fuel pump ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 349 of 1503

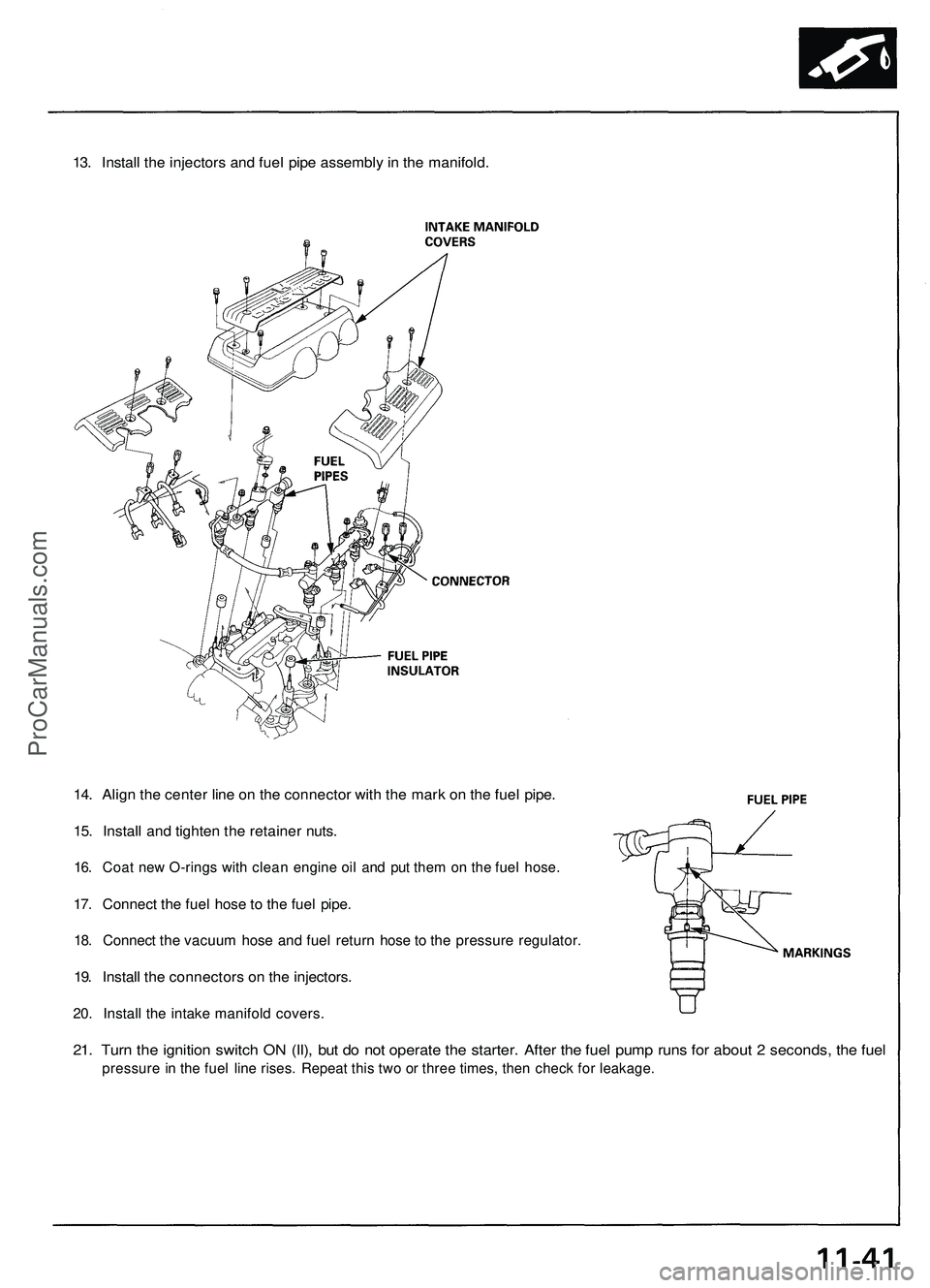

13. Install the injectors and fuel pipe assembly in the manifold.

14. Align the center line on the connector with the mark on the fuel pipe.

15. Install and tighten the retainer nuts.

16. Coat new O-rings with clean engine oil and put them on the fuel hose.

17. Connect the fuel hose to the fuel pipe.

18. Connect the vacuum hose and fuel return hose to the pressure regulator.

19. Install the connectors on the injectors.

20. Install the intake manifold covers.

21. Turn the ignition switch ON (II), but do not operate the starter. After the fuel pump runs for about 2 seconds, the fuel

pressure in the fuel line rises. Repeat this two or three times, then check for leakage.ProCarManuals.com

Page 368 of 1503

3-13

TDesign Specifications

(cont’d)

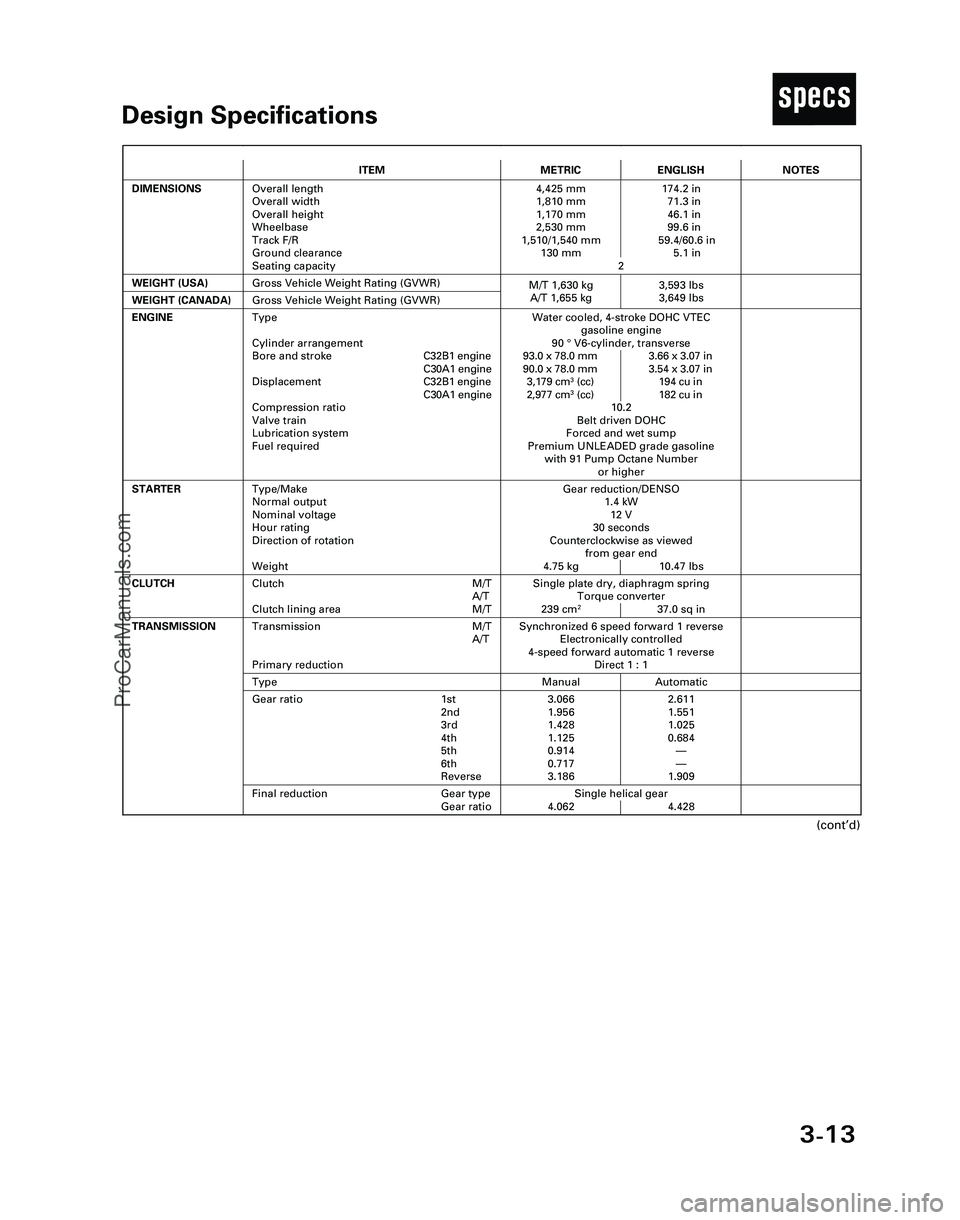

ITEMMETRICENGLISH

DIMENSIONSOverall length

Overall width

Overall height

Wheelbase

Track F/R

Ground clearance

Seating capacity4,425 mm 174.2 in

1,810 mm 71.3 in

1,170 mm 46.1 in

2,530 mm 99.6 in

1,510/1,540 mm 59.4/60.6 in

130 mm 5.1 in

2

WEIGHT (USA)

Single plate dry, diaphragm spring

Torque converter

239 cm

237.0 sq in

CLUTCHClutch M/T

A/T

Clutch lining area M/T

Gross Vehicle Weight Rating (GVWR)

NOTES

Gear reduction/DENSO

1.4 kW

12 V

30 seconds

Counterclockwise as viewed

from gear end

4.75 kg 10.47 lbs

ENGINEWater cooled, 4-stroke DOHC VTEC

gasoline engine

90 °V6-cylinder, transverse

93.0 x 78.0 mm 3.66 x 3.07 in

90.0 x 78.0 mm 3.54 x 3.07 in

3,179 cm

3(cc) 194 cu in

2,977 cm3(cc) 182 cu in

10.2

Belt driven DOHC

Forced and wet sump

Premium UNLEADED grade gasoline

with 91 Pump Octane Number

or higher

STARTERType/Make

Normal output

Nominal voltage

Hour rating

Direction of rotation

Weight

WEIGHT (CANADA)Gross Vehicle Weight Rating (GVWR)

