alternator ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 141 of 1503

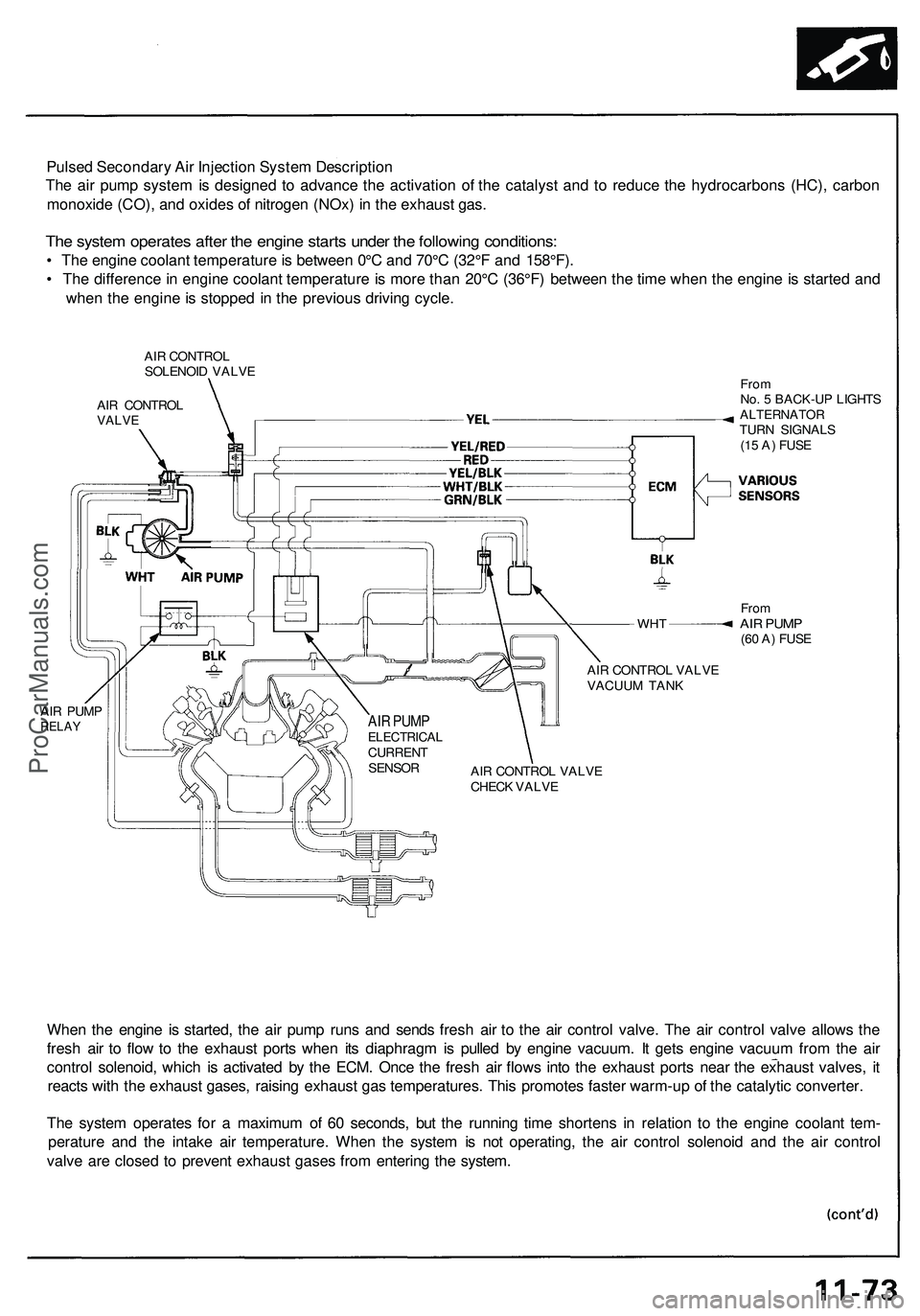

Pulsed Secondary Air Injection System Description

The air pump system is designed to advance the activation of the catalyst and to reduce the hydrocarbons (HC), carbon

monoxide (CO), and oxides of nitrogen (NOx) in the exhaust gas.

The system operates after the engine starts under the following conditions:

• The engine coolant temperature is between 0°C and 70°C (32°F and 158°F).

• The difference in engine coolant temperature is more than 20°C (36°F) between the time when the engine is started and

when the engine is stopped in the previous driving cycle.

AIR CONTROL

SOLENOID VALVE

AIR CONTROL

VALVE

WHT

AIR PUMP

RELAY

From

No. 5 BACK-UP LIGHTS

ALTERNATOR

TURN SIGNALS

(15 A) FUSE

From

AIR PUMP

(60 A) FUSE

AIR CONTROL VALVE

VACUUM TANK

AIR CONTROL VALVE

CHECK VALVE

When the engine is started, the air pump runs and sends fresh air to the air control valve. The air control valve allows the

fresh air to flow to the exhaust ports when its diaphragm is pulled by engine vacuum. It gets engine vacuum from the air

control solenoid, which is activated by the ECM. Once the fresh air flows into the exhaust ports near the exhaust valves, it

reacts with the exhaust gases, raising exhaust gas temperatures. This promotes faster warm-up of the catalytic converter.

The system operates for a maximum of 60 seconds, but the running time shortens in relation to the engine coolant tem-

perature and the intake air temperature. When the system is not operating, the air control solenoid and the air control

valve are closed to prevent exhaust gases from entering the system.

