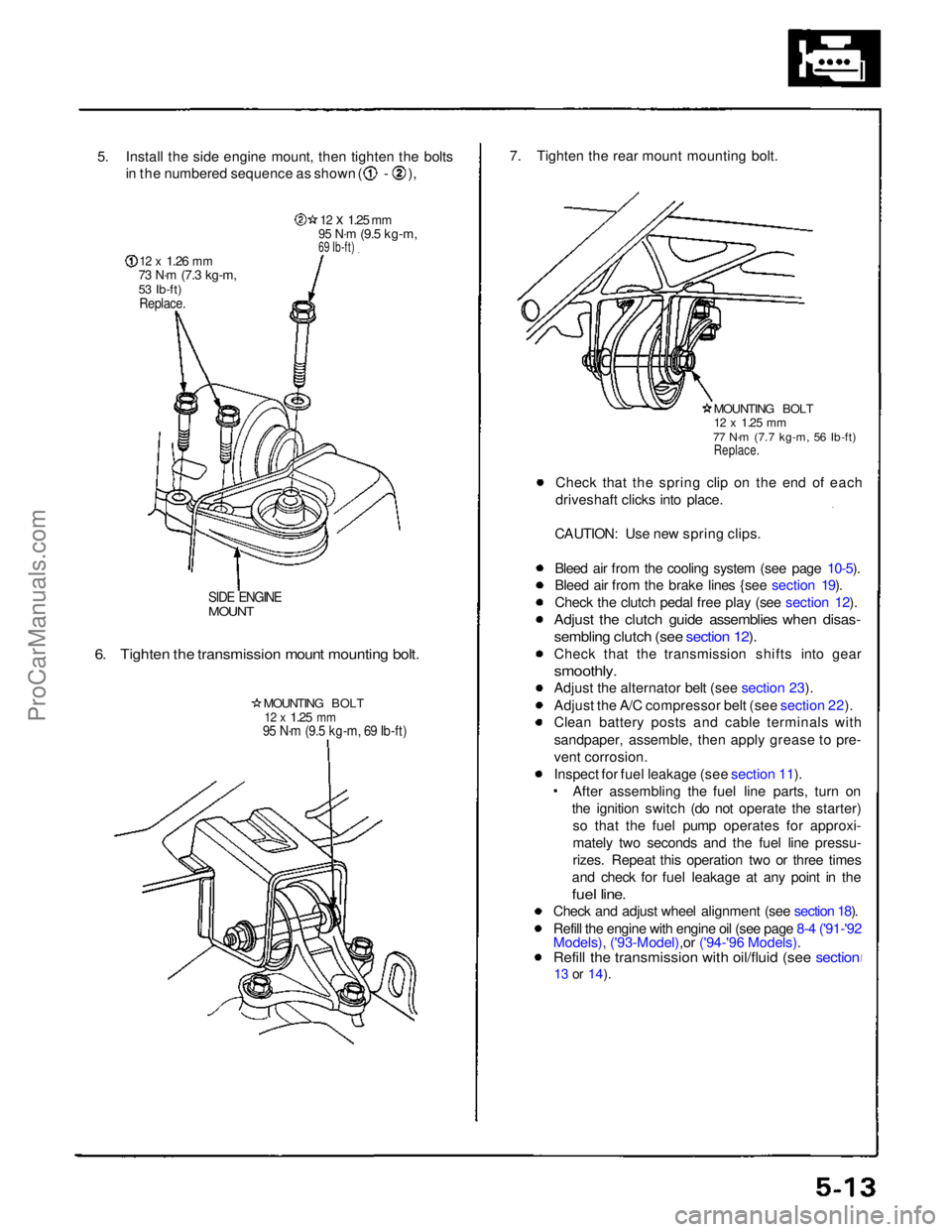

5. Install the side engine mount, then tighten the bolts

in the numbered sequence as shown ( - ),

12 x

1.26

mm

73 N·m

(7.3 kg-m,

53 Ib-ft)

Replace.

12 x

1.25

mm

95 N·m

(9.5 kg-m,

69 Ib-ft)

SIDE ENGINE

MOUNT

6. Tighten the transmission mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

95 N·m (9.5 kg-m, 69 Ib-ft)

7. Tighten the rear mount mounting bolt.

MOUNTING BOLT

12 x

1.25

mm

77 N·m (7.7 kg-m, 56 Ib-ft)

Replace.

Check that the spring clip on the end of each

driveshaft clicks into place.

CAUTION: Use new spring clips.

