coolant temperature ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 141 of 1503

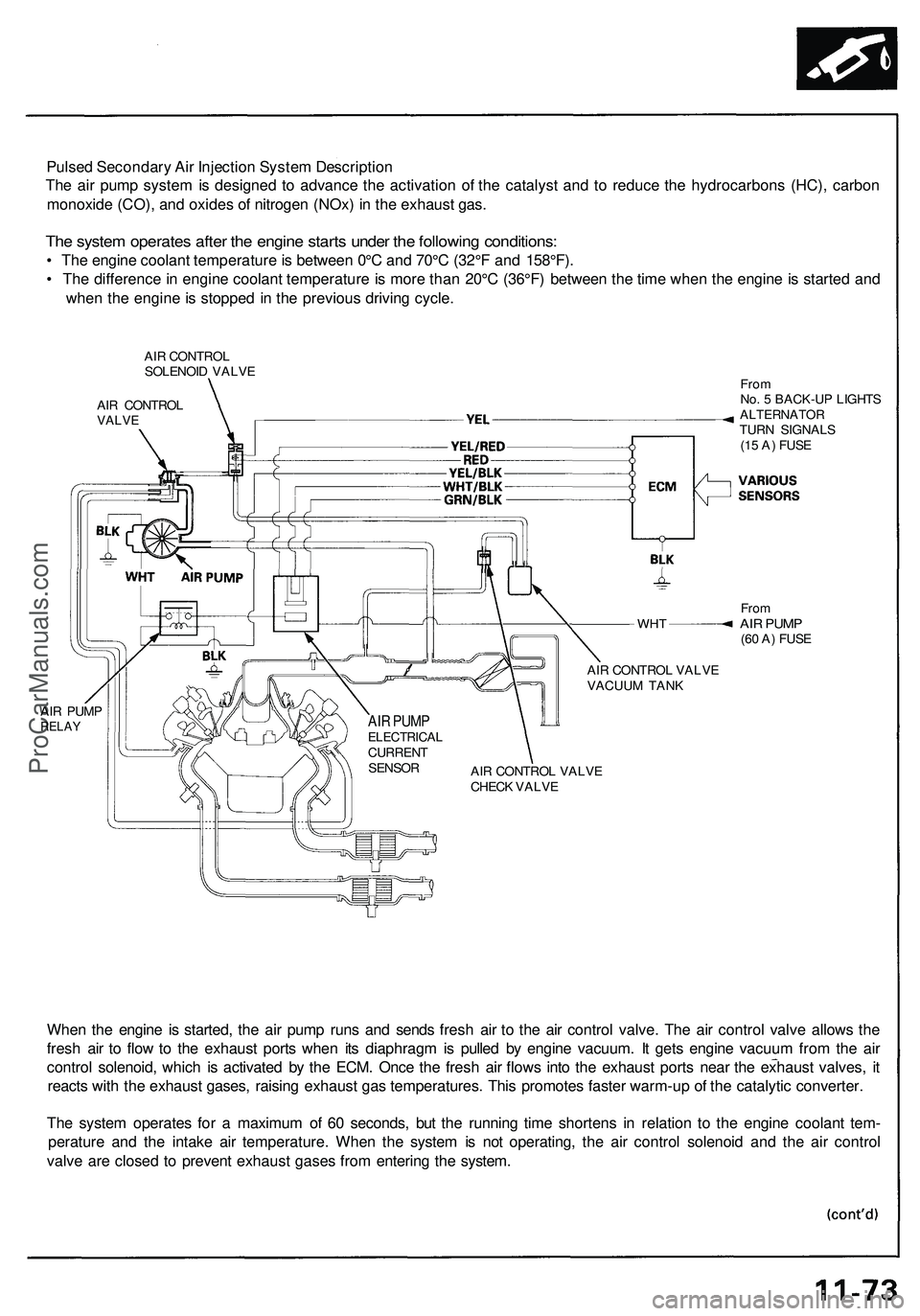

Pulsed Secondary Air Injection System Description

The air pump system is designed to advance the activation of the catalyst and to reduce the hydrocarbons (HC), carbon

monoxide (CO), and oxides of nitrogen (NOx) in the exhaust gas.

The system operates after the engine starts under the following conditions:

• The engine coolant temperature is between 0°C and 70°C (32°F and 158°F).

• The difference in engine coolant temperature is more than 20°C (36°F) between the time when the engine is started and

when the engine is stopped in the previous driving cycle.

AIR CONTROL

SOLENOID VALVE

AIR CONTROL

VALVE

WHT

AIR PUMP

RELAY

From

No. 5 BACK-UP LIGHTS

ALTERNATOR

TURN SIGNALS

(15 A) FUSE

From

AIR PUMP

(60 A) FUSE

AIR CONTROL VALVE

VACUUM TANK

AIR CONTROL VALVE

CHECK VALVE

When the engine is started, the air pump runs and sends fresh air to the air control valve. The air control valve allows the

fresh air to flow to the exhaust ports when its diaphragm is pulled by engine vacuum. It gets engine vacuum from the air

control solenoid, which is activated by the ECM. Once the fresh air flows into the exhaust ports near the exhaust valves, it

reacts with the exhaust gases, raising exhaust gas temperatures. This promotes faster warm-up of the catalytic converter.

The system operates for a maximum of 60 seconds, but the running time shortens in relation to the engine coolant tem-

perature and the intake air temperature. When the system is not operating, the air control solenoid and the air control

valve are closed to prevent exhaust gases from entering the system.

