headlights ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 275 of 1503

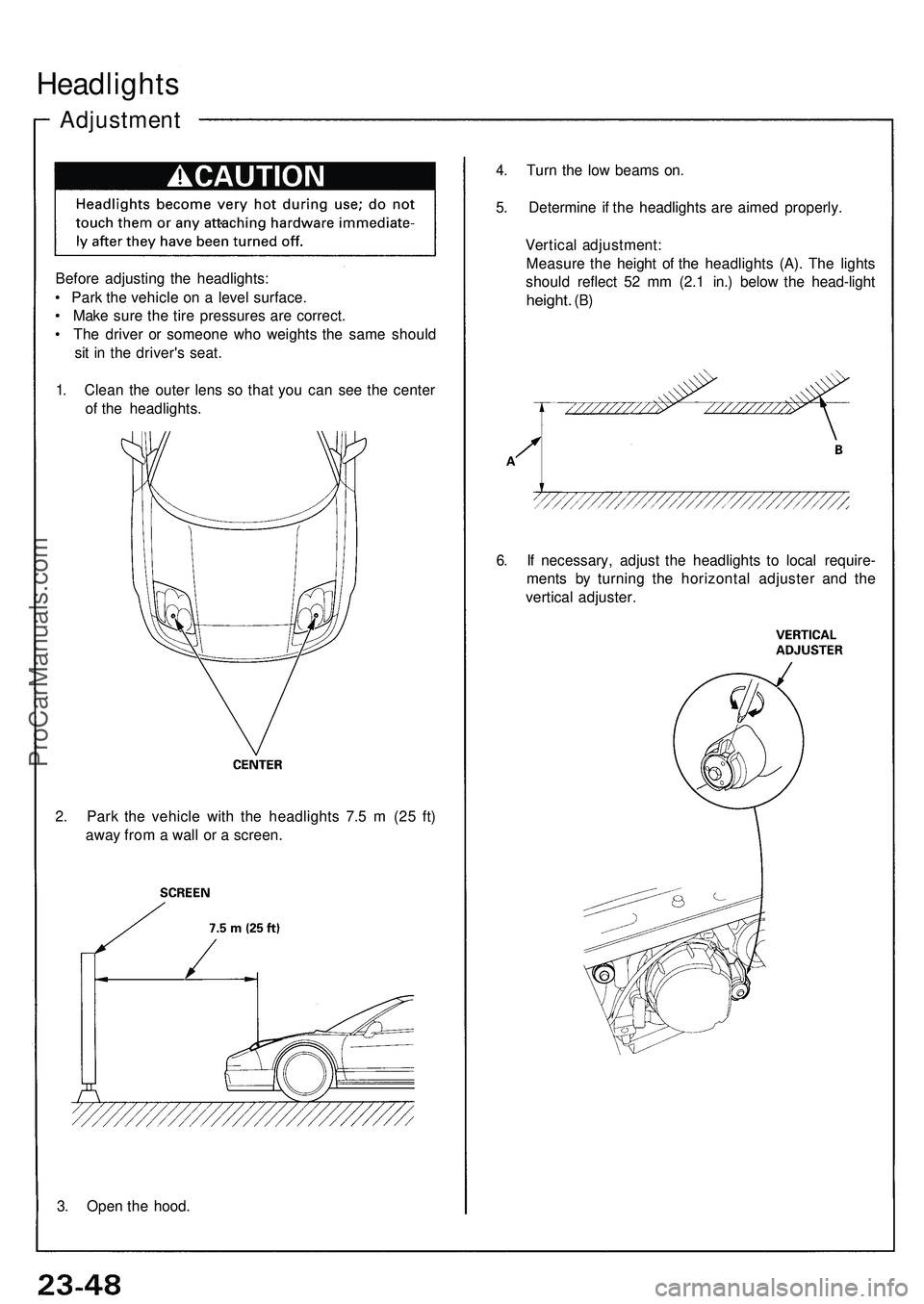

Headlights

Adjustmen t

Before adjustin g th e headlights :

• Par k th e vehicl e o n a leve l surface .

• Mak e sur e th e tir e pressure s ar e correct .

• Th e drive r o r someon e wh o weight s th e sam e shoul d

si t i n th e driver' s seat .

1 . Clea n th e oute r len s s o tha t yo u ca n se e th e cente r

o f th e headlights . 4

. Tur n th e lo w beam s on .

5 . Determin e i f th e headlight s ar e aime d properly .

Vertica l adjustment :

Measur e th e heigh t o f th e headlight s (A) . Th e light s

shoul d reflec t 5 2 m m (2. 1 in. ) belo w th e head-ligh t

height. (B)

6. I f necessary , adjus t th e headlight s t o loca l require -

ment s b y turnin g th e horizonta l adjuste r an d th e

vertica l adjuster .

2 . Par k th e vehicl e wit h th e headlight s 7. 5 m (2 5 ft )

awa y fro m a wal l o r a screen .

3 . Ope n th e hood .

