Timing ACURA RL KA9 1996 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 545 of 1954

Troubleshooting

Troubleshooting Procedures (cont'd)

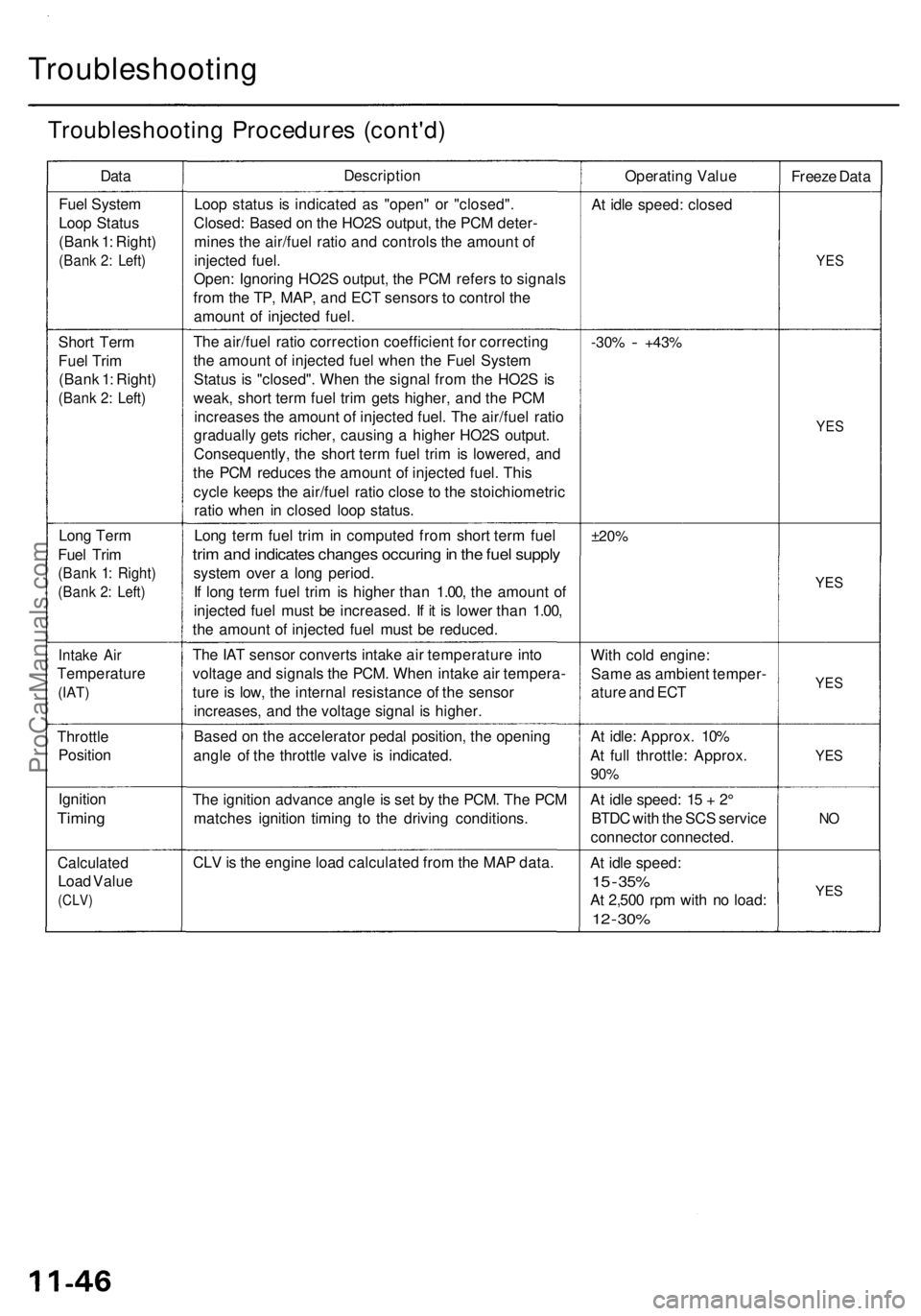

Data

Description

Operating Value

Freeze Data

Fuel System

Loop Status

(Bank 1: Right)

(Bank 2: Left)

Loop status is indicated as "open" or "closed".

Closed: Based on the HO2S output, the PCM deter-

mines the air/fuel ratio and controls the amount of

injected fuel.

Open: Ignoring HO2S output, the PCM refers to signals

from the TP, MAP, and ECT sensors to control the

amount of injected fuel.

At idle speed: closed

YES

Short Term

Fuel Trim

(Bank 1: Right)

(Bank 2: Left)

The air/fuel ratio correction coefficient for correcting

the amount of injected fuel when the Fuel System

Status is "closed". When the signal from the HO2S is

weak, short term fuel trim gets higher, and the PCM

increases the amount of injected fuel. The air/fuel ratio

gradually gets richer, causing a higher HO2S output.

Consequently, the short term fuel trim is lowered, and

the PCM reduces the amount of injected fuel. This

cycle keeps the air/fuel ratio close to the stoichiometric

ratio when in closed loop status.

-30%

-

+43%

YES

Long Term

Fuel Trim

(Bank 1: Right)

(Bank 2: Left)

Long term fuel trim in computed from short term fuel

trim and indicates changes occuring in the fuel supply

system over a long period.

If long term fuel trim is higher than 1.00, the amount of

injected fuel must be increased. If it is lower than 1.00,

the amount of injected fuel must be reduced.

±20%

YES

Intake Air

Temperature

(IAT)

The IAT sensor converts intake air temperature into

voltage and signals the PCM. When intake air tempera-

ture is low, the internal resistance of the sensor

increases, and the voltage signal is higher.

With cold engine:

Same as ambient temper-

ature and ECT

YES

Throttle

Position

Based on the accelerator pedal position, the opening

angle of the throttle valve is indicated.

At idle: Approx. 10%

At full throttle: Approx.

90%

YES

Ignition

Timing

The ignition advance angle is set by the PCM. The PCM

matches ignition timing to the driving conditions.

At idle speed: 15 + 2°

BTDC with the SCS service

connector connected.

NO

Calculated

Load Value

(CLV)

CLV is the engine load calculated from the MAP data.

