low oil pressure ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 573 of 1503

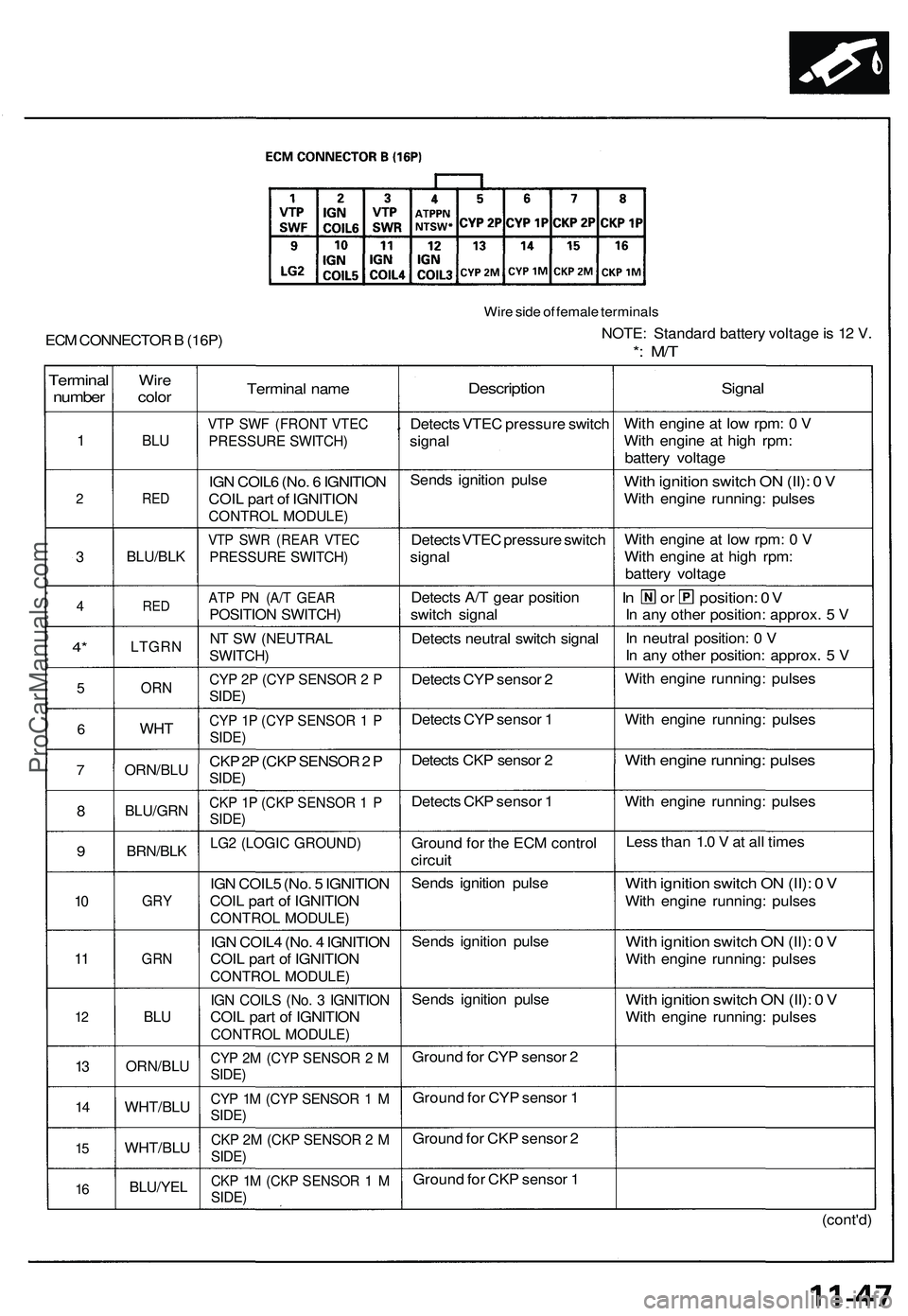

Terminal

number

1

2

3

4

4*

5

6

7

8

9

10

11

12

13

14

15

16

Wire

color

BLU

RED

BLU/BLK

RED

LTGRN

ORN

WHT

ORN/BLU

BLU/GRN

BRN/BLK

GRY

GRN

BLU

ORN/BLU

WHT/BLU

WHT/BLU

BLU/YEL

Terminal name

VTP SWF (FRONT VTEC

PRESSURE SWITCH)

IGN COIL6 (No. 6 IGNITION

COIL part of IGNITION

CONTROL MODULE)

VTP SWR (REAR VTEC

PRESSURE SWITCH)

ATP PN (A/T GEAR

POSITION SWITCH)

NT SW (NEUTRAL

SWITCH)

CYP 2P (CYP SENSOR 2 P

SIDE)

CYP 1P (CYP SENSOR 1 P

SIDE)

CKP 2P (CKP SENSOR 2 P

SIDE)

CKP 1P (CKP SENSOR 1 P

SIDE)

LG2 (LOGIC GROUND)

IGN COIL5 (No. 5 IGNITION

COIL part of IGNITION

CONTROL MODULE)

IGN COIL4 (No. 4 IGNITION

COIL part of IGNITION

CONTROL MODULE)

IGN COILS (No. 3 IGNITION

COIL part of IGNITION

CONTROL MODULE)

CYP 2M (CYP SENSOR 2 M

SIDE)

CYP 1M (CYP SENSOR 1 M

SIDE)