ProCarManuals.com

Page 370 of 1503

3-15

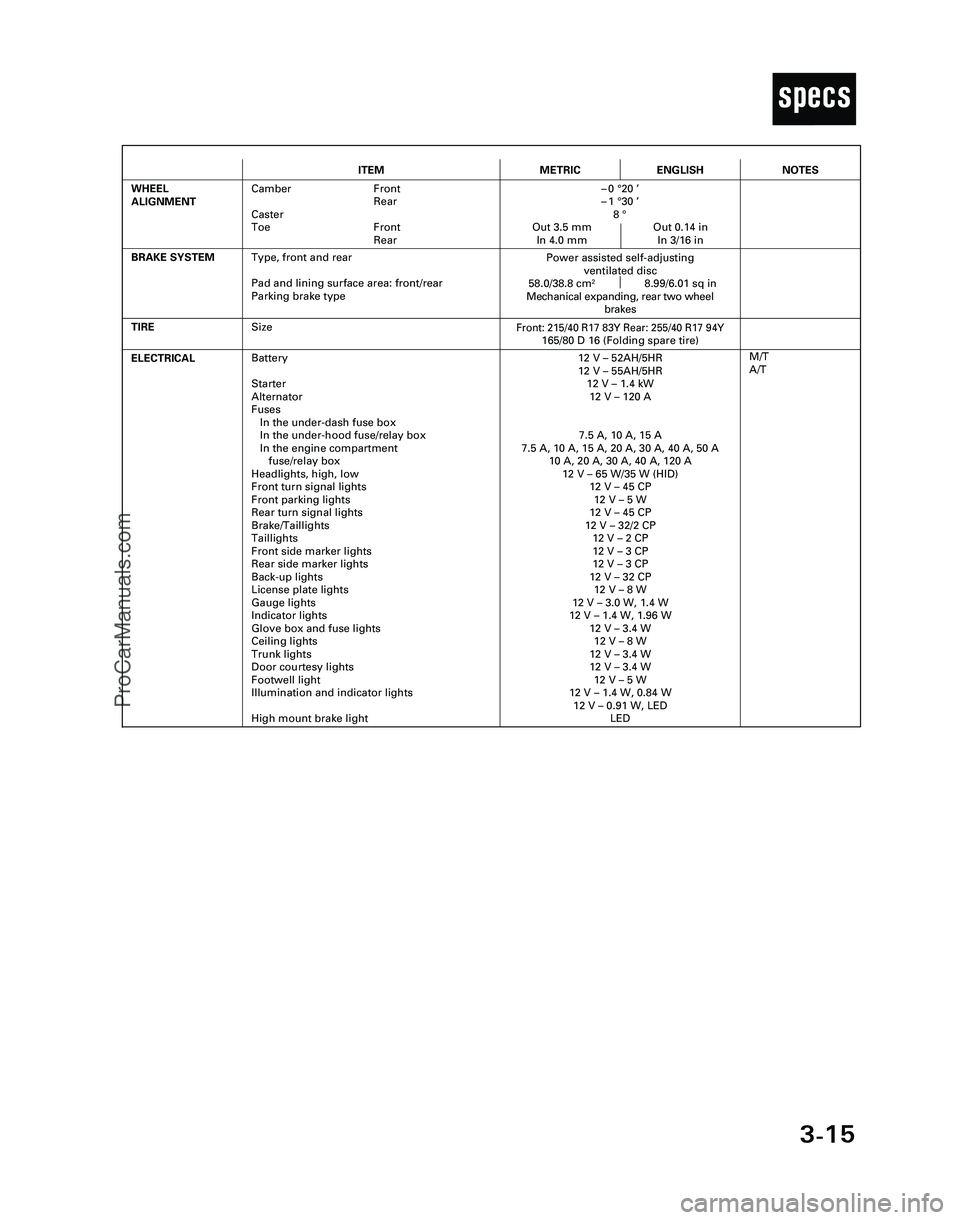

T

ITEMMETRICENGLISH

ELECTRICALBattery

Starter

Alternator

Fuses

In the under-dash fuse box

In the under-hood fuse/relay box

In the engine compartment

fuse/relay box

Headlights, high, low

Front turn signal lights

Front parking lights

Rear turn signal lights

Brake/Taillights

Taillights

Front side marker lights

Rear side marker lights

Back-up lights

License plate lights

Gauge lights

Indicator lights

Glove box and fuse lights

Ceiling lights

Trunk lights

Door courtesy lights

Footwell light

Illumination and indicator lights

High mount brake light12 V – 52AH/5HR

12 V – 55AH/5HR

12 V – 1.4 kW

12 V – 120 A

7.5 A, 10 A, 15 A

7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A, 50 A

10 A, 20 A, 30 A, 40 A, 120 A

12 V – 65 W/35 W (HID)

12 V – 45 CP

12 V – 5 W

12 V – 45 CP

12 V – 32/2 CP

12 V – 2 CP

12 V – 3 CP

12 V – 3 CP

12 V – 32 CP

12 V – 8 W

12 V – 3.0 W, 1.4 W

12 V – 1.4 W, 1.96 W

12 V – 3.4 W

12 V – 8 W

12 V – 3.4 W

12 V – 3.4 W

12 V – 5 W

12 V – 1.4 W, 0.84 W

12 V – 0.91 W, LED

LED

TIRE

M/T

A/T

BRAKE SYSTEM

Front: 215/40 R17 83Y Rear: 255/40 R17 94Y165/80 D 16 (Folding spare tire)

Power assisted self-adjusting

ventilated disc

58.0/38.8 cm

28.99/6.01 sq in

Mechanical expanding, rear two wheel

brakes

WHEEL

ALIGNMENTCamber Front

Rear

Caster

Toe Front

Rear–0 °20 ’

–1 °30 ’

