key ACURA RL KA9 1996 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 393 of 1954

Timing Bel t an d Balance r Bel t

Installatio n

Install th e timin g bel t an d balance r bel t i n th e revers e

orde r o f removal ; onl y ke y point s ar e describe d here .

CAUTION : D o no t rotat e th e crankshaf t pulle y o r cam -

shaf t pulley s wit h th e timin g bel t removed . Th e piston s

may hi t th e valve s an d caus e damage .

NOTE: Whe n installin g onl y th e balance r belt , g o to ste p

12.

1. Remov e th e spar k plugs .

2. Remov e th e balance r bel t driv e pulle y an d timin g

belt guid e plat e (se e pag e 6-4 ).

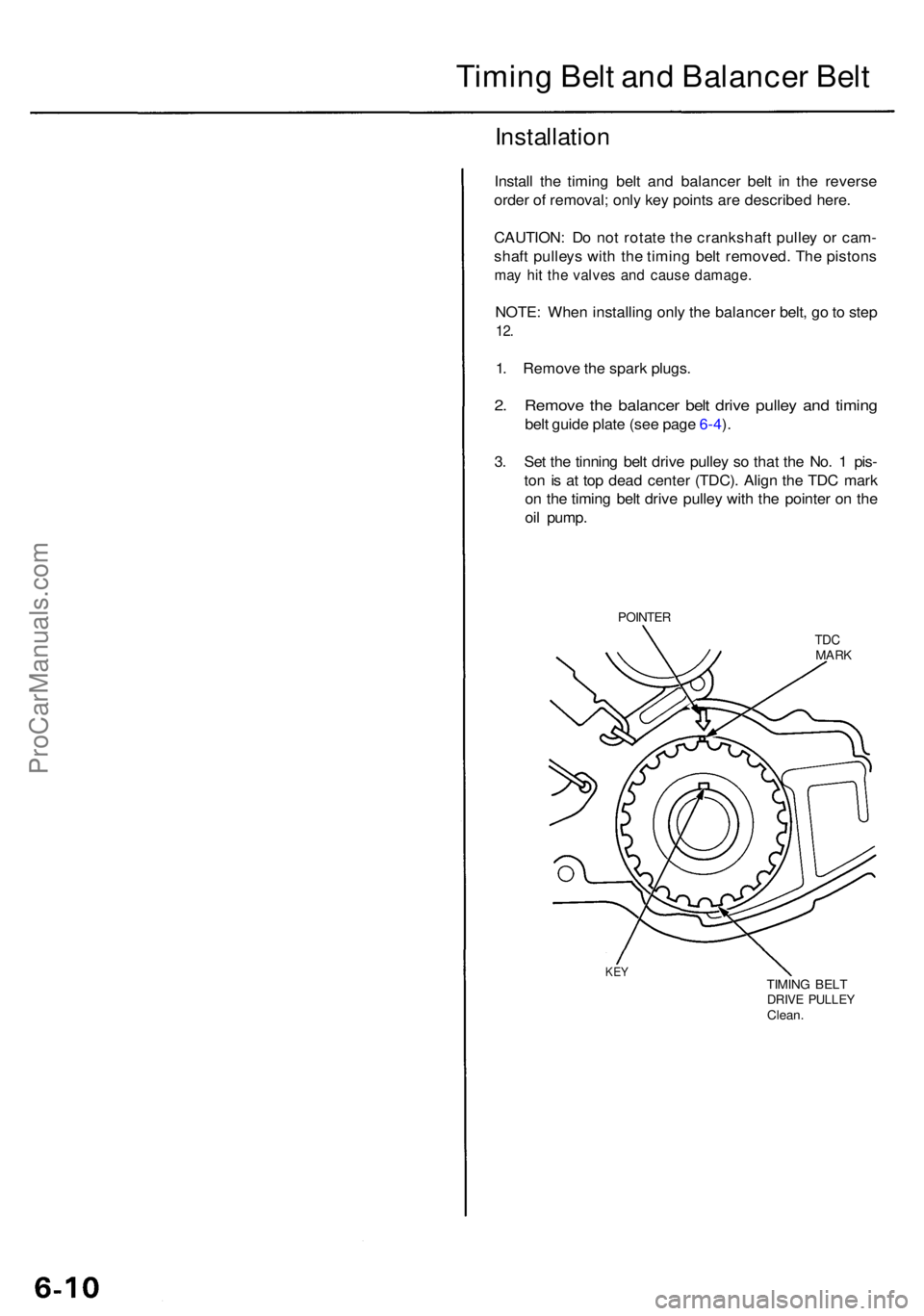

3 . Se t th e tinnin g bel t driv e pulle y s o tha t th e No . 1 pis -

to n is a t to p dea d cente r (TDC) . Alig n th e TD C mar k

o n th e timin g bel t driv e pulle y wit h th e pointe r o n th e

oi l pump .

POINTE R

TDCMAR K

KEYTIMIN G BEL TDRIV E PULLE YClean.

ProCarManuals.com

Page 440 of 1954

Crankshaft

Inspection

• Clean the crankshaft oil passages with pipe cleaners

or a suitable brush.

• Check the keyway and threads.

