boot ACURA RL KA9 1996 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 1023 of 1954

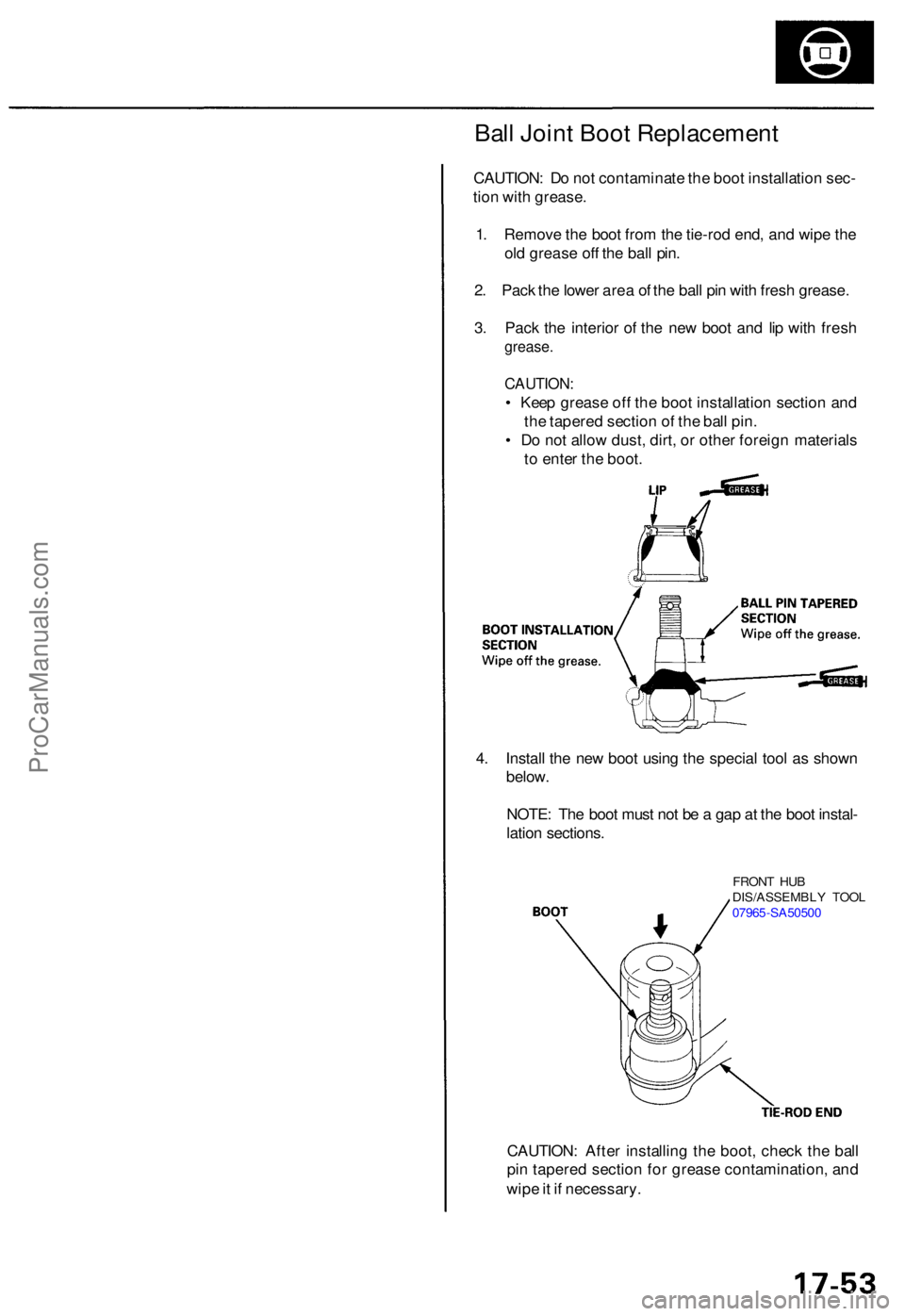

Ball Join t Boo t Replacemen t

CAUTION: D o no t contaminat e th e boo t installatio n sec -

tio n wit h grease .

1 . Remov e th e boo t fro m th e tie-ro d end , an d wip e th e

ol d greas e of f th e bal l pin .

