sensor ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 811 of 1954

Road Tes t

NOTE : War m u p th e engin e to norma l operatin g temperatur e (th e radiato r fa n come s on) .

1. Appl y parkin g brak e an d bloc k th e wheels . Star t th e engine , the n shif t t o positio n whil e pressin g th e brak e pedal .

Pres s th e accelerato r peda l an d releas e it suddenly . Th e engin e shoul d no t stall .

2. Repea t th e sam e tes t i n position .

3. Test-driv e th e vehicl e o n th e fla t roa d in position . Chec k tha t th e shif t point s occu r a t th e approximat e speed s

shown o n th e nex t page . Als o chec k fo r abnorma l nois e an d clutc h slippage .

NOTE : Throttl e positio n senso r voltag e represent s th e throttl e opening .

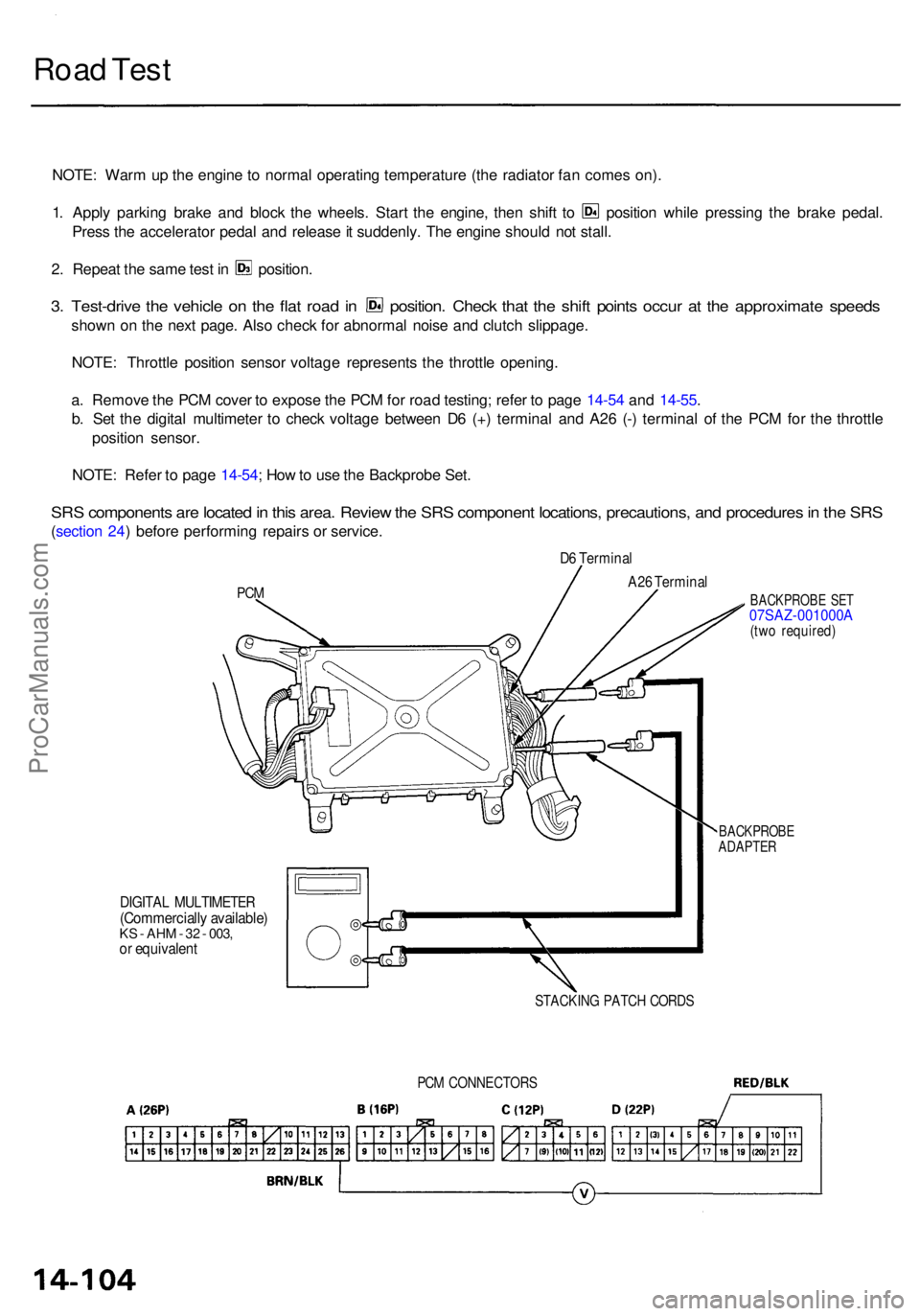

a . Remov e th e PC M cove r t o expos e th e PC M fo r roa d testing ; refe r t o pag e 14-5 4 an d 14-55 .

b . Se t th e digita l multimete r t o chec k voltag e betwee n D 6 (+ ) termina l an d A2 6 (- ) termina l o f th e PC M fo r th e throttl e

positio n sensor .

NOTE : Refe r t o pag e 14-54 ; Ho w to us e th e Backprob e Set .

SRS component s ar e locate d in thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s in th e SR S

(sectio n 24 ) befor e performin g repair s o r service .

PCM

D6 Termina l

DIGITAL MULTIMETE R(Commercially available )KS - AH M - 3 2 - 003 ,or equivalen t

BACKPROB E SE T07SAZ-001000A(two required )

