width ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 114 of 1640

Valve Seat s

Reconditionin g

1. Rene w th e valv e seat s i n th e cylinde r hea d usin g a

valv e sea t grinder .

NOTE : I f guide s ar e wor n (se e pag e 6-39 ), replac e

the m (se e pag e 6-40 ) befor e grindin g th e valv e seats .

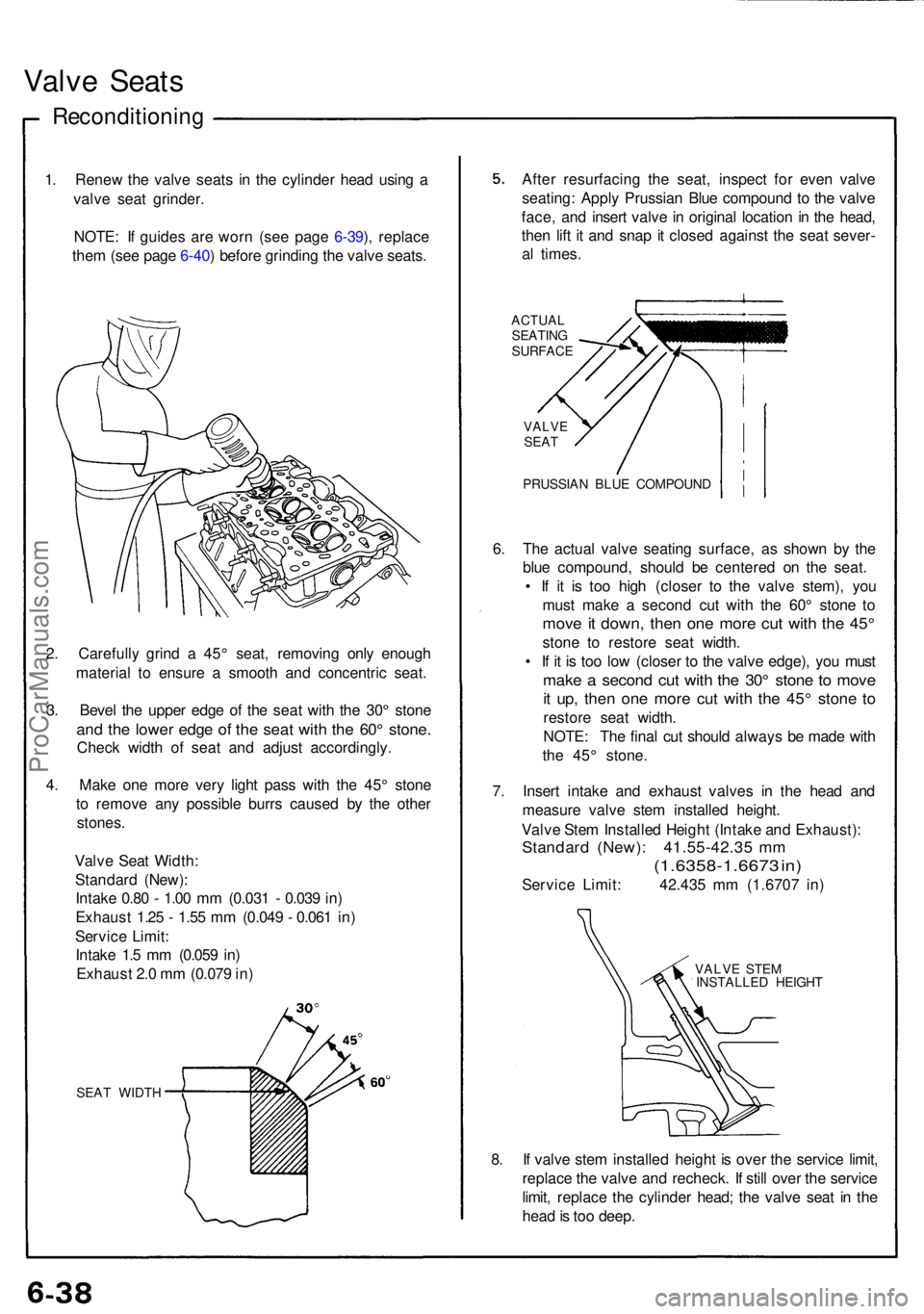

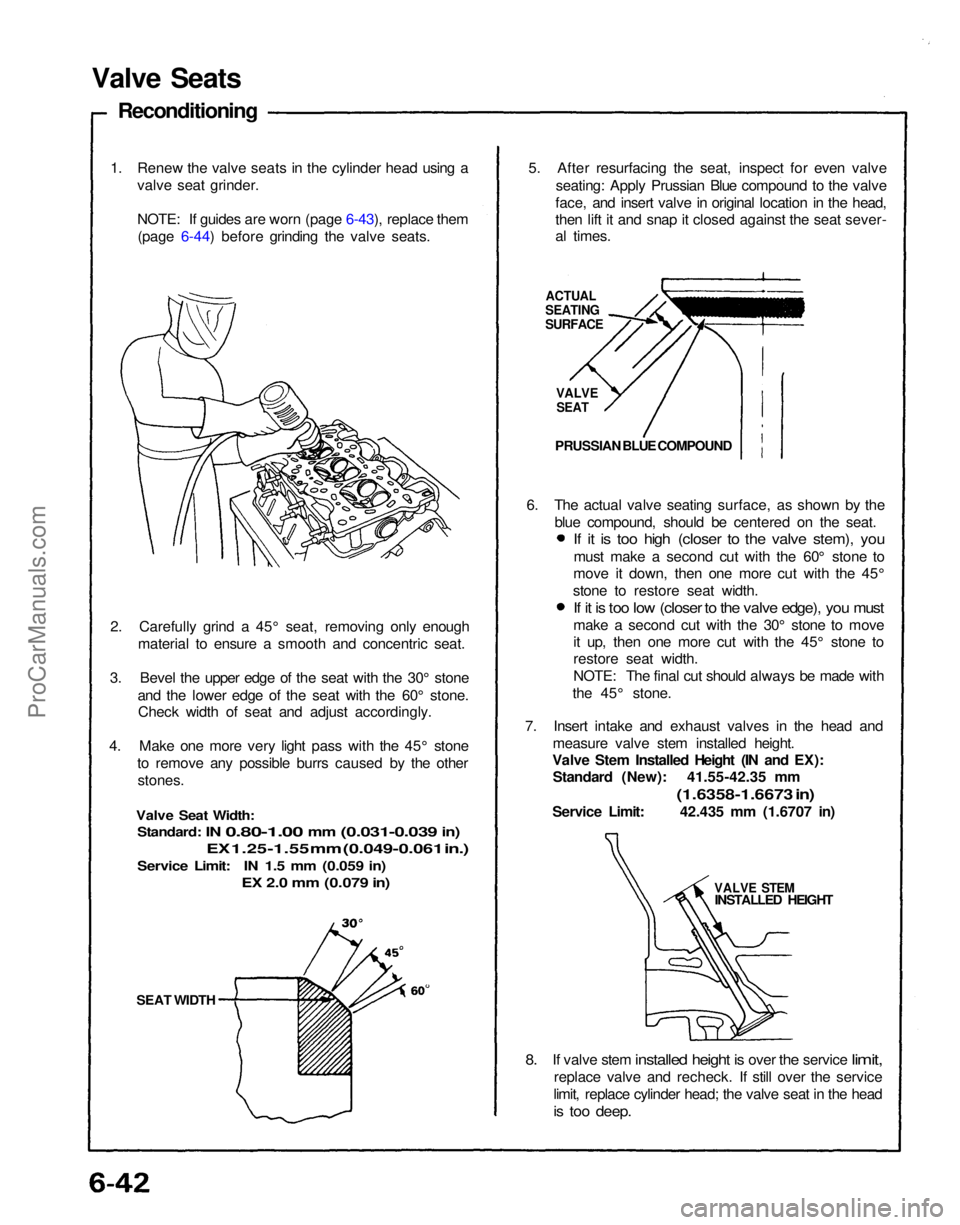

2 . Carefull y grin d a 45 ° seat , removin g onl y enoug h

materia l t o ensur e a smoot h an d concentri c seat .

3 . Beve l th e uppe r edg e o f th e sea t wit h th e 30 ° ston e

and th e lowe r edg e of the sea t wit h th e 60 ° stone .

Check widt h o f sea t an d adjus t accordingly .

4 . Mak e on e mor e ver y ligh t pas s wit h th e 45 ° ston e

t o remov e an y possibl e burr s cause d b y th e othe r

stones .

Valv e Sea t Width :

Standar d (New) :

Intak e 0.8 0 - 1.0 0 m m (0.03 1 - 0.03 9 in )

Exhaus t 1.2 5 - 1.5 5 m m (0.04 9 - 0.06 1 in )

Servic e Limit :

Intak e 1. 5 m m (0.05 9 in )

Exhaus t 2. 0 m m (0.07 9 in )

SEA T WIDT H

After resurfacin g th e seat , inspec t fo r eve n valv e

seating : Appl y Prussia n Blu e compoun d t o th e valv e

face , an d inser t valv e in origina l locatio n in th e head ,