8 °

Out 3.5 mm Out 0.14 in

In 4.0 mm In 3/16 in

NOTES

Size

Type, front and rear

Pad and lining surface area: front/rear

Parking brake type

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-15

ProCarManuals.com

Page 604 of 1503

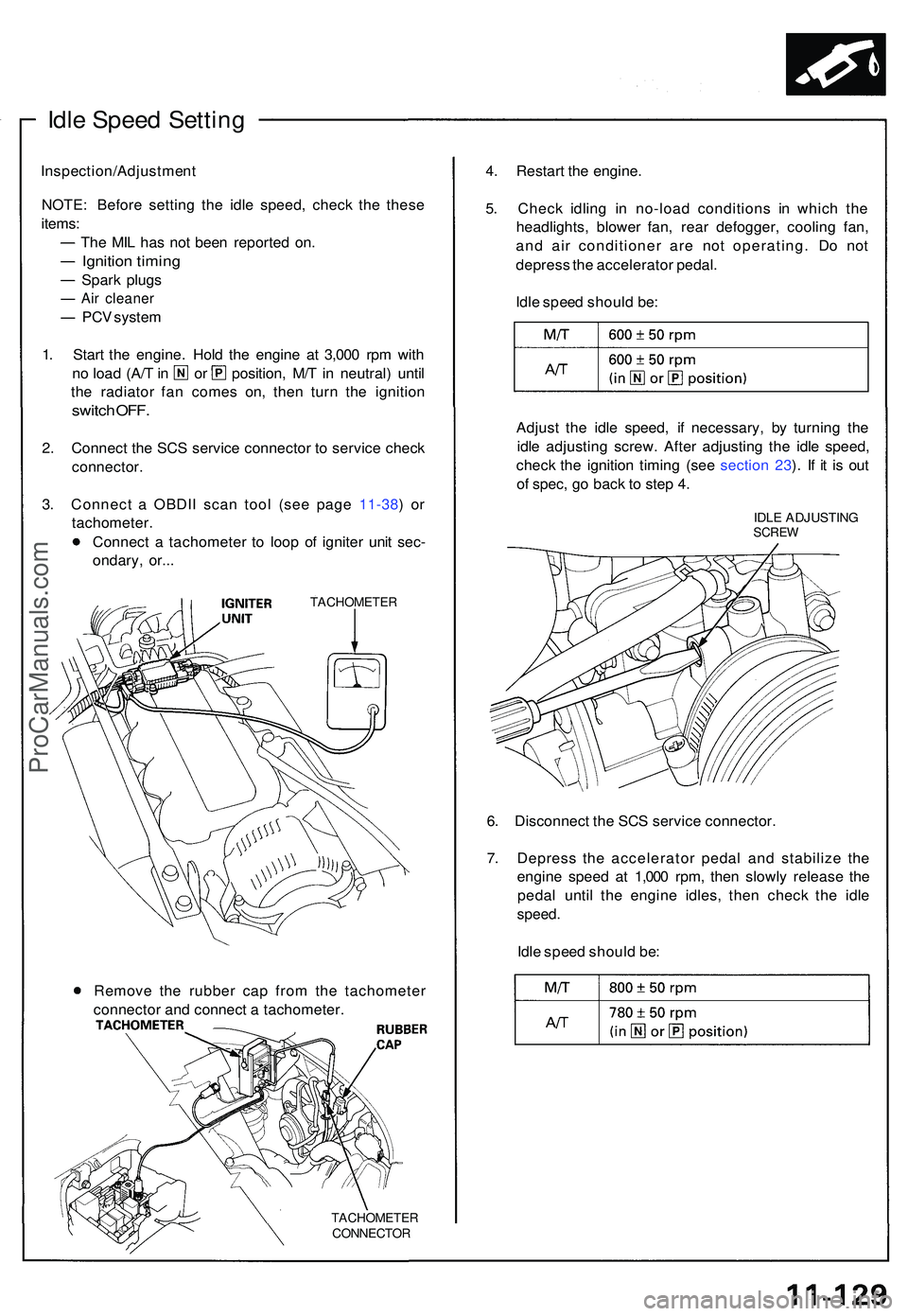

Idle Spee d Settin g

Inspection/Adjustmen t

NOTE : Befor e settin g th e idl e speed , chec k th e thes e

items :

Th e MI L ha s no t bee n reporte d on .

Ignitio n timin g

Spark plug s

Air cleane r

PCV syste m

1 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T in o r position , M/ T in neutral ) unti l

th e radiato r fa n come s on , the n tur n th e ignitio n

switch OFF .

2. Connec t th e SC S servic e connecto r t o servic e chec k

connector .

3. Connec t a OBDI I sca n too l (se e pag e 11-38 ) o r

tachometer .

Connec t a tachomete r t o loo p o f ignite r uni t sec -

ondary , or.. .

TACHOMETE R

TACHOMETE R

CONNECTOR

4. Restar t th e engine .

5 . Chec k idlin g i n no-loa d condition s i n whic h th e

headlights , blowe r fan , rea r defogger , coolin g fan ,

an d ai r conditione r ar e no t operating . D o no t

depres s th e accelerato r pedal .

Idl e spee d shoul d be :

Adjus t th e idl e speed , i f necessary , b y turnin g th e

idl e adjustin g screw . Afte r adjustin g th e idl e speed ,

chec k th e ignitio n timin g (se e sectio n 23 ). I f i t i s ou t

o f spec , g o bac k t o ste p 4 .

IDL E ADJUSTIN GSCREW

6. Disconnec t th e SC S servic e connector .

7 . Depres s th e accelerato r peda l an d stabiliz e th e

engin e spee d a t 1,00 0 rpm , the n slowl y releas e th e

peda l unti l th e engin e idles , the n chec k th e idl e

speed .

Idle spee d shoul d be :

Remov e th e rubbe r ca p fro m th e tachomete r

connecto r an d connec t a tachometer .

ProCarManuals.com

Page 632 of 1503

Emission Contro l Syste m

System Descriptio n

The emissio n contro l syste m include s tw o Thre e Wa y

Catalyti c Converter s (TWCs) , Exhaus t Ga s Recirculatio n

(EGR ) system , Positiv e Crankcas e Ventilatio n (PCV ) sys -

te m an d Evaporativ e Emissio n (EVAP ) Contro l system .

Th e emissio n contro l syste m is designe d t o mee t federa l

an d stat e emissio n standards .

Tailpipe Emissio n

1. Star t th e engine . Hol d th e engine at 3,00 0 rp m wit h

no loa d (A/ T in o r position , M/ T in neutral ) unti l

th e radiato r fa n come s on , the n le t i t idle .

2 . Connec t a tachometer .

3 . Chec k an d adjus t th e idl e speed , i f necessar y (se e

pag e 11-129 ).

4 . War m u p an d calibrat e th e C O mete r accordin g t o

th e mete r manufacturer' s instructions .

5 . Chec k idl e C O wit h th e headlights , heate r blower ,

rea r windo w defogger , coolin g fan , an d ai r condi -

tione r off .

NOTE : (Canada ) Pul l th e parkin g brak e leve r up .

Star t th e engine , the n chec k tha t th e headlight s ar e

off.

CO mete r shoul d indicat e 0.1 % maximum .

Inspection

any ope n flam e awa y fro m you r wor k area .