AIR PUMP

ELECTRICAL

CURRENT

SENSORProCarManuals.com

Page 370 of 1503

3-15

T

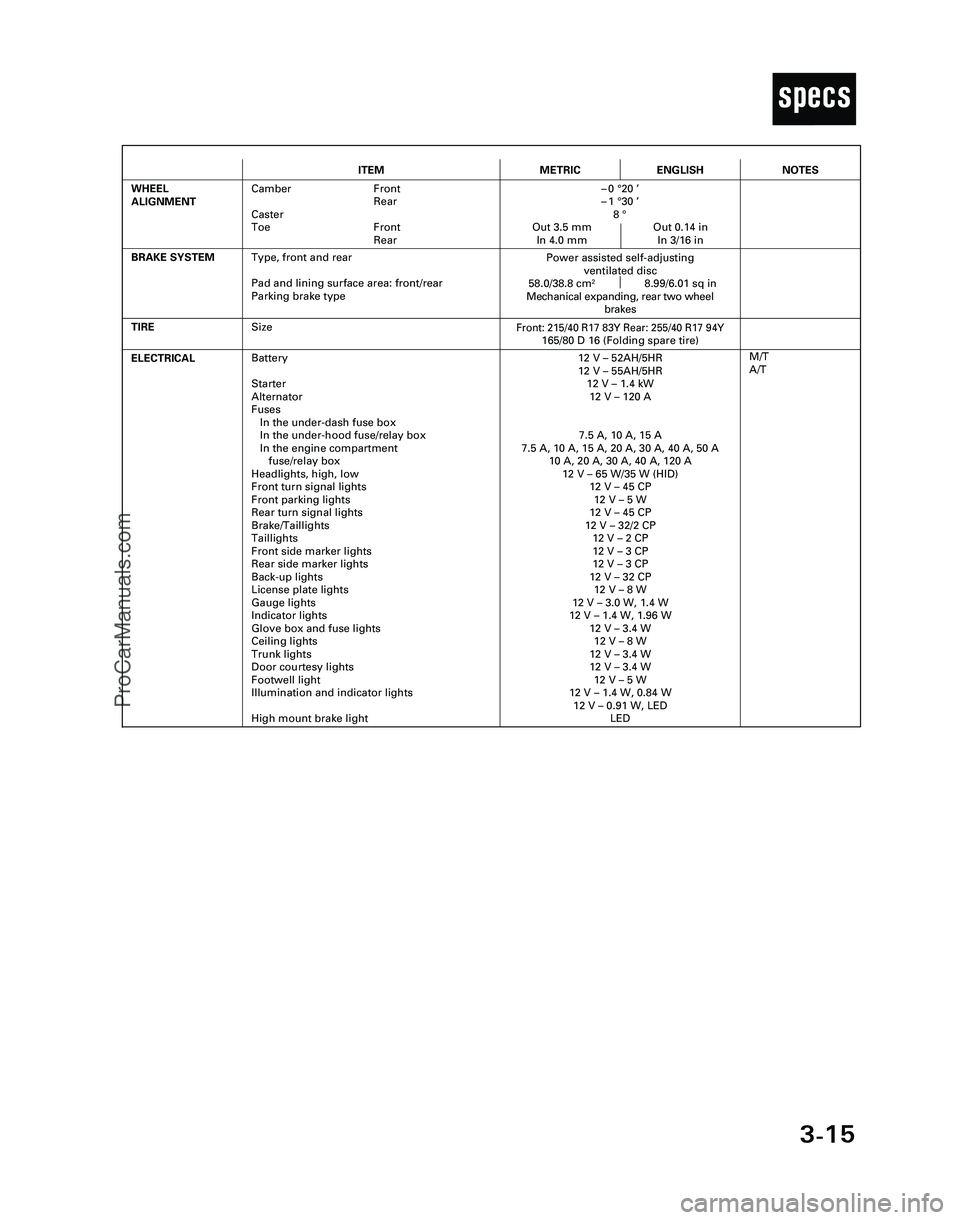

ITEMMETRICENGLISH

ELECTRICALBattery

Starter

Alternator

Fuses

In the under-dash fuse box

In the under-hood fuse/relay box

In the engine compartment

fuse/relay box

Headlights, high, low

Front turn signal lights

Front parking lights

Rear turn signal lights

Brake/Taillights

Taillights

Front side marker lights

Rear side marker lights

Back-up lights

License plate lights

Gauge lights

Indicator lights

Glove box and fuse lights

Ceiling lights

Trunk lights

Door courtesy lights

Footwell light

Illumination and indicator lights

High mount brake light12 V – 52AH/5HR

12 V – 55AH/5HR

12 V – 1.4 kW

12 V – 120 A

7.5 A, 10 A, 15 A

7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A, 50 A

10 A, 20 A, 30 A, 40 A, 120 A

12 V – 65 W/35 W (HID)

12 V – 45 CP

12 V – 5 W

12 V – 45 CP

12 V – 32/2 CP

12 V – 2 CP

12 V – 3 CP

12 V – 3 CP

12 V – 32 CP

12 V – 8 W

12 V – 3.0 W, 1.4 W

12 V – 1.4 W, 1.96 W

12 V – 3.4 W

12 V – 8 W

12 V – 3.4 W

12 V – 3.4 W

12 V – 5 W

12 V – 1.4 W, 0.84 W

12 V – 0.91 W, LED

LED

TIRE

M/T

A/T

BRAKE SYSTEM

Front: 215/40 R17 83Y Rear: 255/40 R17 94Y165/80 D 16 (Folding spare tire)

Power assisted self-adjusting

ventilated disc

58.0/38.8 cm

28.99/6.01 sq in

Mechanical expanding, rear two wheel

brakes

WHEEL

ALIGNMENTCamber Front

Rear

Caster

Toe Front

Rear–0 °20 ’

–1 °30 ’