AIR PUMP

ELECTRICAL

CURRENT

SENSORProCarManuals.com

Page 164 of 1503

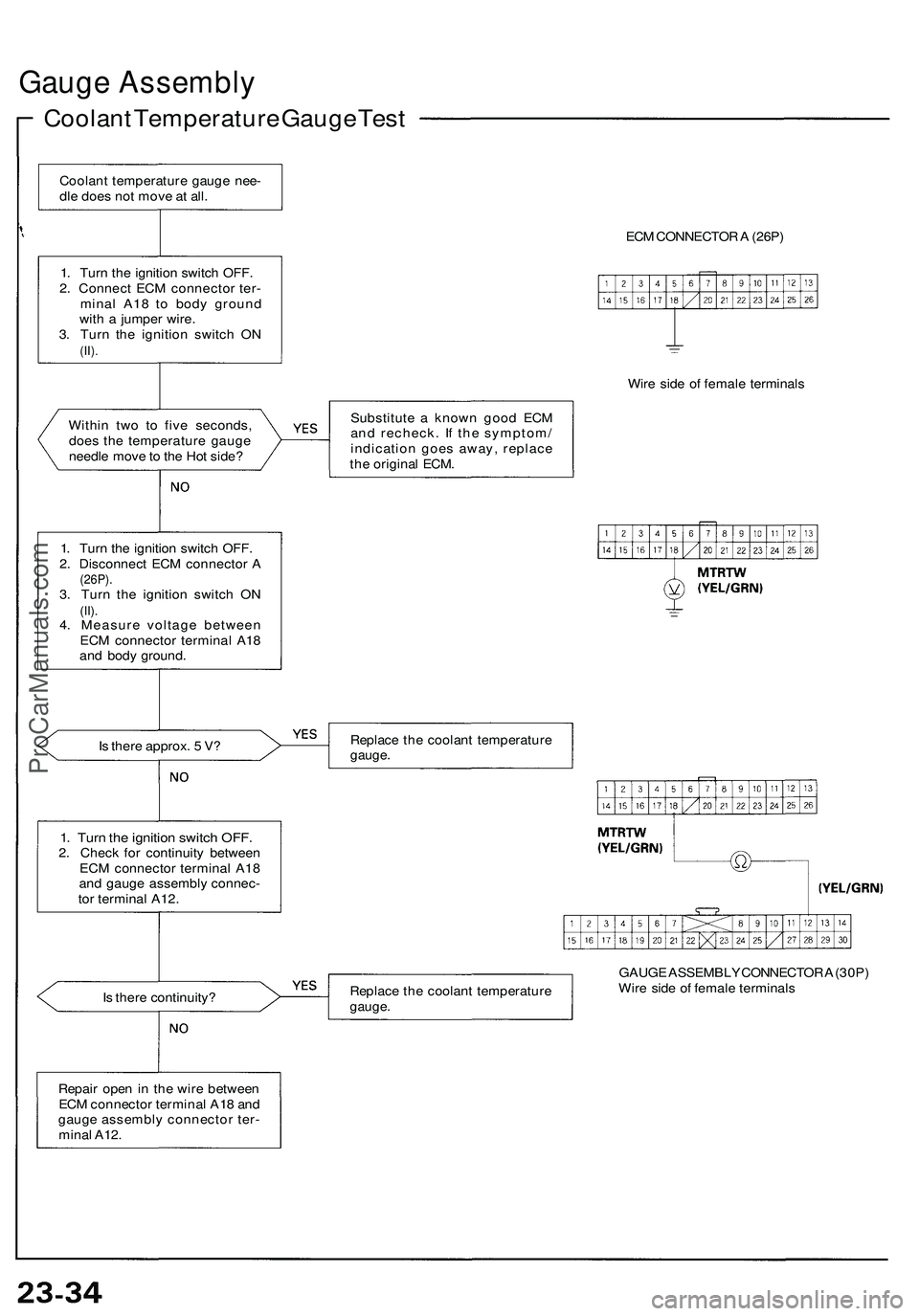

Gauge Assembly

Coolant Temperature Gauge Test

Within two to five seconds,

does the temperature gauge

needle move to the Hot side?

Is there approx. 5 V?

1. Turn the ignition switch OFF.

2. Check for continuity between

ECM connector terminal A18

and gauge assembly connec-

tor terminal A12.

Is there continuity?

ECM CONNECTOR A (26P)

Wire side of female terminals

Substitute a known good ECM

and recheck. If the symptom/

indication goes away, replace

the original ECM.

Replace the coolant temperature

gauge.

Replace the coolant temperature

gauge.

GAUGE ASSEMBLY CONNECTOR A (30P)

Wire side of female terminals

Coolant temperature gauge nee-

dle does not move at all.

1. Turn the ignition switch OFF.

2. Connect ECM connector ter-

minal A18 to body ground

with a jumper wire.

3. Turn the ignition switch ON

(II).

1. Turn the ignition switch OFF.

2. Disconnect ECM connector A

(26P).

3. Turn the ignition switch ON

(II).

4. Measure voltage between

ECM connector terminal A18

and body ground.

