charging ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 595 of 1503

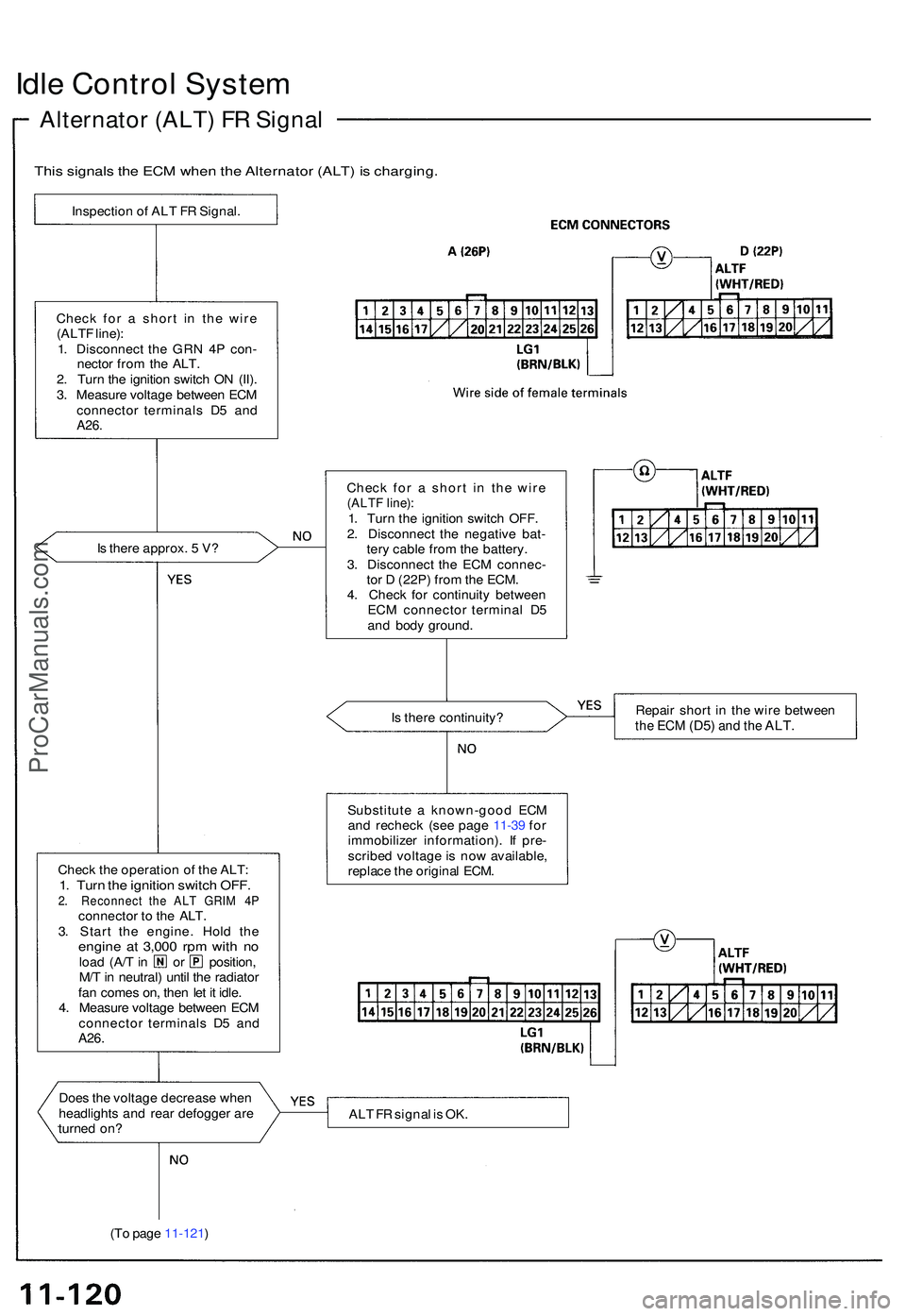

Idle Contro l Syste m

Alternato r (ALT ) F R Signa l

This signal s th e EC M whe n th e Alternato r (ALT ) i s charging .

Inspection o f AL T F R Signal .

Chec k fo r a shor t i n th e wir e

(ALT F line) :

1 . Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

2 . Tur n th e ignitio n switc h O N (II) .

3 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d

A26.

Is ther e approx . 5 V ?

Chec k th e operatio n o f th e ALT :

1. Tur n th e ignitio n switc h OFF .2. Reconnec t th e AL T GRI M 4 Pconnecto r t o th e ALT .

3 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n oloa d (A/ T in o r position ,

M/ T in neutral ) unti l th e radiato r

fa n come s on , the n le t i t idle .

4 . Measur e voltag e betwee n EC M

connecto r terminal s D 5 an d

A26 .

I

Doe s th e voltag e decreas e whe n

headlight s an d rea r defogge r ar e

turne d on ?

(T o pag e 11-121 ) Chec

k fo r a shor t i n th e wir e

(ALT F line) :1. Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e EC M connec -

to r D (22P ) fro m th e ECM .

4 . Chec k fo r continuit y betwee n

EC M connecto r termina l D 5

an d bod y ground .

I s ther e continuity ? Repai

r shor t i n th e wir e betwee n

the EC M (D5 ) and th e ALT .

Substitut e a known-goo d EC M

an d rechec k (se e pag e 11-3 9 fo r

immobilize r information) . I f pre -

scribe d voltag e is no w available ,

replac e th e origina l ECM .

AL T F R signa l i s OK .

