sensor ACURA RL KA9 1996 Service Owners Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 729 of 1954

Description

Electronic Contro l Syste m (cont'd )

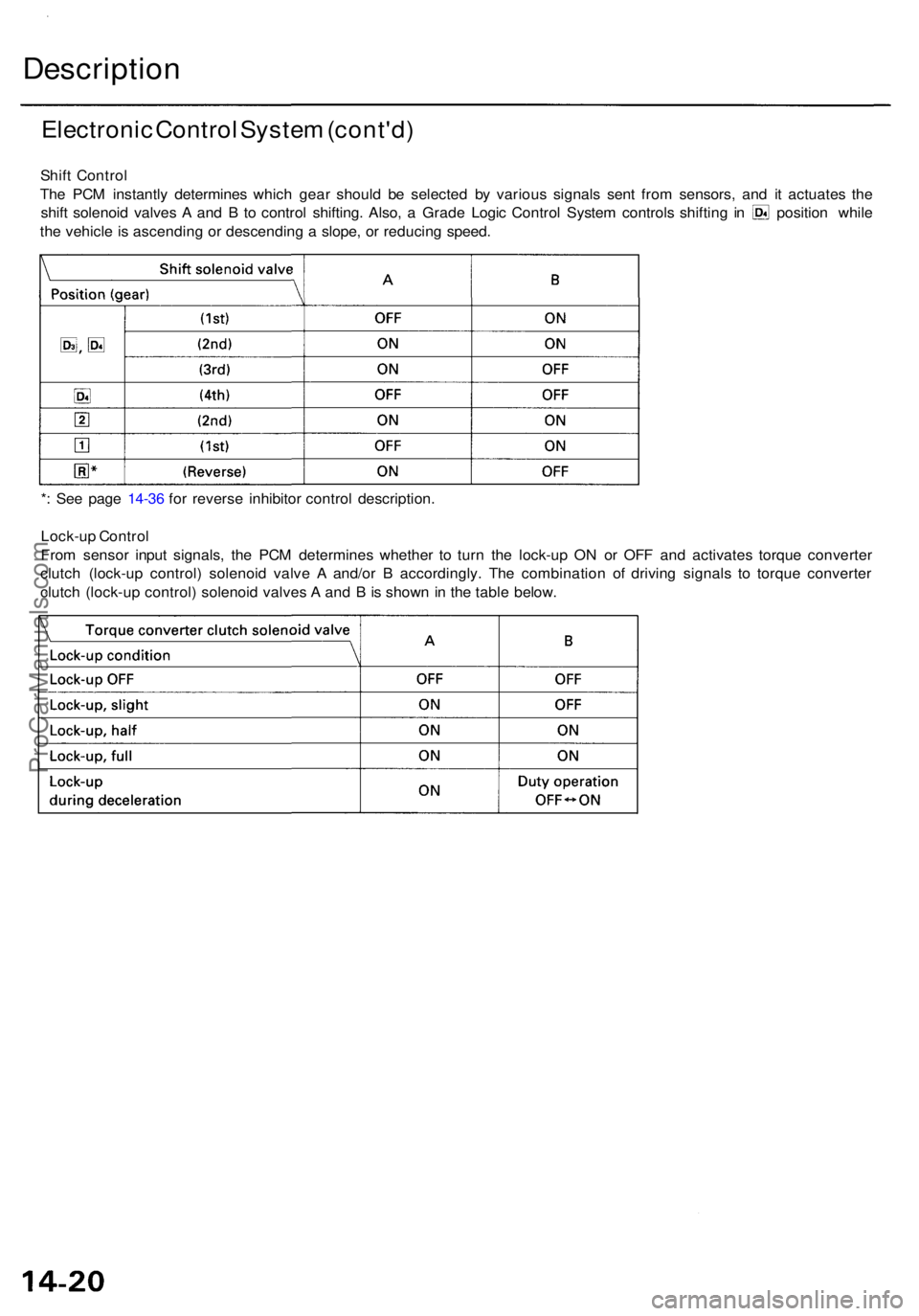

Shift Contro l

Th e PC M instantl y determine s whic h gea r shoul d b e selecte d b y variou s signal s sen t fro m sensors , an d i t actuate s th e

shif t solenoi d valve s A an d B to contro l shifting . Also , a Grad e Logi c Contro l Syste m control s shiftin g i n positio n whil e

th e vehicl e is ascendin g o r descendin g a slope , o r reducin g speed .

* : Se e pag e 14-3 6 fo r revers e inhibito r contro l description .

Lock-u p Contro l

Fro m senso r inpu t signals , th e PC M determine s whethe r t o tur n th e lock-u p O N o r OF F an d activate s torqu e converte r

clutc h (lock-u p control ) solenoi d valv e A and/o r B accordingly . Th e combinatio n o f drivin g signal s t o torqu e converte r

clutc h (lock-u p control ) solenoi d valve s A an d B is show n in th e tabl e below .

ProCarManuals.com

Page 730 of 1954

Grade Logic Control System

How it works:

The PCM compares actual driving conditions with driving conditions memorized in the PCM, based on the input from the

vehicle speed sensor, throttle position sensor, engine coolant temperature sensor, barometric pressure sensor, brake

pedal position switch signal and shift lever position signal, to control shifting while a vehicle is ascending or descending a