Alignment

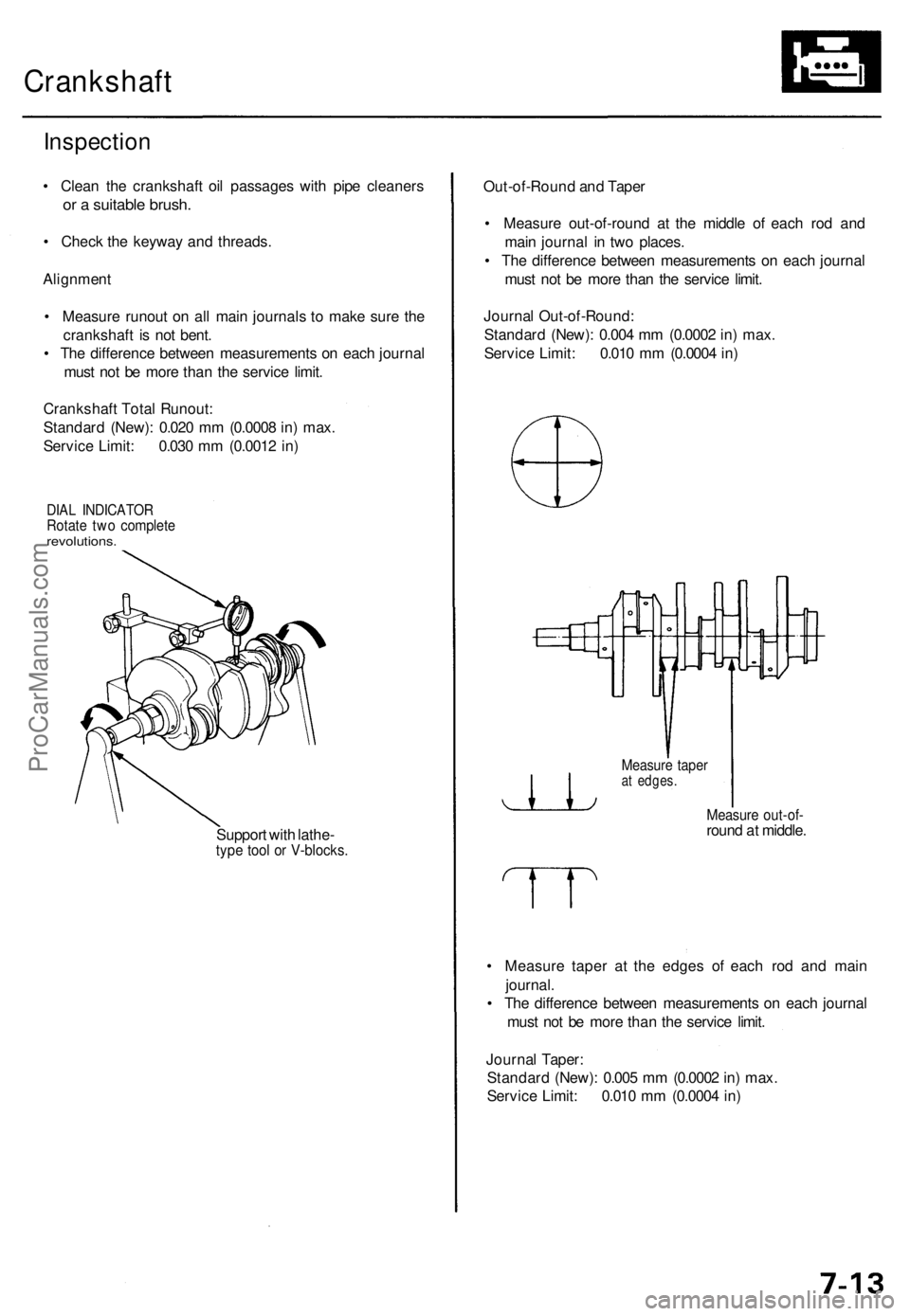

• Measure runout on all main journals to make sure the

crankshaft is not bent.

• The difference between measurements on each journal

must not be more than the service limit.

Crankshaft Total Runout:

Standard (New): 0.020 mm (0.0008 in) max.

Service Limit: 0.030 mm (0.0012 in)

DIAL INDICATOR

Rotate two complete

revolutions.

Support with lathe-

type tool or V-blocks.

Out-of-Round and Taper

• Measure out-of-round at the middle of each rod and

main journal in two places.

• The difference between measurements on each journal

must not be more than the service limit.

Journal Out-of-Round:

Standard (New): 0.004 mm (0.0002 in) max.

Service Limit: 0.010 mm (0.0004 in)

Measure taper

at edges.

Measure out-of-

round at middle.

• Measure taper at the edges of each rod and main

journal.

• The difference between measurements on each journal

must not be more than the service limit.

Journal Taper:

Standard (New): 0.005 mm (0.0002 in) max.

Service Limit: 0.010 mm (0.0004 in)ProCarManuals.com

Page 541 of 1954

PCM

PCM

COVER

9.8 N-m

(1.0 kgf-m,

7.2 Ibf-ft)

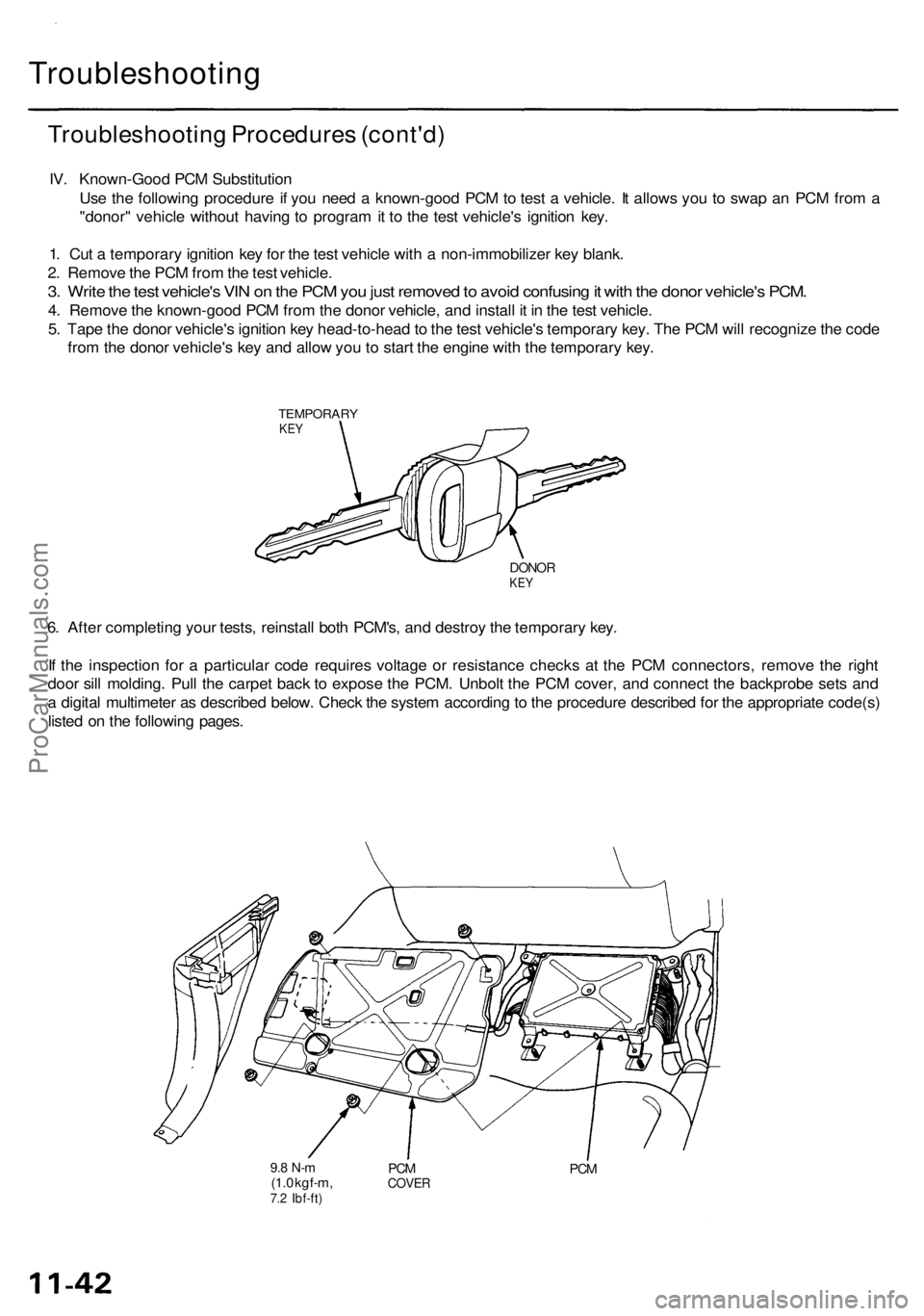

6. After completing your tests, reinstall both PCM's, and destroy the temporary key.

If the inspection for a particular code requires voltage or resistance checks at the PCM connectors, remove the right

door sill molding. Pull the carpet back to expose the PCM. Unbolt the PCM cover, and connect the backprobe sets and

a digital multimeter as described below. Check the system according to the procedure described for the appropriate code(s)

listed on the following pages.

