ESP ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 316 of 1503

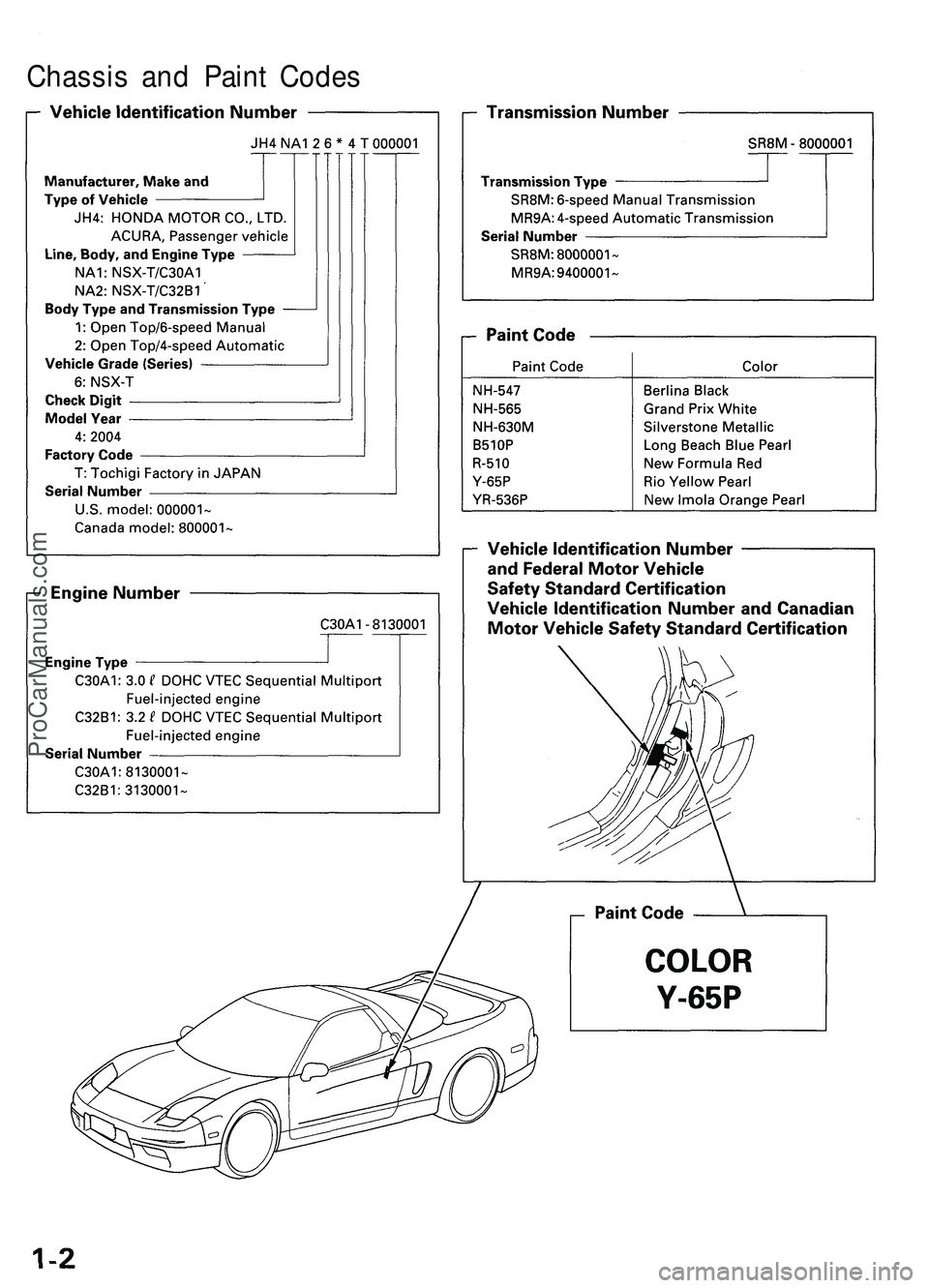

Chassis and Paint CodesProCarManuals.com

Page 381 of 1503

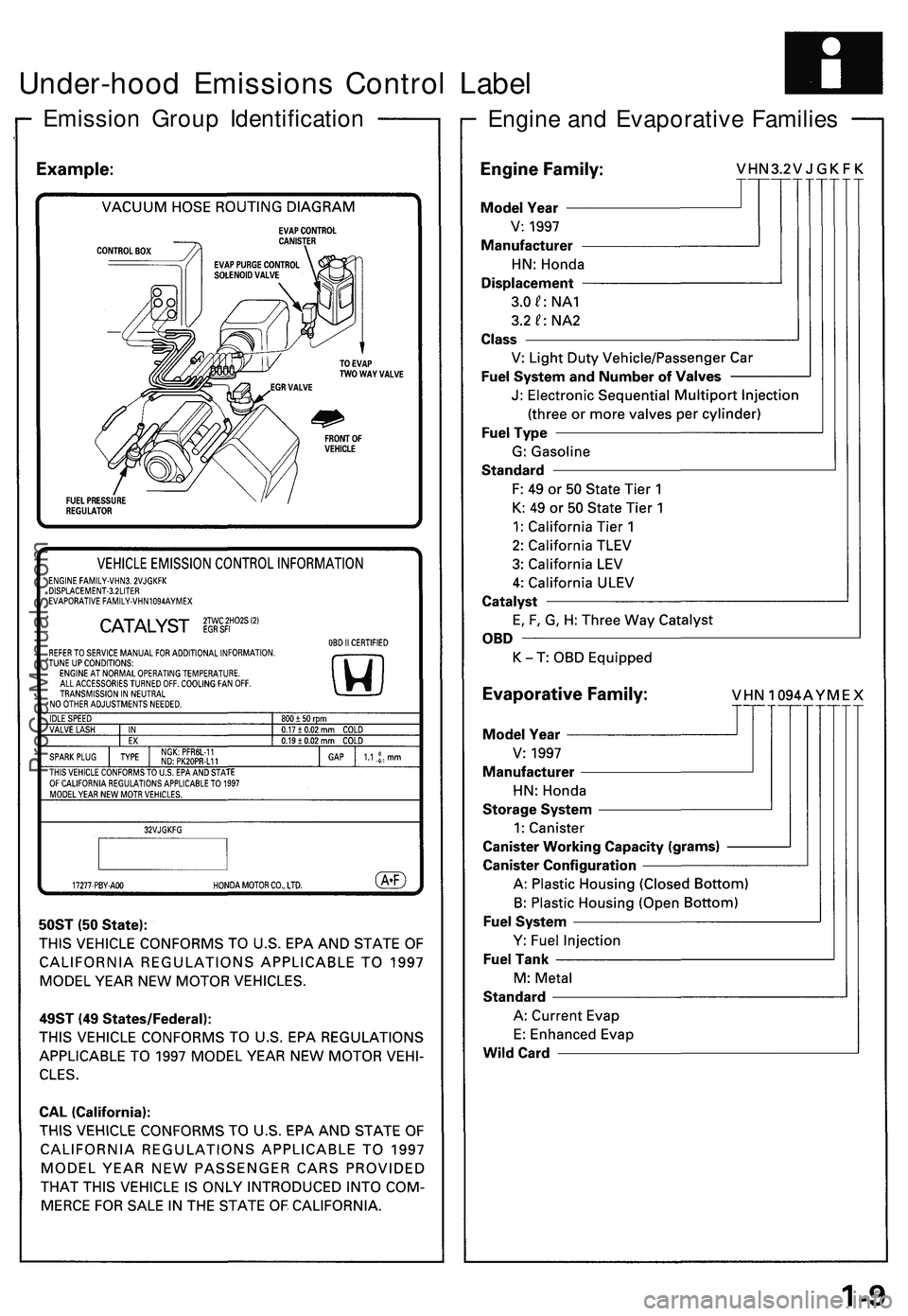

Under-hood Emissions Control Label

Emission Group Identification

Engine and Evaporative FamiliesProCarManuals.com

Page 481 of 1503

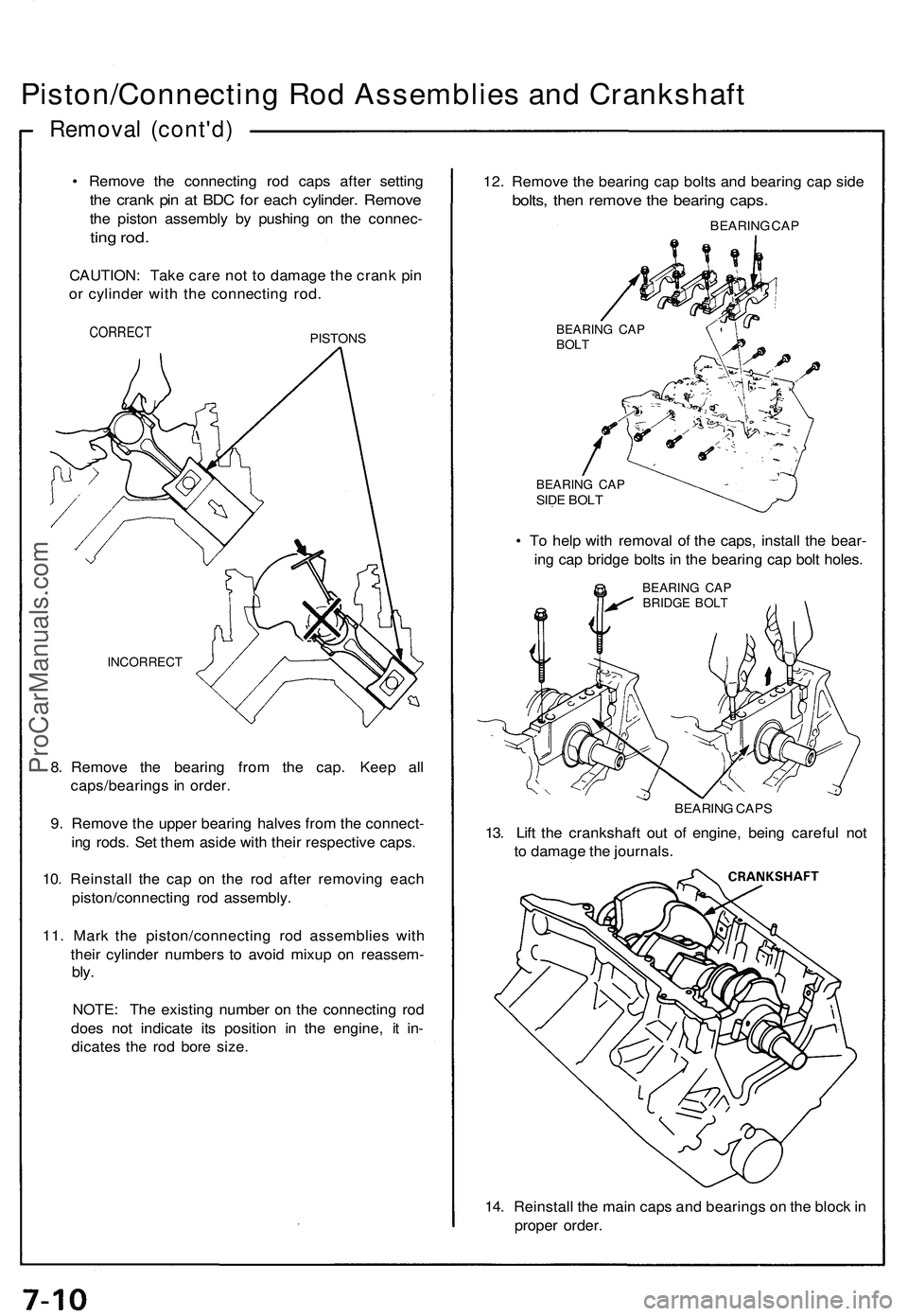

Piston/Connecting Ro d Assemblie s an d Crankshaf t

Removal (cont'd )

• Remov e th e connectin g ro d cap s afte r settin g

the cran k pi n a t BD C fo r eac h cylinder . Remov e

the pisto n assembl y b y pushin g o n th e connec -

ting rod .

CAUTION : Tak e car e no t t o damag e th e cran k pi n

o r cylinde r wit h th e connectin g rod .

CORREC TPISTONS

INCORREC T

8. Remov e th e bearin g fro m th e cap . Kee p al l

caps/bearing s i n order .

9 . Remov e th e uppe r bearin g halve s fro m th e connect -

in g rods . Se t the m asid e wit h thei r respectiv e caps .

10 . Reinstal l th e ca p o n th e ro d afte r removin g eac h

piston/connectin g ro d assembly .

11 . Mar k th e piston/connectin g ro d assemblie s wit h

thei r cylinde r number s t o avoi d mixu p o n reassem -

bly.

NOTE : Th e existin g numbe r o n th e connectin g ro d

doe s no t indicat e it s positio n i n th e engine , i t in -

dicate s th e ro d bor e size . 12

. Remov e th e bearin g ca p bolt s an d bearin g ca p sid e

bolts , the n remov e th e bearin g caps .

BEARIN G CA P

BEARIN G CA PBOL T

BEARIN G CA PSIDE BOL T

• T o hel p wit h remova l o f th e caps , instal l th e bear -

in g ca p bridg e bolt s i n th e bearin g ca p bol t holes .

BEARIN G CA PBRIDG E BOL T

BEARIN G CAP S

13. Lif t th e crankshaf t ou t o f engine , bein g carefu l no t

t o damag e th e journals .

14 . Reinstal l th e mai n cap s an d bearing s o n th e bloc k in

prope r order .

