hood open ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 193 of 1503

Radiator

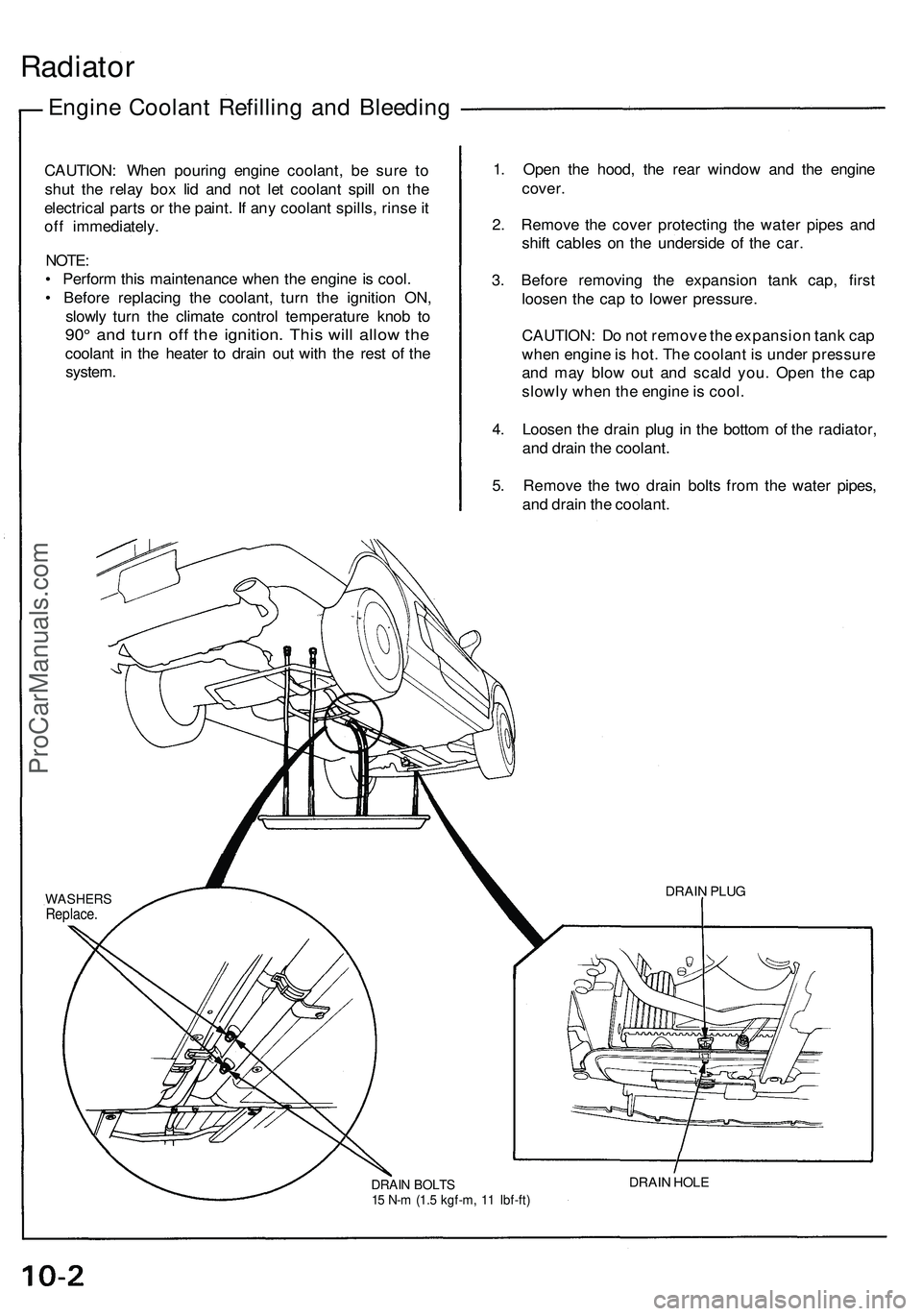

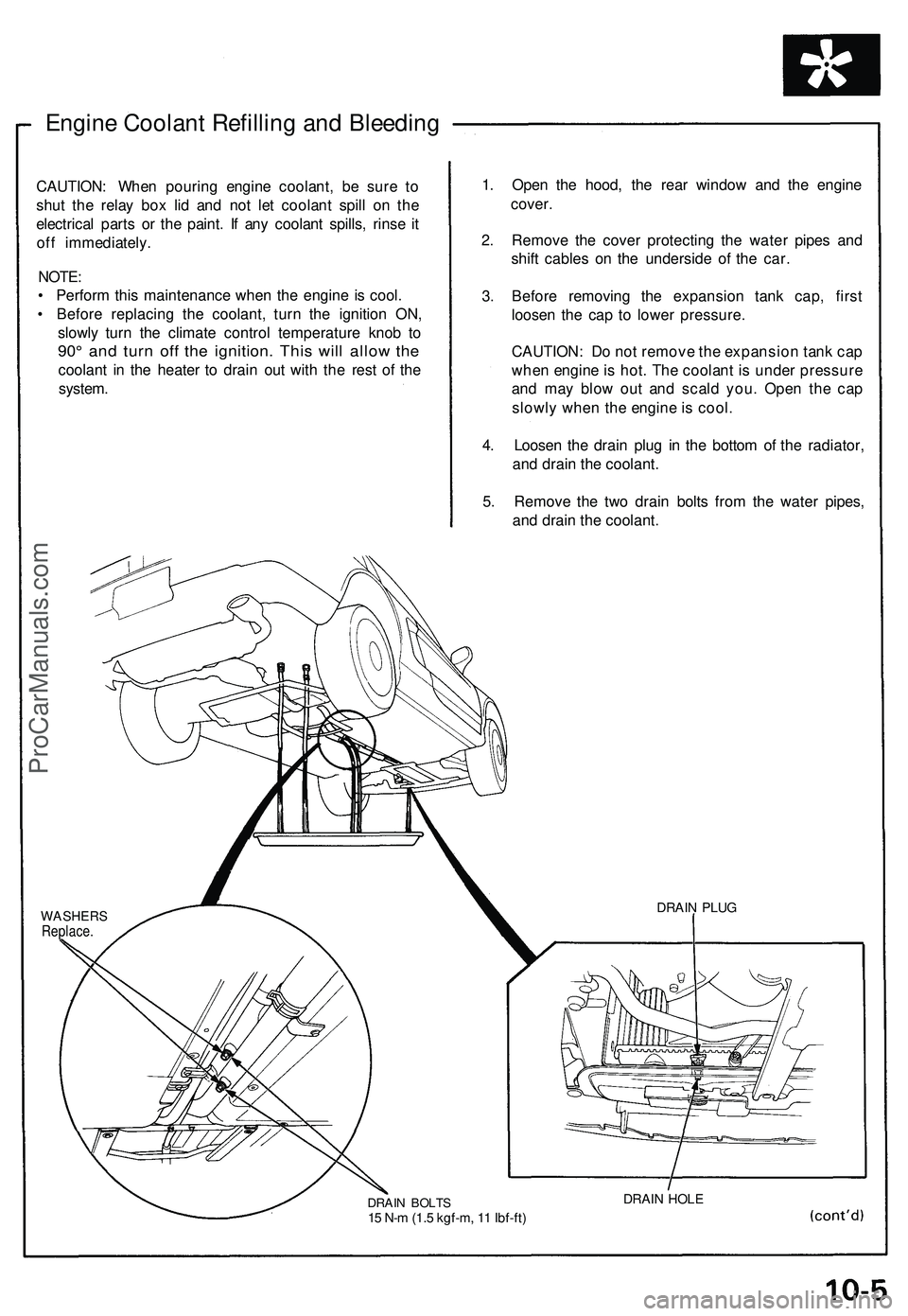

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

DRAIN BOLTS

15 N-m (1.5 kgf-m, 11 Ibf-ft)

DRAIN HOLE

DRAIN PLUG

WASHERS

Replace.ProCarManuals.com

Page 271 of 1503

