air condition ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1 of 1503

General Info

Specifications

Maintenance

Engine

Cooling

Fuel and Emissions

*Transaxle

SteeringSuspension

*Brakes (Including ABS)

*Body

*Heating, Ventilation and

Air Conditioning

*Body Electrical

*Engine Electrical

*SRS

1997-200 5 NSX Main Menu

As sections w/ * include SRS components,

special precautions are required when servicing.

ProCarManuals.com

Page 55 of 1503

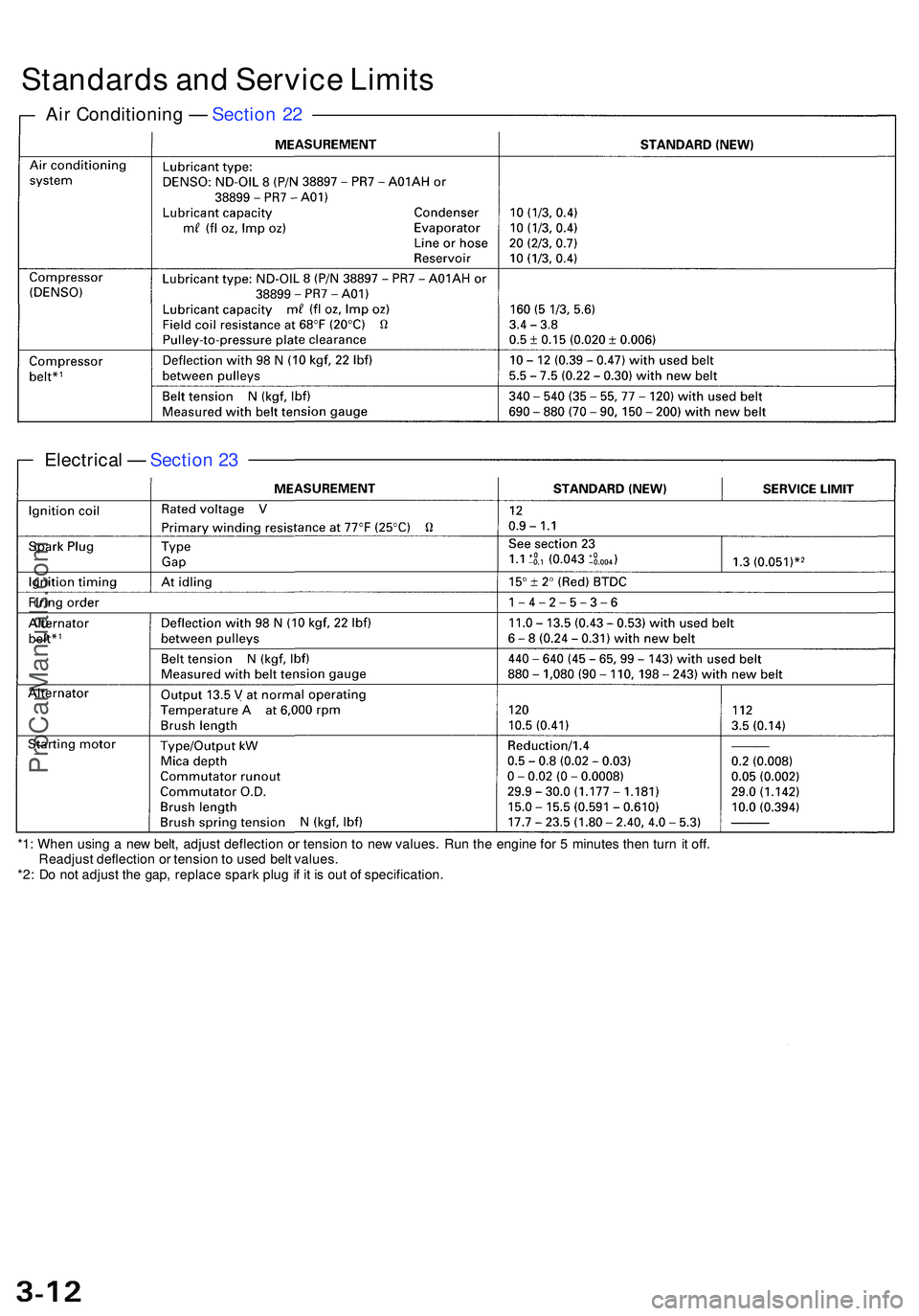