Repair open in the wire between

ECM connector terminal A18 and

gauge assembly connector ter-

minal A12.ProCarManuals.com

Page 165 of 1503

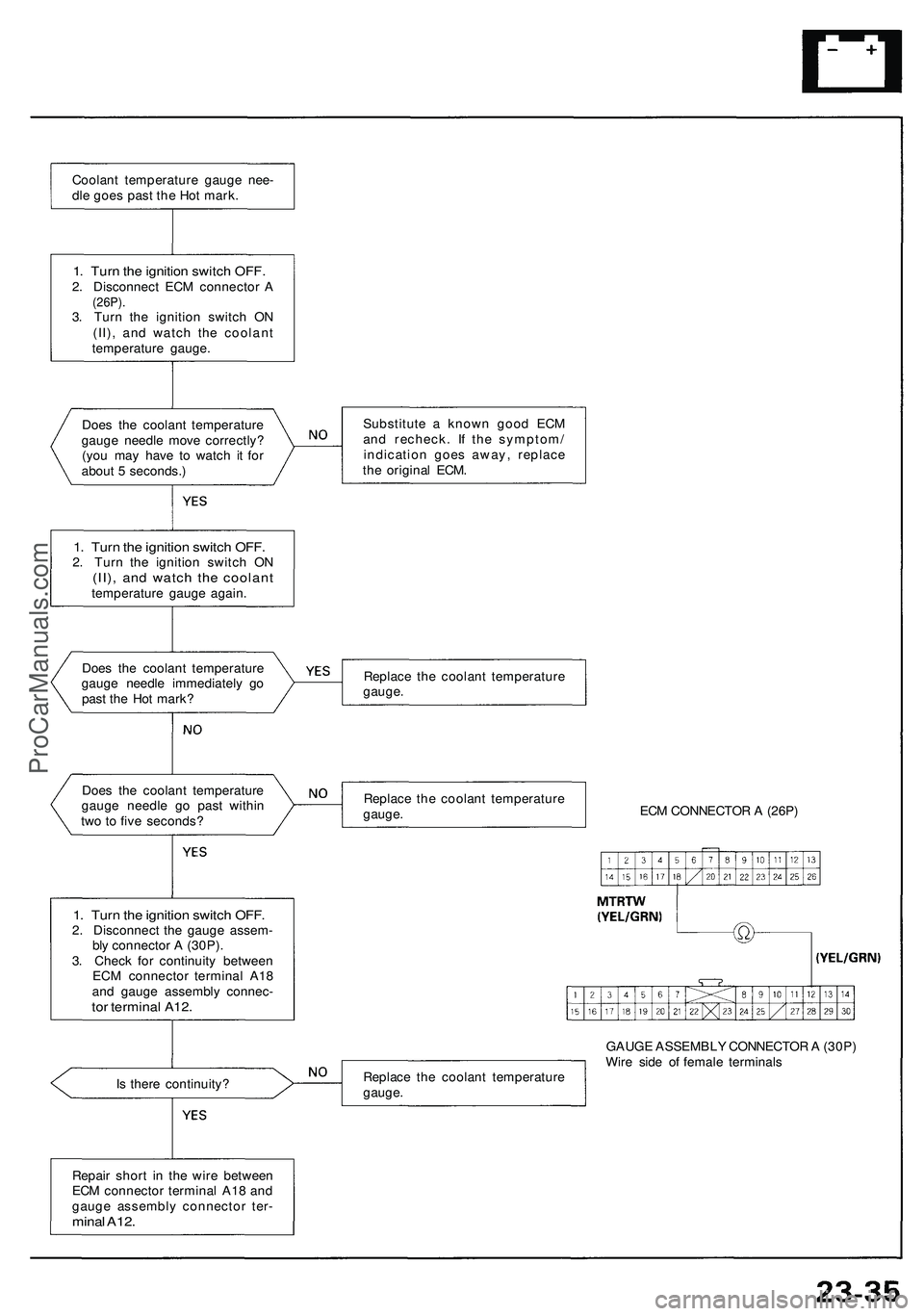

Does the coolant temperature

gauge needle move correctly?

(you may have to watch it for

about 5 seconds.)

1. Turn the ignition switch OFF.

2. Turn the ignition switch ON

(II), and watch the coolant

temperature gauge again.

Does the coolant temperature

gauge needle immediately go

past the Hot mark?

Does the coolant temperature

gauge needle go past within

two to five seconds?

1. Turn the ignition switch OFF.

2. Disconnect the gauge assem-

bly connector A (30P).

3. Check for continuity between

ECM connector terminal A18

and gauge assembly connec-

tor terminal A12.

Is there continuity?

Substitute a known good ECM

and recheck. If the symptom/

indication goes away, replace

the original ECM.

Replace the coolant temperature

gauge.

Replace the coolant temperature

gauge.

ECM CONNECTOR A (26P)

Replace the coolant temperature

gauge.

GAUGE ASSEMBLY CONNECTOR A (30P)

Wire side of female terminals

Repair short in the wire between

ECM connector terminal A18 and

gauge assembly connector ter-

minal A12.

1. Turn the ignition switch OFF.

2. Disconnect ECM connector A

(26P).

3. Turn the ignition switch ON

(II), and watch the coolant

temperature gauge.