slope.ProCarManuals.com

Page 758 of 1954

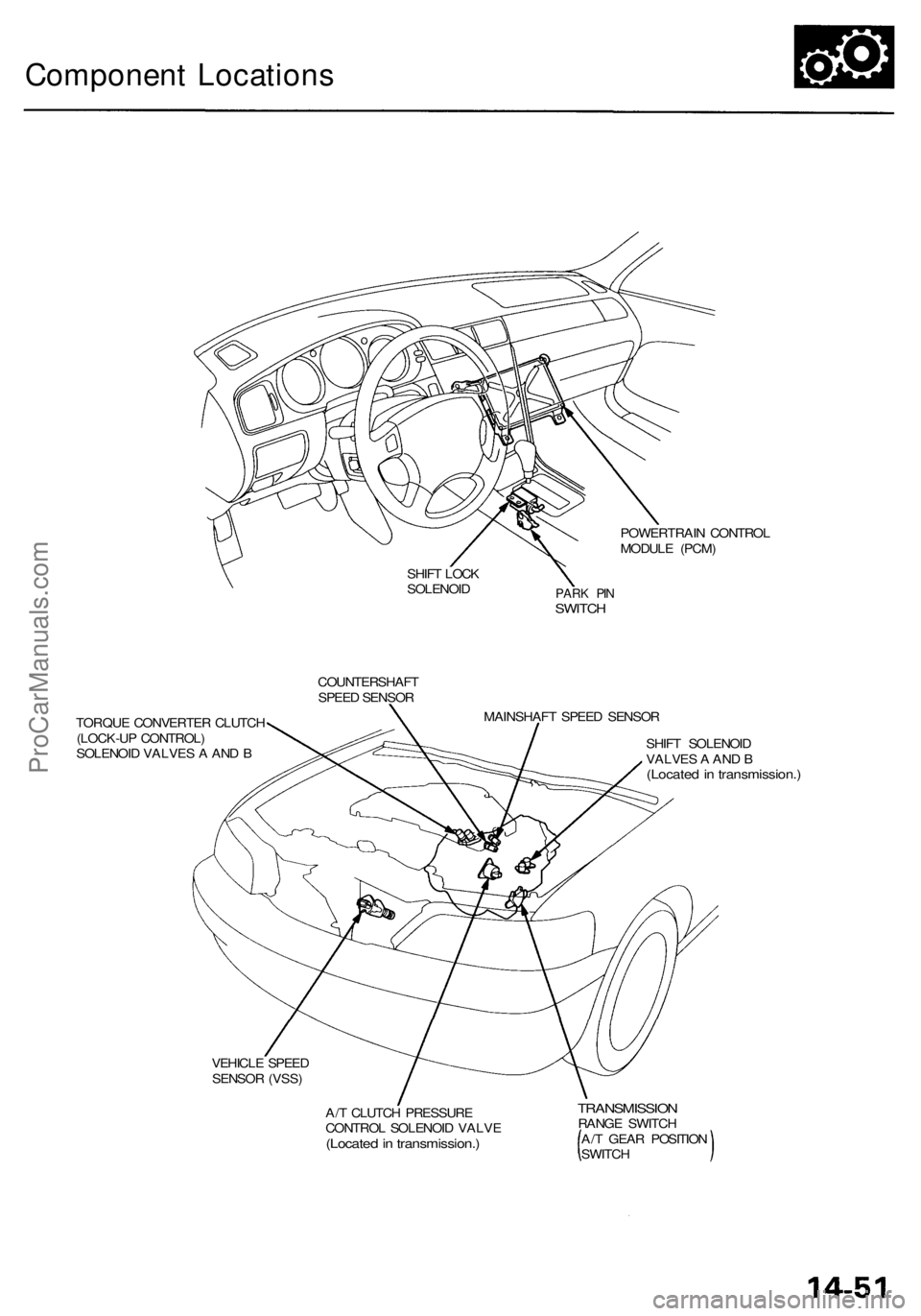

Component Locations

POWERTRAIN CONTROL

MODULE (PCM)

SHIFT LOCK

SOLENOID

PARK PIN

SWITCH

COUNTERSHAFT

SPEED SENSOR

TORQUE CONVERTER CLUTCH

(LOCK-UP CONTROL)

SOLENOID VALVES A AND B

MAINSHAFT SPEED SENSOR

SHIFT SOLENOID

VALVES A AND B

(Located in transmission.)

VEHICLE SPEED

SENSOR (VSS)

A/T CLUTCH PRESSURE

CONTROL SOLENOID VALVE

(Located in transmission.)