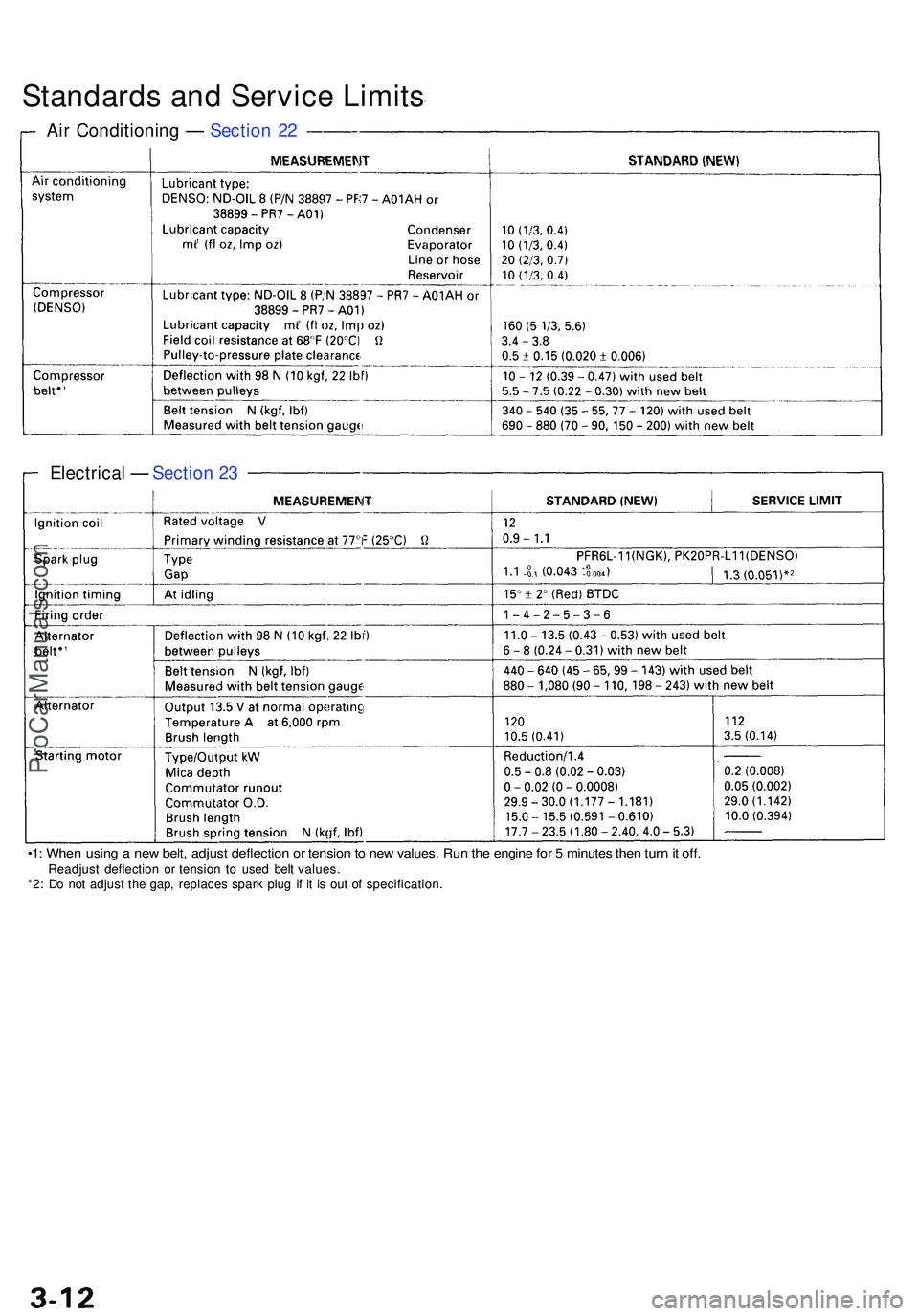

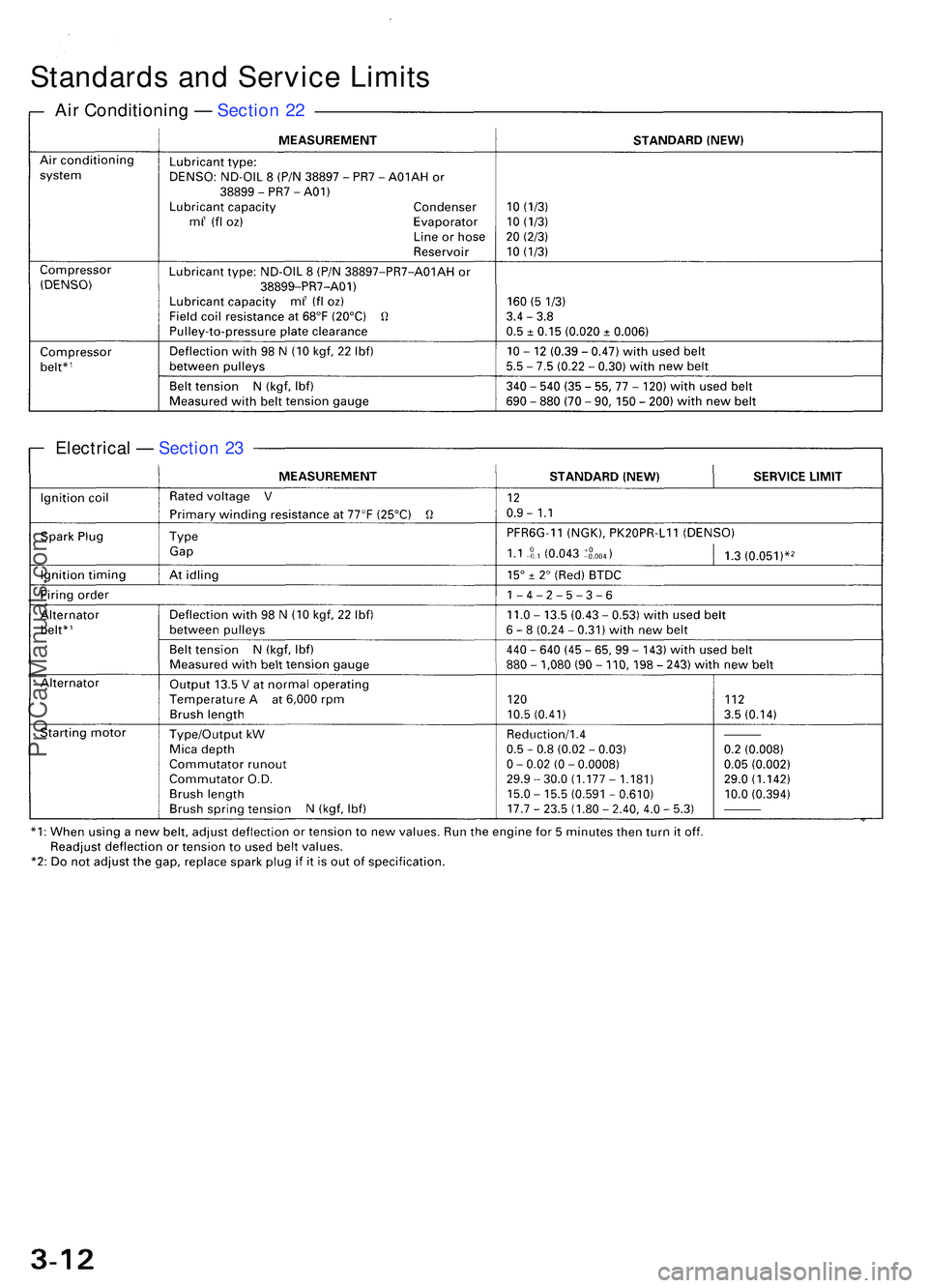

Standards an d Servic e Limit s

Air Conditionin g — Sectio n 2 2

Electrica l — Sectio n 2 3

*1 : Whe n usin g a ne w belt , adjus t deflectio n o r tensio n t o ne w values . Ru n th e engin e fo r 5 minute s the n tur n it off .

Readjus t deflectio n o r tensio n to use d bel t values .

*2 : D o no t adjus t th e gap , replac e spar k plu g if i t i s ou t o f specification .