ProCarManuals.com

Page 572 of 1503

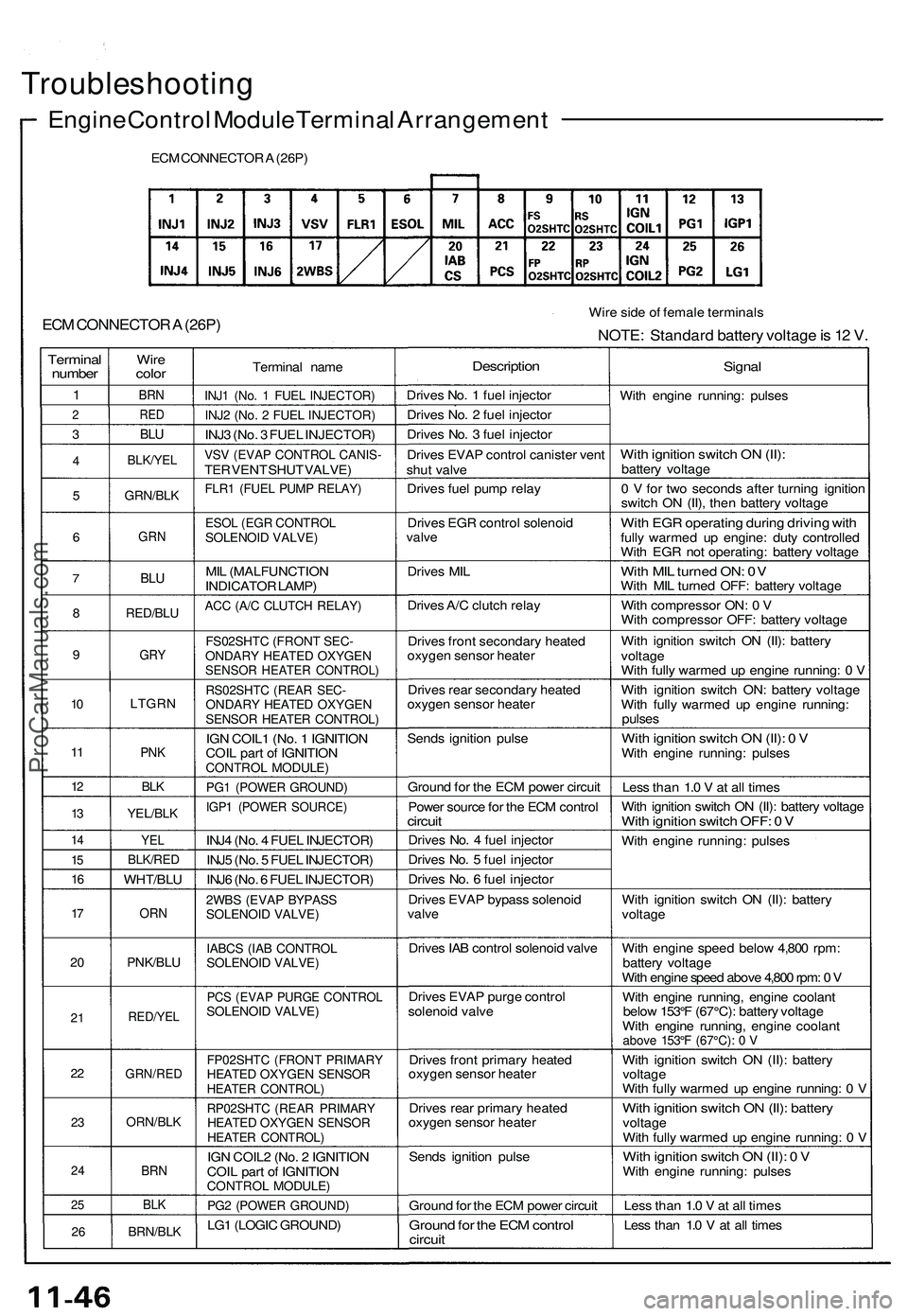

Troubleshooting

Engine Control Module Terminal Arrangement

ECM CONNECTOR A (26P)

ECM CONNECTOR A (26P)

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

Terminal

number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

20

21

22

23

24

25

26

Wire

color

BRN

RED

BLU

BLK/YEL

GRN/BLK

GRN

BLU

RED/BLU

GRY

LTGRN

PNK

BLK

YEL/BLK

YEL

BLK/RED

WHT/BLU

ORN

PNK/BLU

RED/YEL

GRN/RED

ORN/BLK

BRN

BLK

BRN/BLK

Terminal name

INJ1 (No. 1 FUEL INJECTOR)

INJ2 (No. 2 FUEL INJECTOR)

INJ3 (No. 3 FUEL INJECTOR)

VSV (EVAP CONTROL CANIS-

TER VENT SHUT VALVE)

FLR1 (FUEL PUMP RELAY)

ESOL (EGR CONTROL

SOLENOID VALVE)

MIL (MALFUNCTION

INDICATOR LAMP)

ACC (A/C CLUTCH RELAY)

FS02SHTC (FRONT SEC-

ONDARY HEATED OXYGEN

SENSOR HEATER CONTROL)

RS02SHTC (REAR SEC-

ONDARY HEATED OXYGEN

SENSOR HEATER CONTROL)

IGN COIL1 (No. 1 IGNITION

COIL part of IGNITION

CONTROL MODULE)

PG1 (POWER GROUND)

IGP1 (POWER SOURCE)

INJ4 (No. 4 FUEL INJECTOR)

INJ5 (No. 5 FUEL INJECTOR)

INJ6 (No. 6 FUEL INJECTOR)

2WBS (EVAP BYPASS

SOLENOID VALVE)

IABCS (IAB CONTROL

SOLENOID VALVE)

PCS (EVAP PURGE CONTROL

SOLENOID VALVE)

FP02SHTC (FRONT PRIMARY

HEATED OXYGEN SENSOR

HEATER CONTROL)

RP02SHTC (REAR PRIMARY

HEATED OXYGEN SENSOR

HEATER CONTROL)

IGN COIL2 (No. 2 IGNITION

COIL part of IGNITION

CONTROL MODULE)

PG2 (POWER GROUND)

LG1 (LOGIC GROUND)

Description

Drives No. 1 fuel injector

Drives No. 2 fuel injector

Drives No. 3 fuel injector

Drives EVAP control canister vent

shut valve

Drives fuel pump relay

Drives EGR control solenoid

valve

Drives MIL

Drives A/C clutch relay

Drives front secondary heated

oxygen sensor heater

Drives rear secondary heated

oxygen sensor heater

Sends ignition pulse

Ground for the ECM power circuit

Power source for the ECM control

circuit

Drives No. 4 fuel injector

Drives No. 5 fuel injector

Drives No. 6 fuel injector

Drives EVAP bypass solenoid

valve

Drives IAB control solenoid valve

Drives EVAP purge control

solenoid valve

Drives front primary heated

oxygen sensor heater

Drives rear primary heated

oxygen sensor heater

Sends ignition pulse

Ground for the ECM power circuit

Ground for the ECM control

circuit

Signal

With engine running: pulses

With ignition switch ON (II):

battery voltage

0 V for two seconds after turning ignition

switch ON (II), then battery voltage

With EGR operating during driving with

fully warmed up engine: duty controlled

With EGR not operating: battery voltage

With MIL turned ON: 0V

With MIL turned OFF: battery voltage

With compressor ON: 0 V

With compressor OFF: battery voltage

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON: battery voltage

With fully warmed up engine running:

pulses

With ignition switch ON (II): 0 V

With engine running: pulses

Less than 1.0 V at all times

With ignition switch ON (II): battery voltage

With ignition switch OFF: 0 V

With engine running: pulses

With ignition switch ON (II): battery

voltage

With engine speed below 4,800 rpm:

battery voltage

With engine speed above 4,800 rpm: 0 V

With engine running, engine coolant

below 153°F (67°C): battery voltage

With engine running, engine coolant

above 153°F (67°C): 0 V

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON (II): 0 V

With engine running: pulses

Less than 1.0 V at all times

Less than 1.0 V at all timesProCarManuals.com

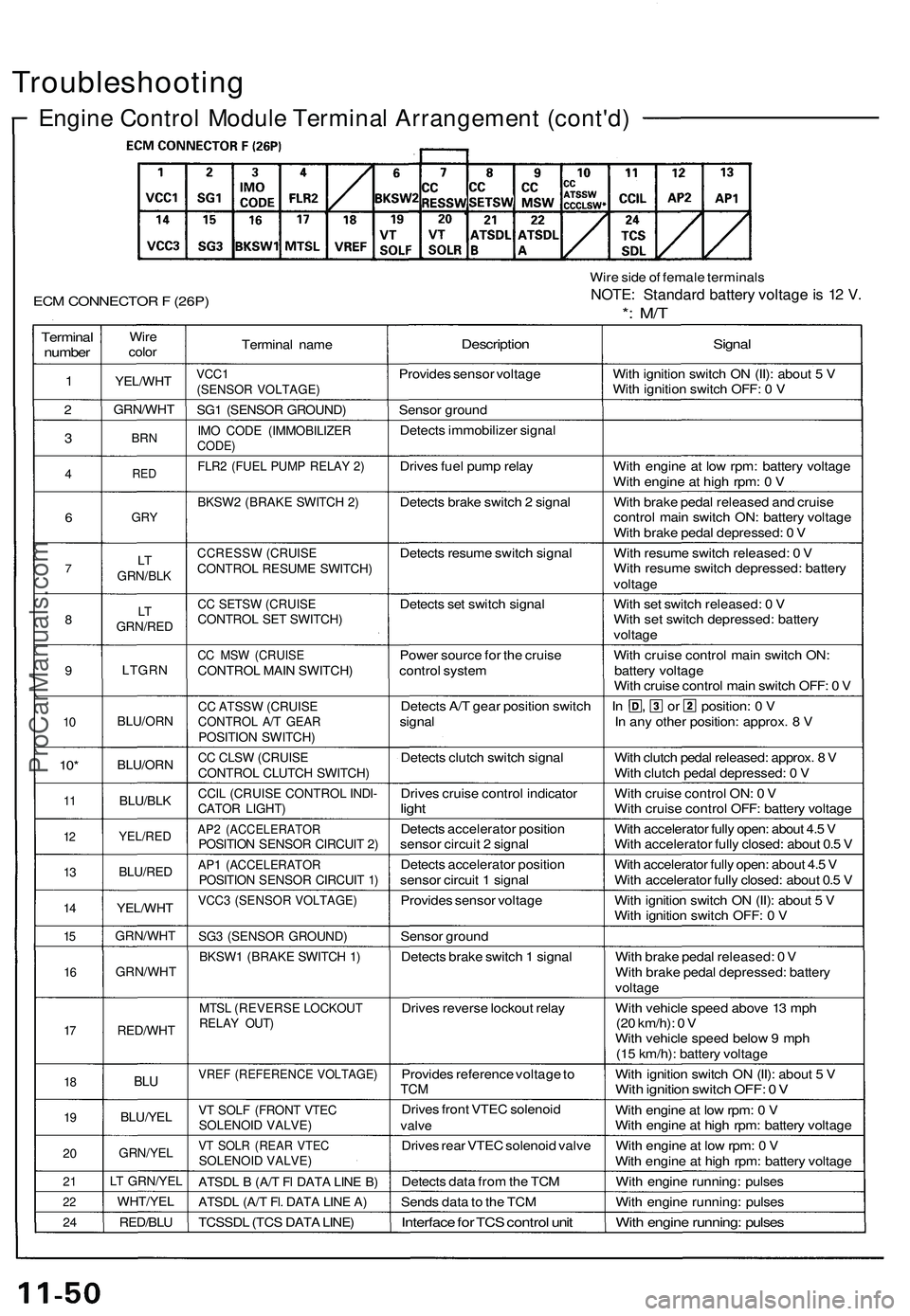

Page 576 of 1503

Troubleshooting

Engine Control Module Terminal Arrangement (cont'd)

ECM CONNECTOR F (26P)

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

*: M/T

Terminal

number

1

2

3

4

6

7

8

9

10

10*

11

12

13

14

15

16

17

18

19

20

21

22

24

Wire

color

YEL/WHT

GRN/WHT

BRN

RED

GRY

LT

GRN/BLK

LT

GRN/RED

LTGRN

BLU/ORN

BLU/ORN

BLU/BLK

YEL/RED

BLU/RED

YEL/WHT

GRN/WHT

GRN/WHT

RED/WHT

BLU

BLU/YEL

GRN/YEL

LT GRN/YEL

WHT/YEL

RED/BLU

Terminal name

VCC1

(SENSOR VOLTAGE)

SG1 (SENSOR GROUND)

IMO CODE (IMMOBILIZER

CODE)

FLR2 (FUEL PUMP RELAY 2)

BKSW2 (BRAKE SWITCH 2)

CCRESSW (CRUISE

CONTROL RESUME SWITCH)

CC SETSW (CRUISE

CONTROL SET SWITCH)

CC MSW (CRUISE

CONTROL MAIN SWITCH)

CC ATSSW (CRUISE

CONTROL A/T GEAR

POSITION SWITCH)

CC CLSW (CRUISE

CONTROL CLUTCH SWITCH)

CCIL (CRUISE CONTROL INDI-

CATOR LIGHT)

AP2 (ACCELERATOR

POSITION SENSOR CIRCUIT 2)

AP1 (ACCELERATOR

POSITION SENSOR CIRCUIT 1)

VCC3 (SENSOR VOLTAGE)

SG3 (SENSOR GROUND)

BKSW1 (BRAKE SWITCH 1)

MTSL (REVERSE LOCKOUT

RELAY OUT)

VREF (REFERENCE VOLTAGE)

VT SOLF (FRONT VTEC

SOLENOID VALVE)

VT SOLR (REAR VTEC

SOLENOID VALVE)

ATSDL B (A/T Fl DATA LINE B)

ATSDL (A/T Fl. DATA LINE A)

TCSSDL (TCS DATA LINE)

Description

Provides sensor voltage

Sensor ground

Detects immobilizer signal

Drives fuel pump relay

Detects brake switch 2 signal

Detects resume switch signal

Detects set switch signal

Power source for the cruise

control system

Detects A/T gear position switch

signal

Detects clutch switch signal

Drives cruise control indicator

light

Detects accelerator position

sensor circuit 2 signal

Detects accelerator position

sensor circuit 1 signal

Provides sensor voltage

Sensor ground

Detects brake switch 1 signal

Drives reverse lockout relay

Provides reference voltage to

TCM

Drives front VTEC solenoid

valve

Drives rear VTEC solenoid valve

Detects data from the TCM

Sends data to the TCM

Interface for TCS control unit

Signal

With ignition switch ON (II): about 5 V

With ignition switch OFF: 0 V

With engine at low rpm: battery voltage

With engine at high rpm: 0 V

With brake pedal released and cruise

control main switch ON: battery voltage

With brake pedal depressed: 0 V

With resume switch released: 0 V

With resume switch depressed: battery

voltage

With set switch released: 0 V

With set switch depressed: battery

voltage

With cruise control main switch ON:

battery voltage

With cruise control main switch OFF: 0 V

In , or position: 0 V

In any other position: approx. 8 V

With clutch pedal released: approx. 8 V

With clutch pedal depressed: 0 V

With cruise control ON: 0 V

With cruise control OFF: battery voltage

With accelerator fully open: about 4.5 V

With accelerator fully closed: about 0.5 V

With accelerator fully open: about 4.5 V

With accelerator fully closed: about 0.5 V

With ignition switch ON (II): about 5 V

With ignition switch OFF: 0 V

With brake pedal released: 0 V

With brake pedal depressed: battery

voltage

With vehicle speed above 13 mph

(20 km/h): 0 V

With vehicle speed below 9 mph

(15 km/h): battery voltage

With ignition switch ON (II): about 5 V

With ignition switch OFF: 0 V

With engine at low rpm: 0 V

With engine at high rpm: battery voltage

With engine at low rpm: 0 V

With engine at high rpm: battery voltage

With engine running: pulses

With engine running: pulses

With engine running: pulsesProCarManuals.com

Page 578 of 1503

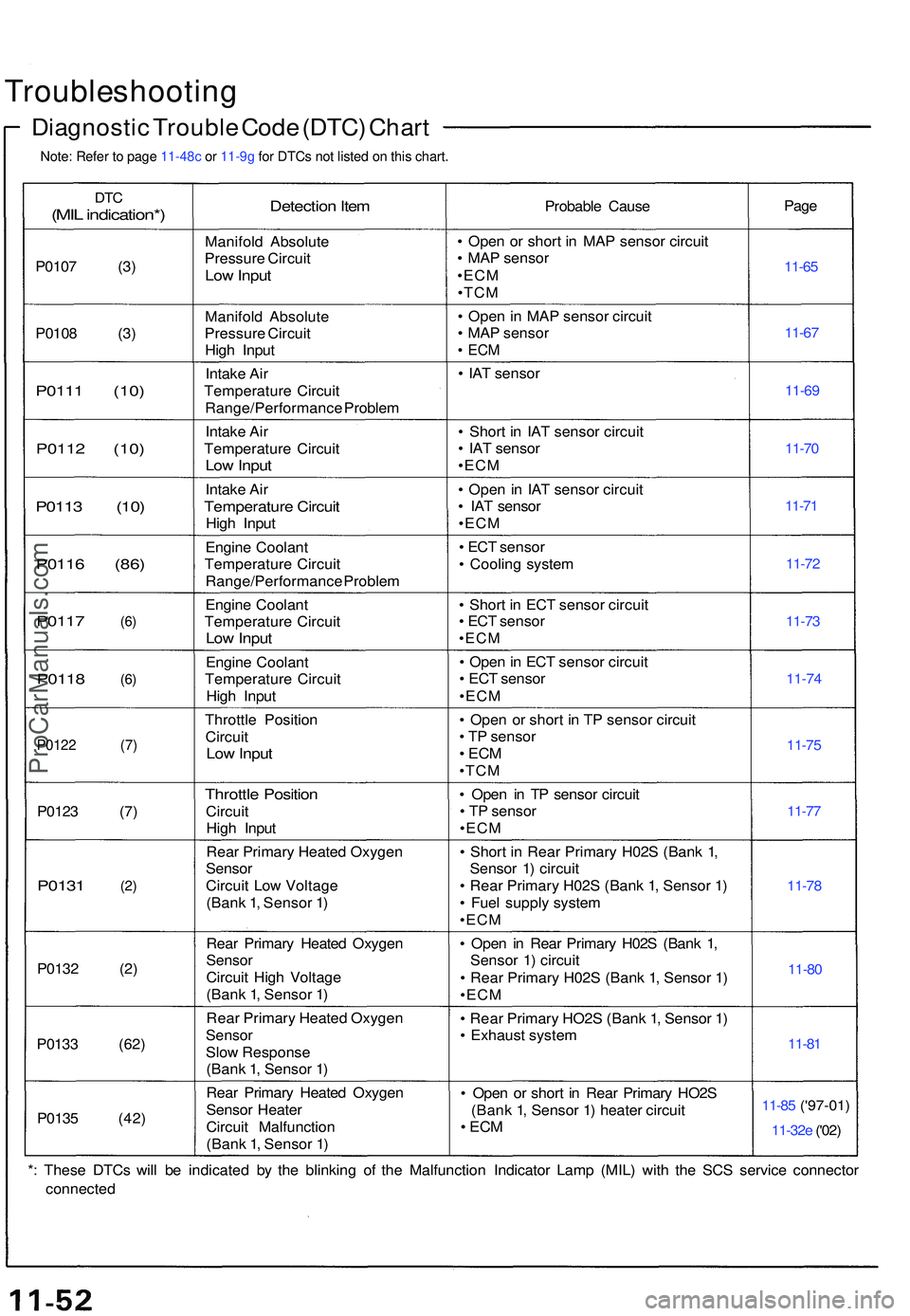

Troubleshooting

Diagnostic Troubl e Cod e (DTC ) Char t

DTC

(MIL indication* )

P0107 (3 )

P010 8 (3 )

P0111 (10 )

P011 2 (10 )

P011 3 (10 )

P011 6 (86 )

P011 7

(6 )

P0118 (6 )

P0122 (7 )

P0123 (7 )

P0131 (2 )

P0132 (2 )

P013 3 (62 )

P013 5 (42 )

Detection Ite m

Manifol d Absolut e

Pressur e Circui t

Low Inpu t

Manifol d Absolut e

Pressur e Circui t

Hig h Inpu t

Intak e Ai r

Temperatur e Circui t

Range/Performanc e Proble m

Intak e Ai r

Temperatur e Circui t

Low Inpu t

Intake Ai r

Temperatur e Circui tHigh Inpu t

Engin e Coolan t

Temperatur e Circui t

Range/Performanc e Proble m

Engin e Coolan t

Temperatur e Circui t

Low Inpu t

Engin e Coolan t

Temperatur e Circui t

Hig h Inpu t

Throttl e Positio n

Circui t

Low Inpu t

Throttl e Positio n

Circuit

Hig h Inpu t

Rea r Primar y Heate d Oxyge n

Senso r

Circui t Lo w Voltag e

(Ban k 1 , Senso r 1 )

Rea r Primar y Heate d Oxyge n

Sensor

Circuit Hig h Voltag e

(Ban k 1 , Senso r 1 )

Rea r Primar y Heate d Oxyge n

Sensor

Slow Respons e

(Ban k 1 , Senso r 1 )

Rea r Primar y Heate d Oxyge n

Senso r Heate r

Circui t Malfunctio n

(Ban k 1 , Senso r 1 ) Probabl

e Caus e

• Ope n o r shor t i n MA P senso r circui t

• MA P senso r

•ECM

•TCM

• Ope n in MA P senso r circui t

• MA P senso r

• EC M

• IA T senso r

• Shor t i n IA T senso r circui t

• IA T senso r

•ECM

• Ope n i n IA T senso r circui t

• IA T senso r

•ECM

• EC T senso r

• Coolin g syste m

• Shor t i n EC T senso r circui t

• EC T senso r

•ECM

• Ope n in EC T senso r circui t

• EC T senso r

•EC M

• Ope n o r shor t i n T P senso r circui t

• T P senso r

• EC M

•TC M

• Ope n i n T P senso r circui t

• T P senso r

•ECM

• Shor t i n Rea r Primar y H02 S (Ban k 1 ,

Senso r 1 ) circui t

• Rea r Primar y H02 S (Ban k 1 , Senso r 1 )

• Fue l suppl y syste m

•EC M

• Ope n i n Rea r Primar y H02 S (Ban k 1 ,

Senso r 1 ) circui t

• Rea r Primar y H02 S (Ban k 1 , Senso r 1 )

•EC M

• Rea r Primar y HO2 S (Ban k 1 , Senso r 1 )

• Exhaus t syste m

• Ope n o r shor t i n Rea r Primar y HO2 S

(Ban k 1 , Senso r 1 ) heate r circui t

• EC M

Pag e

11-6 5

11-6 7

11-6 9

11-70

11-7 1

11-7 2

11-7 3

11-7 4

11-7 5

11-7 7

11-7 8

11-8 0

11-8 1

11-8 5 ('97-01)

*: Thes e DTC s wil l b e indicate d b y th e blinkin g o f th e Malfunctio n Indicato r Lam p (MIL ) wit h th e SC S servic e connecto r

connecte d

Note: Refer to page 11-48c or 11-9g for DTCs not listed on this chart.

11-32e ('02)

ProCarManuals.com

Page 579 of 1503

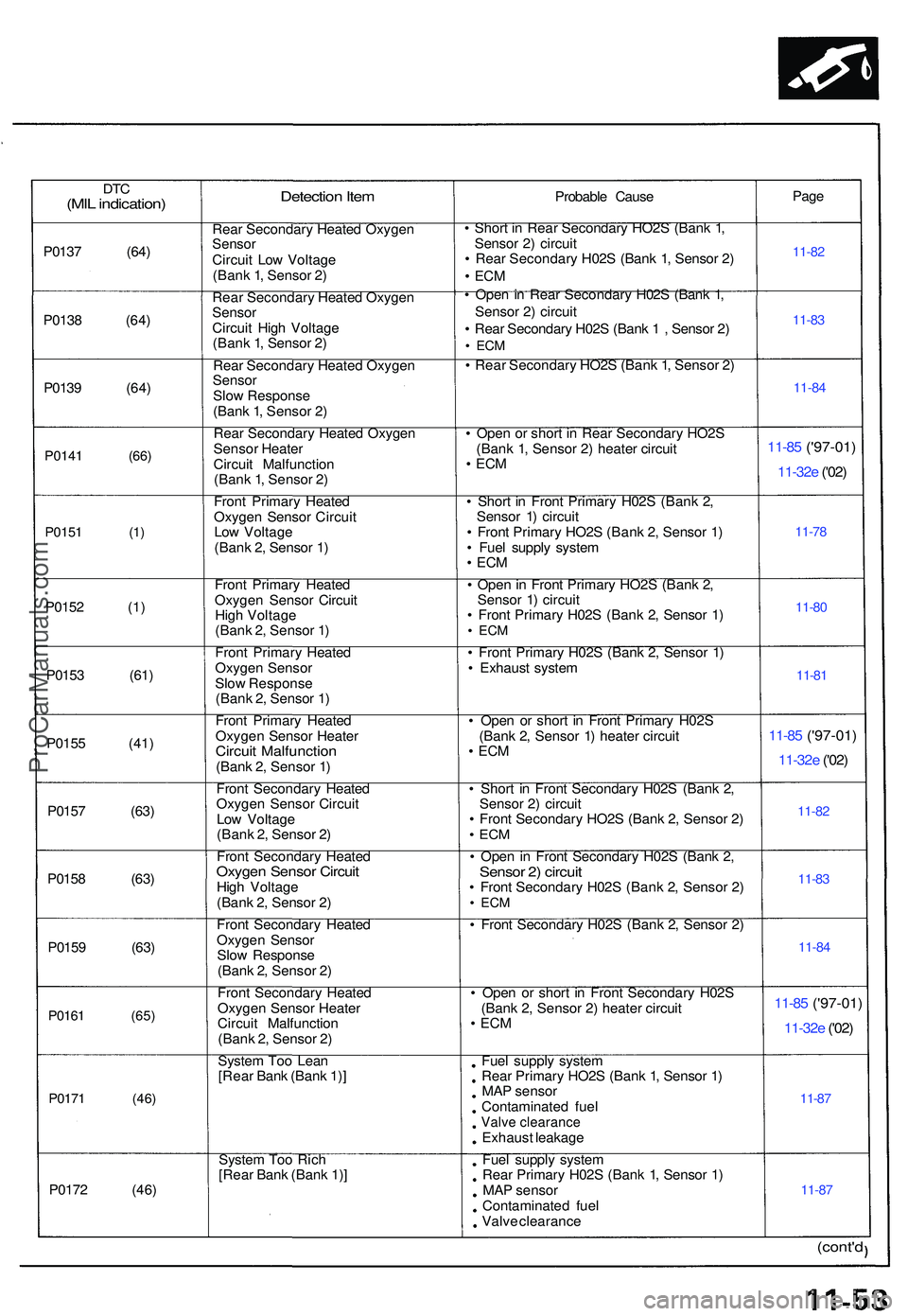

DTC(MI L indication )

P0137 (64 )

P013 8 (64 )

P013 9 (64 )

P0141 (66 )

P015 1

(1 )

P0152 (1 )

P015 3 (61 )

P015 5 (41 )

P015 7 (63 )

P015 8 (63 )

P015 9 (63 )

P0161 (65 )

P017 1 (46 )

P0172 (46 )

Detection Ite m

Rea r Secondar y Heate d Oxyge nSensorCircuit Lo w Voltag e

(Ban k 1 , Senso r 2 )

Rea r Secondar y Heate d Oxyge n

Senso r

Circui t Hig h Voltag e

(Ban k 1 , Senso r 2 )

Rea r Secondar y Heate d Oxyge n

Senso r

Slo w Respons e

(Ban k 1 , Senso r 2 )

Rea r Secondar y Heate d Oxyge n

Senso r Heate r

Circui t Malfunctio n

(Ban k 1 , Senso r 2 )

Fron t Primar y Heate d

Oxyge n Senso r Circui t

Lo w Voltag e

(Ban k 2 , Senso r 1 )

Fron t Primar y Heate d

Oxyge n Senso r Circui t

Hig h Voltag e

(Ban k 2 , Senso r 1 )

Fron t Primar y Heate d

Oxyge n Senso r

Slo w Respons e

(Ban k 2 , Senso r 1 )

Fron t Primar y Heate d

Oxyge n Senso r Heate r

Circuit Malfunctio n(Bank 2 , Senso r 1 )

Fron t Secondar y Heate d

Oxyge n Senso r Circui t

Lo w Voltag e

(Ban k 2 , Senso r 2 )

Fron t Secondar y Heate d

Oxygen Senso r Circui tHigh Voltag e

(Ban k 2 , Senso r 2 )

Fron t Secondar y Heate d

Oxyge n Senso r

Slo w Respons e

(Ban k 2 , Senso r 2 )

Fron t Secondar y Heate d

Oxyge n Senso r Heate r

Circui t Malfunctio n

(Ban k 2 , Senso r 2 )

Syste m To o Lea n

[Rea r Ban k (Ban k 1) ]

Syste m To o Ric h

[Rea r Ban k (Ban k 1) ] Probabl

e Caus e

• Shor t i n Rea r Secondar y HO2 S (Ban k 1 ,

Senso r 2 ) circui t

• Rea r Secondar y H02 S (Ban k 1 , Senso r 2 )

• EC M

• Ope n in Rea r Secondar y H02 S (Ban k 1 ,

Senso r 2 ) circui t

• Rea r Secondar y H02 S (Ban k 1 , Senso r 2 )

• EC M

• Rea r Secondar y HO2 S (Ban k 1 , Senso r 2 )

• Ope n o r shor t i n Rea r Secondar y HO2 S

(Ban k 1 , Senso r 2 ) heate r circui t

• EC M

• Shor t i n Fron t Primar y H02 S (Ban k 2 ,

Senso r 1 ) circui t

• Fron t Primar y HO2 S (Ban k 2 , Senso r 1 )

• Fue l suppl y syste m

• EC M

• Ope n in Fron t Primar y HO2 S (Ban k 2 ,

Senso r 1 ) circui t

• Fron t Primar y H02 S (Ban k 2 , Senso r 1 )

• EC M

• Fron t Primar y H02 S (Ban k 2 , Senso r 1 )

• Exhaus t syste m

• Ope n o r shor t i n Fron t Primar y H02 S

(Ban k 2 , Senso r 1 ) heate r circui t

• EC M

• Shor t i n Fron t Secondar y H02 S (Ban k 2 ,

Senso r 2 ) circui t

• Fron t Secondar y HO2 S (Ban k 2 , Senso r 2 )

• EC M

• Ope n i n Fron t Secondar y H02 S (Ban k 2 ,Senso r 2 ) circui t• Fron t Secondar y H02 S (Ban k 2 , Senso r 2 )• EC M

• Fron t Secondar y H02 S (Ban k 2 , Senso r 2 )

• Ope n o r shor t i n Fron t Secondar y H02 S

(Ban k 2 , Senso r 2 ) heate r circui t

• EC M

Fuel suppl y syste m

Rea r Primar y HO2 S (Ban k 1 , Senso r 1 )

MA P senso r

Contaminate d fue l

Valv e clearanc eExhaust leakag e

Fue l suppl y syste m

Rea r Primar y H02 S (Ban k 1 , Senso r 1 )

MA P senso r

Contaminate d fue l

Valv e clearanc e Pag

e

11-8 2

11-8 3

11-8 4

11-7 8

11-8 0

11-8 1

11-8 2

11-8 3

11-8 4

11-8 7

11-8 7

(cont' d

11-85 ('97-01)

11-32e ('02)

11-8 5 ('97-01)

11-32e ('02)

11-8 5 ('97-01)

11-32e ('02)

ProCarManuals.com

Page 612 of 1503

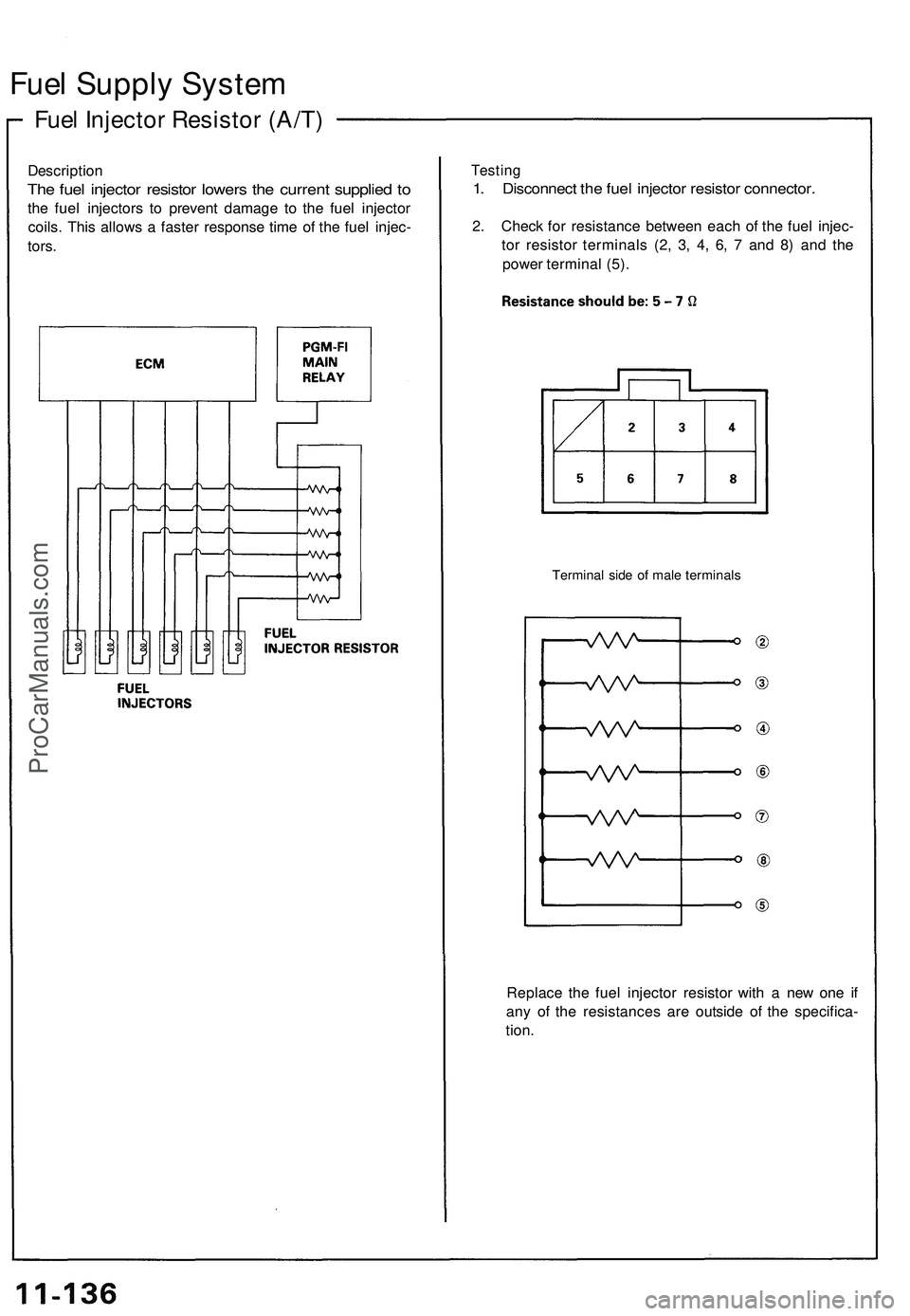

Fuel Supply System

Fuel Injector Resistor (A/T)

Description

The fuel injector resistor lowers the current supplied to

the fuel injectors to prevent damage to the fuel injector

coils. This allows a faster response time of the fuel injec-

tors.

Testing

1. Disconnect the fuel injector resistor connector.

2. Check for resistance between each of the fuel injec-

tor resistor terminals (2, 3, 4, 6, 7 and 8) and the

power terminal (5).

Terminal side of male terminals

Replace the fuel injector resistor with a new one if

any of the resistances are outside of the specifica-

tion.ProCarManuals.com

Page 713 of 1503

Description

The automatic transmission is a combination of a 3-element torque converter and a triple-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with the

engine.

Torque Converter, Gears, and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the torque converter is a ring gear which meshes with the starter pinion when the engine is being

started. The entire torque converter assembly serves as a flywheel while transmitting power to the transmission main-

shaft. The transmission has three parallel shafts: the mainshaft, the countershaft, and the secondary shaft. The mainshaft

is in line with the engine crankshaft.

The mainshaft includes the 1st and 4th clutches, and gears for 3rd, 4th, reverse, and 1st (3rd gear is integral with the main-

shaft, while reverse gear is integral with 4th gear).

The countershaft includes the 1st-hold and 3rd clutches, and gears for 2nd, 3rd, 4th, reverse, 1st, and parking.

The secondary shaft includes the 2nd clutch and gears for 2nd and 3rd.

The 4th and reverse gears can be locked to the countershaft at its center, providing 4th gear or reverse, depending on

which way the selector is moved.

The gears on the mainshaft and secondary shaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the mainshaft

to the countershaft to provide positions.

Electronic Control

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid, a shift switch,

and 4 solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located on the insulator center bulkhead, behind the driver's seat.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, servo body, regulator valve body, throttle valve

body, lock-up valve body, and the 2nd accumulator body.

They are bolted to the torque converter housing as an assembly.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, 3-4 shift valve, relief valve, one-way relief

valve, and oil pump gears.

The secondary valve body contains the 3-2 kick-down valve, clutch pressure control (CPC) valve, 2nd orifice control valve, 3rd

orifice control valve, modulator valve, 4th exhaust valve, servo control valve, 2nd exhaust valve, and 4-3 kick-down valve.

The servo body contains the accumulator pistons and servo valve. The throttle valve body includes the throttle valve B

which is bolted to the servo body.

The regulator valve body contains the pressure regulator valve, lock-up control valve, and cooler relief valve. Fluid from

the regulator passes through the manual valve to the various control valves.

The lock-up valve body contains the lock-up timing B valve and lock-up shift valve. The 2nd accumulator body contains

the accumulator pistons and limited slip differential relief valve.

The torque converter check valve is located in the torque converter housing, under the main valve body.

The 1st, 1st-hold, 3rd, and 4th clutches receive fluid from their respective feed pipes and the 2nd clutch receives fluid from

the internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift control solenoid valve the TCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches, engaging that clutch and its corresponding gear.

Lock-up Mechanism

In position and position in 2nd, 3rd, and 4th, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the tim-

ing of the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. The lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)ProCarManuals.com

Page 774 of 1503

• Whil e testing , b e carefu l o f th e rotatin g rea r wheels .

• Mak e sur e lift s ar e place d properl y (se e sectio n 1 ).

CAUTION :

• Befor e testing , b e sur e th e transmissio n flui d is fille d

to th e prope r level .

• War m u p th e engin e befor e testing .

1 . Rais e th e vehicl e (se e sectio n 1 ).

2 . War m u p th e engine , the n sto p th e engin e an d con -

nec t a tachometer .

3 . Connec t a pressur e gaug e t o eac h inspectio n hole .

18N-m(1.8kgf-m,13lbf-ft )

CAUTION: Connec t th e pressur e gaug e securely ;

b e sur e no t t o allo w dus t an d othe r foreig n parti -

cle s t o ente r th e inspectio n hole .

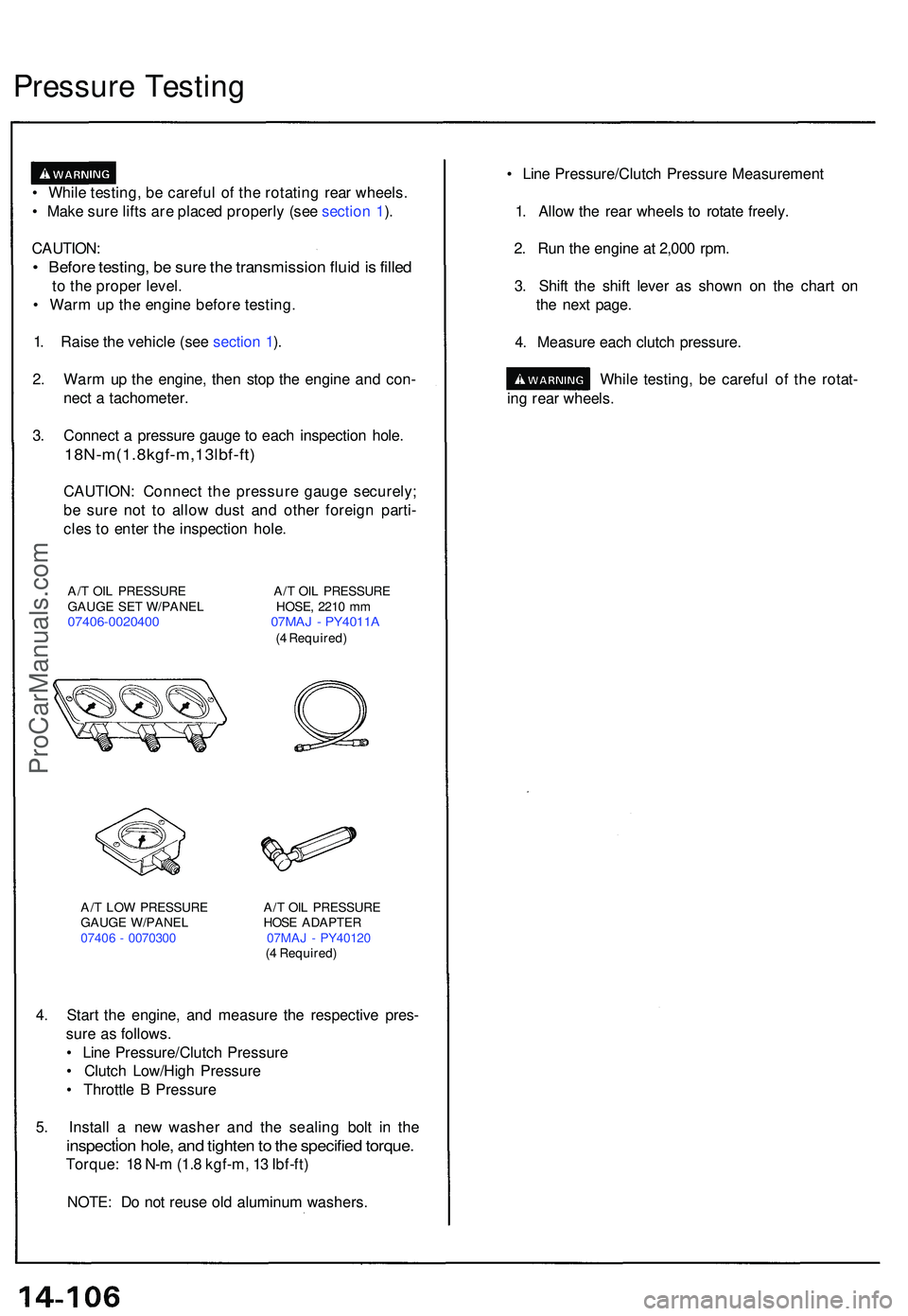

A/T OI L PRESSUR E A/ T OI L PRESSUR E

GAUG E SE T W/PANE L HOSE , 221 0 m m

07406-002040 0 07MA J - PY4011 A(4 Required )

A/ T LO W PRESSUR E A/ T OI L PRESSUR E

GAUG E W/PANE L HOS E ADAPTE R

0740 6 - 007030 0 07MA J - PY4012 0

( 4 Required )

4. Star t th e engine , an d measur e th e respectiv e pres -

sur e a s follows .

• Lin e Pressure/Clutc h Pressur e

• Clutc h Low/Hig h Pressur e

• Throttl e B Pressur e

5 . Instal l a ne w washe r an d th e sealin g bol t i n th e

inspectio n hole , an d tighte n to th e specifie d torque .

Torque : 1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

NOTE : D o no t reus e ol d aluminu m washers . •

Lin e Pressure/Clutc h Pressur e Measuremen t

1 . Allo w th e rea r wheel s t o rotat e freely .

2 . Ru n th e engin e a t 2,00 0 rpm .

3 . Shif t th e shif t leve r a s show n o n th e char t o n

th e nex t page .

4 . Measur e eac h clutc h pressure .

While testing , b e carefu l o f th e rotat -

in g rea r wheels .

Pressur e Testin g

ProCarManuals.com