BACKPROB EADAPTER

STACKIN G PATC H CORD S

A26 Termina l

PCM CONNECTOR S

ProCarManuals.com

Page 840 of 1954

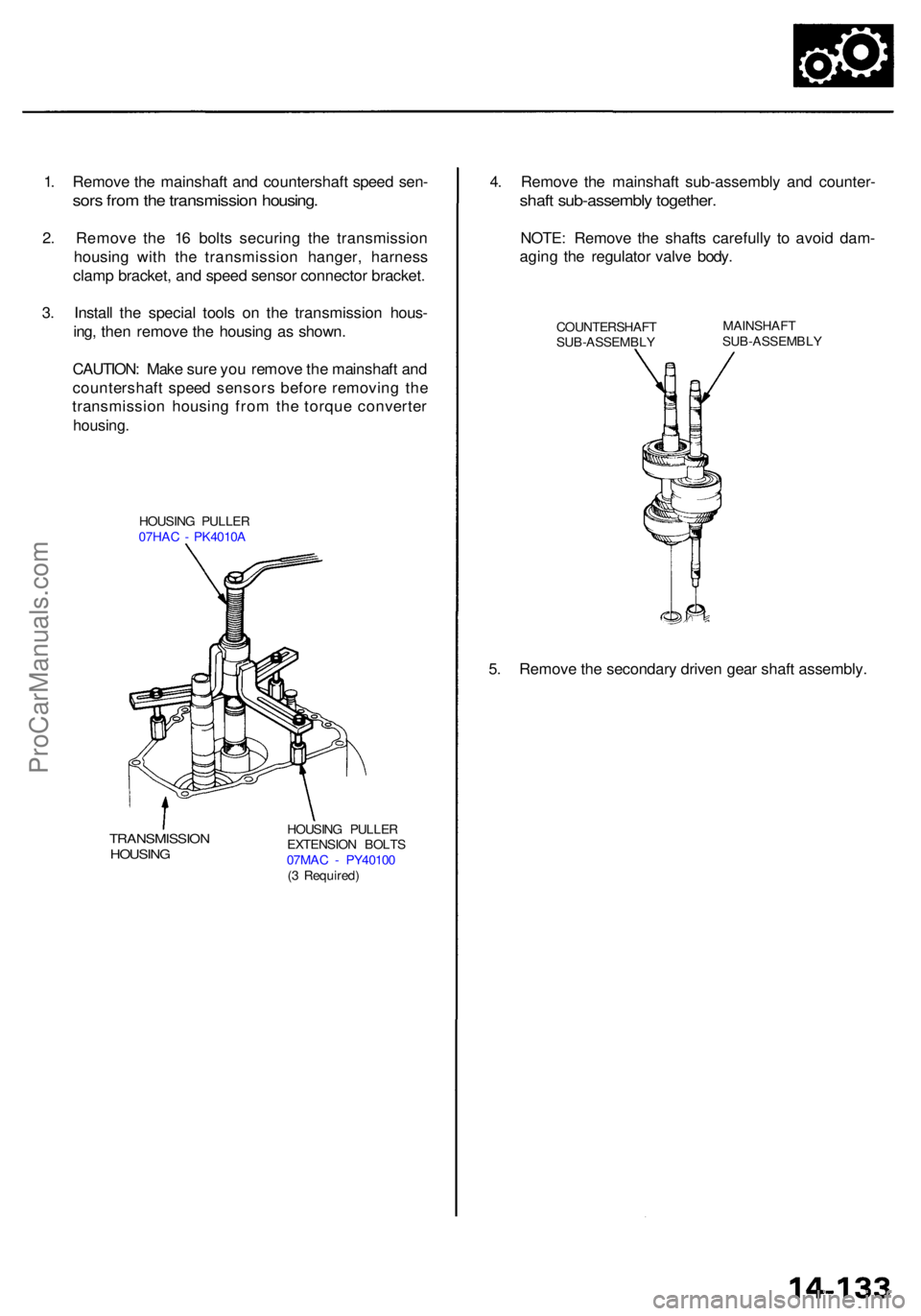

1. Remov e th e mainshaf t an d countershaf t spee d sen -

sors fro m th e transmissio n housing .

2. Remov e th e 1 6 bolts securin g th e transmissio n

housin g wit h th e transmissio n hanger , harnes s

clam p bracket , an d spee d senso r connecto r bracket .

3 . Instal l th e specia l tool s o n th e transmissio n hous -

ing , the n remov e th e housin g a s shown .

CAUTION : Mak e sur e yo u remov e th e mainshaf t an d

countershaf t spee d sensor s befor e removin g th e

transmissio n housin g fro m th e torqu e converte r

housing.

HOUSIN G PULLE R

07HA C - PK4010 A

TRANSMISSIO NHOUSING

HOUSING PULLE R

EXTENSIO N BOLT S

07MA C - PY4010 0

( 3 Required )

4. Remov e th e mainshaf t sub-assembl y an d counter -

shaft sub-assembl y together .

NOTE: Remov e th e shaft s carefull y t o avoi d dam-

agin g th e regulato r valv e body .

COUNTERSHAF T

SUB-ASSEMBL YMAINSHAF

T

SUB-ASSEMBL Y

5. Remov e th e secondar y drive n gea r shaf t assembly .

ProCarManuals.com

Page 893 of 1954

Transmission

Reassembly (cont'd )

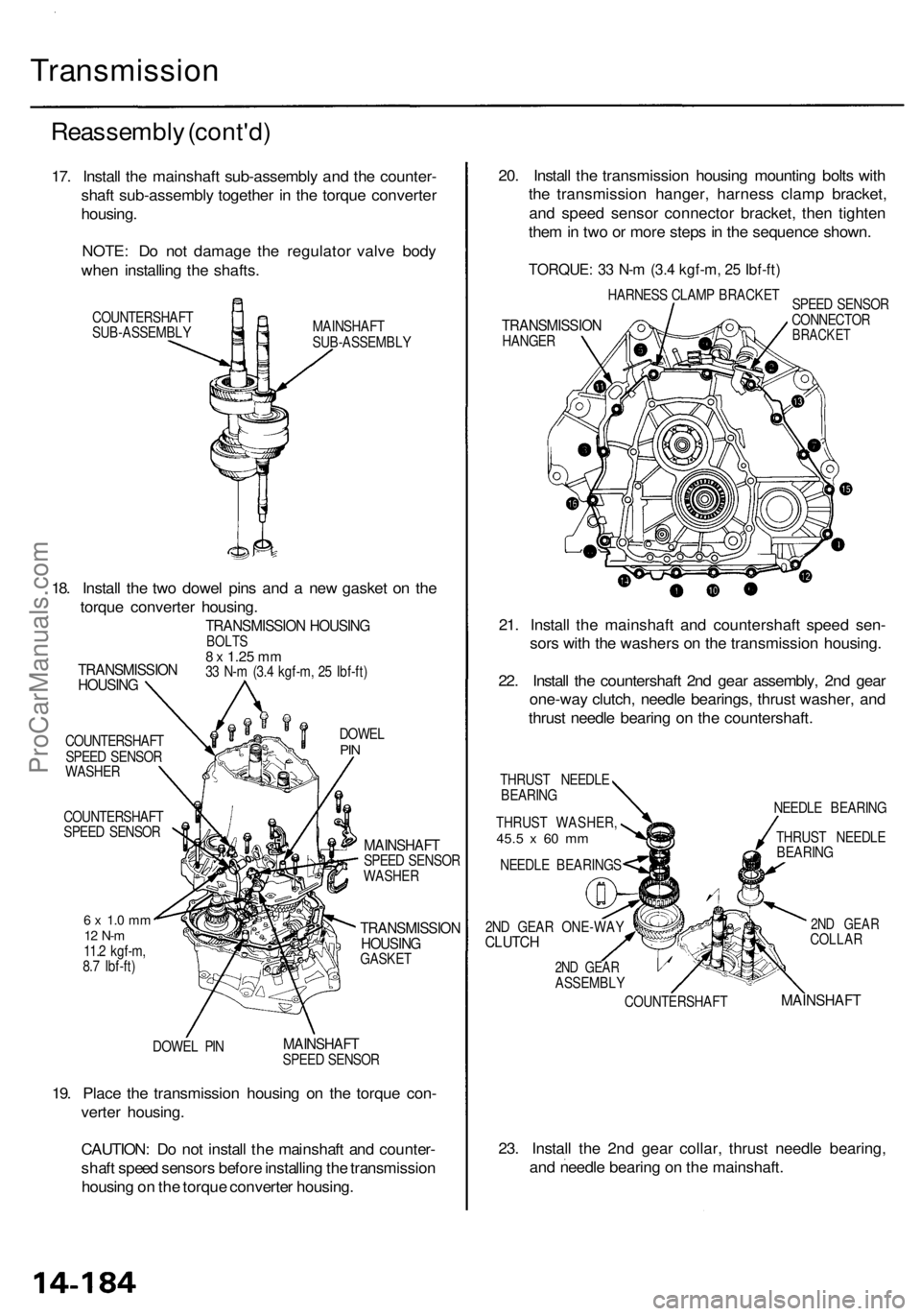

17. Instal l th e mainshaf t sub-assembl y an d th e counter -

shaf t sub-assembl y togethe r i n th e torqu e converte r

housing .

