torque ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 368 of 1503

3-13

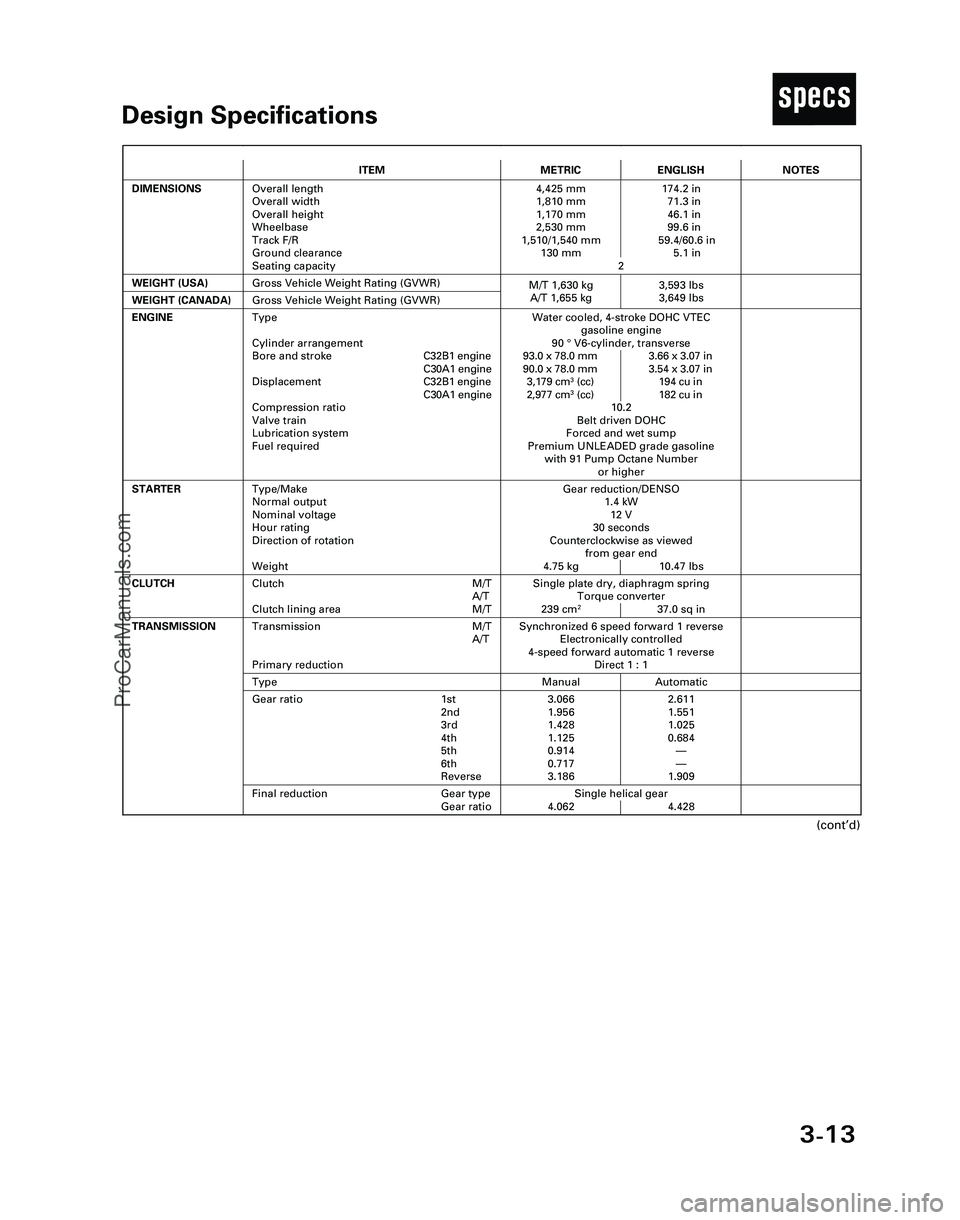

TDesign Specifications

(cont’d)

ITEMMETRICENGLISH

DIMENSIONSOverall length

Overall width

Overall height

Wheelbase

Track F/R

Ground clearance

Seating capacity4,425 mm 174.2 in

1,810 mm 71.3 in

1,170 mm 46.1 in

2,530 mm 99.6 in

1,510/1,540 mm 59.4/60.6 in

130 mm 5.1 in

2

WEIGHT (USA)

Single plate dry, diaphragm spring

Torque converter

239 cm

237.0 sq in

CLUTCHClutch M/T

A/T

Clutch lining area M/T

Gross Vehicle Weight Rating (GVWR)

NOTES

Gear reduction/DENSO

1.4 kW

12 V

30 seconds

Counterclockwise as viewed

from gear end

4.75 kg 10.47 lbs

ENGINEWater cooled, 4-stroke DOHC VTEC

gasoline engine

90 °V6-cylinder, transverse

93.0 x 78.0 mm 3.66 x 3.07 in

90.0 x 78.0 mm 3.54 x 3.07 in

3,179 cm

3(cc) 194 cu in

2,977 cm3(cc) 182 cu in

10.2

Belt driven DOHC

Forced and wet sump

Premium UNLEADED grade gasoline

with 91 Pump Octane Number

or higher

STARTERType/Make

Normal output

Nominal voltage

Hour rating

Direction of rotation

Weight

WEIGHT (CANADA)Gross Vehicle Weight Rating (GVWR)