TRANSMISSION

RANGE SWITCH

A/T GEAR POSITION

SWITCHProCarManuals.com

Page 769 of 1954

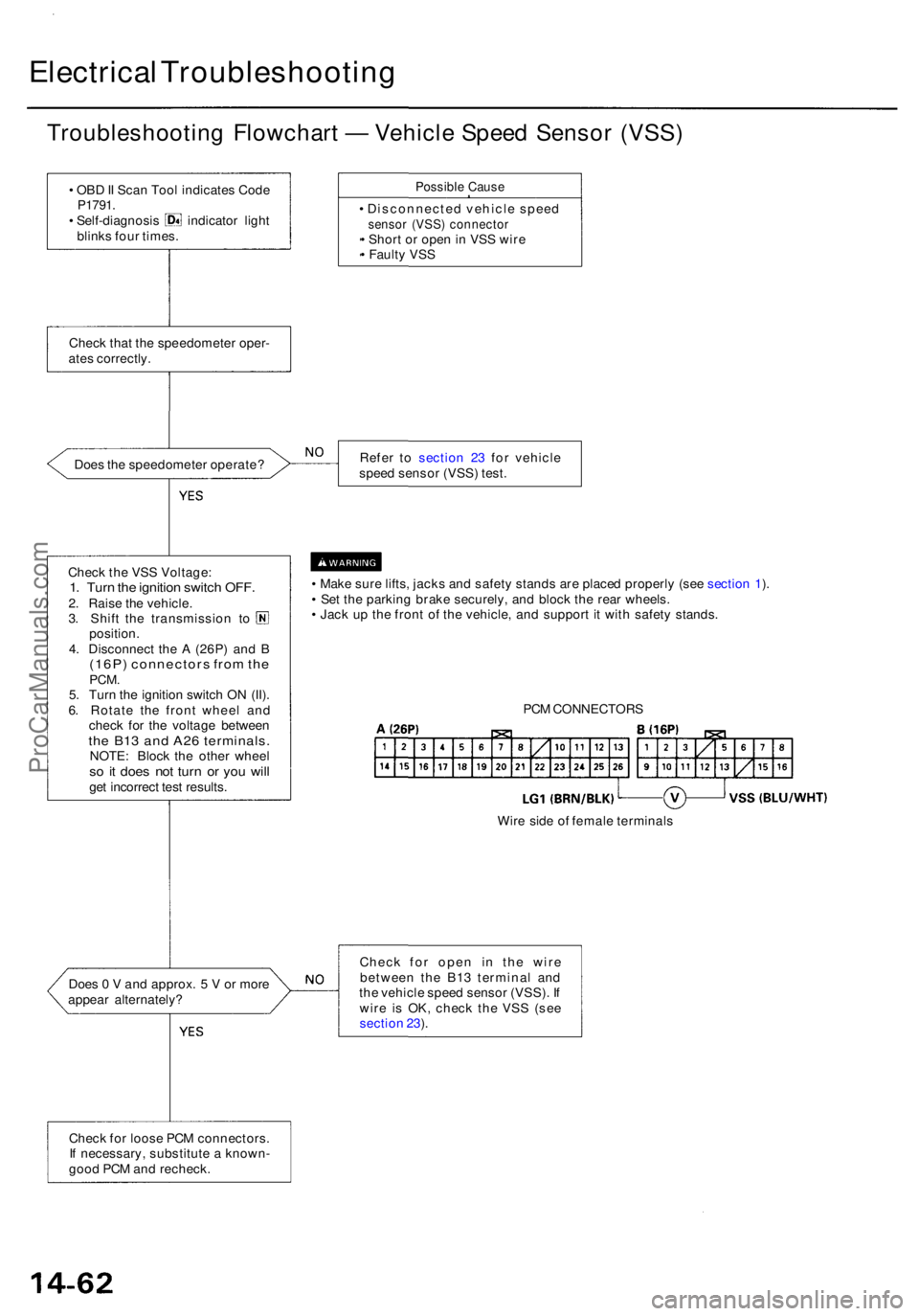

Electrical Troubleshootin g

Troubleshooting Flowchar t — Vehicl e Spee d Senso r (VSS )

• OB D II Sca n Too l indicate s Cod eP1791 .• Self-diagnosi s indicato r ligh t

blink s fou r times .

Possibl e Caus e

• Disconnecte d vehicl e spee dsensor (VSS ) connecto r• Shor t o r ope n in VS S wir e

• Fault y VS S

Chec k tha t th e speedomete r oper -

ate s correctly .

Doe s th e speedomete r operate ? Refe

r t o sectio n 2 3 fo r vehicl e

spee d senso r (VSS ) test .

Chec k th e VS S Voltage :

1. Tur n th e ignitio n switc h OFF .2. Rais e th e vehicle .3. Shif t th e transmissio n t o

position .

4 . Disconnec t th e A (26P ) an d B

(16P ) connector s fro m th ePCM .5. Tur n th e ignitio n switc h O N (II) .

6 . Rotat e th e fron t whee l an d

chec k fo r th e voltag e betwee n

the B1 3 an d A2 6 terminals .NOTE: Bloc k th e othe r whee lso i t doe s no t tur n o r yo u wil lget incorrec t tes t results . •

Mak e sur e lifts , jack s an d safet y stand s ar e place d properl y (se e sectio n 1 ).

• Se t th e parkin g brak e securely , an d bloc k th e rea r wheels .

• Jac k u p th e fron t o f th e vehicle , an d suppor t i t wit h safet y stands .

Doe s 0 V and approx . 5 V or mor e

appea r alternately ? Chec

k fo r ope n i n th e wir e

betwee n th e B1 3 termina l an d

th e vehicl e spee d senso r (VSS) . I f

wir e i s OK , chec k th e VS S (se e

sectio n 23 ).

Chec k fo r loos e PC M connectors .