NOTE : D o no t damag e th e regulato r valv e bod y

whe n installin g th e shafts .

COUNTERSHAF T

SUB-ASSEMBL Y MAINSHAF

T

SUB-ASSEMBL Y

COUNTERSHAF T

SPEE D SENSO R

WASHE R

COUNTERSHAF T

SPEE D SENSO R

6 x 1. 0 m m12 N- m11.2 kgf-m ,

8. 7 Ibf-ft )

DOWE L PI N DOWE

L

PIN

MAINSHAF TSPEED SENSO R

WASHE R

TRANSMISSIO NHOUSINGGASKET

MAINSHAF TSPEED SENSO R

19. Plac e th e transmissio n housin g o n th e torqu e con -

verte r housing .

CAUTION : D o no t instal l th e mainshaf t an d counter -

shaf t spee d sensor s befor e installin g th e transmissio n

housin g o n th e torqu e converte r housing . 20

. Instal l th e transmissio n housin g mountin g bolt s wit h

th e transmissio n hanger , harnes s clam p bracket ,

an d spee d senso r connecto r bracket , the n tighte n

the m in tw o o r mor e step s in th e sequenc e shown .

TORQUE : 3 3 N- m (3. 4 kgf-m , 2 5 Ibf-ft )

HARNES S CLAM P BRACKE T

TRANSMISSIO NHANGER SPEE

D SENSO R

CONNECTO RBRACKET

21. Instal l th e mainshaf t an d countershaf t spee d sen -

sor s wit h th e washer s o n th e transmissio n housing .

22 . Instal l th e countershaf t 2n d gea r assembly , 2n d gea r

one-wa y clutch , needl e bearings , thrus t washer , an d

thrus t needl e bearin g o n th e countershaft .

THRUST NEEDL E

BEARIN G

THRUS T WASHER ,

45.5 x 60 m m

NEEDL E BEARING S NEEDL

E BEARIN G

COUNTERSHAF TTHRUS

T NEEDL E

BEARIN G

2ND GEA RCOLLA R

MAINSHAF T

23. Instal l th e 2n d gea r collar , thrus t needl e bearing ,

an d needl e bearin g o n th e mainshaft .

TRANSMISSIO NHOUSING

TRANSMISSIO N HOUSIN GBOLTS8 x 1.2 5 mm33 N- m (3. 4 kgf-m , 2 5 Ibf-ft )

18. Instal l th e tw o dowe l pin s an d a ne w gaske t o n th e

torqu e converte r housing .

2ND GEA R ONE-WA YCLUTCH

2ND GEA RASSEMBL Y

ProCarManuals.com

Page 917 of 1954

Differential Assembl y

Removal (cont'd )

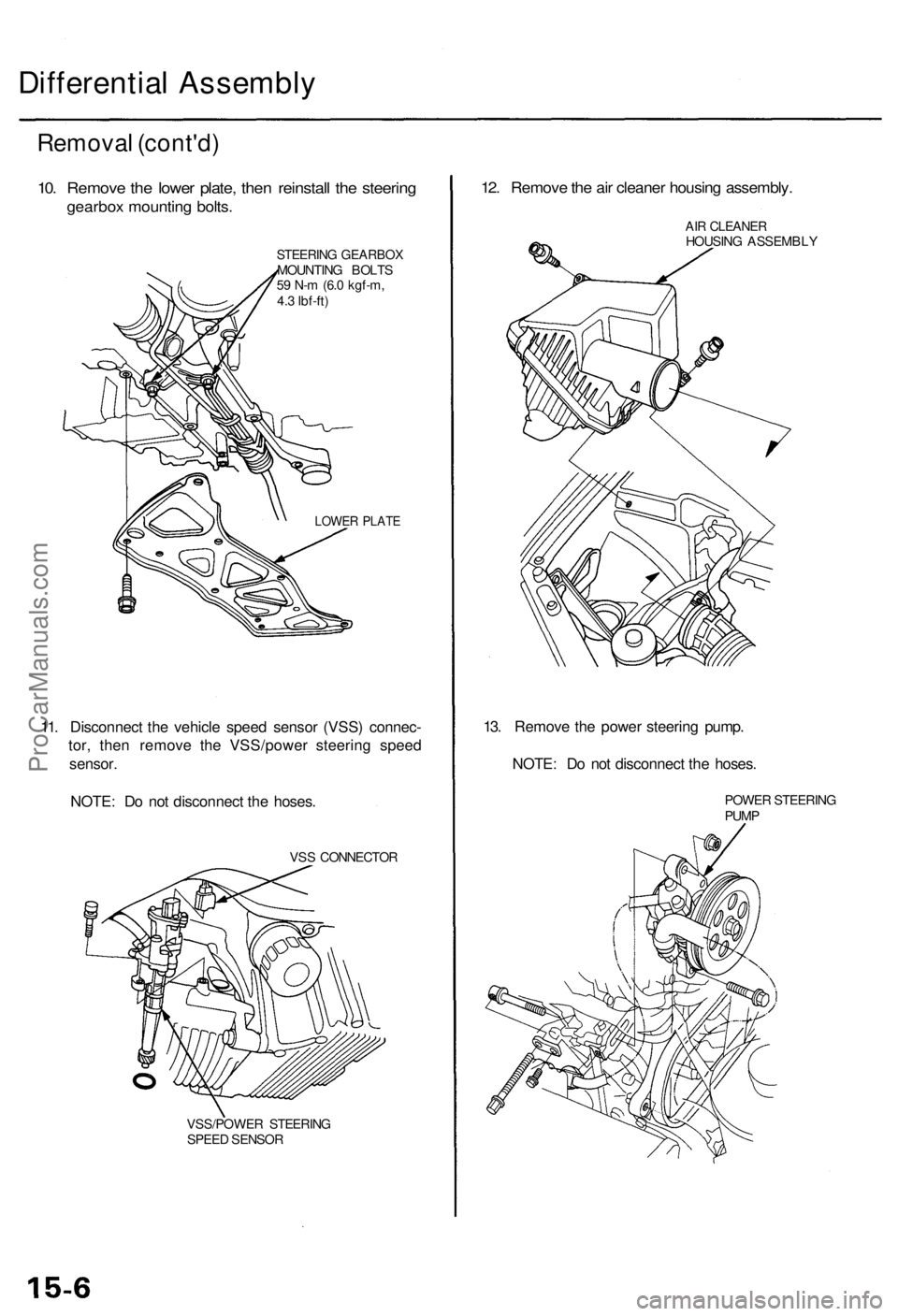

10. Remov e th e lowe r plate , the n reinstal l th e steerin g

gearbo x mountin g bolts .