8 °

Out 3.5 mm Out 0.14 in

In 4.0 mm In 3/16 in

NOTES

Size

Type, front and rear

Pad and lining surface area: front/rear

Parking brake type

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-15

ProCarManuals.com

Page 375 of 1503

4-6

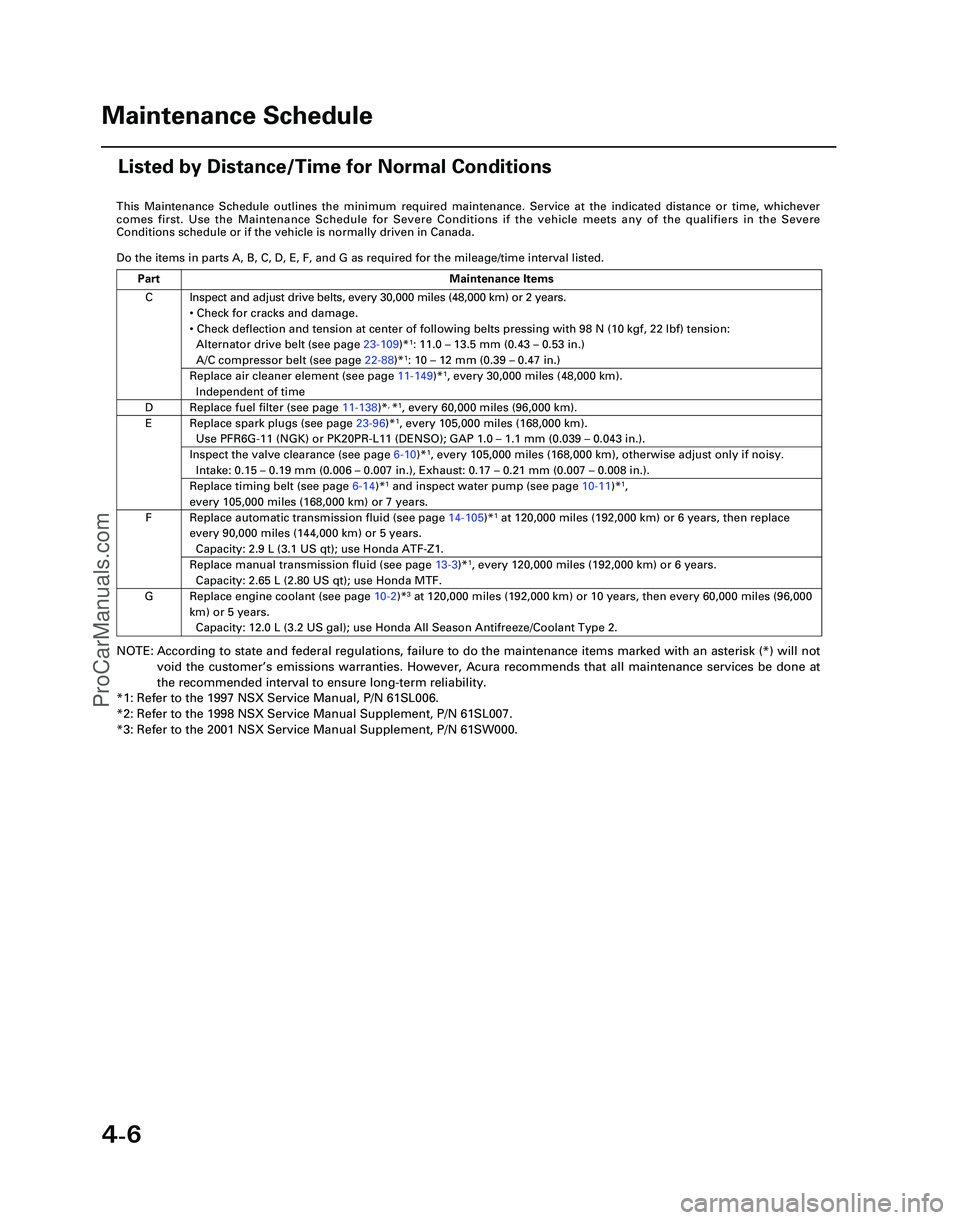

This Maintenance Schedule outlines the minimum required maintenance. Ser\

vice at the indicated distance or time, whichever

comes first. Use the Maintenance Schedule for Severe Conditions if the v\

ehicle meets any of the qualifiers in the Severe

Conditions schedule or if the vehicle is normally driven in Canada.

Do the items in parts A, B, C, D, E, F, and G as required for the mileag\

e/time interval listed.

NOTE: According to state and federal regulations, failure to do the maintenanc\

e items marked with an asterisk (*) will not

void the customer ’s emissions warranties. However, Acura recommends that all maintenance s\

ervices be done at

the recommended interval to ensure long-term reliability.

*1: Refer to the 1997 NSX Service Manual, P/N 61SL006.

*2: Refer to the 1998 NSX Service Manual Supplement, P/N 61SL007.

*3: Refer to the 2001 NSX Service Manual Supplement, P/N 61SW000.

C

D

E

F

G Inspect and adjust drive belts, every 30,000 miles (48,000 km) or 2 ye\

ars.

•

Check for cracks and damage.

• Check deflection and tension at center of following belts pressing with\

98 N (10 kgf, 22 lbf) tension:

Alternator drive belt (see page 23-109)*

1: 11.0 – 13.5 mm (0.43 – 0.53 in.)

A/C compressor belt (see page 22-88)*1: 10 – 12 mm (0.39 – 0.47 in.)

Replace air cleaner element (see page 11-149)*1, every 30,000 miles (48,000 km).

Independent of time

Replace fuel filter (see page 11-138)*, *1, every 60,000 miles (96,000 km).

Replace spark plugs (see page 23-96)*1, every 105,000 miles (168,000 km).

Use PFR6G-11 (NGK) or PK20PR-L11 (DENSO); GAP 1.0 – 1.1 mm (0.039 – 0.043 in.).

Inspect the valve clearance (see page 6-10)*1, every 105,000 miles (168,000 km), otherwise adjust only if noisy.

Intake: 0.15 – 0.19 mm (0.006 – 0.007 in.), Exhaust: 0.17 – 0.21 mm (0.007 – 0.008 in.).

Replace timing belt (see page 6-14)*1 and inspect water pump (see page 10-11)*1,

every 105,000 miles (168,000 km) or 7 years.

Replace automatic transmission fluid (see page 14-105)*1 at 120,000 miles (192,000 km) or 6 years, then replace

every 90,000 miles (144,000 km) or 5 years.

Capacity: 2.9 L (3.1 US qt); use Honda ATF-Z1.

Replace manual transmission fluid (see page 13-3)*1, every 120,000 miles (192,000 km) or 6 years.

Capacity: 2.65 L (2.80 US qt); use Honda MTF.

Replace engine coolant (see page 10-2 )*3 at 120,000 miles (192,000 km) or 10 years, then every 60,000 miles (9\

6,000

km) or 5 years. Capacity: 12.0 L (3.2 US gal); use Honda All Season Antifreeze/Coolant\

Type 2.