Coolant temperature gauge nee-

dle goes past the Hot mark.ProCarManuals.com

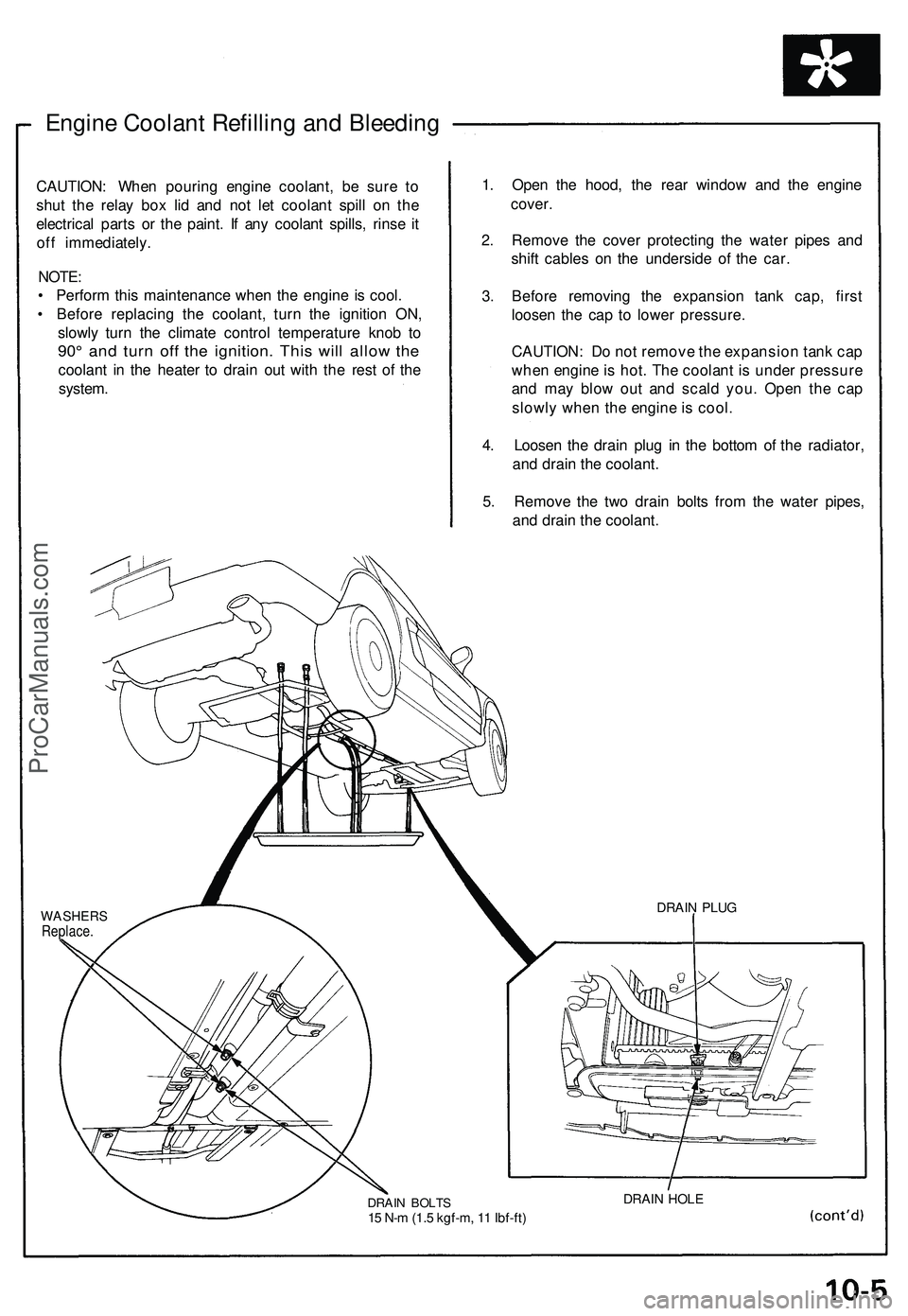

Page 193 of 1503

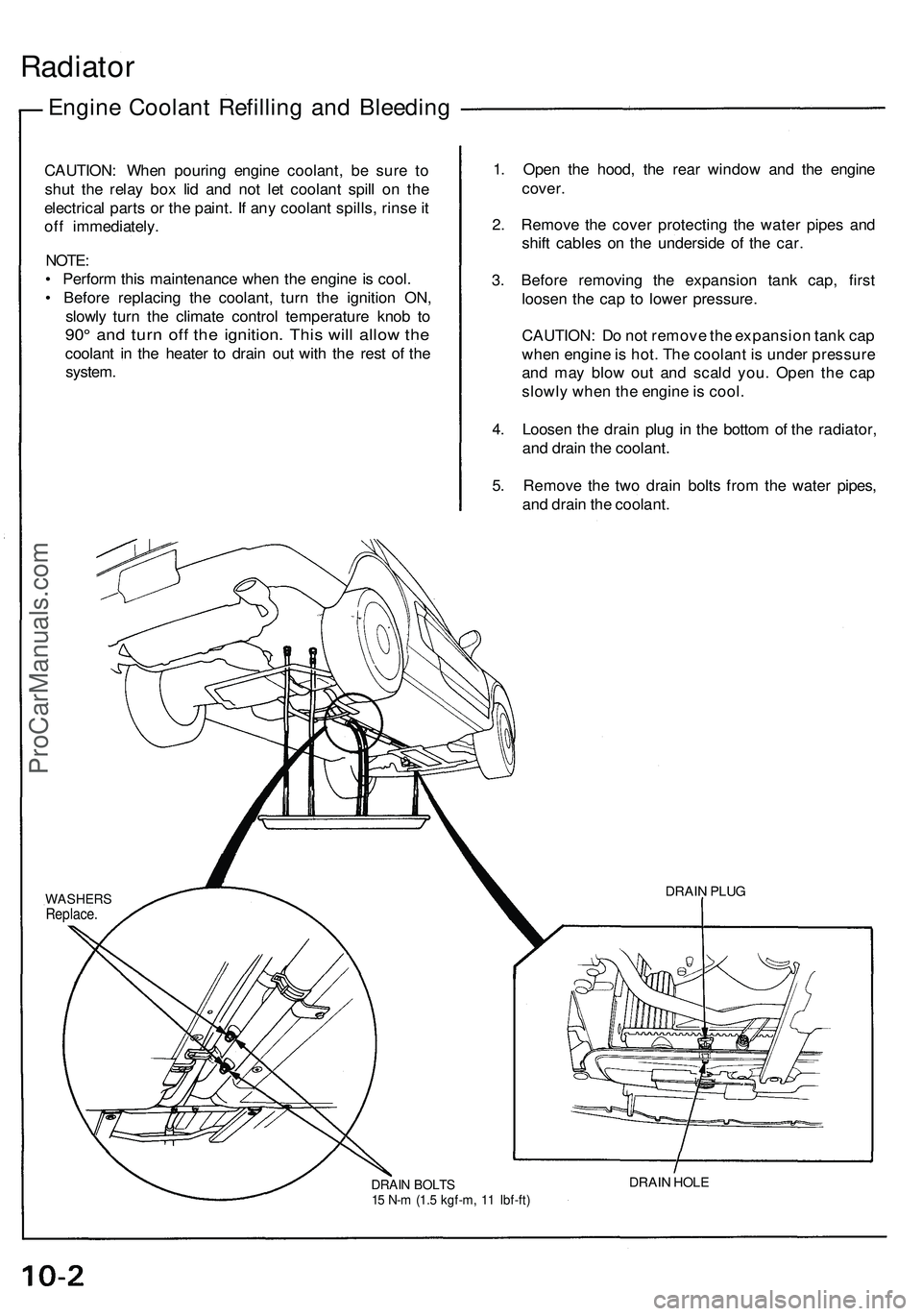

Radiator

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

DRAIN BOLTS

15 N-m (1.5 kgf-m, 11 Ibf-ft)

DRAIN HOLE

DRAIN PLUG

WASHERS

Replace.ProCarManuals.com

Page 438 of 1503

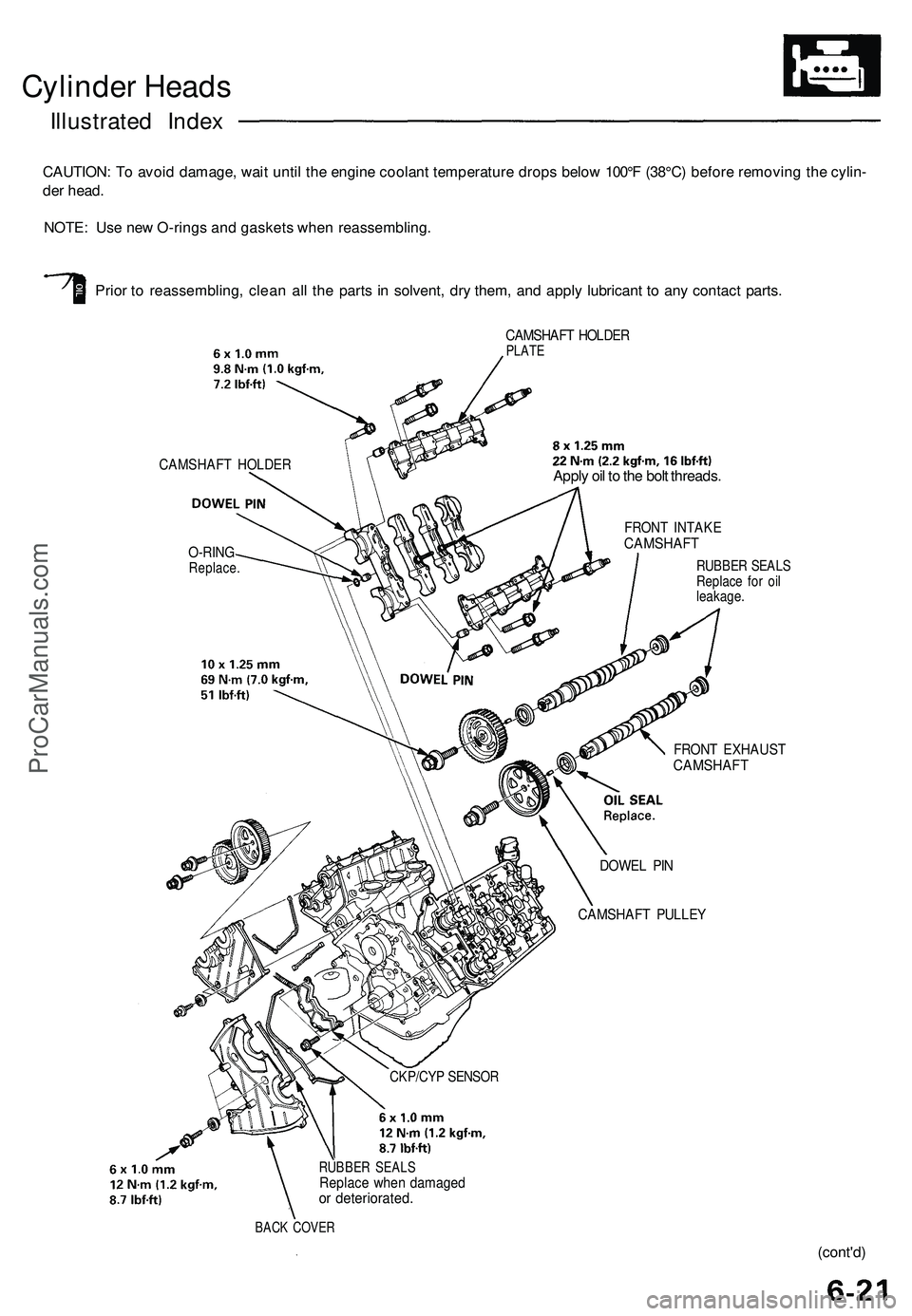

Cylinder Heads

Illustrated Index

CAUTION: To avoid damage, wait until the engine coolant temperature drops below 100°F (38°C) before removing the cylin-

der head.

NOTE: Use new O-rings and gaskets when reassembling.

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact parts.

CAMSHAFT HOLDER

O-RING

Replace.

CAMSHAFT HOLDER

PLATE

CKP/CYP SENSOR

RUBBER SEALS

Replace when damaged

or deteriorated.

BACK COVER

Apply oil to the bolt threads.

FRONT INTAKE

CAMSHAFT

RUBBER SEALS

Replace for oil

leakage.

FRONT EXHAUST

CAMSHAFT

DOWEL PIN

CAMSHAFT PULLEY

(cont'd)ProCarManuals.com

Page 521 of 1503

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

WASHERS

Replace.