Synchronized 6 speed forward 1 reverse

Electronically controlled

4-speed forward automatic 1 reverse

Direct 1 : 1Transmission M/T

A/T

Primary reduction

Manual AutomaticType

3.066 2.611

1.956 1.551

1.428 1.025

1.125 0.684

0.914—

0.717—

3.186 1.909Gear ratio 1st

2nd

3rd

4th

5th

6th

Reverse

Single helical gear

4.062 4.428

TRANSMISSION

Final reduction Gear type

Gear ratio

Type

Cylinder arrangement

Bore and strokeC32B1 engine

C30A1 engine

DisplacementC32B1 engine

C30A1 engine

Compression ratio

Valve train

Lubrication system

Fuel required

M/T 1,630 kg 3,593 lbs

A/T 1,655 kg 3,649 lbs

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-13

ProCarManuals.com

Page 375 of 1503

4-6

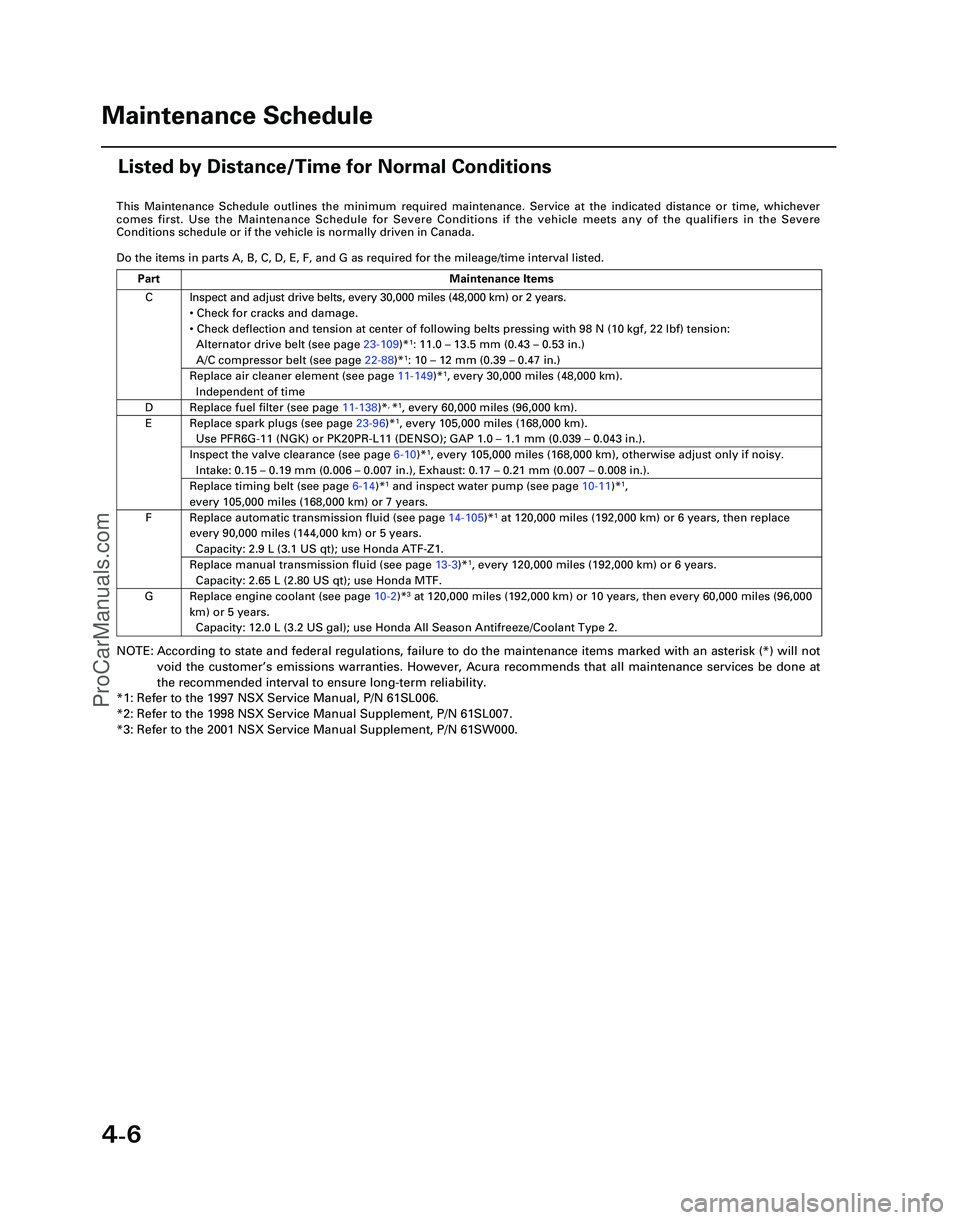

This Maintenance Schedule outlines the minimum required maintenance. Ser\

vice at the indicated distance or time, whichever

comes first. Use the Maintenance Schedule for Severe Conditions if the v\

ehicle meets any of the qualifiers in the Severe

Conditions schedule or if the vehicle is normally driven in Canada.

Do the items in parts A, B, C, D, E, F, and G as required for the mileag\

e/time interval listed.

NOTE: According to state and federal regulations, failure to do the maintenanc\

e items marked with an asterisk (*) will not

void the customer ’s emissions warranties. However, Acura recommends that all maintenance s\

ervices be done at

the recommended interval to ensure long-term reliability.

*1: Refer to the 1997 NSX Service Manual, P/N 61SL006.

*2: Refer to the 1998 NSX Service Manual Supplement, P/N 61SL007.

*3: Refer to the 2001 NSX Service Manual Supplement, P/N 61SW000.

C

D

E

F

G Inspect and adjust drive belts, every 30,000 miles (48,000 km) or 2 ye\

ars.

•

Check for cracks and damage.

• Check deflection and tension at center of following belts pressing with\

98 N (10 kgf, 22 lbf) tension:

Alternator drive belt (see page 23-109)*

1: 11.0 – 13.5 mm (0.43 – 0.53 in.)

A/C compressor belt (see page 22-88)*1: 10 – 12 mm (0.39 – 0.47 in.)

Replace air cleaner element (see page 11-149)*1, every 30,000 miles (48,000 km).

Independent of time

Replace fuel filter (see page 11-138)*, *1, every 60,000 miles (96,000 km).

Replace spark plugs (see page 23-96)*1, every 105,000 miles (168,000 km).

Use PFR6G-11 (NGK) or PK20PR-L11 (DENSO); GAP 1.0 – 1.1 mm (0.039 – 0.043 in.).

Inspect the valve clearance (see page 6-10)*1, every 105,000 miles (168,000 km), otherwise adjust only if noisy.

Intake: 0.15 – 0.19 mm (0.006 – 0.007 in.), Exhaust: 0.17 – 0.21 mm (0.007 – 0.008 in.).

Replace timing belt (see page 6-14)*1 and inspect water pump (see page 10-11)*1,

every 105,000 miles (168,000 km) or 7 years.

Replace automatic transmission fluid (see page 14-105)*1 at 120,000 miles (192,000 km) or 6 years, then replace

every 90,000 miles (144,000 km) or 5 years.

Capacity: 2.9 L (3.1 US qt); use Honda ATF-Z1.

Replace manual transmission fluid (see page 13-3)*1, every 120,000 miles (192,000 km) or 6 years.

Capacity: 2.65 L (2.80 US qt); use Honda MTF.

Replace engine coolant (see page 10-2 )*3 at 120,000 miles (192,000 km) or 10 years, then every 60,000 miles (9\

6,000

km) or 5 years. Capacity: 12.0 L (3.2 US gal); use Honda All Season Antifreeze/Coolant\

Type 2.

Part Maintenance Items

Maintenance Schedule

Listed by Distance/Time for Normal Conditions

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-6

ProCarManuals.com

Page 410 of 1503

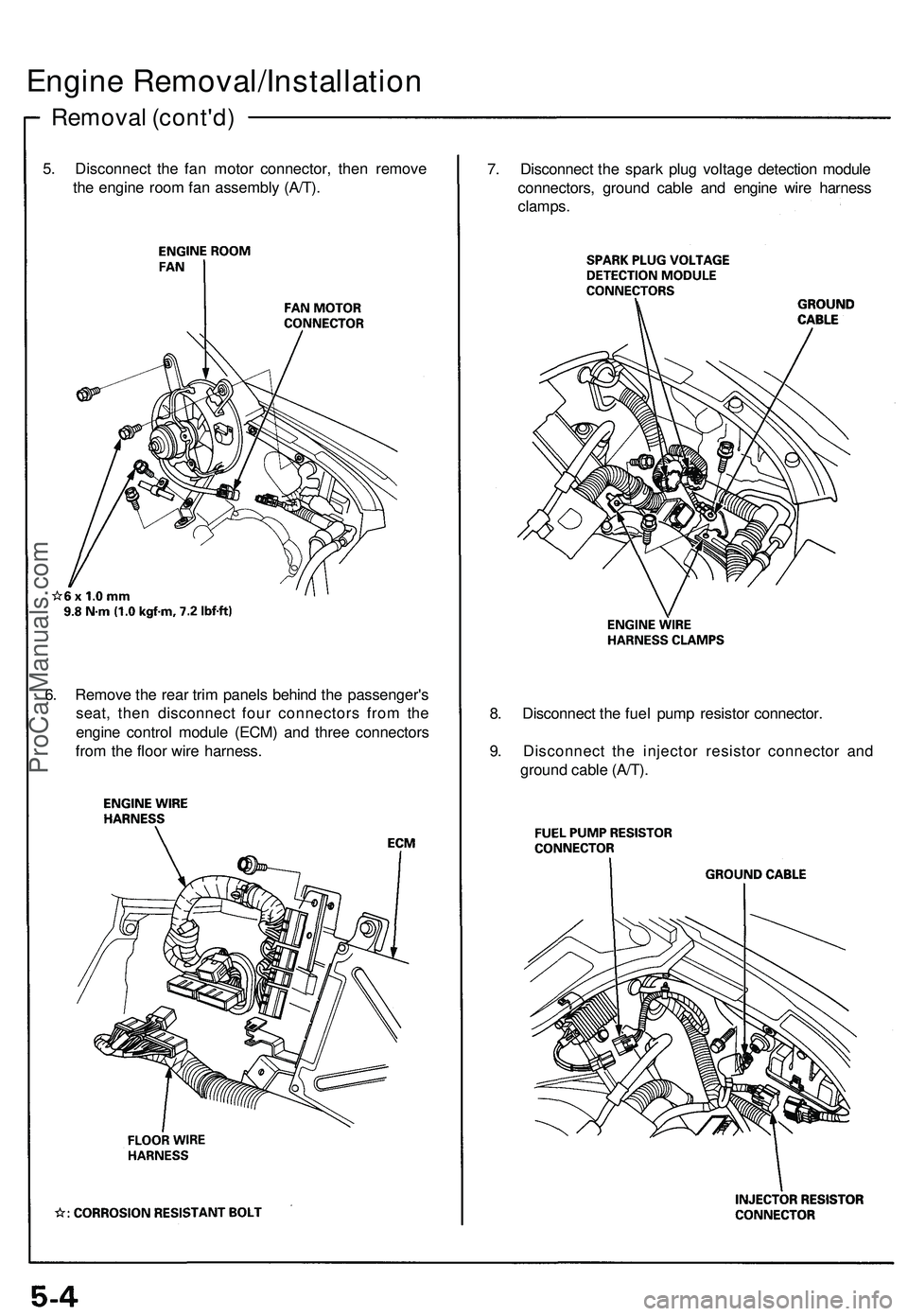

Removal (cont'd)

Engine Removal/Installation

5. Disconnect the fan motor connector, then remove

the engine room fan assembly (A/T).

