oil level ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 33 of 1640

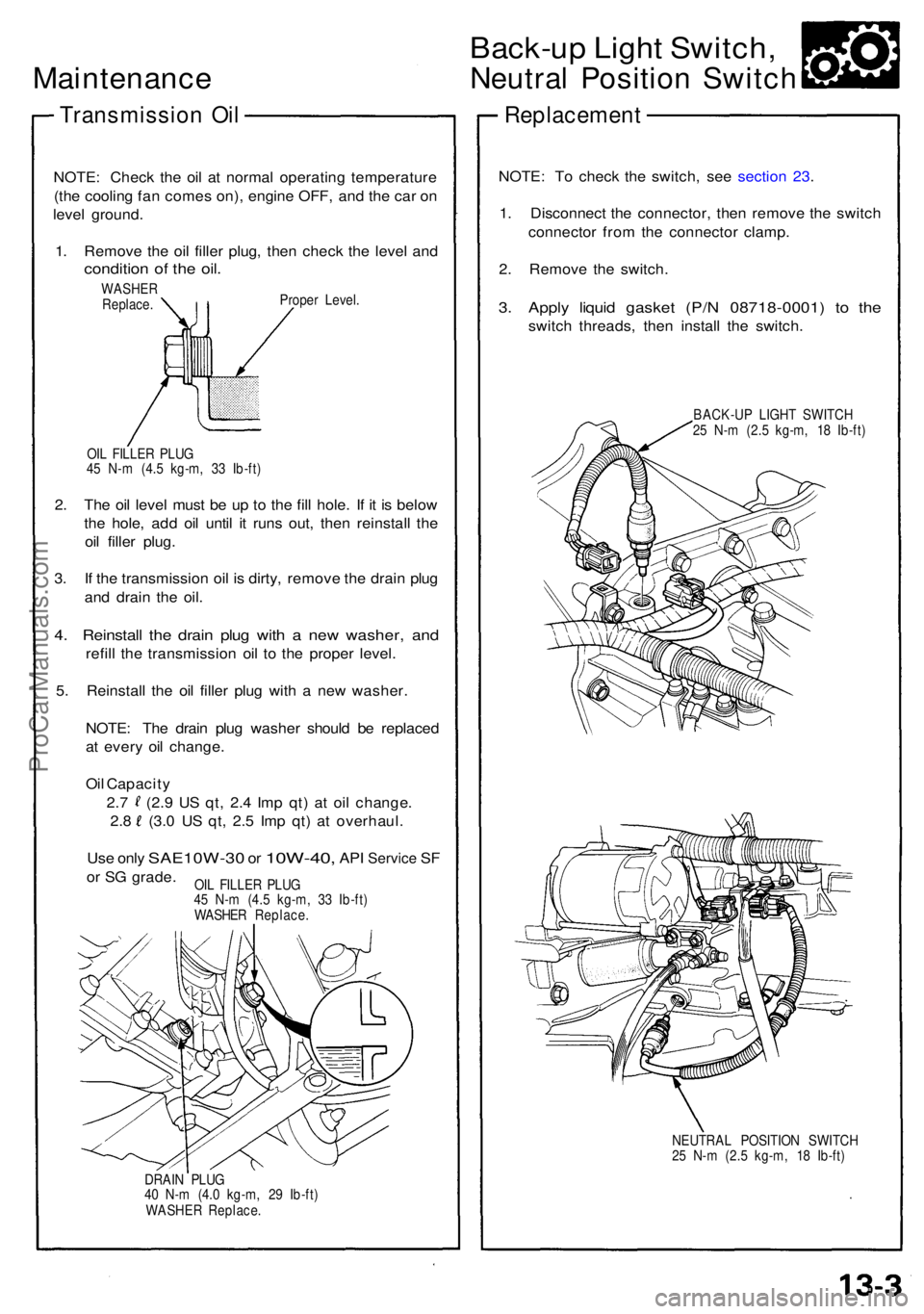

Maintenance

Transmissio n Oi l

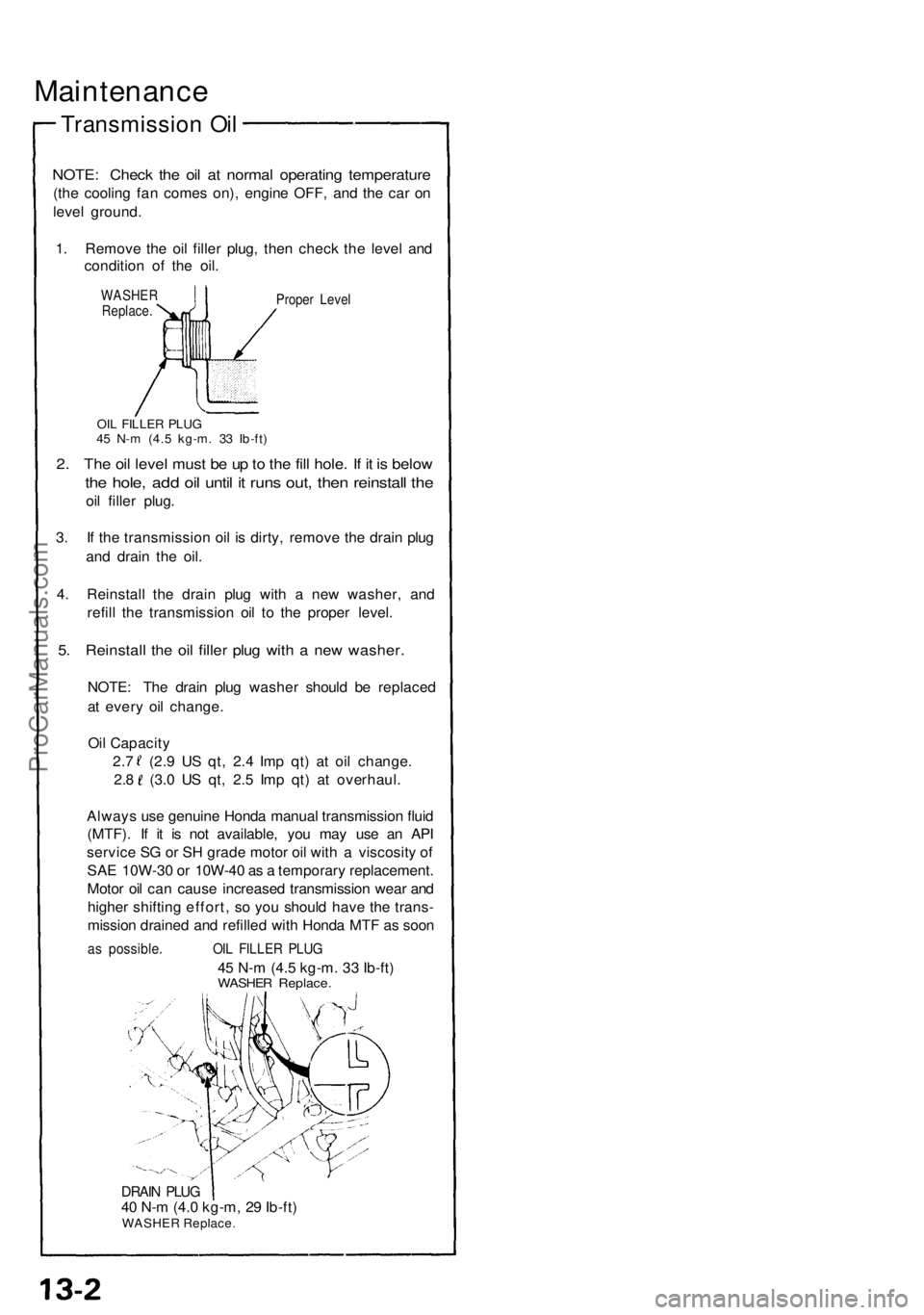

NOTE : Chec k th e oi l a t norma l operatin g temperatur e

(the coolin g fa n come s on) , engin e OFF , an d th e ca r o n

leve l ground .

1 . Remov e th e oi l fille r plug , the n chec k th e leve l an d

conditio n o f th e oil .

WASHE RReplace .Proper Leve l

OIL FILLE R PLU G45 N- m (4. 5 kg-m . 3 3 Ib-ft )

2. Th e oi l leve l mus t b e u p to th e fil l hole . I f i t i s belo w

the hole , ad d oi l unti l i t run s out , the n reinstal l th e

oil fille r plug .

3 . I f th e transmissio n oi l i s dirty , remov e th e drai n plu g

an d drai n th e oil .

4 . Reinstal l th e drai n plu g wit h a ne w washer , an d

refil l th e transmissio n oi l t o th e prope r level .

5. Reinstal l th e oi l fille r plu g wit h a ne w washer .

NOTE: Th e drai n plu g washe r shoul d b e replace d

a t ever y oi l change .

Oi l Capacit y

2. 7 ( 2.9 U S qt , 2. 4 Im p qt ) a t oi l change .

2.8 (3. 0 U S qt , 2. 5 Im p qt ) a t overhaul .

Alway s us e genuin e Hond a manua l transmissio n flui d

(MTF) . I f i t i s no t available , yo u ma y us e a n AP I

servic e S G o r S H grad e moto r oi l wit h a viscosit y o f

SA E 10W-3 0 o r 10W-4 0 a s a temporar y replacement .

Moto r oi l ca n caus e increase d transmissio n wea r an d

highe r shiftin g effort , s o yo u shoul d hav e th e trans -

missio n draine d an d refille d wit h Hond a MT F a s soo n

as possible . OIL FILLE R PLU G

45 N- m (4. 5 kg-m . 3 3 Ib-ft )WASHE R Replace .

DRAIN PLU G40 N- m (4. 0 kg-m , 2 9 Ib-ft )WASHE R Replac e

ProCarManuals.com

Page 125 of 1640

Camshafts

Installation

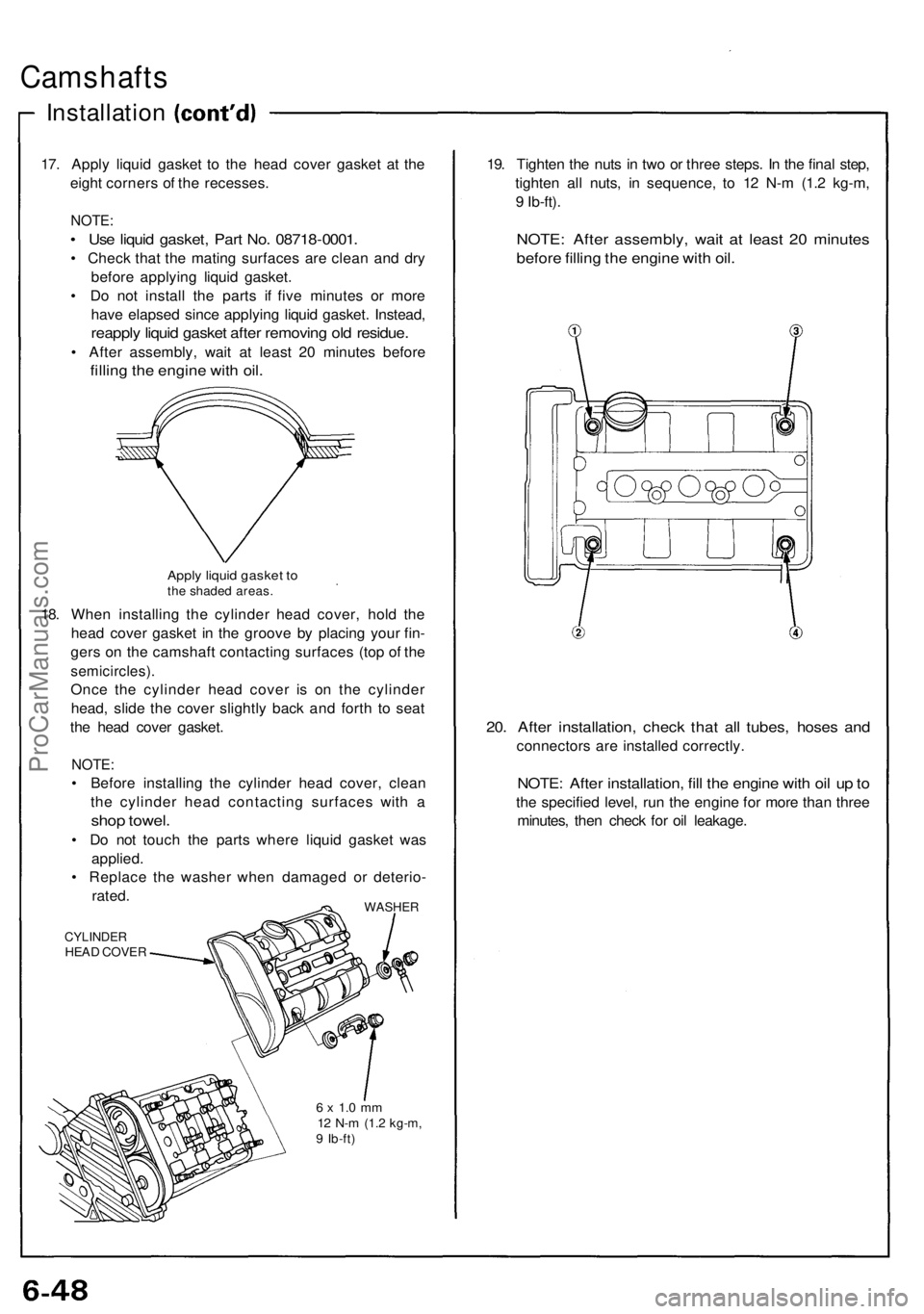

17. Appl y liqui d gaske t t o th e hea d cove r gaske t a t th e

eigh t corner s o f th e recesses .

NOTE:

• Us e liqui d gasket , Par t No . 0871 8-0001 .

• Chec k tha t th e matin g surface s ar e clea n an d dr y

befor e applyin g liqui d gasket .

• D o no t instal l th e part s i f fiv e minute s o r mor e

hav e elapse d sinc e applyin g liqui d gasket . Instead ,

reapply liqui d gaske t afte r removin g ol d residue .

• Afte r assembly , wai t a t leas t 2 0 minute s befor e

filling th e engin e wit h oil .

Appl y liqui d gaske t t oth e shade d areas .

18. Whe n installin g th e cylinde r hea d cover , hol d th e

hea d cove r gaske t i n th e groov e b y placin g you r fin -

ger s o n th e camshaf t contactin g surface s (to p o f th e

semicircles) .

Once th e cylinde r hea d cove r i s o n th e cylinde r

head , slid e th e cove r slightl y bac k an d fort h t o sea t

th e hea d cove r gasket .

NOTE:

• Befor e installin g th e cylinde r hea d cover , clea n

th e cylinde r hea d contactin g surface s wit h a

sho p towel .

• D o no t touc h th e part s wher e liqui d gaske t wa s

applied .

• Replac e th e washe r whe n damage d o r deterio -

rated .

WASHE R

CYLINDE RHEAD COVE R

6 x 1. 0 m m12 N- m (1. 2 kg-m ,9 Ib-ft )

19. Tighte n th e nut s i n tw o o r thre e steps . I n th e fina l step ,

tighte n al l nuts , i n sequence , t o 1 2 N- m (1. 2 kg-m ,

9 Ib-ft) .

NOTE : Afte r assembly , wai t a t leas t 2 0 minute s

before fillin g th e engin e wit h oil .

20. Afte r installation , chec k tha t al l tubes , hose s an d

connector s ar e installe d correctly .

NOTE: Afte r installation , fil l th e engin e wit h oi l u p to

th e specifie d level , ru n th e engin e fo r mor e tha n thre e

minutes , the n chec k fo r oi l leakage .

ProCarManuals.com

Page 149 of 1640

Engine Oil

Inspection

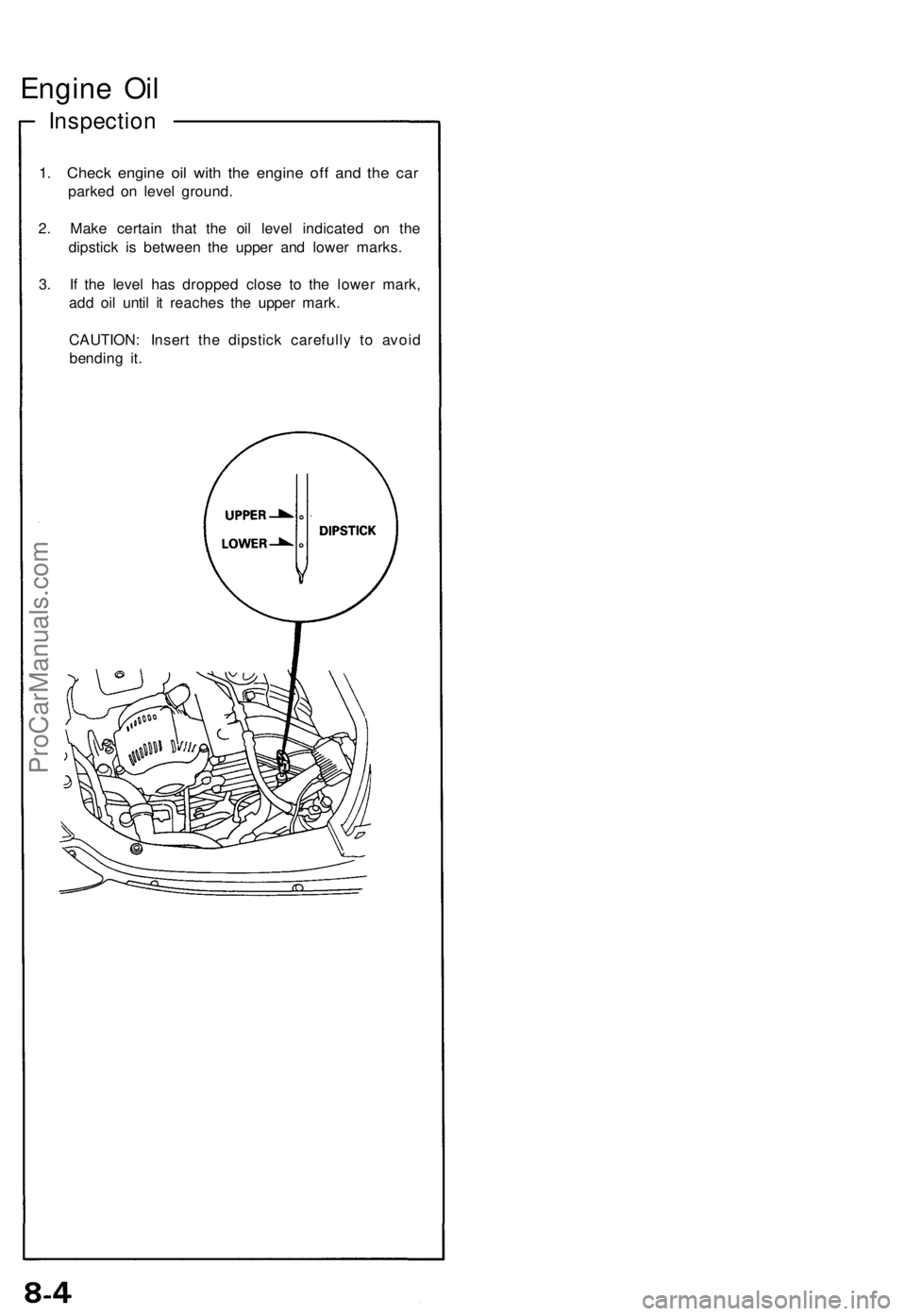

1. Check engine oil with the engine off and the car

parked on level ground.

2. Make certain that the oil level indicated on the

dipstick is between the upper and lower marks.

3. If the level has dropped close to the lower mark,

add oil until it reaches the upper mark.

CAUTION: Insert the dipstick carefully to avoid

bending it.ProCarManuals.com

Page 151 of 1640

Oil Pressur e

Testing

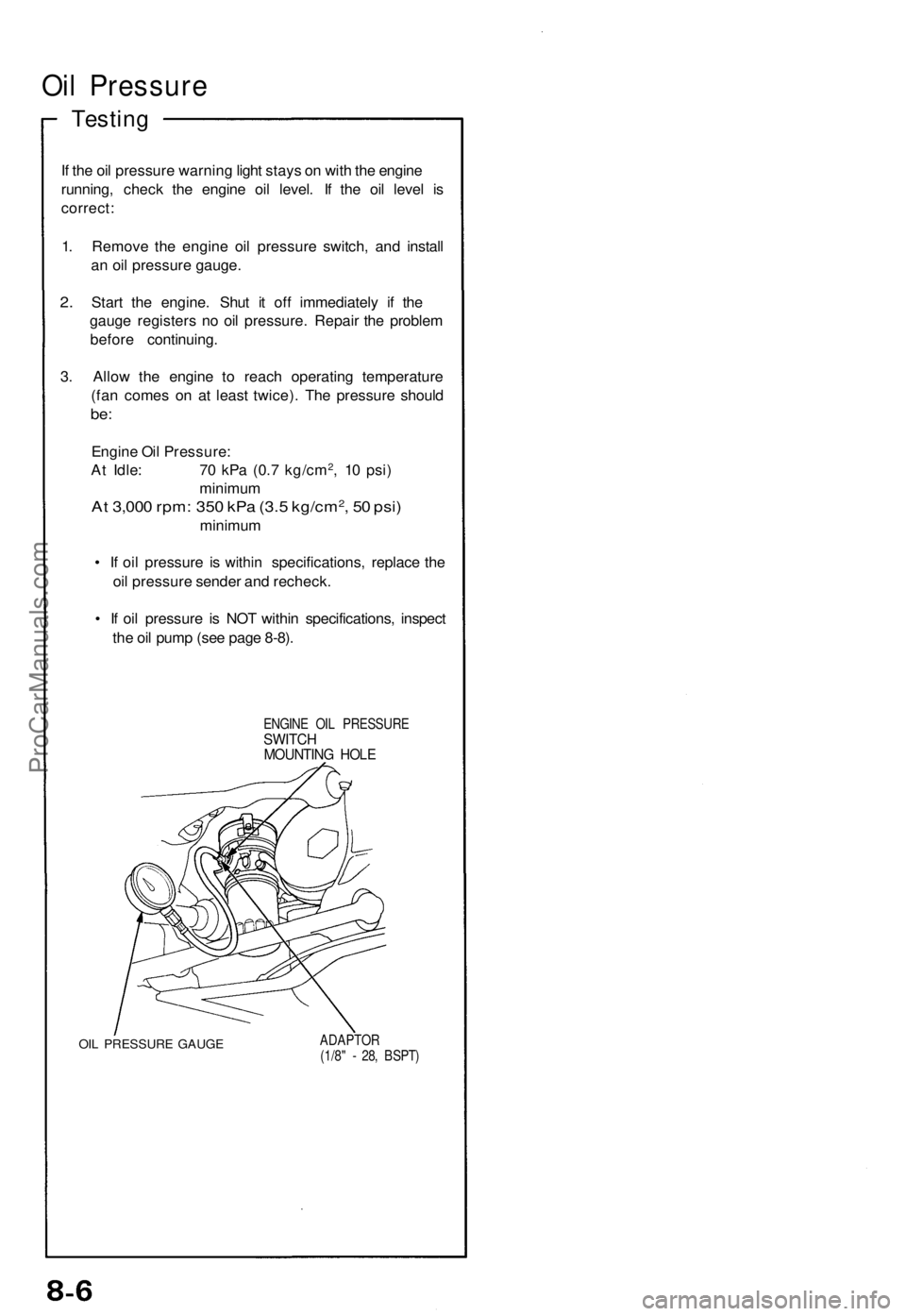

If th e oi l pressur e warnin g ligh t stay s o n wit h th e engin e

running , chec k th e engin e oi l level . I f th e oi l leve l i s

correct :

1 . Remov e th e engin e oi l pressur e switch , an d instal l

a n oi l pressur e gauge .

2. Star t th e engine . Shu t i t of f immediatel y i f th e

gaug e register s n o oi l pressure . Repai r th e proble m

befor e continuing .

3 . Allo w th e engin e t o reac h operatin g temperatur e

(fa n come s o n a t leas t twice) . Th e pressur e shoul d

be:

Engin e Oi l Pressure :

A t Idle : 7 0 kP a (0. 7 kg/cm2, 1 0 psi )

minimu m

At 3,00 0 rpm : 35 0 kP a (3. 5 kg/cm2, 5 0 psi )

minimu m

• I f oi l pressur e i s

within specifications , replac e th e

oi l pressur e sende r an d recheck .

• I f oi l pressur e i s NO T withi n specifications , inspec t

th e oi l pum p (se e pag e 8-8) .

ENGIN E OI L PRESSUR ESWITCHMOUNTIN G HOL E

OIL PRESSUR E GAUG E ADAPTO R

(1/8 " - 28 , BSPT )

ProCarManuals.com

Page 301 of 1640

Maintenance

Transmissio n Oi l

NOTE : Chec k th e oi l a t norma l operatin g temperatur e

(th e coolin g fa n come s on) , engin e OFF , an d th e ca r o n

leve l ground .

1 . Remov e th e oi l fille r plug , the n chec k th e leve l an d

conditio n o f th e oil .

WASHE R

Replace . Prope

r Level .

OI L FILLE R PLU G

4 5 N- m (4. 5 kg-m , 3 3 Ib-ft )

2. Th e oi l leve l mus t b e u p t o th e fill hole . I f i t i s belo w

th e hole , ad d oi l unti l i t run s out , the n reinstal l th e

oi l fille r plug .

3 . I f th e transmissio n oi l i s dirty , remov e th e drai n plu g

an d drai n th e oil .

4. Reinstal l th e drai n plu g wit h a ne w washer , an d

refil l th e transmissio n oi l t o th e prope r level .

5 . Reinstal l th e oi l fille r plu g wit h a ne w washer .

NOTE : Th e drai n plu g washe r shoul d b e replace d

a t ever y oi l change .

Oi l Capacity

2. 7 (2. 9 U S qt , 2. 4 Im p qt ) a t oi l change .

2.8 (3. 0 U S qt , 2. 5 Im p qt ) a t overhaul .

Use onl y SAE10W-3 0 or 10W-40 , API Servic e SF

or S G grade .

DRAIN PLU G

4 0 N- m (4. 0 kg-m , 2 9 Ib-ft )

WASHE R Replace .

Back-up Ligh t Switch ,

Neutral Positio n Switc h

Replacemen t

NOTE: T o chec k th e switch , se e sectio n 23 .

1 . Disconnec t th e connector , the n remov e th e switc h

connecto r fro m th e connecto r clamp .

2 . Remov e th e switch .

3. Appl y liqui d gaske t (P/ N 08718-0001 ) t o th e

switc h threads , the n instal l th e switch .

BACK-U P LIGH T SWITC H

2 5 N- m (2. 5 kg-m , 1 8 Ib-ft )

NEUTRA L POSITIO N SWITC H

2 5 N- m (2. 5 kg-m , 1 8 Ib-ft )

OI

L FILLE R PLU G

4 5 N- m (4. 5 kg-m , 3 3 Ib-ft )

WASHE R Replace .

ProCarManuals.com

Page 966 of 1640

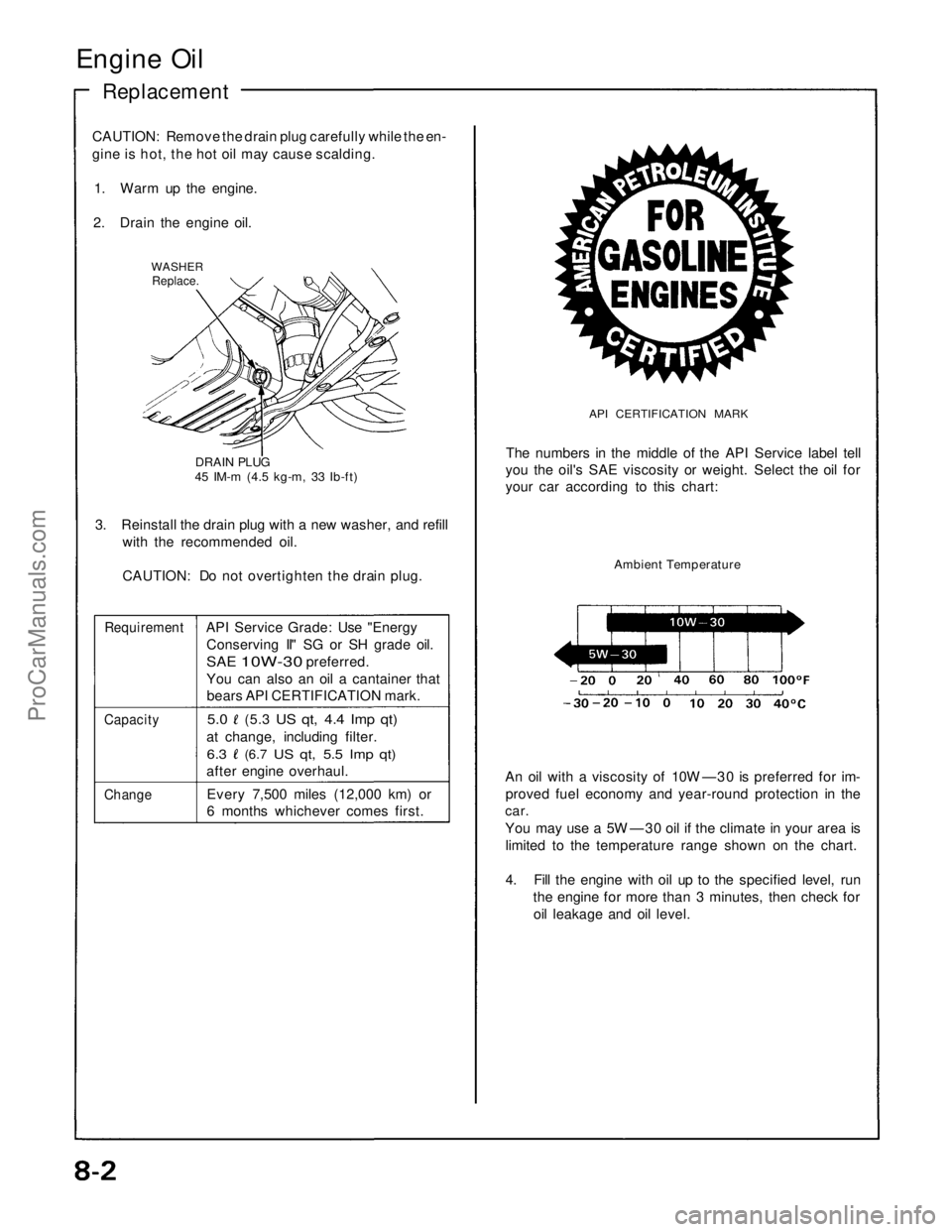

Engine Oil

Replacement

CAUTION: Remove the drain plug carefully while the en-

gine is hot, the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

WASHER

Replace.

DRAIN PLUG

45 IM-m (4.5 kg-m, 33 Ib-ft)

3. Reinstall the drain plug with a new washer, and refill

with the recommended oil.

CAUTION: Do not overtighten the drain plug.

Requirement

API Service Grade: Use "Energy

Conserving II" SG or SH grade oil.

SAE

10W-30

preferred.

You can also an oil a cantainer that

bears API CERTIFICATION mark.

Capacity

5.0

(5.3

US qt, 4.4 Imp qt)

at change, including filter.

6.3

(6.7

US qt, 5.5 Imp qt)

after engine overhaul.

Change

Every 7,500 miles (12,000 km) or

6 months whichever comes first.

API CERTIFICATION MARK

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight. Select the oil for

your car according to this chart:

Ambient Temperature

An oil with a viscosity of 10W —30 is preferred for im-

proved fuel economy and year-round protection in the

car.

You may use a 5W —30 oil if the climate in your area is

limited to the temperature range shown on the chart.

4. Fill the engine with oil up to the specified level, run

the engine for more than 3 minutes, then check for

oil leakage and oil level.ProCarManuals.com

Page 975 of 1640

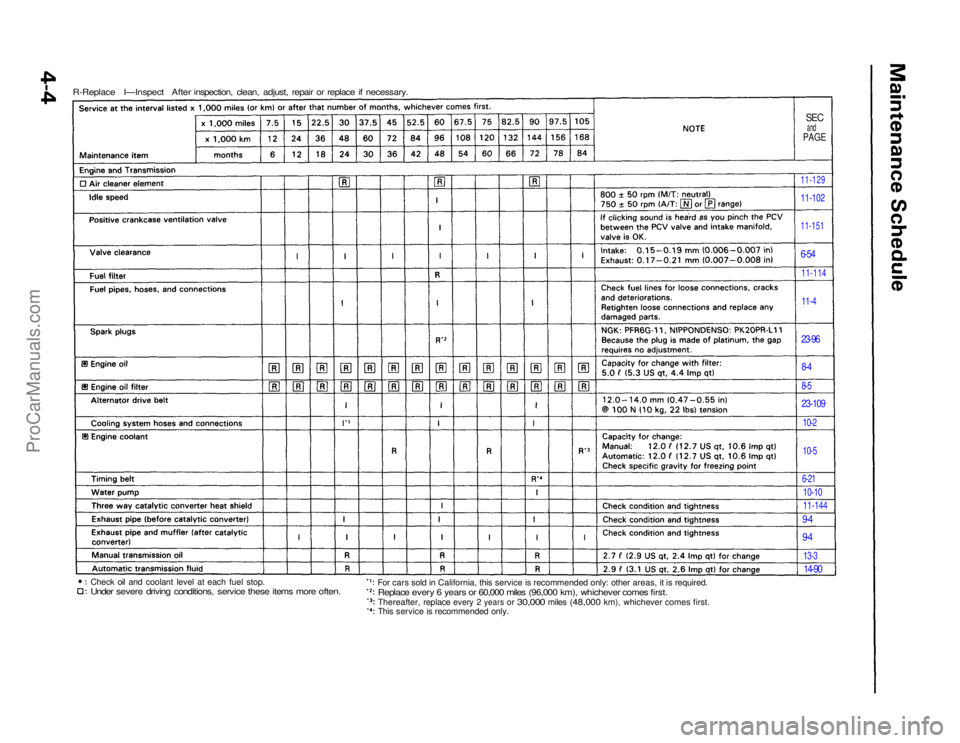

R-Replace I—Inspect After inspection, clean, adjust, repair or replace if necessary.

SEC

and

PAGE

11-129

11-102

11-151

6-54

11-114

11-4

23-96

8-4

8-5

23-109

10-2

10-5

6-21

10-10

11-144

9-4

9-4

13-3

14-90

For cars sold in California, this service is recommended only: other areas, it is required.

Replace every 6 years or 60,000 miles (96,000 km), whichever comes first.

Thereafter, replace

every

2

years

or

30,000

miles

(48,000

km), whichever comes first.

This service is recommended only.

Check oil and coolant level at each fuel stop.

Under severe driving conditions, service these items more often.ProCarManuals.com

Page 1002 of 1640

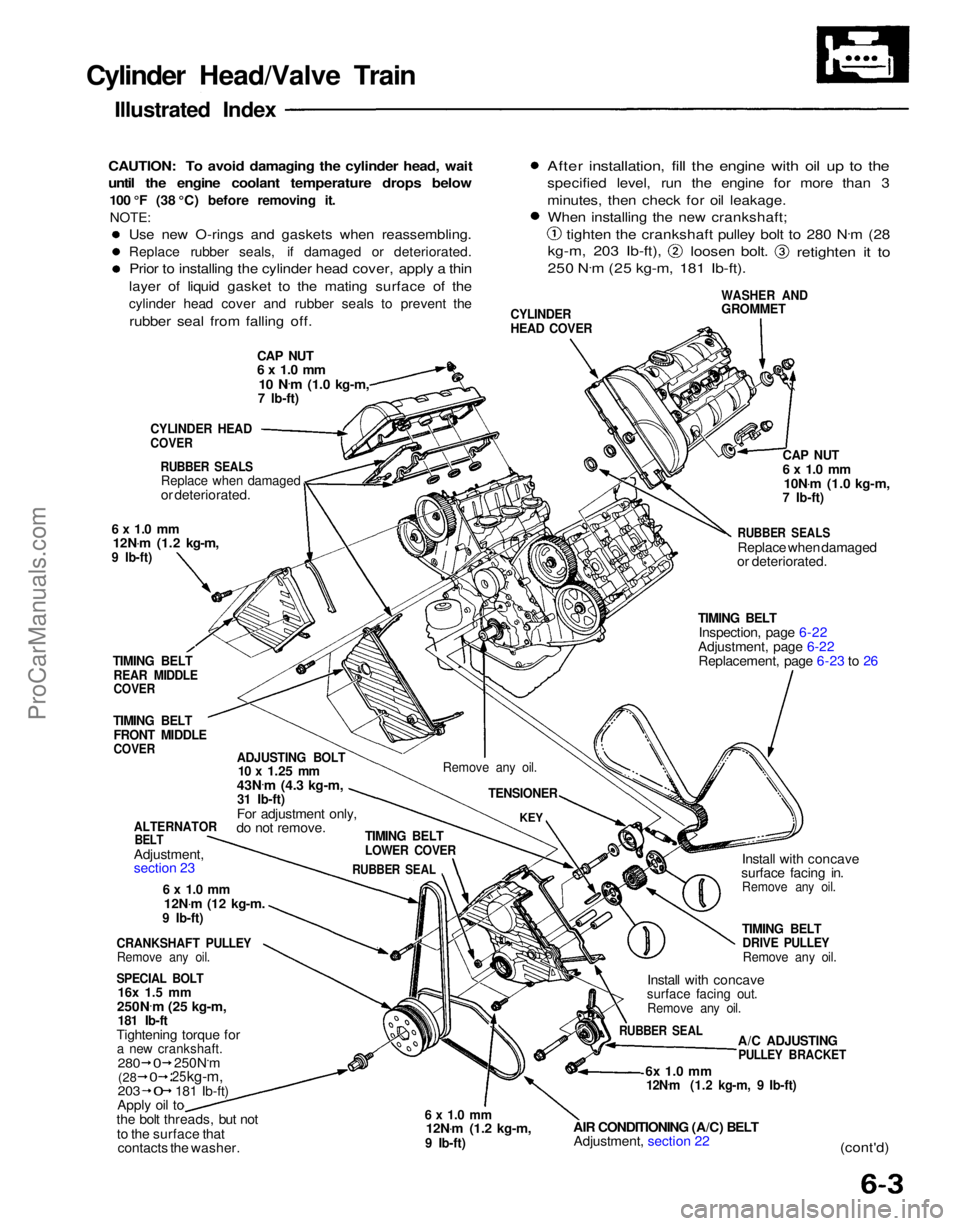

Cylinder Head/Valve Train

Illustrated Index

CAUTION: To avoid damaging the cylinder head, wait

until the engine coolant temperature drops below

100 °F (38 °C) before removing it.NOTE:

CAP NUT

6 x 1.0 mm

10 N .

m

(1.0 kg-m,

7 Ib-ft)

CYLINDER

HEAD COVER

WASHER AND

GROMMET

After installation, fill the engine with oil up to the

specified level, run the engine for more than 3

minutes, then check for oil leakage.

When installing the new crankshaft;

tighten the crankshaft pulley bolt to 280 N .

m (28

kg-m, 203 Ib-ft),

loosen bolt.

retighten it to

250 N .

m (25 kg-m, 181 Ib-ft).

CYLINDER HEAD

COVER

RUBBER SEALS

Replace when damaged

or deteriorated.

6 x 1.0 mm

12N .

m (1.2 kg-m,

9 Ib-ft)

TIMING BELT

REAR MIDDLE

COVER

TIMING BELT

FRONT MIDDLE

COVER

ADJUSTING BOLT

10 x

1.25

mm

43N .

m (4.3 kg-m,

31 Ib-ft)

For adjustment only,

do not remove.

ALTERNATOR

BELT

Adjustment,

section 23

6 x 1.0 mm

12N .

m

(12

kg-m.

9 Ib-ft)

CRANKSHAFT PULLEY

Remove any oil.

SPECIAL BOLT

16x 1.5 mm

250N .

m (25 kg-m,

181 Ib-ft

Tightening torque for

a new crankshaft.

203

Apply oil to

the bolt threads, but not

to the surface that contacts the washer.

6 x 1.0 mm

12N .

m (1.2 kg-m,

9 Ib-ft)

AIR CONDITIONING (A/C) BELT

Adjustment, section 22

6x 1.0 mm

12N .

m (1.2 kg-m, 9 Ib-ft)

(cont'd)

A/C ADJUSTING

PULLEY BRACKET

RUBBER SEAL

Install with concave

surface facing out.

Remove any oil.

TIMING BELT

DRIVE PULLEY

Remove any oil.

Install with concave

surface facing in.

Remove any oil.

TIMING BELT

Inspection, page 6-22

Adjustment, page 6-22 Replacement, page 6-23 to 26

RUBBER SEALS

Replace when damaged

or deteriorated.

CAP NUT

6 x 1.0 mm

10N .

m (1.0 kg-m,

7 Ib-ft)

TIMING BELT

LOWER COVER

RUBBER SEAL

KEY

Remove any oil.

TENSIONER

280

250N.m

25

kg-m,

181 Ib-ft)

(28

0

0

0

Use new O-rings and gaskets when reassembling.

Replace rubber seals, if damaged or deteriorated.

Prior to installing the cylinder head cover, apply a thin

layer of liquid gasket to the mating surface of the

cylinder head cover and rubber seals to prevent the

rubber seal from falling off.ProCarManuals.com

Page 1007 of 1640

Remove any oil.

TIMING BELT

Inspection, page 6-22

Adjustment, page 6-22

6 x 1.0 mm

12N .

m(1.2kg-m,9 Ib-ft)

Timing Belt

Illustrated Index

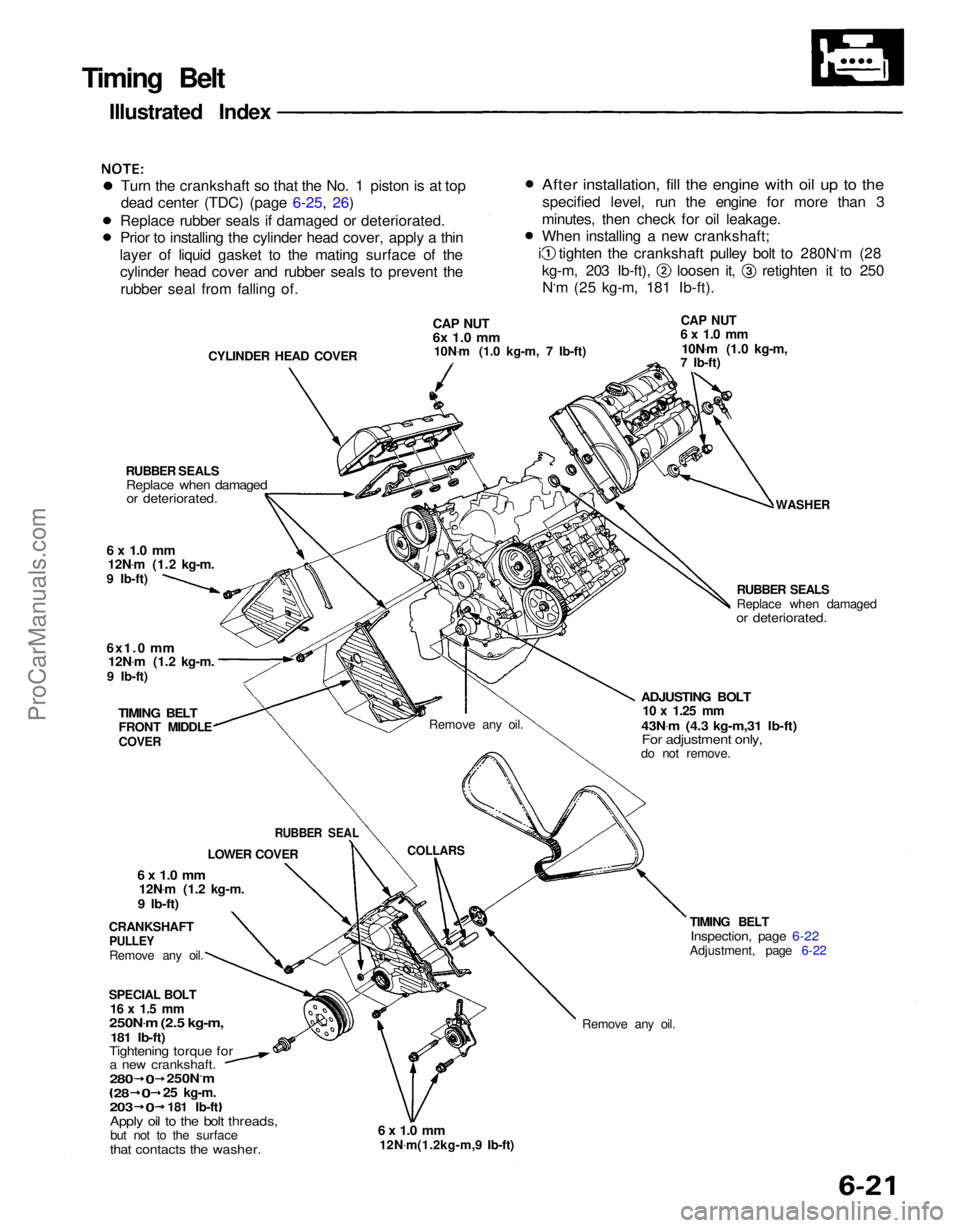

Turn the crankshaft so that the No. 1 piston is at top

dead center (TDC) (page 6-25, 26)

Replace rubber seals if damaged or deteriorated.

Prior to installing the cylinder head cover, apply a thin

layer of liquid gasket to the mating surface of the cylinder head cover and rubber seals to prevent the

rubber seal from falling of.

CYLINDER HEAD COVER

CAP NUT

6x 1.0 mm

10N .

m (1.0 kg-m, 7 Ib-ft)

CAP NUT

6 x 1.0 mm

10N .

m (1.0 kg-m,

7 Ib-ft)

WASHER

RUBBER SEALS

Replace when damaged

or deteriorated.

ADJUSTING BOLT

10 x

1.25

mm

43N .

m (4.3 kg-m,31 Ib-ft)

For adjustment only,

do not remove.

Remove any oil.

COLLARS

RUBBER SEALS

Replace when damaged

or deteriorated.

6 x 1.0 mm

12N .

m (1.2 kg-m.

9 Ib-ft)

6x1.0

mm

12N .

m (1.2 kg-m.

9 Ib-ft)

TIMING BELT

FRONT MIDDLE

COVER

CRANKSHAFT

PULLEY

Remove any oil.

6 x 1.0 mm

12N .

m (1.2 kg-m.

9 Ib-ft)

SPECIAL BOLT

16 x 1.5 mm

250N .

m (2.5 kg-m,

181 Ib-ft)

Tightening torque for

a new crankshaft.

Apply oil to the bolt threads,

but not to the surface

that contacts the washer.

280

0

250N.m

28

0

25

kg-m.

203

0

181 Ib-ft LOWER COVER

RUBBER SEAL

After installation, fill the engine with oil up to the

specified level, run the engine for more than 3

minutes, then check for oil leakage.

When installing a new crankshaft; i tighten the crankshaft pulley bolt to 280N.m (28

kg-m, 203 Ib-ft), loosen it, retighten it to 250

N.m (25 kg-m, 181 Ib-ft).ProCarManuals.com

Page 1012 of 1640

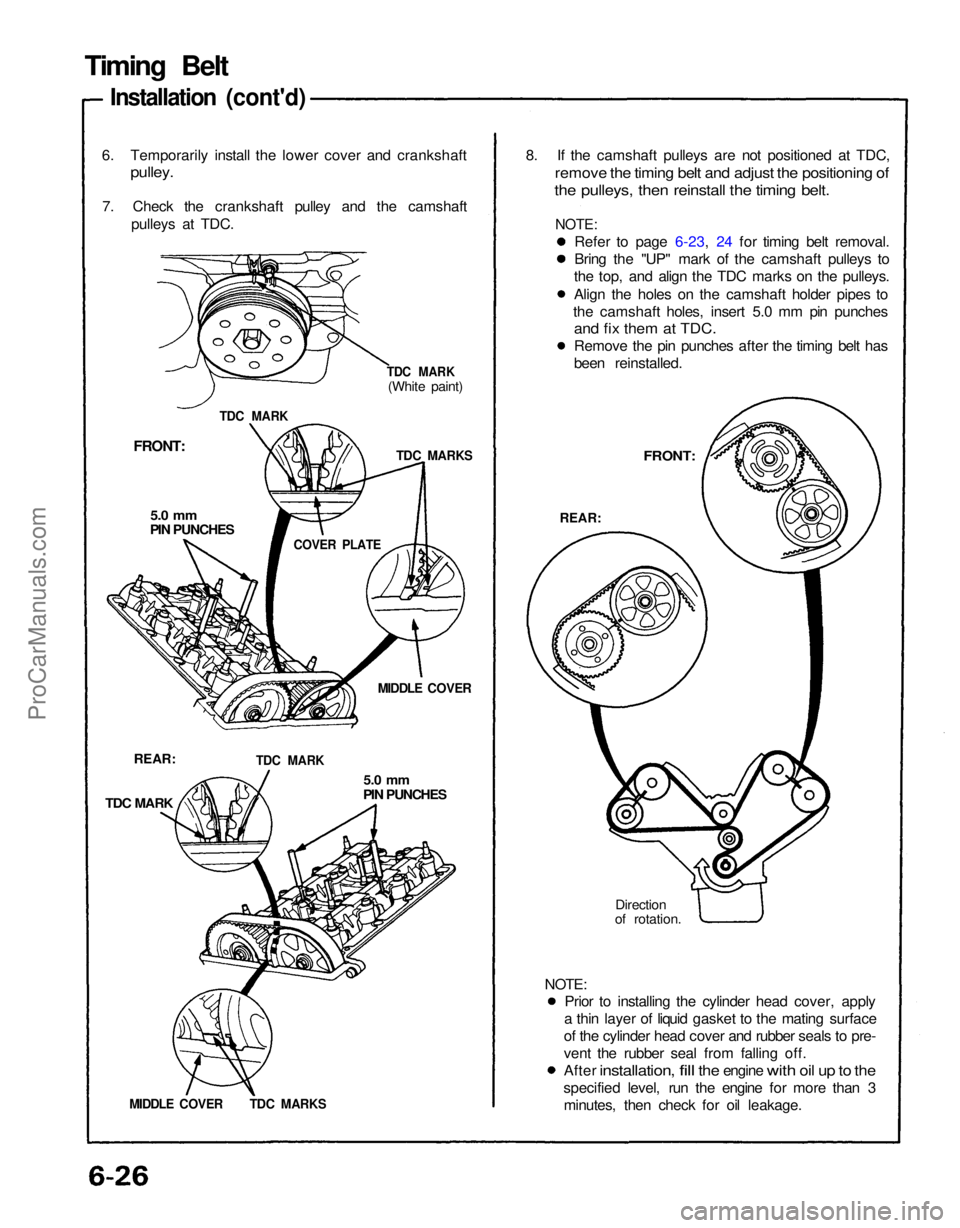

Prior to installing the cylinder head cover, apply

a thin layer of liquid gasket to the mating surface

of the cylinder head cover and rubber seals to pre-

vent the rubber seal from falling off.

After

installation,

fill

the

engine

with

oil up to the

specified level, run the engine for more than 3 minutes, then check for oil leakage.

8. If the camshaft pulleys are not positioned at TDC,

remove the timing belt and adjust the positioning of

the pulleys, then reinstall the timing belt.

6. Temporarily install the lower cover and crankshaft

pulley.

7. Check the crankshaft pulley and the camshaft pulleys at TDC.

FRONT:

5.0 mm

PIN PUNCHES

MIDDLE COVER

REAR:

TDC MARK

5.0 mm

PIN PUNCHES

Direction

of rotation.

FRONT:

REAR:

TDC MARK

TDC MARK

(White paint)

TDC MARKS

COVER PLATE

TDC MARK

MIDDLE COVER TDC MARKS

Timing Belt

Installation (cont'd)

Refer to page 6-23, 24 for timing belt removal.

Bring the "UP" mark of the camshaft pulleys to

the top, and align the TDC marks on the pulleys.

Align the holes on the camshaft holder pipes to

the camshaft holes, insert 5.0 mm pin punches

and fix them at TDC.

Remove the pin punches after the timing belt has

been reinstalled.

NOTE:

NOTE:ProCarManuals.com