At idle speed:

15

-

35%

At 2,500 rpm with no load:

12

-

30%

YESProCarManuals.com

Page 712 of 1954

Description

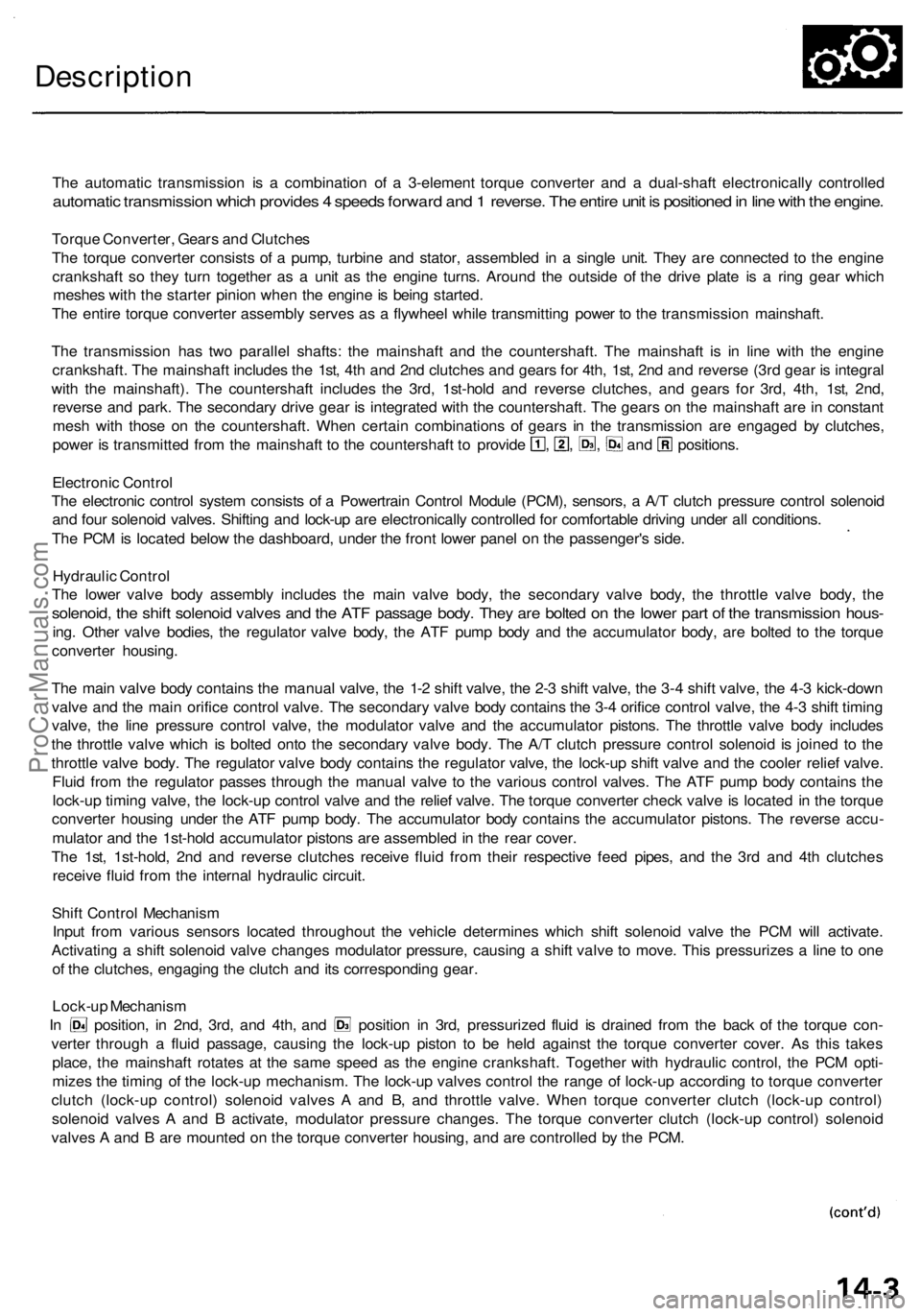

The automatic transmission is a combination of a 3-element torque converter and a dual-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 reverse. The entire unit is positioned in line with the engine.

Torque Converter, Gears and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the drive plate is a ring gear which

meshes with the starter pinion when the engine is being started.

The entire torque converter assembly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in line with the engine

crankshaft. The mainshaft includes the 1st, 4th and 2nd clutches and gears for 4th, 1st, 2nd and reverse (3rd gear is integral

with the mainshaft). The countershaft includes the 3rd, 1st-hold and reverse clutches, and gears for 3rd, 4th, 1st, 2nd,

reverse and park. The secondary drive gear is integrated with the countershaft. The gears on the mainshaft are in constant

mesh with those on the countershaft. When certain combinations of gears in the transmission are engaged by clutches,

power is transmitted from the mainshaft to the countershaft to provide , , , and positions.

Electronic Control

The electronic control system consists of a Powertrain Control Module (PCM), sensors, a A/T clutch pressure control solenoid

and four solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The PCM is located below the dashboard, under the front lower panel on the passenger's side.

Hydraulic Control

The lower valve body assembly includes the main valve body, the secondary valve body, the throttle valve body, the

solenoid, the shift solenoid valves and the ATF passage body. They are bolted on the lower part of the transmission hous-

ing. Other valve bodies, the regulator valve body, the ATF pump body and the accumulator body, are bolted to the torque

converter housing.

The main valve body contains the manual valve, the 1-2 shift valve, the 2-3 shift valve, the 3-4 shift valve, the 4-3 kick-down

valve and the main orifice control valve. The secondary valve body contains the 3-4 orifice control valve, the 4-3 shift timing

valve, the line pressure control valve, the modulator valve and the accumulator pistons. The throttle valve body includes

the throttle valve which is bolted onto the secondary valve body. The A/T clutch pressure control solenoid is joined to the

throttle valve body. The regulator valve body contains the regulator valve, the lock-up shift valve and the cooler relief valve.

Fluid from the regulator passes through the manual valve to the various control valves. The ATF pump body contains the

lock-up timing valve, the lock-up control valve and the relief valve. The torque converter check valve is located in the torque

converter housing under the ATF pump body. The accumulator body contains the accumulator pistons. The reverse accu-

mulator and the 1st-hold accumulator pistons are assembled in the rear cover.

The 1st, 1st-hold, 2nd and reverse clutches receive fluid from their respective feed pipes, and the 3rd and 4th clutches

receive fluid from the internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift solenoid valve the PCM will activate.

Activating a shift solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a line to one

of the clutches, engaging the clutch and its corresponding gear.

Lock-up Mechanism

In position, in 2nd, 3rd, and 4th, and position in 3rd, pressurized fluid is drained from the back of the torque con-

verter through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes

place, the mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the PCM opti-

mizes the timing of the lock-up mechanism. The lock-up valves control the range of lock-up according to torque converter

clutch (lock-up control) solenoid valves A and B, and throttle valve. When torque converter clutch (lock-up control)

solenoid valves A and B activate, modulator pressure changes. The torque converter clutch (lock-up control) solenoid

valves A and B are mounted on the torque converter housing, and are controlled by the PCM.ProCarManuals.com