Part Maintenance Items

Maintenance Schedule

Listed by Distance/Time for Normal Conditions

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-6

ProCarManuals.com

Page 416 of 1503

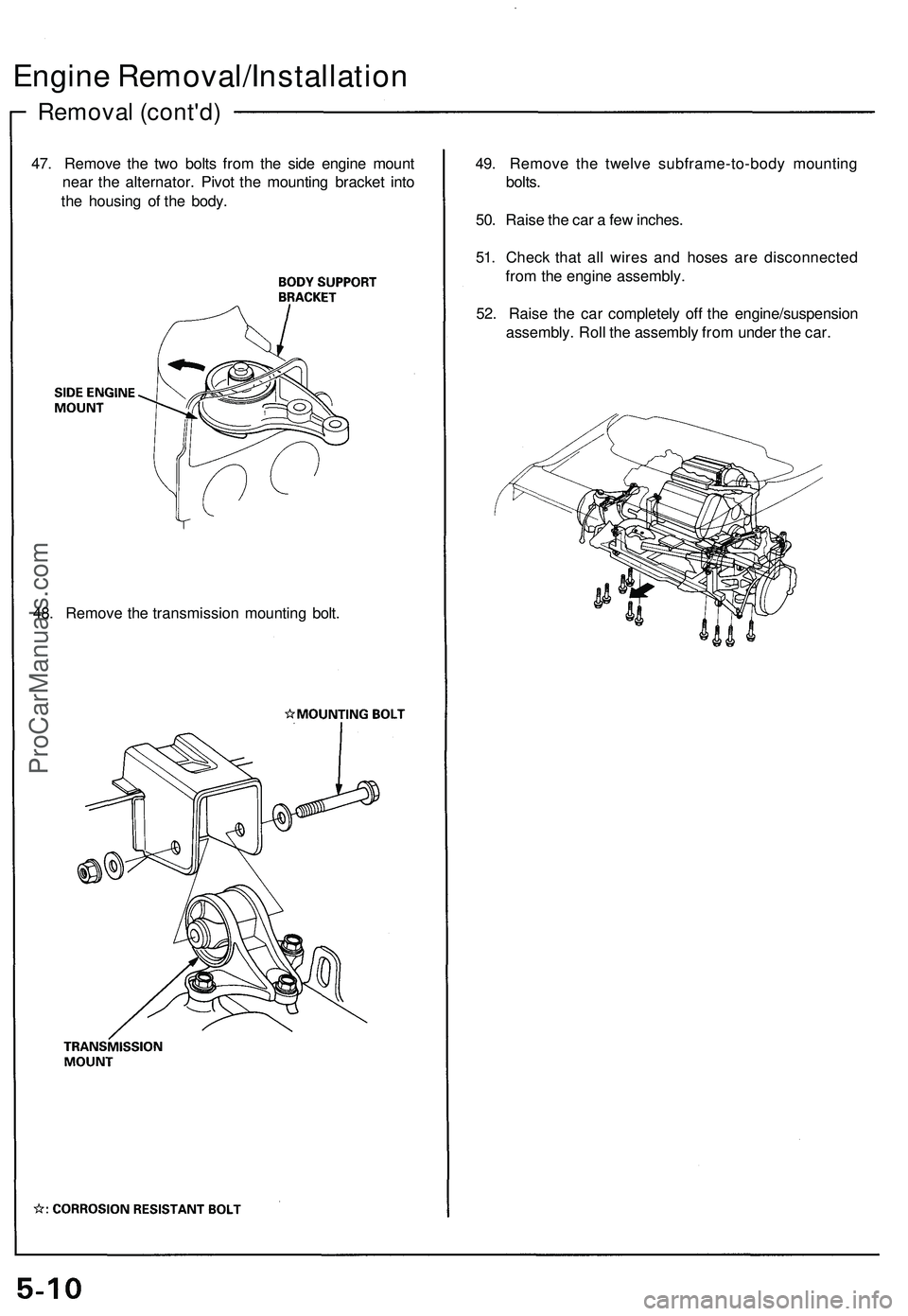

Removal (cont'd)

Engine Removal/Installation

47. Remove the two bolts from the side engine mount

near the alternator. Pivot the mounting bracket into

the housing of the body.

49. Remove the twelve subframe-to-body mounting

bolts.

50. Raise the car a few inches.

51. Check that all wires and hoses are disconnected

from the engine assembly.

52. Raise the car completely off the engine/suspension

assembly. Roll the assembly from under the car.

48. Remove the transmission mounting bolt.ProCarManuals.com

Page 433 of 1503

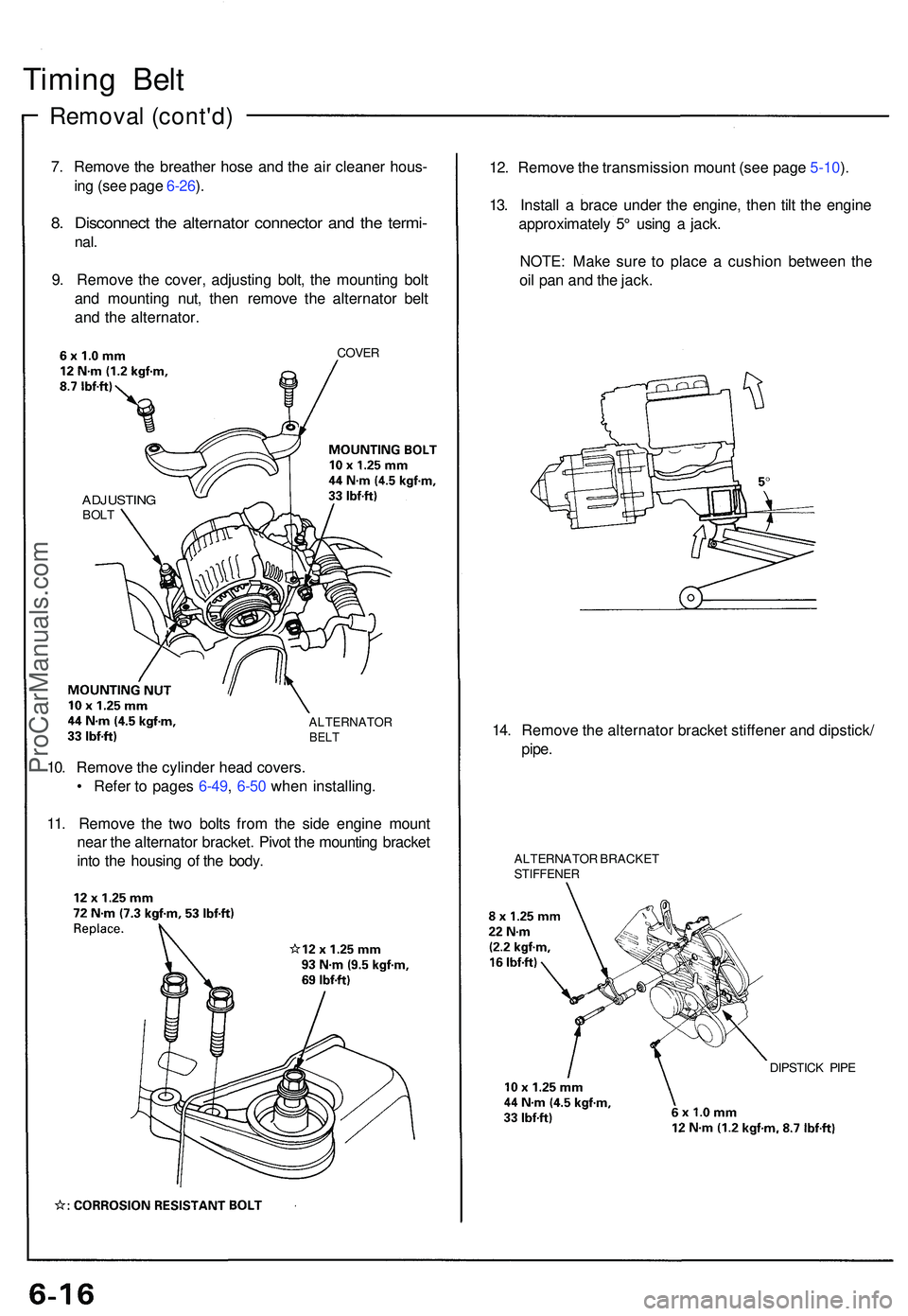

Timing Bel t

Remova l (cont'd )

7. Remov e th e breathe r hos e an d th e ai r cleaner hous-

in g (se e pag e 6-26 ).

8 . Disconnec t th e alternato r connecto r an d th e termi -

nal.

9. Remov e th e cover , adjustin g bolt , th e mountin g bol t

an d mountin g nut , the n remov e th e alternato r bel t

an d th e alternator .

COVER

ADJUSTIN GBOLT

ALTERNATO RBELT

12. Remov e th e transmissio n moun t (se e pag e 5-10 ).

13 . Instal l a brac e unde r th e engine , the n til t th e engin e

approximatel y 5 ° usin g a jack .