I f necessary , substitut e a known -

goo d PC M an d recheck . PC

M CONNECTOR S

Wir e sid e o f femal e terminal s

ProCarManuals.com

Page 779 of 1954

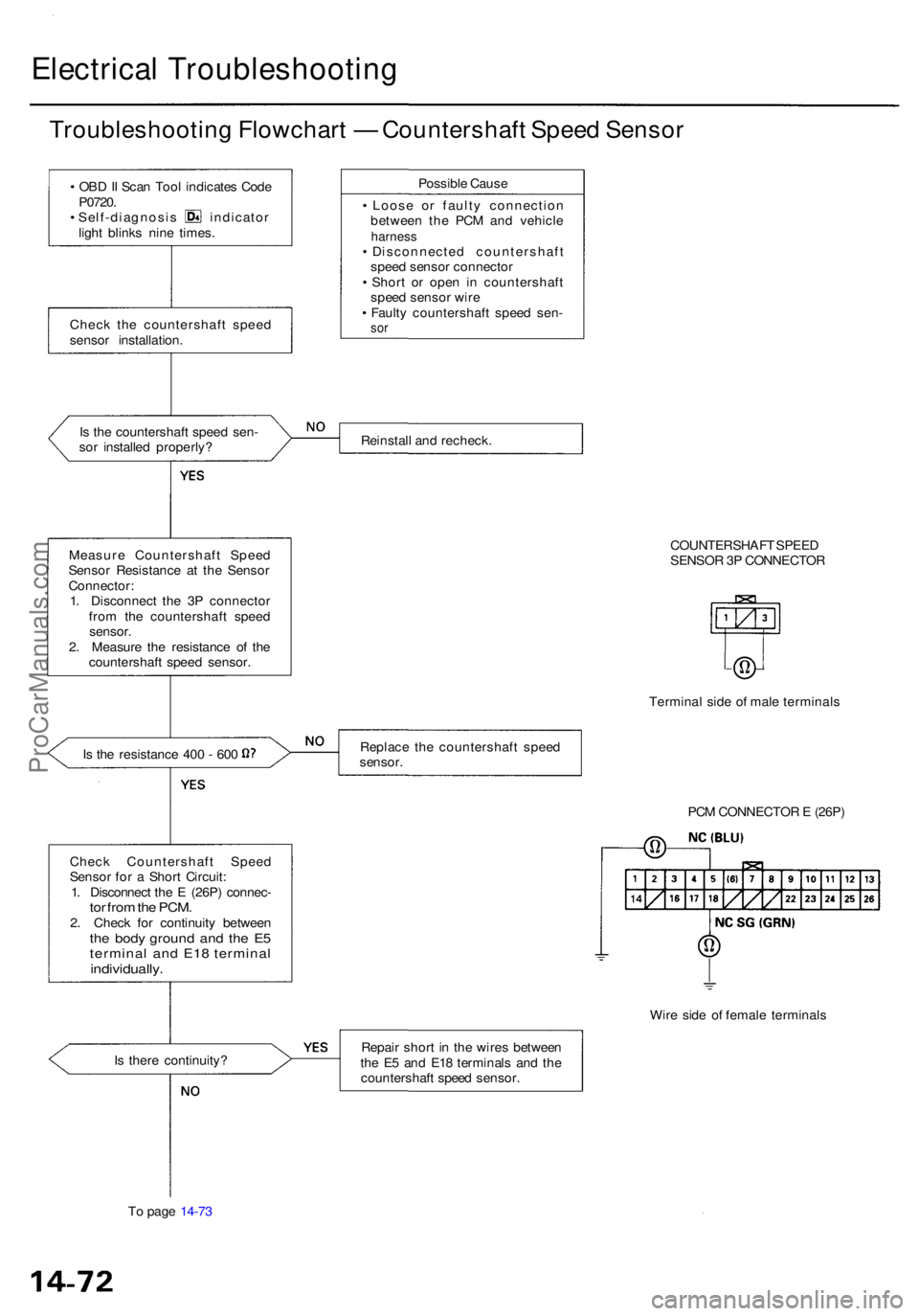

Electrical Troubleshootin g

Troubleshooting Flowchar t — Countershaf t Spee d Senso r

• OB D II Sca n Too l indicate s Cod e

P0720 .

• Self-diagnosi s indicato r

ligh t blink s nin e times .

Chec k th e countershaf t spee d

senso r installation .

I s th e countershaf t spee d sen -

so r installe d properly ?

Measur e Countershaf t Spee d

Senso r Resistanc e a t th e Senso r

Connector :

1 . Disconnec t th e 3 P connecto r

fro m th e countershaf t spee d

sensor .

2 . Measur e th e resistanc e o f th e

countershaf t spee d sensor .

Is th e resistanc e 40 0 - 60 0

Chec k Countershaf t Spee d

Senso r fo r a Shor t Circuit :

1 . Disconnec t th e E (26P ) connec -

tor fro m th e PCM .2. Chec k fo r continuit y betwee nthe bod y groun d an d th e E 5

termina l an d E1 8 termina l

individually .

Possible Caus e

• Loos e o r fault y connectio n

betwee n th e PC M an d vehicl e

harness• Disconnecte d countershaf t

spee d senso r connecto r

• Shor t o r ope n i n countershaf t

spee d senso r wir e

• Fault y countershaf t spee d sen -

sor

Reinstal l an d recheck .

COUNTERSHAFT SPEE D

SENSO R 3 P CONNECTO R

Termina l sid e o f mal e terminal s

Replac e th e countershaf t spee d

sensor .

Wire sid e o f femal e terminal s

I s ther e continuity ? Repai

r shor t i n th e wire s betwee n

th e E 5 an d E1 8 terminal s an d th e

countershaf t spee d sensor .

T o pag e 14-7 3 PC

M CONNECTO R E (26P )