Lighting System

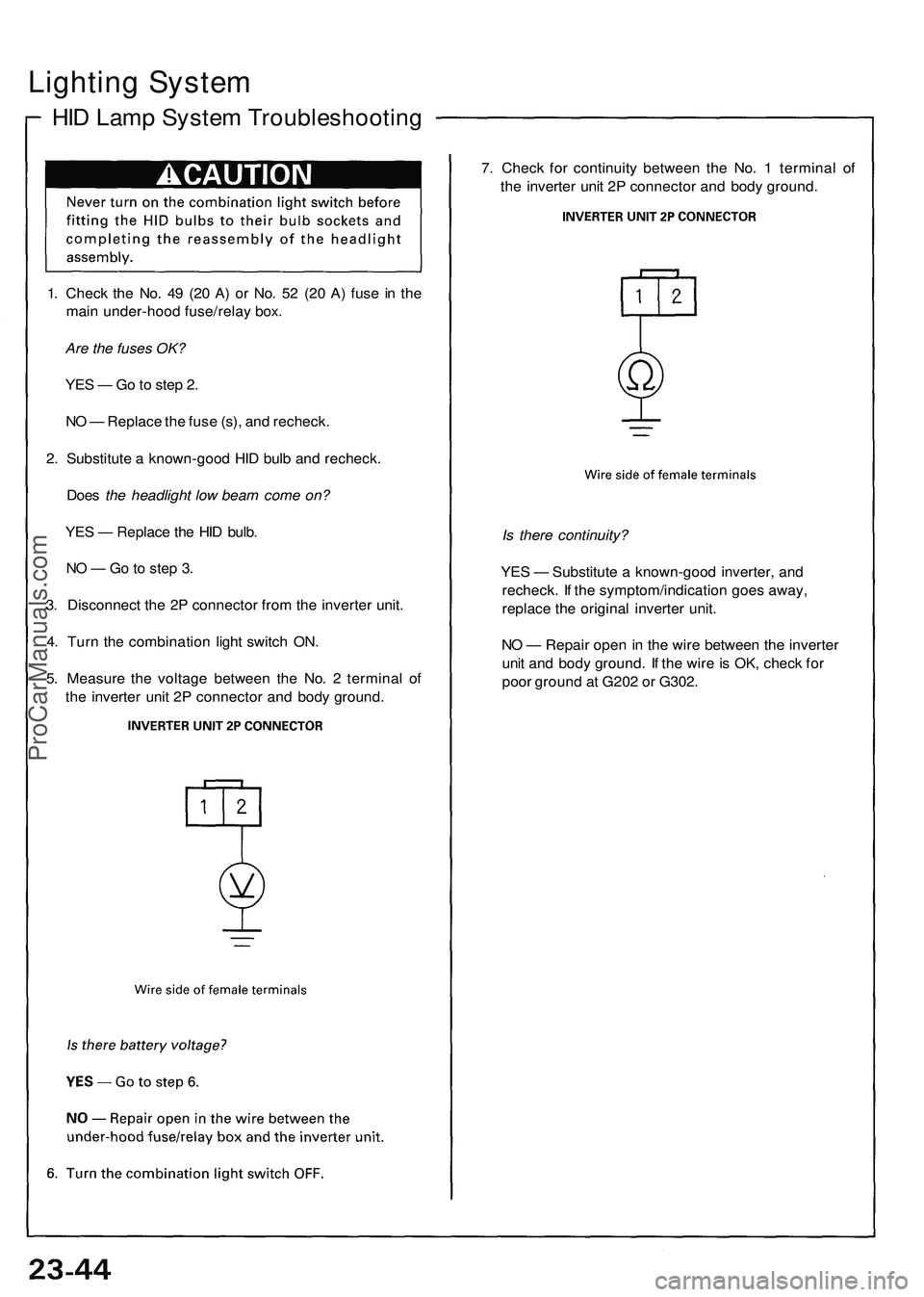

HID Lamp System Troubleshooting

1. Check the No. 49 (20 A) or No. 52 (20 A) fuse in the

main under-hood fuse/relay box.

Are the fuses OK?

YES — Go to step 2.

NO — Replace the fuse (s), and recheck.

2. Substitute a known-good HID bulb and recheck.

Does the headlight low beam come on?