ProCarManuals.com

Page 141 of 1503

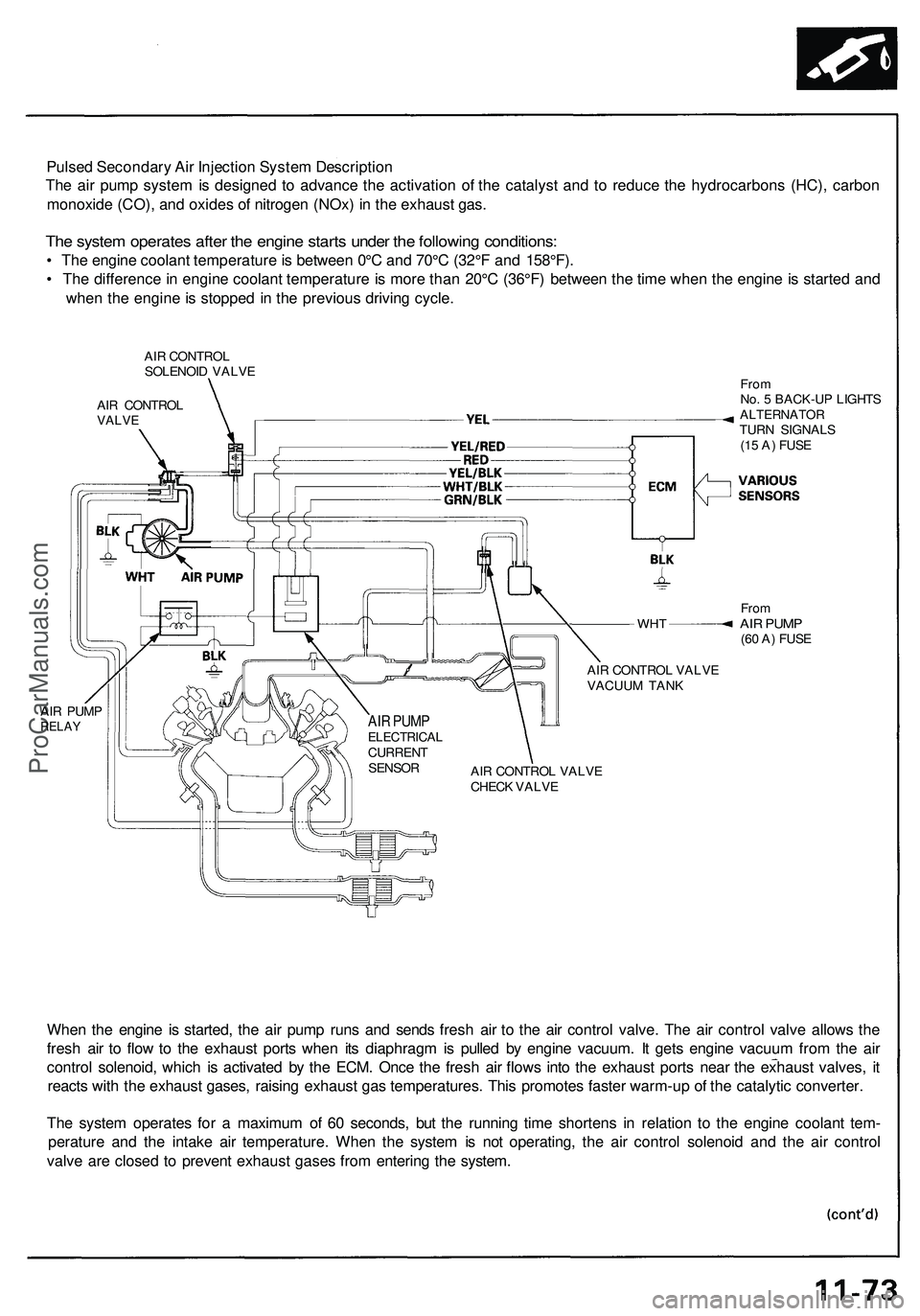

Pulsed Secondary Air Injection System Description

The air pump system is designed to advance the activation of the catalyst and to reduce the hydrocarbons (HC), carbon

monoxide (CO), and oxides of nitrogen (NOx) in the exhaust gas.

The system operates after the engine starts under the following conditions:

• The engine coolant temperature is between 0°C and 70°C (32°F and 158°F).

• The difference in engine coolant temperature is more than 20°C (36°F) between the time when the engine is started and

when the engine is stopped in the previous driving cycle.

AIR CONTROL

SOLENOID VALVE

AIR CONTROL

VALVE

WHT

AIR PUMP

RELAY

From

No. 5 BACK-UP LIGHTS

ALTERNATOR

TURN SIGNALS

(15 A) FUSE

From

AIR PUMP

(60 A) FUSE

AIR CONTROL VALVE

VACUUM TANK

AIR CONTROL VALVE

CHECK VALVE

When the engine is started, the air pump runs and sends fresh air to the air control valve. The air control valve allows the

fresh air to flow to the exhaust ports when its diaphragm is pulled by engine vacuum. It gets engine vacuum from the air

control solenoid, which is activated by the ECM. Once the fresh air flows into the exhaust ports near the exhaust valves, it

reacts with the exhaust gases, raising exhaust gas temperatures. This promotes faster warm-up of the catalytic converter.

The system operates for a maximum of 60 seconds, but the running time shortens in relation to the engine coolant tem-

perature and the intake air temperature. When the system is not operating, the air control solenoid and the air control

valve are closed to prevent exhaust gases from entering the system.

AIR PUMP

ELECTRICAL

CURRENT

SENSORProCarManuals.com

Page 145 of 1503

Troubleshooting Precaution s

EPS Indicato r Ligh t

Unde r norma l conditions , th e EP S indicato r i n th e gaug e assembl y come s o n whe n th e ignitio n switc h is turne d t o th e O N

(II ) position , the n goe s of f afte r th e engin e i s started . Thi s indicate s tha t th e bul b an d it s circuit s ar e operatin g correctly . I f

ther e i s an y troubl e i n th e system , th e EP S indicato r turn s o n durin g driving , an d th e powe r steerin g assis t i s turne d off .