7. Disconnect the spark plug voltage detection module

connectors, ground cable and engine wire harness

clamps.

8. Disconnect the fuel pump resistor connector.

9. Disconnect the injector resistor connector and

ground cable (A/T).

6. Remove the rear trim panels behind the passenger's

seat, then disconnect four connectors from the

engine control module (ECM) and three connectors

from the floor wire harness.ProCarManuals.com

Page 572 of 1503

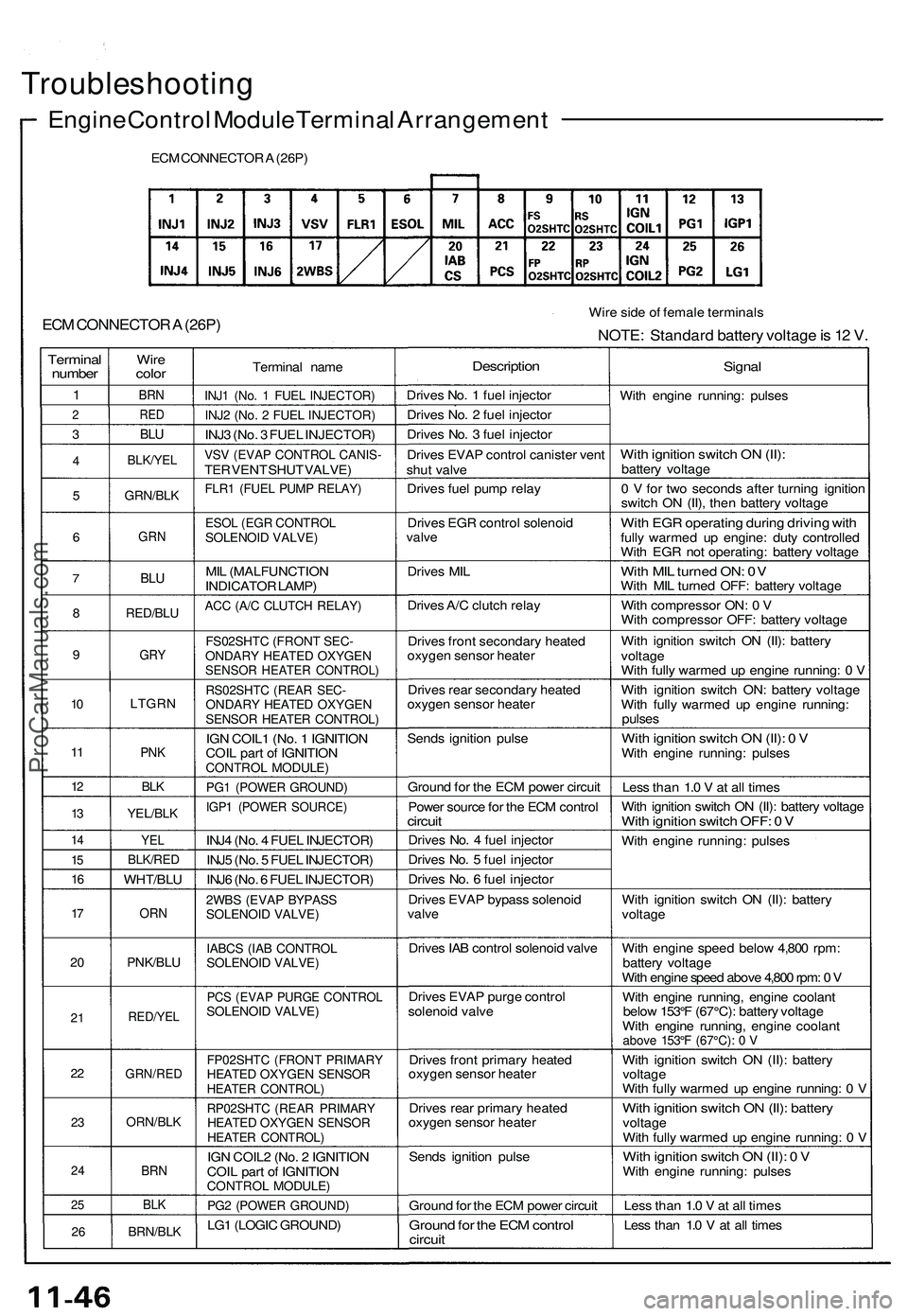

Troubleshooting

Engine Control Module Terminal Arrangement

ECM CONNECTOR A (26P)

ECM CONNECTOR A (26P)

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

Terminal

number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

20

21

22

23

24

25

26

Wire

color

BRN

RED

BLU

BLK/YEL

GRN/BLK

GRN

BLU

RED/BLU

GRY

LTGRN

PNK

BLK

YEL/BLK

YEL

BLK/RED

WHT/BLU

ORN

PNK/BLU

RED/YEL

GRN/RED

ORN/BLK

BRN

BLK

BRN/BLK

Terminal name

INJ1 (No. 1 FUEL INJECTOR)

INJ2 (No. 2 FUEL INJECTOR)

INJ3 (No. 3 FUEL INJECTOR)

VSV (EVAP CONTROL CANIS-

TER VENT SHUT VALVE)

FLR1 (FUEL PUMP RELAY)

ESOL (EGR CONTROL

SOLENOID VALVE)

MIL (MALFUNCTION

INDICATOR LAMP)

ACC (A/C CLUTCH RELAY)

FS02SHTC (FRONT SEC-

ONDARY HEATED OXYGEN

SENSOR HEATER CONTROL)

RS02SHTC (REAR SEC-

ONDARY HEATED OXYGEN

SENSOR HEATER CONTROL)

IGN COIL1 (No. 1 IGNITION

COIL part of IGNITION

CONTROL MODULE)

PG1 (POWER GROUND)

IGP1 (POWER SOURCE)

INJ4 (No. 4 FUEL INJECTOR)

INJ5 (No. 5 FUEL INJECTOR)

INJ6 (No. 6 FUEL INJECTOR)