STEERIN G GEARBO XMOUNTING BOLT S

5 9 N- m (6. 0 kgf-m ,

4. 3 Ibf-ft )

LOWE R PLAT E

11. Disconnec t th e vehicl e spee d senso r (VSS ) connec -

tor , the n remov e th e VSS/powe r steerin g spee d

sensor .

NOTE : D o no t disconnec t th e hoses .

VSS CONNECTO R

VSS/POWE R STEERIN G

SPEE D SENSO R

12. Remov e th e ai r cleane r housin g assembly .

AIR CLEANE RHOUSING ASSEMBL Y

13. Remov e th e powe r steerin g pump .

NOTE : D o no t disconnec t th e hoses .

POWER STEERIN G

PUM P

ProCarManuals.com

Page 941 of 1954

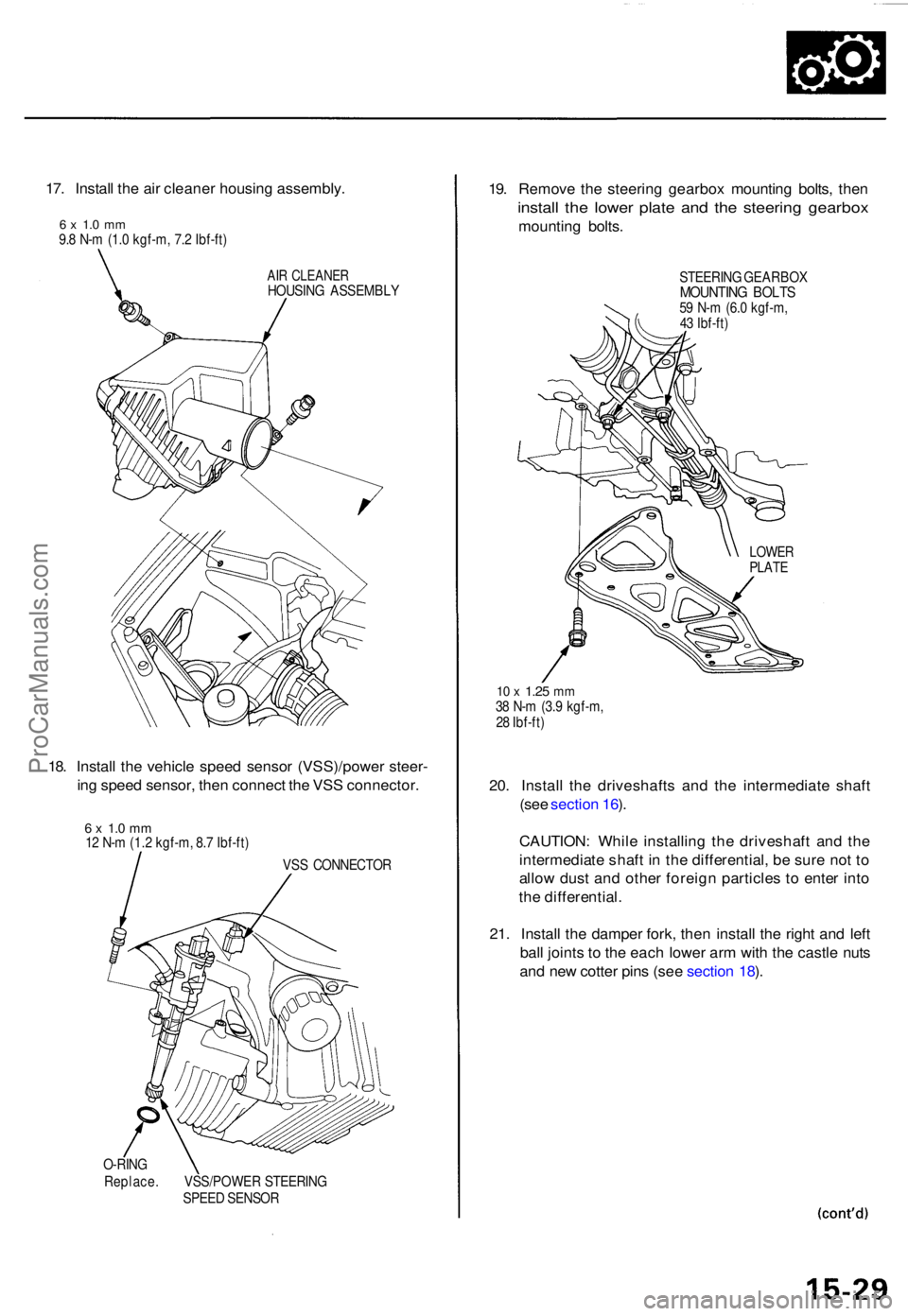

17. Instal l th e ai r cleane r housin g assembly .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

AIR CLEANE RHOUSING ASSEMBL Y

18. Instal l th e vehicl e spee d senso r (VSS)/powe r steer -

in g spee d sensor , the n connec t th e VS S connector .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

VSS CONNECTO R

O-RIN G

Replace . VSS/POWE R STEERIN G

SPEE D SENSO R

19. Remov e th e steerin g gearbo x mountin g bolts , the n

instal l th e lowe r plat e an d th e steerin g gearbo x

mounting bolts .

STEERIN G GEARBO XMOUNTING BOLT S59 N- m (6. 0 kgf-m ,

4 3 Ibf-ft )

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

20. Instal l th e driveshaft s an d th e intermediat e shaf t

(se e sectio n 16 ).

CAUTION : Whil e installin g th e driveshaf t an d th e

intermediat e shaf t i n th e differential , b e sur e no t t o

allo w dus t an d othe r foreig n particle s t o ente r int o

th e differential .

21 . Instal l th e dampe r fork , the n instal l th e righ t an d lef t

bal l joint s t o th e eac h lowe r ar m wit h th e castl e nut s

an d ne w cotte r pin s (se e sectio n 18 ).