Whe n th e EP S indicato r come s on , th e contro l uni t memorize s th e DTC . I n thi s case , th e contro l uni t doe s no t activat e th e

EP S syste m afte r th e engin e start s agai n bu t i t keep s th e EP S indicato r on .

Whe n a proble m is detected , th e EP S indicato r come s on . Unde r som e conditio n th e indicato r stay s o n unti l th e ignitio n switc h

i s turne d OFF . Unde r othe r conditions , however , th e indicato r goe s of f automaticall y whe n th e syste m return s to normal .

Fo r DTC s 2 3 an d 31 , th e indicato r goe s of f automaticall y whe n th e syste m return s t o normal . Fo r al l othe r codes , th e indicato r

stay s in unti l th e ignitio n switc h is turne d OFF .

Fo r DTC s 2 4 an d 25 , th e EP S indicato r goe s of f whe n th e syste m is O K afte r th e ignitio n switc h is turne d fro m OF F to O N

(ID .

Diagnosti c Troubl e Cod e (DTC )

• Th e lowes t DT C is indicate d first .

• Th e DTC s continu e blinkin g unti l th e ignitio n switc h i s turne d off .

• Th e DTC s ar e erase d fro m th e contro l uni t whe n th e EP S contro l uni t VB U powe r suppl y o r connecto r i s disconnected .

• Th e EP S syste m ca n b e rese t an d th e contro l unit' s memor y ca n b e erase d b y disconnectin g th e CLOC K (7. 5 A ) fus e fo r

mor e tha n te n second s (excep t DTC s 2 4 an d 25) .

Self-diagnosis :

The CP U (centra l processin g unit ) control s th e followin g whe n it detect s a proble m durin g self-diagnosis :

1 . Turn s th e EP S indicato r O N to aler t th e driver .

2 . Powe r assis t stops , an d norma l manua l steerin g operatio n resume s (excep t DT C 33) .

3 . Th e EP S contro l uni t memorize s th e diagnosti c troubl e cod e (DTC) .

4 . Afte r th e DT C is store d in th e contro l unit , th e CP U stop s self-diagnosis .

Troubleshooting :

• Befor e startin g th e troubleshooting , clea r th e DT C b y disconnectin g th e CLOC K (7. 5 A ) fus e fo r te n second s o r more ,

an d test-driv e th e vehicle . Chec k tha t th e sympto m o f th e troubl e appear s again , an d the n troubleshoot . I f th e proble m

i s a n intermitten t problem , th e syste m doe s no t becom e activ e afte r th e engin e start s eve n thoug h th e proble m is

solved .