Page 734 of 1954

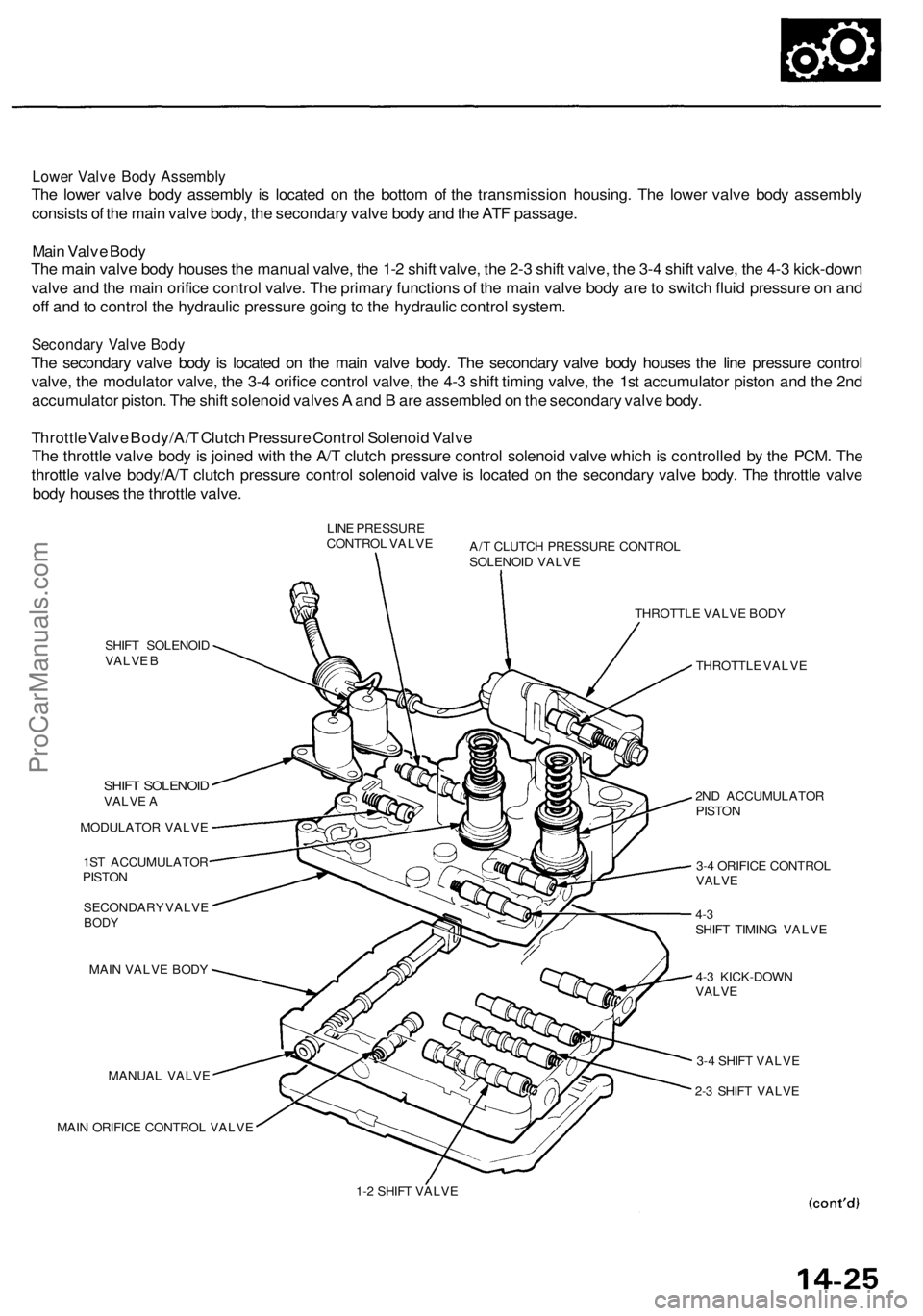

Lower Valve Body Assembly

The lower valve body assembly is located on the bottom of the transmission housing. The lower valve body assembly

consists of the main valve body, the secondary valve body and the ATF passage.

Main Valve Body

The main valve body houses the manual valve, the 1-2 shift valve, the 2-3 shift valve, the 3-4 shift valve, the 4-3 kick-down

valve and the main orifice control valve. The primary functions of the main valve body are to switch fluid pressure on and

off and to control the hydraulic pressure going to the hydraulic control system.

Secondary Valve Body

The secondary valve body is located on the main valve body. The secondary valve body houses the line pressure control

valve, the modulator valve, the 3-4 orifice control valve, the 4-3 shift timing valve, the 1st accumulator piston and the 2nd

accumulator piston. The shift solenoid valves A and B are assembled on the secondary valve body.

Throttle Valve Body/A/T Clutch Pressure Control Solenoid Valve

The throttle valve body is joined with the A/T clutch pressure control solenoid valve which is controlled by the PCM. The

throttle valve body/A/T clutch pressure control solenoid valve is located on the secondary valve body. The throttle valve

body houses the throttle valve.

LINE PRESSURE

CONTROL VALVE

A/T CLUTCH PRESSURE CONTROL

SOLENOID VALVE

SHIFT SOLENOID

VALVE B

SHIFT SOLENOID

VALVE A

MODULATOR VALVE

1ST ACCUMULATOR

PISTON

SECONDARY VALVE

BODY

MAIN VALVE BODY

MANUAL VALVE

MAIN ORIFICE CONTROL VALVE

THROTTLE VALVE BODY

THROTTLE VALVE

2ND ACCUMULATOR

PISTON

3-4 ORIFICE CONTROL

VALVE

4-3

SHIFT TIMING VALVE

4-3 KICK-DOWN

VALVE

3-4 SHIFT VALVE

2-3 SHIFT VALVE

1-2 SHIFT VALVEProCarManuals.com

Page 735 of 1954

Hydraulic Control (cont'd)

