wheel bolt torque ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 45 of 1640

Service Precaution s

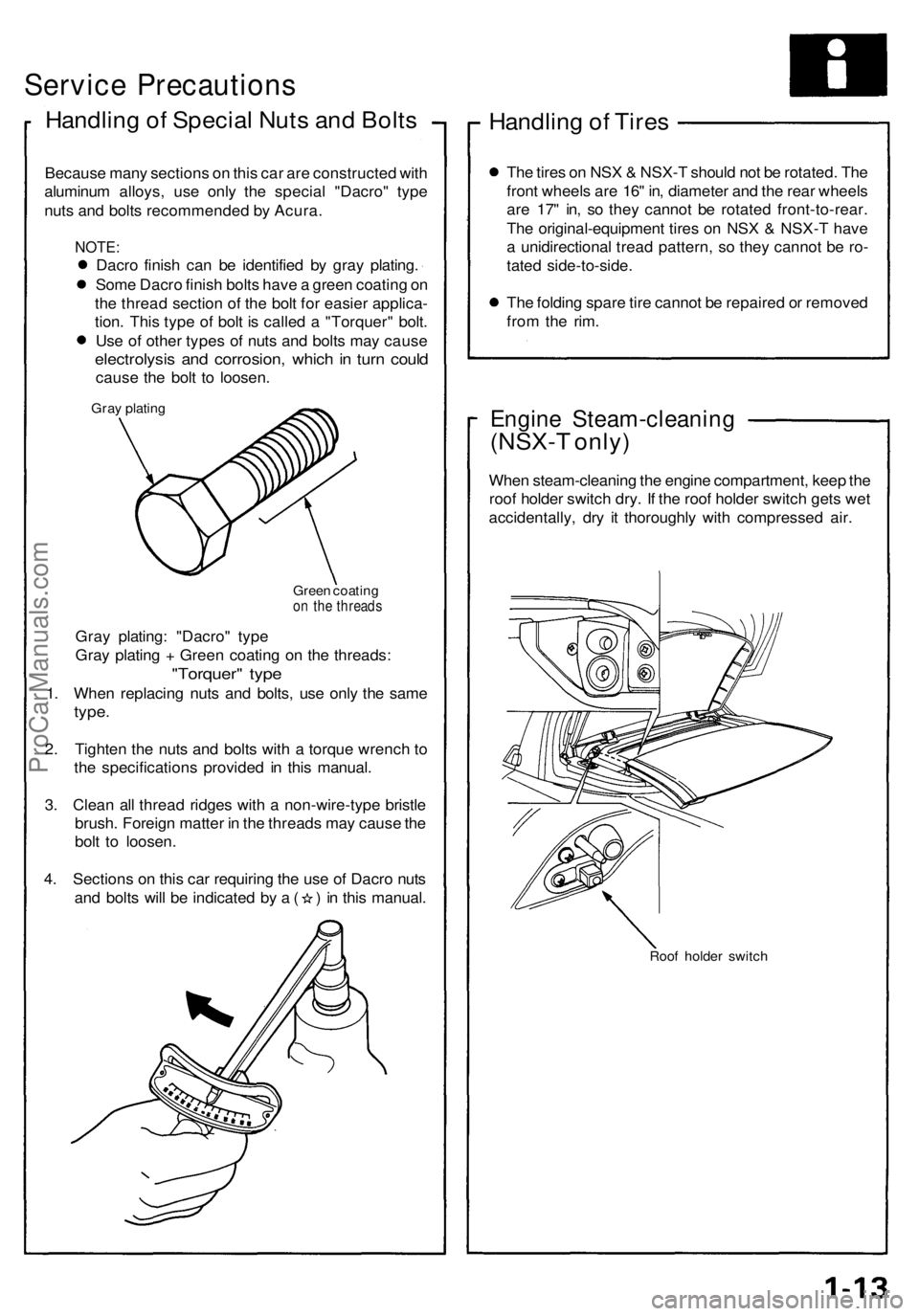

Handling o f Specia l Nut s an d Bolt s

Becaus e man y section s o n thi s ca r ar e constructe d wit h

aluminu m alloys , us e onl y th e specia l "Dacro " typ e

nut s an d bolt s recommende d b y Acura .

NOTE:

Dacro finis h ca n b e identifie d b y gra y plating .

Som e Dacr o finis h bolt s hav e a gree n coatin g o n

th e threa d sectio n of the bol t fo r easie r applica -

tion . Thi s typ e of bol t i s calle d a "Torquer " bolt .

Us e o f othe r type s of nut s an d bolt s ma y caus e

electrolysi s an d corrosion , whic h in tur n coul d

caus e th e bol t t o loosen .

Gray platin g

Green coatin g

on th e thread s

Gray plating : "Dacro " typ e

Gra y platin g + Gree n coatin g o n th e threads :

"Torquer " typ e

1. Whe n replacin g nut s an d bolts , us e onl y th e sam e

type.

2. Tighte n th e nut s an d bolt s with a torqu e wrenc h t o

th e specification s provide d i n thi s manual .

3 . Clea n al l threa d ridge s wit h a non-wire-typ e bristl e

brush . Foreig n matte r i n th e thread s ma y caus e th e

bol t t o loosen .

4 . Section s o n thi s ca r requirin g th e us e o f Dacr o nut s

and bolt s wil l b e indicate d b y a ( ) in thi s manual .

Handling o f Tire s

The tire s o n NS X & NSX- T shoul d no t b e rotated . Th e

fron t wheel s ar e 16 " in , diamete r an d th e rea r wheel s

ar e 17 " in , s o the y canno t b e rotate d front-to-rear .

Th e original-equipmen t tire s o n NS X & NSX- T hav e

a unidirectiona l trea d pattern , s o the y canno t b e ro -

tate d side-to-side .

Th e foldin g spar e tir e canno t b e repaire d o r remove d

fro m th e rim .

Engin e Steam-cleanin g

(NSX-T only )

When steam-cleanin g th e engin e compartment , kee p th e

roo f holde r switc h dry . I f th e roo f holde r switc h get s we t

accidentally , dr y i t thoroughl y wit h compresse d air .

Roo f holde r switc h

ProCarManuals.com

Page 496 of 1640

6. Clea n th e calipe r thoroughly ; remov e an y rust , an d

chec k fo r groove s an d cracks .

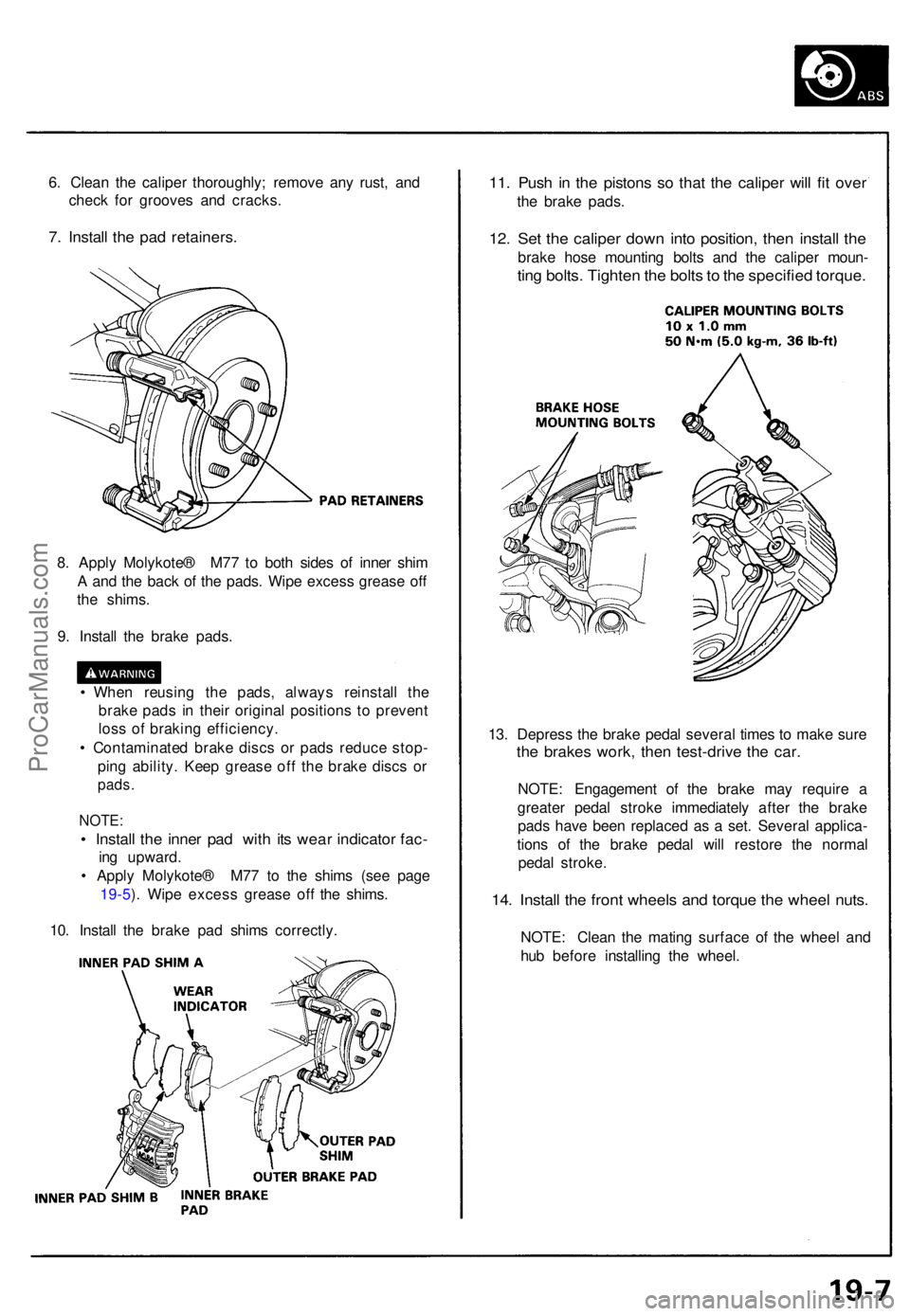

7. Instal l th e pa d retainers .

11. Pus h i n th e piston s s o tha t th e calipe r wil l fi t ove r

the brak e pads .

12. Se t th e calipe r dow n int o position , the n instal l th e

brak e hos e mountin g bolt s an d th e calipe r moun -

ting bolts . Tighte n th e bolt s to th e specifie d torque .

8. Appl y Molykote ® M7 7 t o bot h side s o f inne r shi m

A an d th e bac k o f th e pads . Wip e exces s greas e of f

th e shims .

9 . Instal l th e brak e pads .

• Whe n reusin g th e pads , alway s reinstal l th e

brak e pad s i n thei r origina l position s t o preven t

los s o f brakin g efficiency .

• Contaminate d brak e disc s o r pad s reduc e stop -

pin g ability . Kee p greas e of f th e brak e disc s o r

pads .

NOTE :

• Instal l th e inne r pa d wit h it s wea r indicato r fac -

ing upward .

• Appl y Molykote ® M7 7 t o th e shim s (se e pag e

19-5 ). Wip e exces s greas e of f th e shims .

10 . Instal l th e brak e pa d shim s correctly . 13

. Depres s th e brak e peda l severa l time s t o mak e sur e

the brake s work , the n test-driv e th e car .

NOTE : Engagemen t of the brak e ma y requir e a

greate r peda l strok e immediatel y afte r th e brak e

pad s hav e bee n replace d a s a set . Severa l applica -

tion s of the brak e peda l wil l restor e th e norma l

peda l stroke .

14. Instal l th e fron t wheel s an d torqu e th e whee l nuts .

NOTE : Clea n th e matin g surfac e o f th e whee l an d

hu b befor e installin g th e wheel .

ProCarManuals.com

Page 507 of 1640

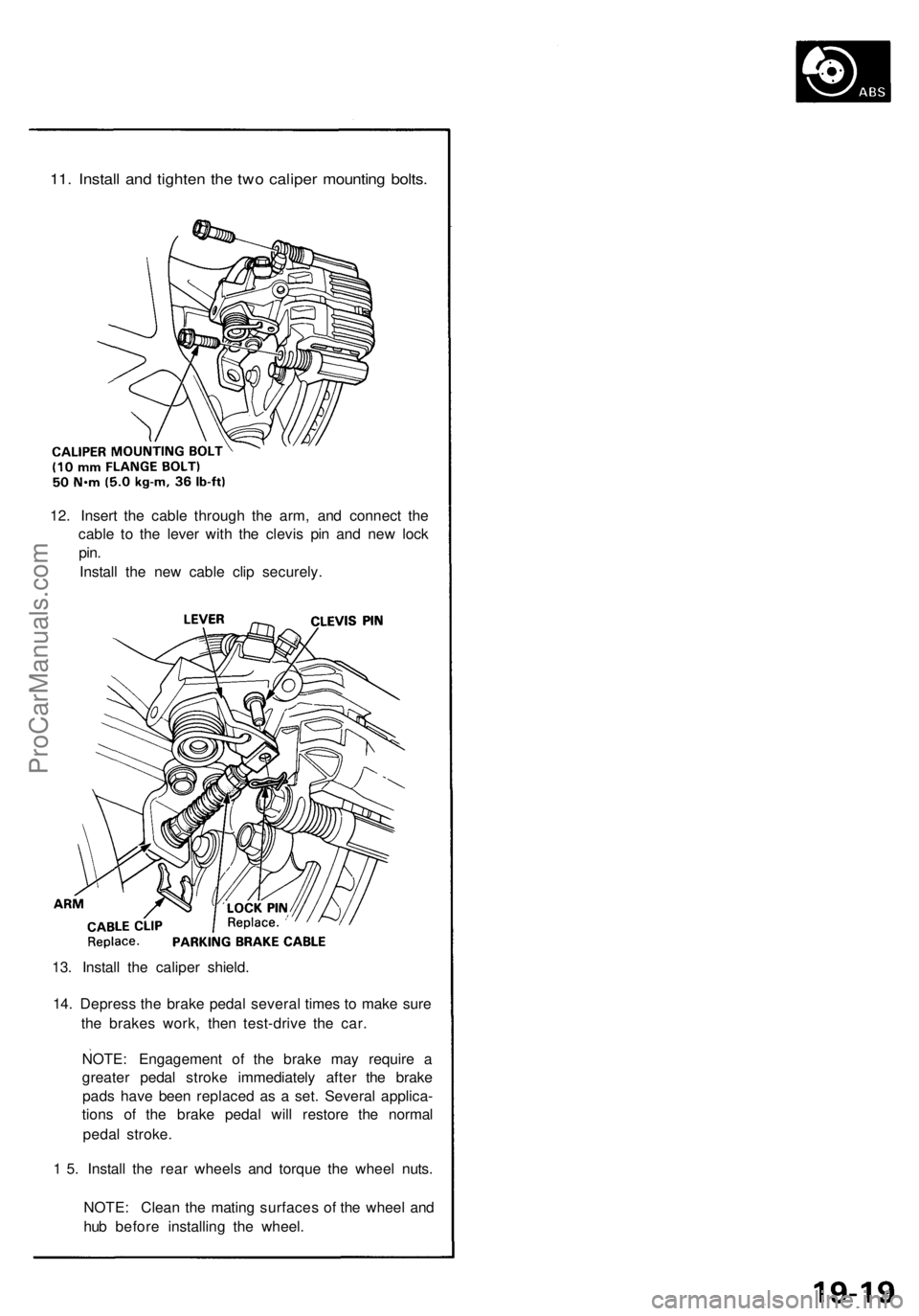

11. Install and tighten the two caliper mounting bolts.

12. Insert the cable through the arm, and connect the

cable to the lever with the clevis pin and new lock

pin.

Install the new cable clip securely.

13. Install the caliper shield.

14. Depress the brake pedal several times to make sure

the brakes work, then test-drive the car.

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normal

pedal stroke.

1 5. Install the rear wheels and torque the wheel nuts.

NOTE: Clean the mating surfaces of the wheel and

hub before installing the wheel.ProCarManuals.com

Page 998 of 1640

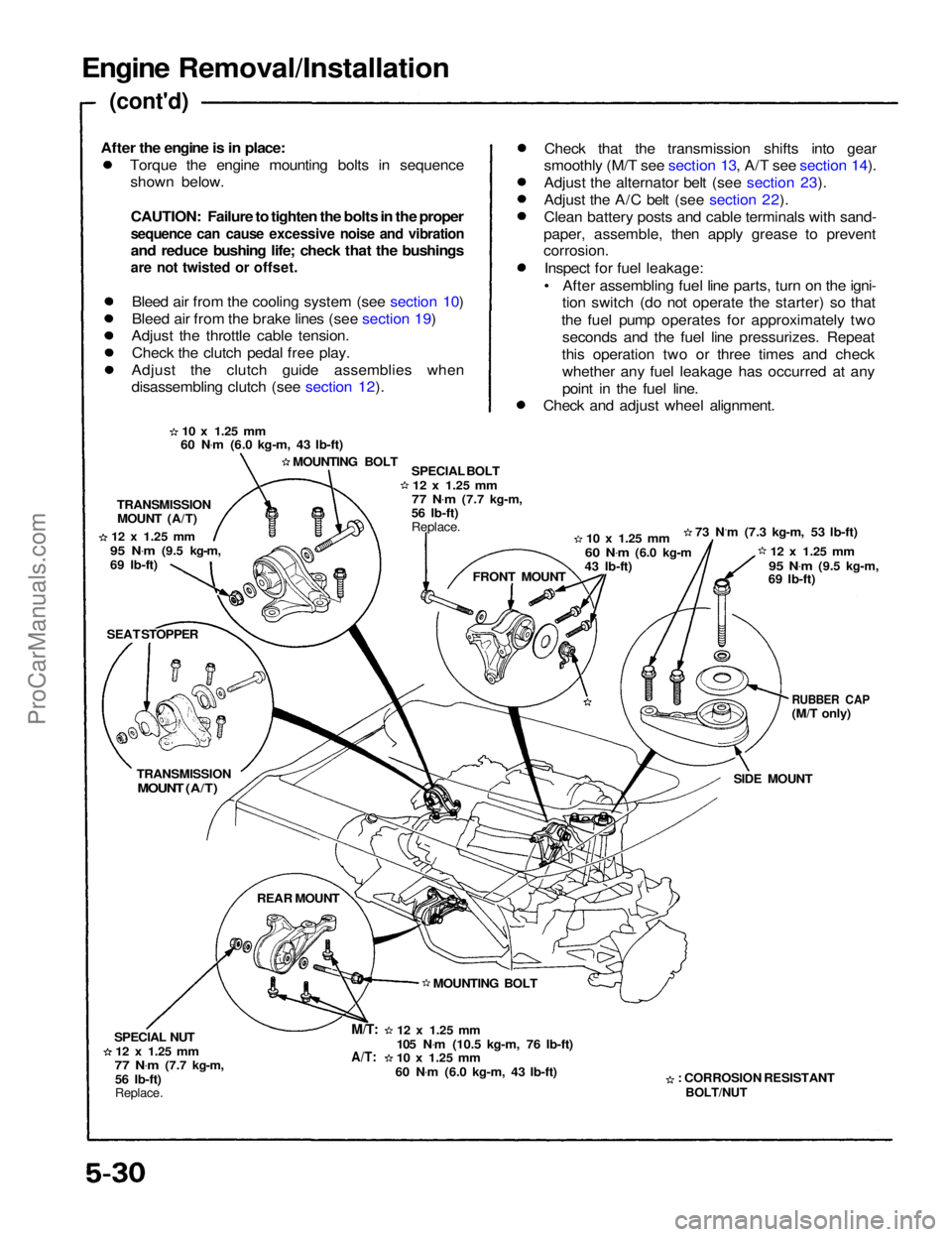

Engine Removal/Installation

(cont'd)

Torque the engine mounting bolts in sequenceshown below.

CAUTION: Failure to tighten the bolts in the proper

sequence can cause excessive noise and vibration

and reduce bushing life; check that the bushings

are not twisted or offset.

Bleed air from the cooling system (see section 10)

Bleed air from the brake lines (see section 19)

Adjust the throttle cable tension.

Check the clutch pedal free play.

Adjust the clutch guide assemblies when

disassembling clutch (see section 12). Check that the transmission shifts into gear

smoothly (M/T see section 13, A/T see section 14).

Adjust the alternator belt (see section 23).

Adjust the A/C belt (see section 22).

Clean battery posts and cable terminals with sand-

paper, assemble, then apply grease to prevent

corrosion.

Inspect for fuel leakage:

• After assembling fuel line parts, turn on the igni- tion switch (do not operate the starter) so that

the fuel pump operates for approximately two seconds and the fuel line pressurizes. Repeat

this operation two or three times and check whether any fuel leakage has occurred at any

point in the fuel line.

Check and adjust wheel alignment.

10 x

1.25

mm

60 N .

m (6.0 kg-m, 43 Ib-ft)

MOUNTING BOLT SPECIAL BOLT

12 x

1.25

mm

77 N .

m

(7.7 kg-m,

56 Ib-ft)

Replace.

10 x

1.25

mm

60 N .

m

(6.0 kg-m

43 Ib-ft) 73 N.m (7.3 kg-m, 53 Ib-ft)

12 x

1.25

mm

95 N .

m

(9.5 kg-m,

69 Ib-ft)

RUBBER CAP

(M/T only)

SIDE MOUNT

: CORROSION RESISTANT

BOLT/NUT

12 x

1.25

mm

105 N .

m (10.5 kg-m, 76 Ib-ft)

10 x

1.25

mm

60 N .

m (6.0 kg-m, 43 Ib-ft) MOUNTING BOLT FRONT MOUNT

TRANSMISSION

MOUNT (A/T)

12 x

1.25

mm

95 N .

m

(9.5 kg-m,

69 Ib-ft)

SEAT STOPPER

TRANSMISSION

MOUNT (A/T)

REAR MOUNT

SPECIAL NUT

12 x

1.25

mm

77 N .

m

(7.7 kg-m,

56 Ib-ft)

Replace.

M/T:

A/T:

After the engine is in place:ProCarManuals.com

Page 1165 of 1640

Description

The automatic transmission is a combination of a 3-element torque converter and a triple-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 in reverse. The entire unit is positioned in line with the

engine.

TORQUE CONVERTER, GEARS AND CLUTCHES

The torque converter consists of a pump, turbine and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the torque converter is a ring gear which meshes with the starter pinion when the engine is being

started. The entire torque converter assembly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts, the mainshaft, the countershaft, and the secondary shaft. The mainshaft is

in line with the engine crankshaft.

The mainshaft includes the clutches for 1st, and 4th, and gears for 3rd, 4th, Reverse and 1st (3rd gear is integral with

the mainshaft, while reverse gear is integral with 4th gear).

The countershaft includes the clutches for 1st-Hold and 3rd, and gears for 2nd, 3rd, 4th, Reverse and 1st.

The secondary shaft includes the 2nd clutch and gears for 2nd and 3rd.

The 4th and reverse gears can be locked to the countershaft at its center, providing 4th gear or Reverse, depending on

which way the selector is moved.

The gears on the mainshaft and secondary shaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the main-

shaft to the countershaft to provide , , , and

ELECTRONIC CONTROL

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid and 4

solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located on the insulator center bulkhead, behind the driver's seat.

HYDRAULIC CONTROL

The valve bodies include the main valve body, secondary valve body, servo body, regulator valve body, throttle valve

body, lock-up valve body and the 2nd accumulator body.

They are bolted to the torque converter housing as an assembly.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, 3-4 shift valve, relief valve, one-way

relief valve and oil pump gears.

The secondary valve body contains the 3-2 kick-down valve, CPC (clutch pressure control) valve, 2nd orifice control

valve, 3rd orifice control valve, modulator valve, 4th exhaust valve, servo control valve, 2nd exhaust valve and 4-3 kick-

down valve.

The servo body contains the accumulator pistons and servo valve. The throttle valve body includes the throttle valve B

which is bolted onto the servo body.

The regulator valve body contains the pressure regulator valve, lock-up control valve and cooler relief valve. Fluid from

the regulator passes through the manual valve to the various control valves.

The lock-up valve body contains the lock-up timing B valve and lock-up shift valve. The 2nd accumulator body contains

the accumulator pistons and limited slip differential (LSD) relief valve.

The torque converter check valve is located in the torque converter housing, under the main valve body.

The 1st, 1st-hold, 3rd and 4th clutches receive oil from their respective feed pipes.

SHIFT CONTROL MECHANISM

Input from various sensors located throughout the car determines which shift control solenoid valve the TCM will ac-

tivate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This

pressurizes a line to one of the clutches, engaging that clutch and its corresponding gear.

LOCK-UP MECHANISM

In position and position in 2nd, 3rd and 4th, pressurized fluid is drained from the back of the torque converter

through an oil passage, causing the lock-up piston to be held, against the torque converter cover. As this takes place, the

mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the

timing of the lock-up mechaism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. The lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)ProCarManuals.com

Page 1225 of 1640

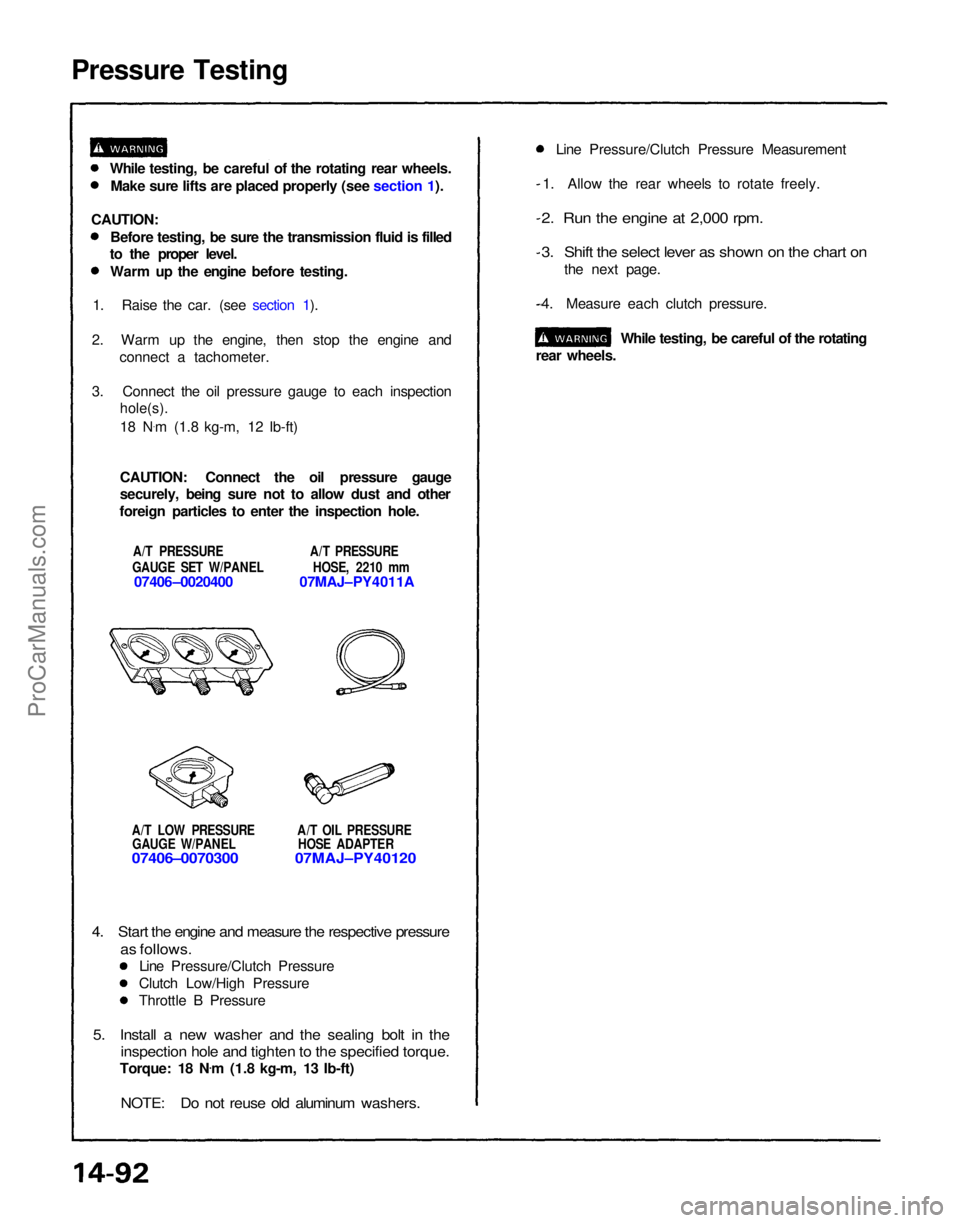

Pressure Testing

A/T LOW PRESSURE A/T OIL PRESSUREGAUGE W/PANEL HOSE ADAPTER

07406–0070300 07MAJ–PY40120

1. Allow the rear wheels to rotate freely.

2. Run the engine at 2,000 rpm.

3. Shift the select lever as shown on the chart on

the next page.

4. Measure each clutch pressure.

While testing, be careful of the rotating

rear wheels.

4. Start the engine and measure the respective pressure

as follows.

Line Pressure/Clutch Pressure

Clutch Low/High Pressure

Throttle B Pressure

5. Install a new washer and the sealing bolt in the

inspection hole and tighten to the specified torque.

Torque: 18 N .

m (1.8 kg-m, 13 Ib-ft)

NOTE: Do not reuse old aluminum washers.

While testing, be careful of the rotating rear wheels.

Make sure lifts are placed properly (see section 1).

CAUTION: Before testing, be sure the transmission fluid is filled

to the proper level.

Warm up the engine before testing.

1. Raise the car. (see section 1).

2. Warm up the engine, then stop the engine and connect a tachometer.

3. Connect the oil pressure gauge to each inspection

hole(s).

18 N .

m (1.8 kg-m, 12 Ib-ft)

CAUTION: Connect the oil pressure gauge

securely, being sure not to allow dust and other

foreign particles to enter the inspection hole.

A/T PRESSURE A/T PRESSURE

GAUGE SET W/PANEL HOSE, 2210 mm

07406–0020400 07MAJ–PY4011A Line Pressure/Clutch Pressure MeasurementProCarManuals.com

Page 1313 of 1640

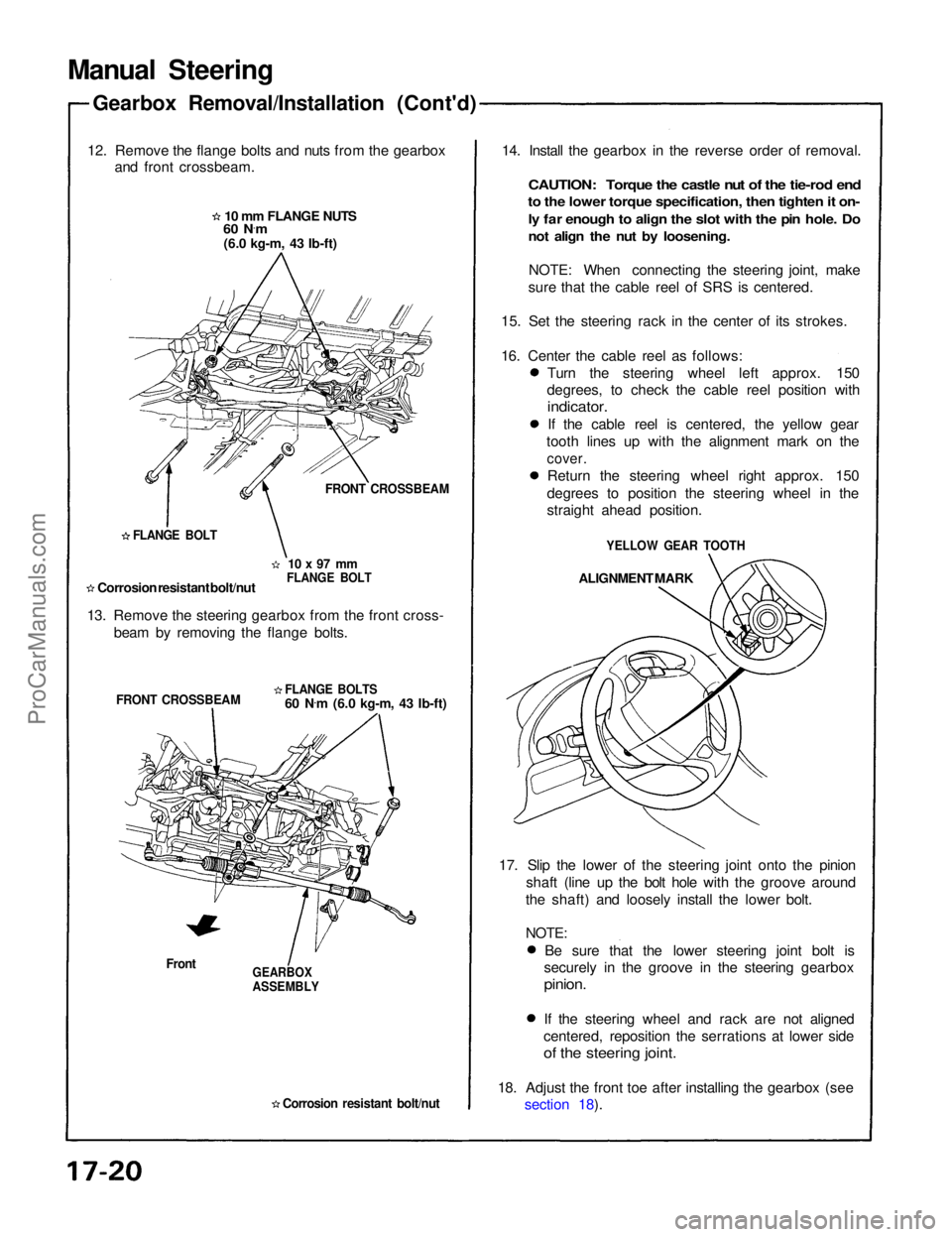

Manual Steering

Gearbox Removal/Installation (Cont'd)

12. Remove the flange bolts and nuts from the gearbox and front crossbeam.

10 mm FLANGE NUTS

60 N ·

m

(6.0 kg-m, 43 Ib-ft)

FRONT CROSSBEAM

10 x 97 mm

FLANGE BOLT

FLANGE BOLT

Corrosion resistant bolt/nut

13. Remove the steering gearbox from the front cross- beam by removing the flange bolts.

FLANGE BOLTS

60 N.

m (6.0 kg-m, 43 Ib-ft)

FRONT CROSSBEAM

Front

GEARBOX

ASSEMBLY

Corrosion resistant bolt/nut

14. Install the gearbox in the reverse order of removal.

CAUTION: Torque the castle nut of the tie-rod end

to the lower torque specification, then tighten it on-

ly far enough to align the slot with the pin hole. Do

not align the nut by loosening.

NOTE: When connecting the steering joint, make

sure that the cable reel of SRS is centered.

15. Set the steering rack in the center of its strokes.

16. Center the cable reel as follows: Turn the steering wheel left approx. 150

degrees, to check the cable reel position with

indicator.

If the cable reel is centered, the yellow gear

tooth lines up with the alignment mark on the

cover.

Return the steering wheel right approx. 150

degrees to position the steering wheel in the

straight ahead position.

YELLOW GEAR TOOTH

ALIGNMENT MARK

17. Slip the lower of the steering joint onto the pinion shaft (line up the bolt hole with the groove around

the shaft) and loosely install the lower bolt.

NOTE:

Be sure that the lower steering joint bolt is

securely in the groove in the steering gearbox

pinion.

If the steering wheel and rack are not aligned

centered, reposition the serrations at lower side

of the steering joint.

18. Adjust the front toe after installing the gearbox (see section 18).ProCarManuals.com

Page 1561 of 1640

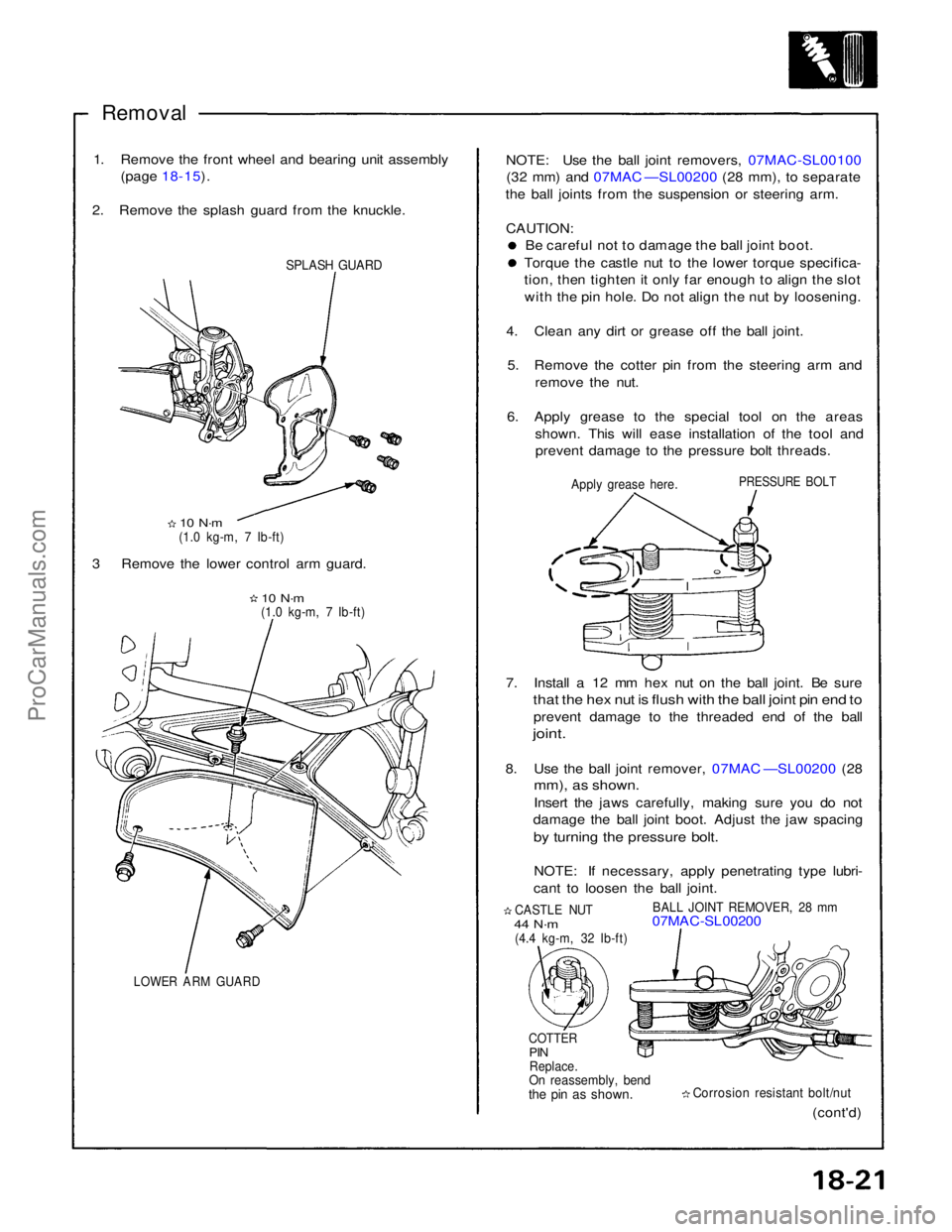

Removal

1. Remove the front wheel and bearing unit assembly (page 18-15).

2. Remove the splash guard from the knuckle.

SPLASH GUARD

10 N·m

(1.0 kg-m, 7 Ib-ft)

3 Remove the lower control arm guard.

10 N·m

(1.0 kg-m, 7 Ib-ft)

LOWER ARM GUARD

(cont'd)

Corrosion resistant bolt/nut

COTTER

PIN

Replace.

On reassembly, bend

the pin as shown.

CASTLE NUT

44 N·m

(4.4 kg-m, 32 Ib-ft)

BALL JOINT REMOVER, 28 mm

07MAC-SL00200

7. Install a 12 mm hex nut on the ball joint. Be sure

that the hex nut is flush with the ball joint pin end to

prevent damage to the threaded end of the ball

joint.

8. Use the ball joint remover, 07MAC —SL00200 (28

mm), as shown.

Insert the jaws carefully, making sure you do not

damage the ball joint boot. Adjust the jaw spacing

by turning the pressure bolt.

NOTE: If necessary, apply penetrating type lubri-

cant to loosen the ball joint.

PRESSURE BOLT

Apply grease here.

NOTE: Use the ball joint removers, 07MAC-SL00100

(32 mm) and 07MAC —SL00200 (28 mm), to separate

the ball joints from the suspension or steering arm.

CAUTION: Be careful not to damage the ball joint boot. Torque the castle nut to the lower torque specifica-

tion, then tighten it only far enough to align the slot

with the pin hole. Do not align the nut by loosening.

4. Clean any dirt or grease off the ball joint. 5. Remove the cotter pin from the steering arm and remove the nut.

6. Apply grease to the special tool on the areas shown. This will ease installation of the tool andprevent damage to the pressure bolt threads.ProCarManuals.com