DONOR

KEY

TEMPORARY

KEY

Troubleshooting

Troubleshooting Procedures (cont'd)

IV. Known-Good PCM Substitution

Use the following procedure if you need a known-good PCM to test a vehicle. It allows you to swap an PCM from a

"donor" vehicle without having to program it to the test vehicle's ignition key.

1. Cut a temporary ignition key for the test vehicle with a non-immobilizer key blank.

2. Remove the PCM from the test vehicle.

3. Write the test vehicle's VIN on the PCM you just removed to avoid confusing it with the donor vehicle's PCM.

4. Remove the known-good PCM from the donor vehicle, and install it in the test vehicle.

5. Tape the donor vehicle's ignition key head-to-head to the test vehicle's temporary key. The PCM will recognize the code

from the donor vehicle's key and allow you to start the engine with the temporary key.ProCarManuals.com

Page 791 of 1954

Electrical Troubleshootin g

Troubleshooting Flowchar t — Interloc k Syste m — Ke y Interloc k Syste m

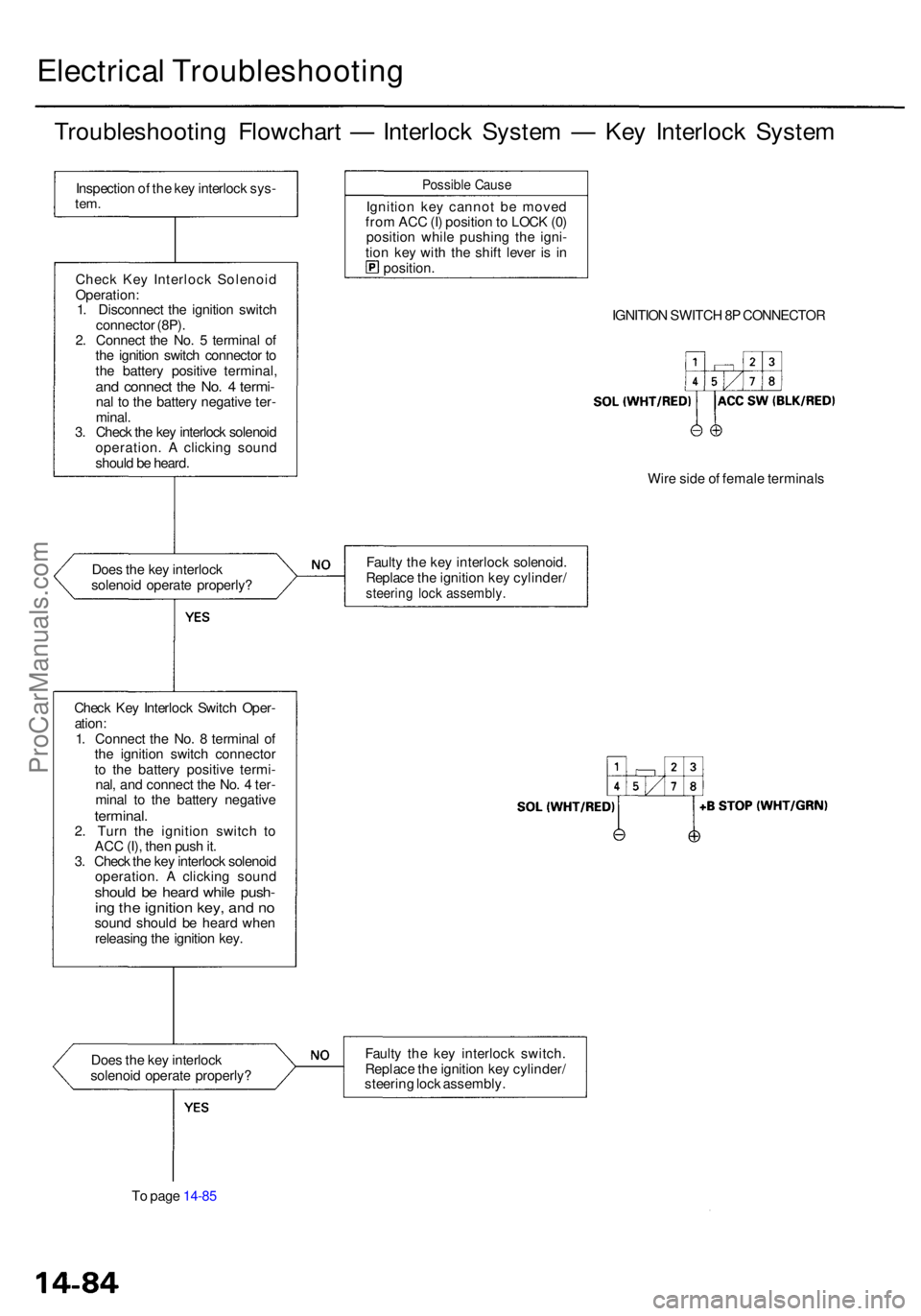

Inspectio n o f th e ke y interloc k sys -tem.

Chec k Ke y Interloc k Solenoi d

Operation :

1 . Disconnec t th e ignitio n switc h

connecto r (8P) .

2 . Connec t th e No . 5 termina l o f

th e ignitio n switc h connecto r t o

th e batter y positiv e terminal ,

and connec t th e No . 4 termi -nal t o th e batter y negativ e ter -

minal .

3 . Chec k th e ke y interloc k solenoi d

operation . A clickin g soun d

shoul d b e heard .

Doe s th e ke y interloc k

solenoi d operat e properly ?

Chec k Ke y Interloc k Switc h Oper -

ation :

1 . Connec t th e No . 8 termina l o f

th e ignitio n switc h connecto r

t o th e batter y positiv e termi -

nal , an d connec t th e No . 4 ter -

mina l t o th e batter y negativ e

terminal.2. Tur n th e ignitio n switc h t o

AC C (I) , the n pus h it .