D

o no t smok e durin g thi s procedure . Kee p

ProCarManuals.com

Page 1331 of 1503

Lighting System

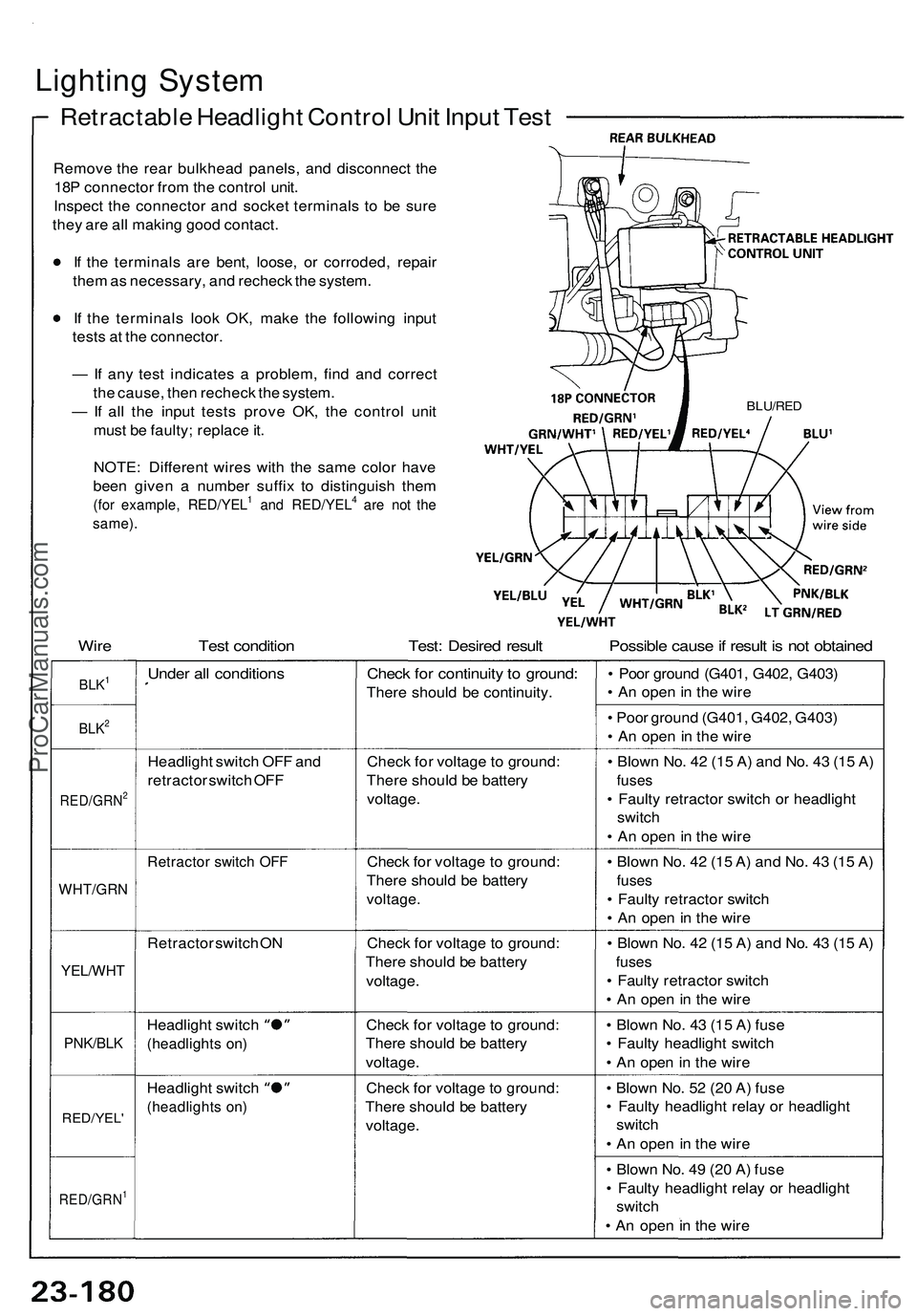

Retractable Headlight Control Unit Input Test

Remove the rear bulkhead panels, and disconnect the

18P connector from the control unit.

Inspect the connector and socket terminals to be sure

they are all making good contact.

If the terminals are bent, loose, or corroded, repair

them as necessary, and recheck the system.

If the terminals look OK, make the following input

tests at the connector.

— If any test indicates a problem, find and correct

the cause, then recheck the system.

— If all the input tests prove OK, the control unit

must be faulty; replace it.

BLU/RED

Wire Test condition Test: Desired result Possible cause if result is not obtained

BLK1

BLK2

RED/GRN2

WHT/GRN

YEL/WHT

PNK/BLK

RED/YEL'

RED/GRN1

Under all conditions

Headlight switch OFF and

retractor switch OFF

Retractor switch OFF

Retractor switch ON

Headlight switch

(headlights on)

Headlight switch

(headlights on)

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery

voltage.

Check for voltage to ground:

There should be battery

voltage.

Check for voltage to ground:

There should be battery

voltage.

Check for voltage to ground:

There should be battery

voltage.

Check for voltage to ground:

There should be battery

voltage.

• Poor ground (G401, G402, G403)

• An open in the wire

• Poor ground (G401, G402, G403)

• An open in the wire

• Blown No. 42 (15 A) and No. 43 (15 A)

fuses

• Faulty retractor switch or headlight

switch

• An open in the wire

• Blown No. 42 (15 A) and No. 43 (15 A)

fuses

• Faulty retractor switch

• An open in the wire

• Blown No. 42 (15 A) and No. 43 (15 A)