Synchronized 6 speed forward 1 reverse

Electronically controlled

4-speed forward automatic 1 reverse

Direct 1 : 1Transmission M/T

A/T

Primary reduction

Manual AutomaticType

3.066 2.611

1.956 1.551

1.428 1.025

1.125 0.684

0.914—

0.717—

3.186 1.909Gear ratio 1st

2nd

3rd

4th

5th

6th

Reverse

Single helical gear

4.062 4.428

TRANSMISSION

Final reduction Gear type

Gear ratio

Type

Cylinder arrangement

Bore and strokeC32B1 engine

C30A1 engine

DisplacementC32B1 engine

C30A1 engine

Compression ratio

Valve train

Lubrication system

Fuel required

M/T 1,630 kg 3,593 lbs

A/T 1,655 kg 3,649 lbs

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-13

ProCarManuals.com

Page 385 of 1503

Service Precautions

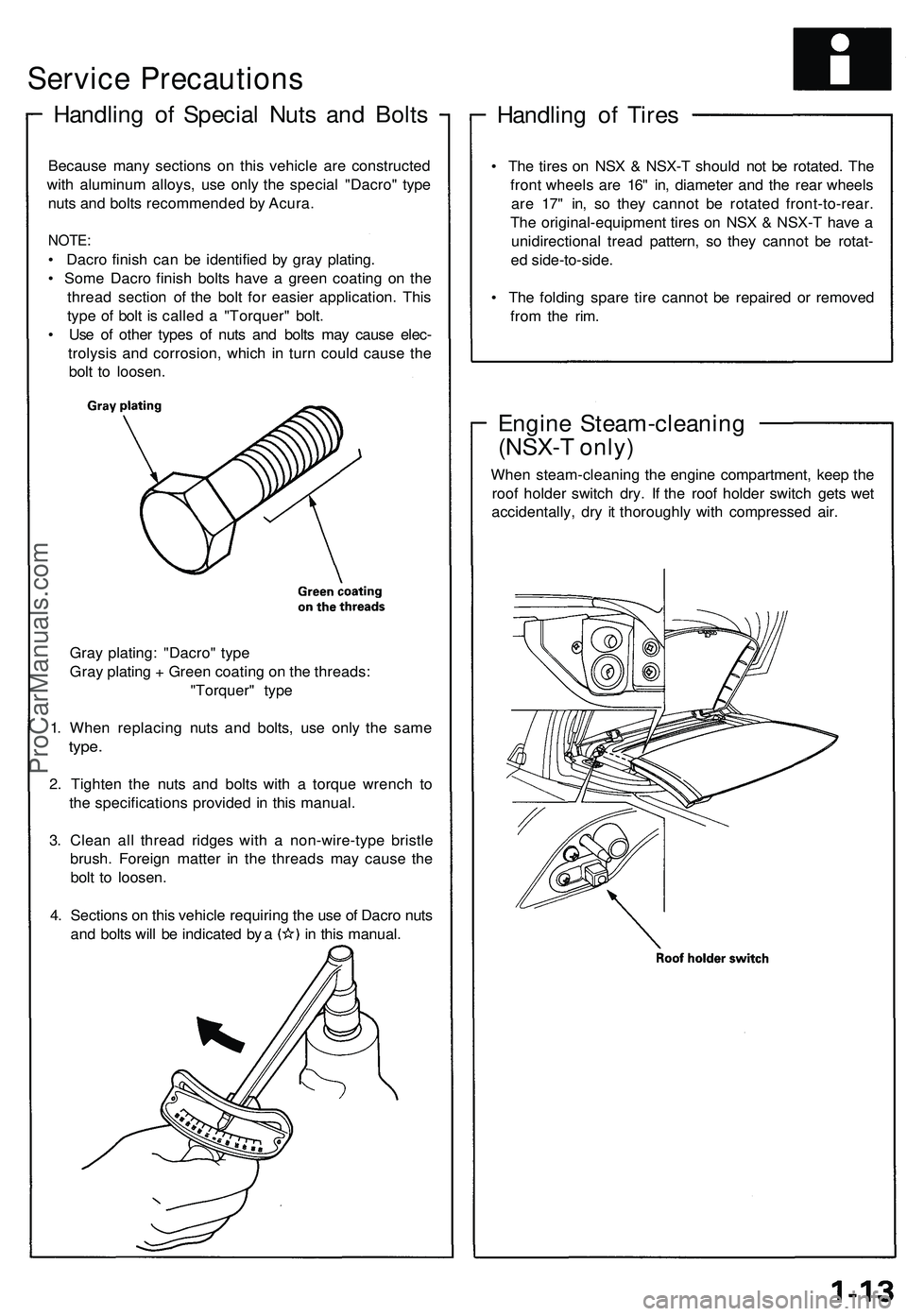

Handling of Special Nuts and Bolts

Handling of Tires

• The tires on NSX & NSX-T should not be rotated. The

front wheels are 16" in, diameter and the rear wheels

are 17" in, so they cannot be rotated front-to-rear.

The original-equipment tires on NSX & NSX-T have a

unidirectional tread pattern, so they cannot be rotat-

ed side-to-side.

• The folding spare tire cannot be repaired or removed

from the rim.

Engine Steam-cleaning

(NSX-T only)

When steam-cleaning the engine compartment, keep the

roof holder switch dry. If the roof holder switch gets wet

accidentally, dry it thoroughly with compressed air.

Because many sections on this vehicle are constructed

with aluminum alloys, use only the special "Dacro" type

nuts and bolts recommended by Acura.

NOTE:

• Dacro finish can be identified by gray plating.

• Some Dacro finish bolts have a green coating on the

thread section of the bolt for easier application. This

type of bolt is called a "Torquer" bolt.

• Use of other types of nuts and bolts may cause elec-

trolysis and corrosion, which in turn could cause the

bolt to loosen.

Gray plating: "Dacro" type

Gray plating + Green coating on the threads:

"Torquer" type

1. When replacing nuts and bolts, use only the same

type.

2. Tighten the nuts and bolts with a torque wrench to

the specifications provided in this manual.

3. Clean all thread ridges with a non-wire-type bristle

brush. Foreign matter in the threads may cause the

bolt to loosen.