2 . Pac k th e lowe r are a o f th e bal l pi n wit h fres h grease .

3 . Pac k th e interio r o f th e ne w boo t an d li p wit h fres h

grease .

CAUTION :

• Kee p greas e of f th e boo t installatio n sectio n an d

th e tapere d sectio n o f th e bal l pin .

• D o no t allo w dust , dirt , o r othe r foreig n material s

t o ente r th e boot .

4 . Instal l th e ne w boo t usin g th e specia l too l a s show n

below .

NOTE : Th e boo t mus t no t b e a ga p a t th e boo t instal -

latio n sections .

CAUTION : Afte r installin g th e boot , chec k th e bal l

pi n tapere d sectio n fo r greas e contamination , an d

wip e it i f necessary .

FRONT HU B

DIS/ASSEMBL Y TOO L

0796 5-SA5050 0

ProCarManuals.com

Page 1027 of 1954

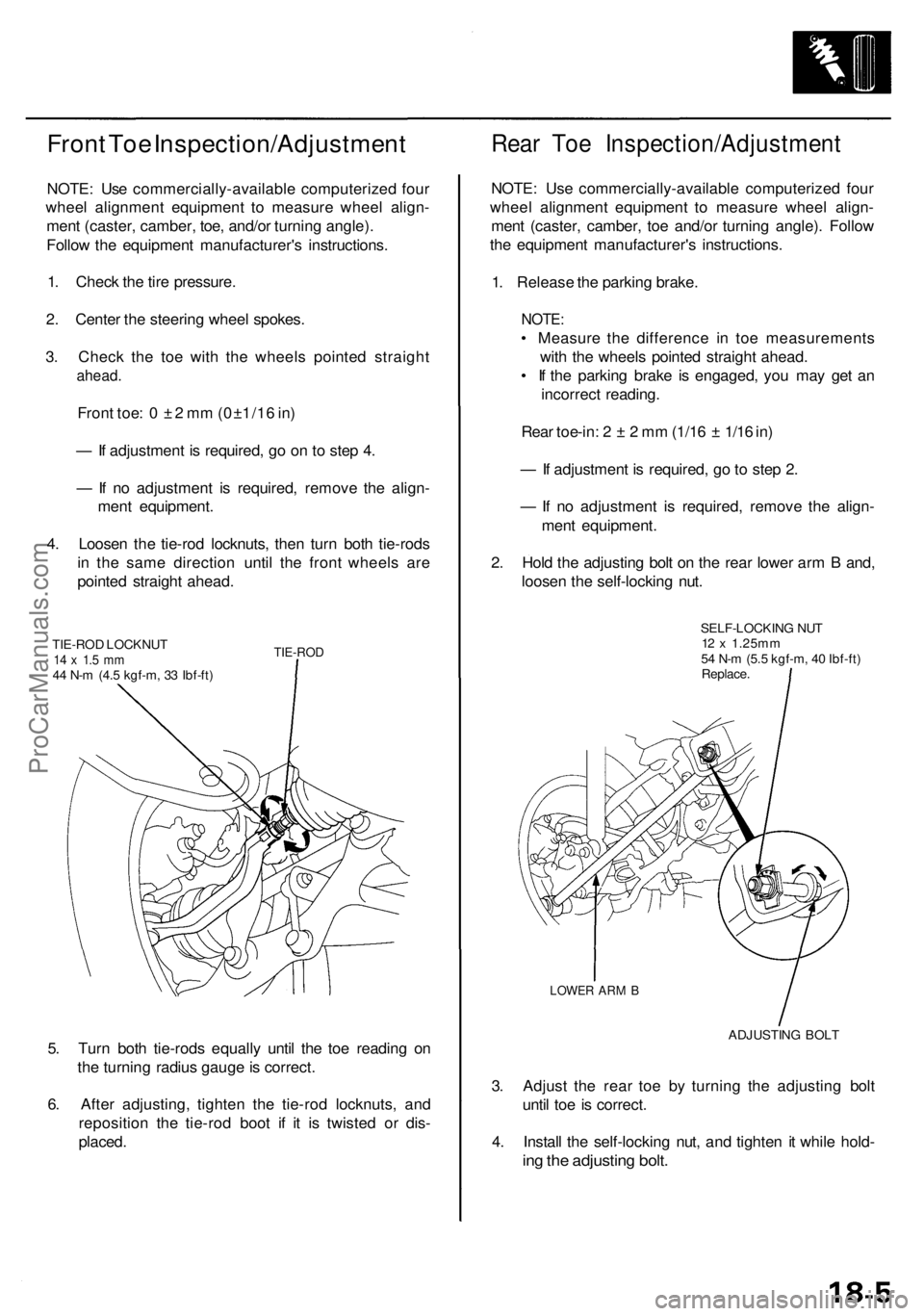

Front Toe Inspection/Adjustment

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and/or turning angle).