2WBS (EVAP BYPASS

SOLENOID VALVE)

IABCS (IAB CONTROL

SOLENOID VALVE)

PCS (EVAP PURGE CONTROL

SOLENOID VALVE)

FP02SHTC (FRONT PRIMARY

HEATED OXYGEN SENSOR

HEATER CONTROL)

RP02SHTC (REAR PRIMARY

HEATED OXYGEN SENSOR

HEATER CONTROL)

IGN COIL2 (No. 2 IGNITION

COIL part of IGNITION

CONTROL MODULE)

PG2 (POWER GROUND)

LG1 (LOGIC GROUND)

Description

Drives No. 1 fuel injector

Drives No. 2 fuel injector

Drives No. 3 fuel injector

Drives EVAP control canister vent

shut valve

Drives fuel pump relay

Drives EGR control solenoid

valve

Drives MIL

Drives A/C clutch relay

Drives front secondary heated

oxygen sensor heater

Drives rear secondary heated

oxygen sensor heater

Sends ignition pulse

Ground for the ECM power circuit

Power source for the ECM control

circuit

Drives No. 4 fuel injector

Drives No. 5 fuel injector

Drives No. 6 fuel injector

Drives EVAP bypass solenoid

valve

Drives IAB control solenoid valve

Drives EVAP purge control

solenoid valve

Drives front primary heated

oxygen sensor heater

Drives rear primary heated

oxygen sensor heater

Sends ignition pulse

Ground for the ECM power circuit

Ground for the ECM control

circuit

Signal

With engine running: pulses

With ignition switch ON (II):

battery voltage

0 V for two seconds after turning ignition

switch ON (II), then battery voltage

With EGR operating during driving with

fully warmed up engine: duty controlled

With EGR not operating: battery voltage

With MIL turned ON: 0V

With MIL turned OFF: battery voltage

With compressor ON: 0 V

With compressor OFF: battery voltage

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON: battery voltage

With fully warmed up engine running:

pulses

With ignition switch ON (II): 0 V

With engine running: pulses

Less than 1.0 V at all times

With ignition switch ON (II): battery voltage

With ignition switch OFF: 0 V

With engine running: pulses

With ignition switch ON (II): battery

voltage

With engine speed below 4,800 rpm:

battery voltage

With engine speed above 4,800 rpm: 0 V

With engine running, engine coolant

below 153°F (67°C): battery voltage

With engine running, engine coolant

above 153°F (67°C): 0 V

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON (II): 0 V

With engine running: pulses

Less than 1.0 V at all times

Less than 1.0 V at all timesProCarManuals.com

Page 576 of 1503

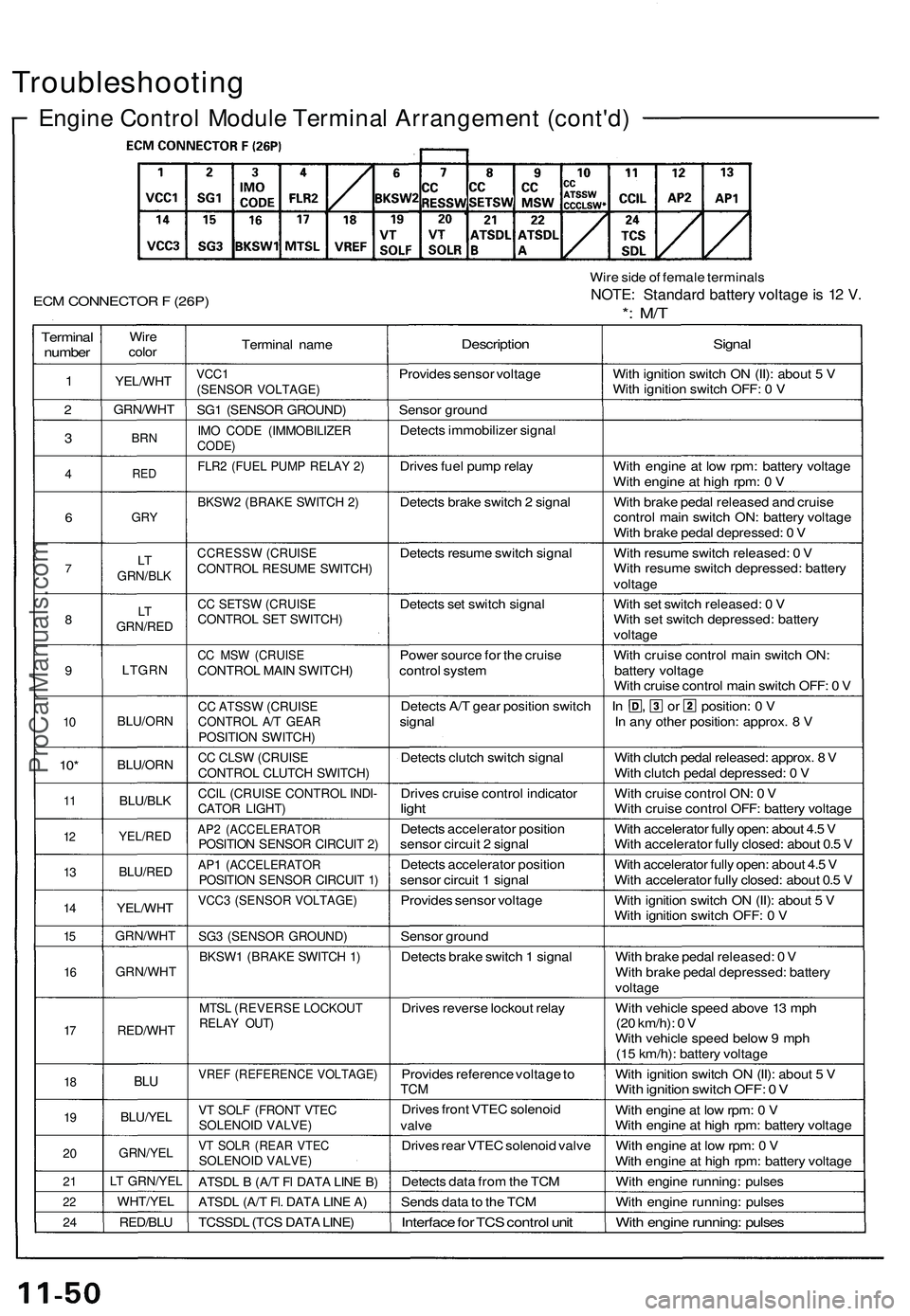

Troubleshooting

Engine Control Module Terminal Arrangement (cont'd)

ECM CONNECTOR F (26P)

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

*: M/T

Terminal

number

1

2

3

4

6

7

8

9

10

10*

11

12

13

14

15

16

17

18

19

20

21

22

24

Wire

color

YEL/WHT

GRN/WHT

BRN

RED

GRY

LT

GRN/BLK

LT

GRN/RED

LTGRN

BLU/ORN

BLU/ORN

BLU/BLK

YEL/RED

BLU/RED

YEL/WHT

GRN/WHT

GRN/WHT

RED/WHT

BLU

BLU/YEL

GRN/YEL

LT GRN/YEL

WHT/YEL

RED/BLU

Terminal name

VCC1

(SENSOR VOLTAGE)