Bleed air from the cooling system (see page 10-5).

Bleed air from the brake lines {see section 19).

Check the clutch pedal free play (see section 12).

Adjust the clutch guide assemblies when disas-

sembling clutch (see section 12).

Check that the transmission shifts into gear

smoothly.

Adjust the alternator belt (see section 23).

Adjust the A/C compressor belt (see section 22).

Clean battery posts and cable terminals with

sandpaper, assemble, then apply grease to pre-

vent corrosion.

Inspect for fuel leakage (see section 11). After assembling the fuel line parts, turn on

the ignition switch (do not operate the starter) so that the fuel pump operates for approxi-

mately two seconds and the fuel line pressu-

rizes. Repeat this operation two or three times

and check for fuel leakage at any point in the

fuel line.

Check and adjust wheel alignment (see section 18).

Refill the engine with engine oil (see page 8-4 ('91-'92

Models), ('93-Model),or ('94-'96 Models).

Refill the transmission with oil/fluid (see section

13 or

14).ProCarManuals.com

Page 82 of 1640

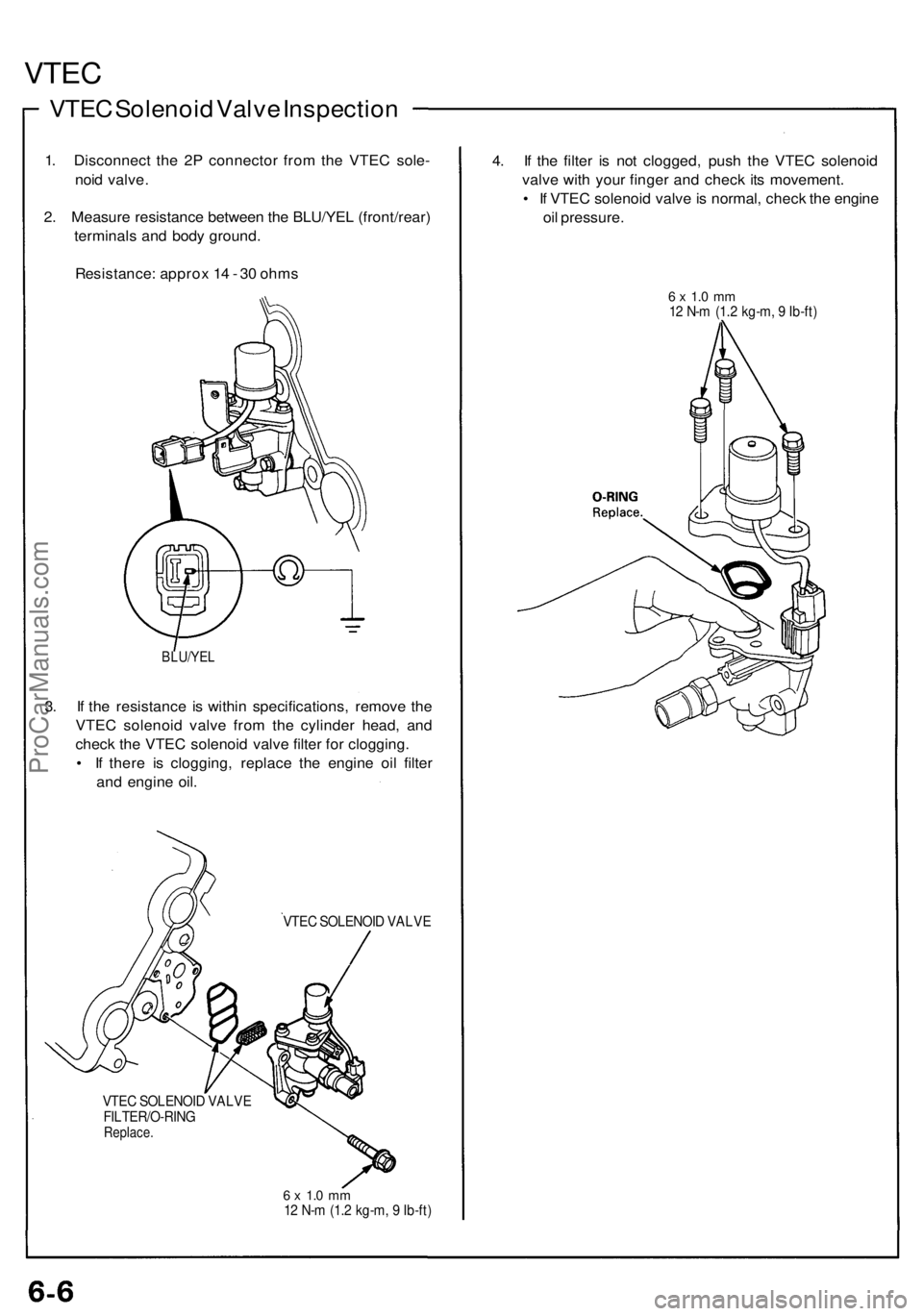

VTEC

VTEC Solenoi d Valv e Inspectio n

1. Disconnec t th e 2 P connecto r fro m th e VTE C sole -

noi d valve .