YES — Replace the HID bulb.

NO — Go to step 3.

3. Disconnect the 2P connector from the inverter unit.

4. Turn the combination light switch ON.

5. Measure the voltage between the No. 2 terminal of

the inverter unit 2P connector and body ground.

7. Check for continuity between the No. 1 terminal of

the inverter unit 2P connector and body ground.

Is there continuity?

YES — Substitute a known-good inverter, and

recheck. If the symptom/indication goes away,

replace the original inverter unit.

NO — Repair open in the wire between the inverter

unit and body ground. If the wire is OK, check for

poor ground at G202 or G302.ProCarManuals.com

Page 276 of 1503

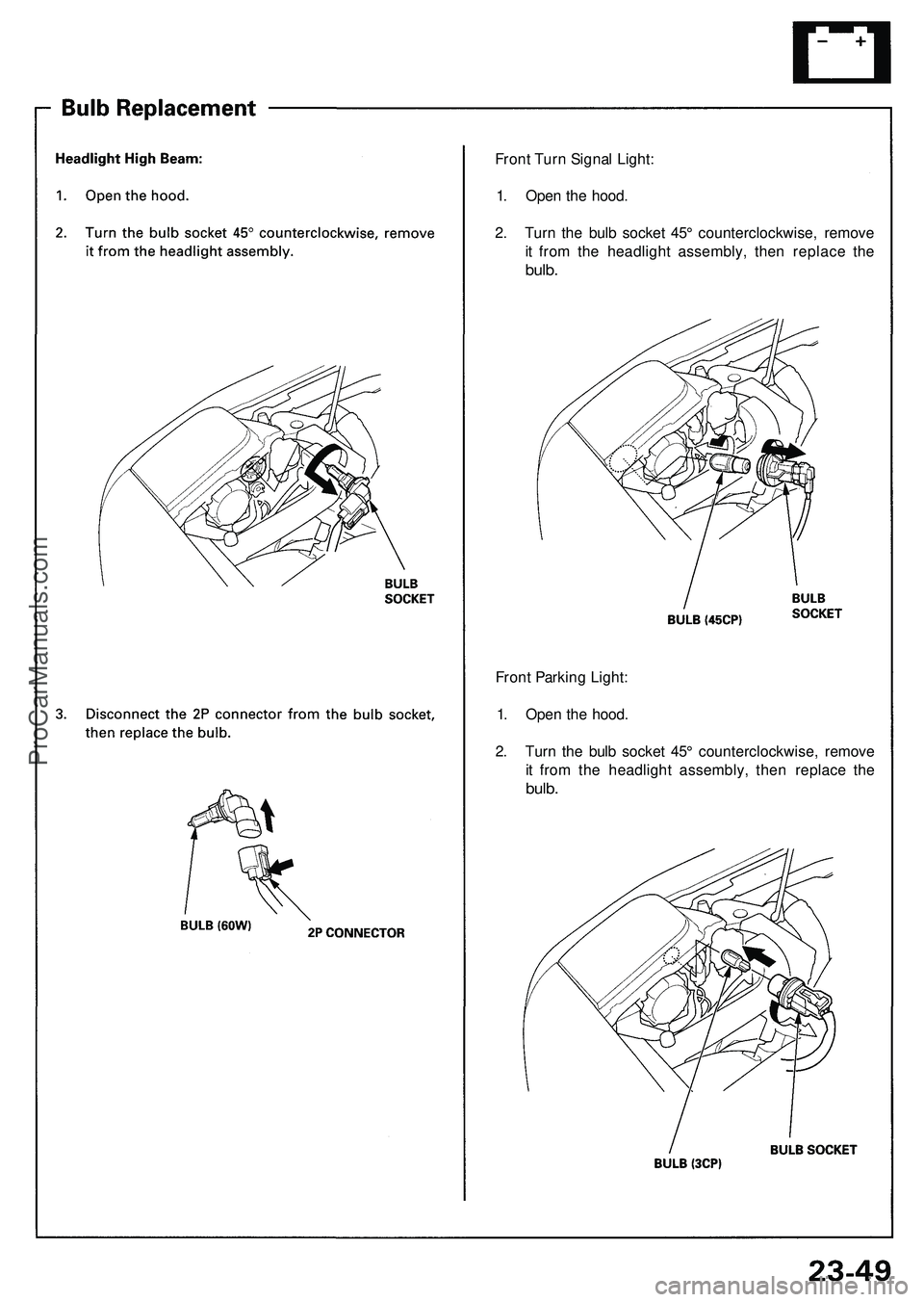

Front Turn Signal Light:

1. Open the hood.

2. Turn the bulb socket 45° counterclockwise, remove

it from the headlight assembly, then replace the

bulb.

Front Parking Light:

1. Open the hood.

2. Turn the bulb socket 45° counterclockwise, remove

it from the headlight assembly, then replace the

bulb.ProCarManuals.com

Page 358 of 1503

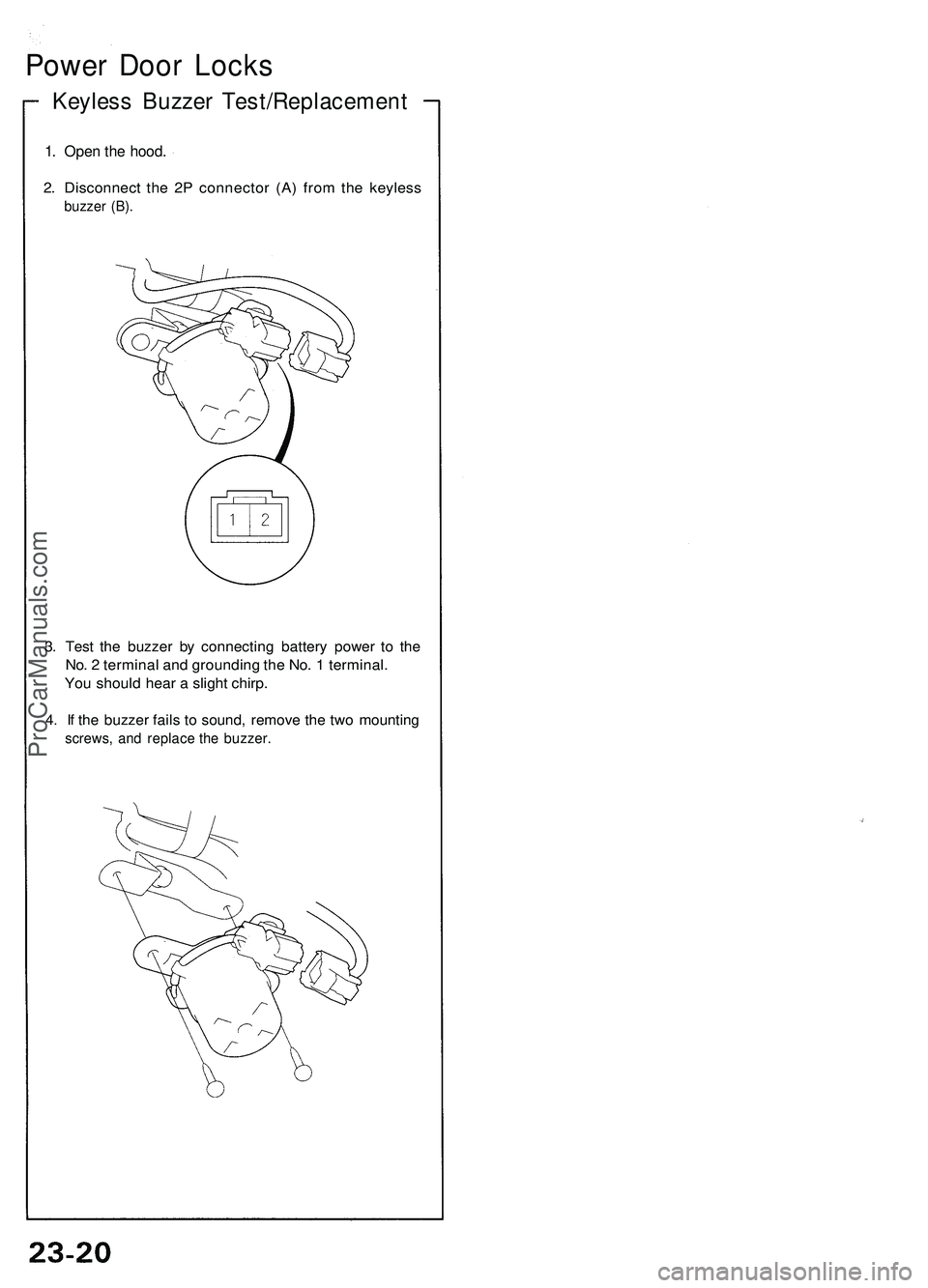

Power Door Locks

Keyless Buzzer Test/Replacement

1. Open the hood.

2. Disconnect the 2P connector (A) from the keyless

buzzer (B).

3. Test the buzzer by connecting battery power to the

No. 2 terminal and grounding the No. 1 terminal.

You should hear a slight chirp.