• Whe n bot h EP S indicato r an d A/ T "D " indicato r com e on , perfor m th e A/ T troubleshootin g first .

• Whe n th e customer' s reporte d proble m canno t b e verifie d i n th e car , as k th e custome r abou t th e condition s whe n th e

EP S indicato r cam e ON , the n test-driv e th e ca r unde r thos e conditions , i f possible . I f th e EP S indicato r doe s no t com e

O N durin g th e test , chec k fo r loos e connection s o r poo r contact s a t th e connector s b y wigglin g th e harness , etc .

• Th e connecto r termina l number s ar e viewe d fro m th e wir e sid e fo r th e femal e terminal s an d fro m th e termina l sid e fo r

th e mal e terminals .

• Afte r th e repair , test-driv e th e ca r an d chec k tha t th e EP S indicato r doe s no t com e O N agai n durin g th e test . (Refe r t o

th e Symptom-to-Syste m Char t fo r diagnosti c period. )

ProCarManuals.com

Page 152 of 1503

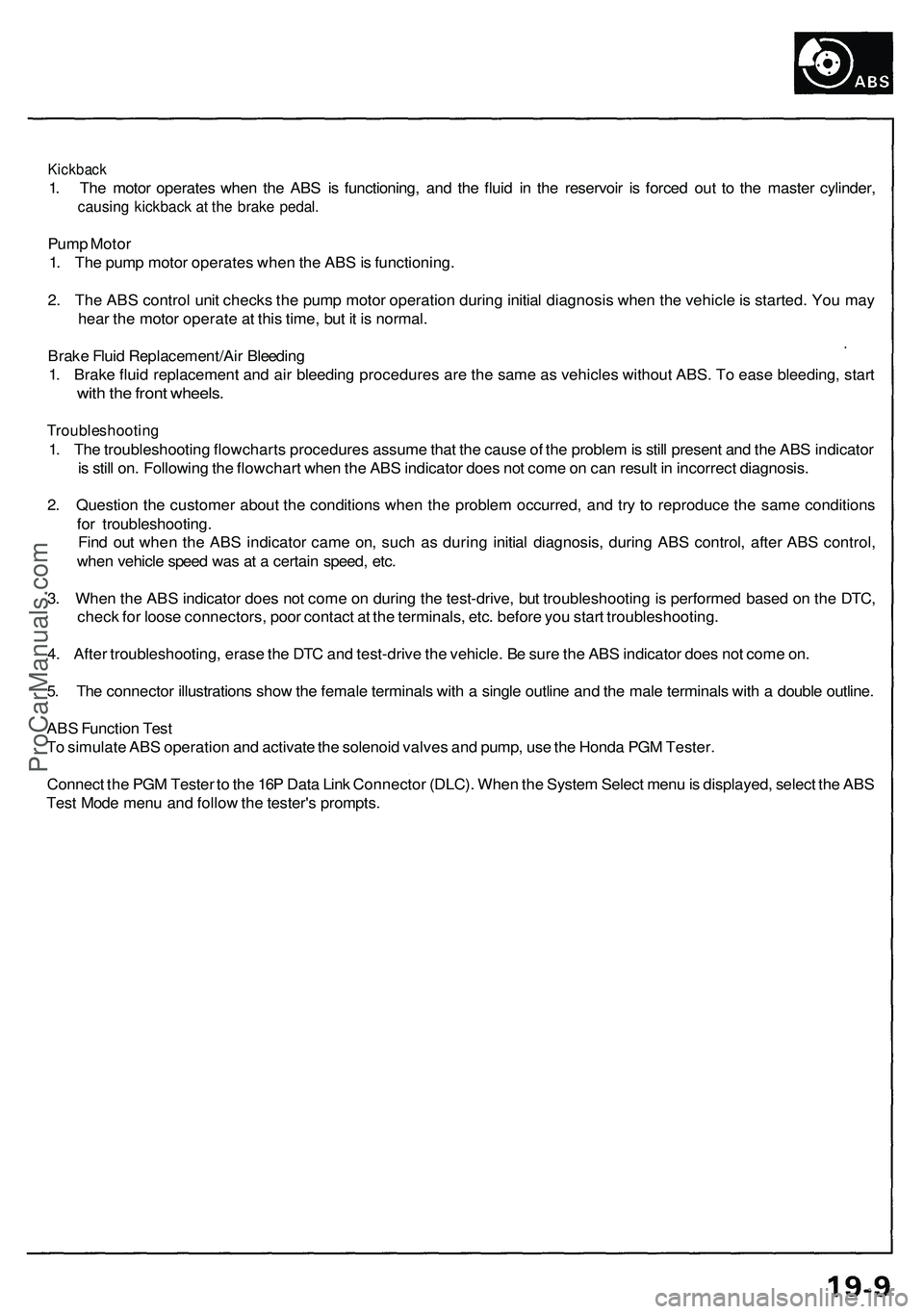

Kickback

1. The motor operates when the ABS is functioning, and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

Pump Motor

1. The pump motor operates when the ABS is functioning.

2. The ABS control unit checks the pump motor operation during initial diagnosis when the vehicle is started. You may

hear the motor operate at this time, but it is normal.