LOWE RPLATE

ProCarManuals.com

Page 977 of 1954

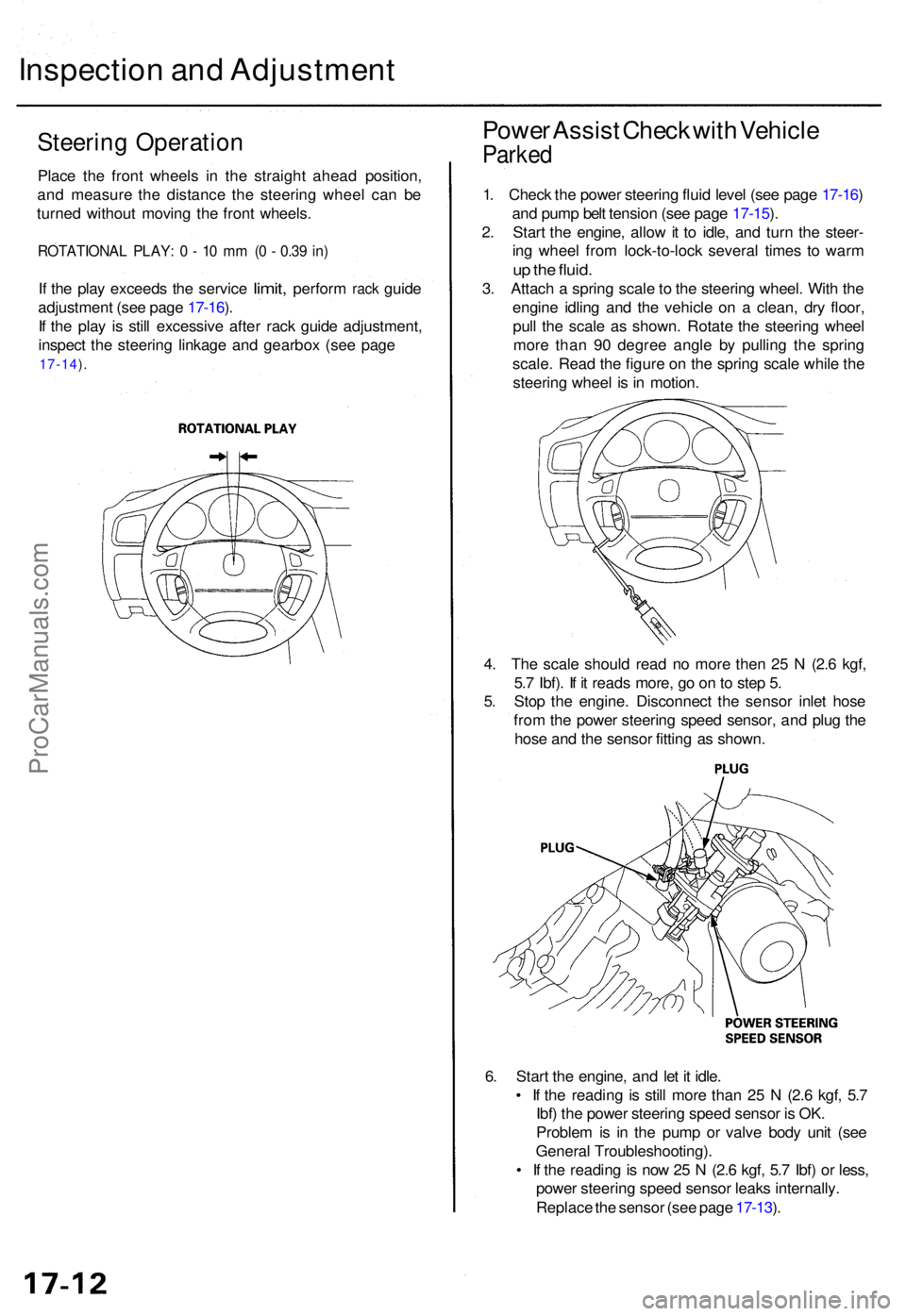

Inspection an d Adjustmen t

Steering Operatio n

Place th e fron t wheel s i n th e straigh t ahea d position ,

an d measur e th e distanc e th e steerin g whee l ca n b e

turne d withou t movin g th e fron t wheels .

ROTATIONA L PLAY : 0 - 1 0 m m (0 - 0.3 9 in )

If th e pla y exceed s th e servic e limit, perfor m rack guid e

adjustmen t (se e pag e 17-16 ).

I f th e pla y i s stil l excessiv e afte r rac k guid e adjustment ,

inspec t th e steerin g linkag e an d gearbo x (se e pag e

17-14 ).

Powe r Assis t Chec k wit h Vehicl e

Parked

1. Chec k th e powe r steerin g flui d leve l (se e pag e 17-16 )

an d pum p bel t tensio n (se e pag e 17-15 ).

2 . Star t th e engine , allo w it t o idle , an d tur n th e steer -

in g whee l fro m lock-to-loc k severa l time s t o war m

up th e fluid .

3. Attac h a sprin g scal e to th e steerin g wheel . Wit h th e

engin e idlin g an d th e vehicl e o n a clean , dr y floor ,

pul l th e scal e a s shown . Rotat e th e steerin g whee l

mor e tha n 9 0 degre e angl e b y pullin g th e sprin g

scale . Rea d th e figur e o n th e sprin g scal e whil e th e

steerin g whee l i s in motion .

4 . Th e scal e shoul d rea d n o mor e the n 2 5 N (2. 6 kgf ,

5. 7 Ibf) . I f i t read s more , g o o n to ste p 5 .

5 . Sto p th e engine . Disconnec t th e senso r inle t hos e

fro m th e powe r steerin g spee d sensor , an d plu g th e

hos e an d th e senso r fittin g a s shown .

6 . Star t th e engine , an d le t i t idle .

• I f th e readin g i s stil l mor e tha n 2 5 N (2. 6 kgf , 5. 7

Ibf ) th e powe r steerin g spee d senso r i s OK .

Proble m is i n th e pum p o r valv e bod y uni t (se e

Genera l Troubleshooting) .

• I f th e readin g is no w 2 5 N (2. 6 kgf , 5. 7 Ibf ) o r less ,

powe r steerin g spee d senso r leak s internally .

Replac e th e senso r (se e pag e 17-13 ).