4. If the buzzer fails to sound, remove the two mounting

screws, and replace the buzzer.ProCarManuals.com

Page 359 of 1503

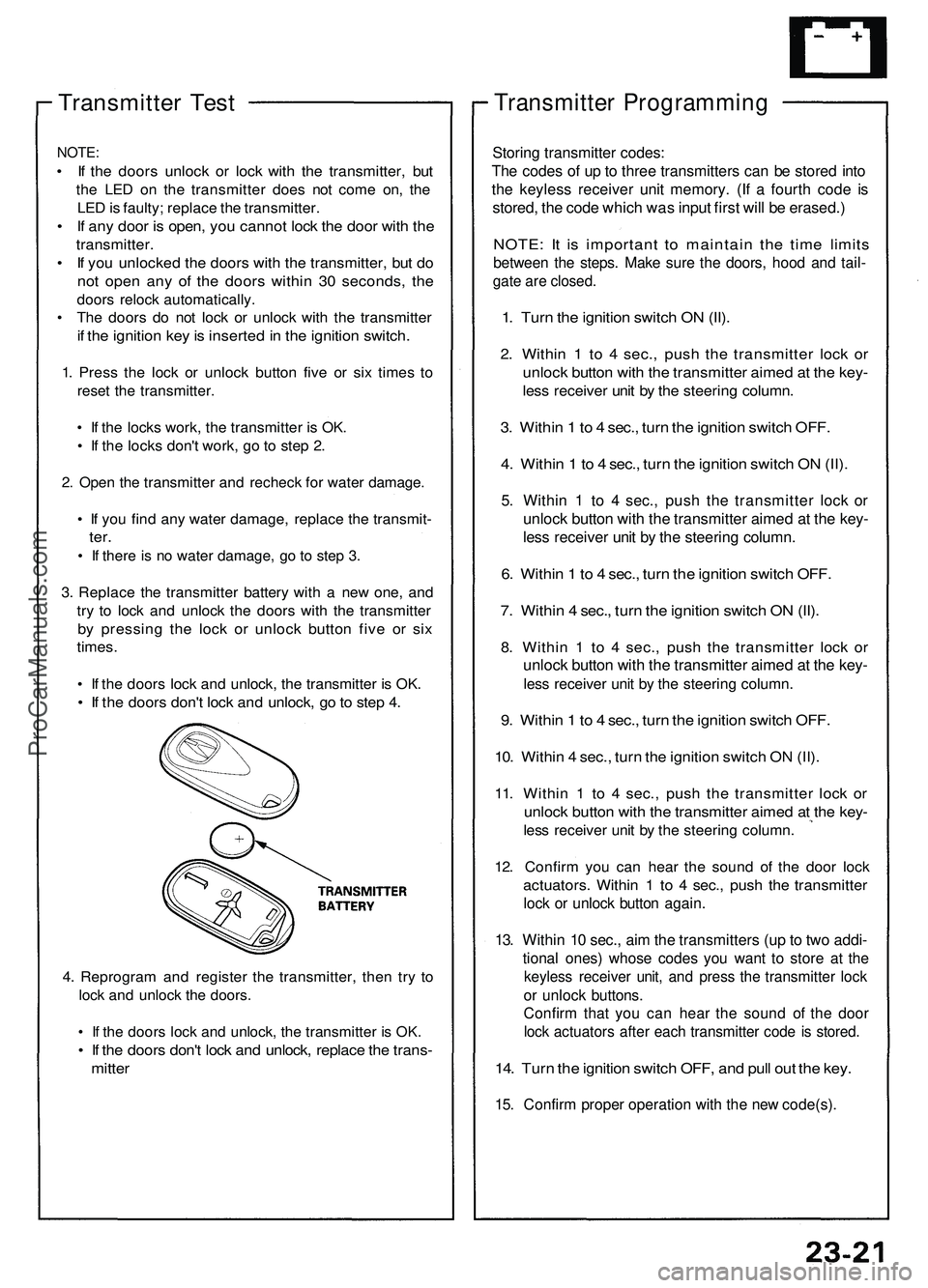

Transmitter Test

NOTE:

• If the doors unlock or lock with the transmitter, but

the LED on the transmitter does not come on, the

LED is faulty; replace the transmitter.

• If any door is open, you cannot lock the door with the

transmitter.

• If you unlocked the doors with the transmitter, but do

not open any of the doors within 30 seconds, the

doors relock automatically.

• The doors do not lock or unlock with the transmitter

if the ignition key is inserted in the ignition switch.

1. Press the lock or unlock button five or six times to

reset the transmitter.

• If the locks work, the transmitter is OK.

• If the locks don't work, go to step 2.

2. Open the transmitter and recheck for water damage.

• If you find any water damage, replace the transmit-

ter.

• If there is no water damage, go to step 3.

3. Replace the transmitter battery with a new one, and

try to lock and unlock the doors with the transmitter

by pressing the lock or unlock button five or six

times.

• If the doors lock and unlock, the transmitter is OK.

• If the doors don't lock and unlock, go to step 4.

4. Reprogram and register the transmitter, then try to

lock and unlock the doors.

• If the doors lock and unlock, the transmitter is OK.

• If the doors don't lock and unlock, replace the trans-

mitter

Transmitter Programming

Storing transmitter codes:

The codes of up to three transmitters can be stored into

the keyless receiver unit memory. (If a fourth code is

stored, the code which was input first will be erased.)

NOTE: It is important to maintain the time limits

between the steps. Make sure the doors, hood and tail-

gate are closed.

1. Turn the ignition switch ON (II).

2. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

3. Within 1 to 4 sec., turn the ignition switch OFF.

4. Within 1 to 4 sec., turn the ignition switch ON (II).

5. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

6. Within 1 to 4 sec., turn the ignition switch OFF.

7. Within 4 sec., turn the ignition switch ON (II).

8. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

9. Within 1 to 4 sec., turn the ignition switch OFF.

10. Within 4 sec., turn the ignition switch ON (II).

11. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the key-

less receiver unit by the steering column.

12. Confirm you can hear the sound of the door lock

actuators. Within 1 to 4 sec., push the transmitter

lock or unlock button again.

13. Within 10 sec., aim the transmitters (up to two addi-

tional ones) whose codes you want to store at the

keyless receiver unit, and press the transmitter lock

or unlock buttons.

Confirm that you can hear the sound of the door

lock actuators after each transmitter code is stored.

14. Turn the ignition switch OFF, and pull out the key.

15. Confirm proper operation with the new code(s).ProCarManuals.com

Page 371 of 1503

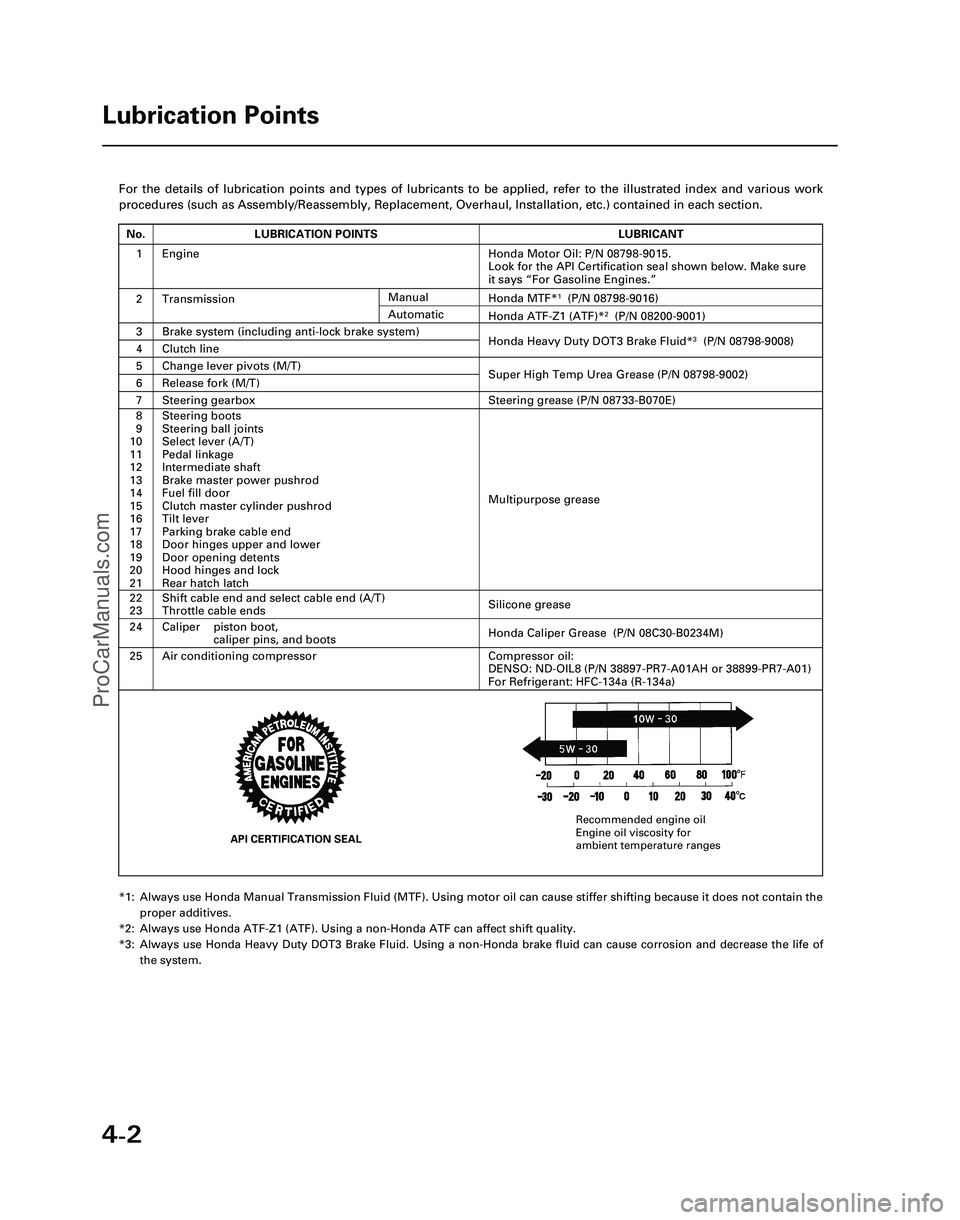

4-2

For the details of lubrication points and types of lubricants to be appl\

ied, refer to the illustrated index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Install\

ation, etc.) contained in each section.

*1: Always use Honda Manual Transmission Fluid (MTF). Using motor oil can \

cause stiffer shifting because it does not contain theproper additives.

*2: Always use Honda ATF-Z1 (ATF). Using a non-Honda ATF can affect shift \

quality.

*3: Always use Honda Heavy Duty DOT3 Brake Fluid. Using a non-Honda brake fl\

uid can cause corrosion and decrease the life of the system.

Lubrication Points

No.LUBRICATION POINTSLUBRICANT

1Honda Motor Oil: P/N 08798-9015.

Look for the API Certification seal shown below. Make sure

it says “For Gasoline Engines.”

2TransmissionHonda MTF*1(P/N 08798-9016)

3Brake system (including anti-lock brake system)Honda Heavy Duty DOT3 Brake Fluid*3(P/N 08798-9008)4Clutch line

5Change lever pivots (M/T)Super High Temp Urea Grease (P/N 08798-9002)6Release fork (M/T)

8

9

10

11

12

13

14

15

16

17

18

19

20

21Steering boots

Steering ball joints

Select lever (A/T)

Pedal linkage

Intermediate shaft

Brake master power pushrod

Fuel fill door

Clutch master cylinder pushrod

Tilt lever

Parking brake cable end

Door hinges upper and lower

Door opening detents

Hood hinges and lock

Rear hatch latch

Multipurpose grease

24

22

23

Caliper piston boot, caliper pins, and boots

Shift cable end and select cable end (A/T)

Throttle cable ends

Honda Caliper Grease (P/N 08C30-B0234M)

Silicone grease

25Air conditioning compressorCompressor oil:

DENSO: ND-OIL8 (P/N 38897-PR7-A01AH or 38899-PR7-A01)

For Refrigerant: HFC-134a (R-134a)

Manual

Honda ATF-Z1 (ATF)*2(P/N 08200-9001)Automatic

7Steering gearboxSteering grease (P/N 08733-B070E)

Engine

API CERTIFICATION SEAL

Recommended engine oil

Engine oil viscosity for

ambient temperature ranges

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-2

ProCarManuals.com

Page 521 of 1503

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

WASHERS

Replace.

DRAIN BOLTS

15 N-m (1.5 kgf-m, 11 Ibf-ft)

DRAIN HOLE

DRAIN PLUGProCarManuals.com

Page 1120 of 1503

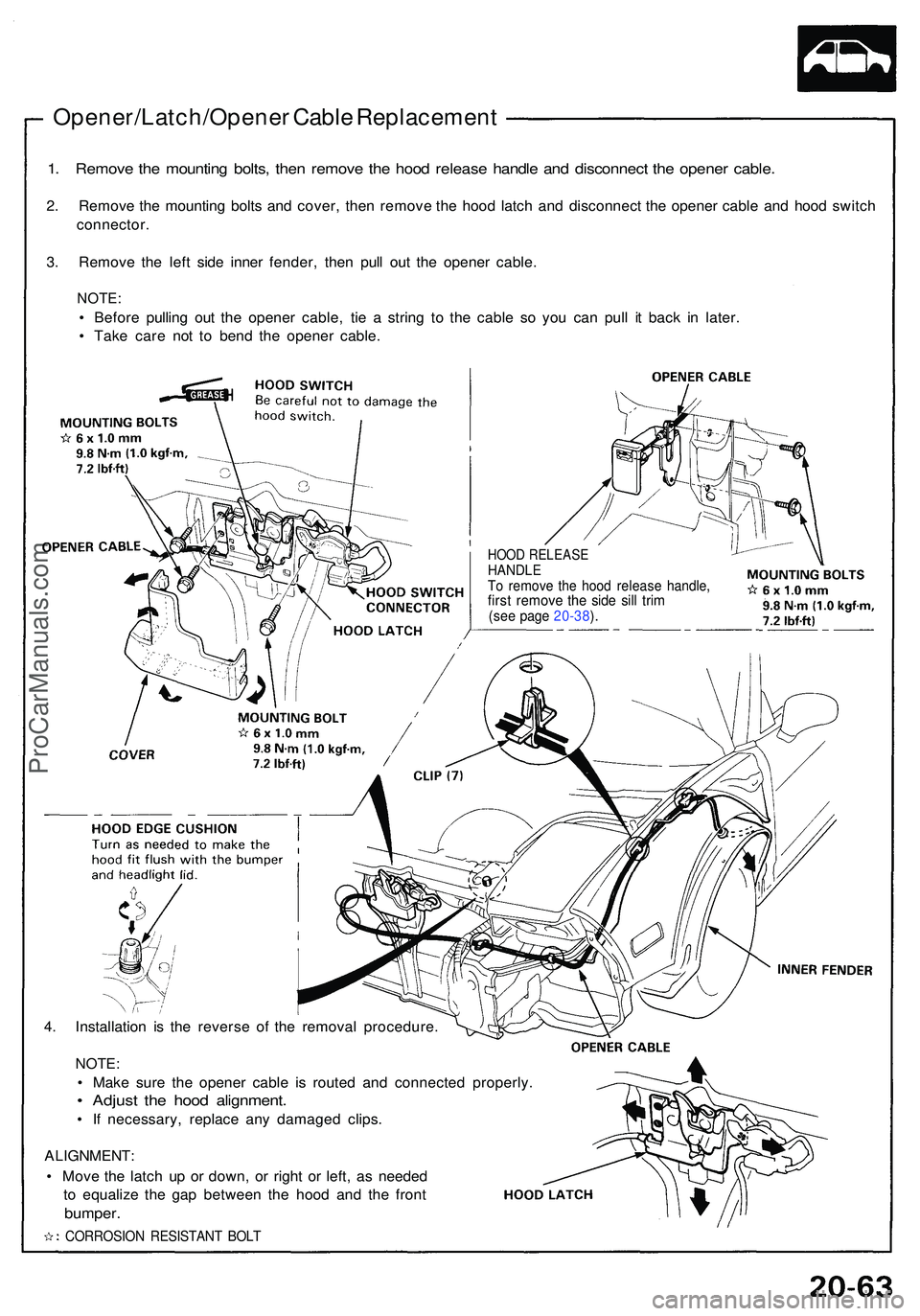

Opener/Latch/Opener Cabl e Replacemen t

1. Remov e th e mountin g bolts , the n remov e th e hoo d releas e handl e an d disconnec t th e opene r cable .

2. Remov e th e mountin g bolt s an d cover , the n remov e th e hoo d latc h an d disconnec t th e opene r cabl e an d hoo d switc h

connector .

3 . Remov e th e lef t sid e inne r fender , the n pul l ou t th e opene r cable .

NOTE:

• Befor e pullin g ou t th e opene r cable , ti e a strin g t o th e cabl e s o yo u ca n pul l i t bac k i n later .

• Tak e car e no t t o ben d th e opene r cable .

HOOD RELEAS EHANDLETo remov e th e hoo d releas e handle ,first remov e th e sid e sil l tri m(se e pag e 20-38 ).

4 . Installatio n i s th e revers e o f th e remova l procedure .

NOTE:

• Mak e sur e th e opene r cabl e i s route d an d connecte d properly .

• Adjus t th e hoo d alignment .

• I f necessary , replac e an y damage d clips .

ALIGNMENT :

• Mov e th e latc h u p o r down , o r righ t o r left , a s neede d

t o equaliz e th e ga p betwee n th e hoo d an d th e fron t

bumper .

CORROSIO N RESISTAN T BOL T

ProCarManuals.com

Page 1394 of 1503

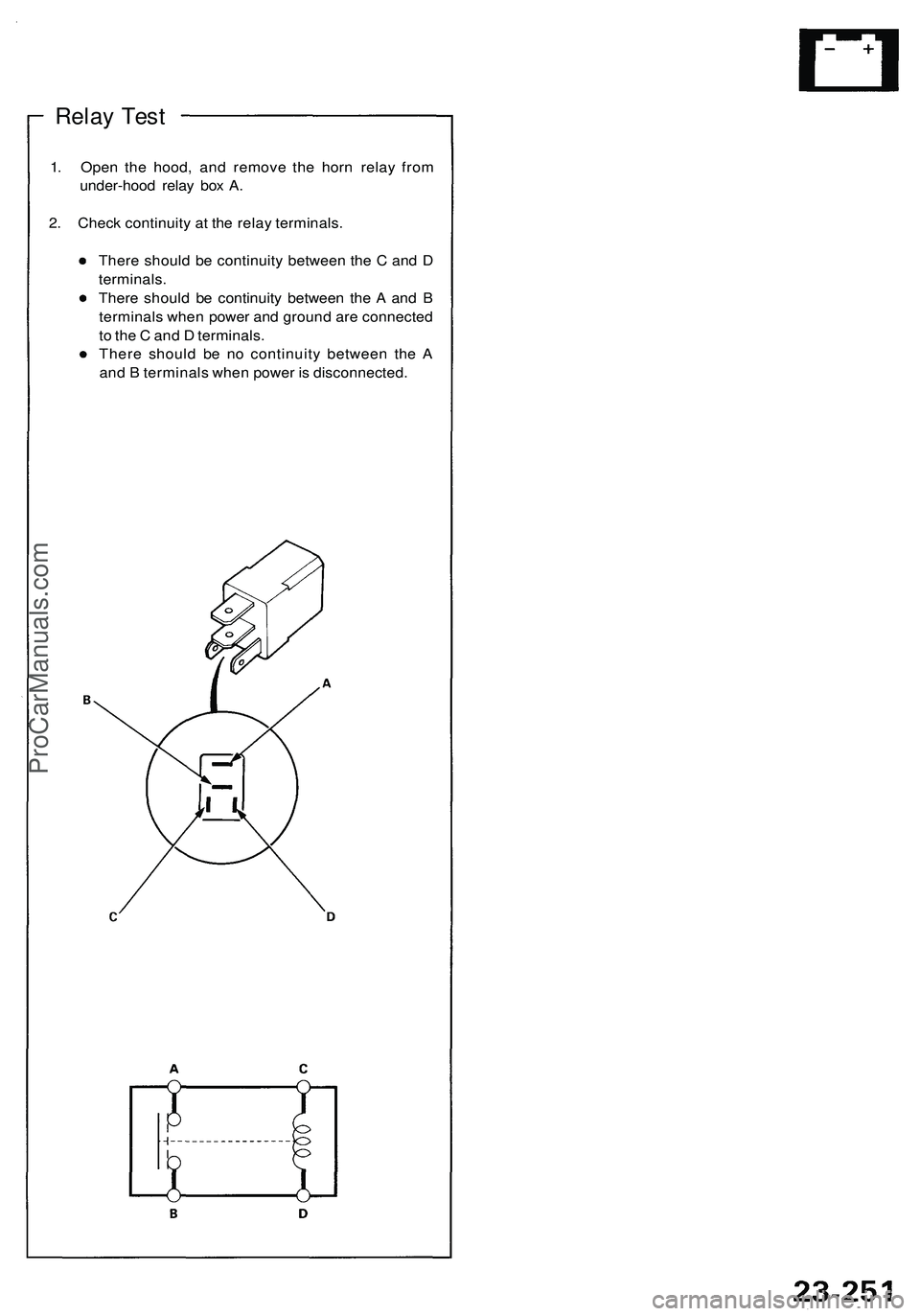

Relay Test

1. Open the hood, and remove the horn relay from

under-hood relay box A.

2. Check continuity at the relay terminals.

There should be continuity between the C and D

terminals.

There should be continuity between the A and B

terminals when power and ground are connected

to the C and D terminals.

There should be no continuity between the A

and B terminals when power is disconnected.ProCarManuals.com

Page 1434 of 1503

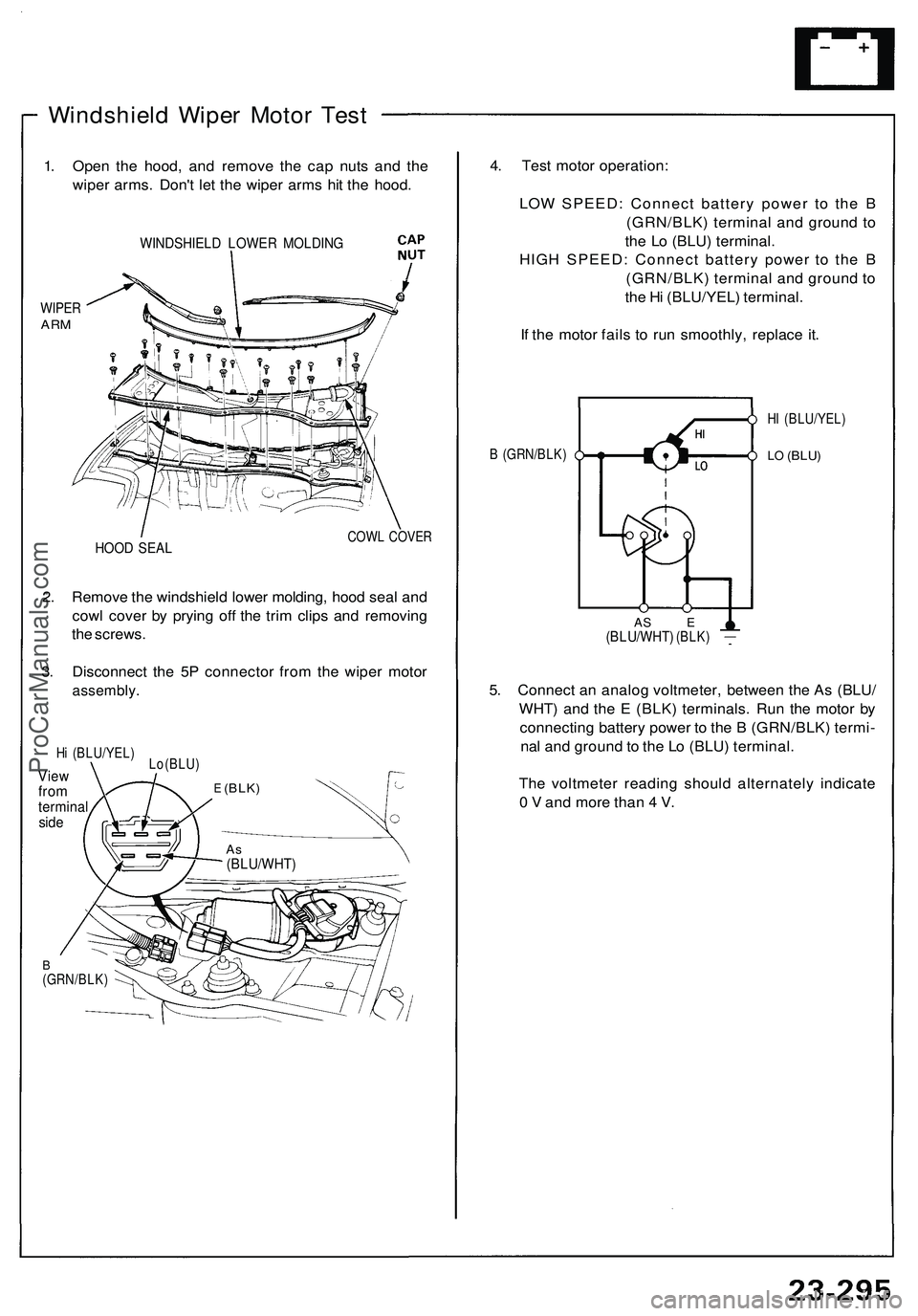

Windshield Wiper Motor Test

1. Open the hood, and remove the cap nuts and the

wiper arms. Don't let the wiper arms hit the hood.

WINDSHIELD LOWER MOLDING

WIPER

ARM

HOOD SEAL

COWL COVER

2. Remove the windshield lower molding, hood seal and

cowl cover by prying off the trim clips and removing

the screws.

3. Disconnect the 5P connector from the wiper motor

assembly.

Hi (BLU/YEL)

View

from

terminal

side

Lo(BLU)

B

(GRN/BLK)

4. Test motor operation:

LOW SPEED: Connect battery power to the B

(GRN/BLK) terminal and ground to

the Lo (BLU) terminal.

HIGH SPEED: Connect battery power to the B

(GRN/BLK) terminal and ground to

the Hi (BLU/YEL) terminal.

If the motor fails to run smoothly, replace it.

5. Connect an analog voltmeter, between the As (BLU/

WHT) and the E (BLK) terminals. Run the motor by

connecting battery power to the B (GRN/BLK) termi-

nal and ground to the Lo (BLU) terminal.

The voltmeter reading should alternately indicate

0 V and more than 4 V.

B (GRN/BLK)

HI (BLU/YEL)

LO

(BLU)

AS E

(BLU/WHT)

(BLK)

E

(BLK)

As

(BLU/WHT)ProCarManuals.com