CKP 2M (CKP SENSOR 2 M

SIDE)

CKP 1M (CKP SENSOR 1 M

SIDE)

Description

Detects VTEC pressure switch

signal

Sends ignition pulse

Detects VTEC pressure switch

signal

Detects A/T gear position

switch signal

Detects neutral switch signal

Detects CYP sensor 2

Detects CYP sensor 1

Detects CKP sensor 2

Detects CKP sensor 1

Ground for the ECM control

circuit

Sends ignition pulse

Sends ignition pulse

Sends ignition pulse

Ground for CYP sensor 2

Ground for CYP sensor 1

Ground for CKP sensor 2

Ground for CKP sensor 1

Signal

With engine at low rpm: 0 V

With engine at high rpm:

battery voltage

With ignition switch ON (II): 0 V

With engine running: pulses

With engine at low rpm: 0 V

With engine at high rpm:

battery voltage

In or position: 0V

In any other position: approx. 5 V

In neutral position: 0 V

In any other position: approx. 5 V

With engine running: pulses

With engine running: pulses

With engine running: pulses

With engine running: pulses

Less than 1.0 V at all times

With ignition switch ON (II): 0 V

With engine running: pulses

With ignition switch ON (II): 0 V

With engine running: pulses

With ignition switch ON (II): 0 V

With engine running: pulses

(cont'd)

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

*: M/T

ECM CONNECTOR B (16P)ProCarManuals.com

Page 776 of 1503

(cont'd)

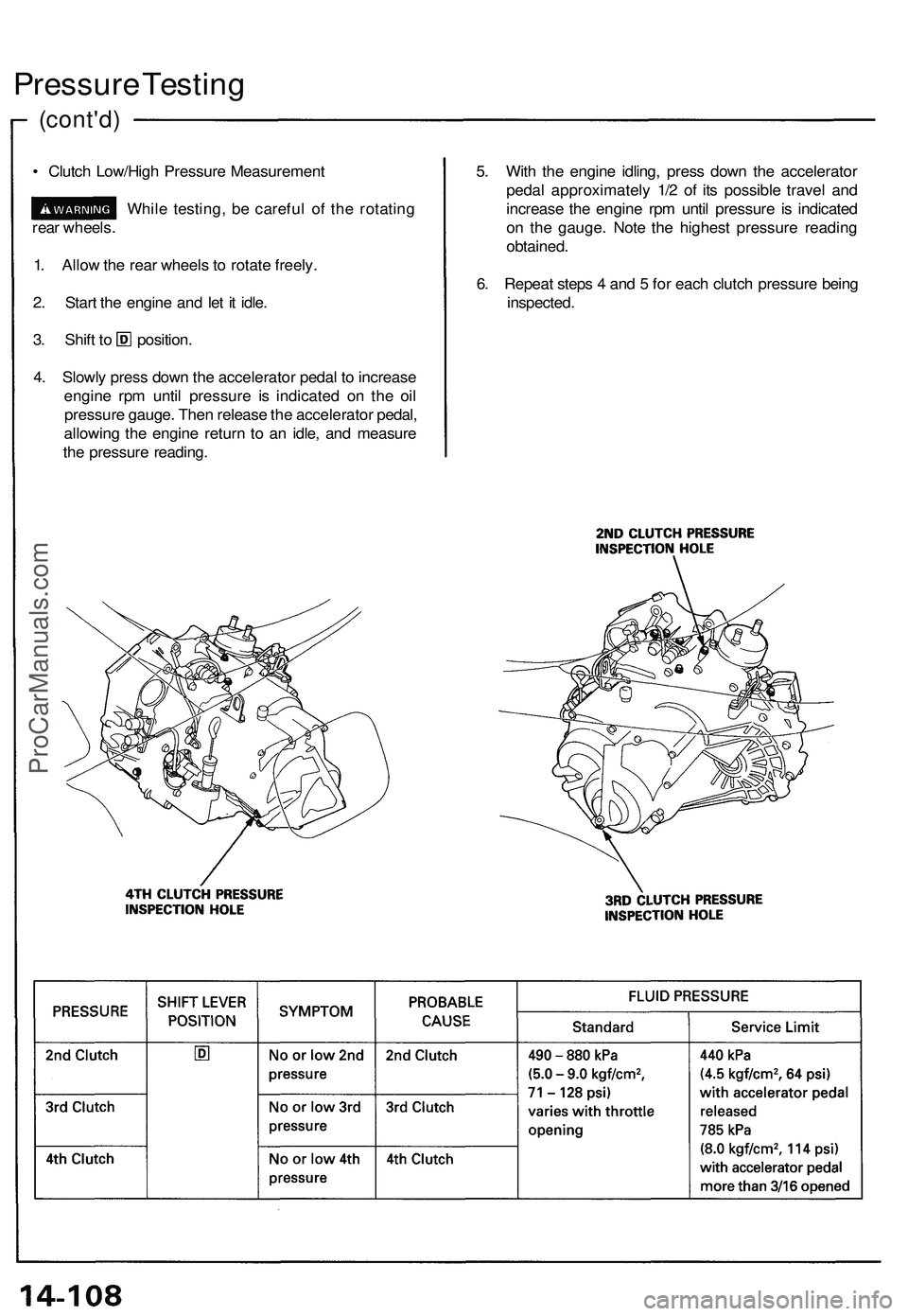

Pressure Testing

• Clutch Low/High Pressure Measurement

While testing, be careful of the rotating

rear wheels.