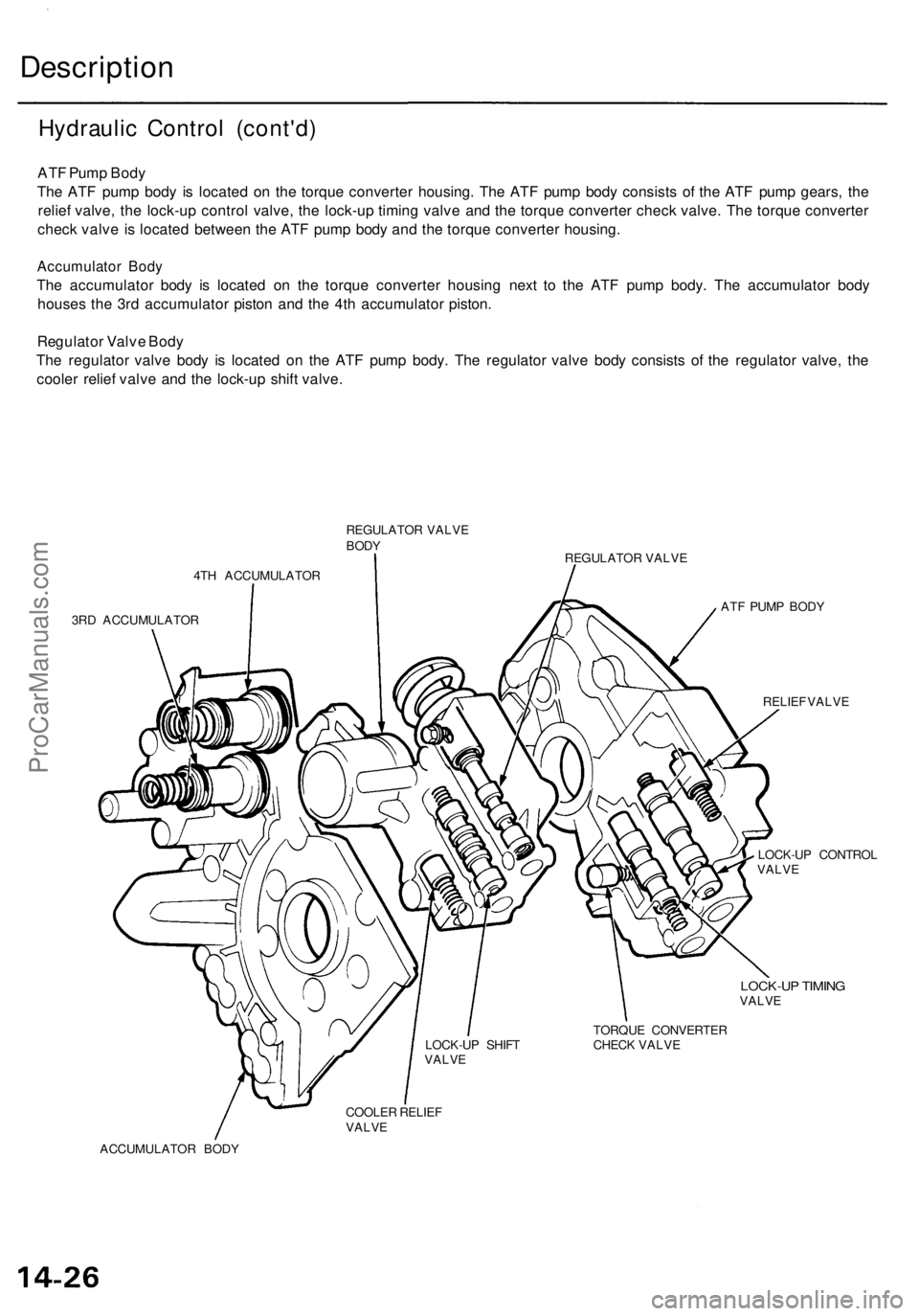

ATF Pump Body

The ATF pump body is located on the torque converter housing. The ATF pump body consists of the ATF pump gears, the

relief valve, the lock-up control valve, the lock-up timing valve and the torque converter check valve. The torque converter

check valve is located between the ATF pump body and the torque converter housing.

Accumulator Body

The accumulator body is located on the torque converter housing next to the ATF pump body. The accumulator body

houses the 3rd accumulator piston and the 4th accumulator piston.

Regulator Valve Body

The regulator valve body is located on the ATF pump body. The regulator valve body consists of the regulator valve, the

cooler relief valve and the lock-up shift valve.

REGULATOR VALVE

BODY

REGULATOR VALVE

4TH ACCUMULATOR

3RD ACCUMULATOR

ATF PUMP BODY

RELIEF VALVE

LOCK-UP CONTROL

VALVE

LOCK-UP TIMING

VALVE

TORQUE CONVERTER

CHECK VALVE

COOLER RELIEF

VALVE

ACCUMULATOR BODY

LOCK-UP SHIFT

VALVE

DescriptionProCarManuals.com

Page 748 of 1954

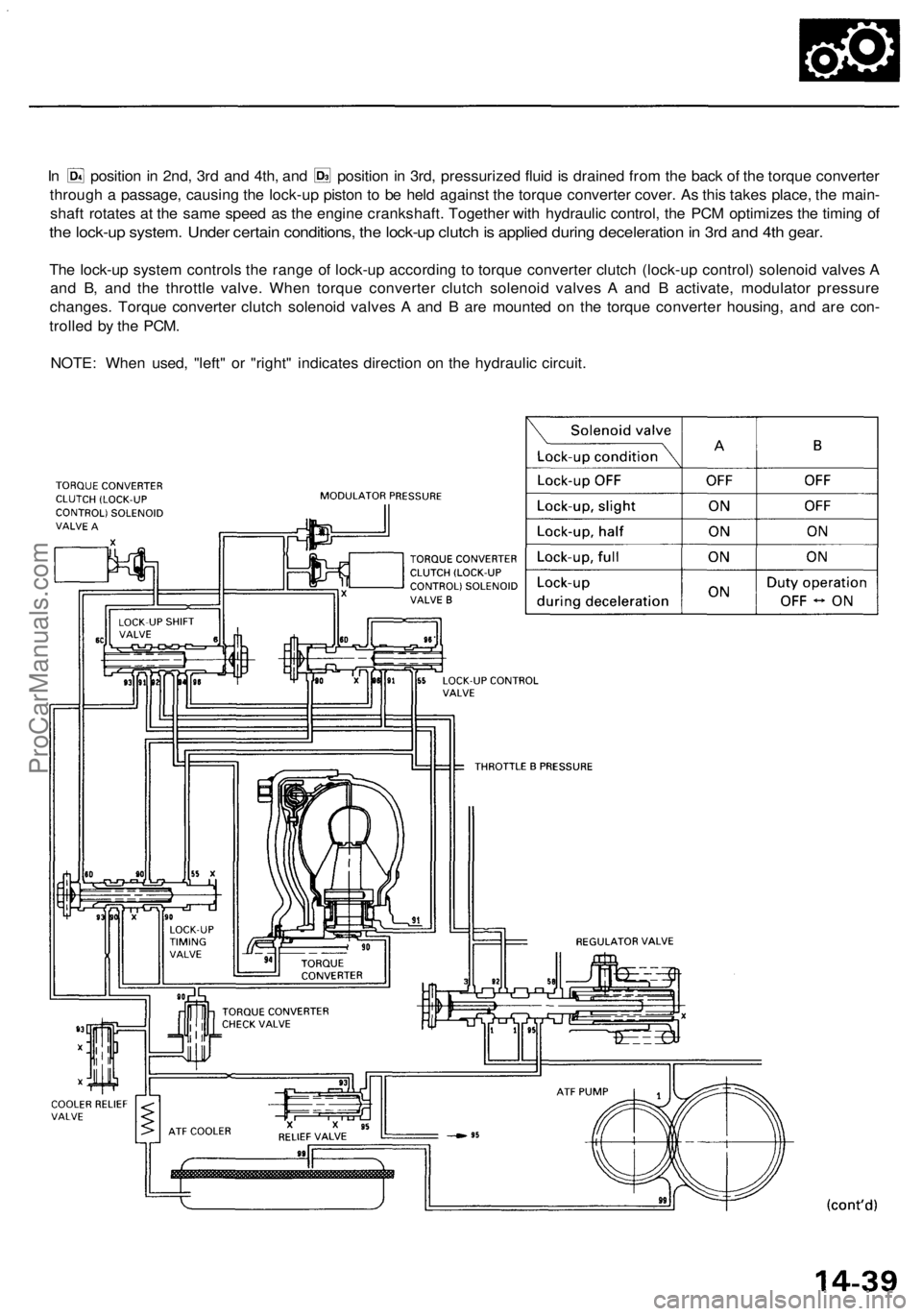

In position in 2nd, 3rd and 4th, and position in 3rd, pressurized fluid is drained from the back of the torque converter

through a passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the main-

shaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the PCM optimizes the timing of

the lock-up system. Under certain conditions, the lock-up clutch is applied during deceleration in 3rd and 4th gear.