SG1 (SENSOR GROUND)

IMO CODE (IMMOBILIZER

CODE)

FLR2 (FUEL PUMP RELAY 2)

BKSW2 (BRAKE SWITCH 2)

CCRESSW (CRUISE

CONTROL RESUME SWITCH)

CC SETSW (CRUISE

CONTROL SET SWITCH)

CC MSW (CRUISE

CONTROL MAIN SWITCH)

CC ATSSW (CRUISE

CONTROL A/T GEAR

POSITION SWITCH)

CC CLSW (CRUISE

CONTROL CLUTCH SWITCH)

CCIL (CRUISE CONTROL INDI-

CATOR LIGHT)

AP2 (ACCELERATOR

POSITION SENSOR CIRCUIT 2)

AP1 (ACCELERATOR

POSITION SENSOR CIRCUIT 1)

VCC3 (SENSOR VOLTAGE)

SG3 (SENSOR GROUND)

BKSW1 (BRAKE SWITCH 1)

MTSL (REVERSE LOCKOUT

RELAY OUT)

VREF (REFERENCE VOLTAGE)

VT SOLF (FRONT VTEC

SOLENOID VALVE)

VT SOLR (REAR VTEC

SOLENOID VALVE)

ATSDL B (A/T Fl DATA LINE B)

ATSDL (A/T Fl. DATA LINE A)

TCSSDL (TCS DATA LINE)

Description

Provides sensor voltage

Sensor ground

Detects immobilizer signal

Drives fuel pump relay

Detects brake switch 2 signal

Detects resume switch signal

Detects set switch signal

Power source for the cruise

control system

Detects A/T gear position switch

signal

Detects clutch switch signal

Drives cruise control indicator

light

Detects accelerator position

sensor circuit 2 signal

Detects accelerator position

sensor circuit 1 signal

Provides sensor voltage

Sensor ground

Detects brake switch 1 signal

Drives reverse lockout relay

Provides reference voltage to

TCM

Drives front VTEC solenoid

valve

Drives rear VTEC solenoid valve

Detects data from the TCM

Sends data to the TCM

Interface for TCS control unit

Signal

With ignition switch ON (II): about 5 V

With ignition switch OFF: 0 V

With engine at low rpm: battery voltage

With engine at high rpm: 0 V

With brake pedal released and cruise

control main switch ON: battery voltage

With brake pedal depressed: 0 V

With resume switch released: 0 V

With resume switch depressed: battery

voltage

With set switch released: 0 V

With set switch depressed: battery

voltage

With cruise control main switch ON:

battery voltage

With cruise control main switch OFF: 0 V

In , or position: 0 V

In any other position: approx. 8 V

With clutch pedal released: approx. 8 V

With clutch pedal depressed: 0 V

With cruise control ON: 0 V

With cruise control OFF: battery voltage

With accelerator fully open: about 4.5 V

With accelerator fully closed: about 0.5 V

With accelerator fully open: about 4.5 V

With accelerator fully closed: about 0.5 V

With ignition switch ON (II): about 5 V

With ignition switch OFF: 0 V

With brake pedal released: 0 V

With brake pedal depressed: battery

voltage

With vehicle speed above 13 mph

(20 km/h): 0 V

With vehicle speed below 9 mph

(15 km/h): battery voltage

With ignition switch ON (II): about 5 V

With ignition switch OFF: 0 V

With engine at low rpm: 0 V

With engine at high rpm: battery voltage

With engine at low rpm: 0 V

With engine at high rpm: battery voltage

With engine running: pulses

With engine running: pulses

With engine running: pulsesProCarManuals.com

Page 607 of 1503

Fuel Supply System

System Description

The fuel supply system consists of a fuel tank, in-tank

high-pressure fuel pump, fuel pump relay, fuel pump

resistor PGM-FI main relay, fuel filter, fuel pressure regu-

lator, fuel injectors, injector resistor (A/T), and fuel deliv-

ery and return lines. This system delivers pressure-regu-

lated fuel to the fuel injectors and cuts the fuel delivery

when the engine is not running.ProCarManuals.com

Page 611 of 1503

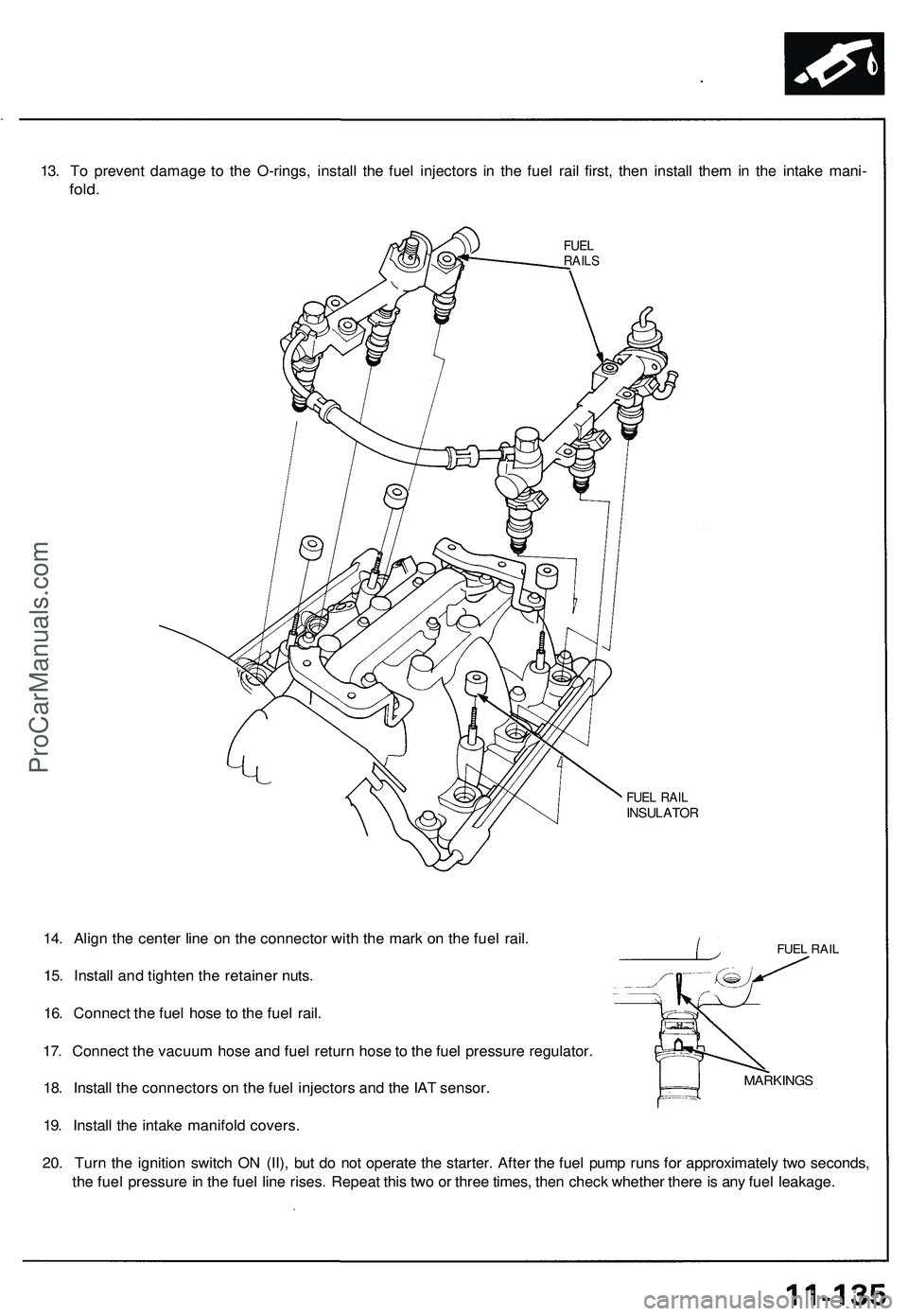

13. To prevent damage to the O-rings, install the fuel injectors in the fuel rail first, then install them in the intake mani-

fold.

FUEL

RAILS

FUEL RAIL

INSULATOR

FUEL RAIL

14. Align the center line on the connector with the mark on the fuel rail.

15. Install and tighten the retainer nuts.

16. Connect the fuel hose to the fuel rail.

17. Connect the vacuum hose and fuel return hose to the fuel pressure regulator.

18. Install the connectors on the fuel injectors and the IAT sensor.

19. Install the intake manifold covers.

20. Turn the ignition switch ON (II), but do not operate the starter. After the fuel pump runs for approximately two seconds,

the fuel pressure in the fuel line rises. Repeat this two or three times, then check whether there is any fuel leakage.

MARKINGSProCarManuals.com

Page 616 of 1503

Fuel Suppl y Syste m

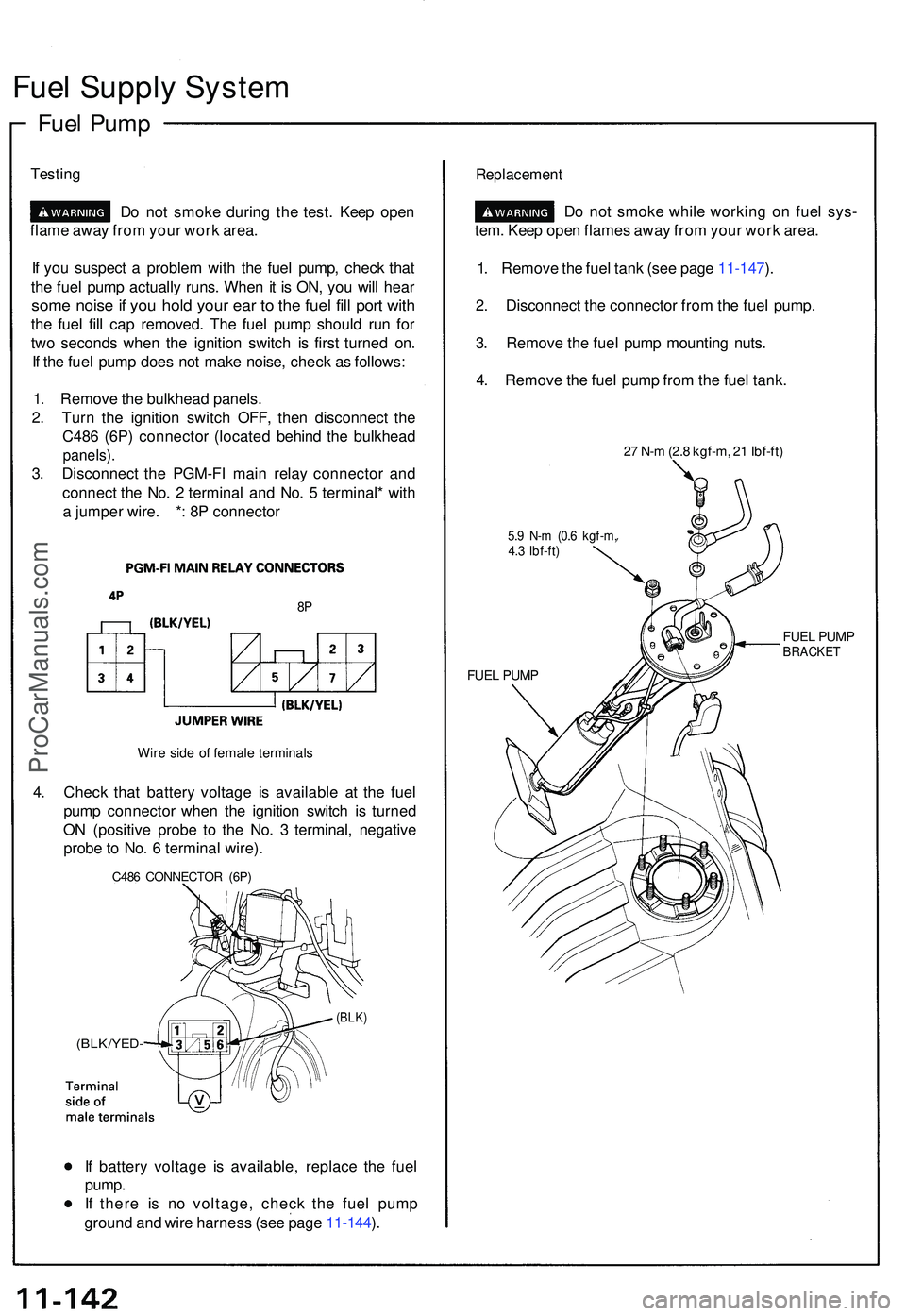

Fuel Pum p

Testin g

Do no t smok e durin g th e test . Kee p ope n

flam e awa y fro m you r wor k area .

I f yo u suspec t a proble m wit h th e fue l pump , chec k tha t

th e fue l pum p actuall y runs . Whe n it i s ON , yo u wil l hea r

some nois e if yo u hol d you r ea r t o th e fue l fil l por t wit h

the fue l fil l ca p removed . Th e fue l pum p shoul d ru n fo r

tw o second s whe n th e ignitio n switc h i s firs t turne d on .

I f th e fue l pum p doe s no t mak e noise , chec k a s follows :

1 . Remov e th e bulkhea d panels .

2 . Tur n th e ignitio n switc h OFF , the n disconnec t th e

C48 6 (6P ) connecto r (locate d behin d th e bulkhea d

panels).