3 . Chec k th e ke y interloc k solenoi d

operation . A clickin g soun d

should b e hear d whil e push -ing th e ignitio n key , an d n osoun d shoul d b e hear d whe n

releasin g th e ignitio n key .

Doe s th e ke y interloc k

solenoi d operat e properly ?

T o pag e 14-8 5

Possibl e Caus e

Ignitio n ke y canno t b e move d

fro m AC C (I ) positio n to LOC K (0 )

positio n whil e pushin g th e igni -

tio n ke y wit h th e shif t leve r i s in

position .

IGNITION SWITC H 8P CONNECTO R

Wir e sid e o f femal e terminal s

Fault y th e ke y interloc k solenoid .

Replac e th e ignitio n ke y cylinder /

steering loc k assembly .

Faulty th e ke y interloc k switch .

Replac e th e ignitio n ke y cylinder /

steerin g loc k assembly .

ProCarManuals.com

Page 804 of 1954

Interlock Syste m

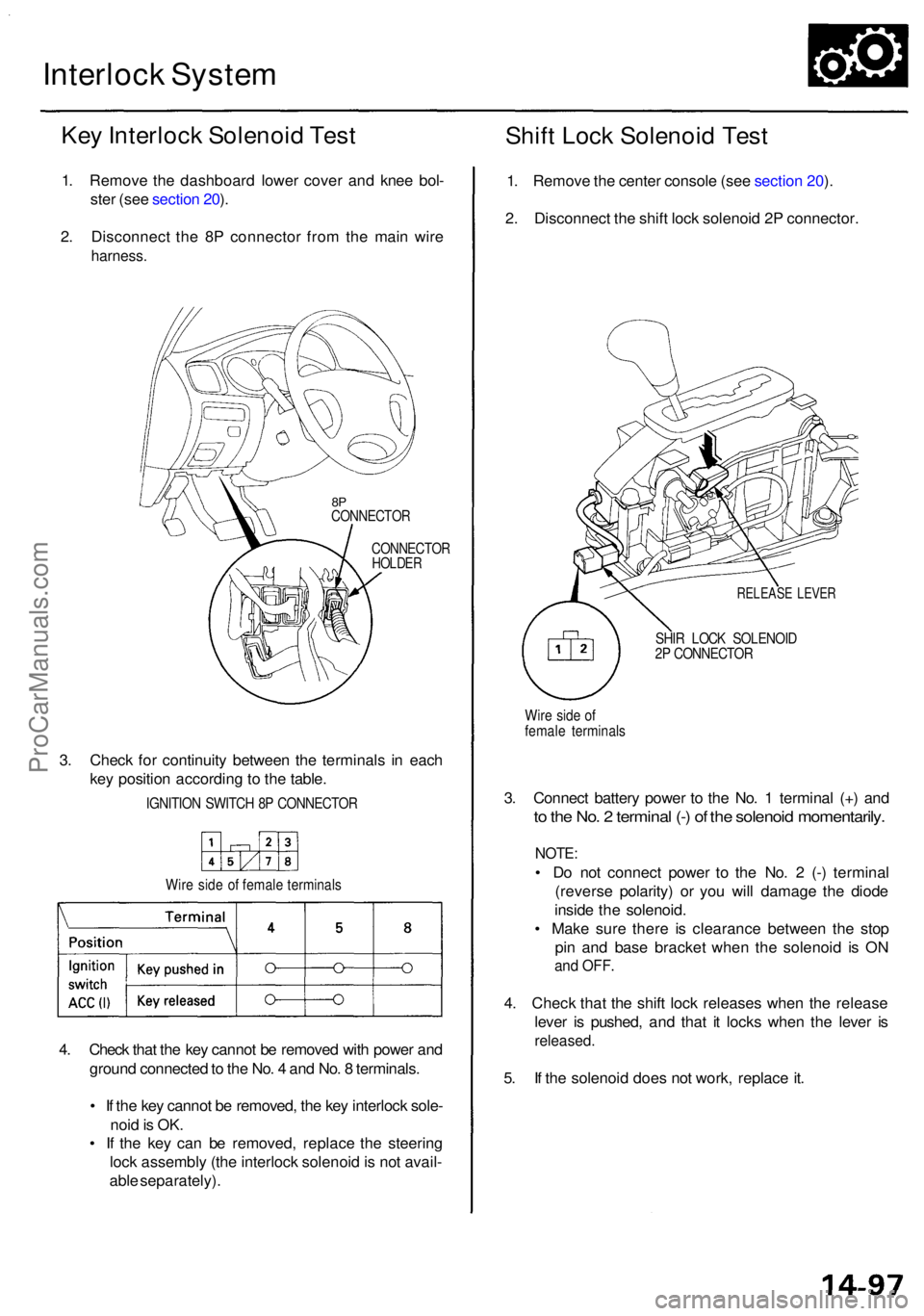

Key Interloc k Solenoi d Tes t

1. Remov e th e dashboar d lowe r cove r an d kne e bol -

ste r (se e sectio n 20 ).

2 . Disconnec t th e 8 P connecto r fro m th e mai n wir e

harness .

CONNECTO RHOLDER

3. Chec k fo r continuit y betwee n th e terminal s i n eac h

ke y positio n accordin g t o th e table .

Wire sid e o f femal e terminal s

4. Chec k tha t th e ke y canno t b e remove d wit h powe r an d

groun d connecte d to th e No . 4 an d No . 8 terminals .

• I f th e ke y canno t b e removed , th e ke y interloc k sole -

noi d is OK .

• I f th e ke y can be removed , replac e th e steerin g

loc k assembl y (th e interloc k solenoi d is no t avail -

abl e separately) .

Shift Loc k Solenoi d Tes t

1. Remov e th e cente r consol e (se e sectio n 20 ).

2 . Disconnec t th e shif t loc k solenoi d 2 P connector .

RELEASE LEVE R

SHIR LOC K SOLENOI D

2 P CONNECTO R

Wir e sid e o f

femal e terminal s

3. Connec t batter y powe r t o th e No . 1 termina l (+ ) an d

to th e No . 2 termina l (- ) o f th e solenoi d momentarily .

NOTE:

• D o no t connec t powe r t o th e No . 2 (- ) termina l

(revers e polarity ) o r yo u wil l damag e th e diod e

insid e th e solenoid .

• Mak e sur e ther e i s clearanc e betwee n th e sto p

pi n an d bas e bracke t whe n th e solenoi d i s O N

and OFF .

4. Chec k tha t th e shif t loc k release s whe n th e releas e

leve r i s pushed , an d tha t i t lock s whe n th e leve r i s

released .

5. I f th e solenoi d doe s no t work , replac e it .

IGNITIO N SWITC H 8 P CONNECTO R

8PCONNECTO R

ProCarManuals.com

Page 1515 of 1954

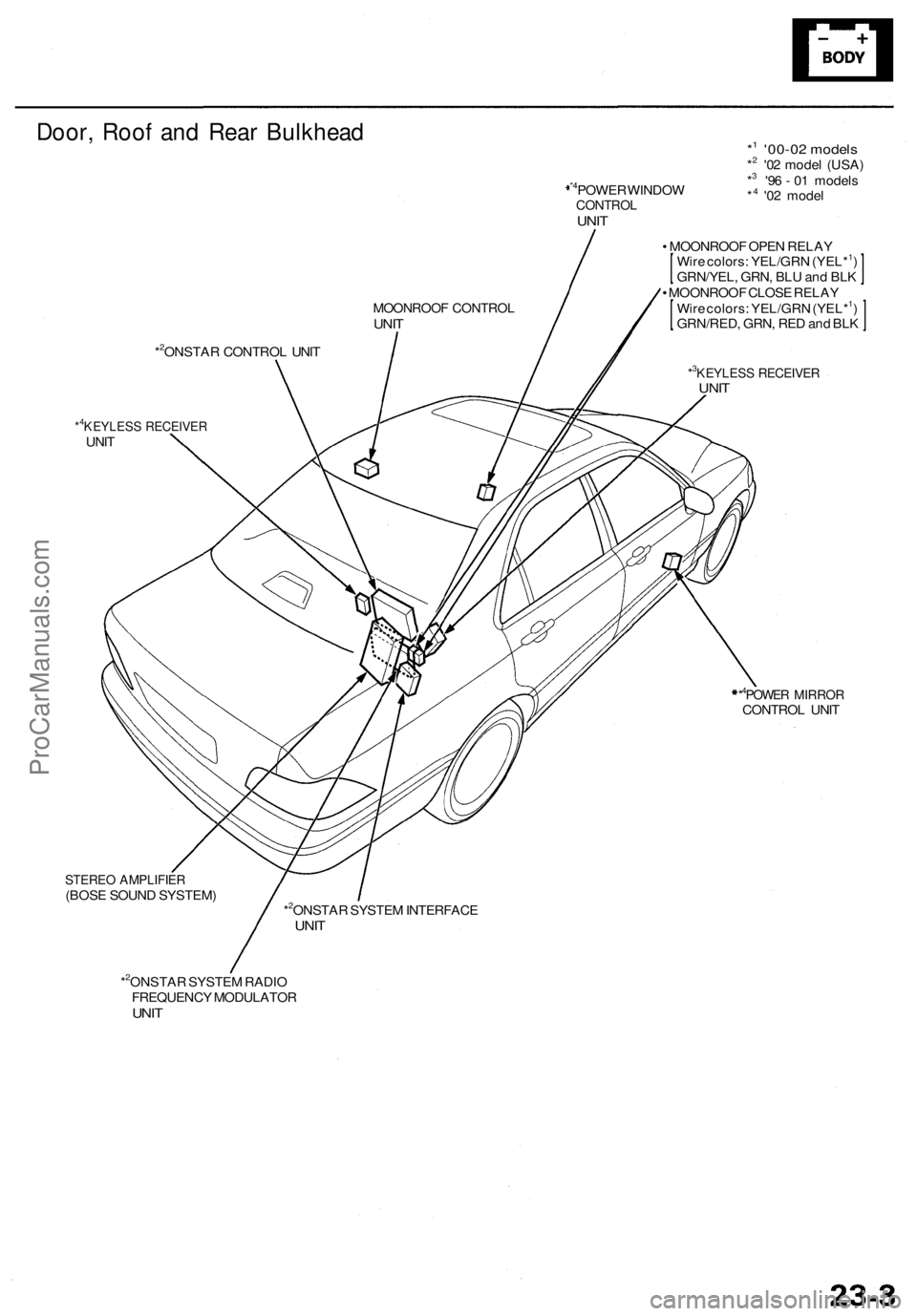

Door, Roo f an d Rea r Bulkhea d

*4POWER WINDO WCONTRO LUNIT

*1 '00-0 2 model s*2 '02 mode l (USA )

*3 '9 6 - 0 1 model s

*4 '0 2 mode l

*

2ONSTA R CONTRO L UNI T

*4KEYLES S RECEIVE RUNIT

*3KEYLES S RECEIVE RUNIT

*4POWE R MIRRO RCONTRO L UNI T

STERE O AMPLIFIE R(BOSE SOUN D SYSTEM )

*2ONSTAR SYSTE M INTERFAC EUNIT

*2ONSTA R SYSTE M RADI O

FREQUENC Y MODULATO R

UNIT

MOONROO F CONTRO LUNIT

• MOONROO F OPE N RELA Y

Wir e colors : YEL/GR N (YEL*1)GRN/YEL , GRN , BL U an d BL K

• MOONROO F CLOS E RELA Y

Wir e colors : YEL/GR N (YEL*

1)GRN/RED , GRN , RE D an d BL K

ProCarManuals.com

Page 1521 of 1954

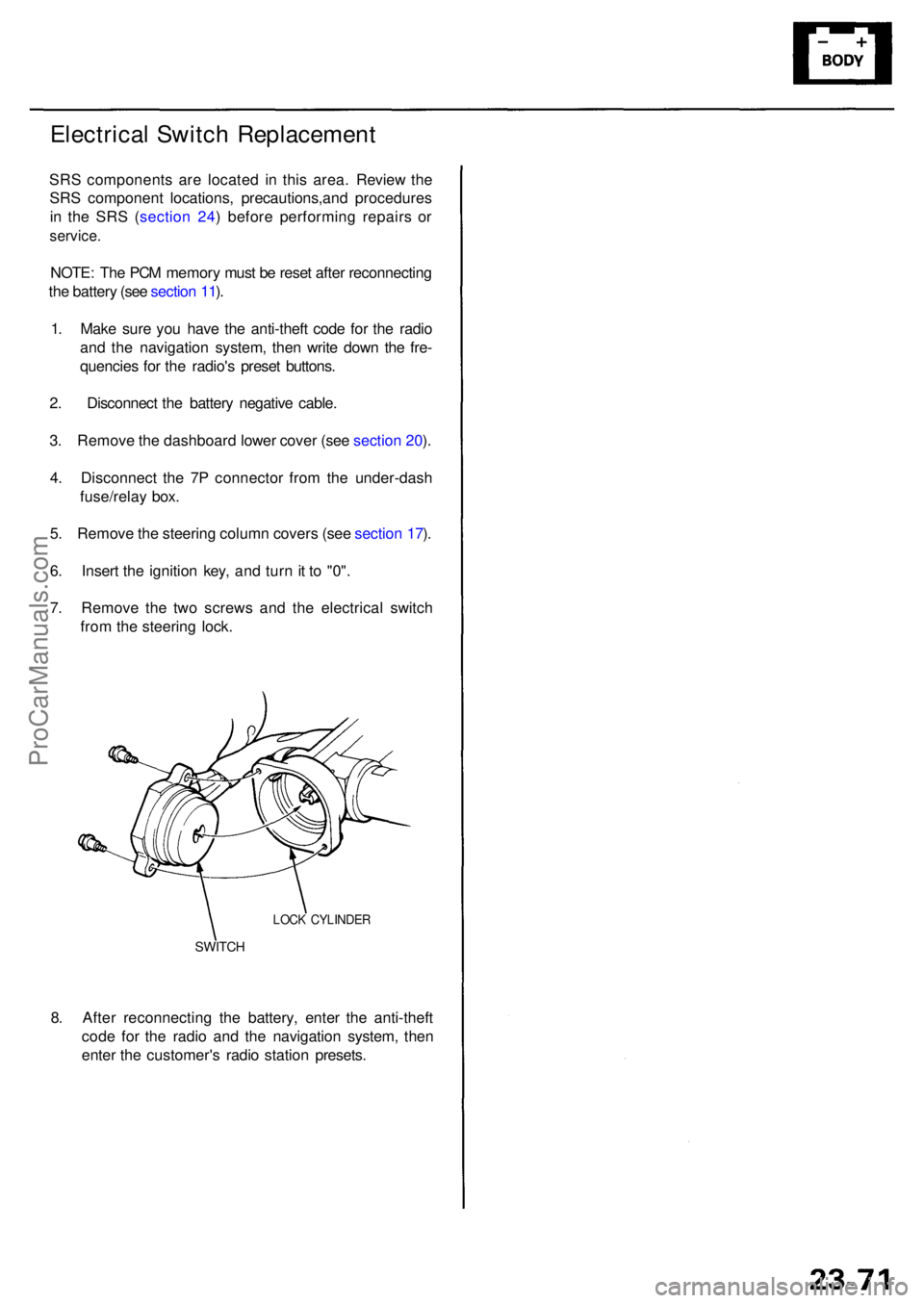

8. Afte r reconnectin g th e battery , ente r th e anti-thef t

cod e fo r th e radi o an d th e navigatio n system , the n

ente r th e customer' s radi o statio n presets .

SWITCH

LOCK CYLINDE R

Electrical Switc h Replacemen t

SRS component s ar e locate d i n thi s area . Review the

SR S componen t locations , precautions,an d procedure s

i n th e SR S ( sectio n 24 ) befor e performin g repair s o r

service .

NOTE: Th e PC M memor y mus t b e rese t afte r reconnectin g

th e batter y (se e sectio n 11 ).

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radi o

an d th e navigatio n system , the n writ e dow n th e fre -

quencie s fo r th e radio' s prese t buttons .

2 . Disconnec t th e batter y negativ e cable .

3 . Remov e th e dashboar d lowe r cove r (se e sectio n 20 ).

4 . Disconnec t th e 7 P connecto r fro m th e under-das h

fuse/rela y box .

5 . Remov e th e steerin g colum n cover s (se e sectio n 17 ).

6 . Inser t th e ignitio n key , an d tur n it t o "0" .

7 . Remov e th e tw o screw s an d th e electrica l switc h

fro m th e steerin g lock .

ProCarManuals.com

Page 1592 of 1954

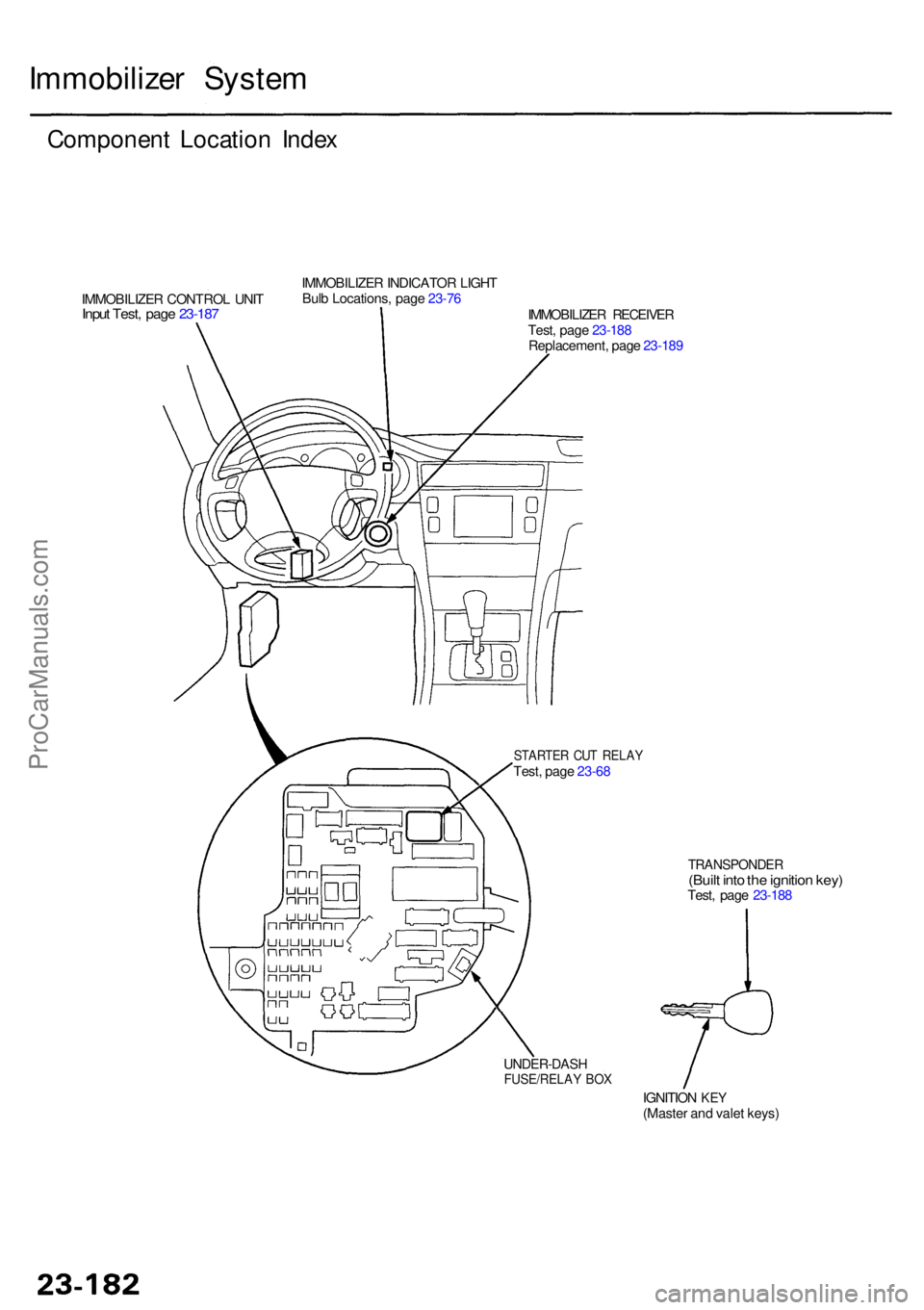

Immobilizer Syste m

Componen t Locatio n Inde x

IMMOBILIZE R CONTRO L UNI TInput Test , pag e 23-18 7

IMMOBILIZE R INDICATO R LIGH T

Bul b Locations , pag e 23-76

IMMOBILIZER RECEIVE R

Test , pag e 23-18 8

Replacement , pag e 23-18 9

STARTE R CU T RELA YTest, pag e 23-6 8

TRANSPONDE R(Built int o th e ignitio n key )Test , pag e 23-18 8

IGNITIO N

KEY(Maste r an d vale t keys )