ProCarManuals.com

Page 978 of 1954

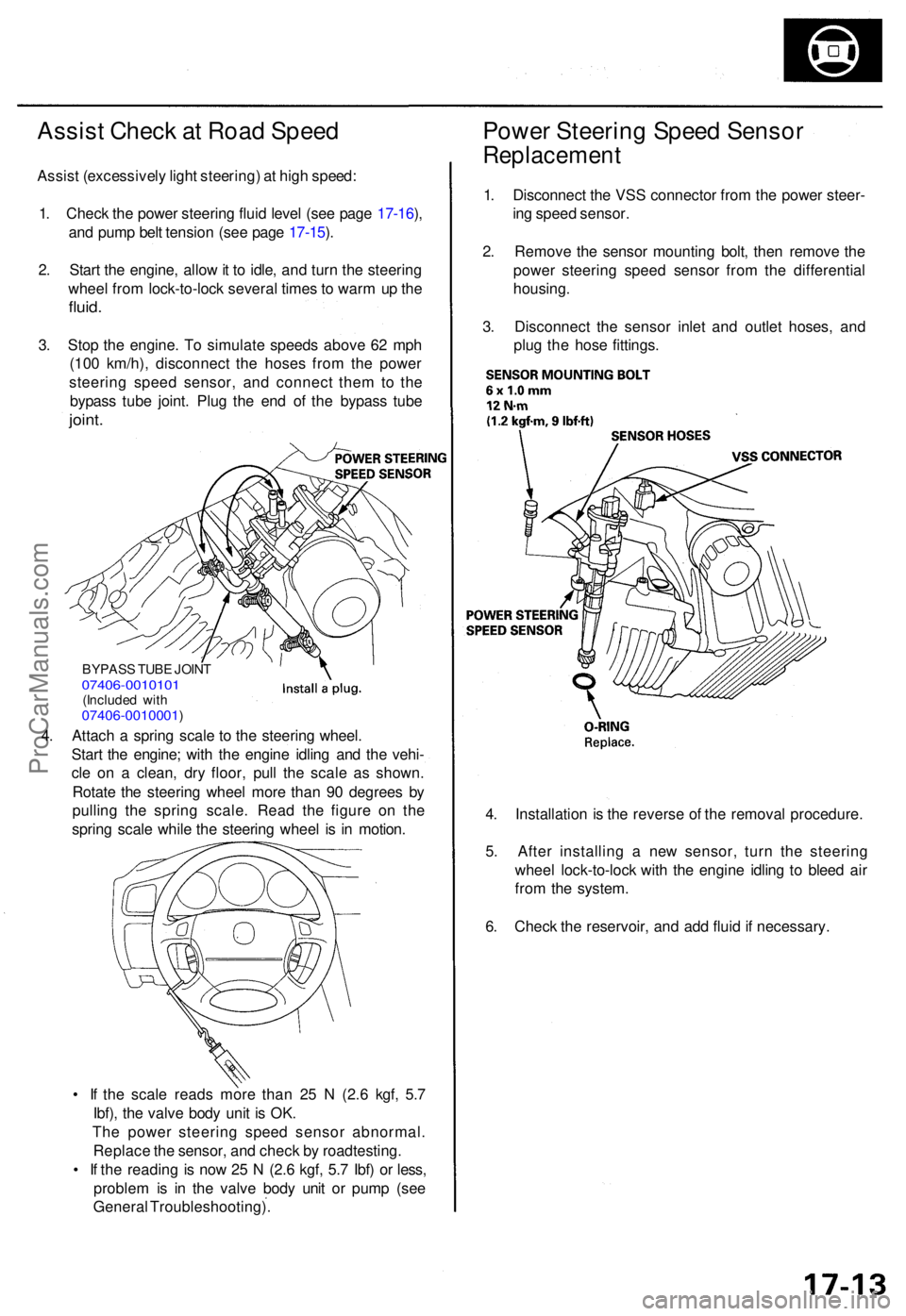

Assist Chec k a t Roa d Spee d

Assist (excessivel y ligh t steering ) a t hig h speed :

1 . Chec k th e powe r steerin g flui d leve l (se e pag e 17-16 ),

an d pum p bel t tensio n (se e pag e 17-15 ).

2 . Star t th e engine , allo w it t o idle , an d tur n th e steerin g

whee l fro m lock-to-loc k severa l time s t o war m u p th e

fluid .

3. Sto p th e engine . T o simulat e speed s abov e 6 2 mp h

(10 0 km/h) , disconnec t th e hose s fro m th e powe r

steerin g spee d sensor , an d connec t the m to th e

bypas s tub e joint . Plu g th e en d o f th e bypas s tub e

joint .

Powe r Steerin g Spee d Senso r

Replacemen t

1. Disconnec t th e VS S connecto r fro m th e powe r steer -

in g spee d sensor .

2 . Remov e th e senso r mountin g bolt , the n remov e th e

powe r steerin g spee d senso r fro m th e differentia l

housing .

3 . Disconnec t th e senso r inle t an d outle t hoses , an d

plu g th e hos e fittings .

4 . Installatio n is th e revers e o f th e remova l procedure .

5 . Afte r installin g a ne w sensor , tur n th e steerin g

whee l lock-to-loc k wit h th e engine idling t o blee d ai r

fro m th e system .

6 . Chec k th e reservoir , an d ad d flui d if necessary .

BYPASS TUB E JOIN T07406-001010 1(Included wit h07406-0010001 )

4. Attac h a sprin g scal e to th e steerin g wheel .

Star t th e engine ; wit h th e engin e idlin g an d th e vehi -

cl e o n a clean , dr y floor , pul l th e scal e a s shown .

Rotat e th e steerin g whee l mor e tha n 9 0 degree s b y

pullin g th e sprin g scale . Rea d th e figur e o n th e

sprin g scal e whil e th e steerin g whee l i s i n motion .

• I f th e scal e read s mor e tha n 2 5 N (2. 6 kgf , 5. 7

Ibf) , th e valv e bod y uni t i s OK .

Th e powe r steerin g spee d senso r abnormal .

Replac e th e sensor , an d chec k b y roadtesting .

• I f th e readin g is no w 2 5 N (2. 6 kgf , 5. 7 Ibf ) o r less ,

proble m is i n th e valv e bod y uni t o r pum p (se e

Genera l Troubleshooting) .