2 . Measur e resistanc e betwee n th e BLU/YE L (front/rear )

terminal s an d bod y ground .

Resistance : appro x 1 4 - 3 0 ohm s

BLU/YE L

3. I f th e resistanc e i s withi n specifications , remov e th e

VTE C solenoi d valv e fro m th e cylinde r head , an d

chec k th e VTE C solenoi d valv e filte r fo r clogging .

• I f ther e i s clogging , replac e th e engin e oi l filte r

an d engin e oil .

VTE C SOLENOI D VALV E

VTE C SOLENOI D VALV E

FILTER/O-RIN G

Replace.

6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )

4. I f th e filte r i s no t clogged , pus h th e VTE C solenoi d

valv e wit h you r finge r an d chec k it s movement .

• I f VTE C solenoi d valv e is normal , chec k th e engin e

oi l pressure .

6 x 1. 0 m m12 N- m (1. 2 kg-m , 9 Ib-ft )

ProCarManuals.com

Page 83 of 1640

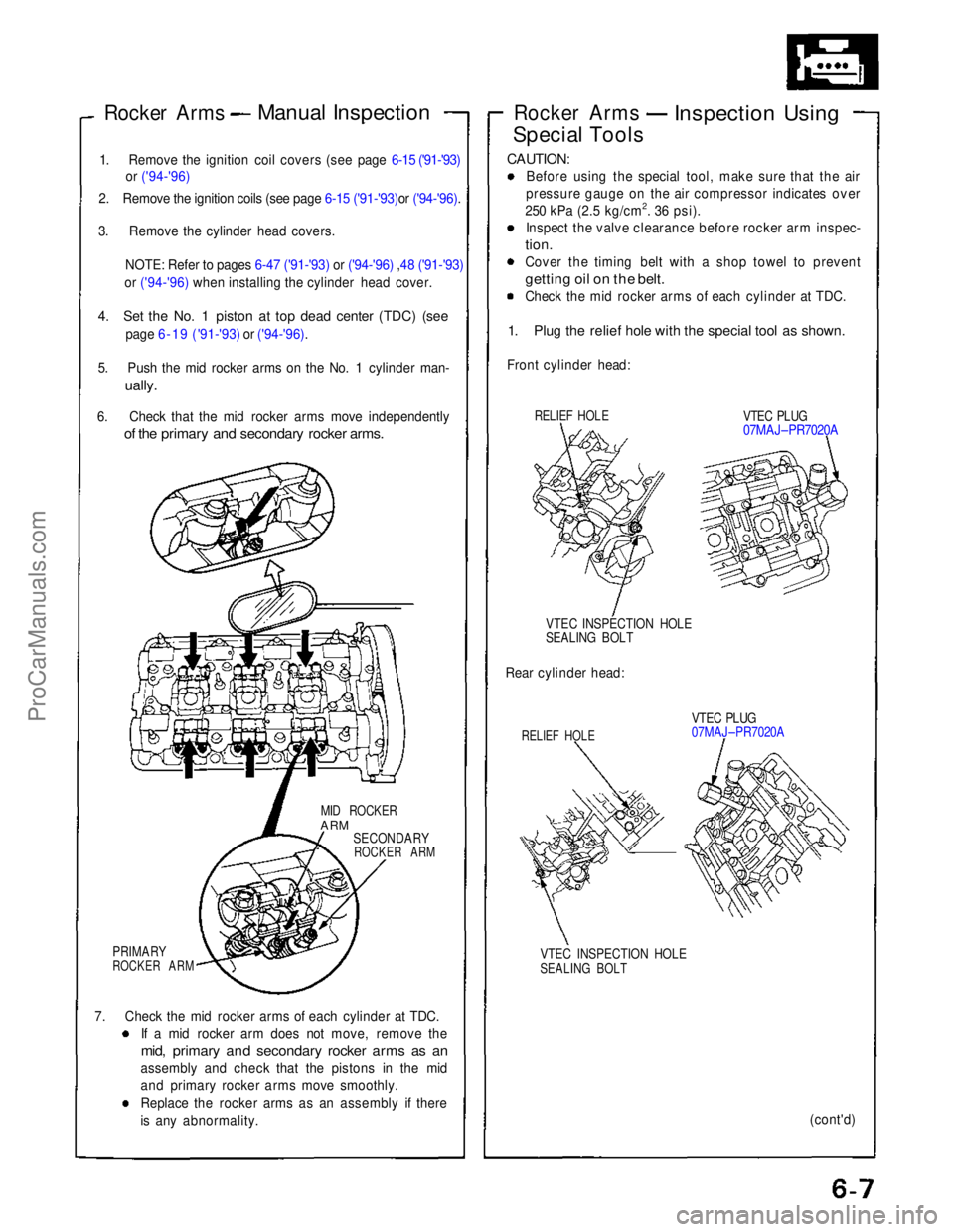

Rocker Arms

Manual Inspection

1. Remove the ignition coil covers (see page 6-15 ('91-'93) or ('94-'96)

2. Remove the ignition coils (see page 6-15 ('91-'93)or ('94-'96).

3. Remove the cylinder head covers.

NOTE: Refer to pages 6-47 ('91-'93)

or ('94-'96) ,48 ('91-'93)

or ('94-'96) when installing the cylinder head cover.