fuses

• Faulty retractor switch

• An open in the wire

• Blown No. 43 (15 A) fuse

• Faulty headlight switch

• An open in the wire

• Blown No. 52 (20 A) fuse

• Faulty headlight relay or headlight

switch

• An open in the wire

• Blown No. 49 (20 A) fuse

• Faulty headlight relay or headlight

switch

• An open in the wire

NOTE: Different wires with the same color have

been given a number suffix to distinguish them

(for example, RED/YEL1 and RED/YEL4 are not the

same).ProCarManuals.com

Page 1332 of 1503

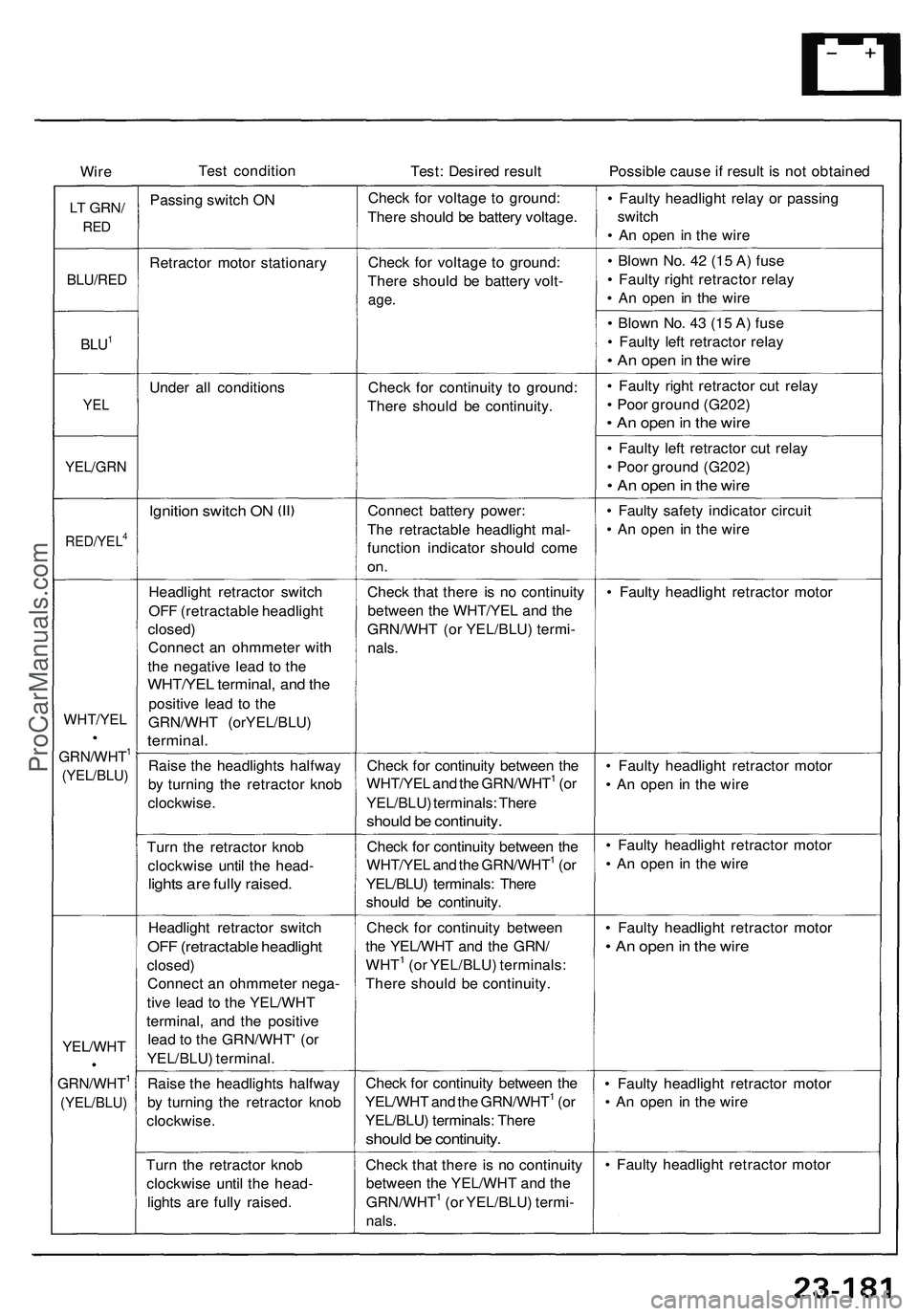

Wire

Test condition

Test: Desired result

Possible cause if result is not obtained

LT

GRN/

RED

Passing switch ON

Check for voltage to ground:

There should be battery voltage.

• Faulty headlight relay or passing

switch

• An open in the wire

BLU/RED

Retractor motor stationary

Check for voltage to ground:

There should be battery volt-

age.

• Blown No. 42 (15 A) fuse

• Faulty right retractor relay

• An open in the wire

BLU1

• Blown No. 43 (15 A) fuse

• Faulty left retractor relay

• An open in the wire

Under all conditions

YEL

Check for continuity to ground:

There should be continuity.

• Faulty right retractor cut relay

• Poor ground (G202)

• An open in the wire

YEL/GRN

• Faulty left retractor cut relay

• Poor ground (G202)

• An open in the wire

Ignition switch ON

RED/YEL4

Connect battery power:

The retractable headlight mal-

function indicator should come

on.

• Faulty safety indicator circuit

• An open in the wire

Headlight retractor switch

OFF (retractable headlight

closed)

Connect an ohmmeter with

the negative lead to the

WHT/YEL terminal, and the

positive lead to the

GRN/WHT (orYEL/BLU)

terminal.

Check that there is no continuity

between the WHT/YEL and the

GRN/WHT (or YEL/BLU) termi-

nals.

• Faulty headlight retractor motor

Raise the headlights halfway

by turning the retractor knob

clockwise.

Check for continuity between the

WHT/YEL and the GRN/WHT1 (or

YEL/BLU) terminals: There

should be continuity.

• Faulty headlight retractor motor

• An open in the wire

Turn the retractor knob

clockwise until the head-

lights are fully raised.

Check for continuity between the

WHT/YEL and the GRN/WHT1 (or

YEL/BLU) terminals: There

should be continuity.

• Faulty headlight retractor motor

• An open in the wire

Headlight retractor switch

OFF (retractable headlight

closed)

Connect an ohmmeter nega-

tive lead to the YEL/WHT

terminal, and the positive

lead to the GRN/WHT' (or

YEL/BLU) terminal.

Check for continuity between

the YEL/WHT and the GRN/

WHT1 (or YEL/BLU) terminals:

There should be continuity.

• Faulty headlight retractor motor

• An open in the wire

Raise the headlights halfway

by turning the retractor knob

clockwise.

Check for continuity between the

YEL/WHT and the GRN/WHT1 (or

YEL/BLU) terminals: There

should be continuity.

• Faulty headlight retractor motor

• An open in the wire

Turn the retractor knob

clockwise until the head-

lights are fully raised.

Check that there is no continuity

between the YEL/WHT and the

GRN/WHT1 (or YEL/BLU) termi-

nals.

• Faulty headlight retractor motor

GRN/WHT1

(YEL/BLU)

WHT/YEL

GRN/WHT1

(YEL/BLU)

YEL/WHTProCarManuals.com

Page 1339 of 1503

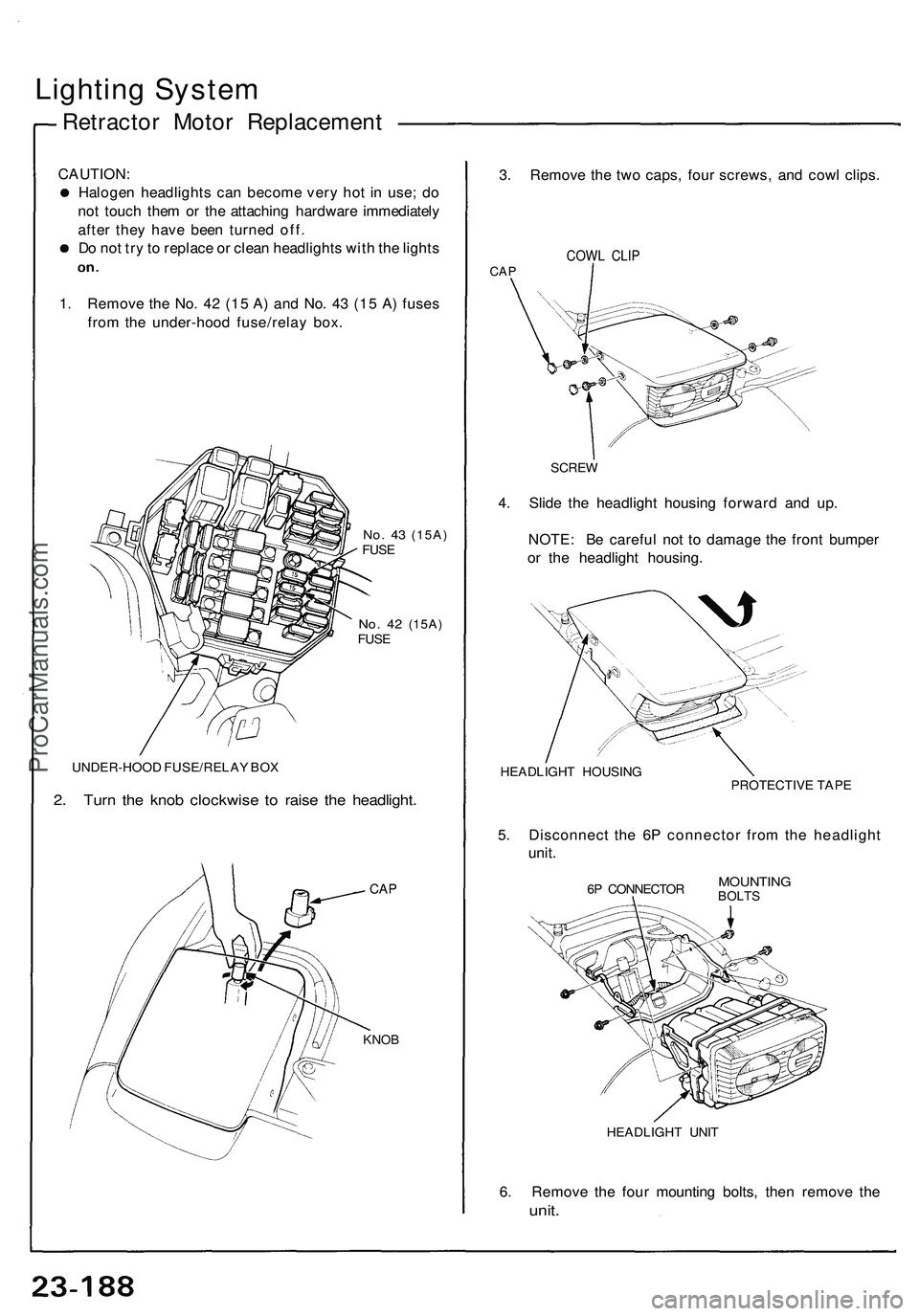

Lighting System

Retractor Motor Replacement

CAUTION:

Halogen headlights can become very hot in use; do

not touch them or the attaching hardware immediately

after they have been turned off.

Do not try to replace or clean headlights with the lights

1. Remove the No. 42 (15 A) and No. 43 (15 A) fuses

from the under-hood fuse/relay box.

No. 43

(15A)

FUSE

No. 42

(15A)

FUSE

UNDER-HOOD FUSE/RELAY BOX

2. Turn the knob clockwise to raise the headlight.

CAP

3. Remove the two caps, four screws, and cowl clips.

COWL CLIP

CAP

4. Slide the headlight housing forward and up.

NOTE: Be careful not to damage the front bumper

or the headlight housing.

HEADLIGHT HOUSING

PROTECTIVE TAPE

5. Disconnect the 6P connector from the headlight

unit.

6P CONNECTOR

MOUNTING

BOLTS

HEADLIGHT UNIT

6. Remove the four mounting bolts, then remove the

unit.

KNOB

SCREWProCarManuals.com

Page 1346 of 1503

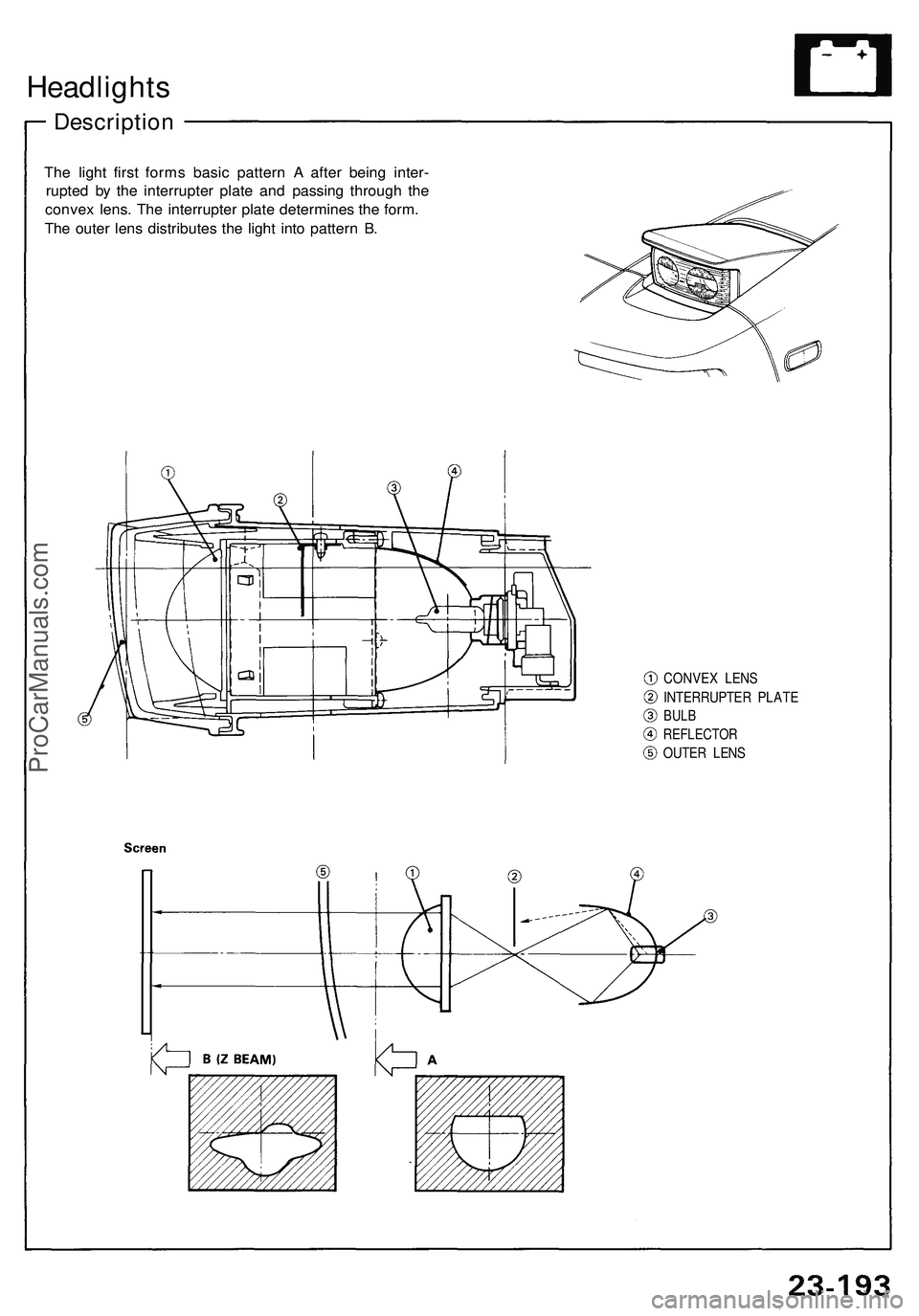

Headlights

Description

The light first forms basic pattern A after being inter-

rupted by the interrupter plate and passing through the

convex lens. The interrupter plate determines the form.

The outer lens distributes the light into pattern B.