NOTE : Mak e sur e t o plac e a cushio n betwee n th e

oi l pa n an d th e jack .

14 . Remov e th e alternato r bracke t stiffene r an d dipstick /

pipe .

ALTERNATO R BRACKE TSTIFFENE R

DIPSTICK PIP E

10. Remov e th e cylinde r hea d covers .

• Refe r t o page s 6-49 , 6-5 0 whe n installing .

11 . Remov e th e tw o bolt s fro m th e sid e engin e moun t

nea r th e alternato r bracket . Pivo t th e mountin g bracke t

int o th e housin g o f th e body .

ProCarManuals.com

Page 445 of 1503

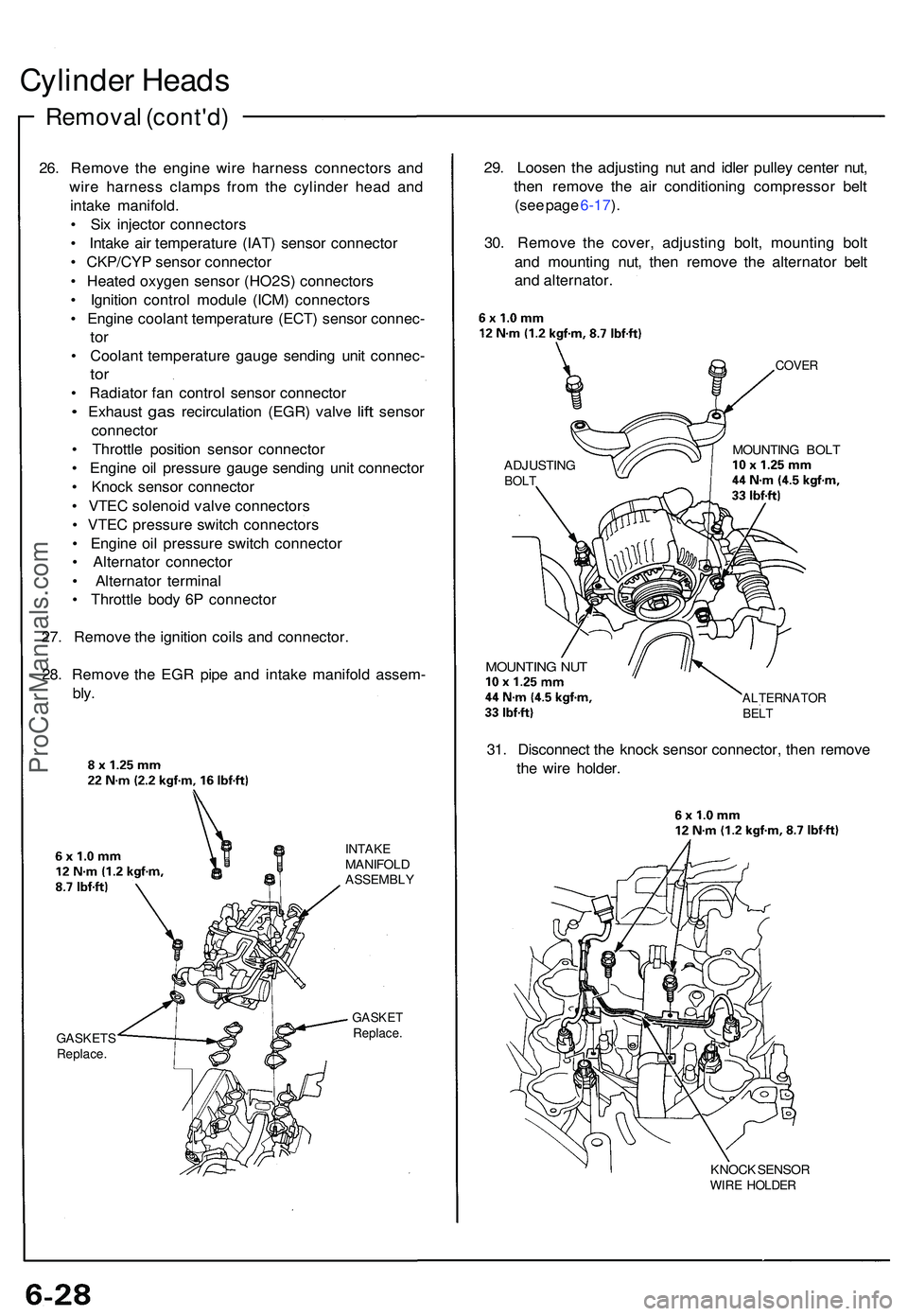

Cylinder Head s

Remova l (cont'd )

26. Remov e th e engin e wir e harnes s connector s an d

wir e harnes s clamp s fro m th e cylinde r hea d an d

intak e manifold .

• Si x injecto r connector s

• Intak e ai r temperatur e (IAT ) senso r connecto r

• CKP/CY P senso r connecto r

• Heate d oxyge n senso r (HO2S ) connector s

• Ignitio n contro l modul e (ICM ) connector s

• Engin e coolan t temperatur e (ECT ) senso r connec -

tor

• Coolan t temperatur e gaug e sendin g uni t connec -

tor

• Radiato r fa n contro l senso r connecto r

• Exhaust gas recirculatio n (EGR ) valv e lift senso r

connecto r

• Throttl e positio n senso r connecto r

• Engin e oi l pressur e gaug e sendin g uni t connecto r

• Knoc k senso r connecto r

• VTE C solenoi d valv e connector s

• VTE C pressur e switc h connector s

• Engin e oi l pressur e switc h connecto r

• Alternato r connecto r

• Alternato r termina l

• Throttl e bod y 6 P connecto r

27 . Remov e th e ignitio n coil s an d connector .

28 . Remov e th e EG R pip e an d intak e manifol d assem -

bly.

GASKET SReplace.

INTAKEMANIFOL DASSEMBL Y

GASKETReplace .

29. Loose n th e adjustin g nu t an d idle r pulle y cente r nut ,

the n remov e th e ai r conditionin g compresso r bel t

(se e pag e 6-17 ).

30 . Remov e th e cover , adjustin g bolt , mountin g bol t

an d mountin g nut , the n remov e th e alternato r bel t

an d alternator .

COVER

ADJUSTIN GBOLT

MOUNTIN G BOL T

MOUNTIN G NU T

ALTERNATO RBELT

31. Disconnec t th e knoc k senso r connector , the n remov e

th e wir e holder .