UNDER-DAS HFUSE/RELAY BO X

ProCarManuals.com

Page 1593 of 1954

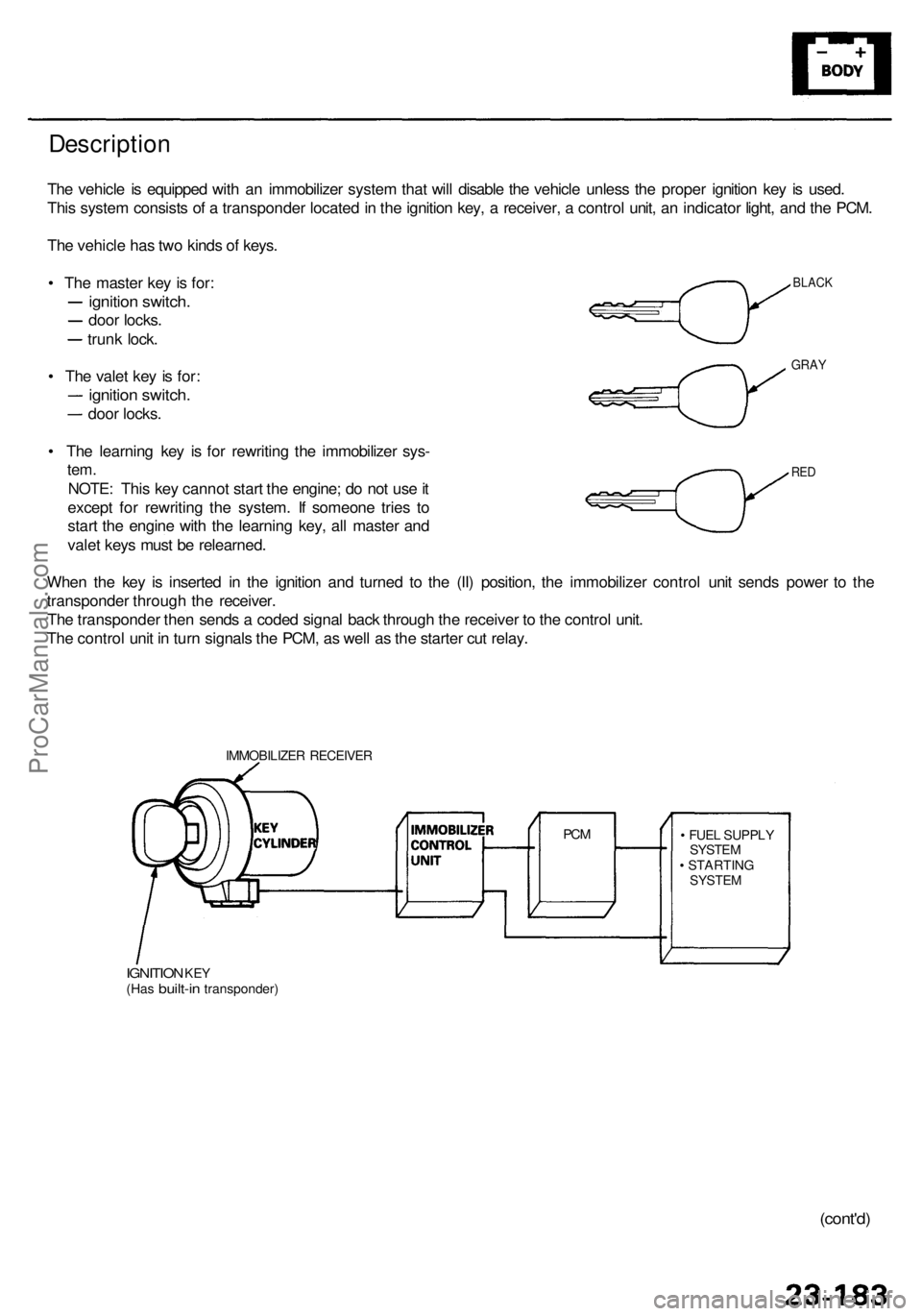

Description

The vehicl e is equippe d wit h a n immobilize r syste m tha t wil l disabl e th e vehicl e unles s th e prope r ignitio n ke y i s used .

Thi s syste m consist s o f a transponde r locate d in th e ignitio n key , a receiver , a contro l unit , a n indicato r light , an d th e PCM .

Th e vehicl e ha s tw o kind s o f keys .

• Th e maste r ke y i s for :

ignitio n switch .

door locks .

trunk lock .

• Th e vale t ke y i s for :

ignitio n switch .

door locks .

• Th e learnin g ke y i s fo r rewritin g th e immobilize r sys -

tem.

NOTE : Thi s ke y canno t star t th e engine ; d o no t us e it

excep t fo r rewritin g th e system . I f someon e trie s t o

star t th e engin e wit h th e learnin g key , al l maste r an d

vale t key s mus t b e relearned .

Whe n th e ke y i s inserte d i n th e ignitio n an d turne d t o th e (II ) position , th e immobilize r contro l uni t send s powe r t o th e

transponde r throug h th e receiver .

Th e transponde r the n send s a code d signa l bac k throug h th e receive r t o th e contro l unit .

Th e contro l uni t i n tur n signal s th e PCM , a s wel l a s th e starte r cu t relay .