The lock-up system controls the range of lock-up according to torque converter clutch (lock-up control) solenoid valves A

and B, and the throttle valve. When torque converter clutch solenoid valves A and B activate, modulator pressure

changes. Torque converter clutch solenoid valves A and B are mounted on the torque converter housing, and are con-

trolled by the PCM.

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit.ProCarManuals.com

Page 750 of 1954

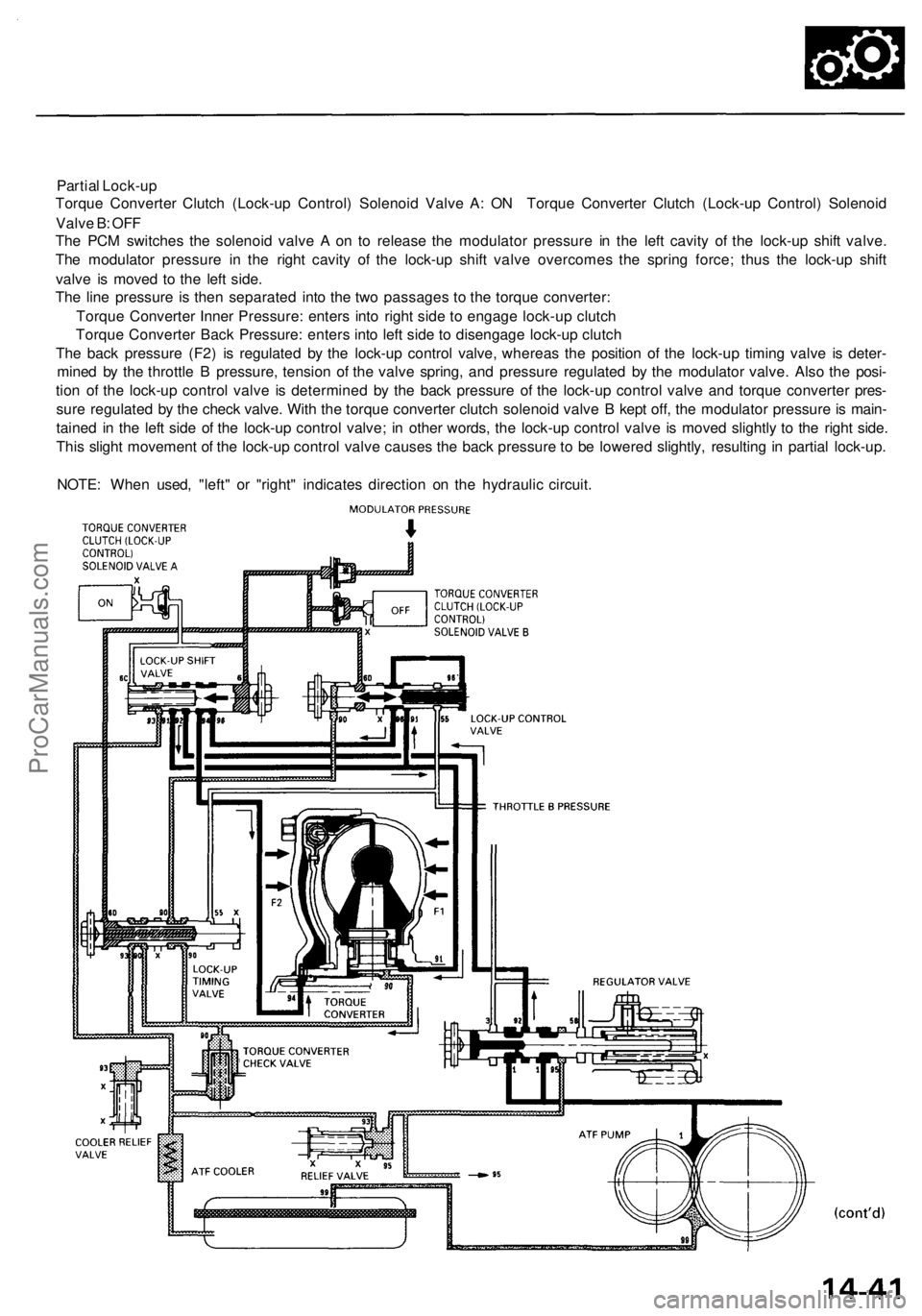

Partial Lock-up

Torque Converter Clutch (Lock-up Control) Solenoid Valve A: ON Torque Converter Clutch (Lock-up Control) Solenoid

Valve B: OFF

The PCM switches the solenoid valve A on to release the modulator pressure in the left cavity of the lock-up shift valve.

The modulator pressure in the right cavity of the lock-up shift valve overcomes the spring force; thus the lock-up shift

valve is moved to the left side.

The line pressure is then separated into the two passages to the torque converter:

Torque Converter Inner Pressure: enters into right side to engage lock-up clutch

Torque Converter Back Pressure: enters into left side to disengage lock-up clutch

The back pressure (F2) is regulated by the lock-up control valve, whereas the position of the lock-up timing valve is deter-

mined by the throttle B pressure, tension of the valve spring, and pressure regulated by the modulator valve. Also the posi-

tion of the lock-up control valve is determined by the back pressure of the lock-up control valve and torque converter pres-

sure regulated by the check valve. With the torque converter clutch solenoid valve B kept off, the modulator pressure is main-

tained in the left side of the lock-up control valve; in other words, the lock-up control valve is moved slightly to the right side.

This slight movement of the lock-up control valve causes the back pressure to be lowered slightly, resulting in partial lock-up.