KNOCK SENSO RWIRE HOLDE R

ProCarManuals.com

Page 587 of 1503

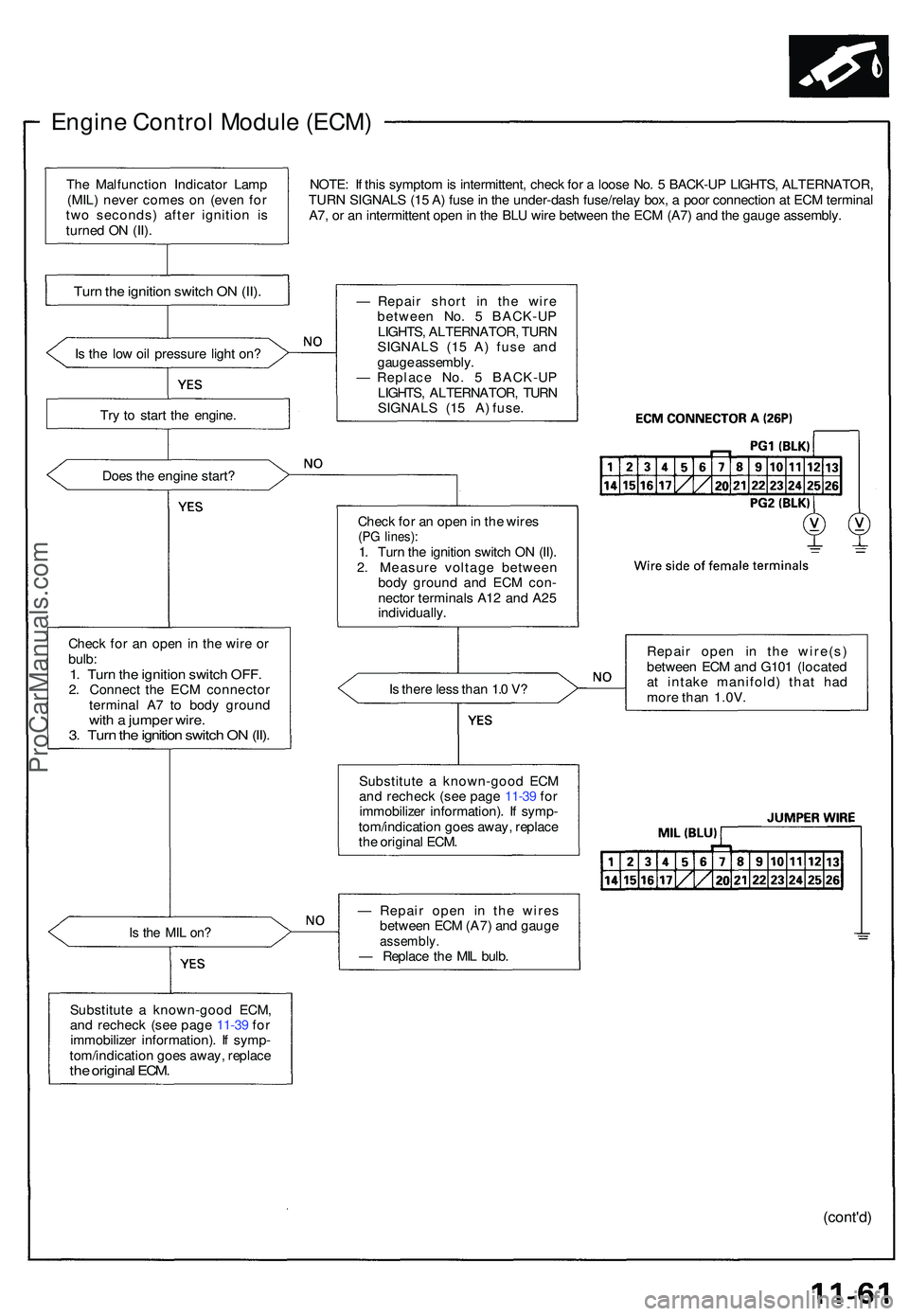

Engine Contro l Modul e (ECM )

NOTE: I f thi s sympto m is intermittent , chec k fo r a loos e No . 5 BACK-U P LIGHTS , ALTERNATOR ,

TUR N SIGNAL S (1 5 A ) fus e in th e under-das h fuse/rela y box , a poo r connectio n a t EC M termina l

A7 , o r a n intermitten t ope n in th e BL U wir e betwee n th e EC M (A7 ) an d th e gaug e assembly .

I s th e lo w oi l pressur e ligh t on ?

Tr y t o star t th e engine .

Doe s th e engin e start ?

Chec k fo r a n ope n in th e wir e o r

bulb :

1. Tur n th e ignitio n switc h OFF .2. Connec t th e EC M connecto r

termina l A 7 t o bod y groun d

with a jumpe r wire .3. Tur n th e ignitio n switc h O N (II) .

Is th e MI L on ?

Substitut e a known-goo d ECM ,

an d rechec k (se e pag e 11-3 9 fo r

immobilize r information) . I f symp -

tom/indicatio n goe s away , replac e

the origina l ECM .

— Repai r shor t i n the wir e

betwee n No . 5 BACK-U P

LIGHTS , ALTERNATOR , TUR N

SIGNAL S (1 5 A ) fus e an d

gaug e assembly .

— Replac e No . 5 BACK-U P

LIGHTS , ALTERNATOR , TUR N

SIGNALS (15 A) fuse.

Chec k fo r a n ope n in th e wire s

(PG lines) :1. Tur n th e ignitio n switc h O N (II) .

2 . Measur e voltag e betwee n

bod y groun d an d EC M con -

necto r terminal s A1 2 an d A2 5

individually .

I s ther e les s tha n 1. 0 V ?

Substitut e a known-goo d EC M

an d rechec k (se e pag e 11-3 9 fo r

immobilize r information) . I f symp -

tom/indicatio n goe s away , replac e

th e origina l ECM . Repai

r ope n i n th e wire(s )

betwee n EC M an d G10 1 (locate d

a t intak e manifold ) tha t ha d

mor e tha n 1.0V .

— Repai r ope n i n th e wire s

betwee n EC M (A7 ) an d gaug e

assembly .— Replac e th e MI L bulb .

(cont'd )

Turn th e ignitio n switc h O N (II) .

The Malfunctio n Indicato r Lam p

(MIL ) neve r come s o n (eve n fo r

tw o seconds ) afte r ignitio n i s

turne d O N (II) .