1. Allow the rear wheels to rotate freely.

2. Start the engine and let it idle.

3. Shift to position.

4. Slowly press down the accelerator pedal to increase

engine rpm until pressure is indicated on the oil

pressure gauge. Then release the accelerator pedal,

allowing the engine return to an idle, and measure

the pressure reading.

5. With the engine idling, press down the accelerator

pedal approximately 1/2 of its possible travel and

increase the engine rpm until pressure is indicated

on the gauge. Note the highest pressure reading

obtained.

6. Repeat steps 4 and 5 for each clutch pressure being

inspected.ProCarManuals.com

Page 1206 of 1503

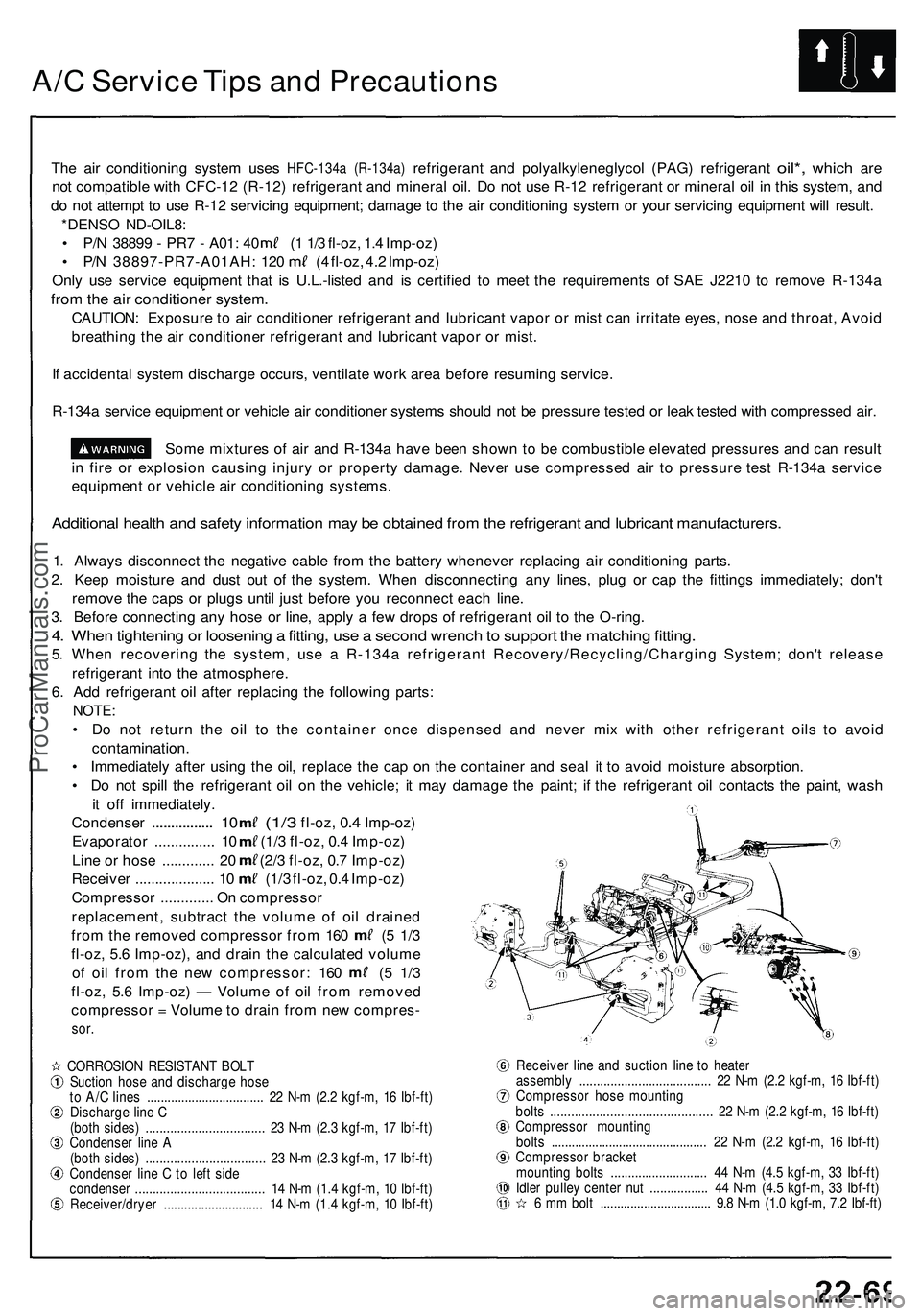

A/C Servic e Tip s an d Precaution s

The ai r conditionin g syste m use s HFC-134 a (R-134a ) refrigeran t and polyalkyleneglyco l (PAG ) refrigeran t oil*, whic h are

not compatibl e wit h CFC-1 2 (R-12 ) refrigeran t an d minera l oil . D o no t us e R-1 2 refrigeran t o r minera l oi l i n thi s system , an d

d o no t attemp t t o us e R-1 2 servicin g equipment ; damag e t o th e ai r conditionin g syste m o r you r servicin g equipmen t wil l result .

*DENS O ND-OIL8 :

• P/N 3889 9 - PR 7 - A01 : 4 0 ( 1 1/ 3 fl-oz , 1. 4 Imp-oz )

• P/ N 38897-PR7-A01AH : 12 0 ( 4 fl-oz , 4. 2 Imp-oz )

Onl y us e servic e equipmen t tha t i s U.L.-liste d an d i s certifie d t o mee t th e requirement s o f SA E J221 0 t o remov e R-134 a

from th e ai r conditione r system .