4. Sections on this vehicle requiring the use of Dacro nuts

and bolts will be indicated by a in this manual.ProCarManuals.com

Page 452 of 1503

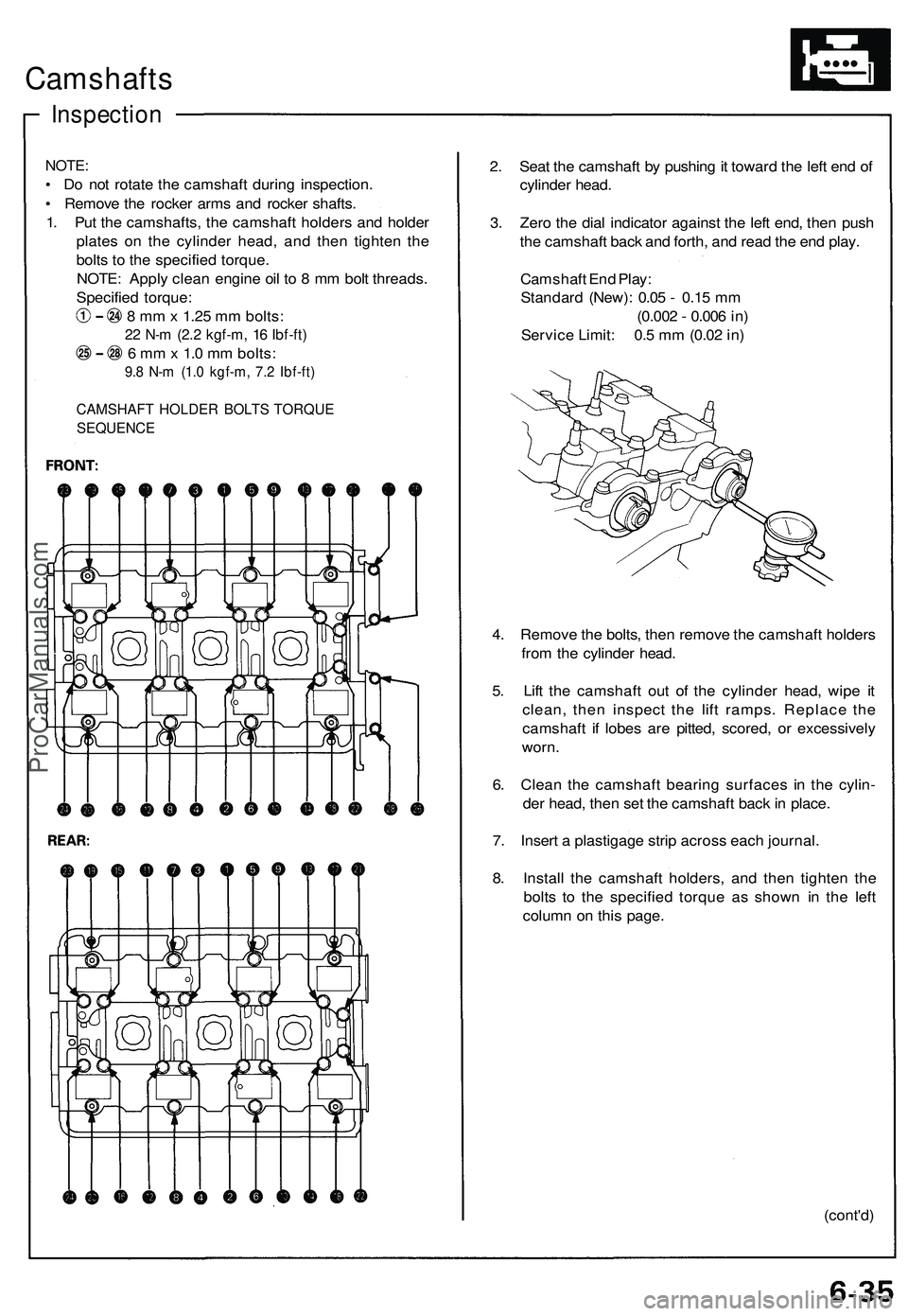

Camshafts

Inspection

NOTE:

• Do not rotate the camshaft during inspection.

• Remove the rocker arms and rocker shafts.

1. Put the camshafts, the camshaft holders and holder

plates on the cylinder head, and then tighten the

bolts to the specified torque.

NOTE: Apply clean engine oil to 8 mm bolt threads.

Specified torque:

8 mm x 1.25 mm bolts:

22 N-m (2.2 kgf-m, 16 Ibf-ft)

6 mm x 1.0 mm bolts:

9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)

CAMSHAFT HOLDER BOLTS TORQUE

SEQUENCE

2. Seat the camshaft by pushing it toward the left end of

cylinder head.

3. Zero the dial indicator against the left end, then push

the camshaft back and forth, and read the end play.

Camshaft End Play:

Standard (New): 0.05 - 0.15 mm

(0.002 - 0.006 in)

Service Limit: 0.5 mm (0.02 in)

4. Remove the bolts, then remove the camshaft holders

from the cylinder head.

5. Lift the camshaft out of the cylinder head, wipe it

clean, then inspect the lift ramps. Replace the

camshaft if lobes are pitted, scored, or excessively

worn.

6. Clean the camshaft bearing surfaces in the cylin-

der head, then set the camshaft back in place.

7. Insert a plastigage strip across each journal.

8. Install the camshaft holders, and then tighten the

bolts to the specified torque as shown in the left

column on this page.

(cont'd)ProCarManuals.com

Page 467 of 1503

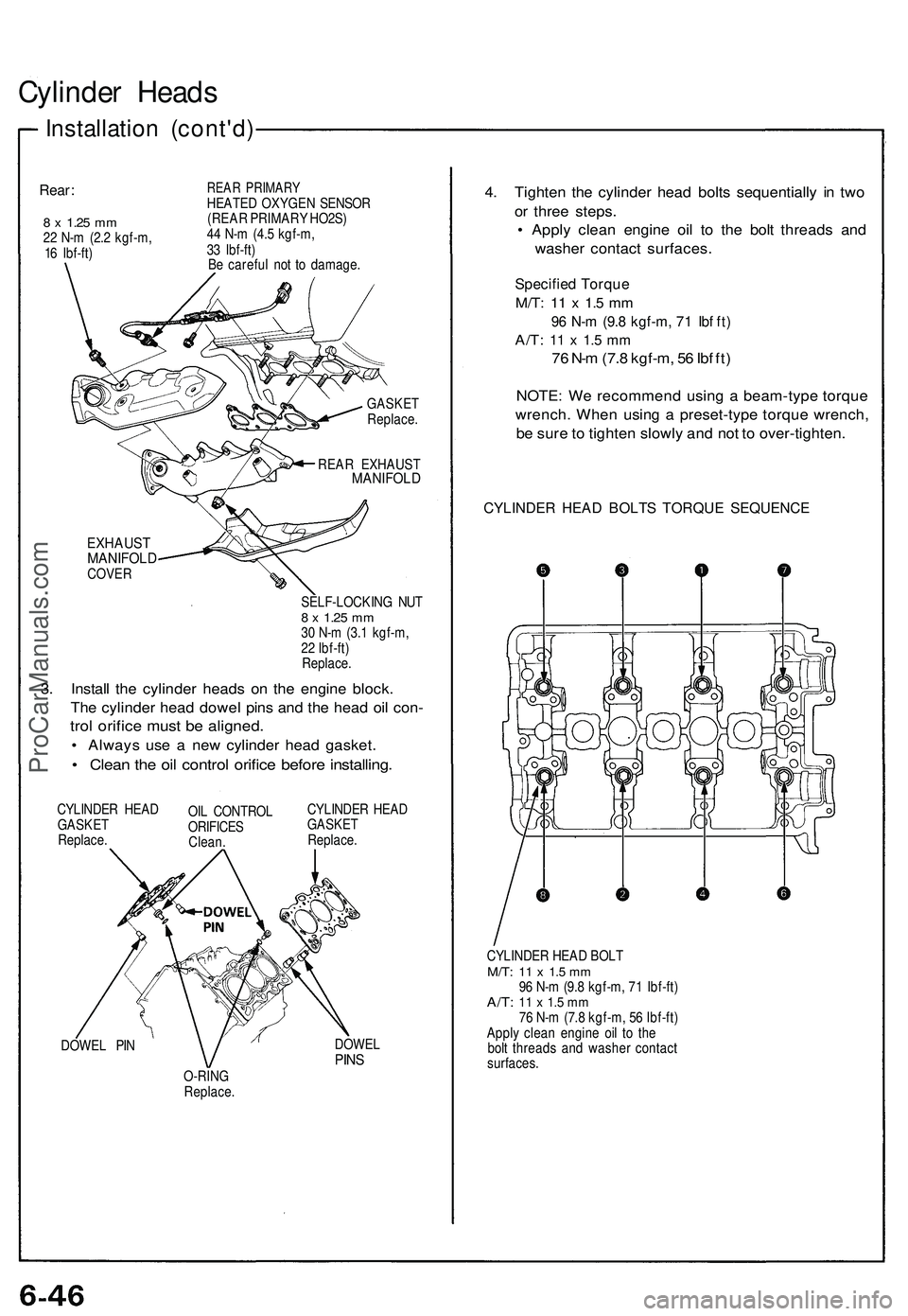

Cylinder Heads

Installation (cont'd)

Rear:

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

REAR PRIMARY

HEATED OXYGEN SENSOR

(REAR PRIMARY HO2S)

44 N-m (4.5 kgf-m,

33 Ibf-ft)

Be careful not to damage.

GASKET

Replace.

REAR EXHAUST

MANIFOLD

EXHAUST

MANIFOLD

COVER

SELF-LOCKING NUT

8 x

1.25

mm

30 N-m (3.1 kgf-m,

22 Ibf-ft)

Replace.

3. Install the cylinder heads on the engine block.

The cylinder head dowel pins and the head oil con-

trol orifice must be aligned.

• Always use a new cylinder head gasket.

• Clean the oil control orifice before installing.

CYLINDER HEAD

GASKET

Replace.

OIL CONTROL

ORIFICES

Clean.

CYLINDER HEAD

GASKET

Replace.

DOWEL PIN

DOWEL

PINS

O-RING

Replace.

4. Tighten the cylinder head bolts sequentially in two

or three steps.

• Apply clean engine oil to the bolt threads and

washer contact surfaces.

Specified Torque

M/T:

11 x 1.5 mm

96 N-m (9.8 kgf-m, 71 Ibf ft)

A/T:

11 x 1.5 mm

76 N-m (7.8 kgf-m, 56 Ibf ft)

NOTE: We recommend using a beam-type torque

wrench. When using a preset-type torque wrench,

be sure to tighten slowly and not to over-tighten.

CYLINDER HEAD BOLTS TORQUE SEQUENCE

CYLINDER HEAD BOLT

M/T:

11 x 1.5 mm

96 N-m (9.8 kgf-m, 71 Ibf-ft)

A/T:

11 x 1.5 mm

76 N-m (7.8 kgf-m, 56 Ibf-ft)

Apply clean engine oil to the

bolt threads and washer contact

surfaces.ProCarManuals.com

Page 470 of 1503

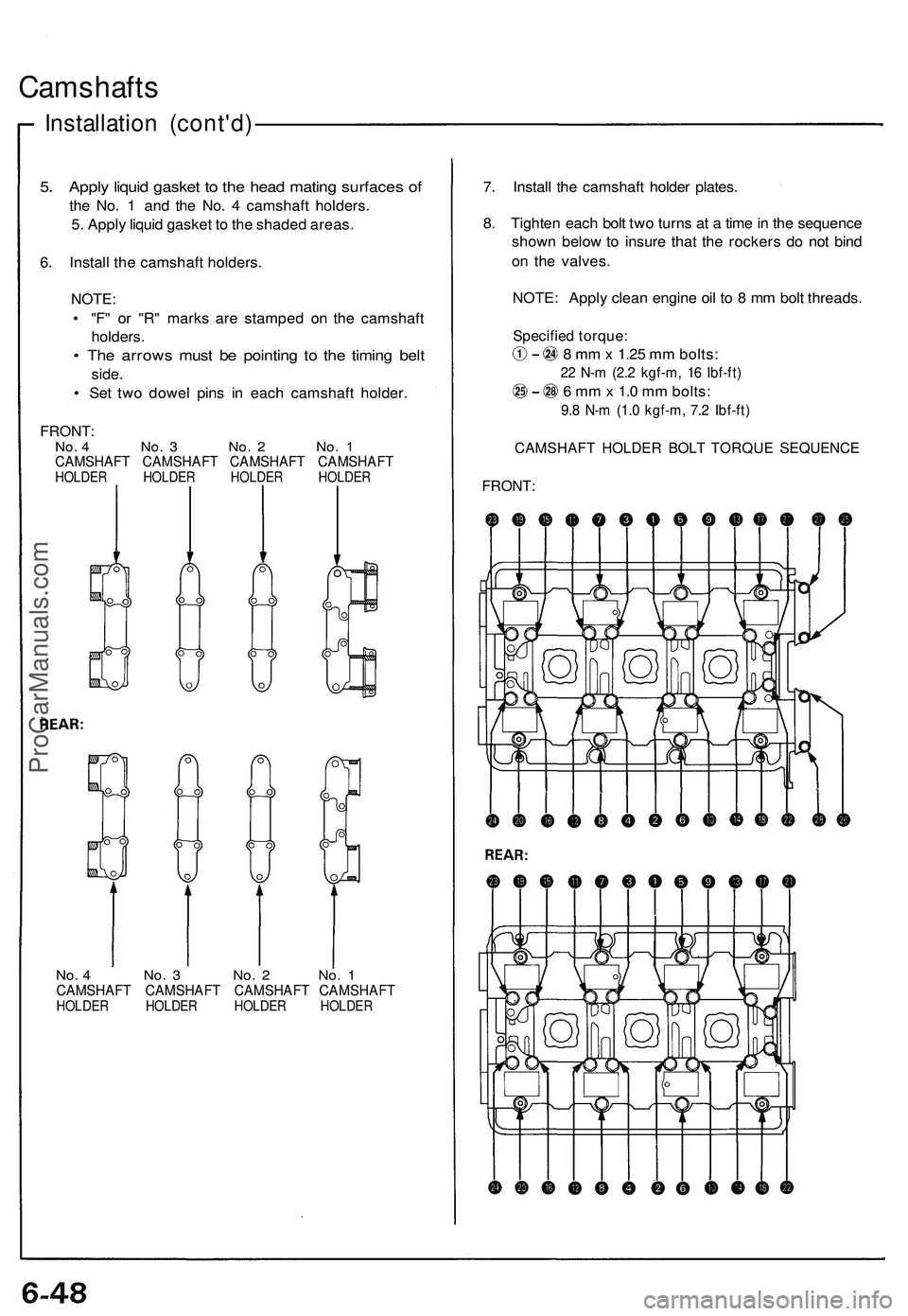

Camshafts

Installation (cont'd)

5. Apply liquid gasket to the head mating surfaces of

the No. 1 and the No. 4 camshaft holders.

5. Apply liquid gasket to the shaded areas.

6. Install the camshaft holders.

NOTE:

• "F" or "R" marks are stamped on the camshaft

holders.

• The arrows must be pointing to the timing belt

side.

• Set two dowel pins in each camshaft holder.

FRONT:

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

7. Install the camshaft holder plates.

8. Tighten each bolt two turns at a time in the sequence

shown below to insure that the rockers do not bind

on the valves.

NOTE: Apply clean engine oil to 8 mm bolt threads.

Specified torque:

8 mm x 1.25 mm bolts:

22 N-m (2.2 kgf-m, 16 Ibf-ft)

6 mm x 1.0 mm bolts:

9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)

CAMSHAFT HOLDER BOLT TORQUE SEQUENCE

FRONT:ProCarManuals.com

Page 495 of 1503

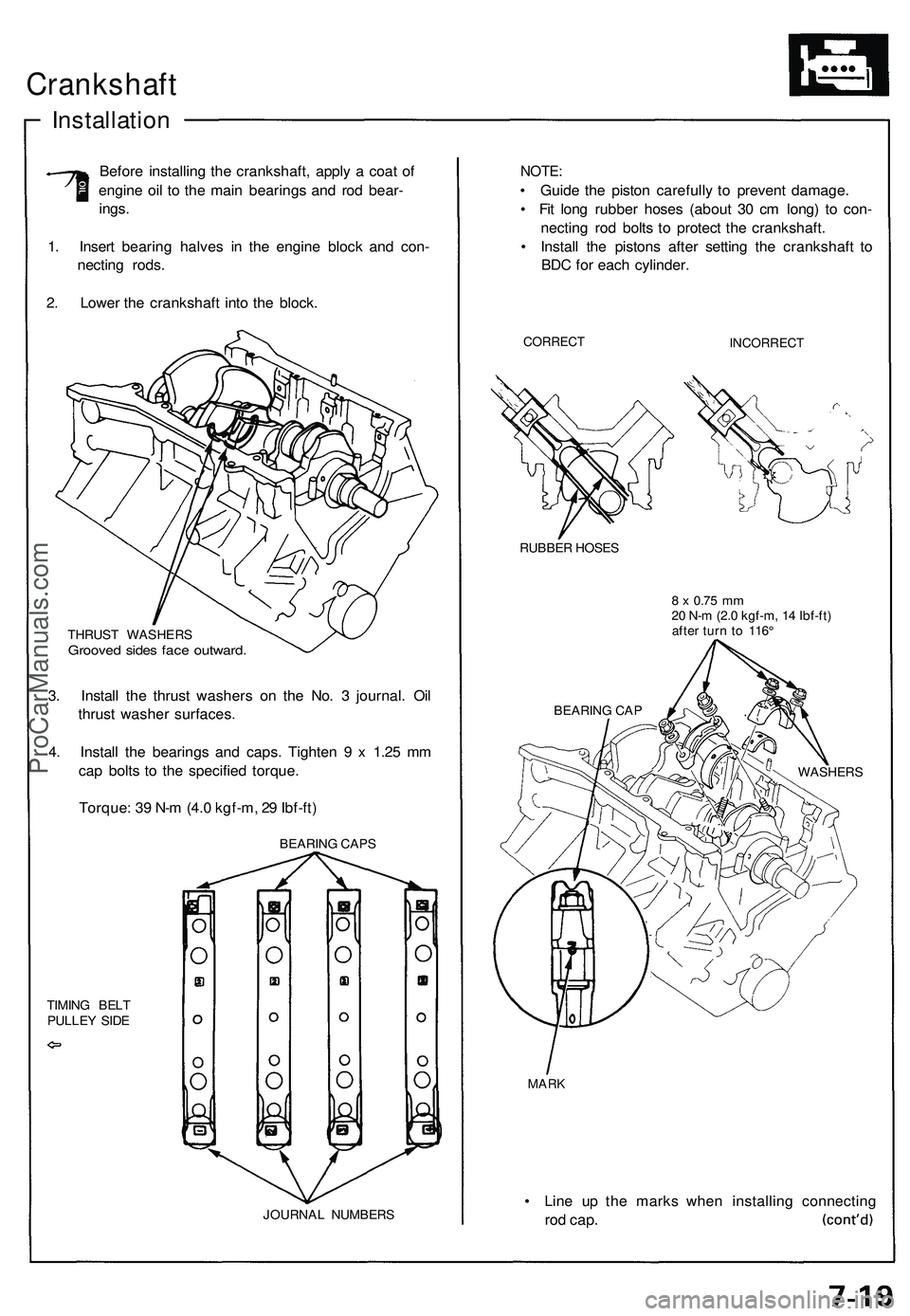

Crankshaft

Installation

Before installing the crankshaft, apply a coat of

engine oil to the main bearings and rod bear-

ings.

1. Insert bearing halves in the engine block and con-

necting rods.

2. Lower the crankshaft into the block.

THRUST WASHERS

Grooved sides face outward.

3. Install the thrust washers on the No. 3 journal. Oil

thrust washer surfaces.

4. Install the bearings and caps. Tighten 9 x 1.25 mm

cap bolts to the specified torque.

Torque: 39 N-m (4.0 kgf-m, 29 Ibf-ft)

TIMING BELT

PULLEY SIDE

JOURNAL NUMBERS

NOTE:

• Guide the piston carefully to prevent damage.

• Fit long rubber hoses (about 30 cm long) to con-

necting rod bolts to protect the crankshaft.

• Install the pistons after setting the crankshaft to

BDC for each cylinder.

CORRECT

INCORRECT

RUBBER HOSES

8 x

0.75

mm

20 N-m (2.0 kgf-m, 14 Ibf-ft)

after turn to 116°

MARK

• Line up the marks when installing connecting

rod

cap.

BEARING CAP

WASHERS

BEARING CAPSProCarManuals.com

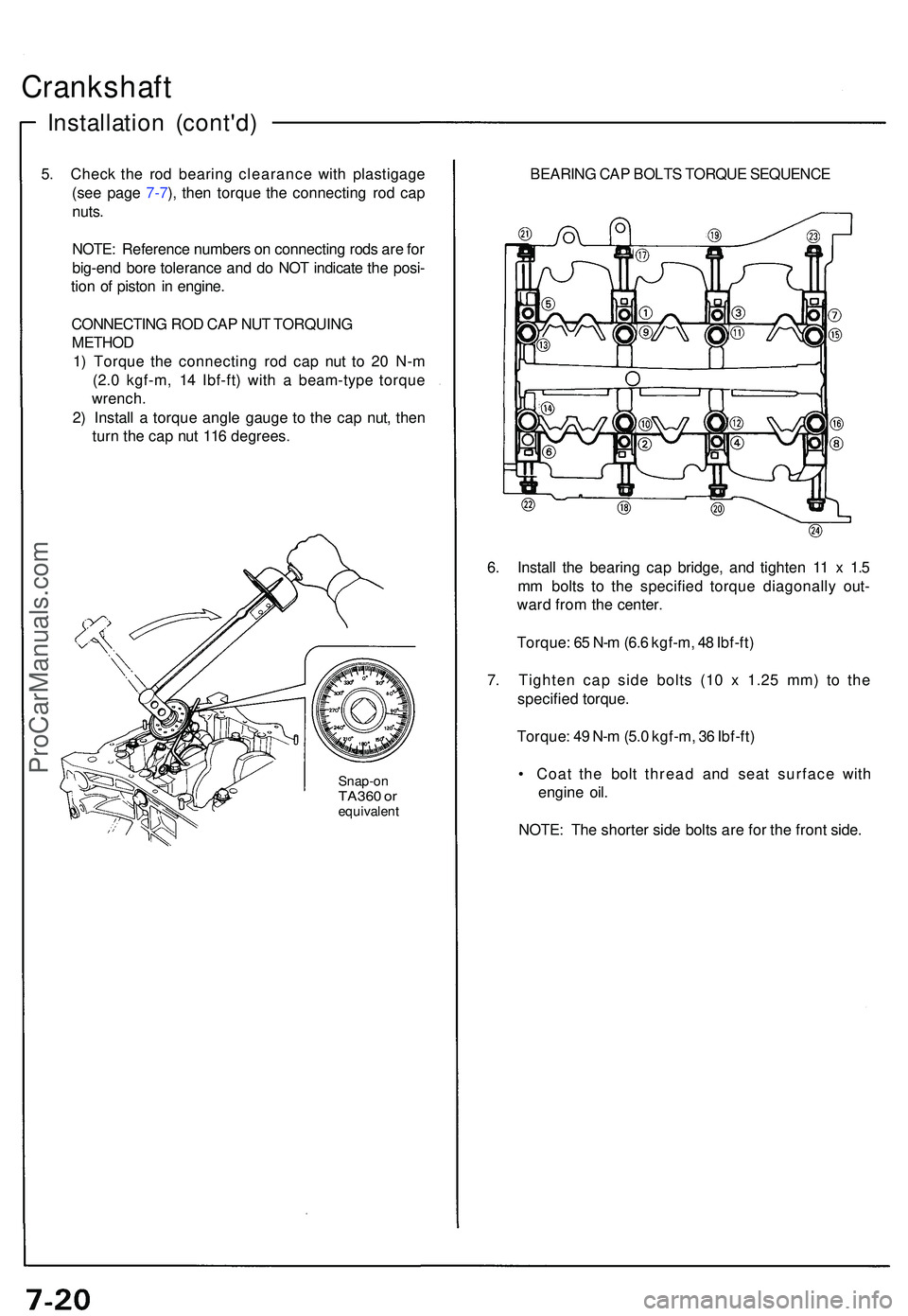

Page 496 of 1503

Crankshaft

Installation (cont'd )

5. Chec k th e ro d bearin g clearanc e wit h plastigag e

(se e pag e 7-7 ), the n torqu e th e connectin g ro d ca p

nuts .

NOTE : Referenc e number s o n connectin g rod s ar e fo r

big-en d bor e toleranc e an d d o NO T indicat e th e posi -

tio n o f pisto n i n engine .

CONNECTIN G RO D CA P NU T TORQUIN G

METHO D

1 ) Torqu e th e connectin g ro d ca p nu t t o 2 0 N- m

(2. 0 kgf-m , 1 4 Ibf-ft ) wit h a beam-typ e torqu e

wrench .

2 ) Instal l a torqu e angl e gaug e t o th e ca p nut , the n

tur n th e ca p nu t 11 6 degrees .

Snap-onTA360 o requivalen t

BEARING CAP BOLTS TORQUE SEQUENCE

6 . Instal l th e bearin g ca p bridge , an d tighte n 1 1 x 1. 5

m m bolt s t o th e specifie d torqu e diagonall y out -

war d fro m th e center .

Torque : 6 5 N- m (6. 6 kgf-m , 4 8 Ibf-ft )

7 . Tighte n ca p sid e bolt s (1 0 x 1.2 5 mm ) t o th e

specifie d torque .

Torque : 4 9 N- m (5. 0 kgf-m , 3 6 Ibf-ft )

• Coa t th e bol t threa d an d sea t surfac e wit h

engin e oil .

NOTE : Th e shorte r sid e bolt s ar e fo r th e fron t side .

ProCarManuals.com

Page 504 of 1503

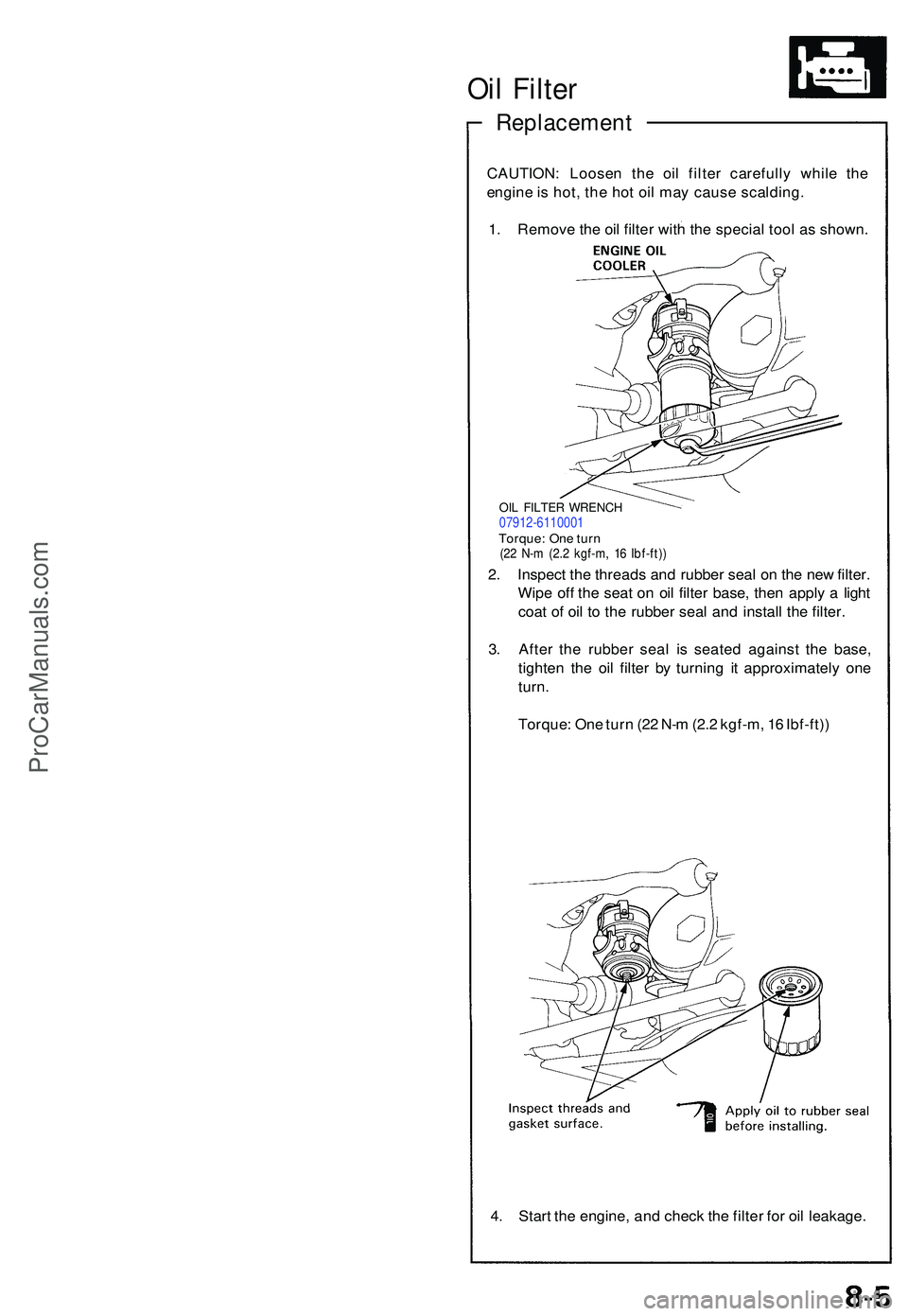

Oil Filte r

Replacemen t

CAUTION: Loose n th e oi l filte r carefull y whil e th e

engin e is hot , the hot oi l ma y cause scalding .

1 . Remov e th e oi l filte r wit h th e specia l too l a s shown .

OIL FILTE R WRENC H07912-611000 1Torque: On e tur n(22 N- m (2. 2 kgf-m , 1 6 Ibf-ft) )

2. Inspec t th e thread s an d rubbe r sea l o n th e ne w filter .

Wip e of f th e sea t o n oi l filte r base , the n appl y a ligh t

coa t o f oi l t o th e rubber seal an d instal l th e filter .

3 . Afte r th e rubbe r sea l i s seate d agains t th e base ,

tighte n th e oi l filte r b y turnin g i t approximatel y on e

turn .

Torque : On e tur n (2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft) )

4 . Star t th e engine , an d chec k th e filte r fo r oi l leakage .

ProCarManuals.com

Page 510 of 1503

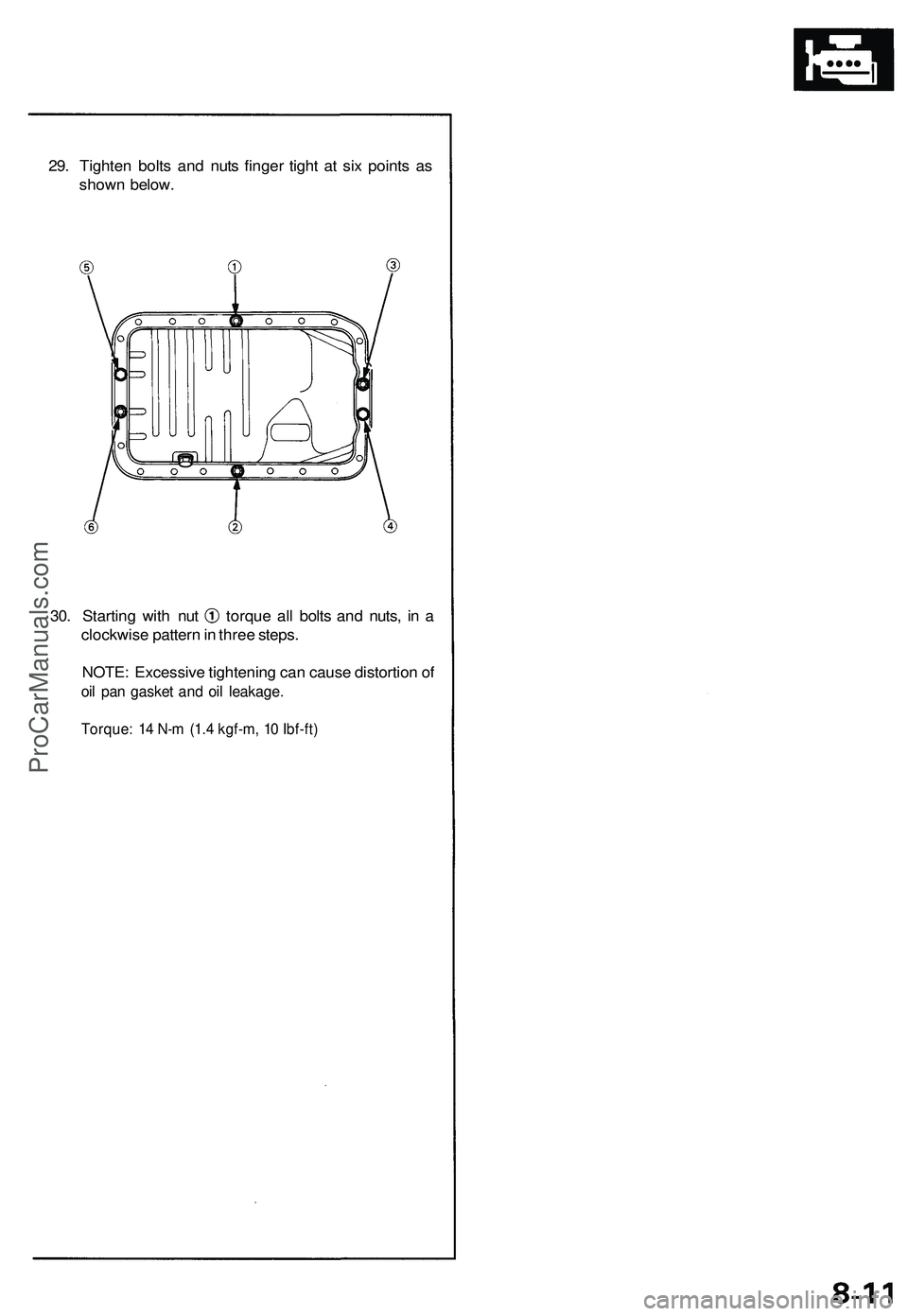

29. Tighten bolts and nuts finger tight at six points as

shown below.

30. Starting with nut torque all bolts and nuts, in a

clockwise pattern in three steps.

NOTE: Excessive tightening can cause distortion of

oil pan gasket and oil leakage.

Torque: 14 N-m (1.4 kgf-m, 10 Ibf-ft)ProCarManuals.com

Page 586 of 1503

PGM-FI System

System Description (cont'd)

3. Fuel Cut-off Control

During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,500 rpm.

Fuel cut-off action also takes place when engine speed exceeds 8,300 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

4. A/C Compressor Clutch Relay

When the ECM receives a demand for cooling from the air conditioning system, it delays the compressor from being

energized, and enriches the mixture to assure smooth translation to the A/C mode.

5. Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is below 153°F (67°C), the ECM controls the EVAP purge control solenoid valve

which cuts vacuum to the EVAP purge control canister diaphragm.

6. Intake Air Bypass (IAB) Control Solenoid Valve

When the engine speed is below 4,800 rpm, the IAB control solenoid valve is activated by a signal from the ECM. Intake

air then flows through the smaller chamber, and high torque is delivered. To increase air flow at engine speeds higher

than 4,800 rpm, the solenoid valve is deactivated by the ECM, and the intake air flows through the larger chamber.

7. Exhaust Gas Recirculation (EGR) Control Solenoid Valve

When the EGR is required for control of oxides of nitrogen (NOx) emissions, the ECM supplies ground to the EGR

control solenoid valve which supplies regulated vacuum to the EGR valve.

ECM Fail-safe/Back-up Functions

1. Fail-Safe Function

When an abnormality occurs in a signal from a sensor, the ECM ignores that signal and assumes a pre-programmed

valve for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM itself, the fuel injectors are controlled by a back-up circuit independent of the

system in order to permit minimal driving.

3. Self-diagnosis Function [Malfunction Indicator Lamp (MIL)]

When an abnormality occurs in a signal from a sensor, the ECM lights the MIL and stores the diagnostic trouble code

in erasable memory. When the ignition is initially turned on, the ECM supplies ground for the MIL for two seconds to

check the MIL bulb condition.

4. Two Trip Detection Method

To prevent false indications, the Two Trip Detection Method is used for the H02S, fuel metering-related, idle control

system, ECT sensor, EGR system self-diagnostic functions and EVAP control system. When an abnormality occurs,

the ECM stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (II)

again, the ECM informs the driver by lighting the MIL.

However, to ease troubleshooting, this function is cancelled when you short the service check connector. The MIL will

then blink immediately when an abnormality occurs.

5. Two (or three) Driving Cycle Detection Method

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. If misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles,

or TWC deterioration is detected during three consecutive driving cycles, the ECM turns the MIL on.

However,

to

ease

troubleshooting,

this

function

is

cancelled when

you

short

the

service check connector.

The MIL

will

then blink immediately when an abnormality occurs.ProCarManuals.com