ProCarManuals.com

Page 628 of 1503

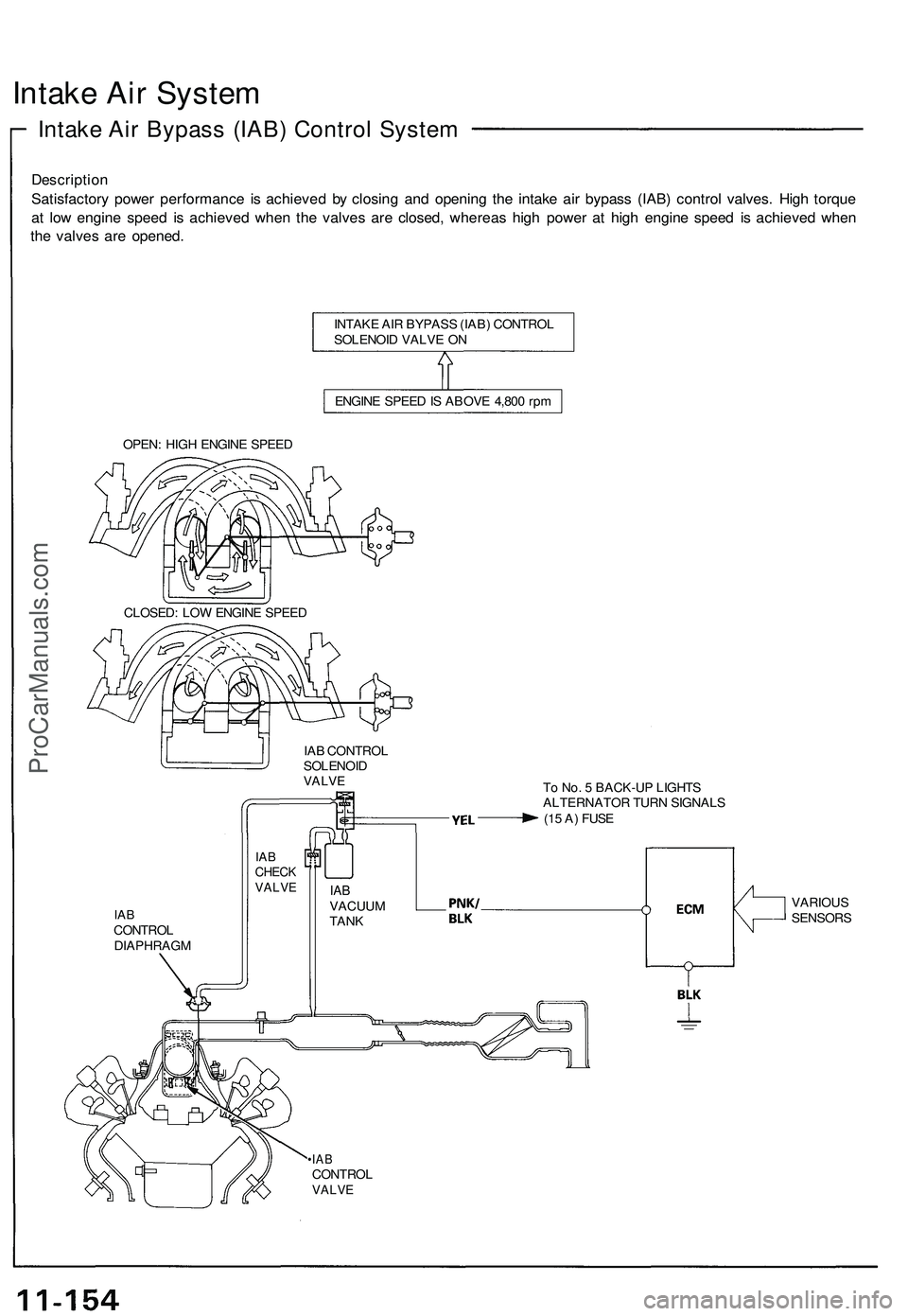

Intake Air System

Intake Air Bypass (IAB) Control System

Description

Satisfactory power performance is achieved by closing and opening the intake air bypass (IAB) control valves. High torque

at low engine speed is achieved when the valves are closed, whereas high power at high engine speed is achieved when

the valves are opened.

INTAKE AIR BYPASS (IAB) CONTROL

SOLENOID VALVE ON

ENGINE SPEED IS ABOVE 4,800 rpm

OPEN: HIGH ENGINE SPEED

CLOSED: LOW ENGINE SPEED

IAB CONTROL

SOLENOID

VALVE

To No. 5 BACK-UP LIGHTS

ALTERNATOR TURN SIGNALS

(15 A) FUSE

IAB

CONTROL

DIAPHRAGM

•IAB

CONTROL

VALVE

IAB

CHECK

VALVE

IAB

VACUUM

TANK

VARIOUS

SENSORSProCarManuals.com

Page 634 of 1503

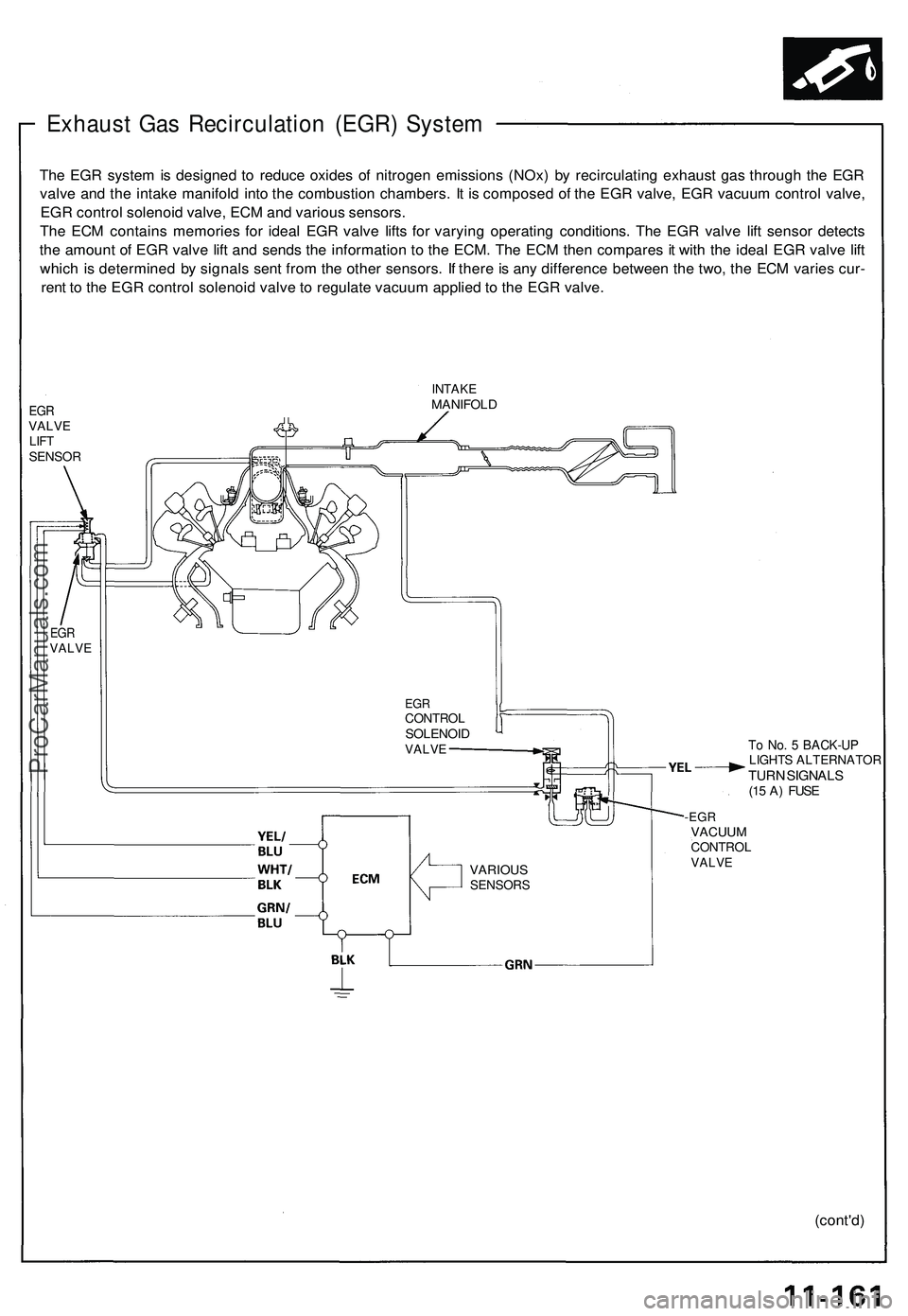

Exhaust Gas Recirculation (EGR) System

The EGR system is designed to reduce oxides of nitrogen emissions (NOx) by recirculating exhaust gas through the EGR

valve and the intake manifold into the combustion chambers. It is composed of the EGR valve, EGR vacuum control valve,

EGR control solenoid valve, ECM and various sensors.

The ECM contains memories for ideal EGR valve lifts for varying operating conditions. The EGR valve lift sensor detects

the amount of EGR valve lift and sends the information to the ECM. The ECM then compares it with the ideal EGR valve lift

which is determined by signals sent from the other sensors. If there is any difference between the two, the ECM varies cur-

rent to the EGR control solenoid valve to regulate vacuum applied to the EGR valve.

EGR

VALVE

LIFT

SENSOR

INTAKE

MANIFOLD

EGR

CONTROL

SOLENOID

VALVE

To No. 5 BACK-UP

LIGHTS ALTERNATOR

TURN SIGNALS

(15 A) FUSE

-EGR

VACUUM

CONTROL

VALVE

(cont'd)

EGR

VALVE

VARIOUS

SENSORSProCarManuals.com

Page 636 of 1503

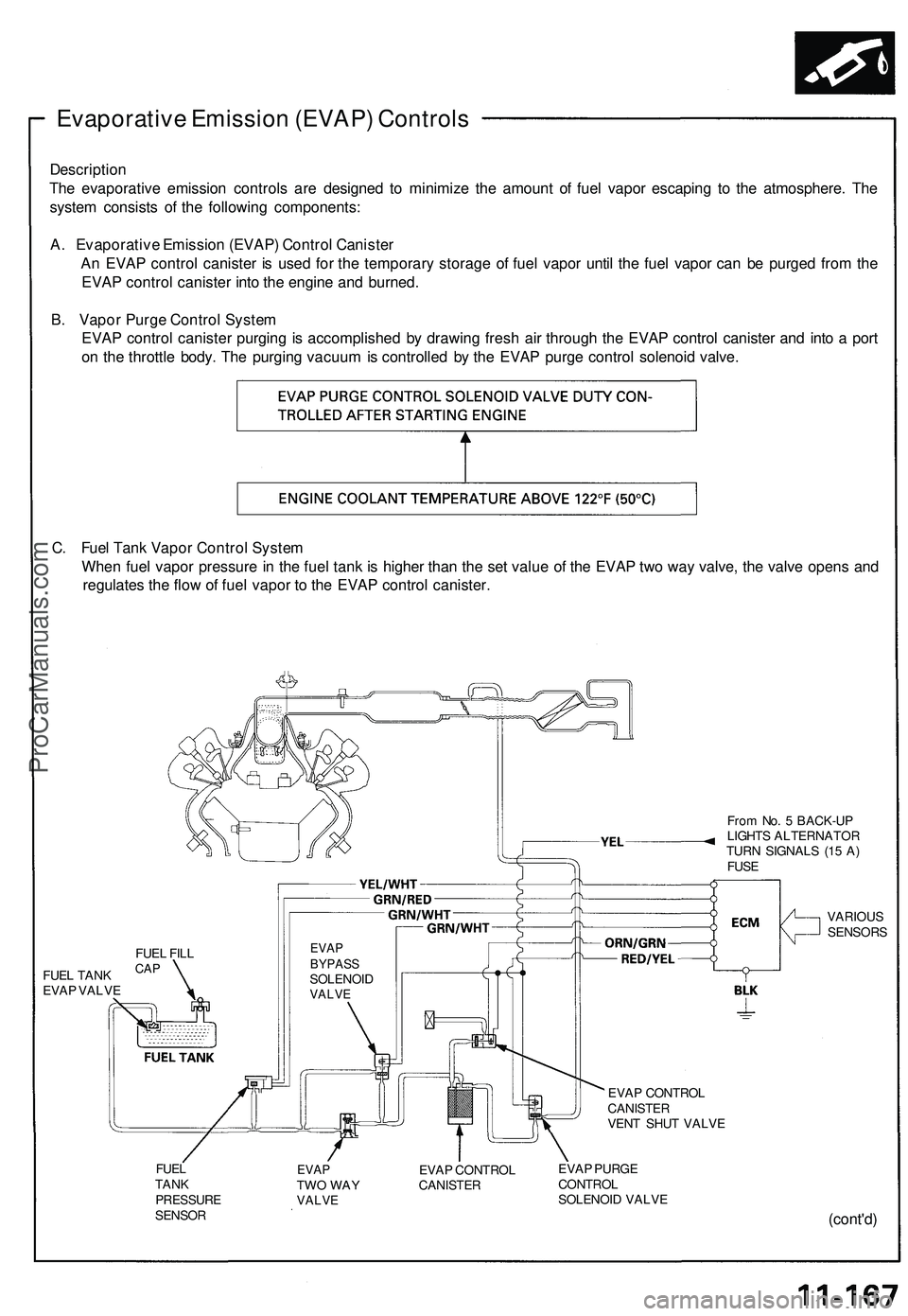

Evaporative Emission (EVAP) Controls

Description

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAP) Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the

EVAP control canister into the engine and burned.

B. Vapor Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a port

on the throttle body. The purging vacuum is controlled by the EVAP purge control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow of fuel vapor to the EVAP control canister.

From No. 5 BACK-UP

LIGHTS ALTERNATOR

TURN SIGNALS (15 A)

FUSE

FUEL TANK

EVAP VALVE

EVAP

BYPASS

SOLENOID

VALVE

VARIOUS

SENSORS

EVAP CONTROL

CANISTER

VENT SHUT VALVE

FUEL

TANK

PRESSURE

SENSOR

EVAP

TWO WAY

VALVE

EVAP CONTROL

CANISTER

EVAP PURGE

CONTROL

SOLENOID VALVE

(cont'd)

FUEL FILL

CAPProCarManuals.com