Brake Fluid Replacement/Air Bleeding

1. Brake fluid replacement and air bleeding procedures are the same as vehicles without ABS. To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowcharts procedures assume that the cause of the problem is still present and the ABS indicator

is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Question the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Find out when the ABS indicator came on, such as during initial diagnosis, during ABS control, after ABS control,

when vehicle speed was at a certain speed, etc.

3. When the ABS indicator does not come on during the test-drive, but troubleshooting is performed based on the DTC,

check for loose connectors, poor contact at the terminals, etc. before you start troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustrations show the female terminals with a single outline and the male terminals with a double outline.

ABS Function Test

To simulate ABS operation and activate the solenoid valves and pump, use the Honda PGM Tester.

Connect the PGM Tester to the 16P Data Link Connector (DLC). When the System Select menu is displayed, select the ABS

Test Mode menu and follow the tester's prompts.ProCarManuals.com

Page 182 of 1503

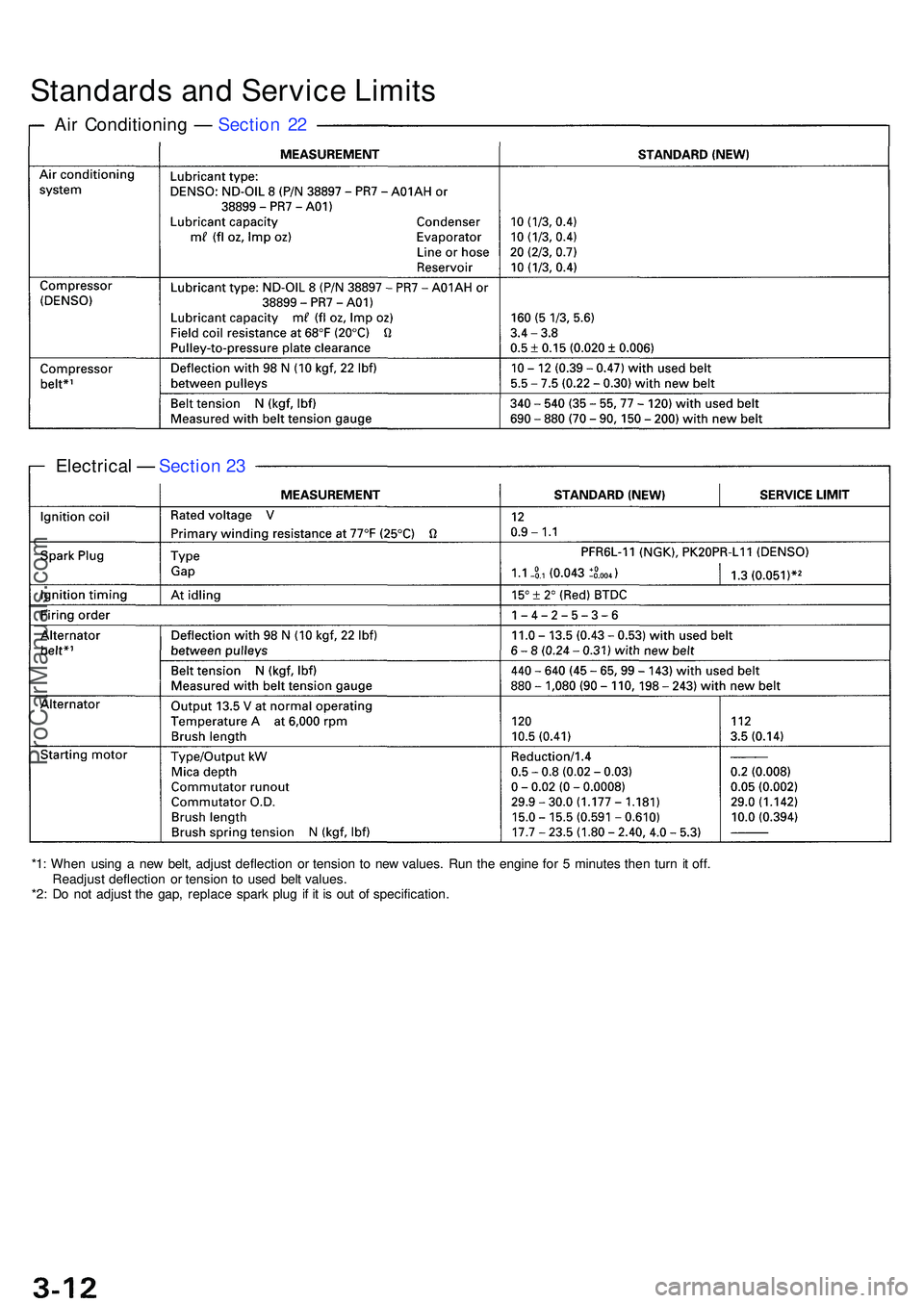

Standards an d Servic e Limit s

Air Conditionin g — Sectio n 2 2

Electrica l — Sectio n 2 3

•1 : Whe n usin g a ne w belt , adjus t deflectio n o r tensio n to ne w values . Ru n th e engin e fo r 5 minute s the n tur n it off .Readjus t deflectio n o r tensio n t o use d bel t values .

*2 : D o no t adjus t th e gap , replace s spar k plu g i f i t i s ou t o f specification .