CONVEX LENS

INTERRUPTER PLATE

BULB

REFLECTOR

OUTER LENSProCarManuals.com

Page 1347 of 1503

Headlights

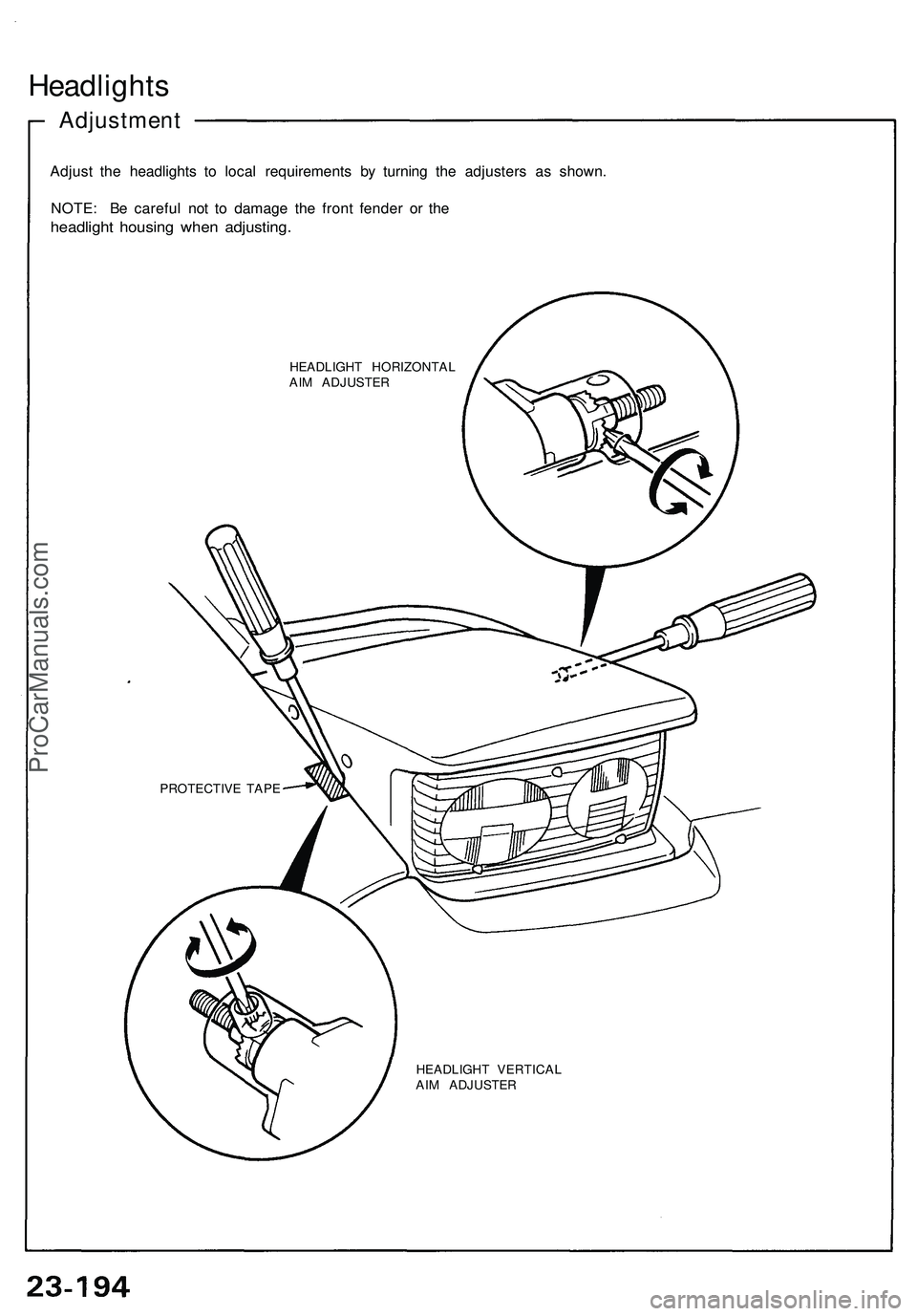

Adjustment

Adjust the headlights to local requirements by turning the adjusters as shown.

NOTE: Be careful not to damage the front fender or the

headlight housing when adjusting.

HEADLIGHT HORIZONTAL

AIM ADJUSTER

HEADLIGHT VERTICAL

AIM ADJUSTER

PROTECTIVE TAPEProCarManuals.com

Page 1349 of 1503

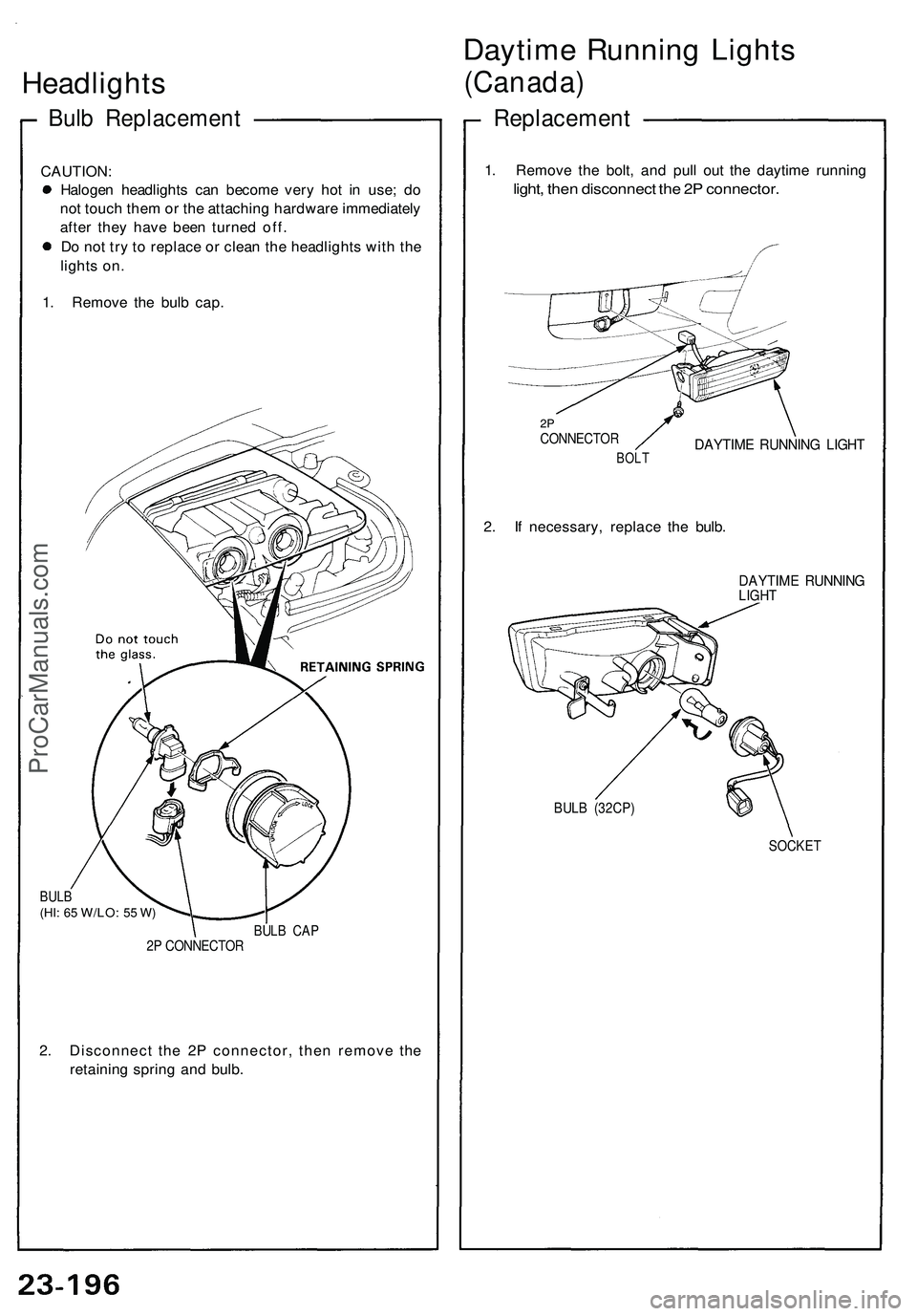

Headlights

Bulb Replacement

CAUTION:

Halogen headlights can become very hot in use; do

not touch them or the attaching hardware immediately

after they have been turned off.

Do not try to replace or clean the headlights with the

lights on.

1. Remove the bulb cap.

BULB

(HI:

65

W/LO:

55 W)

BULB CAP

2P CONNECTOR

2. Disconnect the 2P connector, then remove the

retaining spring and bulb.

Daytime Running Lights

(Canada)

Replacement

1. Remove the bolt, and pull out the daytime running

light, then disconnect the 2P connector.

2P

CONNECTOR

DAYTIME RUNNING LIGHT

BOLT

2. If necessary, replace the bulb.

DAYTIME RUNNING

LIGHT

BULB (32CP)

SOCKETProCarManuals.com