DRAIN BOLTS

15 N-m (1.5 kgf-m, 11 Ibf-ft)

DRAIN HOLE

DRAIN PLUGProCarManuals.com

Page 570 of 1503

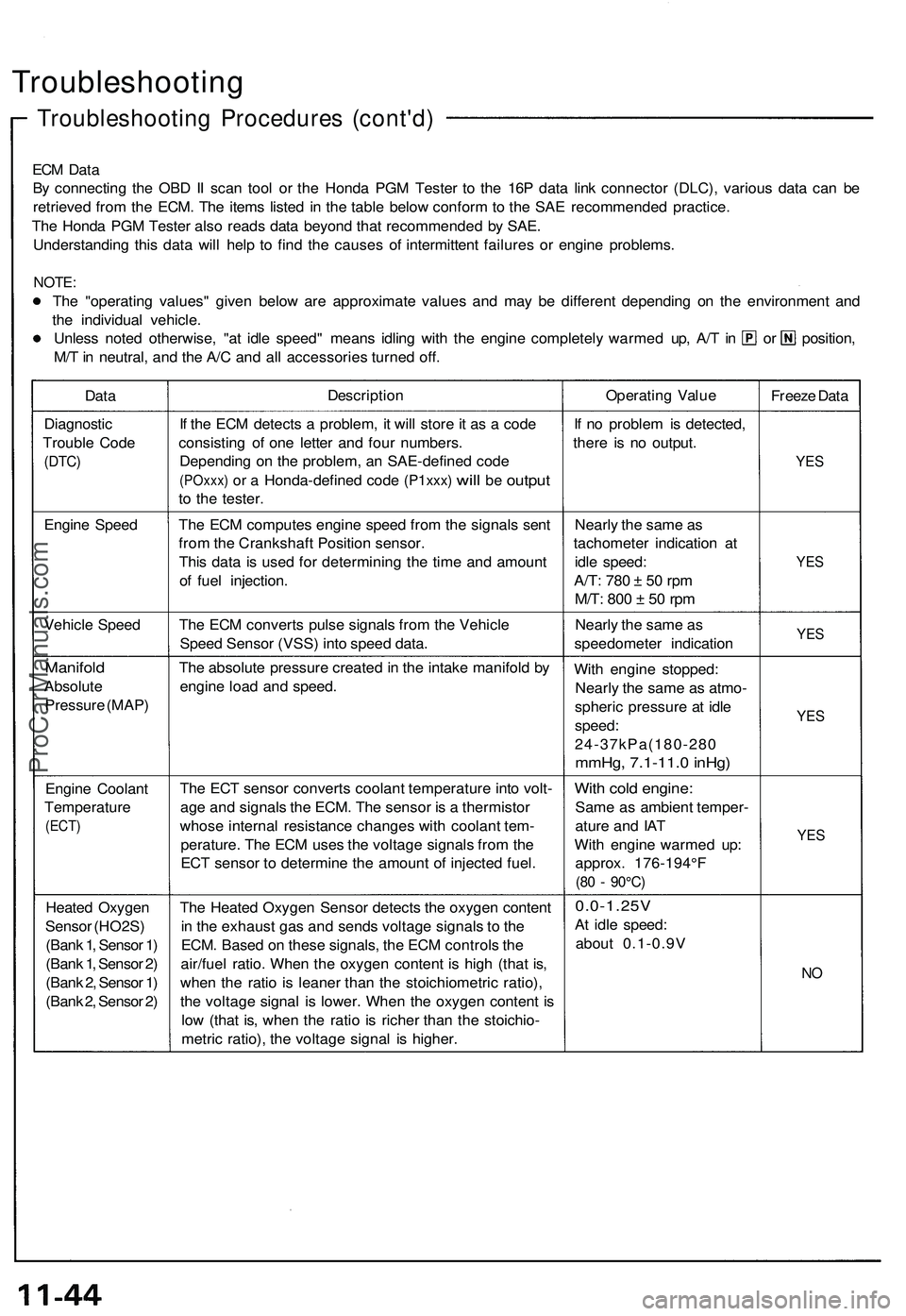

Troubleshooting

Troubleshooting Procedures (cont'd)

ECM Data

By connecting the OBD II scan tool or the Honda PGM Tester to the 16P data link connector (DLC), various data can be

retrieved from the ECM. The items listed in the table below conform to the SAE recommended practice.

The Honda PGM Tester also reads data beyond that recommended by SAE.

Understanding this data will help to find the causes of intermittent failures or engine problems.

NOTE:

The "operating values" given below are approximate values and may be different depending on the environment and

the individual vehicle.

Unless noted otherwise, "at idle speed" means idling with the engine completely warmed up, A/T in or position,

M/T in neutral, and the A/C and all accessories turned off.

Data

Description

Operating Value

Freeze Data

Diagnostic

Trouble Code

(DTC)

If the ECM detects a problem, it will store it as a code

consisting of one letter and four numbers.

Depending on the problem, an SAE-defined code

(POxxx)

or a

Honda-defined code

(P1xxx)

will

be

output

to the tester.

If no problem is detected,

there is no output.

YES

Engine Speed

The ECM computes engine speed from the signals sent

from the Crankshaft Position sensor.

This data is used for determining the time and amount

of fuel injection.

Nearly the same as

tachometer indication at

idle speed:

A/T:

780 ± 50 rpm

M/T:

800 ± 50 rpm

YES

Vehicle Speed

The ECM converts pulse signals from the Vehicle

Speed Sensor (VSS) into speed data.

Nearly the same as

speedometer indication

YES

Manifold

Absolute

Pressure (MAP)

The absolute pressure created in the intake manifold by

engine load and speed.

With engine stopped:

Nearly the same as atmo-

spheric pressure at idle

speed:

24-37kPa(180-280

mmHg, 7.1-11.0 inHg)

YES

Engine Coolant

Temperature

(ECT)

The ECT sensor converts coolant temperature into volt-

age and signals the ECM. The sensor is a thermistor

whose internal resistance changes with coolant tem-

perature. The ECM uses the voltage signals from the

ECT sensor to determine the amount of injected fuel.

With cold engine:

Same as ambient temper-

ature and IAT

With engine warmed up:

approx. 176-194°F

(80 - 90°C)

YES

Heated Oxygen

Sensor (HO2S)

(Bank 1, Sensor 1)

(Bank 1, Sensor 2)

(Bank 2, Sensor 1)

(Bank 2, Sensor 2)

The Heated Oxygen Sensor detects the oxygen content

in the exhaust gas and sends voltage signals to the

ECM. Based on these signals, the ECM controls the

air/fuel ratio. When the oxygen content is high (that is,

when the ratio is leaner than the stoichiometric ratio),

the voltage signal is lower. When the oxygen content is

low (that is, when the ratio is richer than the stoichio-

metric ratio), the voltage signal is higher.

0.0-1.25V

At idle speed:

about 0.1-0.9V

NOProCarManuals.com

Page 586 of 1503

PGM-FI System

System Description (cont'd)

3. Fuel Cut-off Control

During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,500 rpm.