IMMOBILIZE R RECEIVE R

IGNITION KEY(Ha s built-i n transponder ) •

FUE L SUPPL Y

SYSTE M

• STARTIN G

SYSTEM

PCM

BLAC K

GRAY

RED

(cont'd )

ProCarManuals.com

Page 1595 of 1954

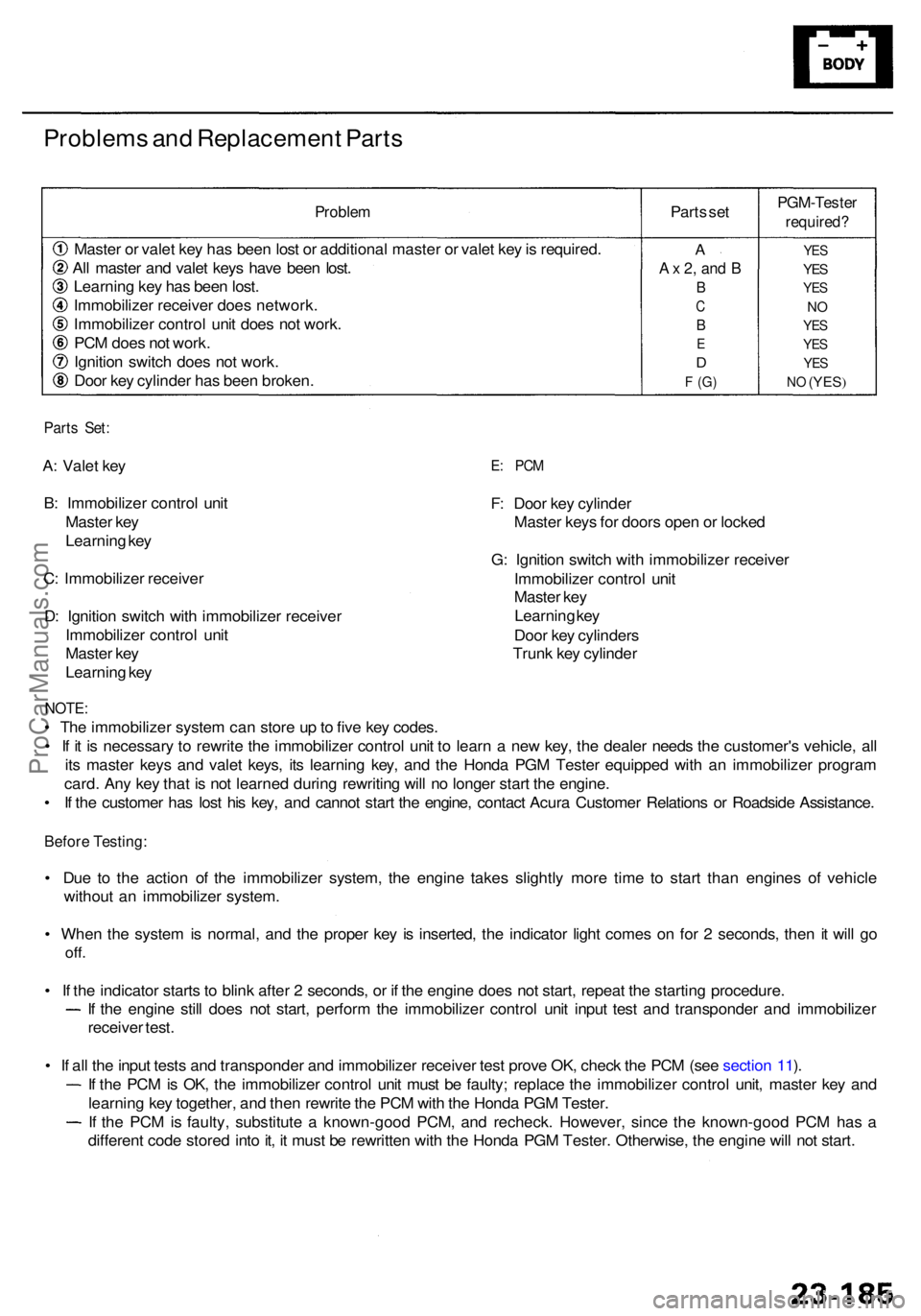

Problems an d Replacemen t Part s

Proble m

Master o r vale t ke y ha s bee n los t o r additiona l maste r o r vale t ke y is required .

Al l maste r an d vale t key s hav e bee n lost .

Learnin g ke y ha s bee n lost .

Immobilize r receive r doe s network .

Immobilize r contro l uni t doe s no t work .

PC M doe s no t work .

Ignitio n switc h doe s no t work .

Doo r ke y cylinde r ha s bee n broken . Part

s se t

PGM-Teste r

required?

YES

YES

YE S

NO

YE S

YE S

YES

NO (YES )

A

A x 2 , an d B

B

C

B

E

D

F (G )

Part s Set :

A: Vale t ke y

B : Immobilize r contro l uni t

Maste r ke y

Learnin g ke y

C : Immobilize r receive r

D : Ignitio n switc h wit h immobilize r receive r

Immobilize r contro l uni t

Maste r ke y

Learnin g ke yE: PC M

F: Doo r ke y cylinde r

Maste r key s fo r door s ope n o r locke d

G : Ignitio n switc h wit h immobilize r receive r

Immobilize r contro l uni t

Maste r ke y

Learnin g ke y

Doo r ke y cylinder s

Trun k ke y cylinde r

NOTE:

• Th e immobilize r syste m ca n stor e u p to fiv e ke y codes .

• I f i t i s necessar y t o rewrit e th e immobilize r contro l uni t t o lear n a ne w key , th e deale r need s th e customer' s vehicle , al l

it s maste r key s an d vale t keys , it s learnin g key , an d th e Hond a PG M Teste r equippe d wit h a n immobilize r progra m

card . An y ke y tha t i s no t learne d durin g rewritin g wil l n o longe r star t th e engine .

• I f th e custome r ha s los t hi s key , an d canno t star t th e engine , contac t Acur a Custome r Relation s o r Roadsid e Assistance .

Before Testing :

• Du e t o th e actio n o f th e immobilize r system , th e engin e take s slightl y mor e tim e t o star t tha n engine s o f vehicl e

withou t a n immobilize r system .

• Whe n th e syste m is normal , an d th e prope r ke y i s inserted , th e indicato r ligh t come s o n fo r 2 seconds , the n i t wil l g o

off .

• I f th e indicato r start s t o blin k afte r 2 seconds , o r i f th e engin e doe s no t start , repea t th e startin g procedure .

If th e engin e stil l doe s no t start , perfor m th e immobilize r contro l uni t inpu t tes t an d transponde r an d immobilize r

receive r test .

• I f al l th e inpu t test s an d transponde r an d immobilize r receive r tes t prov e OK , chec k th e PC M (se e sectio n 11 ).

I f th e PC M is OK , th e immobilize r contro l uni t mus t b e faulty ; replac e th e immobilize r contro l unit , maste r ke y an d

learnin g ke y together , an d the n rewrit e th e PC M wit h th e Hond a PG M Tester .

If th e PC M is faulty , substitut e a known-goo d PCM , an d recheck . However , sinc e th e known-goo d PC M ha s a

differen t cod e store d int o it , i t mus t b e rewritte n wit h th e Hond a PG M Tester . Otherwise , th e engin e wil l no t start .

ProCarManuals.com