ProCarManuals.com

Page 780 of 1954

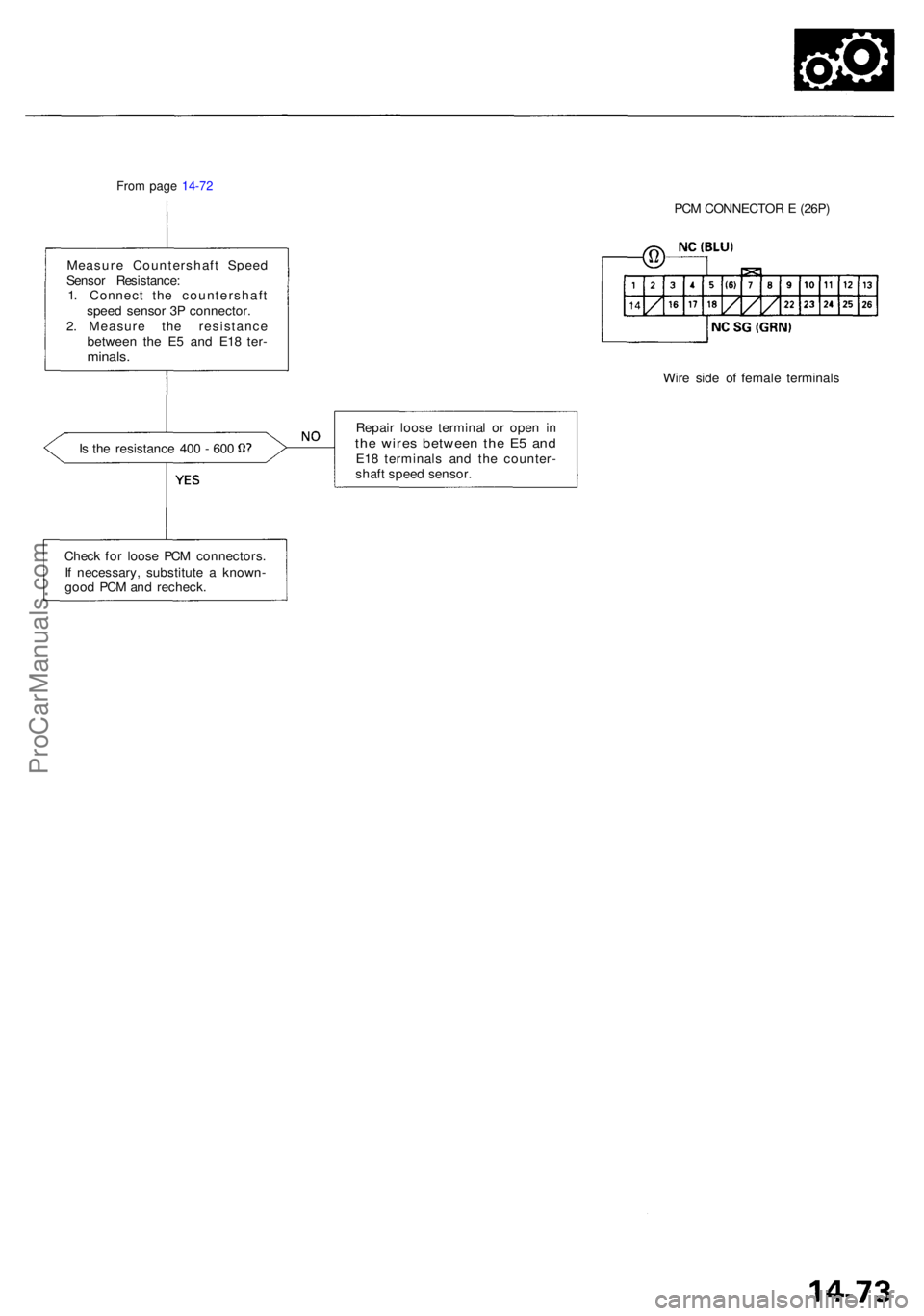

From pag e 14-7 2

PCM CONNECTO R E (26P )

Measur e Countershaf t Spee d

Senso r Resistance :

1 . Connec t th e countershaf t

spee d senso r 3 P connector .

2 . Measur e th e resistanc e

betwee n th e E 5 an d E1 8 ter -

minals .

Wire sid e o f femal e terminal s

Is th e resistanc e 40 0 - 60 0 Repai

r loos e termina l o r ope n i nth e wire s betwee n th e E 5 an dE18 terminal s an d th e counter -

shaf t spee d sensor .

Chec k fo r loos e PC M connectors .

I f necessary , substitut e a known -

goo d PC M an d recheck .

ProCarManuals.com

Page 781 of 1954

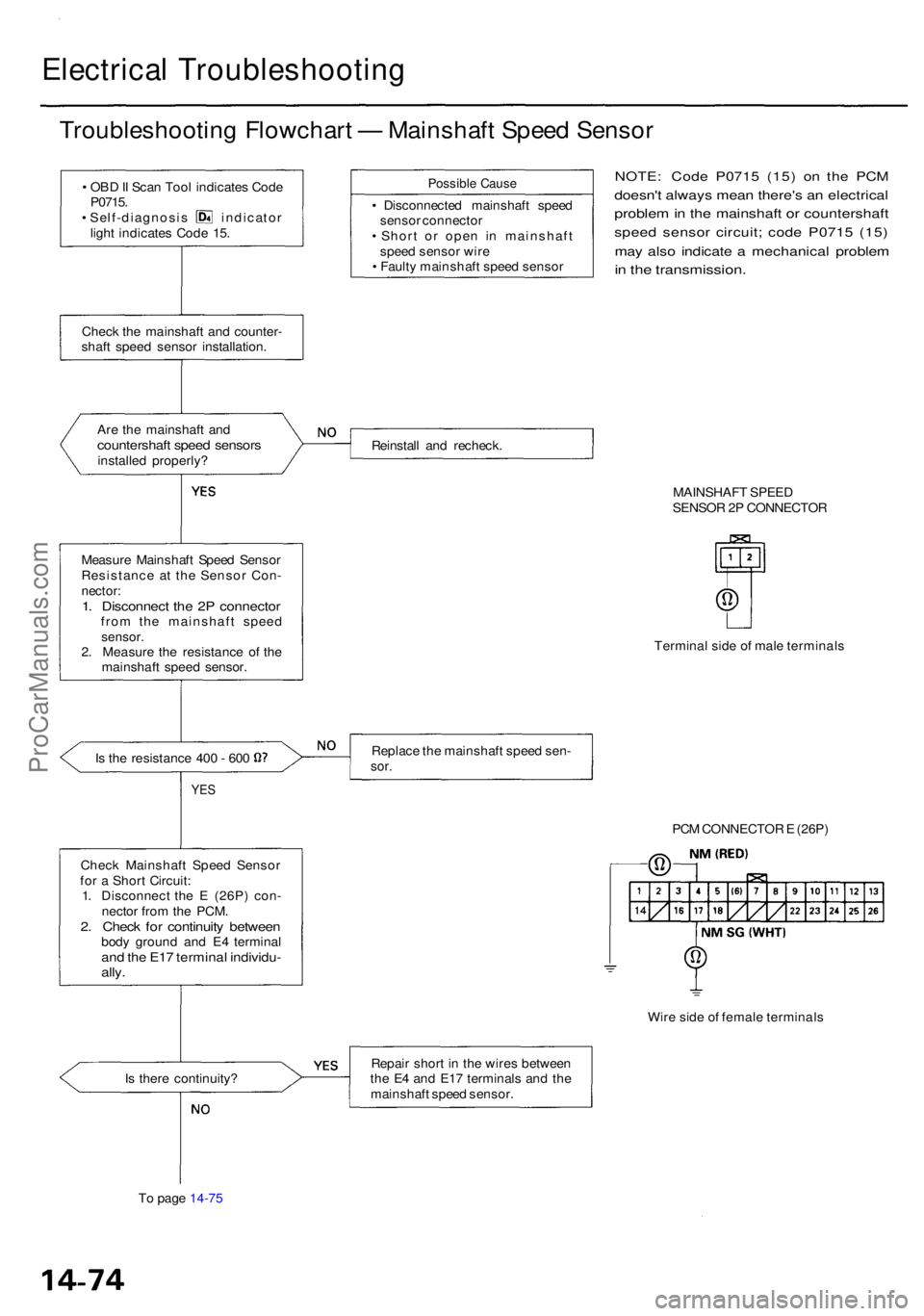

Electrical Troubleshootin g

Troubleshooting Flowchar t — Mainshaf t Spee d Senso r

• OB D II Sca n Too l indicate s Cod e

P0715 .

• Self-diagnosi s indicato r

ligh t indicate s Cod e 15 .

Chec k th e mainshaf t an d counter -

shaf t spee d senso r installation .

Ar e th e mainshaf t an d

countershaf t spee d sensor sinstalled properly ?

Measur e Mainshaf t Spee d Senso r

Resistanc e a t th e Senso r Con -

nector :1. Disconnec t th e 2 P connecto rfrom th e mainshaf t spee dsensor .2. Measur e th e resistanc e o f th e

mainshaf t spee d sensor .