Fuel cut-off action also takes place when engine speed exceeds 8,300 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

4. A/C Compressor Clutch Relay

When the ECM receives a demand for cooling from the air conditioning system, it delays the compressor from being

energized, and enriches the mixture to assure smooth translation to the A/C mode.

5. Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is below 153°F (67°C), the ECM controls the EVAP purge control solenoid valve

which cuts vacuum to the EVAP purge control canister diaphragm.

6. Intake Air Bypass (IAB) Control Solenoid Valve

When the engine speed is below 4,800 rpm, the IAB control solenoid valve is activated by a signal from the ECM. Intake

air then flows through the smaller chamber, and high torque is delivered. To increase air flow at engine speeds higher

than 4,800 rpm, the solenoid valve is deactivated by the ECM, and the intake air flows through the larger chamber.

7. Exhaust Gas Recirculation (EGR) Control Solenoid Valve

When the EGR is required for control of oxides of nitrogen (NOx) emissions, the ECM supplies ground to the EGR

control solenoid valve which supplies regulated vacuum to the EGR valve.

ECM Fail-safe/Back-up Functions

1. Fail-Safe Function

When an abnormality occurs in a signal from a sensor, the ECM ignores that signal and assumes a pre-programmed

valve for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM itself, the fuel injectors are controlled by a back-up circuit independent of the

system in order to permit minimal driving.

3. Self-diagnosis Function [Malfunction Indicator Lamp (MIL)]

When an abnormality occurs in a signal from a sensor, the ECM lights the MIL and stores the diagnostic trouble code

in erasable memory. When the ignition is initially turned on, the ECM supplies ground for the MIL for two seconds to

check the MIL bulb condition.

4. Two Trip Detection Method

To prevent false indications, the Two Trip Detection Method is used for the H02S, fuel metering-related, idle control

system, ECT sensor, EGR system self-diagnostic functions and EVAP control system. When an abnormality occurs,

the ECM stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (II)

again, the ECM informs the driver by lighting the MIL.

However, to ease troubleshooting, this function is cancelled when you short the service check connector. The MIL will

then blink immediately when an abnormality occurs.

5. Two (or three) Driving Cycle Detection Method

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. If misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles,

or TWC deterioration is detected during three consecutive driving cycles, the ECM turns the MIL on.

However,

to

ease

troubleshooting,

this

function

is

cancelled when

you

short

the

service check connector.

The MIL

will

then blink immediately when an abnormality occurs.ProCarManuals.com

Page 756 of 1503

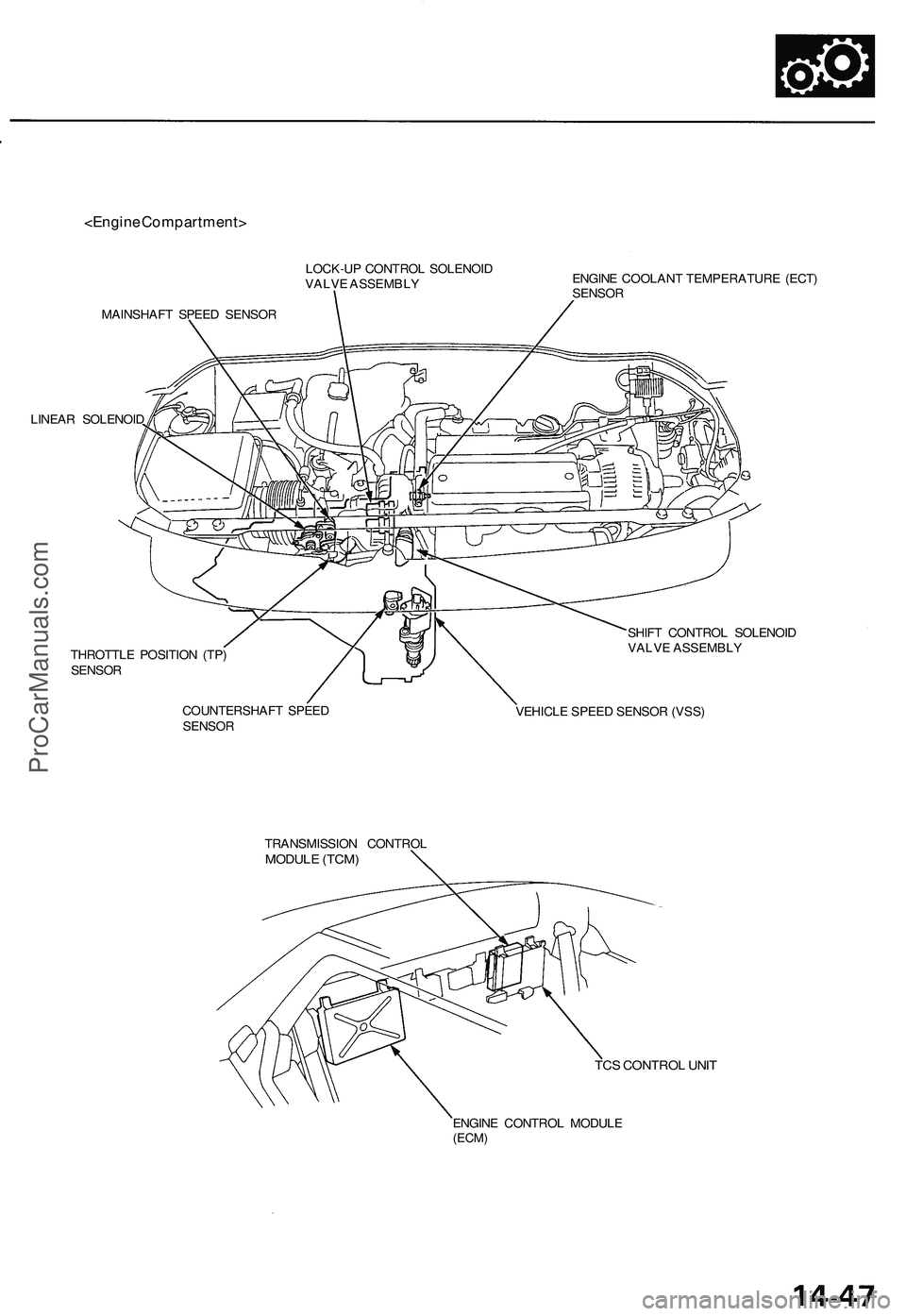

LOCK-UP CONTROL SOLENOID

VALVE ASSEMBLY

MAINSHAFT SPEED SENSOR

LINEAR SOLENOID

ENGINE COOLANT TEMPERATURE (ECT)