CAUTION : Exposur e t o ai r conditione r refrigeran t an d lubrican t vapo r o r mis t ca n irritat e eyes , nos e an d throat , Avoi d

breathin g th e ai r conditione r refrigeran t an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k are a befor e resumin g service .

R-134 a servic e equipmen t o r vehicl e ai r conditione r system s shoul d no t b e pressur e teste d o r lea k teste d wit h compresse d air .

Som e mixture s o f ai r an d R-134 a hav e bee n show n t o b e combustibl e elevate d pressure s an d ca n resul t

i n fir e o r explosio n causin g injur y o r propert y damage . Neve r us e compresse d ai r t o pressur e tes t R-134 a servic e

equipmen t o r vehicl e ai r conditionin g systems .

Additional healt h an d safet y informatio n ma y b e obtaine d fro m th e refrigeran t an d lubrican t manufacturers .

1. Alway s disconnec t th e negativ e cabl e fro m th e batter y wheneve r replacin g ai r conditionin g parts .

2 . Kee p moistur e an d dus t ou t o f th e system . Whe n disconnectin g an y lines , plu g o r ca p th e fitting s immediately ; don' t

remov e th e cap s o r plug s unti l jus t befor e yo u reconnec t eac h line .

3 . Befor e connectin g an y hos e o r line , appl y a fe w drop s o f refrigeran t oi l t o th e O-ring .

4. Whe n tightenin g o r loosenin g a fitting , us e a secon d wrenc h to suppor t th e matchin g fitting .

5. Whe n recoverin g th e system , us e a R-134 a refrigeran t Recovery/Recycling/Chargin g System ; don' t releas e

refrigeran t int o th e atmosphere .

6 . Ad d refrigeran t oi l afte r replacin g th e followin g parts :

NOTE :

• D o no t retur n th e oi l t o th e containe r onc e dispense d an d neve r mi x wit h othe r refrigeran t oil s t o avoi d

contamination .

• Immediatel y afte r usin g th e oil , replac e th e ca p o n th e containe r an d sea l i t t o avoi d moistur e absorption .

• D o no t spil l th e refrigeran t oi l o n th e vehicle ; i t ma y damag e th e paint ; i f th e refrigeran t oi l contact s th e paint , was h

i t of f immediately .

Condense r

............... . 1 0 (1/ 3 fl-oz, 0.4 Imp-oz )

Evaporato r .............. . 1 0 (1/ 3 fl-oz , 0. 4 Imp-oz )

Lin e o r hos e ............ . 2 0 (2/ 3 fl-oz , 0. 7 Imp-oz )

Receive r ................... . 1 0 (1/ 3 fl-oz , 0. 4 Imp-oz )

Compresso r ............ . O n compresso r

replacement , subtrac t th e volum e o f oi l draine d

from th e remove d compresso r fro m 16 0 ( 5 1/ 3

fl-oz , 5. 6 Imp-oz) , an d drai n th e calculate d volum e

of oi l fro m th e ne w compressor : 16 0 ( 5 1/ 3

fl-oz , 5. 6 Imp-oz ) — Volum e o f oi l fro m remove d

compresso r = Volum e t o drai n fro m ne w compres -

sor.

CORROSIO N RESISTAN T BOL T

Suctio n hos e an d discharg e hos e

t o A/ C line s ................................. . 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Discharg e lin e C

(bot h sides ) .................................. 23 N- m (2. 3 kgf-m , 1 7 Ibf-ft )

Condense r lin e A

(bot h sides ) ................................. . 2 3 N- m (2. 3 kgf-m , 1 7 Ibf-ft )

Condense r lin e C to lef t sid e

condense r .................................... . 1 4 N- m (1. 4 kgf-m , 1 0 Ibf-ft )

Receiver/drye r ............................ . 1 4 N- m (1. 4 kgf-m , 1 0 Ibf-ft ) Receive

r lin e an d suctio n lin e t o heate r

assembl y ..................................... . 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Compresso r hos e mountin g

bolt s ............................................. . 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Compresso r mountin g

bolt s ............................................. . 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Compresso r bracke t

mountin g bolt s ........................... . 4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

Idle r pulle y cente r nu t ................ . 4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

6 m m bol t ................................ . 9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 1261 of 1503