ProCarManuals.com

Page 985 of 1954

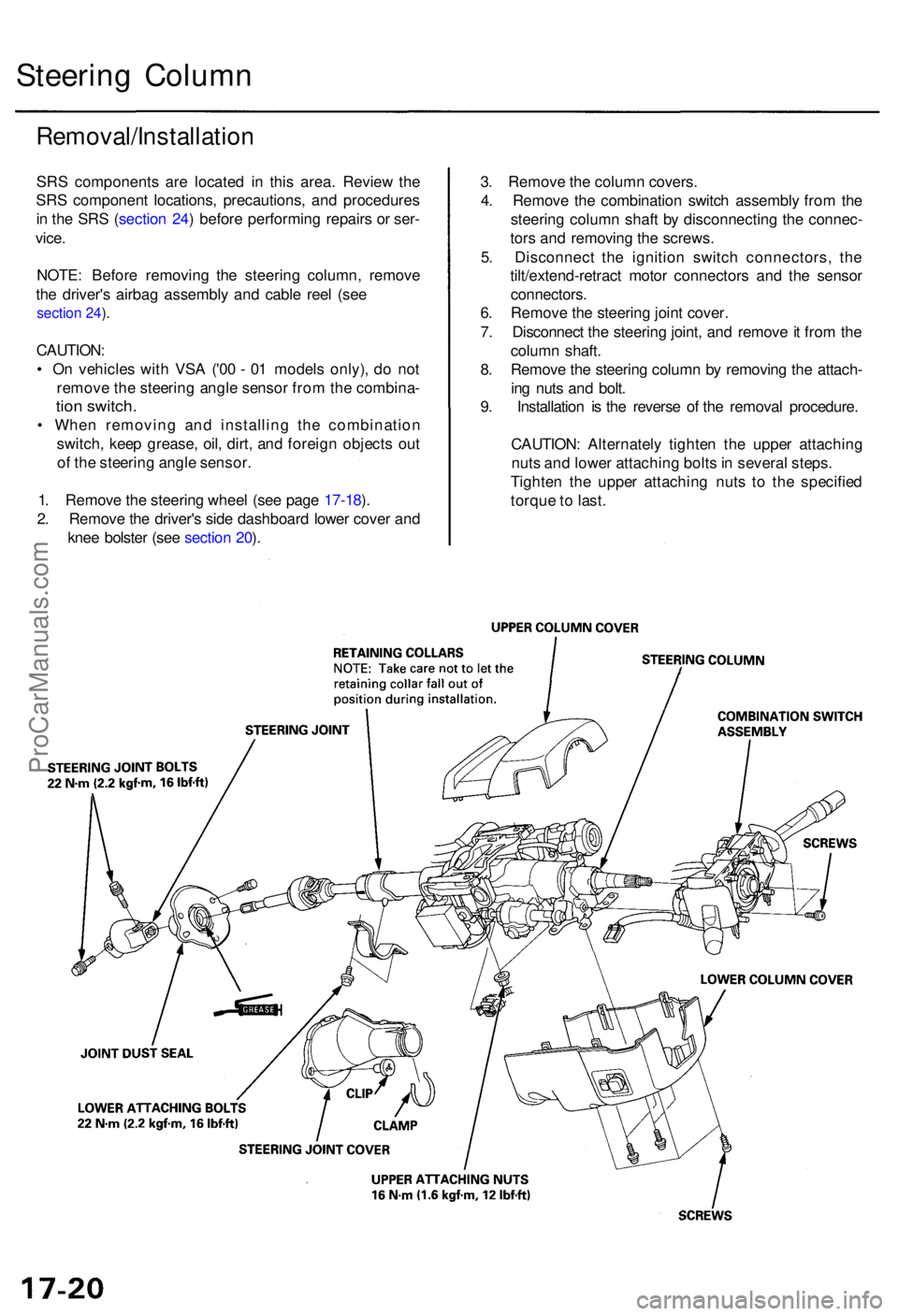

Steering Colum n

Removal/Installatio n

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S (sectio n 24 ) befor e performin g repair s o r ser -

vice .

NOTE : Befor e removin g th e steerin g column , remov e

th e driver' s airba g assembl y an d cabl e ree l (se e

section 24 ).

CAUTION :

• O n vehicle s wit h VS A ('0 0 - 0 1 model s only) , d o no t

remov e th e steerin g angl e senso r fro m th e combina -

tion switch .

• Whe n removin g an d installin g th e combinatio n

switch , kee p grease , oil , dirt , an d foreig n object s ou t

o f th e steerin g angl e sensor .

1 . Remov e th e steerin g whee l (se e pag e 17-18 ).

2 . Remov e th e driver' s sid e dashboar d lowe r cove r an d

kne e bolste r (se e sectio n 20 ). 3

. Remov e th e colum n covers .

4 . Remov e th e combinatio n switc h assembl y fro m th e

steerin g colum n shaf t b y disconnectin g th e connec -

tor s an d removin g th e screws .

5 . Disconnec t th e ignitio n switc h connectors , th e

tilt/extend-retrac t moto r connector s an d th e senso r

connectors .

6 . Remov e th e steerin g join t cover .

7 . Disconnec t th e steerin g joint , an d remov e it fro m th e

colum n shaft .

8 . Remov e th e steerin g colum n b y removin g th e attach -

in g nut s an d bolt .

9 . Installatio n i s th e revers e o f th e remova l procedure .

CAUTION : Alternatel y tighte n th e uppe r attachin g

nut s an d lowe r attachin g bolt s in severa l steps .

Tighte n th e uppe r attachin g nut s t o th e specifie d

torqu e to last .