4. Set the No. 1 piston at top dead center (TDC) (see

page 6-19 ('91-'93)

or ('94-'96).

5. Push the mid rocker arms on the No. 1 cylinder man-

ually.

6. Check that the mid rocker arms move independently

of the primary and secondary rocker arms.

MID ROCKER

ARM

SECONDARY

ROCKER ARM

PRIMARY

ROCKER ARM

7. Check the mid rocker arms of each cylinder at TDC. If a mid rocker arm does not move, remove the

mid, primary and secondary rocker arms as an

assembly and check that the pistons in the mid

and primary rocker arms move smoothly.

Replace the rocker arms as an assembly if there

is any abnormality. Rocker Arms

Inspection Using

Special Tools

CAUTION:

Before using the special tool, make sure that the air

pressure gauge on the air compressor indicates over

250 kPa (2.5 kg/cm2. 36 psi). Inspect the valve clearance before rocker arm inspec-

tion.

Cover the timing belt with a shop towel to prevent

getting oil on the belt.

Check the mid rocker arms of each cylinder at TDC.

1. Plug the relief hole with the special tool as shown.

Front cylinder head:

RELIEF HOLE

VTEC PLUG

07MAJ–PR7020A

VTEC INSPECTION HOLE

SEALING BOLT

Rear cylinder head:

RELIEF HOLE

VTEC PLUG

07MAJ–PR7020A

VTEC INSPECTION HOLE

SEALING BOLT

(cont'd)ProCarManuals.com

Page 88 of 1640

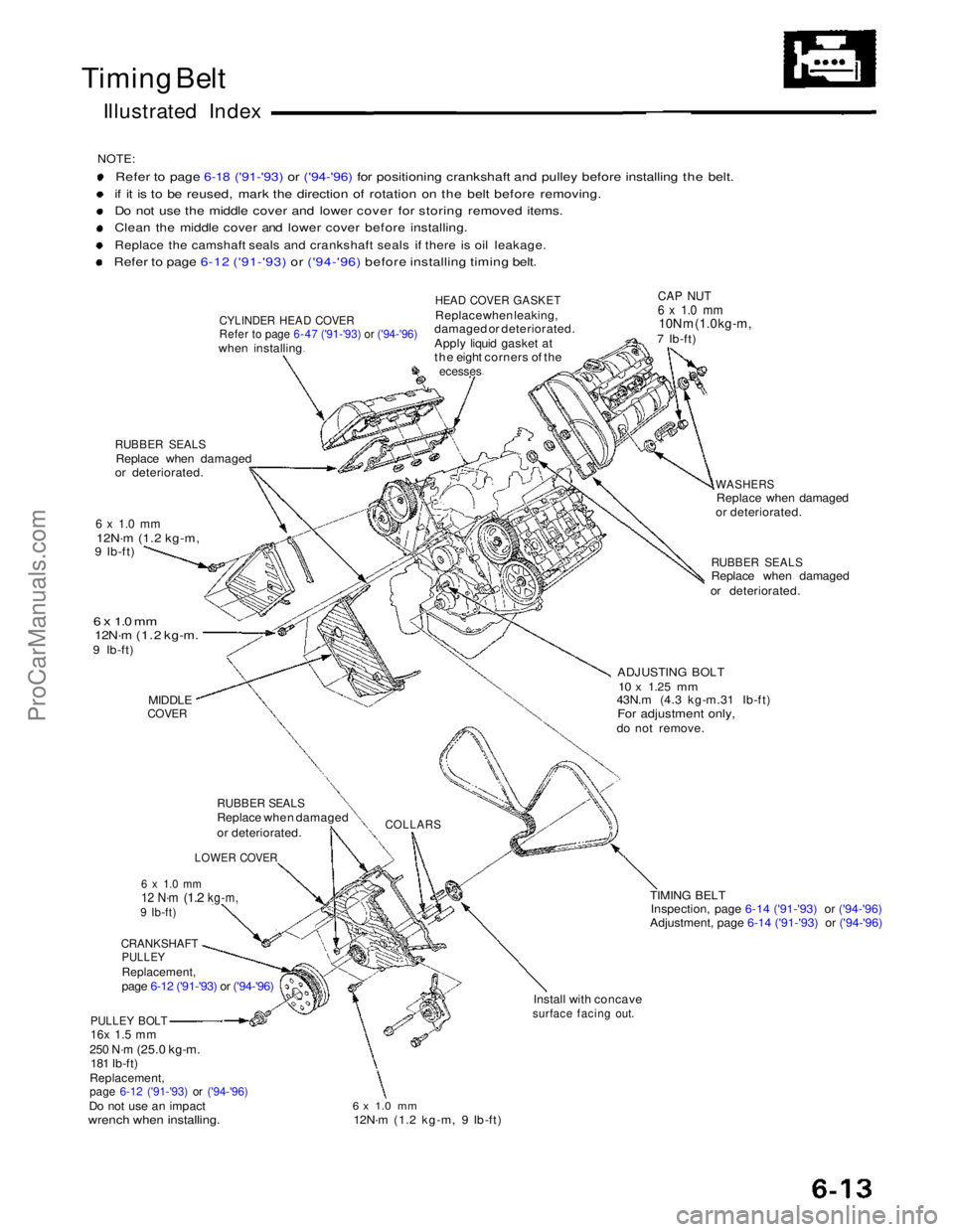

Timing Belt

Illustrated Index

NOTE:

Refer to page 6-18 ('91-'93) or ('94-'96) for positioning crankshaft and pulley before installing the belt.

if it is to be reused, mark the direction of rotation on the belt before removing.

Do not use the middle cover and lower cover for storing removed items.

Clean the middle cover and lower cover before installing.

Replace the camshaft seals and crankshaft seals if there is oil leakage.

Refer to page 6-12 ('91-'93) or ('94-'96) before installing timing belt.

CYLINDER HEAD COVER

Refer to page 6-47 ('91-'93) or ('94-'96)

when installing

RUBBER SEALS

Replace when damaged

or deteriorated.

6 x 1.0 mm

12N·m (1.2 kg-m,

9 Ib-ft)

6 x 1.0 mm

12N·m (1.2 kg-m.

9 Ib-ft)

MIDDLE

COVER

RUBBER SEALS

Replace when damaged

or deteriorated.

LOWER COVER

6 x 1.0 mm

12 N·m

(1.2

kg-m,

9 Ib-ft)

CRANKSHAFT

PULLEY

Replacement,

page 6-12 ('91-'93) or ('94-'96)

PULLEY BOLT

16x 1.5 mm

250 N·m

(25.0 kg-m. 181 Ib-ft)

Replacement,

page 6-12 ('91-'93)

or ('94-'96)

Do not use an impact

wrench when installing.

HEAD COVER GASKET

Replace when leaking,

damaged or deteriorated.

Apply liquid gasket at

the eight corners of the

ecesses

CAP NUT

6 x 1.0 mm

10N m (1.0 kg-m,

7 Ib-ft)

WASHERS

Replace when damaged

or deteriorated.

RUBBER SEALS

Replace when damaged

or deteriorated.

ADJUSTING BOLT

10 x

1.25

mm

43N.m (4.3 kg-m.31 Ib-ft)

For adjustment only,

do not remove.

COLLARS

TIMING BELTInspection, page 6-14 ('91-'93) or ('94-'96)

Adjustment, page 6-14 ('91-'93) or ('94-'96)

Install with concave

surface facing out.

6 x 1.0 mm

12N·m (1.2 kg-m, 9 Ib-ft)ProCarManuals.com