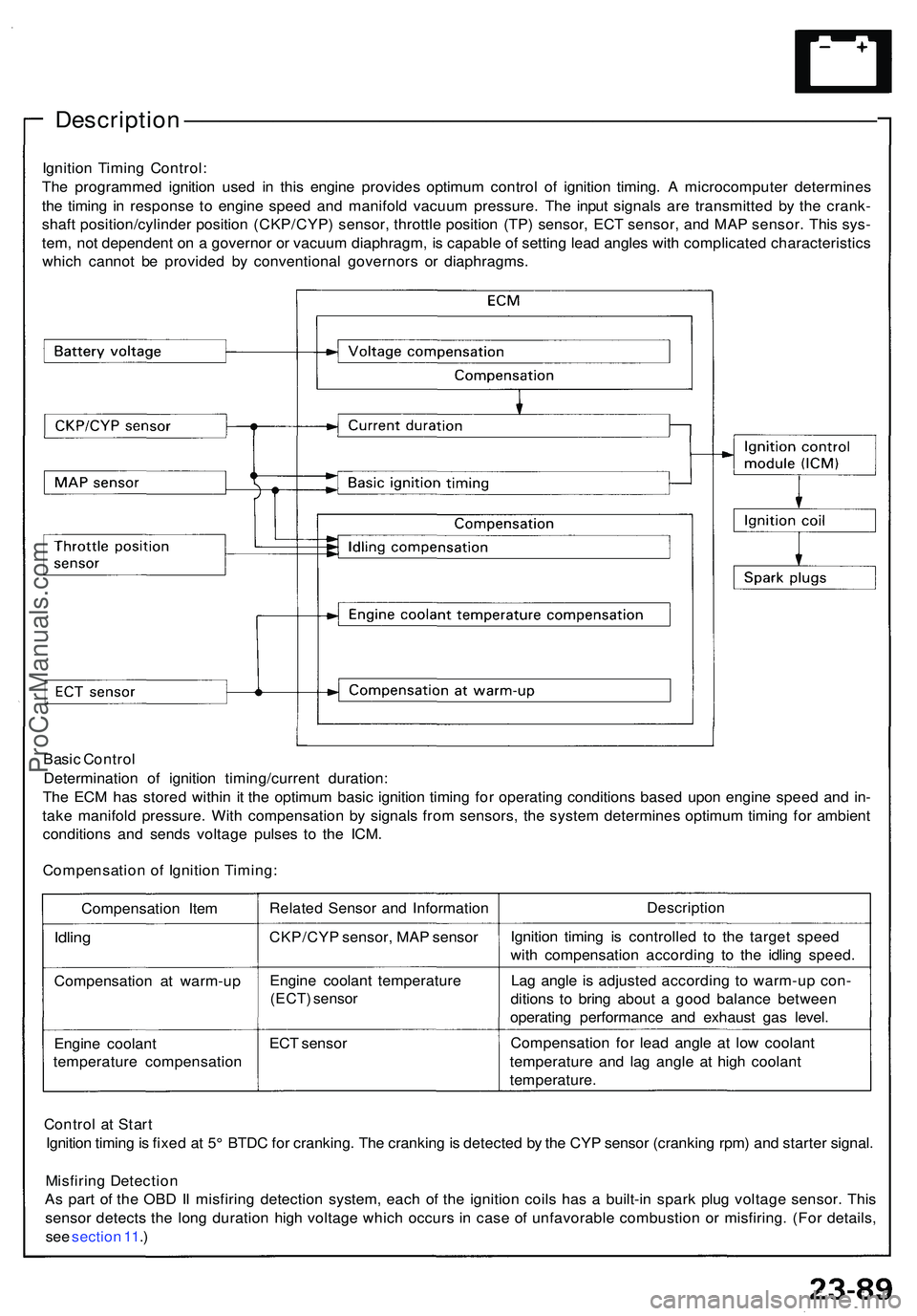

Description ——————————————————\

——————————————————\

———

Ignition Timin g Control :

Th e programme d ignitio n use d i n thi s engin e provide s optimu m contro l o f ignitio n timing . A microcompute r determine s

th e timin g i n respons e t o engin e spee d an d manifol d vacuu m pressure . Th e inpu t signal s ar e transmitte d b y th e crank -

shaf t position/cylinde r positio n (CKP/CYP ) sensor , throttl e positio n (TP ) sensor , EC T sensor , an d MA P sensor . Thi s sys -

tem , no t dependen t o n a governo r o r vacuu m diaphragm , i s capabl e o f settin g lea d angle s wit h complicate d characteristic s

whic h canno t b e provide d b y conventiona l governor s o r diaphragms .

Basi c Contro l

Determinatio n of ignitio n timing/curren t duration :

Th e EC M ha s store d withi n i t th e optimu m basi c ignitio n timin g fo r operatin g condition s base d upo n engin e spee d an d in -

tak e manifol d pressure . Wit h compensatio n b y signal s fro m sensors , th e syste m determine s optimu m timin g fo r ambien t

condition s an d send s voltag e pulse s t o th e ICM .

Compensatio n o f Ignitio n Timing :

Compensatio n Ite m

Idlin g

Compensatio n a t warm-u p

Engin e coolan t

temperatur e compensatio nRelate

d Senso r an d Informatio n

CKP/CY P sensor , MA P senso r

Engin e coolan t temperatur e

(ECT) senso r

ECT senso r Descriptio

n

Ignitio n timin g i s controlle d t o th e targe t spee d

wit h compensatio n accordin g t o th e idlin g speed .

La g angl e i s adjuste d accordin g t o warm-u p con -

dition s t o brin g abou t a goo d balanc e betwee n

operatin g performanc e an d exhaus t ga s level .

Compensatio n fo r lea d angl e a t low coolan t

temperatur e an d la g angl e a t hig h coolan t

temperature .

Contro l a t Star t

Ignitio n timin g is fixe d a t 5 ° BTD C fo r cranking . Th e crankin g is detecte d b y th e CY P senso r (crankin g rpm ) an d starte r signal .

Misfirin g Detectio n

A s par t o f th e OB D II misfirin g detectio n system , eac h o f th e ignitio n coil s ha s a built-i n spar k plu g voltag e sensor . Thi s

senso r detect s th e lon g duratio n hig h voltag e whic h occur s i n cas e o f unfavorabl e combustio n o r misfiring . (Fo r details ,

se e sectio n 11 .)

ProCarManuals.com

Page 1284 of 1503

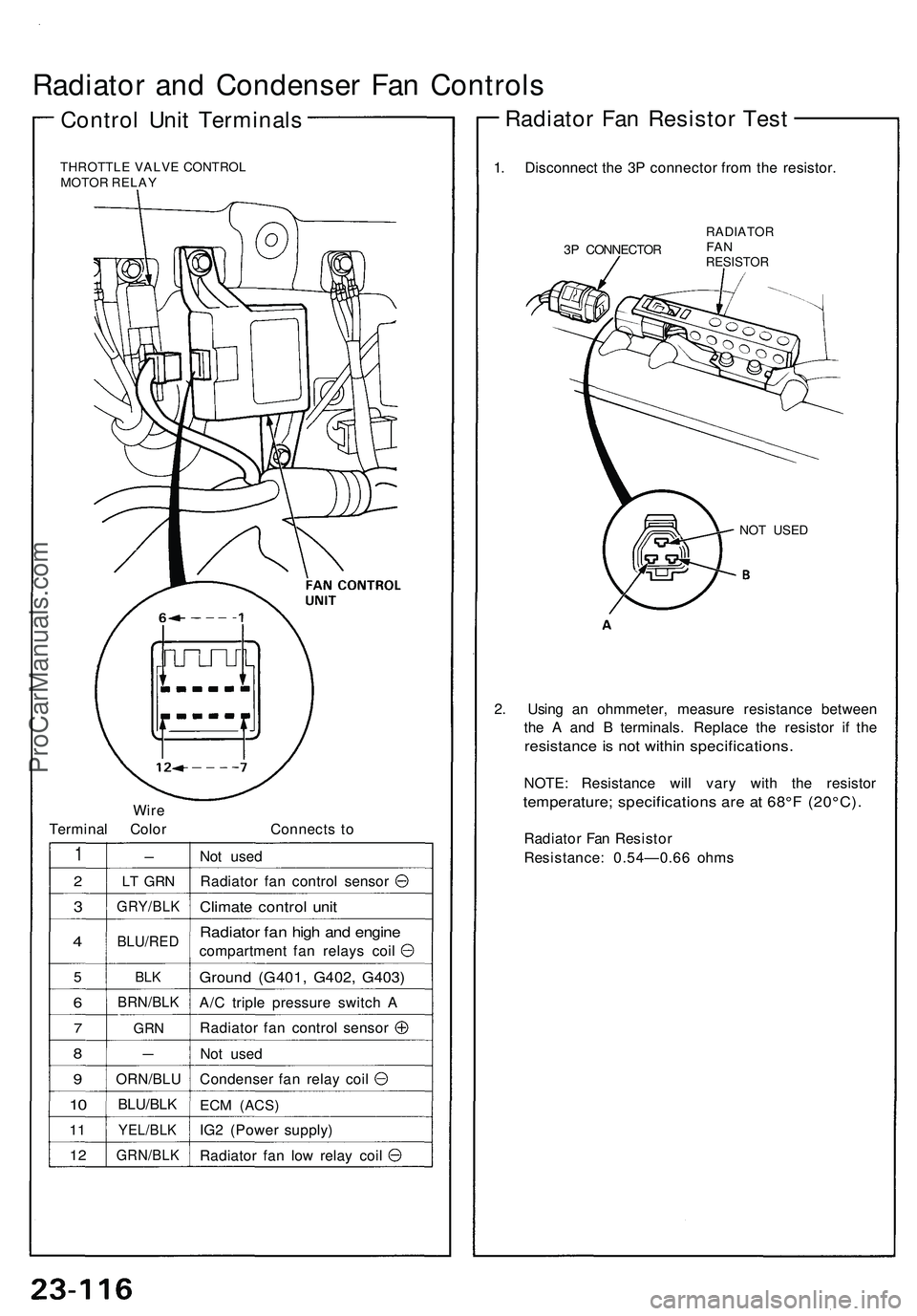

Radiator and Condenser Fan Controls

Control Unit Terminals

THROTTLE VALVE CONTROL

MOTOR RELAY

Wire

Terminal Color

Connects to

1

2

3

4

5

6

7

8

9

10

11

12

-

LT GRN

GRY/BLK

BLU/RED

BLK

BRN/BLK

GRN

—

ORN/BLU

BLU/BLK

YEL/BLK

GRN/BLK

Not used

Radiator fan control sensor

Climate control unit

Radiator fan high and engine

compartment fan relays coil

Ground (G401, G402, G403)

A/C triple pressure switch A

Radiator fan control sensor

Not used

Condenser fan relay coil

ECM

(ACS)

IG2 (Power supply)

Radiator fan low relay coil

1. Disconnect the 3P connector from the resistor.

3P CONNECTOR

RADIATOR

FAN

RESISTOR

NOT USED

2. Using an ohmmeter, measure resistance between

the A and B terminals. Replace the resistor if the

resistance is not within specifications.

NOTE: Resistance will vary with the resistor

temperature; specifications are at 68°F (20°C).

Radiator Fan Resistor

Resistance: 0.54—0.66 ohms

Radiator Fan Resistor TestProCarManuals.com

Page 1292 of 1503

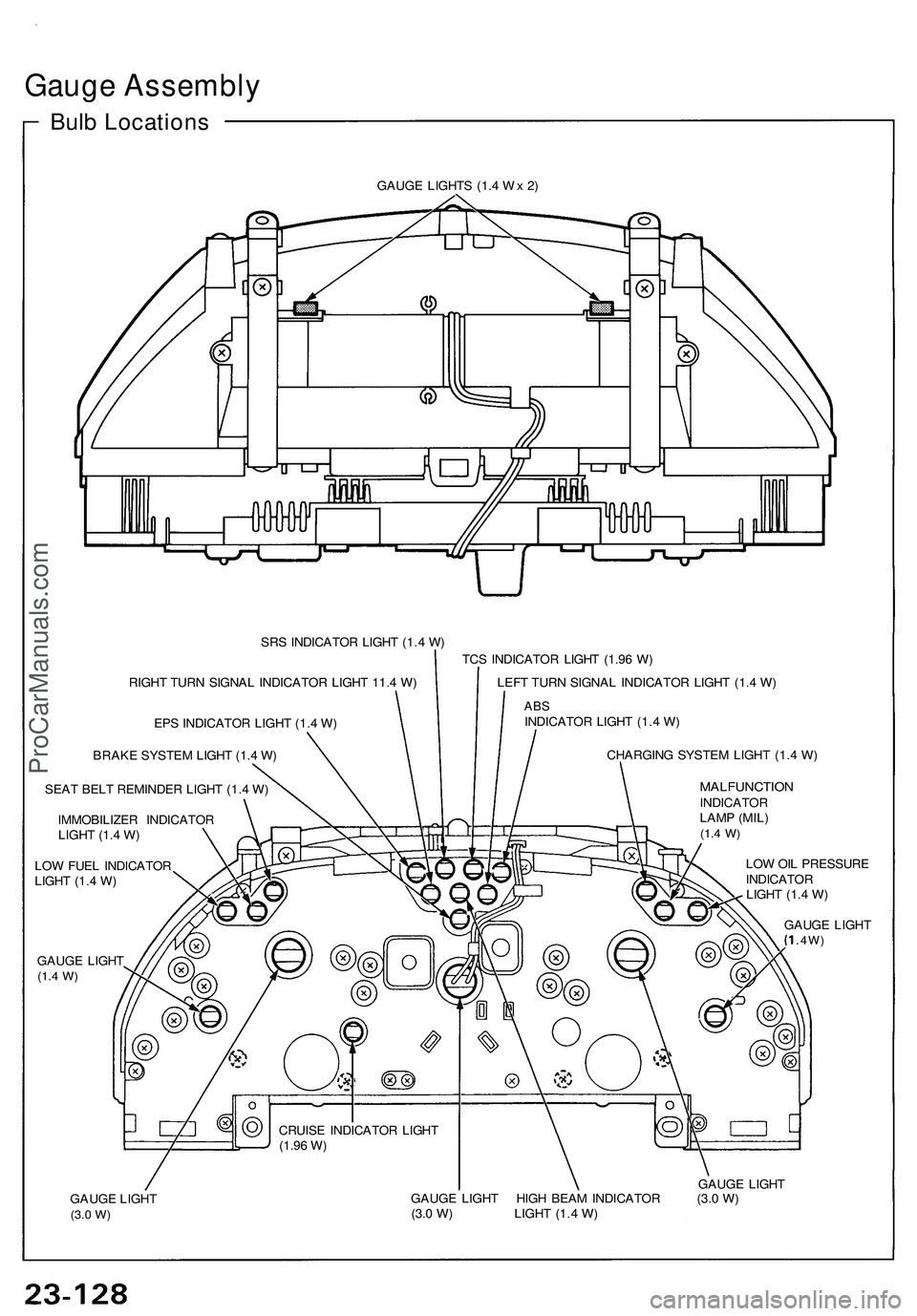

Gauge Assembly

Bulb Locations

GAUGE LIGHTS (1.4 Wx 2)

SRS INDICATOR LIGHT (1.4 W)

RIGHT TURN SIGNAL INDICATOR LIGHT 11.4 W)

EPS INDICATOR LIGHT (1.4 W)

BRAKE SYSTEM LIGHT (1.4 W)

SEAT BELT REMINDER LIGHT (1.4 W)

IMMOBILIZER INDICATOR

LIGHT (1.4 W)

LOW FUEL INDICATOR

LIGHT (1.4 W)

GAUGE LIGHT

(1.4

W)

TCS INDICATOR LIGHT (1.96 W)

LEFT TURN SIGNAL INDICATOR LIGHT (1.4 W)

ABS

INDICATOR LIGHT (1.4 W)

CHARGING SYSTEM LIGHT (1.4 W)

MALFUNCTION

INDICATOR

LAMP (MIL)

(1.4

W)

CRUISE INDICATOR LIGHT

(1.96

W)

LOW OIL PRESSURE

INDICATOR

LIGHT (1.4 W)

GAUGE LIGHT

.4W)

GAUGE LIGHT

(3.0

W)

GAUGE LIGHT

GAUGE LIGHT HIGH BEAM INDICATOR (3.0 W)

(3.0 W) LIGHT (1.4 W)ProCarManuals.com

Page 1323 of 1503

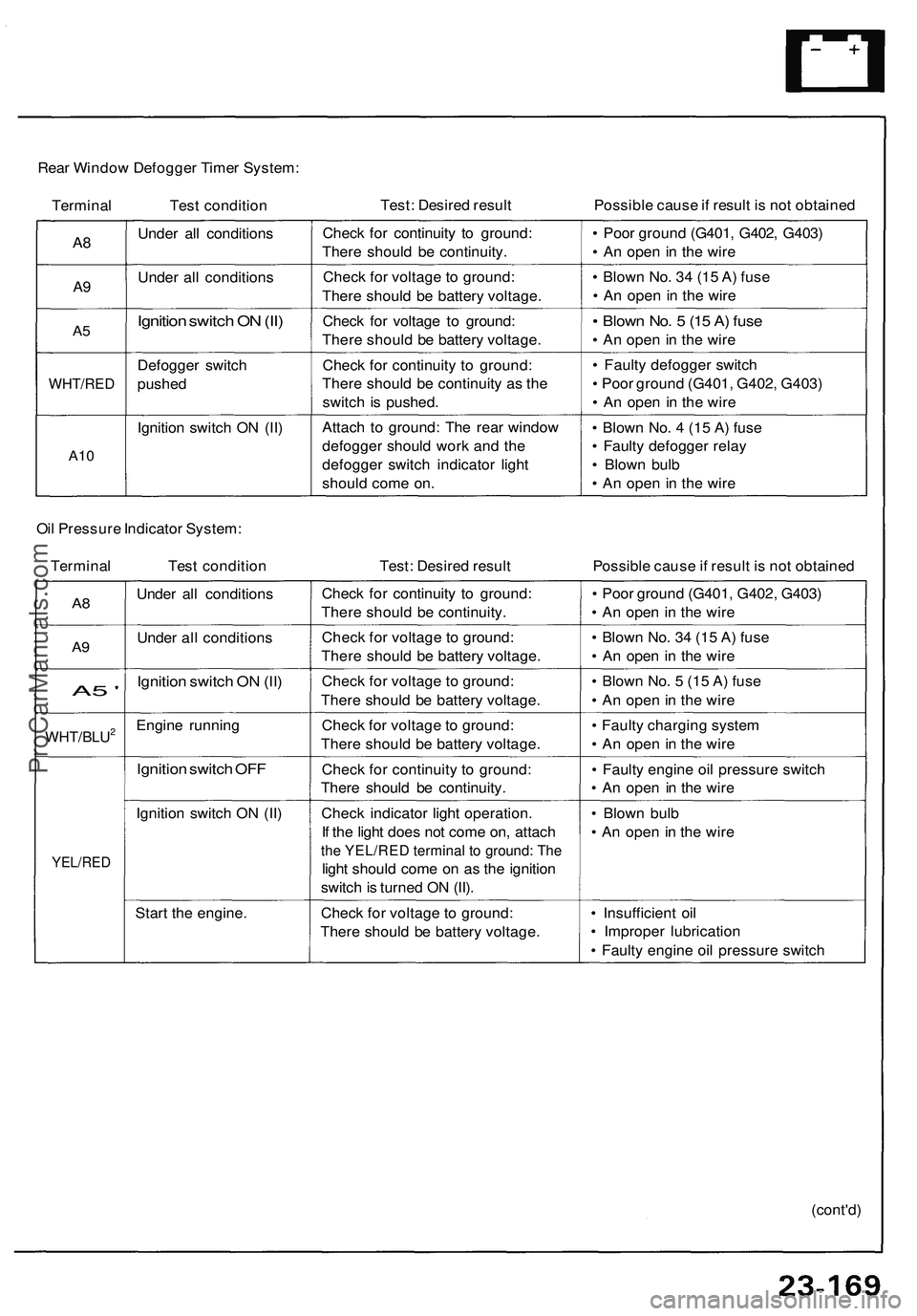

Rear Window Defogger Timer System:

Terminal Test condition

Test: Desired result

Possible cause if result is not obtained

A8

A9

A5

WHT/RED

A10

Under all conditions

Under all conditions

Ignition switch ON (II)

Defogger switch

pushed

Ignition switch ON (II)

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

Check for continuity to ground:

There should be continuity as the

switch is pushed.

Attach to ground: The rear window

defogger should work and the

defogger switch indicator light

should come on.

• Poor ground (G401, G402, G403)

• An open in the wire

• Blown No. 34 (15 A) fuse

• An open in the wire

• Blown No. 5 (15 A) fuse

• An open in the wire

• Faulty defogger switch

• Poor ground (G401, G402, G403)

• An open in the wire

• Blown No. 4 (15 A) fuse

• Faulty defogger relay

• Blown bulb

• An open in the wire

Oil Pressure Indicator System:

Terminal Test condition

Test: Desired result

Possible cause if result is not obtained

A8

A9

A5 '

WHT/BLU2

YEL/RED

Under all conditions

Under all conditions

Ignition switch ON (II)

Engine running

Ignition switch OFF

Ignition switch ON (II)

Start the engine.

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

Check for continuity to ground:

There should be continuity.

Check indicator light operation.

If the light does not come on, attach

the YEL/RED terminal to ground: The

light should come on as the ignition

switch is turned ON (II).

Check for voltage to ground:

There should be battery voltage.

• Poor ground (G401, G402, G403)

• An open in the wire

• Blown No. 34 (15 A) fuse

• An open in the wire

• Blown No. 5 (15 A) fuse

• An open in the wire

• Faulty charging system

• An open in the wire

• Faulty engine oil pressure switch

• An open in the wire

• Blown bulb

• An open in the wire

• Insufficient oil

• Improper lubrication

• Faulty engine oil pressure switch

(cont'd)ProCarManuals.com