Follow the equipment manufacturer's instructions.

1. Check the tire pressure.

2. Center the steering wheel spokes.

3. Check the toe with the wheels pointed straight

ahead.

Front toe: 0 ± 2 mm (0±1/16 in)

— If adjustment is required, go on to step 4.

— If no adjustment is required, remove the align-

ment equipment.

4. Loosen the tie-rod locknuts, then turn both tie-rods

in the same direction until the front wheels are

pointed straight ahead.

TIE-ROD LOCKNUT

14 x 1.5 mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

TIE-ROD

5. Turn both tie-rods equally until the toe reading on

the turning radius gauge is correct.

6. After adjusting, tighten the tie-rod locknuts, and

reposition the tie-rod boot if it is twisted or dis-

placed.

Rear Toe Inspection/Adjustment

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe and/or turning angle). Follow

the equipment manufacturer's instructions.

1. Release the parking brake.

NOTE:

• Measure the difference in toe measurements

with the wheels pointed straight ahead.

• If the parking brake is engaged, you may get an

incorrect reading.

Rear toe-in: 2 ± 2 mm (1/16 ± 1/16 in)

— If adjustment is required, go to step 2.

— If no adjustment is required, remove the align-

ment equipment.

2. Hold the adjusting bolt on the rear lower arm B and,

loosen the self-locking nut.

SELF-LOCKING NUT

12 x 1.25mm

54 N-m (5.5 kgf-m, 40 Ibf-ft)

Replace.

LOWER ARM B

ADJUSTING BOLT

3. Adjust the rear toe by turning the adjusting bolt

until toe is correct.