the n lif t i t an d sna p it close d agains t th e sea t sever -

a l times .

ACTUA L

SEATIN G

SURFAC E

VALVESEAT

PRUSSIA N BLU E COMPOUN D

6. Th e actua l valv e seatin g surface , a s show n b y th e

blu e compound , shoul d b e centere d o n th e seat .

• I f i t i s to o hig h (close r t o th e valv e stem) , yo u

mus t mak e a secon d cu t wit h th e 60 ° ston e t o

mov e it down , the n on e mor e cu t wit h th e 45 °

ston e t o restor e sea t width .

• I f i t i s to o lo w (close r t o th e valv e edge) , yo u mus t

make a secon d cu t wit h th e 30 ° ston e t o mov e

it up , the n on e mor e cu t wit h th e 45 ° ston e t o

restor e sea t width .

NOTE : Th e fina l cu t shoul d alway s b e mad e wit h

th e 45 ° stone .

7 . Inser t intak e an d exhaus t valve s i n th e hea d an d

measur e valv e ste m installe d height .

Valv e Ste m Installe d Heigh t (Intak e an d Exhaust) :

Standard (New) : 41.55-42.3 5 m m

(1.6358-1.667 3 in )

Servic e Limit : 42.43 5 m m (1.670 7 in )

VALV E STE M

INSTALLE D HEIGH T

8. I f valv e ste m installe d heigh t i s ove r th e servic e limit ,

replac e th e valv e an d recheck . I f stil l ove r th e servic e

limit , replac e th e cylinde r head ; th e valv e sea t i n th e

hea d is to o deep .

ProCarManuals.com

Page 311 of 1640

Reverse Shift Arm, Reverse Shift Fork

Clearance Inspection

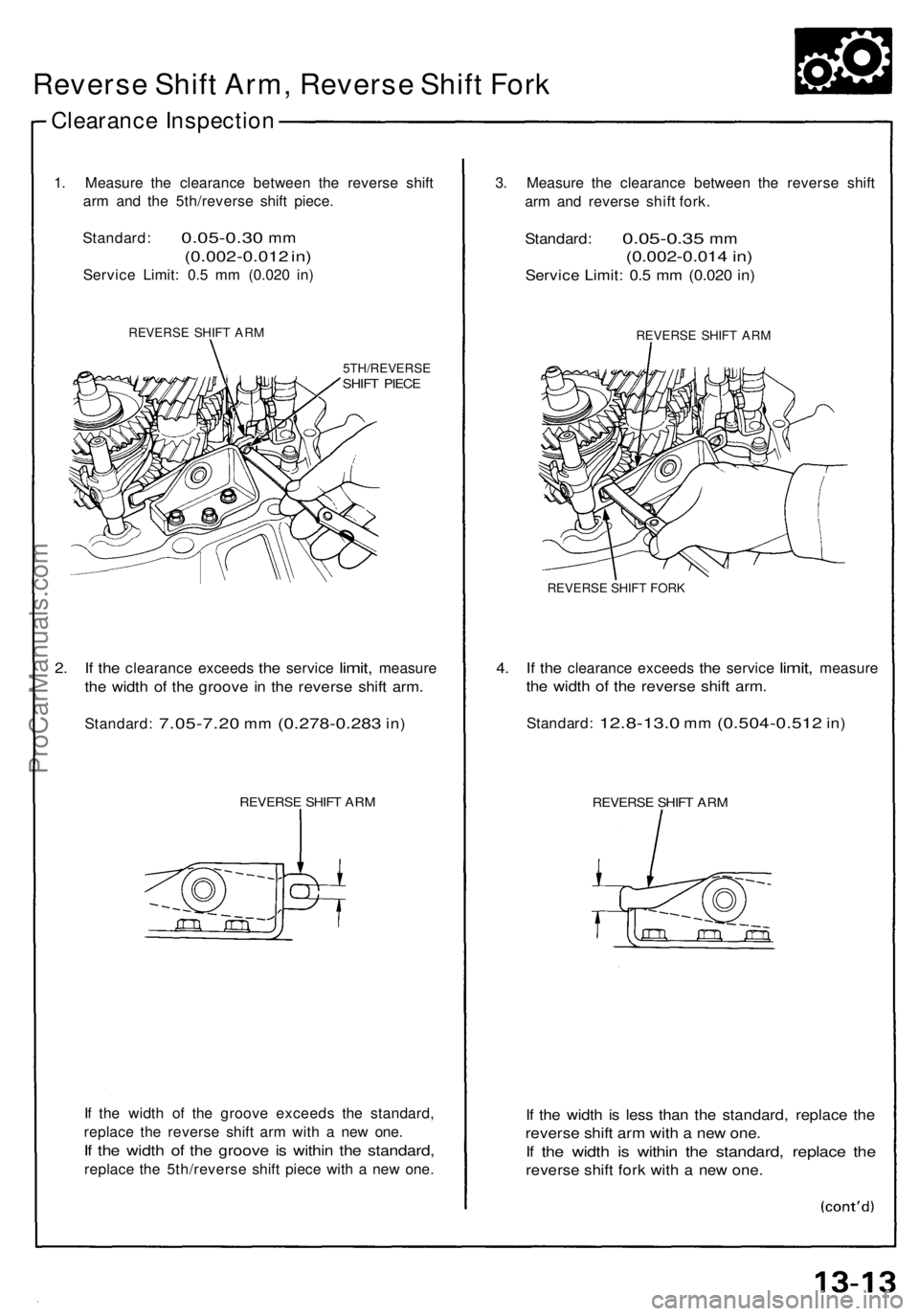

1. Measure the clearance between the reverse shift

arm and the 5th/reverse shift piece.

Standard:

0.05-0.30

mm

(0.002-0.012 in)

Service Limit: 0.5 mm (0.020 in)

REVERSE SHIFT ARM

5TH/REVERSE

SHIFT PIECE

2. If the

clearance exceeds

the

service

limit,

measure

the width of the groove in the reverse shift arm.

Standard:

7.05-7.20

mm

(0.278-0.283

in)

REVERSE SHIFT ARM

If the width of the groove exceeds the standard,

replace the reverse shift arm with a new one.

If the width of the groove is within the standard,

replace the 5th/reverse shift piece with a new one.

3. Measure the clearance between the reverse shift

arm and reverse shift fork.

Standard:

0.05-0.35

mm

(0.002-0.014 in)

Service Limit: 0.5 mm (0.020 in)

REVERSE SHIFT ARM

REVERSE SHIFT FORK

4. If the

clearance exceeds

the

service

limit,

measure

the width of the reverse shift arm.

Standard:

12.8-13.0

mm

(0.504-0.512

in)

REVERSE SHIFT ARM

If the width is less than the standard, replace the

reverse shift arm with a new one.

If the width is within the standard, replace the

reverse shift fork with a new one.ProCarManuals.com

Page 321 of 1640

Change Holder Assembly, Shift Fork

Clearance Inspection

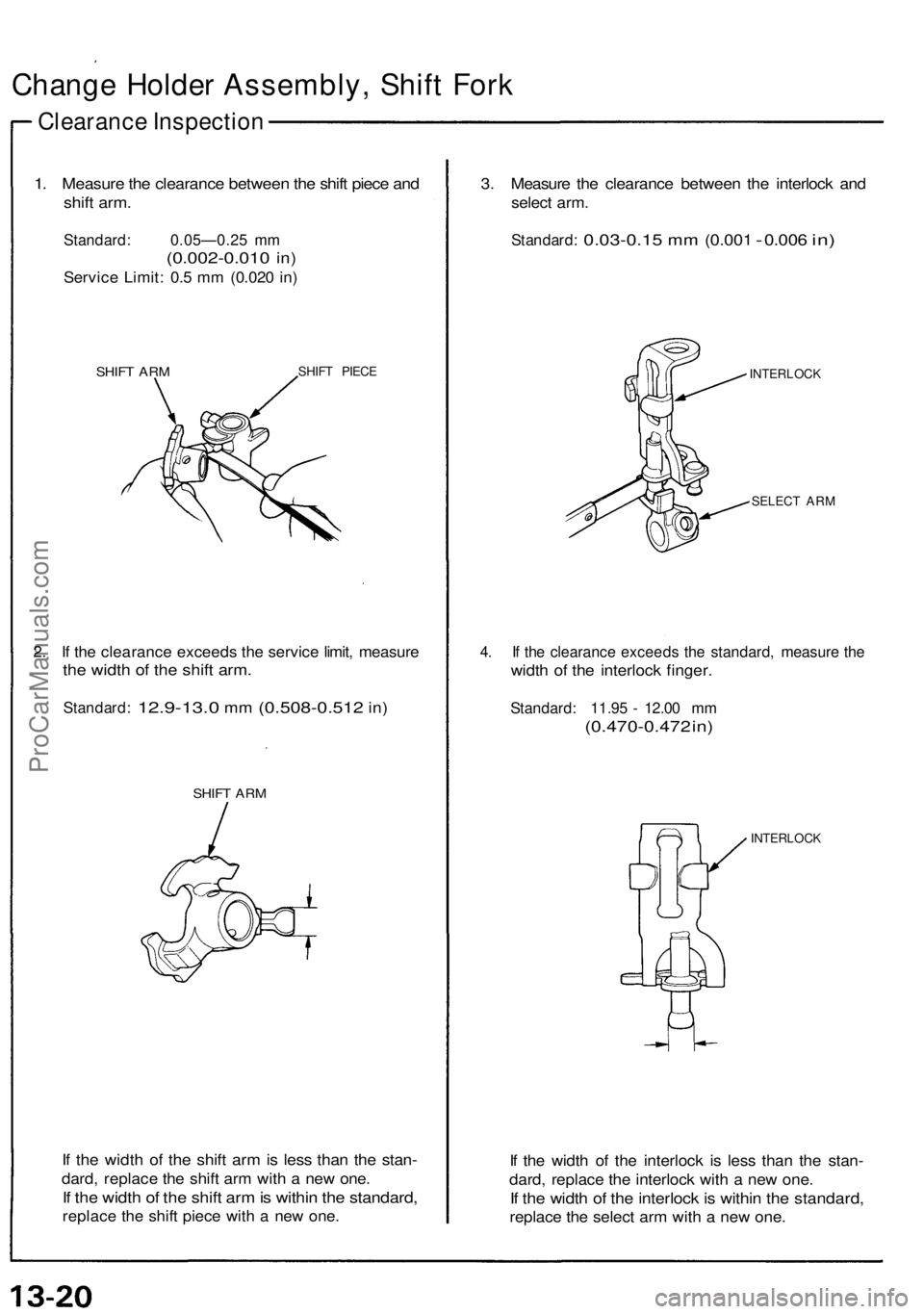

1. Measure the clearance between the shift piece and

shift arm.

Standard: 0.05—0.25 mm

(0.002-0.010

in)

Service Limit: 0.5 mm (0.020 in)

SHIFT ARM

SHIFT PIECE

2. If the clearance exceeds the service limit, measure

the width of the shift arm.

Standard:

12.9-13.0

mm

(0.508-0.512

in)

SHIFT ARM

If the width of the shift arm is less than the stan-

dard, replace the shift arm with a new one.

If the width of the shift arm is within the standard,

replace the shift piece with a new one.

3. Measure the clearance between the interlock and

select arm.

Standard:

0.03-0.15

mm

(0.001

-

0.006

in)

INTERLOCK

SELECT ARM

4. If the clearance exceeds the standard, measure the

width of the interlock finger.

Standard: 11.95 - 12.00 mm

(0.470-0.472 in)

INTERLOCK

If the width of the interlock is less than the stan-

dard, replace the interlock with a new one.

If the width of the interlock is within the standard,

replace the select arm with a new one.ProCarManuals.com

Page 322 of 1640

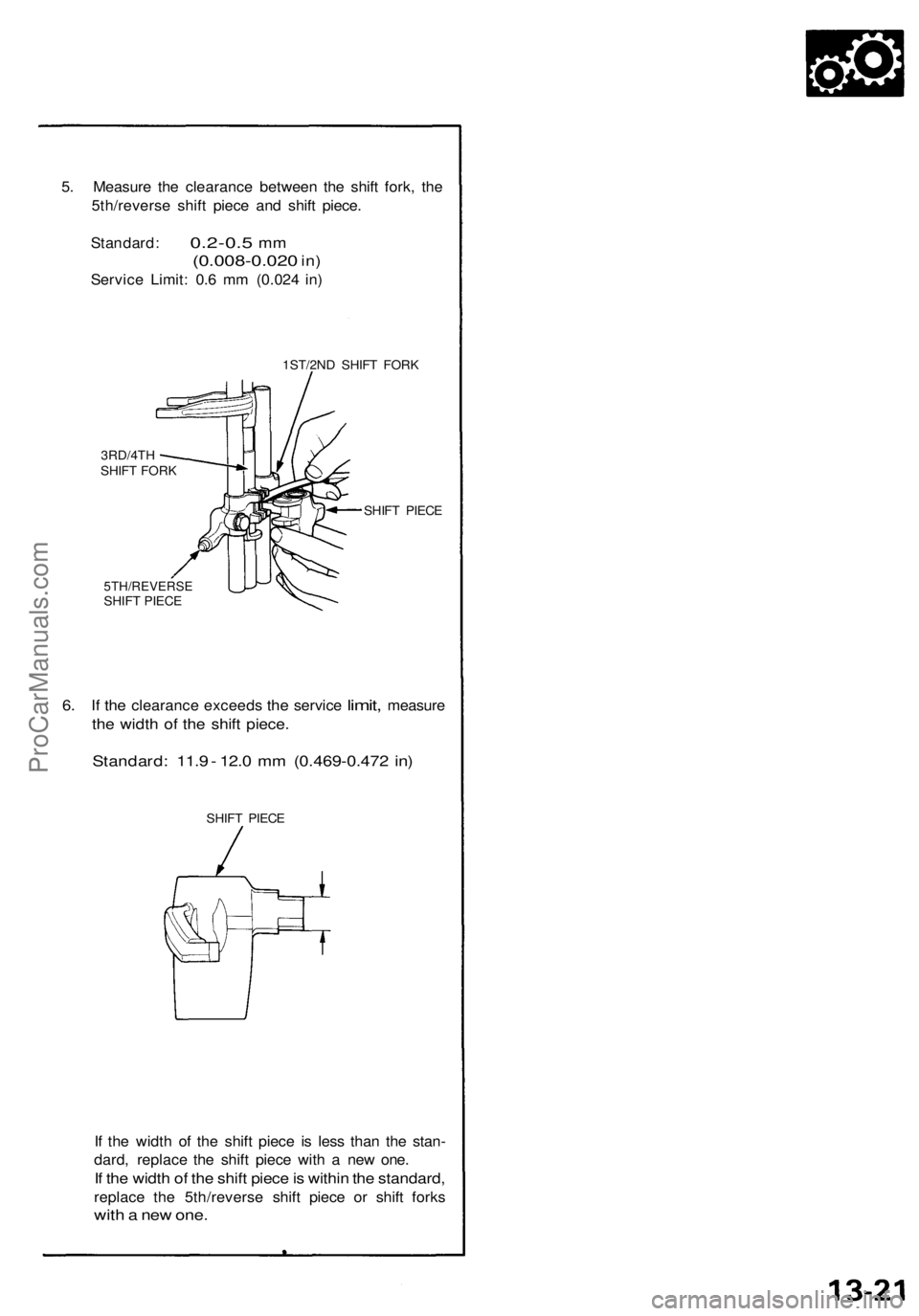

5. Measure the clearance between the shift fork, the

5th/reverse shift piece and shift piece.

Standard:

0.2-0.5

mm

(0.008-0.020

in)

Service Limit: 0.6 mm (0.024 in)

1ST/2ND SHIFT FORK

5TH/REVERSE

SHIFT PIECE

6. If the

clearance exceeds

the

service

limit,

measure

the width of the shift piece.

Standard: 11.9 - 12.0 mm (0.469-0.472 in)

SHIFT PIECE

If the width of the shift piece is less than the stan-

dard, replace the shift piece with a new one.

If the width of the shift piece is within the standard,

replace the 5th/reverse shift piece or shift forks

with a new one.

3RD/4TH

SHIFT FORK

SHIFT PIECEProCarManuals.com

Page 323 of 1640

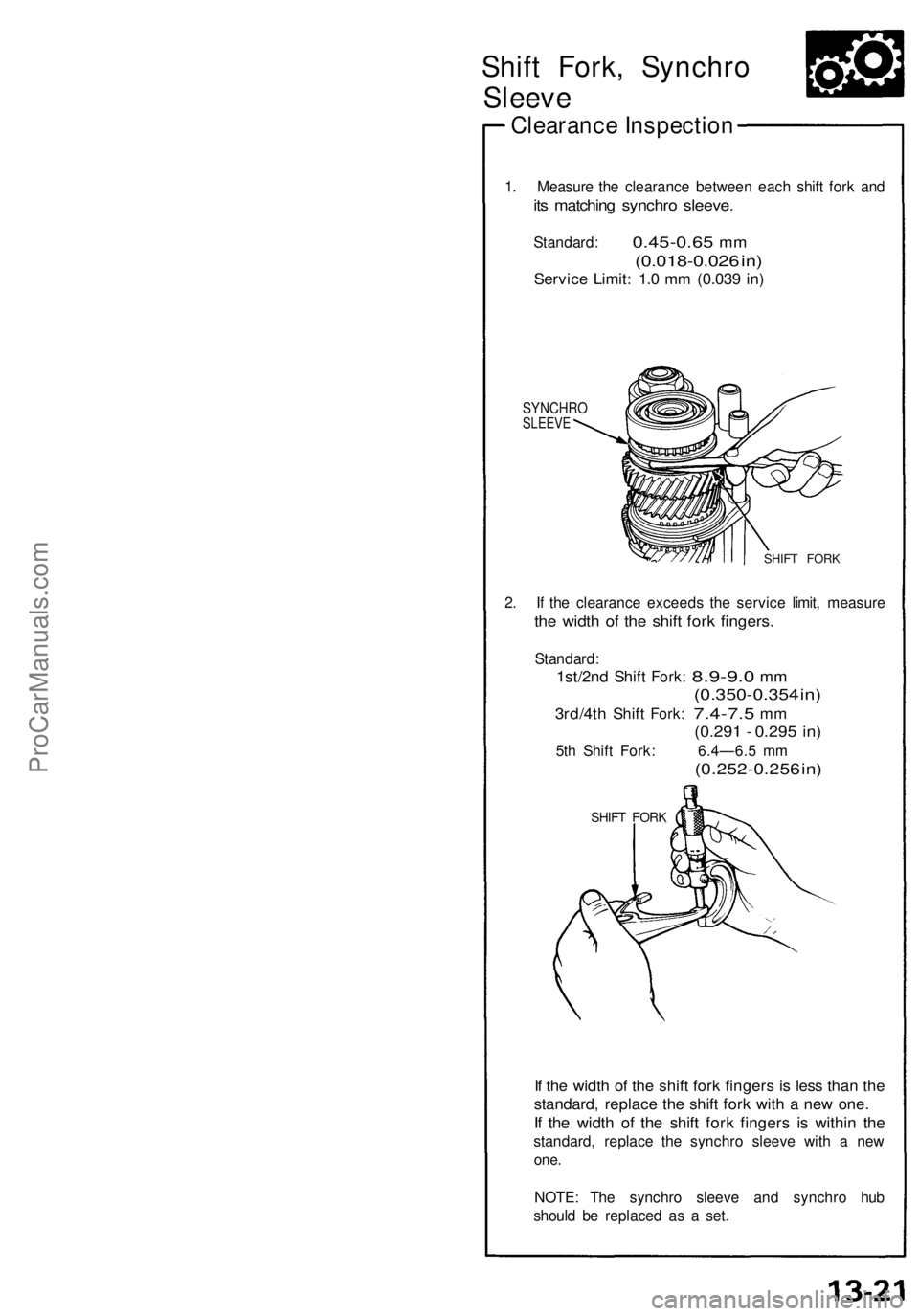

Shift Fork, Synchro

Sleeve

Clearance Inspection

1. Measure the clearance between each shift fork and

its matching synchro sleeve.

Standard:

0.45-0.65

mm

(0.018-0.026 in)

Service Limit: 1.0 mm (0.039 in)

SYNCHRO

SLEEVE

SHIFT FORK

2. If the clearance exceeds the service limit, measure

the width of the shift fork fingers.

Standard:

1st/2nd

Shift

Fork:

8.9-9.0

mm

(0.350-0.354 in)

3rd/4th

Shift

Fork:

7.4-7.5

mm

(0.291 - 0.295 in)

5th Shift Fork: 6.4—6.5 mm

(0.252-0.256 in)

SHIFT FORK

If the width of the shift fork fingers is less than the

standard, replace the shift fork with a new one.

If the width of the shift fork fingers is within the

standard, replace the synchro sleeve with a new

one.

NOTE: The synchro sleeve and synchro hub

should be replaced as a set.ProCarManuals.com

Page 414 of 1640

System Description

Function and Operation

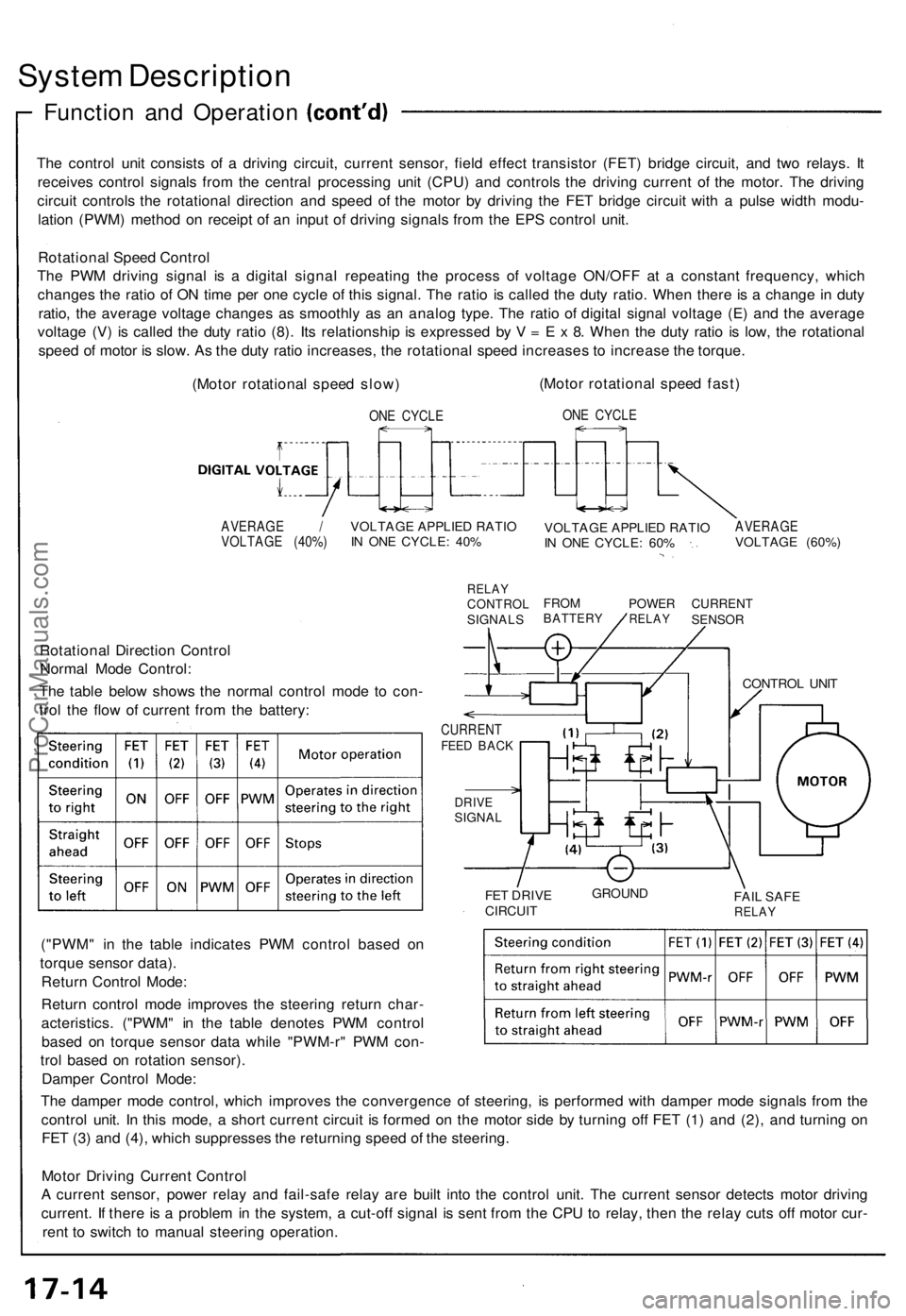

The control unit consists of a driving circuit, current sensor, field effect transistor (FET) bridge circuit, and two relays. It

receives control signals from the central processing unit (CPU) and controls the driving current of the motor. The driving

circuit controls the rotational direction and speed of the motor by driving the FET bridge circuit with a pulse width modu-

lation (PWM) method on receipt of an input of driving signals from the EPS control unit.

Rotational Speed Control

The PWM driving signal is a digital signal repeating the process of voltage ON/OFF at a constant frequency, which

changes the ratio of ON time per one cycle of this signal. The ratio is called the duty ratio. When there is a change in duty

ratio, the average voltage changes as smoothly as an analog type. The ratio of digital signal voltage (E) and the average

voltage (V) is called the duty ratio (8). Its relationship is expressed by V = E x 8. When the duty ratio is low, the rotational

speed of motor is slow. As the duty ratio increases, the rotational speed increases to increase the torque.

(Motor rotational speed slow)

ONE CYCLE

(Motor rotational speed fast)

ONE CYCLE

AVERAGE /

VOLTAGE (40%)

VOLTAGE APPLIED RATIO

IN ONE CYCLE: 40%

RELAY

CONTROL

SIGNALS

VOLTAGE APPLIED RATIO

IN ONE CYCLE: 60%

AVERAGE

VOLTAGE (60%)

FROM

BATTERY

POWER

RELAY

CURRENT

SENSOR

Rotational Direction Control

Normal Mode Control:

The table below shows the normal control mode to con-

trol the flow of current from the battery:

CURRENT

FEED BACK

DRIVE

SIGNAL

FET DRIVE

CIRCUIT

GROUND

FAIL SAFE

RELAY

("PWM" in the table indicates PWM control based on

torque sensor data).

Return Control Mode:

Return control mode improves the steering return char-

acteristics. ("PWM" in the table denotes PWM control

based on torque sensor data while "PWM-r" PWM con-

trol based on rotation sensor).

Damper Control Mode:

The damper mode control, which improves the convergence of steering, is performed with damper mode signals from the

control unit. In this mode, a short current circuit is formed on the motor side by turning off FET (1) and (2), and turning on

FET (3) and (4), which suppresses the returning speed of the steering.

Motor Driving Current Control

A current sensor, power relay and fail-safe relay are built into the control unit. The current sensor detects motor driving

current. If there is a problem in the system, a cut-off signal is sent from the CPU to relay, then the relay cuts off motor cur-

rent to switch to manual steering operation.

CONTROL UNITProCarManuals.com

Page 450 of 1640

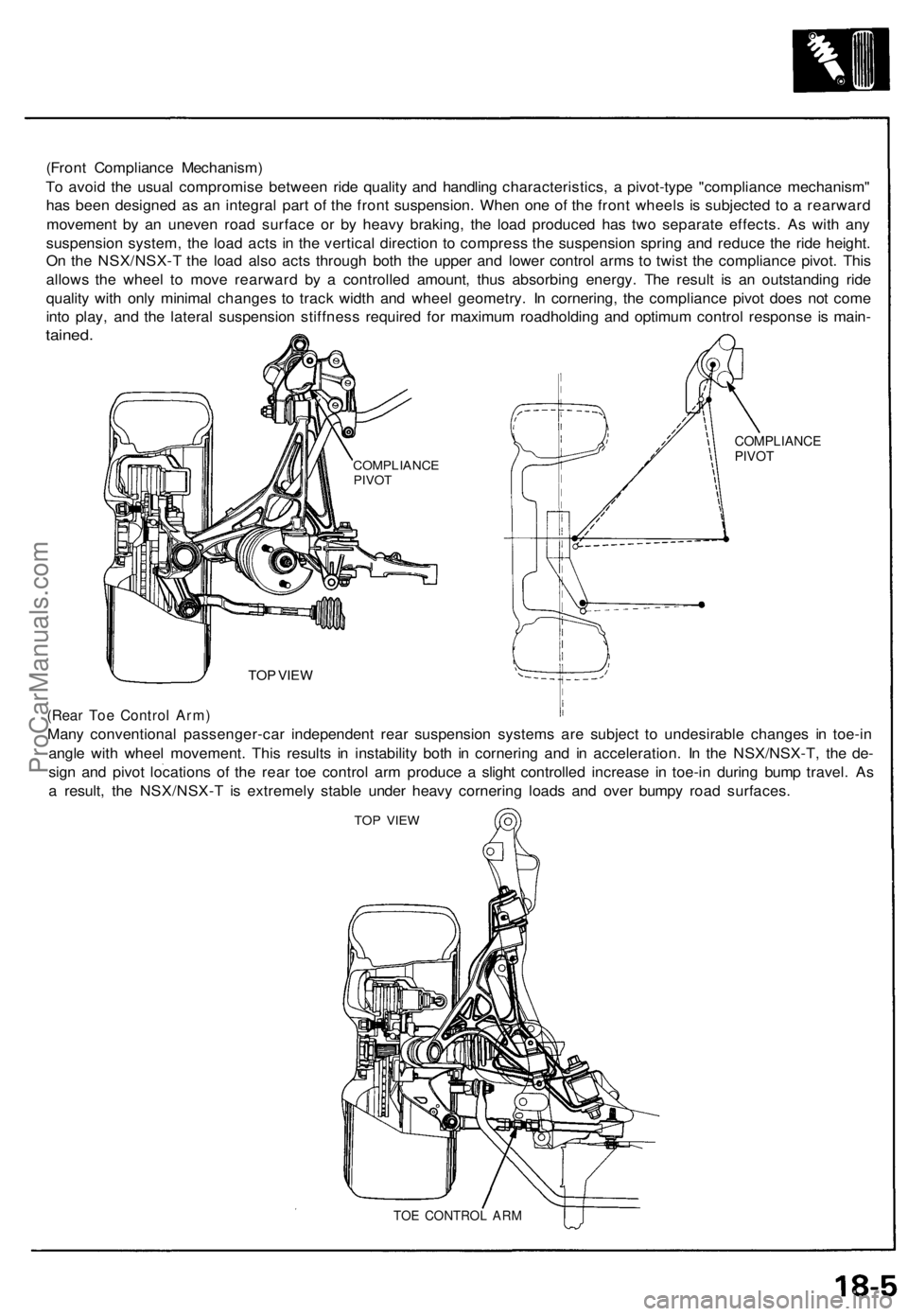

(Front Compliance Mechanism)