ProCarManuals.com

Page 987 of 1954

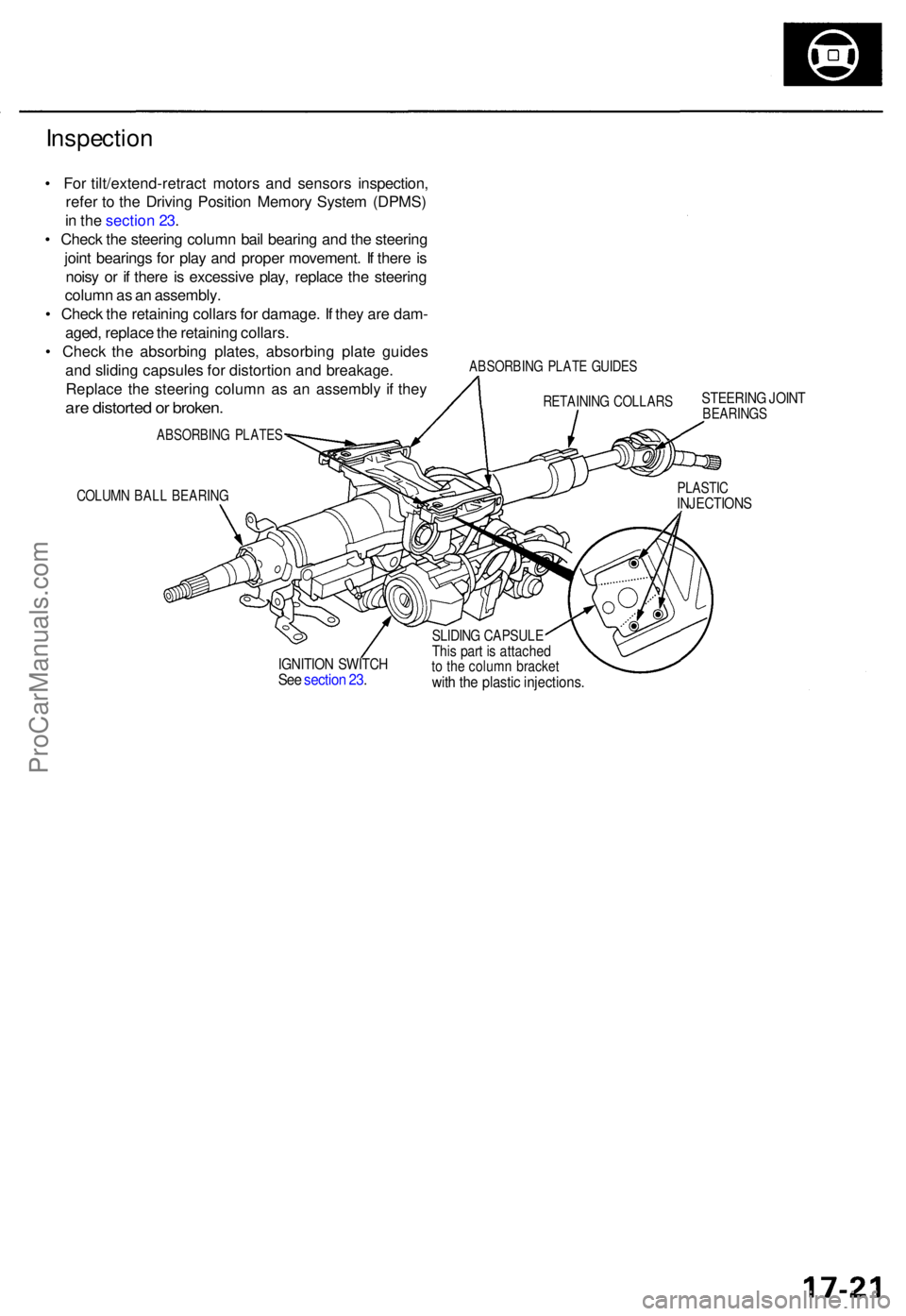

Inspection

• Fo r tilt/extend-retrac t motor s an d sensor s inspection ,

refe r t o th e Drivin g Positio n Memor y Syste m (DPMS )

i n th e sectio n 23 .

• Chec k th e steerin g colum n bai l bearin g an d th e steerin g

join t bearing s fo r pla y an d prope r movement . I f ther e is

nois y o r i f ther e is excessiv e play , replac e th e steerin g

colum n a s a n assembly .

• Chec k th e retainin g collar s fo r damage . I f the y ar e dam -

aged , replac e th e retainin g collars .

• Chec k th e absorbin g plates , absorbin g plat e guide s

an d slidin g capsule s fo r distortio n an d breakage .

Replac e th e steerin g colum n a s a n assembl y i f the y

are distorte d o r broken .

ABSORBIN G PLATE S

COLUMN BAL L BEARIN G

ABSORBIN G PLAT E GUIDE S

STEERIN G JOIN TBEARING S

PLASTICINJECTION S

IGNITION SWITC HSee sectio n 23 .

SLIDIN G CAPSUL EThis par t i s attache dto th e colum n bracke twith th e plasti c injections .

RETAININ G COLLAR S

ProCarManuals.com

Page 1000 of 1954

Power Steering Gearbox

Removal (cont'd)

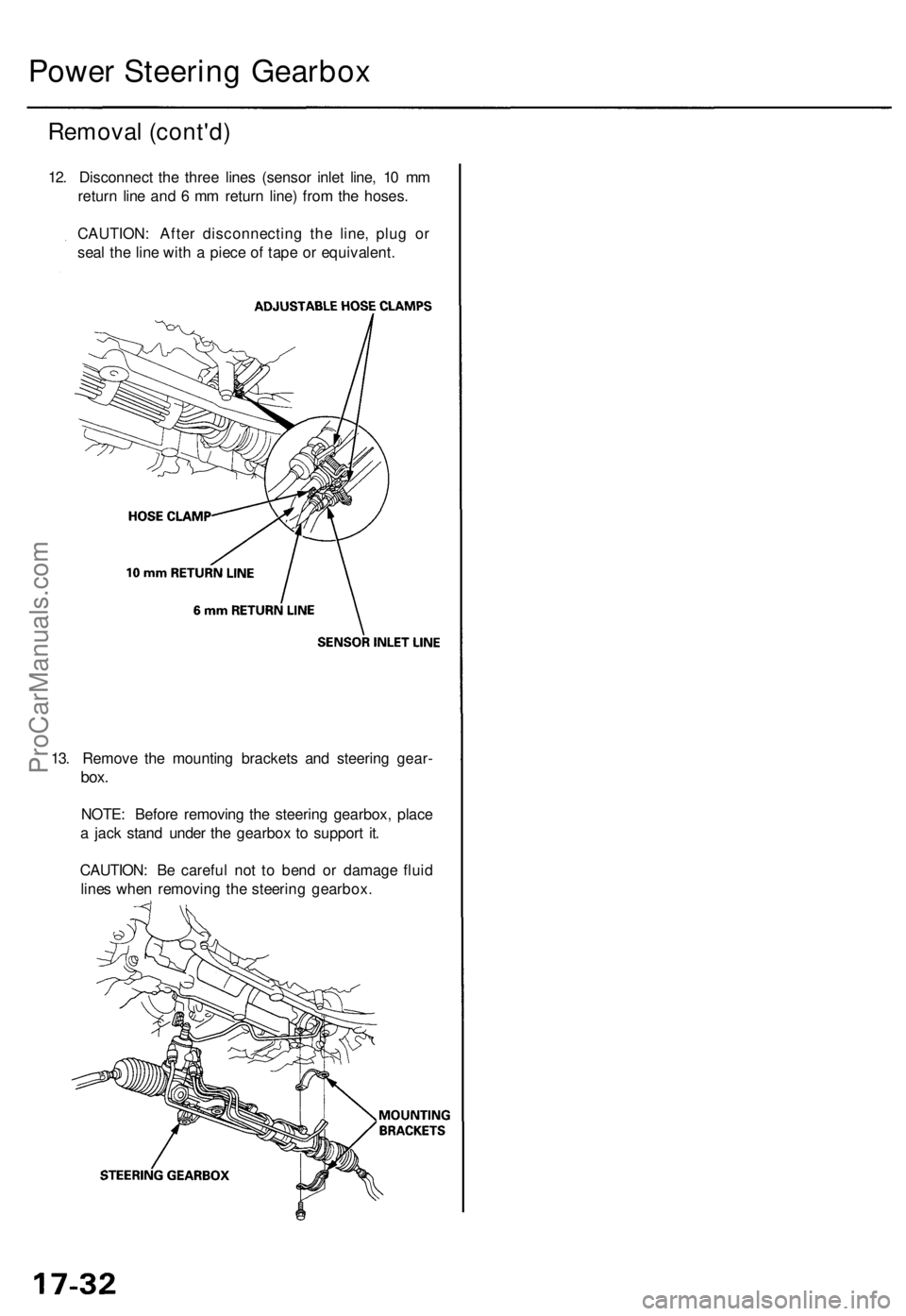

12. Disconnect the three lines (sensor inlet line, 10 mm

return line and 6 mm return line) from the hoses.

CAUTION: After disconnecting the line, plug or

seal the line with a piece of tape or equivalent.

13. Remove the mounting brackets and steering gear-

box.

NOTE: Before removing the steering gearbox, place

a jack stand under the gearbox to support it.

CAUTION: Be careful not to bend or damage fluid

lines when removing the steering gearbox.ProCarManuals.com