4. Install the self-locking nut, and tighten it while hold-

ing the adjusting bolt.ProCarManuals.com

Page 1032 of 1954

Front Suspensio n

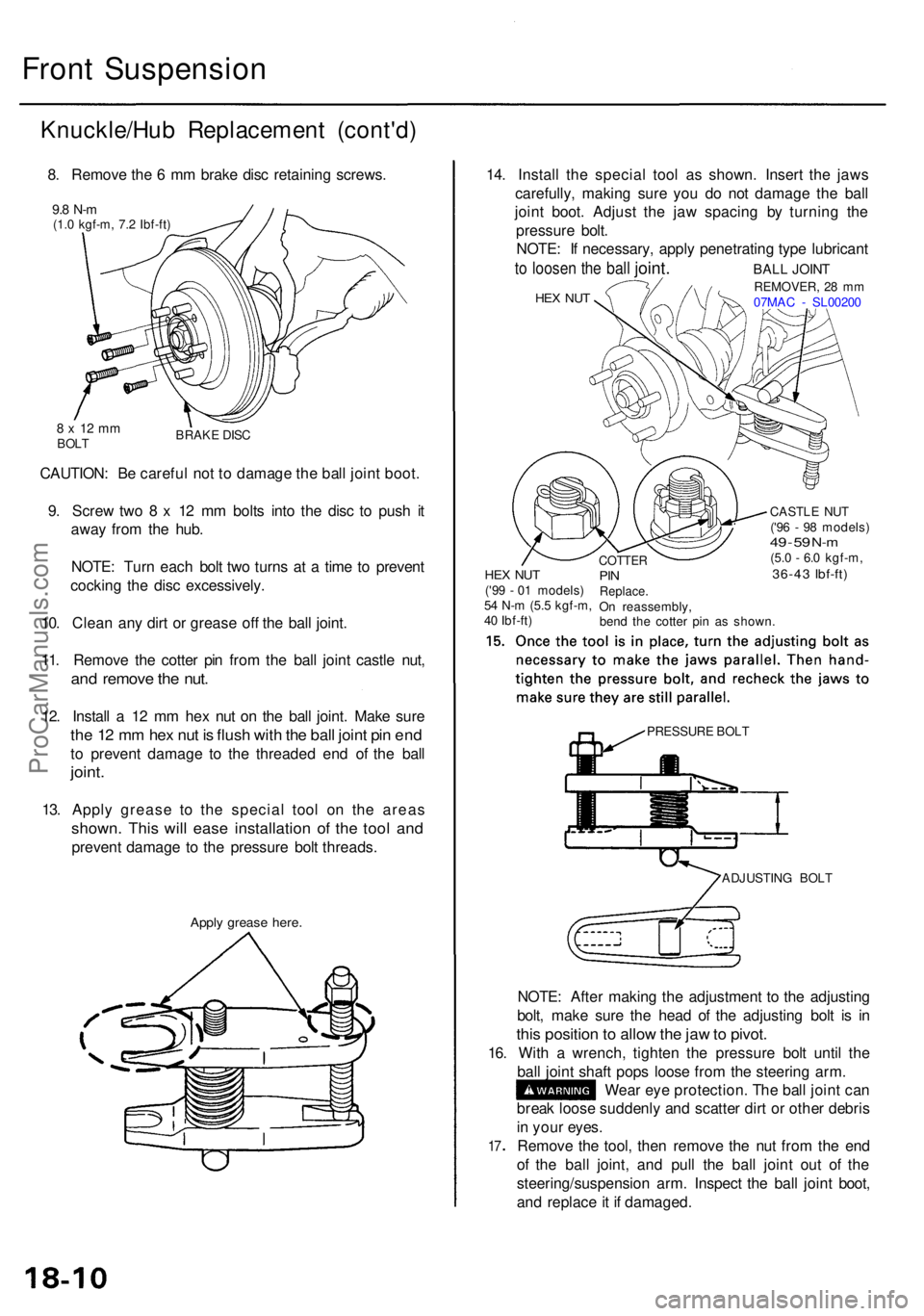

Knuckle/Hu b Replacemen t (cont'd )

8. Remov e th e 6 m m brak e dis c retainin g screws .

9.8 N- m(1.0 kgf-m , 7. 2 Ibf-ft )

CAUTION : B e carefu l no t t o damag e th e bal l join t boot .

9 . Scre w tw o 8 x 1 2 m m bolt s int o th e dis c t o pus h i t

awa y fro m th e hub .

NOTE : Tur n eac h bol t tw o turn s a t a tim e t o preven t

cockin g th e dis c excessively .

10 . Clea n an y dir t o r greas e of f th e bal l joint .

11 . Remov e th e cotte r pi n fro m th e bal l join t castl e nut ,

and remov e th e nut .

12. Instal l a 12 m m he x nu t o n th e bal l joint . Mak e sur e

the 1 2 m m he x nu t i s flus h wit h th e bal l join t pi n en d

to preven t damag e t o th e threade d en d o f th e bal l

joint .

13. Appl y greas e t o th e specia l too l o n th e area s

shown . Thi s wil l eas e installatio n o f th e too l an d

preven t damag e t o th e pressur e bol t threads .

Apply greas e here .

ADJUSTIN G BOL T

NOTE : Afte r makin g th e adjustmen t t o th e adjustin g

bolt , mak e sur e th e hea d o f th e adjustin g bol t i s i n

thi s positio n to allo w th e ja w to pivot .

16. Wit h a wrench , tighte n th e pressur e bol t unti l th e

bal l join t shaf t pop s loos e fro m th e steerin g arm .

Wea r ey e protection . Th e bal l join t ca n

brea k loos e suddenl y an d scatte r dir t o r othe r debri s

i n you r eyes .

Remov e th e tool , the n remov e th e nu t fro m th e en d

o f th e bal l joint , an d pul l th e bal l join t ou t of the

steering/suspensio n arm . Inspec t th e bal l join t boot ,

an d replac e it i f damaged .

17

HE X NU TREMOVER , 2 8 m m

07MA C - SL0020 0

14. Instal l th e specia l too l a s shown . Inser t th e jaw s

carefully , makin g sur e yo u d o no t damag e th e bal l

join t boot . