turn signal ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 100 of 1503

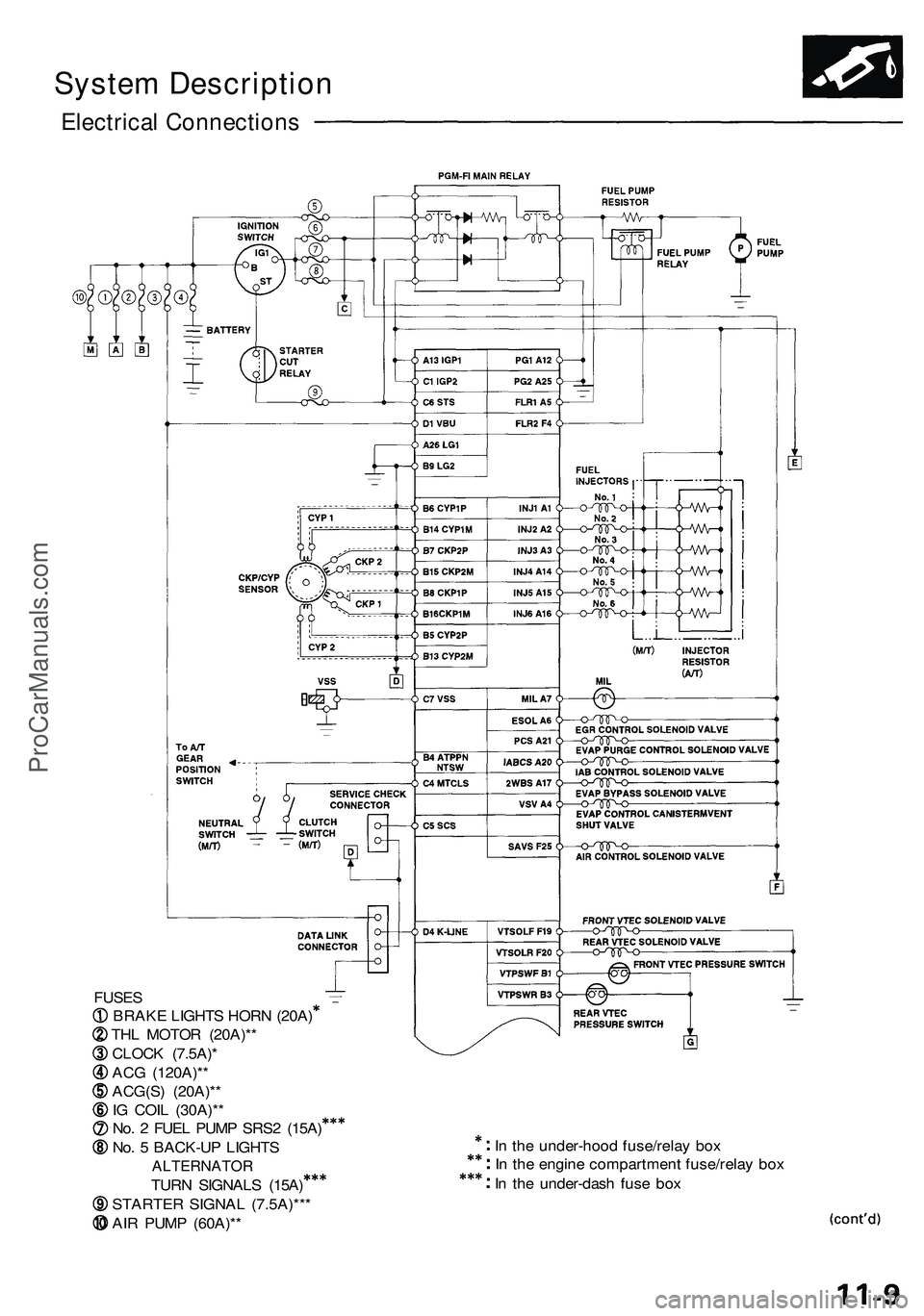

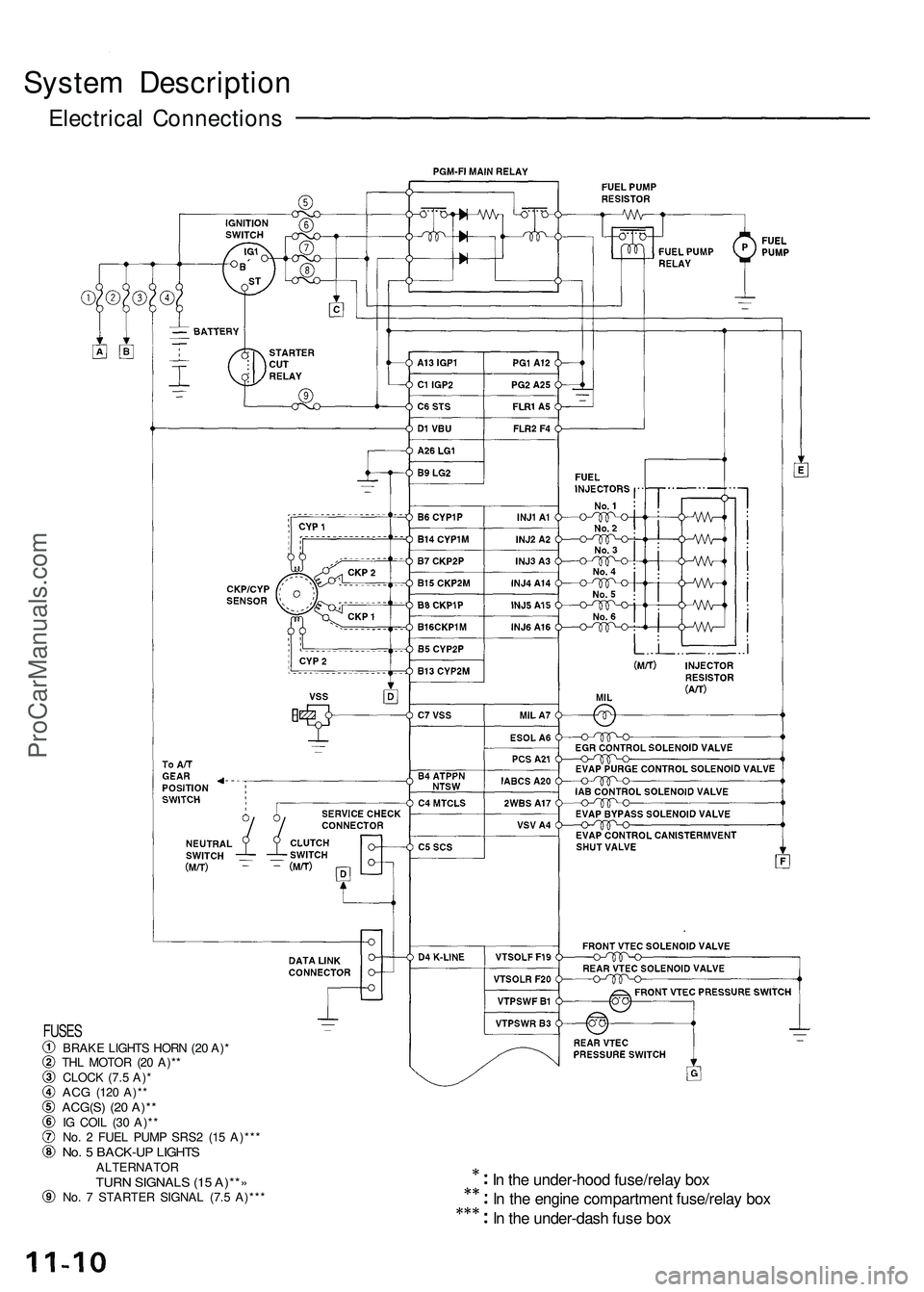

Electrical Connection s

FUSES

BRAK E LIGHT S HOR N (20A )

TH L MOTO R (20A)* *

CLOC K (7.5A) *

AC G (120A)* *

ACG(S ) (20A)* *

I G COI L (30A)* *

No . 2 FUE L PUM P SRS 2 (15A )

No . 5 BACK-U P LIGHT S

ALTERNATO R

TURN SIGNAL S (15A )

STARTE R SIGNA L (7.5A)** *

AI R PUM P (60A)* * I

n th e under-hoo d fuse/rela y bo x

I n th e engin e compartmen t fuse/rela y bo x

I n th e under-das h fus e bo x

System Description

ProCarManuals.com

Page 141 of 1503

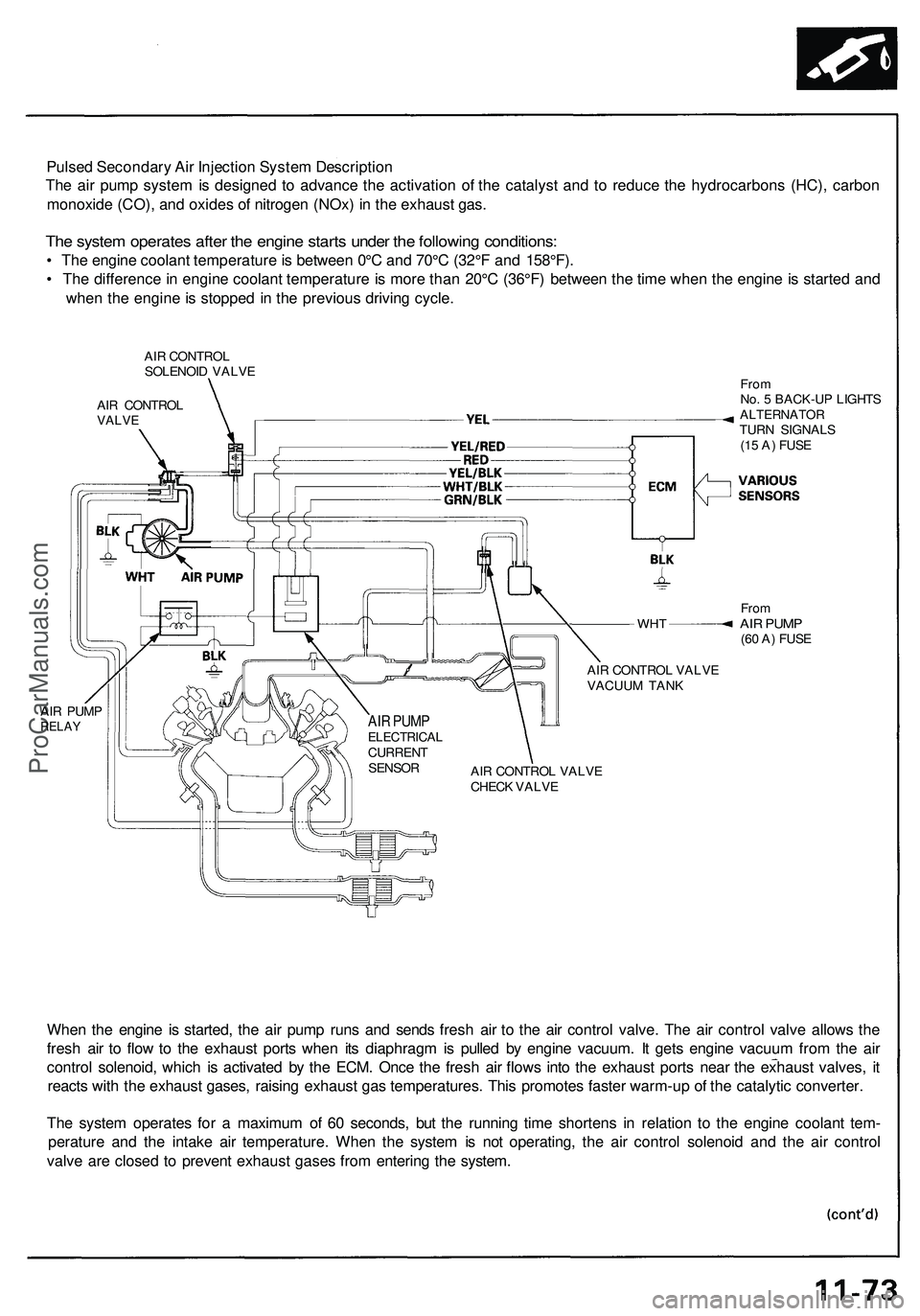

Pulsed Secondary Air Injection System Description

The air pump system is designed to advance the activation of the catalyst and to reduce the hydrocarbons (HC), carbon

monoxide (CO), and oxides of nitrogen (NOx) in the exhaust gas.

The system operates after the engine starts under the following conditions:

• The engine coolant temperature is between 0°C and 70°C (32°F and 158°F).

• The difference in engine coolant temperature is more than 20°C (36°F) between the time when the engine is started and

when the engine is stopped in the previous driving cycle.

AIR CONTROL

SOLENOID VALVE

AIR CONTROL

VALVE

WHT

AIR PUMP

RELAY

From

No. 5 BACK-UP LIGHTS

ALTERNATOR

TURN SIGNALS

(15 A) FUSE

From

AIR PUMP

(60 A) FUSE

AIR CONTROL VALVE

VACUUM TANK

AIR CONTROL VALVE

CHECK VALVE

When the engine is started, the air pump runs and sends fresh air to the air control valve. The air control valve allows the

fresh air to flow to the exhaust ports when its diaphragm is pulled by engine vacuum. It gets engine vacuum from the air

control solenoid, which is activated by the ECM. Once the fresh air flows into the exhaust ports near the exhaust valves, it

reacts with the exhaust gases, raising exhaust gas temperatures. This promotes faster warm-up of the catalytic converter.

The system operates for a maximum of 60 seconds, but the running time shortens in relation to the engine coolant tem-

perature and the intake air temperature. When the system is not operating, the air control solenoid and the air control

valve are closed to prevent exhaust gases from entering the system.

AIR PUMP

ELECTRICAL

CURRENT

SENSORProCarManuals.com

Page 276 of 1503

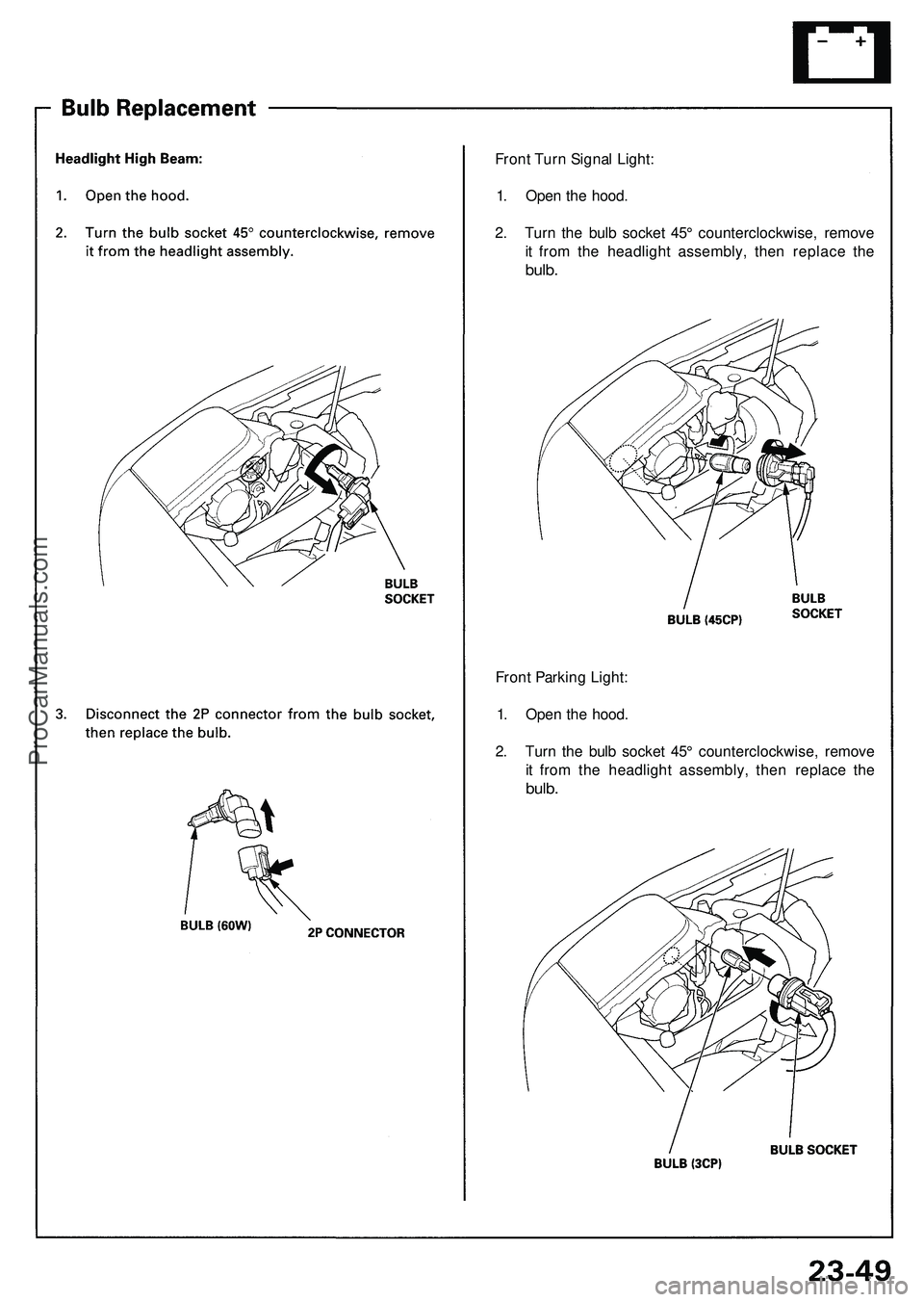

Front Turn Signal Light:

1. Open the hood.

2. Turn the bulb socket 45° counterclockwise, remove

it from the headlight assembly, then replace the

bulb.

Front Parking Light:

1. Open the hood.

2. Turn the bulb socket 45° counterclockwise, remove

it from the headlight assembly, then replace the

bulb.ProCarManuals.com

Page 370 of 1503

3-15

T

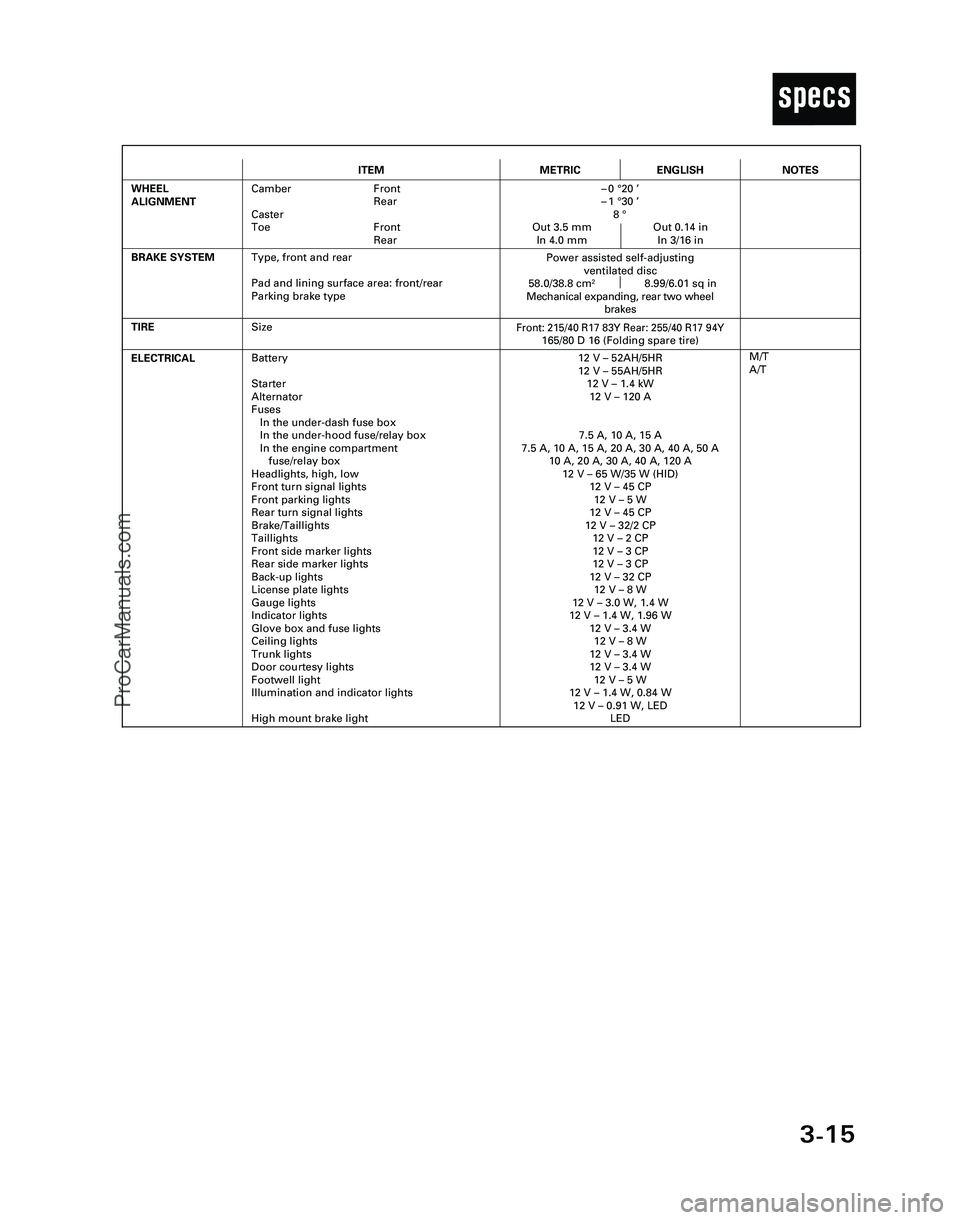

ITEMMETRICENGLISH

ELECTRICALBattery

Starter

Alternator

Fuses

In the under-dash fuse box

In the under-hood fuse/relay box

In the engine compartment

fuse/relay box

Headlights, high, low

Front turn signal lights

Front parking lights

Rear turn signal lights

Brake/Taillights

Taillights

Front side marker lights

Rear side marker lights

Back-up lights

License plate lights

Gauge lights

Indicator lights

Glove box and fuse lights

Ceiling lights

Trunk lights

Door courtesy lights

Footwell light

Illumination and indicator lights

High mount brake light12 V – 52AH/5HR

12 V – 55AH/5HR

12 V – 1.4 kW

12 V – 120 A

7.5 A, 10 A, 15 A

7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A, 50 A

10 A, 20 A, 30 A, 40 A, 120 A

12 V – 65 W/35 W (HID)

12 V – 45 CP

12 V – 5 W

12 V – 45 CP

12 V – 32/2 CP

12 V – 2 CP

12 V – 3 CP

12 V – 3 CP

12 V – 32 CP

12 V – 8 W

12 V – 3.0 W, 1.4 W

12 V – 1.4 W, 1.96 W

12 V – 3.4 W

12 V – 8 W

12 V – 3.4 W

12 V – 3.4 W

12 V – 5 W

12 V – 1.4 W, 0.84 W

12 V – 0.91 W, LED

LED

TIRE

M/T

A/T

BRAKE SYSTEM

Front: 215/40 R17 83Y Rear: 255/40 R17 94Y165/80 D 16 (Folding spare tire)

Power assisted self-adjusting

ventilated disc

58.0/38.8 cm

28.99/6.01 sq in

Mechanical expanding, rear two wheel

brakes

WHEEL

ALIGNMENTCamber Front

Rear

Caster

Toe Front

Rear–0 °20 ’

–1 °30 ’

8 °

Out 3.5 mm Out 0.14 in

In 4.0 mm In 3/16 in

NOTES

Size

Type, front and rear

Pad and lining surface area: front/rear

Parking brake type

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-15

ProCarManuals.com

Page 536 of 1503

System Descriptio n

Electrical Connection s

In th e under-hoo d fuse/rela y bo x

I n th e engin e compartmen t fuse/rela y bo x

I n th e under-das h fus e bo x

FUSE SBRAK E LIGHT S HOR N (2 0 A) *

TH L MOTO R (2 0 A)* *

CLOC K (7. 5 A) *

AC G (12 0 A)* *ACG(S ) (2 0 A)* *IG COI L (3 0 A)* *

No . 2 FUE L PUM P SRS 2 (1 5 A)** *

No. 5 BACK-U P LIGHT SALTERNATO RTURN SIGNAL S (1 5 A)** »No. 7 STARTE R SIGNA L (7. 5 A)** *

ProCarManuals.com

Page 570 of 1503

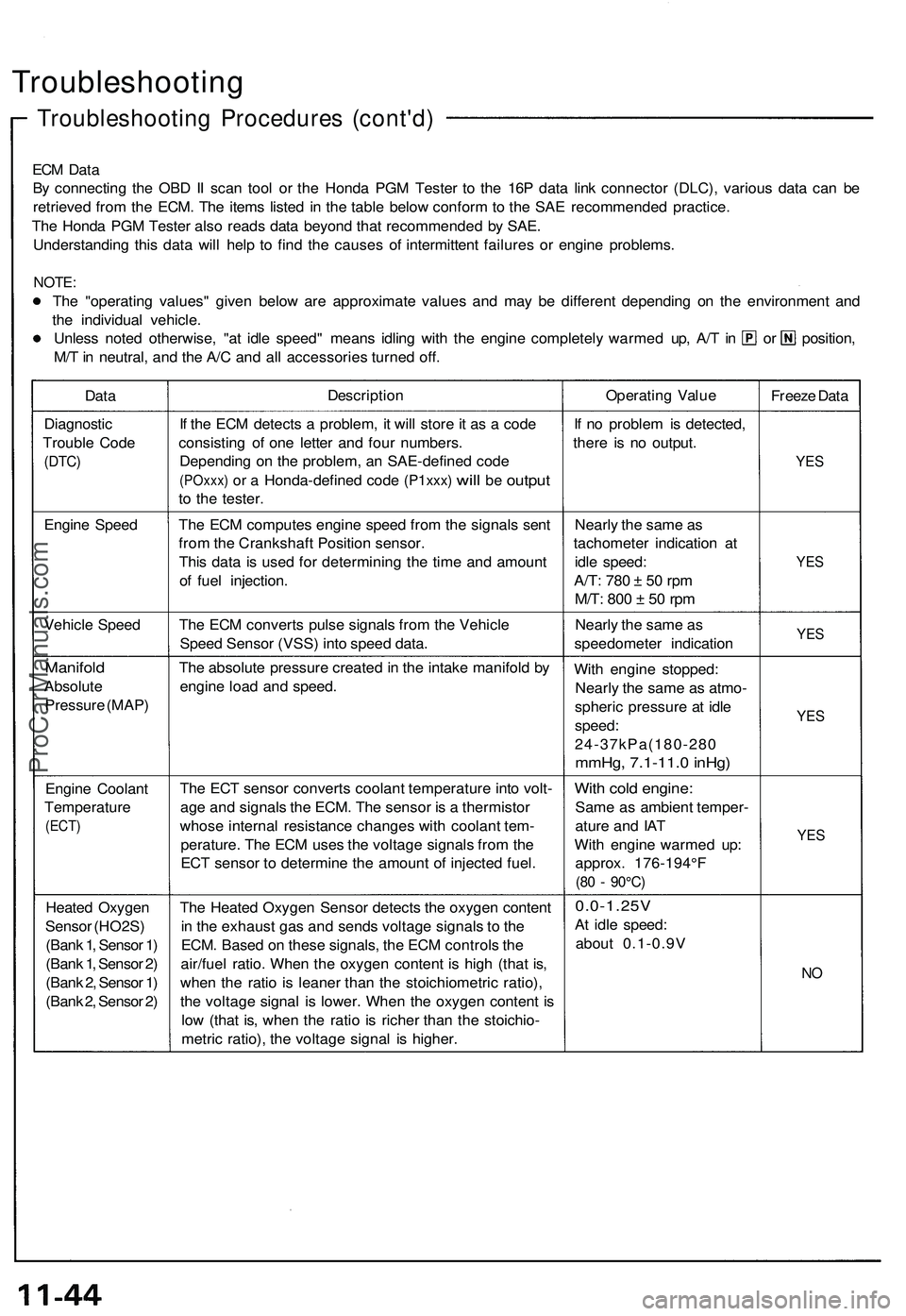

Troubleshooting

Troubleshooting Procedures (cont'd)

ECM Data

By connecting the OBD II scan tool or the Honda PGM Tester to the 16P data link connector (DLC), various data can be

retrieved from the ECM. The items listed in the table below conform to the SAE recommended practice.

The Honda PGM Tester also reads data beyond that recommended by SAE.

Understanding this data will help to find the causes of intermittent failures or engine problems.

NOTE:

The "operating values" given below are approximate values and may be different depending on the environment and

the individual vehicle.

Unless noted otherwise, "at idle speed" means idling with the engine completely warmed up, A/T in or position,

M/T in neutral, and the A/C and all accessories turned off.

Data

Description

Operating Value

Freeze Data

Diagnostic

Trouble Code

(DTC)

If the ECM detects a problem, it will store it as a code

consisting of one letter and four numbers.

Depending on the problem, an SAE-defined code

(POxxx)

or a

Honda-defined code

(P1xxx)

will

be

output

to the tester.

If no problem is detected,

there is no output.

YES

Engine Speed

The ECM computes engine speed from the signals sent

from the Crankshaft Position sensor.

This data is used for determining the time and amount

of fuel injection.

Nearly the same as

tachometer indication at

idle speed:

A/T:

780 ± 50 rpm

M/T:

800 ± 50 rpm

YES

Vehicle Speed

The ECM converts pulse signals from the Vehicle

Speed Sensor (VSS) into speed data.

Nearly the same as

speedometer indication

YES

Manifold

Absolute

Pressure (MAP)

The absolute pressure created in the intake manifold by

engine load and speed.

With engine stopped:

Nearly the same as atmo-

spheric pressure at idle

speed:

24-37kPa(180-280

mmHg, 7.1-11.0 inHg)

YES

Engine Coolant

Temperature

(ECT)

The ECT sensor converts coolant temperature into volt-

age and signals the ECM. The sensor is a thermistor

whose internal resistance changes with coolant tem-

perature. The ECM uses the voltage signals from the

ECT sensor to determine the amount of injected fuel.

With cold engine:

Same as ambient temper-

ature and IAT

With engine warmed up:

approx. 176-194°F

(80 - 90°C)

YES

Heated Oxygen

Sensor (HO2S)

(Bank 1, Sensor 1)

(Bank 1, Sensor 2)

(Bank 2, Sensor 1)

(Bank 2, Sensor 2)

The Heated Oxygen Sensor detects the oxygen content

in the exhaust gas and sends voltage signals to the

ECM. Based on these signals, the ECM controls the

air/fuel ratio. When the oxygen content is high (that is,

when the ratio is leaner than the stoichiometric ratio),

the voltage signal is lower. When the oxygen content is

low (that is, when the ratio is richer than the stoichio-

metric ratio), the voltage signal is higher.

0.0-1.25V

At idle speed:

about 0.1-0.9V

NOProCarManuals.com

Page 572 of 1503

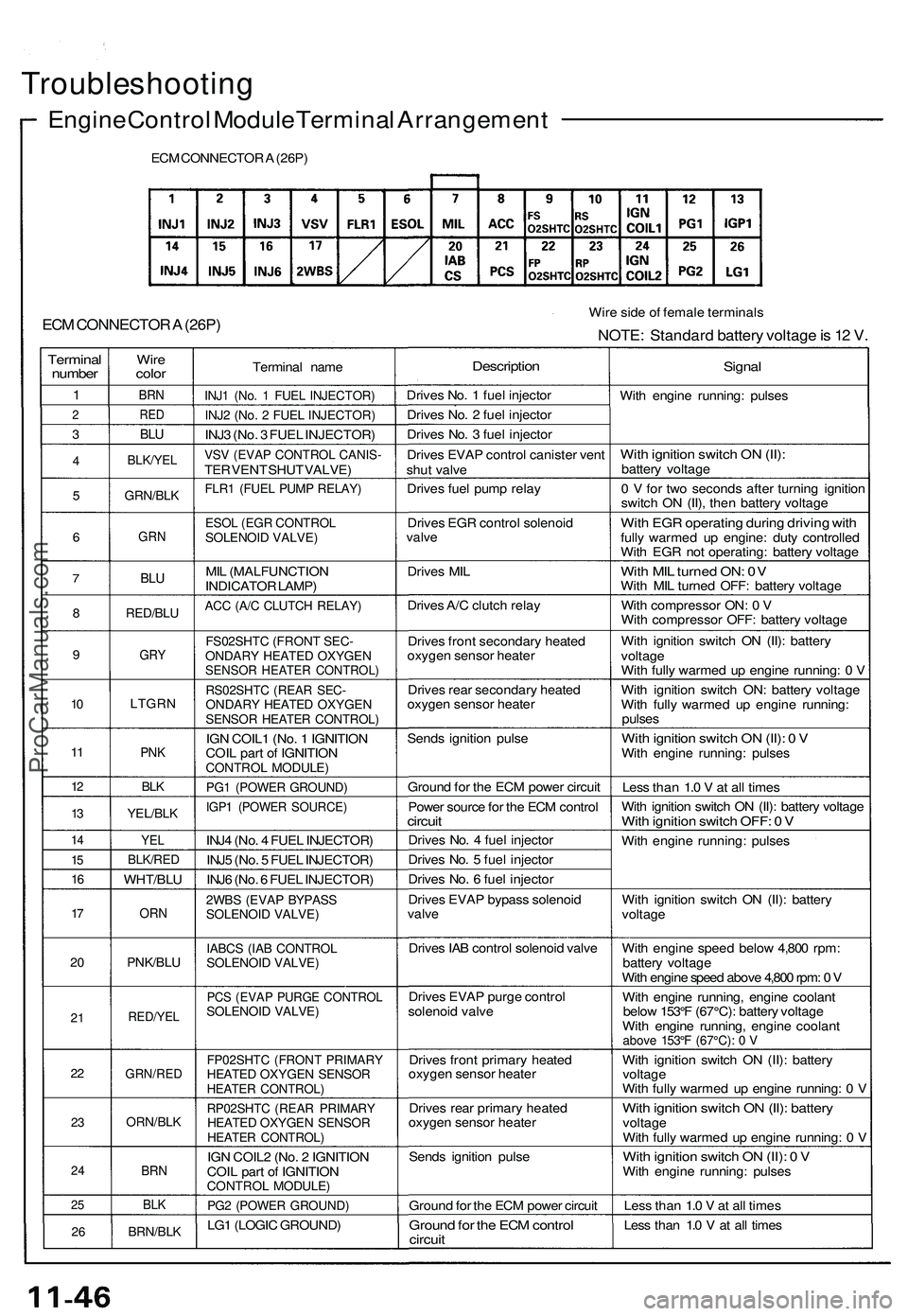

Troubleshooting

Engine Control Module Terminal Arrangement

ECM CONNECTOR A (26P)

ECM CONNECTOR A (26P)

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

Terminal

number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

20

21

22

23

24

25

26

Wire

color

BRN

RED

BLU

BLK/YEL

GRN/BLK

GRN

BLU

RED/BLU

GRY

LTGRN

PNK

BLK

YEL/BLK

YEL

BLK/RED

WHT/BLU

ORN

PNK/BLU

RED/YEL

GRN/RED

ORN/BLK

BRN

BLK

BRN/BLK

Terminal name

INJ1 (No. 1 FUEL INJECTOR)

INJ2 (No. 2 FUEL INJECTOR)

INJ3 (No. 3 FUEL INJECTOR)

VSV (EVAP CONTROL CANIS-

TER VENT SHUT VALVE)

FLR1 (FUEL PUMP RELAY)

ESOL (EGR CONTROL

SOLENOID VALVE)

MIL (MALFUNCTION

INDICATOR LAMP)

ACC (A/C CLUTCH RELAY)

FS02SHTC (FRONT SEC-

ONDARY HEATED OXYGEN

SENSOR HEATER CONTROL)

RS02SHTC (REAR SEC-

ONDARY HEATED OXYGEN

SENSOR HEATER CONTROL)

IGN COIL1 (No. 1 IGNITION

COIL part of IGNITION

CONTROL MODULE)

PG1 (POWER GROUND)

IGP1 (POWER SOURCE)

INJ4 (No. 4 FUEL INJECTOR)

INJ5 (No. 5 FUEL INJECTOR)

INJ6 (No. 6 FUEL INJECTOR)

2WBS (EVAP BYPASS

SOLENOID VALVE)

IABCS (IAB CONTROL

SOLENOID VALVE)

PCS (EVAP PURGE CONTROL

SOLENOID VALVE)

FP02SHTC (FRONT PRIMARY

HEATED OXYGEN SENSOR

HEATER CONTROL)

RP02SHTC (REAR PRIMARY

HEATED OXYGEN SENSOR

HEATER CONTROL)

IGN COIL2 (No. 2 IGNITION

COIL part of IGNITION

CONTROL MODULE)

PG2 (POWER GROUND)

LG1 (LOGIC GROUND)

Description

Drives No. 1 fuel injector

Drives No. 2 fuel injector

Drives No. 3 fuel injector

Drives EVAP control canister vent

shut valve

Drives fuel pump relay

Drives EGR control solenoid

valve

Drives MIL

Drives A/C clutch relay

Drives front secondary heated

oxygen sensor heater

Drives rear secondary heated

oxygen sensor heater

Sends ignition pulse

Ground for the ECM power circuit

Power source for the ECM control

circuit

Drives No. 4 fuel injector

Drives No. 5 fuel injector

Drives No. 6 fuel injector

Drives EVAP bypass solenoid

valve

Drives IAB control solenoid valve

Drives EVAP purge control

solenoid valve

Drives front primary heated

oxygen sensor heater

Drives rear primary heated

oxygen sensor heater

Sends ignition pulse

Ground for the ECM power circuit

Ground for the ECM control

circuit

Signal

With engine running: pulses

With ignition switch ON (II):

battery voltage

0 V for two seconds after turning ignition

switch ON (II), then battery voltage

With EGR operating during driving with

fully warmed up engine: duty controlled

With EGR not operating: battery voltage

With MIL turned ON: 0V

With MIL turned OFF: battery voltage

With compressor ON: 0 V

With compressor OFF: battery voltage

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON: battery voltage

With fully warmed up engine running:

pulses

With ignition switch ON (II): 0 V

With engine running: pulses

Less than 1.0 V at all times

With ignition switch ON (II): battery voltage

With ignition switch OFF: 0 V

With engine running: pulses

With ignition switch ON (II): battery

voltage

With engine speed below 4,800 rpm:

battery voltage

With engine speed above 4,800 rpm: 0 V

With engine running, engine coolant

below 153°F (67°C): battery voltage

With engine running, engine coolant

above 153°F (67°C): 0 V

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON (II): battery

voltage

With fully warmed up engine running: 0 V

With ignition switch ON (II): 0 V

With engine running: pulses

Less than 1.0 V at all times

Less than 1.0 V at all timesProCarManuals.com

Page 574 of 1503

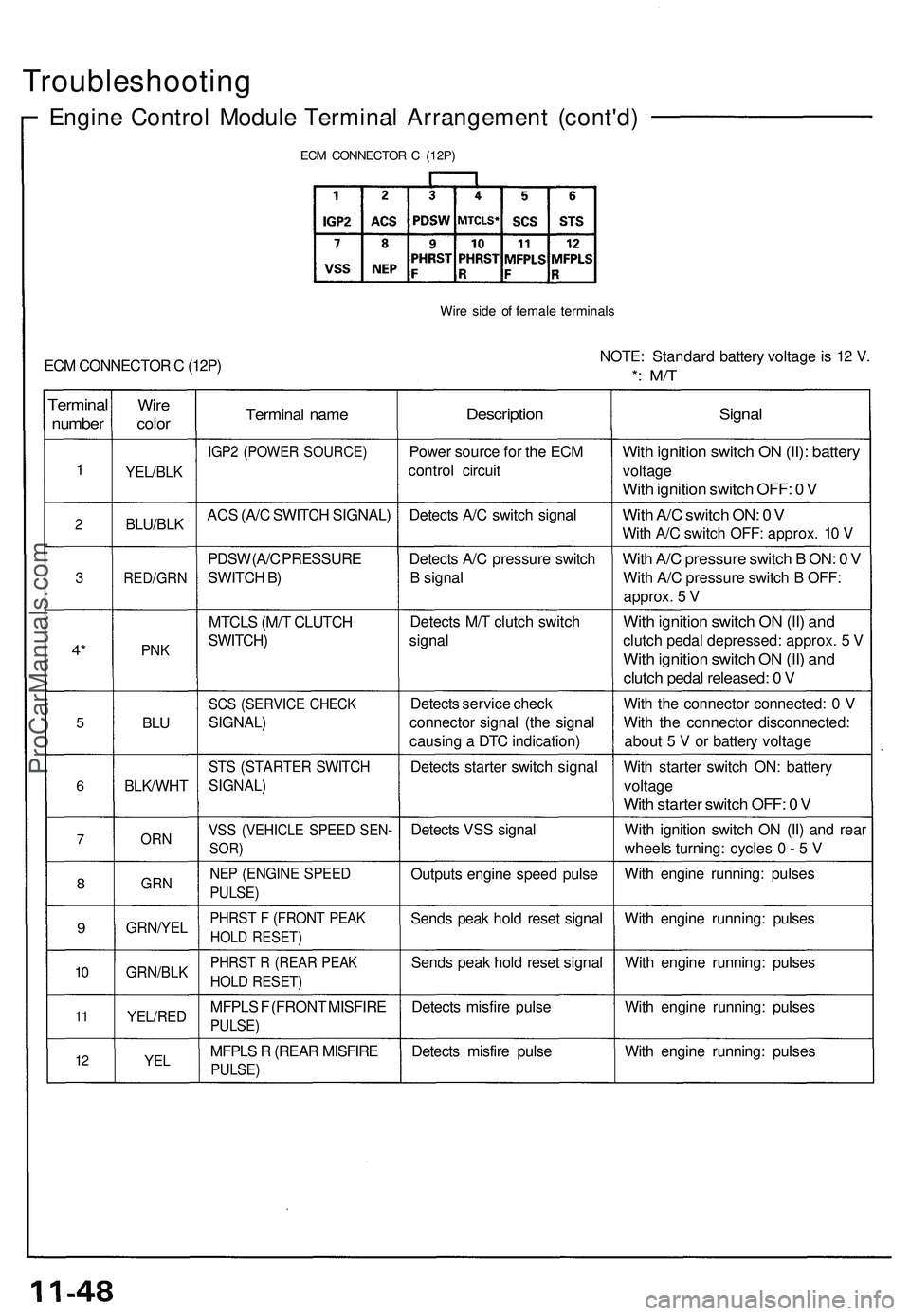

Troubleshooting

Engine Contro l Modul e Termina l Arrangemen t (cont'd )

ECM CONNECTO R C (12P )

Wire sid e o f femal e terminal s

ECM CONNECTO R C (12P ) NOTE

: Standar d batter y voltag e is 1 2 V .*: M/ T

Termina l

number

1

2

3

4*

5

6

7

8

9

10

1 1

1 2

Wir e

colo r

YEL/BL K

BLU/BLK

RED/GR N

PNK

BLU

BLK/WH T

ORN

GR N

GRN/YE L

GRN/BLK

YEL/RED

YEL

Termina l nam e

IGP2 (POWE R SOURCE )

ACS (A/ C SWITC H SIGNAL )

PDS W (A/ C PRESSUR E

SWITC H B )

MTCL S (M/ T CLUTC H

SWITCH )

SCS (SERVIC E CHEC K

SIGNAL )

STS (STARTE R SWITC H

SIGNAL )

VSS (VEHICL E SPEE D SEN -

SOR)

NEP (ENGIN E SPEE D

PULSE )

PHRST F (FRON T PEA K

HOLD RESET )

PHRST R (REA R PEA K

HOLD RESET )

MFPLS F (FRON T MISFIR E

PULSE)

MFPLS R (REA R MISFIR E

PULSE)

Descriptio n

Power sourc e fo r th e EC M

contro l circui t

Detect s A/ C switc h signa l

Detect s A/ C pressur e switc h

B signa l

Detect s M/ T clutc h switc h

signa l

Detect s servic e chec k

connecto r signa l (th e signa l

causin g a DT C indication )

Detect s starte r switc h signa l

Detect s VS S signa l

Output s engin e spee d puls e

Send s pea k hol d rese t signa l

Send s pea k hol d rese t signa l

Detect s misfir e puls e

Detect s misfir e puls e

Signa l

With ignitio n switc h O N (II) : batter y

voltage

With ignitio n switc h OFF : 0 V

Wit h A/ C switc h ON : 0 V

Wit h A/ C switc h OFF : approx . 1 0 V

Wit h A/ C pressur e switc h B ON : 0 V

Wit h A/ C pressur e switc h B OFF :

approx . 5 V

Wit h ignitio n switc h O N (II ) an d

clutc h peda l depressed : approx . 5 V

Wit h ignitio n switc h O N (II ) an d

clutc h peda l released : 0 V

Wit h th e connecto r connected : 0 V

Wit h th e connecto r disconnected :

abou t 5 V or batter y voltag e

Wit h starte r switc h ON : batter y

voltag e

With starte r switc h OFF : 0 V

Wit h ignitio n switc h O N (II ) an d rea r

wheel s turning : cycle s 0 - 5 V

Wit h engin e running : pulse s

Wit h engin e running : pulse s

Wit h engin e running : pulse s

Wit h engin e running : pulse s

Wit h engin e running : pulse s

ProCarManuals.com

Page 585 of 1503

PGM-FI Syste m

System Descriptio n

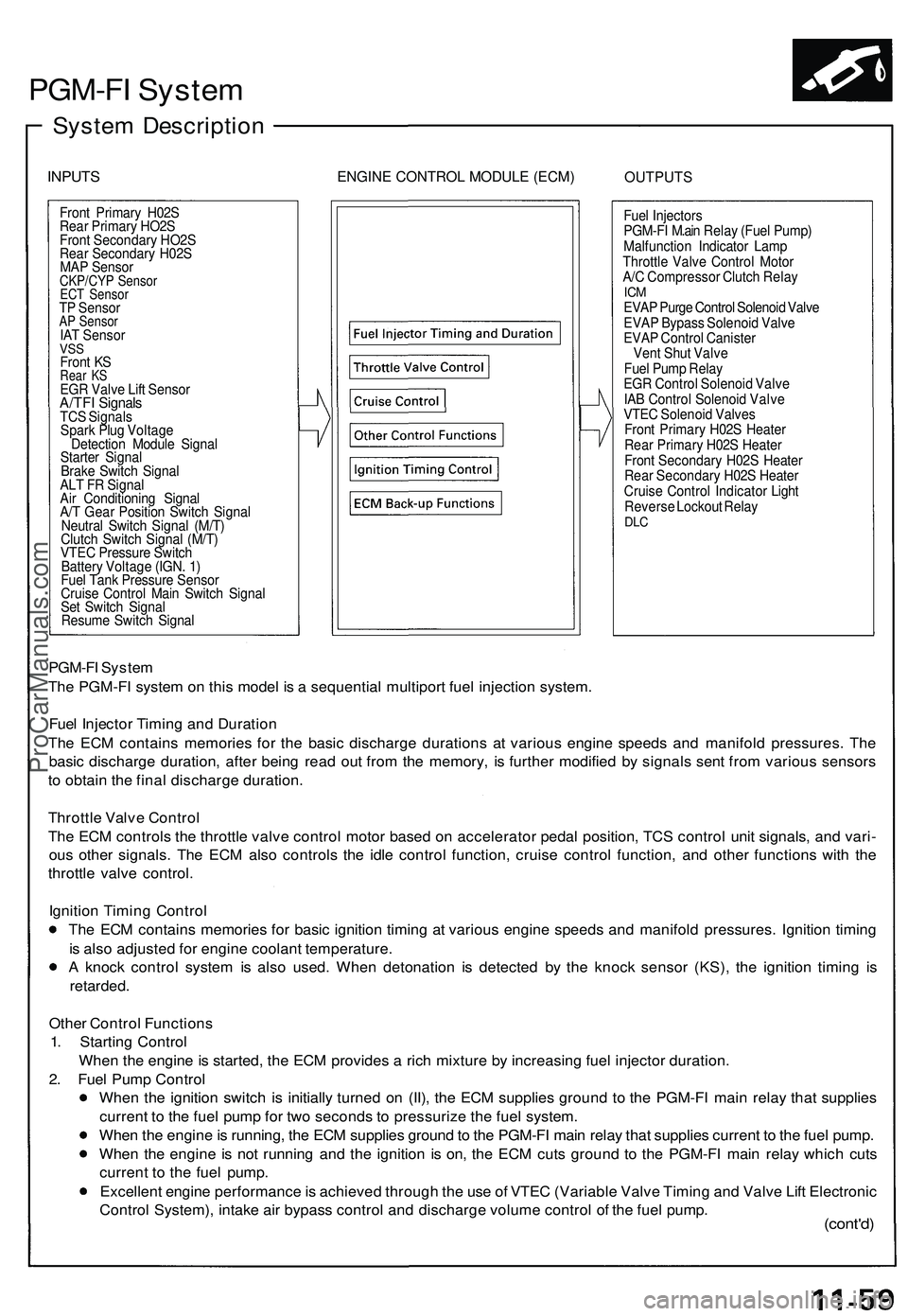

INPUTSENGIN E CONTRO L MODUL E (ECM )OUTPUT S

Front Primar y H02 S

Rea r Primar y HO2 S

Fron t Secondar y HO2 S

Rea r Secondar y H02 S

MA P Senso r

CKP/CY P Senso rECT Senso rTP Senso rAP Senso rIAT Senso rVSSFron t K SRea r K SEG R Valv e Lif t Senso rA/TFI Signal sTCS Signal s

Spar k Plu g Voltag e

Detectio n Modul e Signa l

Starte r Signa l

Brak e Switc h Signa l

AL T F R Signa l

Ai r Conditionin g Signa l

A/ T Gea r Positio n Switc h Signa l

Neutra l Switc h Signa l (M/T )

Clutc h Switc h Signa l (M/T )

VTE C Pressur e Switc h

Batter y Voltag e (IGN . 1 )

Fue l Tan k Pressur e Senso r

Cruis e Contro l Mai n Switc h Signa l

Se t Switc h Signa l

Resum e Switc h Signa l Fue

l Injector s

PGM-F I M.ai n Rela y (Fue l Pump )

Malfunctio n Indicato r Lam p

Throttl e Valv e Contro l Moto r

A/ C Compresso r Clutc h Rela y

ICMEVA P Purg e Contro l Solenoi d Valv e

EVA P Bypas s Solenoi d Valv e

EVA P Contro l Caniste r

Ven t Shu t Valv e

Fue l Pum p Rela y

EG R Contro l Solenoi d Valv e

IA B Contro l Solenoi d Valv e

VTE C Solenoi d Valve s

Fron t Primar y H02 S Heate r

Rea r Primar y H02 S Heate r

Fron t Secondar y H02 S Heate r

Rea r Secondar y H02 S Heate r

Cruis e Contro l Indicato r Ligh t

Revers e Lockou t Rela y

DLC

PGM-F I Syste m

Th e PGM-F I syste m o n thi s mode l i s a sequentia l multipor t fue l injectio n system .

Fue l Injecto r Timin g an d Duratio n

Th e EC M contain s memorie s fo r th e basi c discharg e duration s a t variou s engin e speed s an d manifol d pressures . Th e

basi c discharg e duration , afte r bein g rea d ou t fro m th e memory , i s furthe r modifie d b y signal s sen t fro m variou s sensor s

t o obtai n th e fina l discharg e duration .

Throttl e Valv e Contro l

Th e EC M control s th e throttl e valv e contro l moto r base d o n accelerato r peda l position , TC S contro l uni t signals , an d vari -

ou s othe r signals . Th e EC M als o control s th e idl e contro l function , cruis e contro l function , an d othe r function s wit h th e

throttl e valv e control .

Ignitio n Timin g Contro l

Th e EC M contain s memorie s fo r basi c ignitio n timin g a t variou s engin e speed s an d manifol d pressures . Ignitio n timin g

i s als o adjuste d fo r engin e coolan t temperature .

A knoc k contro l syste m is als o used . Whe n detonatio n i s detecte d b y th e knoc k senso r (KS) , th e ignitio n timin g i s

retarded .

Other Contro l Function s

1 . Startin g Contro l

Whe n th e engin e is started , th e EC M provide s a ric h mixtur e b y increasin g fue l injecto r duration .

2 . Fue l Pum p Contro l

Whe n th e ignitio n switc h i s initiall y turne d o n (II) , th e EC M supplie s groun d t o th e PGM-F I mai n rela y tha t supplie s

curren t t o th e fue l pum p fo r tw o second s t o pressuriz e th e fue l system .

Whe n th e engin e is running , th e EC M supplie s groun d to th e PGM-F I mai n rela y tha t supplie s curren t t o th e fue l pump .

Whe n th e engin e i s no t runnin g an d th e ignitio n i s on , th e EC M cut s groun d t o th e PGM-F I mai n rela y whic h cut s

curren t t o th e fue l pump .

Excellen t engin e performanc e is achieve d throug h th e us e o f VTE C (Variabl e Valv e Timin g an d Valv e Lif t Electroni c

Contro l System) , intak e ai r bypas s contro l an d discharg e volum e contro l o f th e fue l pump .

(cont'd )

ProCarManuals.com

Page 586 of 1503

PGM-FI System

System Description (cont'd)

3. Fuel Cut-off Control

During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,500 rpm.

Fuel cut-off action also takes place when engine speed exceeds 8,300 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

4. A/C Compressor Clutch Relay

When the ECM receives a demand for cooling from the air conditioning system, it delays the compressor from being

energized, and enriches the mixture to assure smooth translation to the A/C mode.

5. Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is below 153°F (67°C), the ECM controls the EVAP purge control solenoid valve

which cuts vacuum to the EVAP purge control canister diaphragm.

6. Intake Air Bypass (IAB) Control Solenoid Valve

When the engine speed is below 4,800 rpm, the IAB control solenoid valve is activated by a signal from the ECM. Intake

air then flows through the smaller chamber, and high torque is delivered. To increase air flow at engine speeds higher

than 4,800 rpm, the solenoid valve is deactivated by the ECM, and the intake air flows through the larger chamber.

7. Exhaust Gas Recirculation (EGR) Control Solenoid Valve

When the EGR is required for control of oxides of nitrogen (NOx) emissions, the ECM supplies ground to the EGR

control solenoid valve which supplies regulated vacuum to the EGR valve.

ECM Fail-safe/Back-up Functions

1. Fail-Safe Function

When an abnormality occurs in a signal from a sensor, the ECM ignores that signal and assumes a pre-programmed

valve for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM itself, the fuel injectors are controlled by a back-up circuit independent of the

system in order to permit minimal driving.

3. Self-diagnosis Function [Malfunction Indicator Lamp (MIL)]

When an abnormality occurs in a signal from a sensor, the ECM lights the MIL and stores the diagnostic trouble code

in erasable memory. When the ignition is initially turned on, the ECM supplies ground for the MIL for two seconds to

check the MIL bulb condition.

4. Two Trip Detection Method

To prevent false indications, the Two Trip Detection Method is used for the H02S, fuel metering-related, idle control

system, ECT sensor, EGR system self-diagnostic functions and EVAP control system. When an abnormality occurs,

the ECM stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (II)

again, the ECM informs the driver by lighting the MIL.

However, to ease troubleshooting, this function is cancelled when you short the service check connector. The MIL will

then blink immediately when an abnormality occurs.

5. Two (or three) Driving Cycle Detection Method

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. If misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles,

or TWC deterioration is detected during three consecutive driving cycles, the ECM turns the MIL on.

However,

to

ease

troubleshooting,

this

function

is

cancelled when

you

short

the

service check connector.

The MIL

will

then blink immediately when an abnormality occurs.ProCarManuals.com