To avoid the usual compromise between ride quality and handling characteristics, a pivot-type "compliance mechanism"

has been designed as an integral part of the front suspension. When one of the front wheels is subjected to a rearward

movement by an uneven road surface or by heavy braking, the load produced has two separate effects. As with any

suspension system, the load acts in the vertical direction to compress the suspension spring and reduce the ride height.

On the NSX/NSX-T the load also acts through both the upper and lower control arms to twist the compliance pivot. This

allows the wheel to move rearward by a controlled amount, thus absorbing energy. The result is an outstanding ride

quality with only minimal changes to track width and wheel geometry. In cornering, the compliance pivot does not come

into play, and the lateral suspension stiffness required for maximum roadholding and optimum control response is main-

tained.

COMPLIANCE

PIVOT

TOP VIEW

(Rear Toe Control Arm)

Many conventional passenger-car independent rear suspension systems are subject to undesirable changes in toe-in

angle with wheel movement. This results in instability both in cornering and in acceleration. In the NSX/NSX-T, the de-

sign and pivot locations of the rear toe control arm produce a slight controlled increase in toe-in during bump travel. As

a result, the NSX/NSX-T is extremely stable under heavy cornering loads and over bumpy road surfaces.

TOP VIEW

TOE CONTROL ARM

COMPLIANCE

PIVOTProCarManuals.com

Page 643 of 1640

Roof

Roof Side Seal/Retainer Replacement

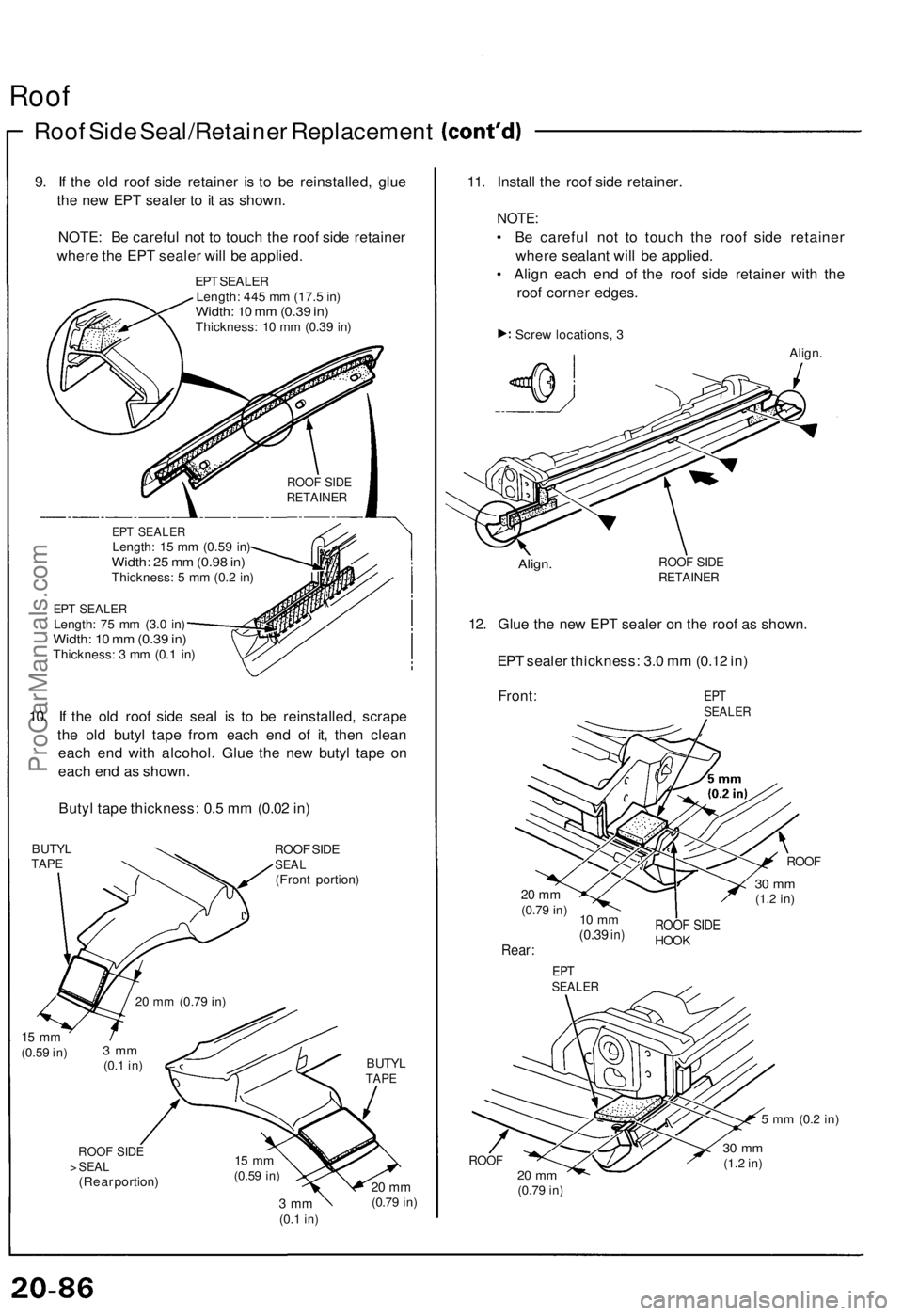

9. If the old roof side retainer is to be reinstalled, glue

the new EPT sealer to it as shown.

NOTE: Be careful not to touch the roof side retainer

where the EPT sealer will be applied.

EPT SEALER

Length: 445 mm (17.5 in)

Width: 10 mm (0.39 in)

Thickness: 10 mm (0.39 in)

EPT SEALER

Length: 15 mm (0.59 in)

Width: 25 mm (0.98 in)

Thickness: 5 mm (0.2 in)

EPT SEALER

Length: 75 mm (3.0 in)

Width: 10 mm (0.39 in)

Thickness: 3 mm (0.1 in)

10. If the old roof side seal is to be reinstalled, scrape

the old butyl tape from each end of it, then clean

each end with alcohol. Glue the new butyl tape on

each end as shown.