SENSOR

THROTTLE POSITION (TP)

SENSOR

COUNTERSHAFT SPEED

SENSOR

SHIFT CONTROL SOLENOID

VALVE ASSEMBLY

VEHICLE SPEED SENSOR (VSS)

TRANSMISSION CONTROL

MODULE (TCM)

TCS CONTROL UNIT

ENGINE CONTROL MODULE

(ECM)ProCarManuals.com

Page 1184 of 1503

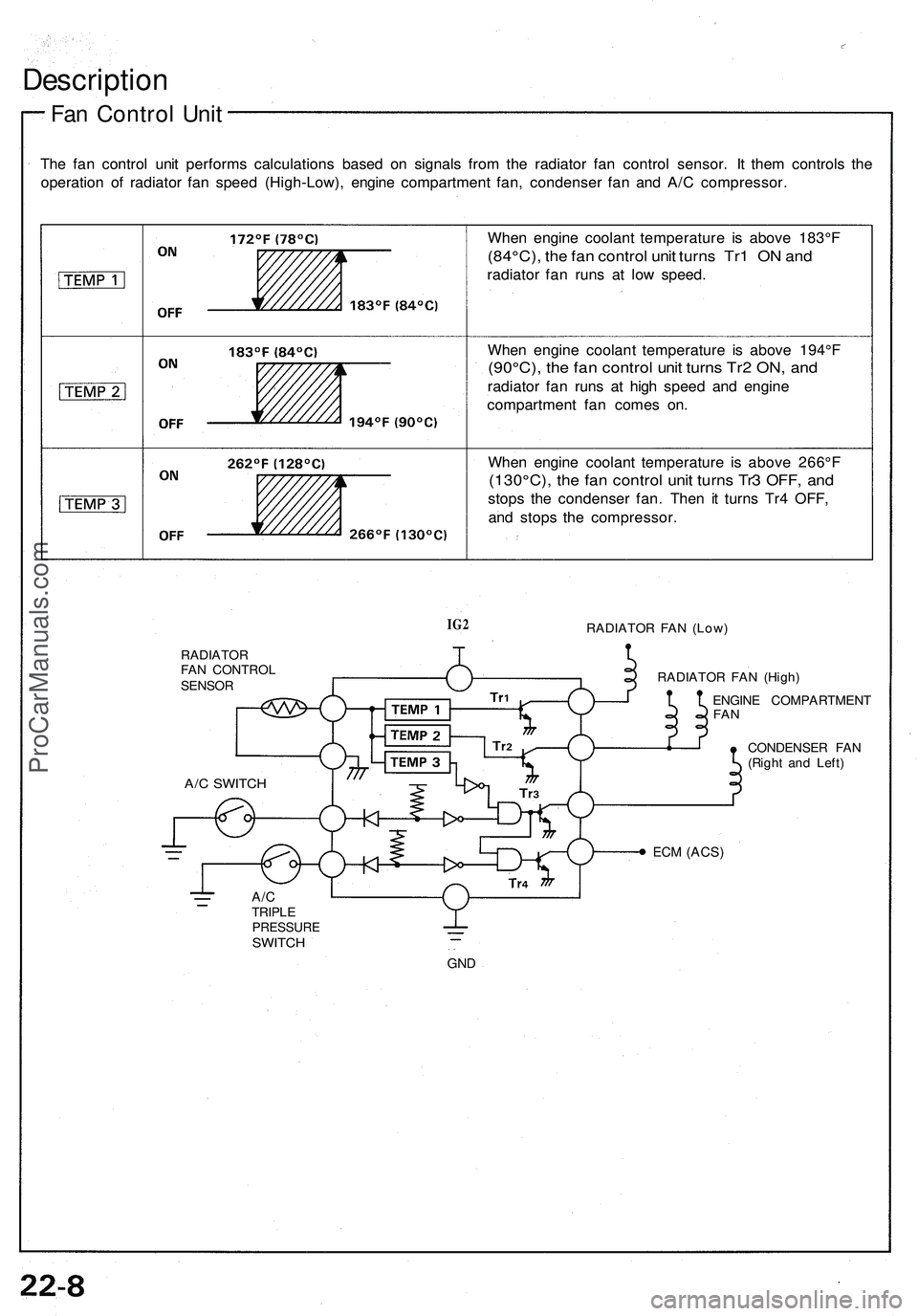

Description

Fan Control Unit

The fan control unit performs calculations based on signals from the radiator fan control sensor. It them controls the

operation of radiator fan speed (High-Low), engine compartment fan, condenser fan and A/C compressor.

When engine coolant temperature is above 183°F

(84°C), the fan control unit turns Tr1 ON and

radiator fan runs at low speed.

When engine coolant temperature is above 194°F

(90°C), the fan control unit turns Tr2 ON, and

radiator fan runs at high speed and engine

compartment fan comes on.

When engine coolant temperature is above 266°F

(130°C), the fan control unit turns Tr3 OFF, and

stops the condenser fan. Then it turns Tr4 OFF,

and stops the compressor.

IG2

RADIATOR FAN (Low)

RADIATOR

FAN CONTROL

SENSOR

RADIATOR FAN (High)

ENGINE COMPARTMENT

FAN

CONDENSER FAN

(Right and Left)

ECM

(ACS)

A/C

TRIPLE

PRESSURE

SWITCH

GND

A/C SWITCHProCarManuals.com