ProCarManuals.com

Page 1207 of 1503

A/C System Service

Performance Test

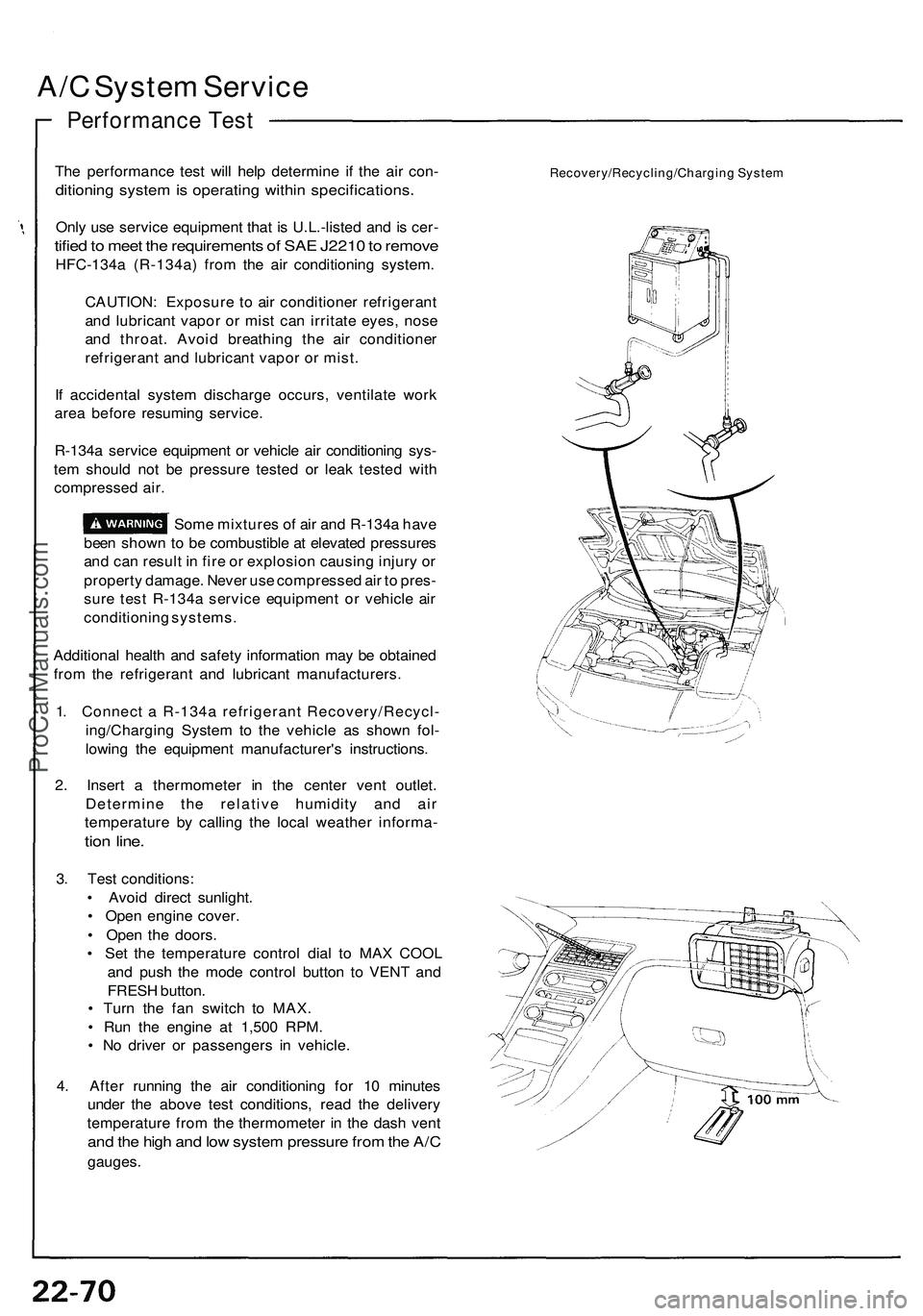

The performance test will help determine if the air con-

ditioning system is operating within specifications.

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioning system.

CAUTION: Exposure to air conditioner refrigerant

and lubricant vapor or mist can irritate eyes, nose

and throat. Avoid breathing the air conditioner

refrigerant and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioning sys-

tem should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have

been shown to be combustible at elevated pressures

and can result in fire or explosion causing injury or

property damage. Never use compressed air to pres-

sure test R-134a service equipment or vehicle air

conditioning systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. Connect a R-134a refrigerant Recovery/Recycl-

ing/Charging System to the vehicle as shown fol-

lowing the equipment manufacturer's instructions.

2. Insert a thermometer in the center vent outlet.

Determine the relative humidity and air

temperature by calling the local weather informa-

tion line.

3. Test conditions:

• Avoid direct sunlight.

• Open engine cover.

• Open the doors.

• Set the temperature control dial to MAX COOL

and push the mode control button to VENT and

FRESH button.

• Turn the fan switch to MAX.

• Run the engine at 1,500 RPM.

• No driver or passengers in vehicle.

4. After running the air conditioning for 10 minutes

under the above test conditions, read the delivery

temperature from the thermometer in the dash vent

and the high and low system pressure from the A/C

gauges.

Recovery/Recycling/Charging SystemProCarManuals.com

Page 1210 of 1503

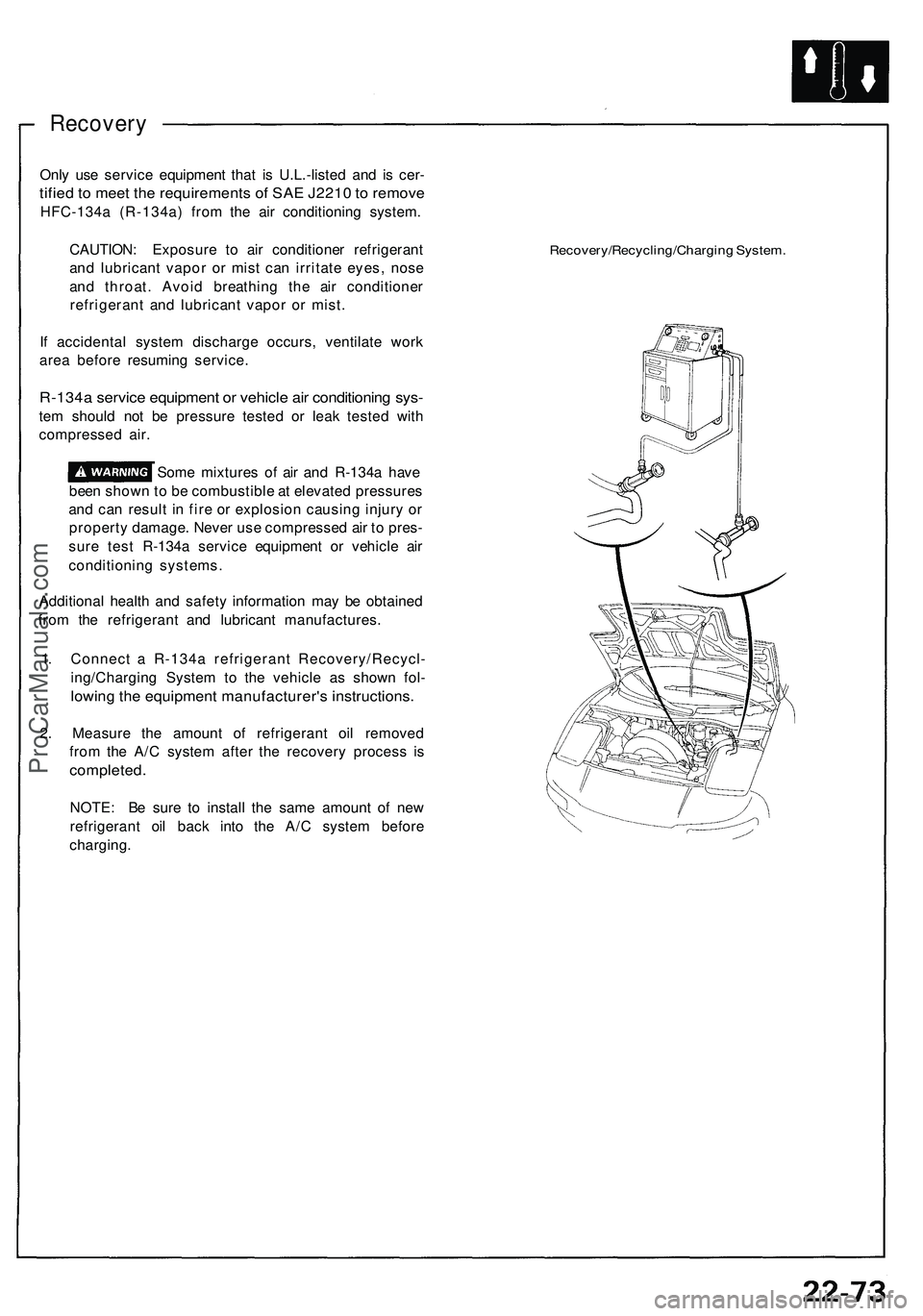

Recovery

Only us e servic e equipmen t tha t i s U.L.-liste d an d i s cer -

tified t o mee t th e requirement s o f SA E J221 0 to remov e

HFC-134 a (R-134a ) fro m th e ai r conditionin g system .

CAUTION : Exposur e t o ai r conditione r refrigeran t

an d lubrican t vapo r o r mis t ca n irritat e eyes , nos e

an d throat . Avoi d breathin g th e ai r conditione r

refrigeran t an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k

are a befor e resumin g service .

R-134a servic e equipmen t o r vehicl e ai r conditionin g sys -

tem shoul d no t b e pressur e teste d o r lea k teste d wit h

compresse d air .

Som e mixture s o f ai r an d R-134 a hav e

bee n show n t o b e combustibl e a t elevate d pressure s

an d ca n resul t i n fir e o r explosio n causin g injur y o r

propert y damage . Neve r us e compresse d ai r t o pres -

sur e tes t R-134 a servic e equipmen t o r vehicl e ai r

conditionin g systems .

Additiona l healt h an d safet y informatio n ma y b e obtaine d

fro m th e refrigeran t an d lubrican t manufactures .

1 . Connec t a R-134 a refrigeran t Recovery/Recycl -

ing/Chargin g Syste m t o th e vehicl e a s show n fol -

lowin g th e equipmen t manufacturer' s instructions .

2. Measur e th e amoun t o f refrigeran t oi l remove d

fro m th e A/ C syste m afte r th e recover y proces s i s

completed .

NOTE: B e sur e t o instal l th e sam e amoun t o f ne w

refrigeran t oi l bac k int o th e A/ C syste m befor e

charging .

Recovery/Recycling/Chargin g System .

ProCarManuals.com

Page 1227 of 1503

A/C System Service

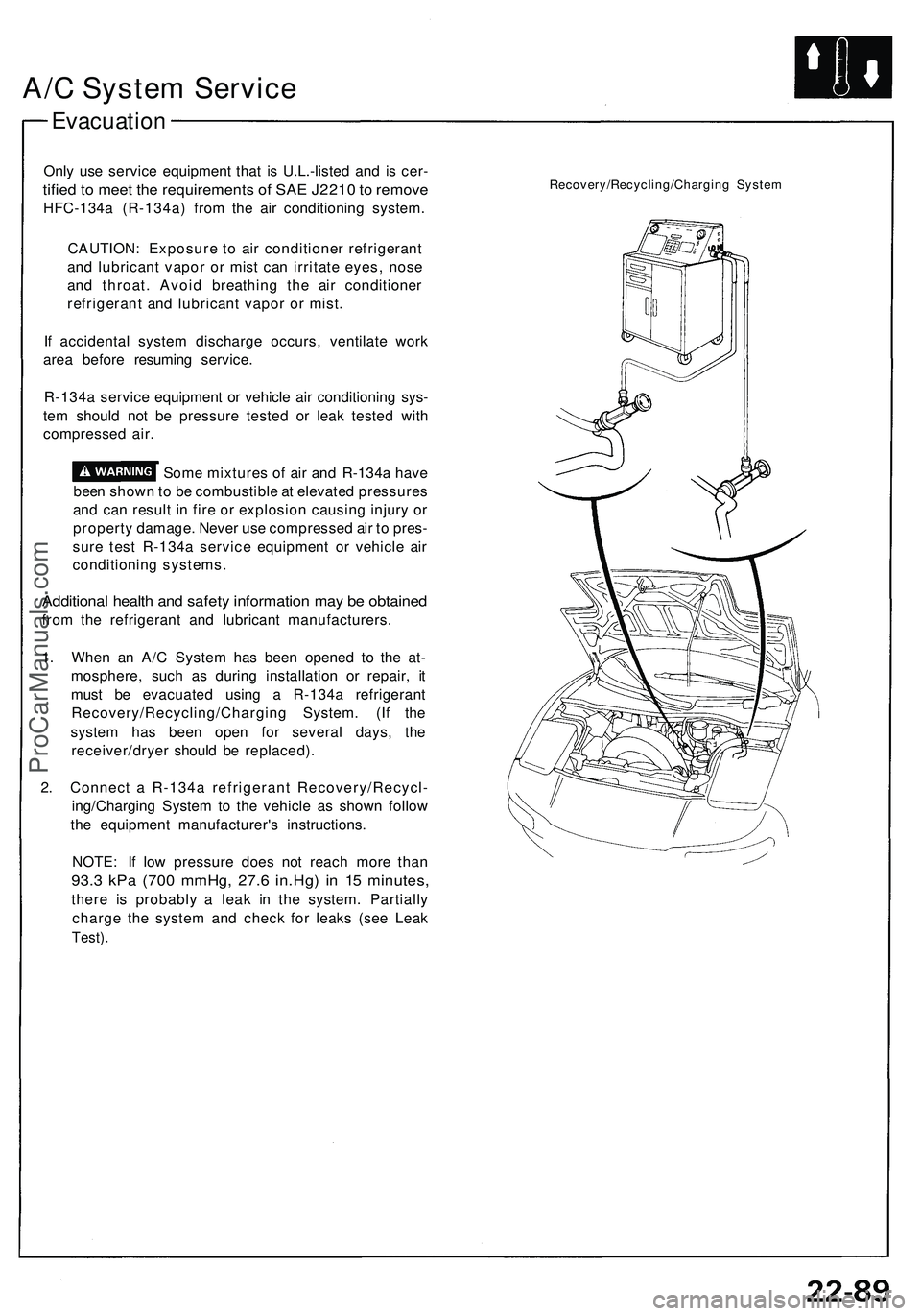

Evacuation

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioning system.

CAUTION: Exposure to air conditioner refrigerant

and lubricant vapor or mist can irritate eyes, nose

and throat. Avoid breathing the air conditioner

refrigerant and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioning sys-

tem should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have

been shown to be combustible at elevated pressures

and can result in fire or explosion causing injury or

property damage. Never use compressed air to pres-

sure test R-134a service equipment or vehicle air

conditioning systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. When an A/C System has been opened to the at-

mosphere, such as during installation or repair, it

must be evacuated using a R-134a refrigerant

Recovery/Recycling/Charging System. (If the

system has been open for several days, the

receiver/dryer should be replaced).

2. Connect a R-134a refrigerant Recovery/Recycl-

ing/Charging System to the vehicle as shown follow

the equipment manufacturer's instructions.

NOTE: If low pressure does not reach more than

93.3 kPa (700 mmHg, 27.6 in.Hg) in 15 minutes,

there is probably a leak in the system. Partially

charge the system and check for leaks (see Leak

Test).

Recovery/Recycling/Charging SystemProCarManuals.com

Page 1228 of 1503

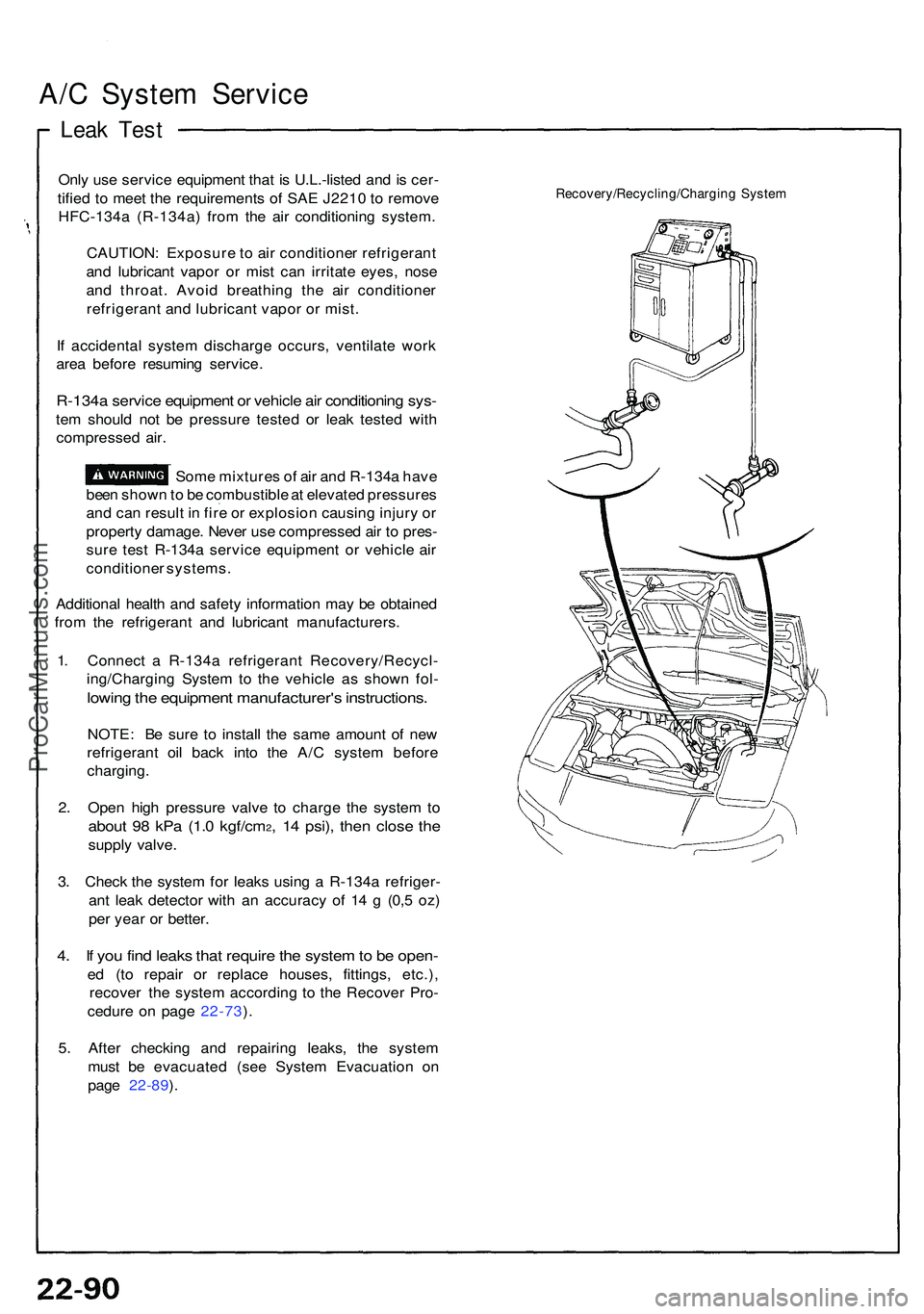

A/C Syste m Servic e

Leak Tes t

Only us e servic e equipmen t tha t i s U.L.-liste d an d is cer -

tifie d t o mee t th e requirement s o f SA E J221 0 t o remov e

HFC-134 a (R-134a ) fro m th e ai r conditionin g system .

CAUTION : Exposur e t o ai r conditione r refrigeran t

an d lubrican t vapo r o r mis t ca n irritat e eyes , nos e

an d throat . Avoi d breathin g th e ai r conditione r

refrigeran t an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k

are a befor e resumin g service .

R-134a servic e equipmen t o r vehicl e ai r conditionin g sys -

tem shoul d no t b e pressur e teste d o r lea k teste d wit h

compresse d air .

Som e mixture s o f ai r an d R-134 a hav e

bee n show n to b e combustibl e a t elevate d pressure s

an d ca n resul t i n fir e o r explosio n causin g injur y o r

propert y damage . Neve r us e compresse d ai r t o pres -

sur e tes t R-134 a servic e equipmen t o r vehicl e ai r

conditione r systems.

Additiona l healt h an d safet y informatio n ma y b e obtaine d

fro m th e refrigeran t an d lubrican t manufacturers .

1 . Connec t a R-134 a refrigeran t Recovery/Recycl -

ing/Chargin g Syste m to th e vehicl e a s show n fol -

lowin g th e equipmen t manufacturer' s instructions .

NOTE: B e sur e t o instal l th e sam e amoun t o f ne w

refrigeran t oi l bac k int o th e A/ C syste m befor e

charging .

2 . Ope n hig h pressur e valv e t o charg e th e syste m to

abou t 9 8 kP a (1. 0 kgf/cm2, 1 4 psi) , the n clos e th e

suppl y valve .

3 . Chec k th e syste m fo r leak s usin g a R-134 a refriger -

an t lea k detecto r wit h a n accurac y o f 1 4 g (0, 5 oz )

pe r yea r o r better .

4. I f yo u fin d leak s tha t requir e th e syste m to b e open -

ed (t o repai r o r replac e houses , fittings , etc.) ,

recove r th e syste m accordin g t o th e Recove r Pro -

cedur e o n pag e 22-73 ).

5 . Afte r checkin g an d repairin g leaks , th e syste m

mus t b e evacuate d (se e Syste m Evacuatio n o n

pag e 22-89 ).

Recovery/Recycling/Chargin g Syste m

ProCarManuals.com

Page 1229 of 1503

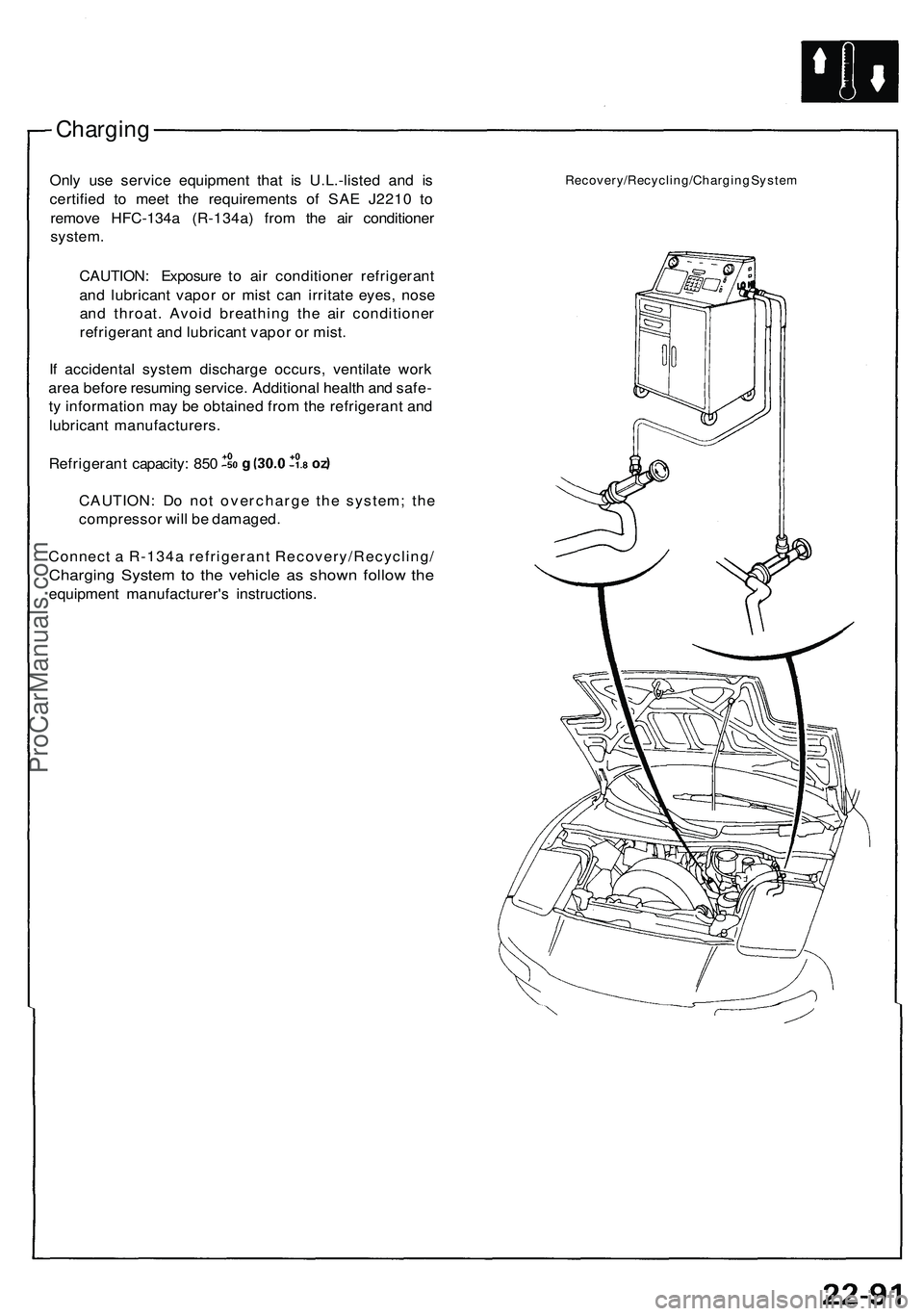

Charging

Only use service equipment that is U.L.-listed and is

certified to meet the requirements of SAE J2210 to

remove HFC-134a (R-134a) from the air conditioner

system.

CAUTION: Exposure to air conditioner refrigerant

and lubricant vapor or mist can irritate eyes, nose

and throat. Avoid breathing the air conditioner

refrigerant and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service. Additional health and safe-

ty information may be obtained from the refrigerant and

lubricant manufacturers.

Refrigerant capacity: 850

CAUTION: Do not overcharge the system; the

compressor will be damaged.

Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle as shown follow the

equipment manufacturer's instructions.

Recovery/Recycling/Charging SystemProCarManuals.com

Page 1269 of 1503

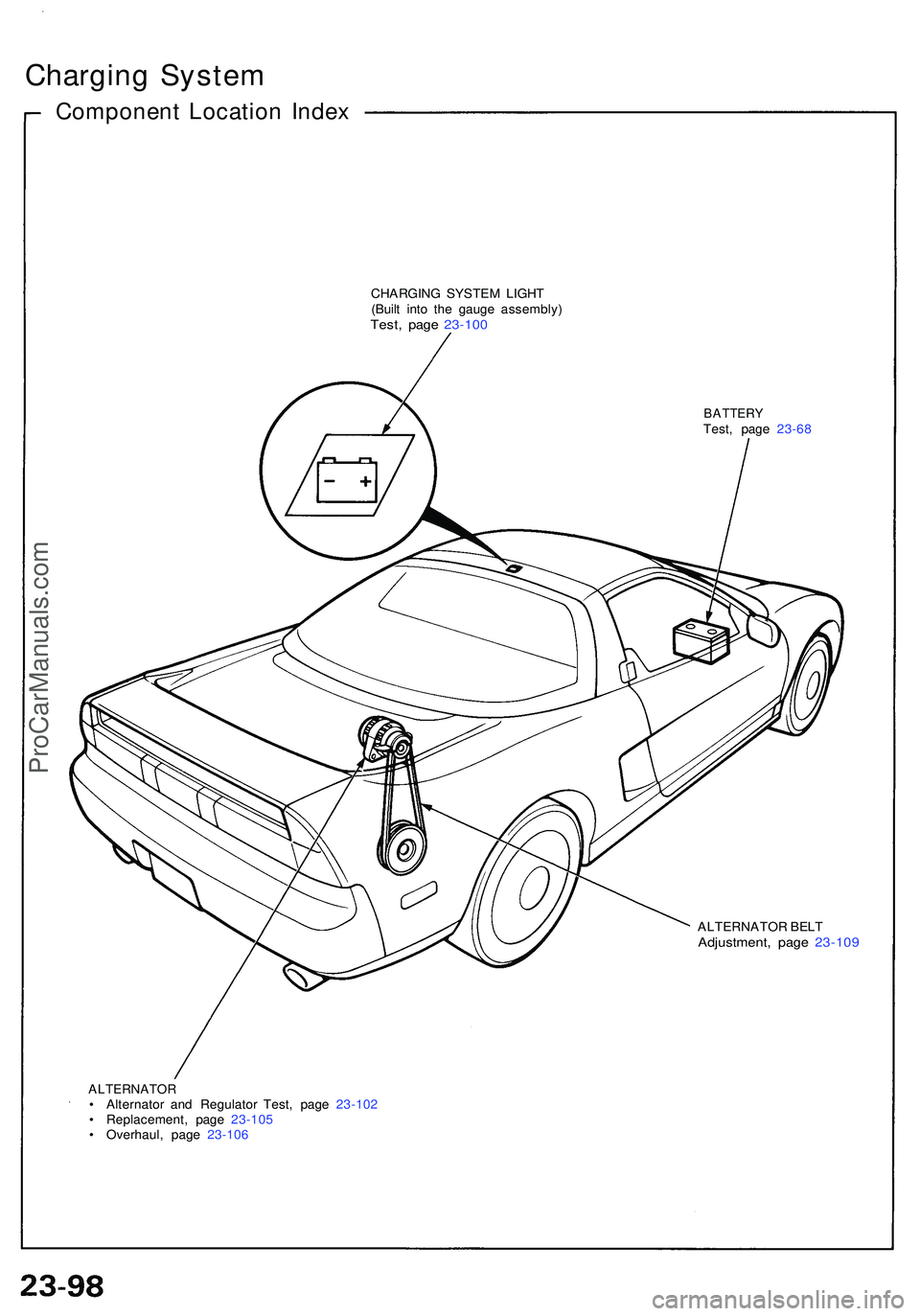

Charging Syste m

Componen t Locatio n Inde x

CHARGIN G SYSTE M LIGH T

(Buil t int o th e gaug e assembly )

Test, pag e 23-10 0

BATTER YTest, pag e 23-6 8

ALTERNATO R BEL T

Adjustment , pag e 23-10 9

ALTERNATO R• Alternato r an d Regulato r Test , pag e 23-10 2

• Replacement , pag e 23-10 5

• Overhaul , pag e 23-10 6

ProCarManuals.com

Page 1270 of 1503

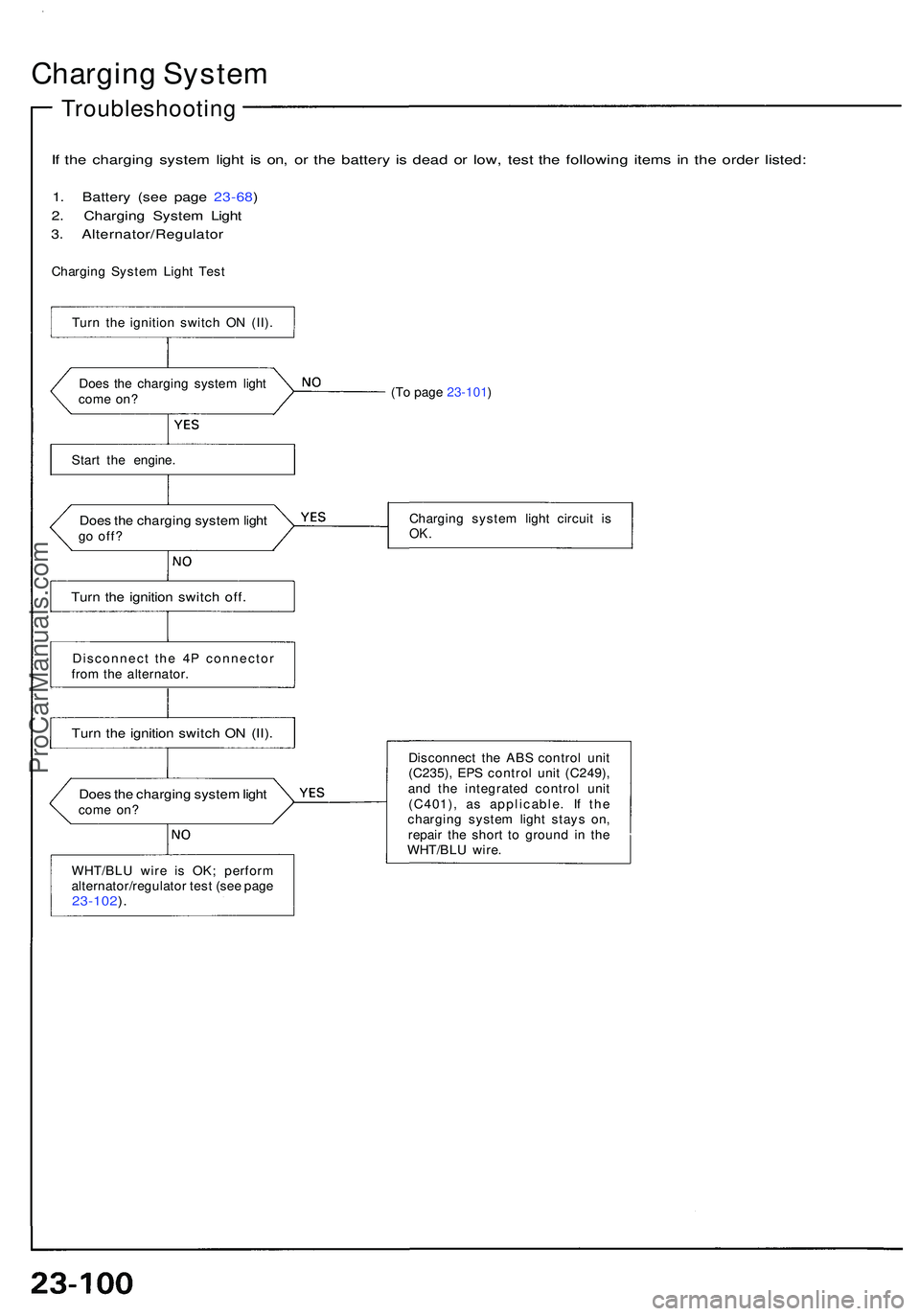

Charging Syste m

Troubleshootin g

If th e chargin g syste m ligh t i s on , o r th e batter y i s dea d o r low , tes t th e followin g item s i n th e orde r listed :

1. Batter y (se e pag e 23-68 )

2 . Chargin g Syste m Ligh t

3 . Alternator/Regulato r

Charging Syste m Ligh t Tes t

Doe s th e chargin g syste m ligh t

com e on ?

Star t th e engine .

Does th e chargin g syste m ligh tgo off ?

Turn th e ignitio n switc h off .

Disconnec t th e 4 P connecto r

fro m th e alternator .

Turn th e ignitio n switc h O N (II) .

WHT/BL U wir e i s OK ; perfor m

alternator/regulato r tes t (se e pag e

23-102 ).

(T o page 23-101 )

Chargin g syste m ligh t circui t i s

OK .

Disconnec t th e AB S contro l uni t

(C235) , EP S contro l uni t (C249) ,

an d th e integrate d contro l uni t

(C401) , a s applicable . I f th e

chargin g syste m ligh t stay s on ,

repai r th e shor t t o groun d i n th e

WHT/BL U wire .

Does th e chargin g syste m ligh tcom e on ?

Tur

n th e ignitio n switc h O N (II) .

ProCarManuals.com

Page 1272 of 1503

Charging System

Troubleshooting (cont'd)

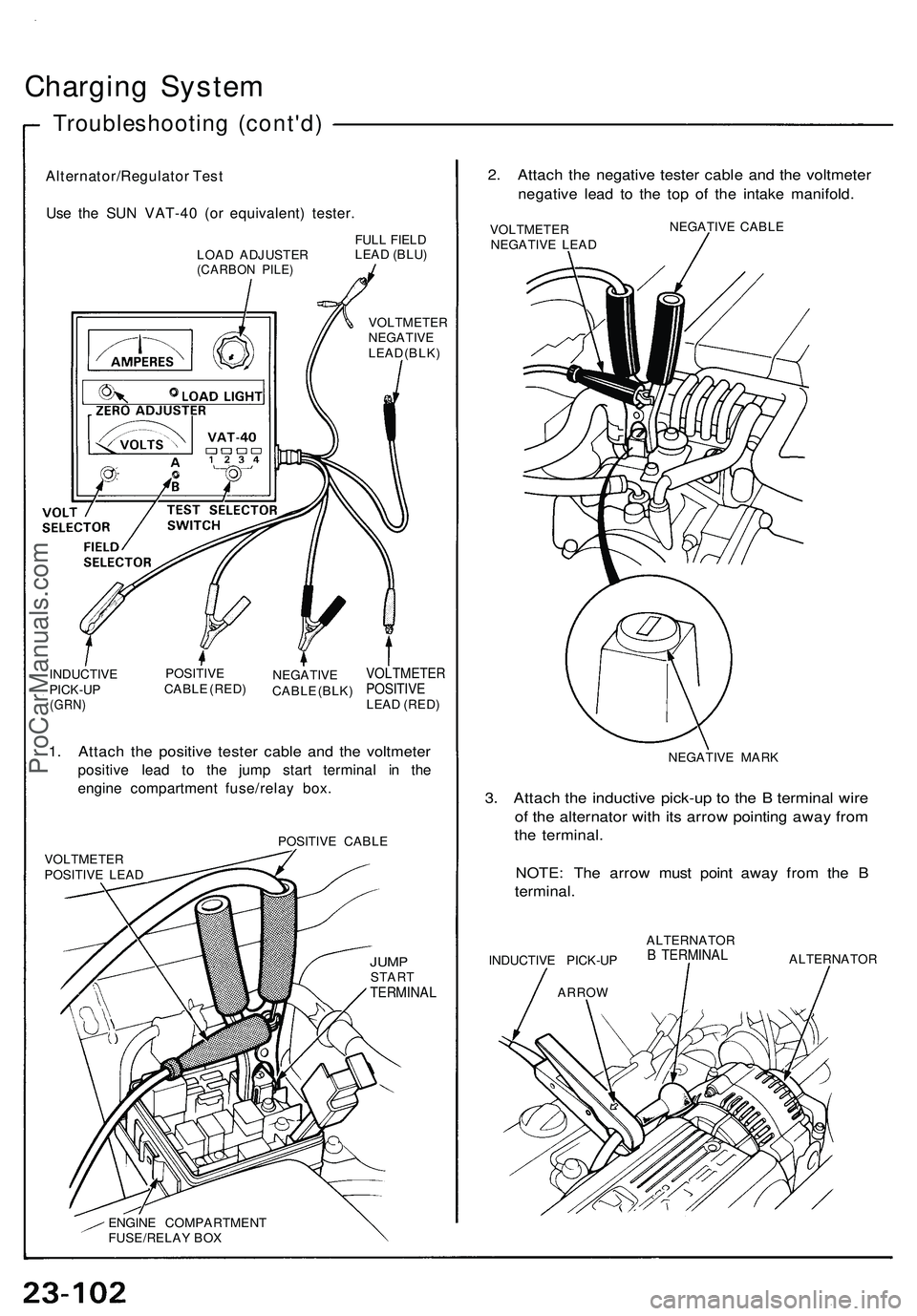

Alternator/Regulator Test

Use the SUN VAT-40 (or equivalent) tester.

LOAD ADJUSTER

(CARBON PILE)

FULL FIELD

LEAD (BLU)

VOLTMETER

NEGATIVE

LEAD (BLK)

INDUCTIVE

PICK-UP

(GRN)

POSITIVE

CABLE (RED)

NEGATIVE

CABLE (BLK)

VOLTMETER

POSITIVE

LEAD (RED)

1. Attach the positive tester cable and the voltmeter

positive lead to the jump start terminal in the

engine compartment fuse/relay box.

POSITIVE CABLE

VOLTMETER

POSITIVE LEAD

JUMP

START

TERMINAL

ENGINE COMPARTMENT

FUSE/RELAY BOX

2. Attach the negative tester cable and the voltmeter

negative lead to the top of the intake manifold.

VOLTMETER

NEGATIVE LEAD

NEGATIVE CABLE

NEGATIVE MARK

3. Attach the inductive pick-up to the B terminal wire

of the alternator with its arrow pointing away from

the terminal.

NOTE: The arrow must point away from the B

terminal.

INDUCTIVE PICK-UP

ARROW

ALTERNATOR

B TERMINAL

ALTERNATORProCarManuals.com

Page 1273 of 1503

NOTE: B e sur e th e batter y i s sufficientl y charge d (se e

page 23-68 ).

Connec t th e Su n VAT-4 0 (se e

pag e 23-102 ) an d tur n th e selec -

to r switc h to positio n 1 (starting) .

Star t th e engine , an d le t i t idl e

unti l i t reache s norma l operatin g

temperature .

Rais e th e engin e spee d t o 2,00 0

rpm , an d hol d i t there .

I s th e voltag e ove r 15. 1 V ?

Replace th e voltag e regulator .

Releas e th e accelerato r pedal ,

an d le t th e engin e idle .

Mak e sur e al l accessorie s ar e

turne d off . Tur n th e selecto r

switch to positio n 2 (charging) .

Remove th e inductiv e pick-up ,

an d zer o th e ammeter .

Attac h th e inductiv e pick-u p t o

th e B termina l wir e o f th e alterna -tor wit h it s arro w pointin g awa y

fro m th e terminal .

Rais e th e engin e spee d t o 2,00 0

rpm , an d hol d it there .

I s th e voltag e les s tha n 13. 9 V ?

Test th e batter y (se e pag e 23-68 ).

(T o page 23-104 )

(cont'd)

ProCarManuals.com