Is th e resistanc e 40 0 - 60 0

YE S

Chec k Mainshaf t Spee d Senso r

fo r a Shor t Circuit :

1 . Disconnec t th e E (26P ) con -

necto r fro m th e PCM .

2. Chec k fo r continuit y betwee nbody groun d an d E 4 termina land th e E1 7 termina l individu -ally.

Possibl e Caus e

• Disconnecte d mainshaf t spee d

senso r connecto r

• Shor t o r ope n i n mainshaf t

spee d senso r wir e

• Fault y mainshaf t spee d senso r

NOTE: Cod e P071 5 (15 ) o n th e PC M

doesn' t alway s mea n there' s a n electrica l

problem in th e mainshaf t o r countershaf t

speed senso r circuit ; cod e P071 5 (15 )

may als o indicat e a mechanica l proble m

in th e transmission .

Reinstall an d recheck .

MAINSHAFT SPEE D

SENSO R 2P CONNECTO R

Termina l sid e o f mal e terminal s

Replac e th e mainshaf t spee d sen -

sor.

Wir e sid e o f femal e terminal s

I s ther e continuity ?

T o pag e 14-7 5 Repai

r shor t i n th e wire s betwee n

th e E 4 an d E1 7 terminal s an d th e

mainshaf t spee d sensor . PC

M CONNECTO R E (26P )

ProCarManuals.com

Page 782 of 1954

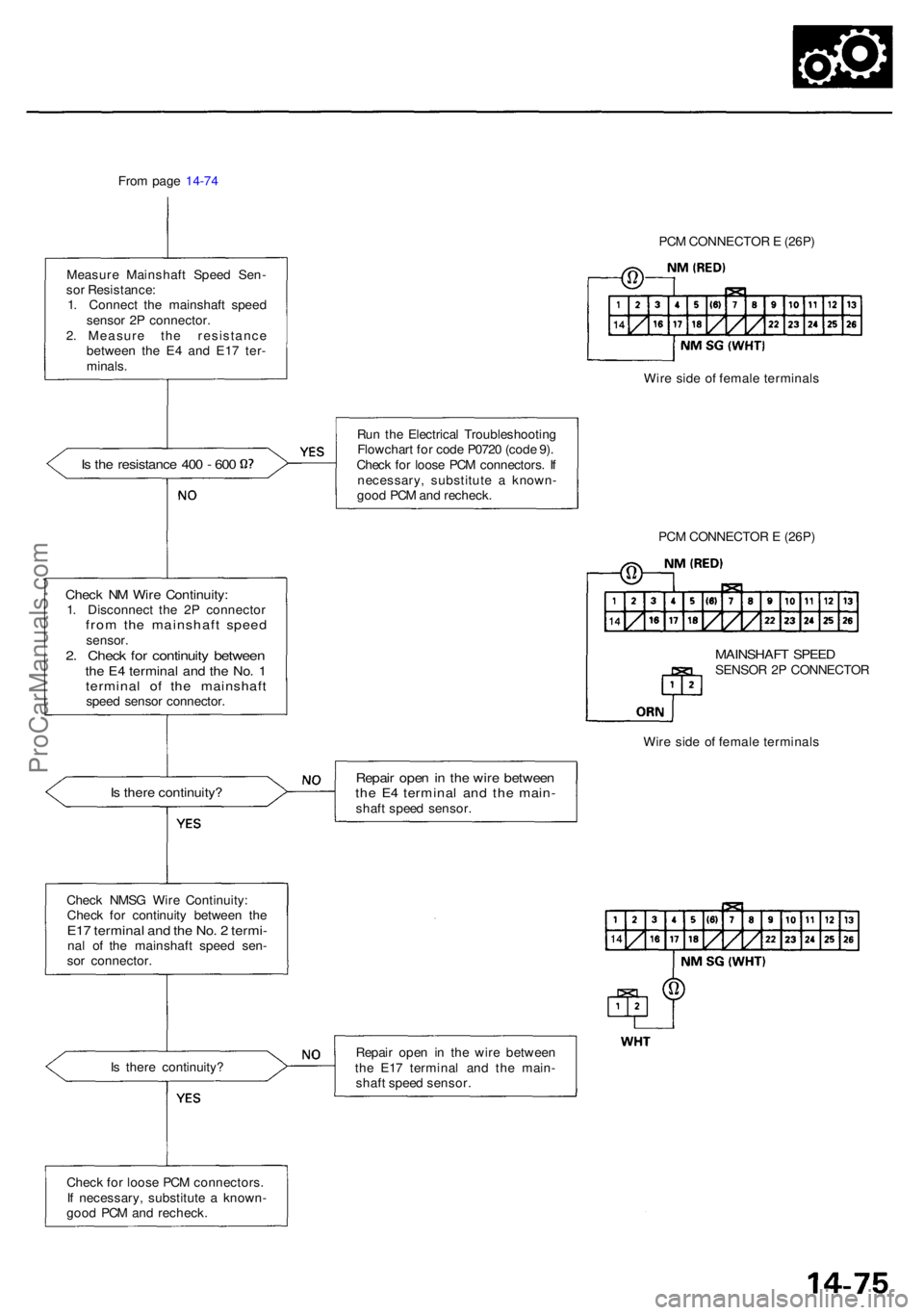

From pag e 14-7 4

Measur e Mainshaf t Spee d Sen -

so r Resistance :

1 . Connec t th e mainshaf t spee d

senso r 2 P connector .

2 . Measur e th e resistanc e

betwee n th e E 4 an d E1 7 ter -

minals .

Is th e resistanc e 40 0 - 60 0

Chec k N M Wir e Continuity :1. Disconnec t th e 2 P connecto rfrom th e mainshaf t spee dsensor .2. Chec k fo r continuit y betwee nthe E 4 termina l an d th e No . 1termina l o f th e mainshaf tspeed senso r connector .

Is ther e continuity ?

Check NMS G Wir e Continuity :

Chec k fo r continuit y betwee n th e

E17 termina l an d th e No . 2 termi -nal o f th e mainshaf t spee d sen -

so r connector . Wir

e sid e o f femal e terminal s

I s ther e continuity ?

Chec k fo r loos e PC M connectors .

I f necessary , substitut e a known -

goo d PC M an d recheck . Ru

n th e Electrica l Troubleshootin g

Flowchar t fo r cod e P072 0 (cod e 9) .

Chec k fo r loos e PC M connectors . I f

necessary , substitut e a known -

goo d PC M an d recheck .

MAINSHAF T SPEE DSENSO R 2 P CONNECTO R

Wir e sid e o f femal e terminal s

Repair ope n in th e wir e betwee nthe E 4 termina l an d th e main -shaft spee d sensor .

Repai r ope n i n th e wir e betwee n

th e E1 7 termina l an d th e main -

shaf t spee d sensor . PC

M CONNECTO R E (26P )

PC M CONNECTO R E (26P )

ProCarManuals.com

Page 797 of 1954

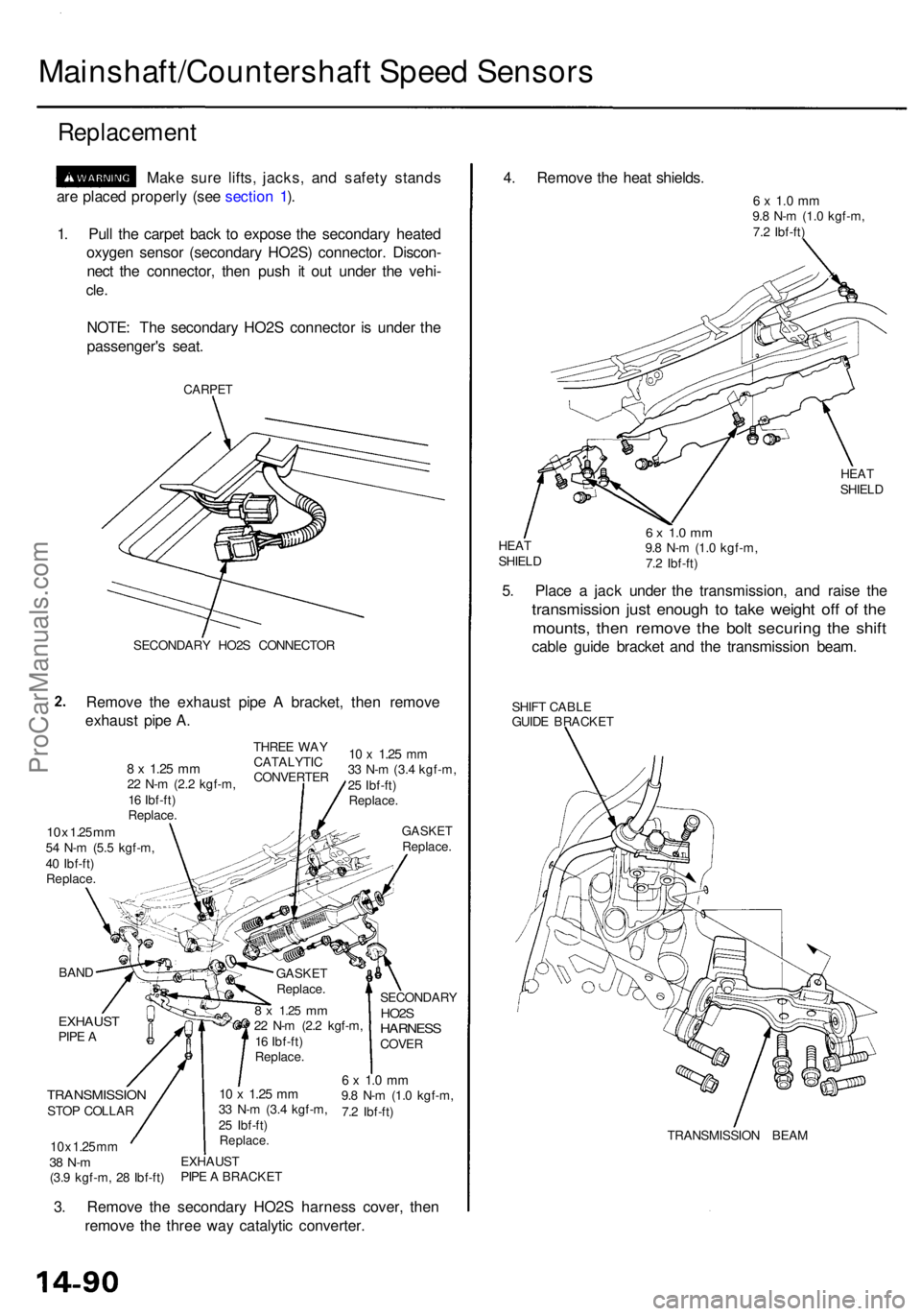

Mainshaft/Countershaft Spee d Sensor s

Replacemen t

Make sur e lifts , jacks , an d safet y stand s

ar e place d properl y (se e sectio n 1 ).

1 . Pul l th e carpe t bac k t o expos e th e secondar y heate d

oxyge n senso r (secondar y HO2S ) connector . Discon -

nec t th e connector , the n pus h i t ou t unde r th e vehi -

cle.

NOTE : Th e secondar y HO2 S connecto r i s unde r th e

passenger' s seat .

SECONDAR Y HO2 S CONNECTO R

Remove th e exhaus t pip e A bracket , the n remov e

exhaus t pip e A .

BAN D

EXHAUS TPIPE A

TRANSMISSIO NSTOP COLLA R THRE

E WA Y

CATALYTI C

CONVERTE R

SECONDAR Y

HO2SHARNES SCOVER

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

3. Remov e th e secondar y HO2 S harnes s cover , the n

remov e th e thre e wa y catalyti c converter . 4

. Remov e th e hea t shields .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

HEATSHIEL D

HEA T

SHIEL D

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

5. Plac e a jac k unde r th e transmission , an d rais e th e

transmissio n jus t enoug h t o tak e weigh t of f o f th e

mounts , the n remov e th e bol t securin g th e shif t

cable guid e bracke t an d th e transmissio n beam .

SHIFT CABL E

GUID E BRACKE T

TRANSMISSIO N BEA M

CARPE T

10 x 1.2 5 mm33 N- m (3. 4 kgf-m ,

2 5 Ibf-ft )

Replace .

GASKETReplace .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

Replace .

10 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

Replace .

GASKETReplace .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

Replace .

10 x 1.2 5 m m38 N- m(3.9 kgf-m , 2 8 Ibf-ft )EXHAUS

T

PIP E A BRACKE T

10 x 1.2 5 mm33 N- m (3. 4 kgf-m ,

2 5 Ibf-ft )

Replace .

ProCarManuals.com

Page 798 of 1954

O-RING

Replace.

COUNTER-

SHAFT

SPEED

SENSOR

O-RING

Replace.

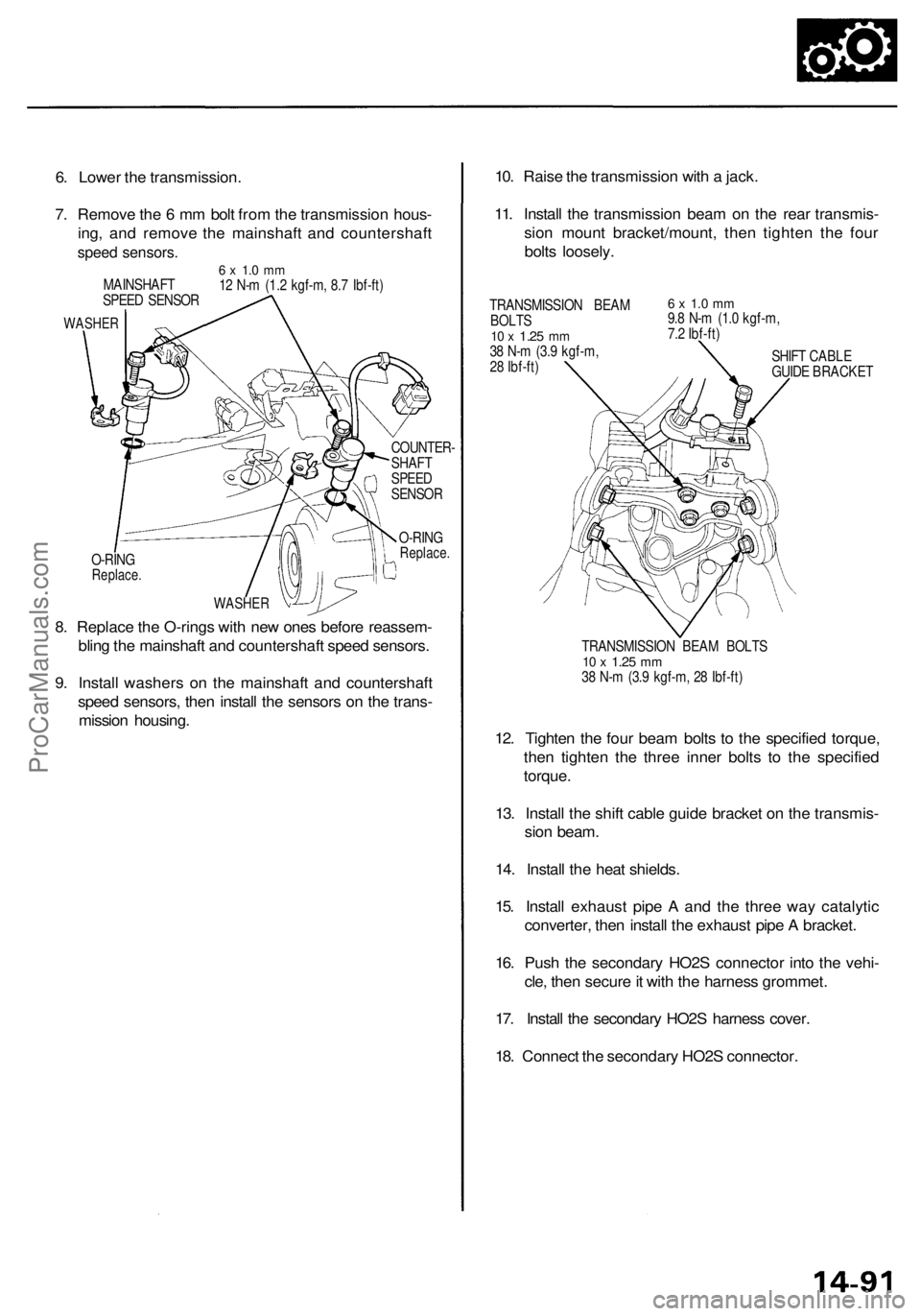

8. Replace the O-rings with new ones before reassem-

bling the mainshaft and countershaft speed sensors.

9. Install washers on the mainshaft and countershaft

speed sensors, then install the sensors on the trans-

mission housing.

10. Raise the transmission with a jack.

11. Install the transmission beam on the rear transmis-

sion mount bracket/mount, then tighten the four

bolts loosely.

TRANSMISSION BEAM

BOLTS

10 x

1.25

mm

38 N-m (3.9 kgf-m,

28 Ibf-ft)

6 x 1.0 mm

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

SHIFT CABLE

GUIDE BRACKET

TRANSMISSION BEAM BOLTS

10 x

1.25

mm

38 N-m (3.9 kgf-m, 28 Ibf-ft)

12. Tighten the four beam bolts to the specified torque,

then tighten the three inner bolts to the specified

torque.

13. Install the shift cable guide bracket on the transmis-

sion beam.

14. Install the heat shields.

15. Install exhaust pipe A and the three way catalytic

converter, then install the exhaust pipe A bracket.

16. Push the secondary HO2S connector into the vehi-

cle, then secure it with the harness grommet.

17. Install the secondary HO2S harness cover.

18. Connect the secondary HO2S connector.

6. Lower the transmission.

7. Remove the 6 mm bolt from the transmission hous-

ing, and remove the mainshaft and countershaft

speed sensors.

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

MAINSHAFT

SPEED SENSOR

WASHER

WASHERProCarManuals.com