Butyl tape thickness: 0.5 mm (0.02 in)

BUTYL

TAPE

ROOF SIDE

SEAL

(Front portion)

15 mm

(0.59

in)

BUTYL

TAPE

ROOF SIDE

> SEAL

(Rear portion)

3 mm

(0.1

in)

20 mm

(0.79

in)

11. Install the roof side retainer.

NOTE:

• Be careful not to touch the roof side retainer

where sealant will be applied.

• Align each end of the roof side retainer with the

roof corner edges.

Screw locations, 3

Align.

Align.

ROOF SIDE

RETAINER

12. Glue the new EPT sealer on the roof as shown.

EPT sealer thickness: 3.0 mm (0.12 in)

Front:

EPT

SEALER

ROOF

20 mm

(0.79

in)

30 mm

(1.2

in)

10 mm

(0.39

in)

Rear:

ROOF SIDE

HOOK

EPT

SEALER

5 mm

(0.2

in)

ROOF

20 mm

(0.79

in)

30 mm

(1.2

in)

3 mm

(0.1

in)

20 mm

(0.79

in)

15 mm

(0.59

in)

ROOF SIDE

RETAINERProCarManuals.com

Page 1029 of 1640

SEAT WIDTH

2. Carefully grind a 45° seat, removing only enough

material to ensure a smooth and concentric seat.

3. Bevel the upper edge of the seat with the 30° stone and the lower edge of the seat with the 60° stone.Check width of seat and adjust accordingly.

4. Make one more very light pass with the 45° stone to remove any possible burrs caused by the otherstones.

Valve Seat Width:

Standard:

IN

0.80-1.00

mm

(0.031-0.039

in)

EX 1.25-1.55 mm (0.049-0.061 in.)

Service Limit: IN 1.5 mm (0.059 in)

EX 2.0 mm (0.079 in)

1. Renew the valve seats in the cylinder head using a

valve seat grinder.

NOTE: If guides are worn (page 6-43), replace them(page 6-44) before grinding the valve seats.

Valve Seats

Reconditioning

5. After resurfacing the seat, inspect for even valveseating: Apply Prussian Blue compound to the valve

face, and insert valve in original location in the head,

then lift it and snap it closed against the seat sever-

al times.

ACTUAL

SEATING

SURFACE

VALVE

SEAT

PRUSSIAN BLUE COMPOUND

7. Insert intake and exhaust valves in the head and measure valve stem installed height.

Valve Stem Installed Height (IN and EX): Standard (New): 41.55-42.35 mm

(1.6358-1.6673 in)

Service Limit: 42.435 mm (1.6707 in)

VALVE STEM

INSTALLED HEIGHT

8. If

valve stem

installed

height

is

over

the

service

limit,

replace valve and recheck. If still over the service

limit, replace cylinder head; the valve seat in the head

is too deep.

6. The actual valve seating surface, as shown by the

blue compound, should be centered on the seat.

If it is too high (closer to the valve stem), you

must make a second cut with the 60° stone to

move it down, then one more cut with the 45°

stone to restore seat width.

If it is too low (closer to the valve edge), you must

make a second cut with the 30° stone to move

it up, then one more cut with the 45° stone to

restore seat width.

NOTE: The final cut should always be made with

the 45° stone.ProCarManuals.com

Page 1331 of 1640

System Description

Power Unit

The power unit consists of a driving circuit, current sensor, field effect transistor (FET) bridge circuit, and two relays.

It receives control signals from the CPU and controls the driving current of the motor. The driving circuit controls the

rotational direction and speed of the motor by driving the FET bridge circuit with a pulse width modulation (PWM) method

on receipt of an input of driving signals from the EPS control unit.

< Rotational Speed Control >

The PWM driving signal is a digital signal repeating the process of voltage ON/OFF at a constant frequency, which changes the ratio of ON time per one cycle of this signal. The ratio is called the duty ratio. When there is a change in duty ratio,

the average voltage changes as smoothly as an analog type. The ratio of digital signal voltage (E) and the average voltage

(Motor rotational speed fast)

ONE CYCLE

AVERAGE

VOLTAGE (60%)

VOLTAGE APPLIED RATIO

IN ONE CYCLE: 60%

CURRENT

SENSOR

POWER

RELAY

FROM

BATTERY

RELAY

CONTROL

SIGNALS

VOLTAGE APPLIED RATIO

IN ONE CYCLE: 40%

AVERAGE

VOLTAGE (40%)

(Motor rotational speed slow)

DIGITAL VOLTAGE

ONE CYCLE

CURRENT

FEED BACK

DRIVE

SIGNAL

< Rotational Direction Control >

Normal Mode Control:

The table below shows the normal control mode to con-

trol the flow of current from the battery:

("PWM" in the table indicates PWM control based on

torque sensor data). Return Control Mode:

Return control mode improves the steering return charac-

teristics. ("PWM" in the table denotes PWM control based on torque sensor data while "PWM-r" PWM con-

trol based on rotation sensor).

POWER UNIT

FET DRIVE

CIRCUIT

GROND

FAIL SAFE

RELAY

Damper Control Mode:

The damper mode control which improves the convergence of steering, is performed with damper mode signals from

the control unit. In this mode, a short current circuit is formed on the motor side by turning off FET (1) and (2), and on FET (3) and (4), which suppresses the returning speed of the steering. < Motor Driving Current Control >

A current sensor, power relay and fail-safe relay are built into the power unit. The current sensor detects motor driving

current and transmits data to the EPS control unit. If there is a problem in the system, a cut-off signal is sent from the EPS

control unit to relay, then the relay cuts off motor current to switch to manual steering operation. (V) is called the duty ratio

of motor is slow. As the duty ratio increases, the rotational speed increases to increase the torque. When the duty ratio is low, the rotational speed

Its relationship is expressed by V = E x

Steering

condition Steering to

rightStraight

ahead

Steering to

left

OFFOFF

ON

FET

(1)

FET

(2)

FET

(3)

FET

(4)

OFF

OFF

OFF

ON

OFF

PWM

OFF

OFF

PWM

Motor operation

Stops

Operates in direction

steering to the left Operates in direction

steering to the right

Steering condition

Return from right steering

to straight ahead

Return from left steering

to straight ahead

FET (1)

PWM-r

OFF

FET (2)

OFF

PWM-r

FET (3)

OFF

PWM

OFF

PWM

FET (4)

MOTORProCarManuals.com