ProCarManuals.com

Page 210 of 1503

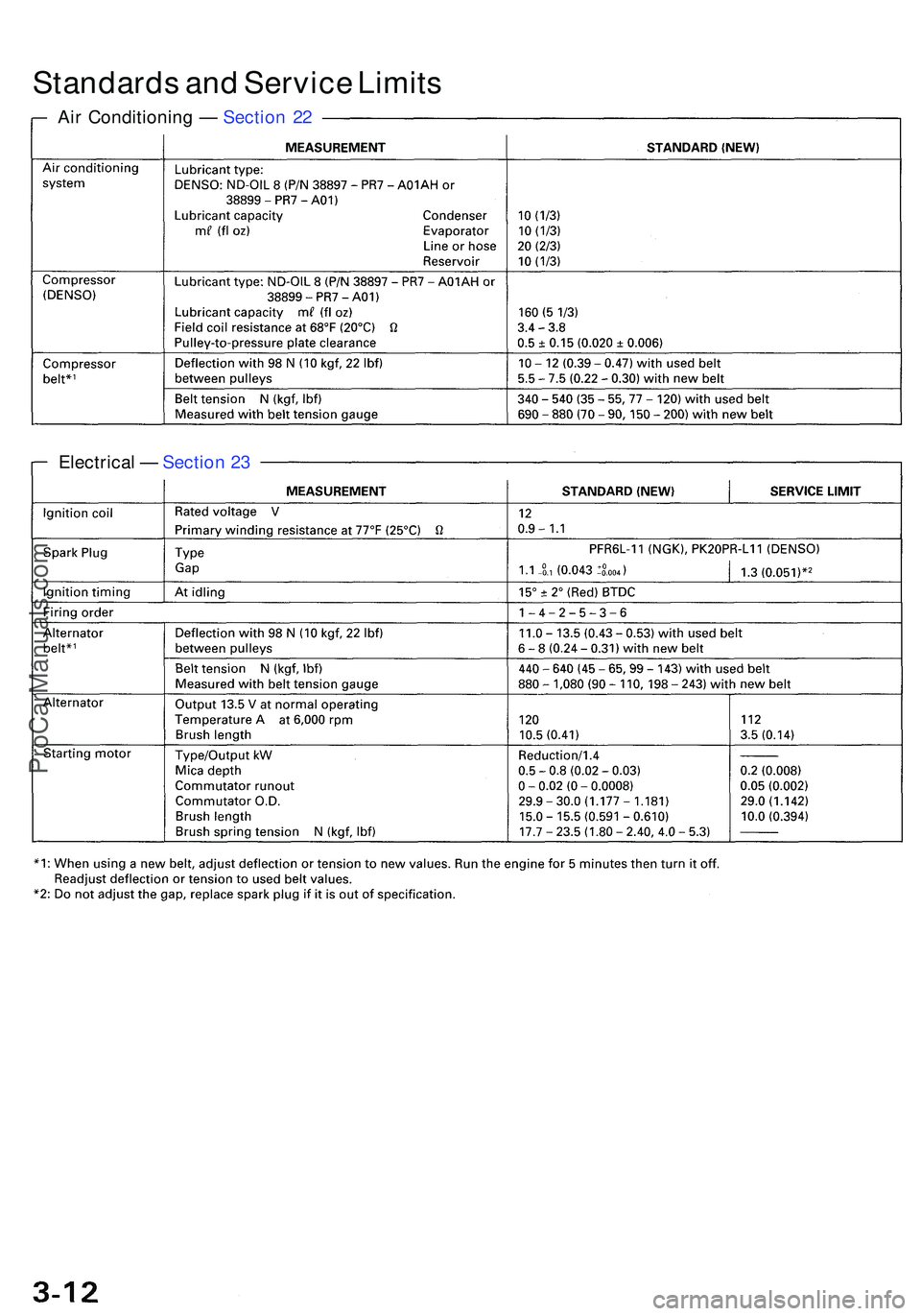

Standards an d Servic e Limit s

Air Conditionin g — Sectio n 2 2

Electrica l — Sectio n 2 3

*1 : Whe n usin g a ne w belt , adjus t deflectio n o r tensio n t o ne w values . Run the engin e fo r 5 minute s the n tur n i t off .

Readjus t deflectio n o r tensio n t o use d bel t values .

*2 : D o no t adjus t th e gap , replac e spar k plu g i f i t i s ou t o f specification .