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit.ProCarManuals.com

Page 751 of 1954

Lock-up System (cont'd)

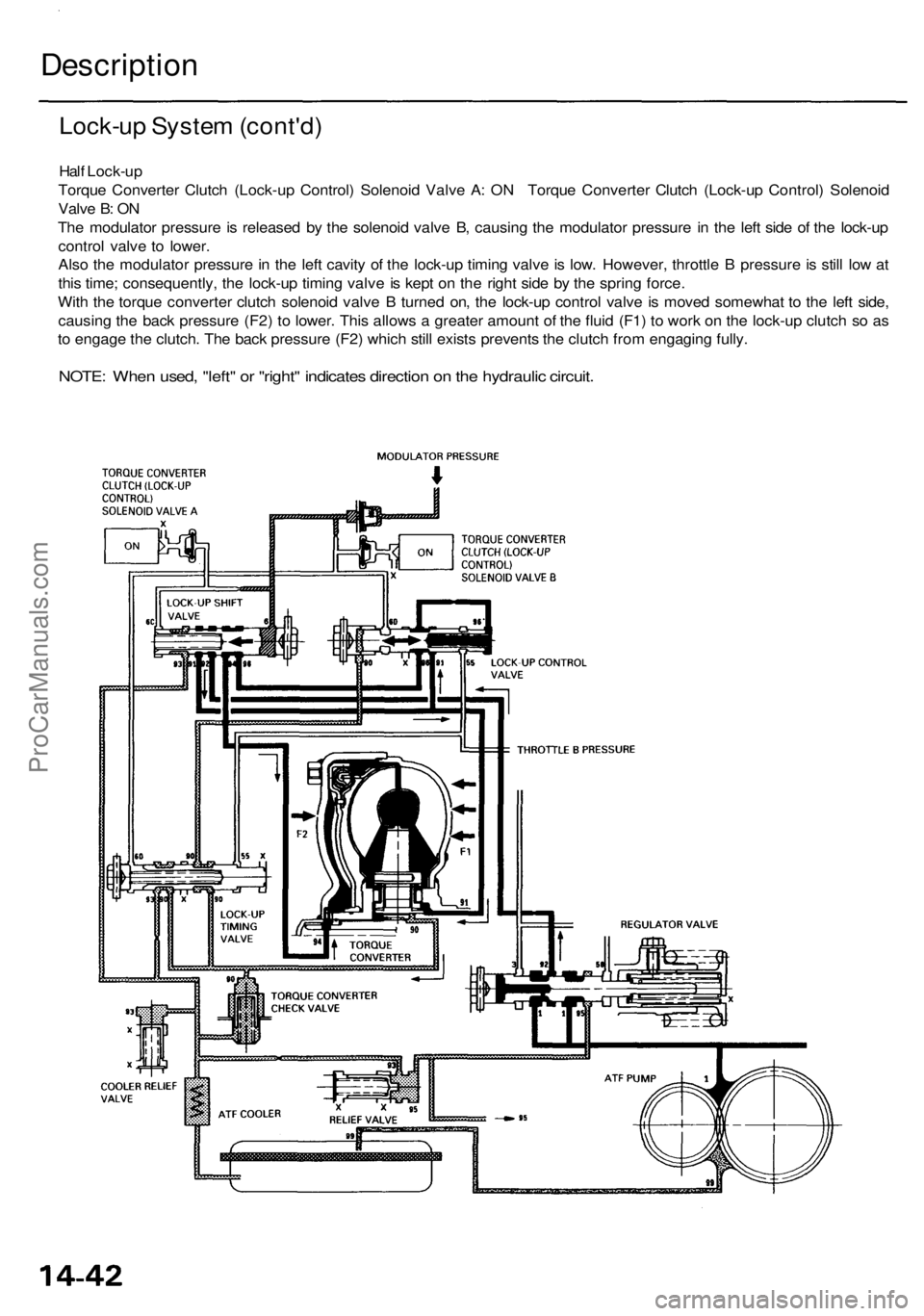

Half Lock-up

Torque Converter Clutch (Lock-up Control) Solenoid Valve A: ON Torque Converter Clutch (Lock-up Control) Solenoid

Valve B: ON

The modulator pressure is released by the solenoid valve B, causing the modulator pressure in the left side of the lock-up

control valve to lower.

Also the modulator pressure in the left cavity of the lock-up timing valve is low. However, throttle B pressure is still low at

this time; consequently, the lock-up timing valve is kept on the right side by the spring force.

With the torque converter clutch solenoid valve B turned on, the lock-up control valve is moved somewhat to the left side,

causing the back pressure (F2) to lower. This allows a greater amount of the fluid (F1) to work on the lock-up clutch so as

to engage the clutch. The back pressure (F2) which still exists prevents the clutch from engaging fully.

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit.

DescriptionProCarManuals.com

Page 752 of 1954

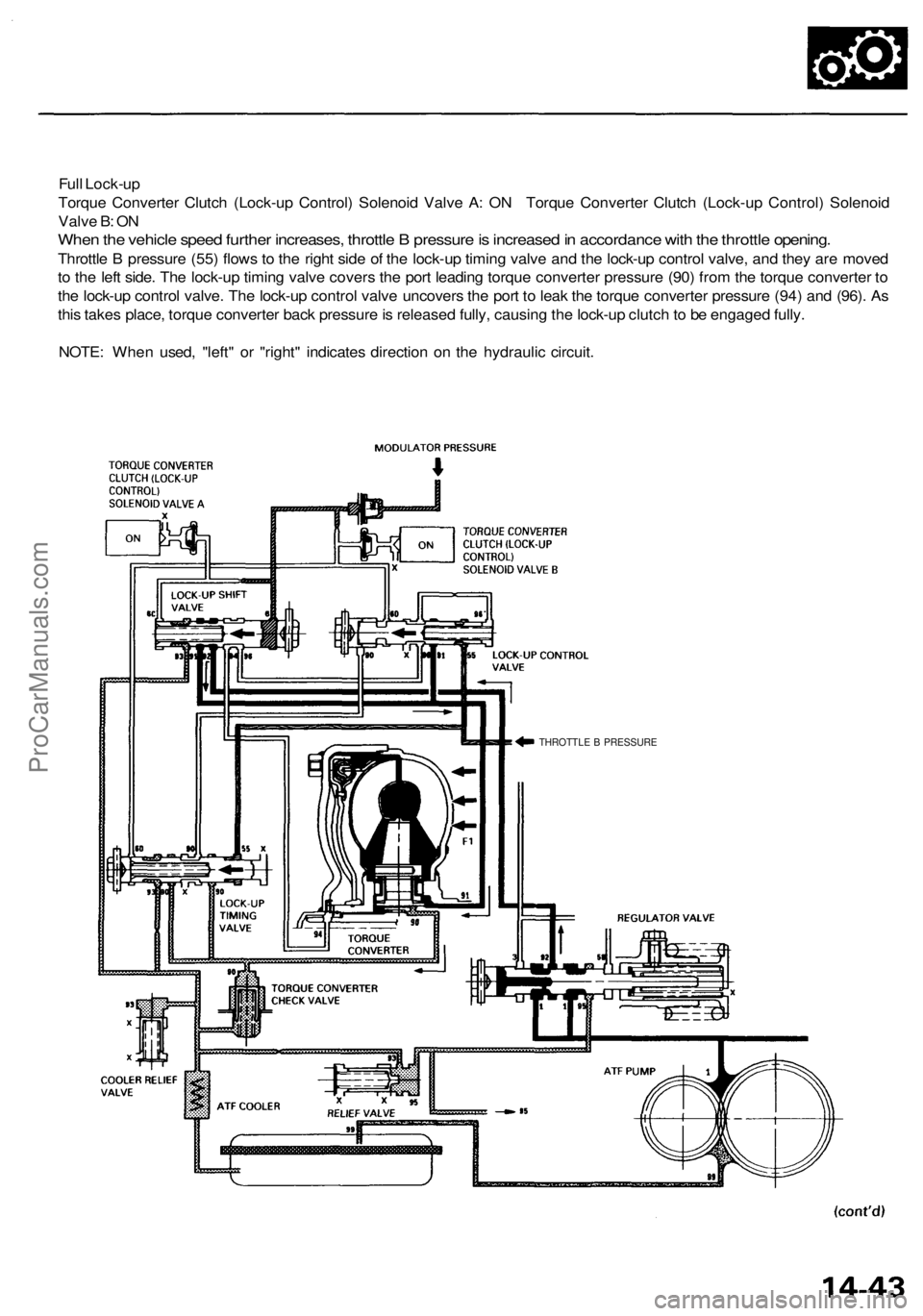

Full Lock-up

Torque Converter Clutch (Lock-up Control) Solenoid Valve A: ON Torque Converter Clutch (Lock-up Control) Solenoid

Valve B: ON

When the vehicle speed further increases, throttle B pressure is increased in accordance with the throttle opening.

Throttle B pressure (55) flows to the right side of the lock-up timing valve and the lock-up control valve, and they are moved

to the left side. The lock-up timing valve covers the port leading torque converter pressure (90) from the torque converter to

the lock-up control valve. The lock-up control valve uncovers the port to leak the torque converter pressure (94) and (96). As

this takes place, torque converter back pressure is released fully, causing the lock-up clutch to be engaged fully.

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit.

THROTTLE B PRESSUREProCarManuals.com

Page 1154 of 1954

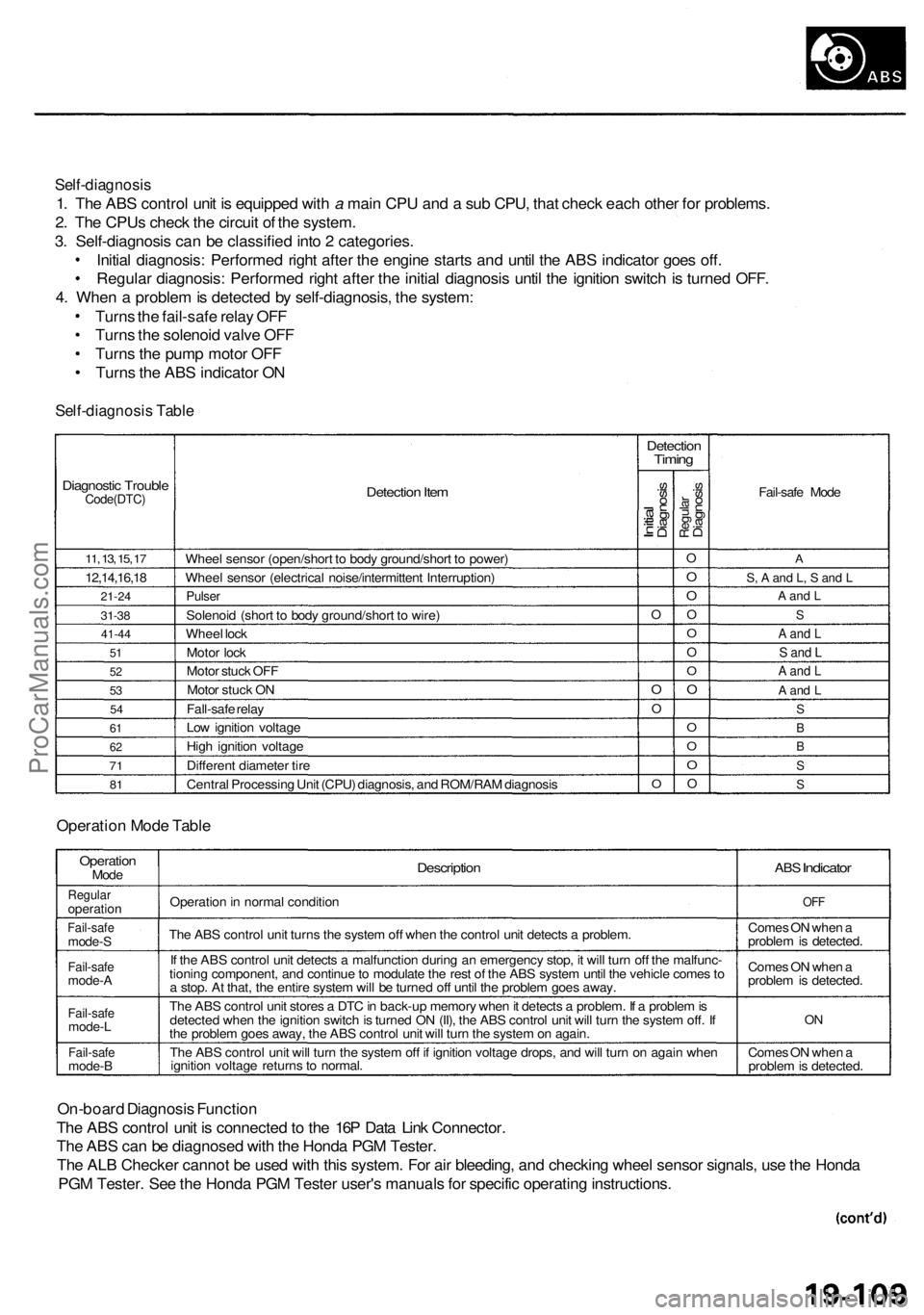

Self-diagnosis

1. The ABS control unit is equipped with a main CPU and a sub CPU, that check each other for problems.

2. The CPUs check the circuit of the system.

3. Self-diagnosis can be classified into 2 categories.

Initial diagnosis: Performed right after the engine starts and until the ABS indicator goes off.

Regular diagnosis: Performed right after the initial diagnosis until the ignition switch is turned OFF.

4. When a problem is detected by self-diagnosis, the system:

Turns the fail-safe relay OFF

Turns the solenoid valve OFF

Turns the pump motor OFF

Turns the ABS indicator ON

Self-diagnosis Table

Diagnostic Trouble

Code(DTC)

11, 13, 15, 17

12,14,16,18

21-24

31-38

41-44

51

52

53

54

61

62

71

81

Detection Item

Wheel sensor (open/short to body ground/short to power)

Wheel sensor (electrical noise/intermittent Interruption)

Pulser

Solenoid (short to body ground/short to wire)

Wheel lock

Motor lock

Motor stuck OFF

Motor stuck ON

Fall-safe relay

Low ignition voltage

High ignition voltage

Different diameter tire

Central Processing Unit (CPU) diagnosis, and ROM/RAM diagnosis

Detection

Timing

Initial

Diagnosis

O

O

O

O

Regular

Diagnosis

O

O

O

O

O

O

O

O

O

O

O

O

Fail-safe Mode

A

S, A and L, S and L

A and L

S

A and L

S and L

A and L

A and L

S

B

B

S

S

Operation Mode Table

Operation

Mode

Regular

operation

Fail-safe

mode-S

Fail-safe

mode-A

Fail-safe

mode-L

Fail-safe

mode-B

Description

Operation in normal condition

The ABS control unit turns the system off when the control unit detects a problem.

If the ABS control unit detects a malfunction during an emergency stop, it will turn off the malfunc-

tioning component, and continue to modulate the rest of the ABS system until the vehicle comes to

a stop. At that, the entire system will be turned off until the problem goes away.

The ABS control unit stores a DTC in back-up memory when it detects a problem. If a problem is

detected when the ignition switch is turned ON (II), the ABS control unit will turn the system off. If

the problem goes away, the ABS control unit will turn the system on again.

The ABS control unit will turn the system off if ignition voltage drops, and will turn on again when

ignition voltage returns to normal.

ABS

Indicator

OFF

Comes ON when a

problem is detected.

Comes ON when a

problem is detected.

ON

Comes ON when a

problem is detected.

On-board Diagnosis Function

The ABS control unit is connected to the 16P Data Link Connector.

The ABS can be diagnosed with the Honda PGM Tester.

The ALB Checker cannot be used with this system. For air bleeding, and checking wheel sensor signals, use the Honda

PGM Tester. See the Honda PGM Tester user's manuals for specific operating instructions.

ProCarManuals.com

Page 1164 of 1954

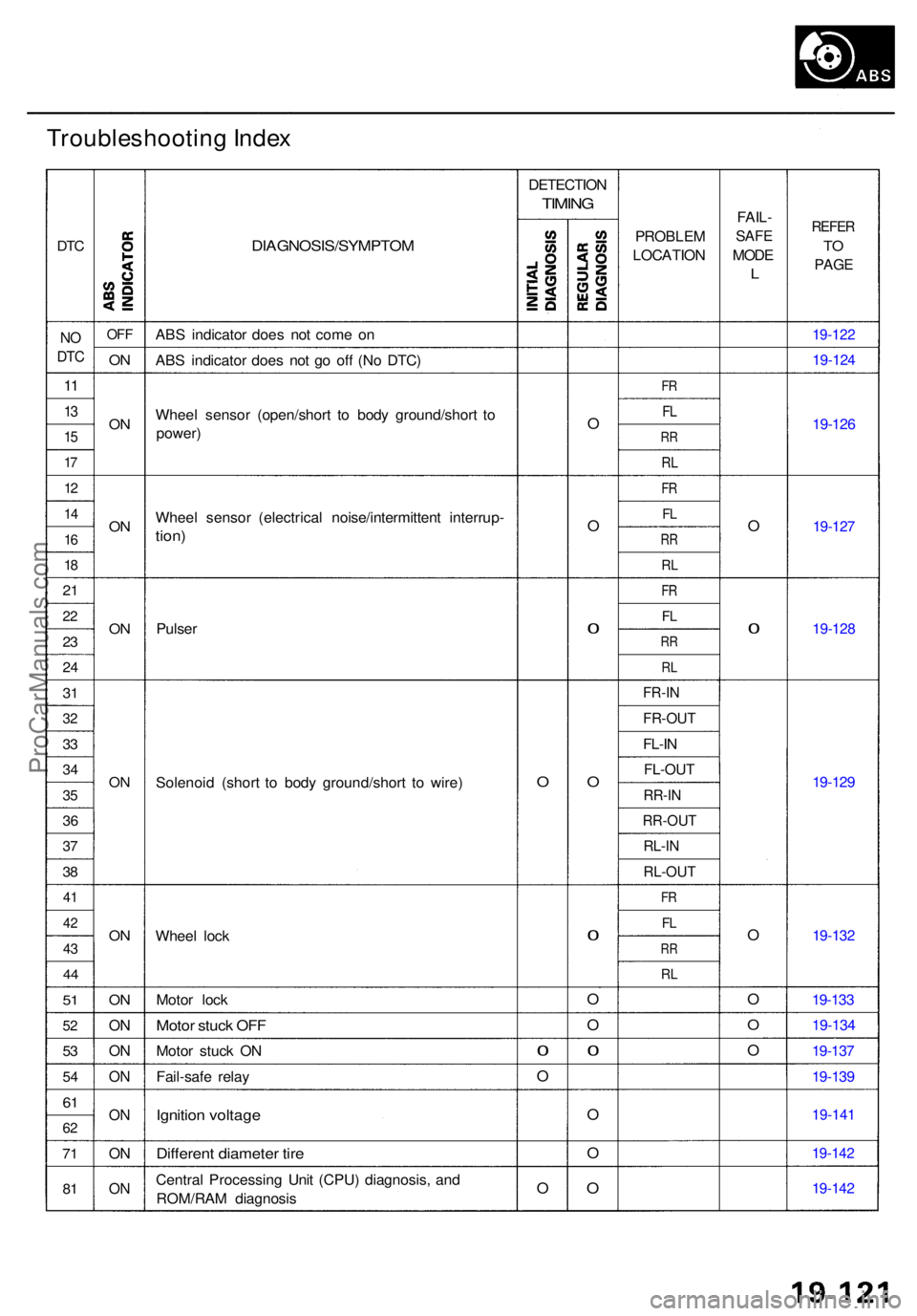

Troubleshooting Inde x

DTC

NO

DT C

11

13

1 5

17

1 2

1 4

16

18

2 1

2 2

23

2 4

31

3 2

33

3 4

35

3 6

37

3 8

4 1

4 2

43

4 4

51

5 2

53

5 4

61

6 2

71

81

OF F

ON

O N

ON

O N

O N

ON

O N

ON

O N

O N

O N

ON

O N

DIAGNOSIS/SYMPTO M

ABS indicato r doe s no t com e o n

AB S indicato r doe s no t g o of f (N o DTC )

Whee l senso r (open/shor t t o bod y ground/shor t t o

power )

Whee l senso r (electrica l noise/intermitten t interrup -

tion)

Pulse r

Solenoi d (shor t t o bod y ground/shor t t o wire )

Whee l loc k

Moto r loc k

Moto r stuc k OF F

Moto r stuc k O N

Fail-saf e rela y

Ignitio n voltag e

Differen t diamete r tir e

Centra l Processin g Uni t (CPU ) diagnosis , an d

ROM/RA M diagnosi s DETECTIO

N

TIMING

O

0

O

O

O

O

0

O

0

O

O

0

O

O

O

PROBLE M

LOCATIO N

FR

FL

R R

RL

FR

FL

R R

RL

FR

FL

R R

R L

FR-I N

FR-OU T

FL-IN

FL-OU T

RR-IN

RR-OU T

RL-IN

RL-OU T

FR

FL

R R

RL

FAIL -

SAFE

MOD E

L

O

0

O

O

O

O

REFE R

TO

PAG E

19-12 2

19-124

19-126

19-127

19-12 8

19-129

19-13 2

19-133

19-13 4

19-13 7

19-13 9

19-14 1

19-142

19-142

ProCarManuals.com