3. Disconnec t th e PGM-F I mai n rela y connecto r an d

connec t th e No . 2 termina l an d No . 5 terminal * wit h

a jumpe r wire . * : 8 P connecto r

8P

Wir e sid e o f femal e terminal s

4. Chec k tha t batter y voltag e i s availabl e a t th e fue l

pum p connecto r whe n th e ignitio n switc h i s turne d

O N (positiv e prob e t o th e No . 3 terminal , negativ e

prob e to No . 6 termina l wire) .

C486 CONNECTO R (6P )

(BLK/YED -

(BLK)

If batter y voltag e i s available , replac e th e fue l

pump .

I f ther e i s n o voltage , chec k th e fue l pum p

groun d an d wir e harnes s (se e pag e 11-144 ).

Replacemen t

Do no t smok e whil e workin g o n fue l sys -

tem . Kee p ope n flame s awa y fro m you r wor k area .

1 . Remov e th e fue l tan k (se e pag e 11-147 ).

2 . Disconnec t th e connecto r fro m th e fue l pump .

3 . Remov e th e fue l pum p mountin g nuts .

4 . Remov e th e fue l pum p fro m th e fue l tank .

27 N- m (2. 8 kgf-m , 2 1 Ibf-ft )

5.9 N- m (0. 6 kgf-m ,4.3 Ibf-ft )

FUEL PUM P FUE

L PUM P

BRACKE T

ProCarManuals.com

Page 617 of 1503

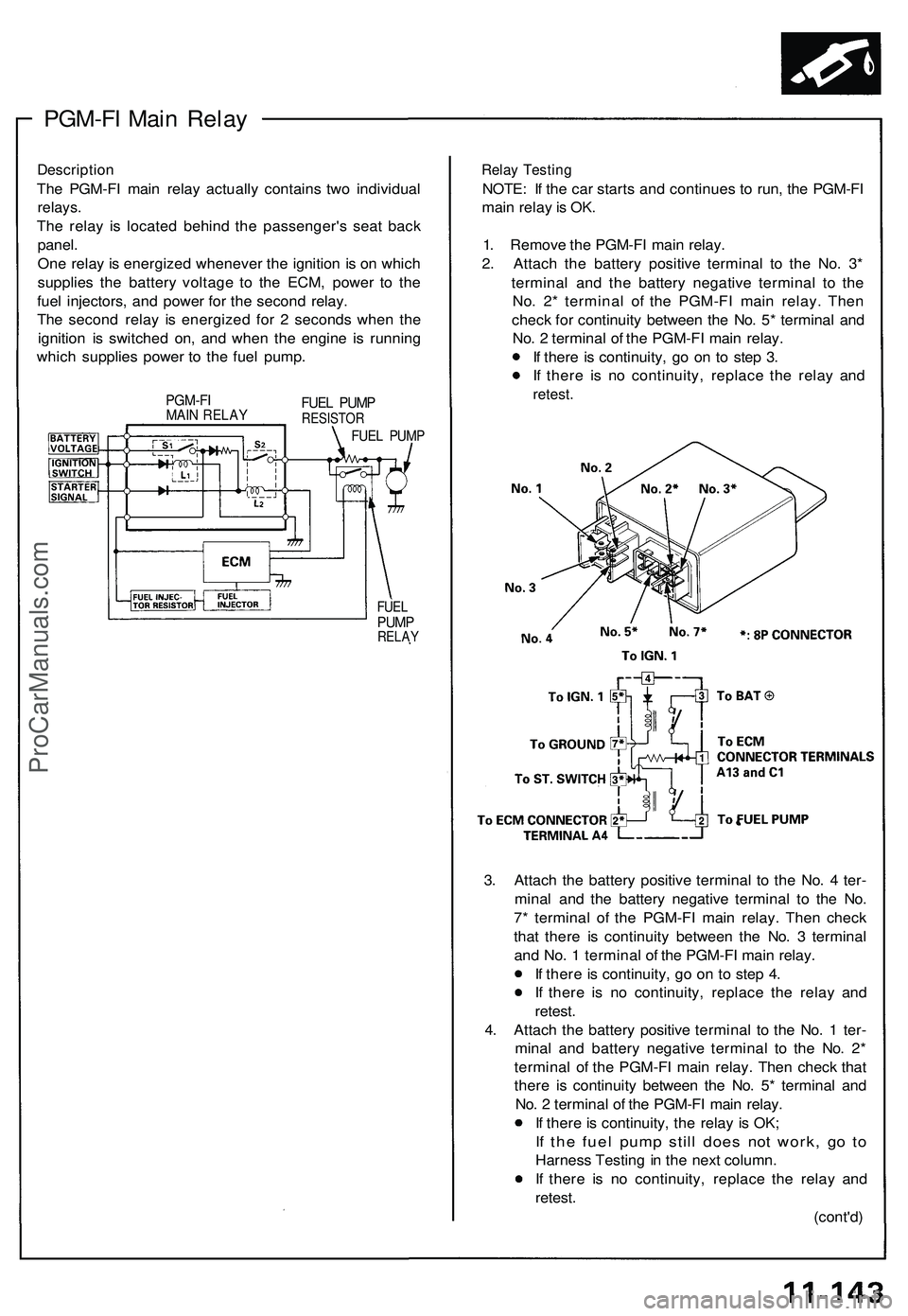

PGM-FI Main Relay

Description

The PGM-FI main relay actually contains two individual

relays.

The relay is located behind the passenger's seat back

panel.

One relay is energized whenever the ignition is on which

supplies the battery voltage to the ECM, power to the

fuel injectors, and power for the second relay.

The second relay is energized for 2 seconds when the

ignition is switched on, and when the engine is running

which supplies power to the fuel pump.

PGM-FI

MAIN RELAY

FUEL PUMP

RESISTOR

FUEL PUMP

FUEL

PUMP

RELAY

Relay Testing

NOTE: If the car starts and continues to run, the PGM-FI

main relay is OK.

1. Remove the PGM-FI main relay.

2. Attach the battery positive terminal to the No. 3*

terminal and the battery negative terminal to the

No. 2* terminal of the PGM-FI main relay. Then

check for continuity between the No. 5* terminal and

No. 2 terminal of the PGM-FI main relay.

If there is continuity, go on to step 3.

If there is no continuity, replace the relay and

retest.

3. Attach the battery positive terminal to the No. 4 ter-

minal and the battery negative terminal to the No.

7* terminal of the PGM-FI main relay. Then check

that there is continuity between the No. 3 terminal

and No. 1 terminal of the PGM-FI main relay.

If there is continuity, go on to step 4.

If there is no continuity, replace the relay and

retest.

4. Attach the battery positive terminal to the No. 1 ter-

minal and battery negative terminal to the No. 2*

terminal of the PGM-FI main relay. Then check that

there is continuity between the No. 5* terminal and

No. 2 terminal of the PGM-FI main relay.

If there is continuity, the relay is OK;

If the fuel pump still does not work, go to

Harness Testing in the next column.

If there is no continuity, replace the relay and

retest.

(cont'd)ProCarManuals.com