ProCarManuals.com

Page 310 of 1503

Standards an d Servic e Limit s

Air Conditionin g — Sectio n 2 2

Electrica l — Sectio n 2 3

ProCarManuals.com

Page 330 of 1503

Standards an d Servic e Limit s

Air Conditionin g — Sectio n 2 2

Electrica l — Sectio n 2 3

ProCarManuals.com

Page 369 of 1503

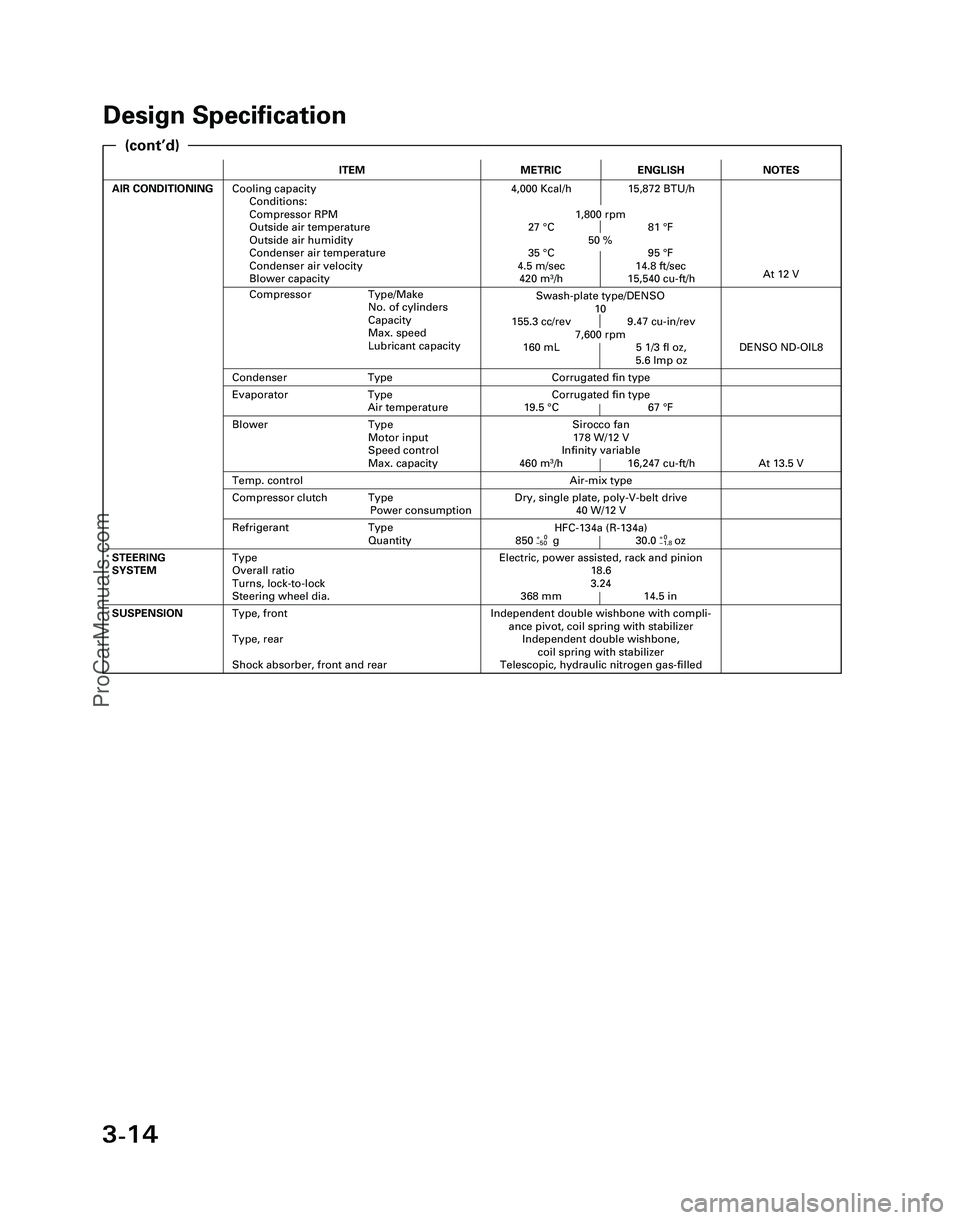

3-14

Design Specification

ITEMMETRICENGLISH

AIR CONDITIONINGCooling capacity

Conditions:

Compressor RPM

Outside air temperature

Outside air humidity

Condenser air temperature

Condenser air velocity

Blower capacity4,000 Kcal/h 15,872 BTU/h

1,800 rpm

27 °C 81 °F

50 %

35 °C 95 °F

4.5 m/sec 14.8 ft/sec

420 m

3/h 15,540 cu-ft/h

Independent double wishbone with compli-

ance pivot, coil spring with stabilizer

Independent double wishbone,

coil spring with stabilizer

Telescopic, hydraulic nitrogen gas-filledSUSPENSIONType, front

Type, rear

Shock absorber, front and rear

Evaporator Type

Air temperatureCorrugated fin type

19.5 °C 67 °F

Compressor Type/Make

No. of cylinders

Capacity

Max. speed

Lubricant capacity

NOTES

Swash-plate type/DENSO

10

155.3 cc/rev 9.47 cu-in/rev

7,600 rpm

160 mL 5 1/3 fl oz,

5.6 lmp oz

At 12 V

Air-mix type

Sirocco fan

178 W/12 V

Infinity variable

460 m

3/h 16,247 cu-ft/h

DENSO ND-OIL8

Condenser TypeCorrugated fin type

Temp. control

Blower Type

Motor input

Speed control

Max. capacity

At 13.5 V

Refrigerant Type

Quantity

Dry, single plate, poly-V-belt drive

40 W/12 VCompressor clutch Type

Power consumption

Electric, power assisted, rack and pinion

18.6

3.24

368 mm 14.5 inSTEERING

SYSTEMType

Overall ratio

Turns, lock-to-lock

Steering wheel dia.

HFC-134a (R-134a)

850+0g 30.0+0oz–50–1.8

(cont’d)

*04-NSX (61SW004)SEC03(01-16) 9/22/04 1:49 PM Page 3-14

ProCarManuals.com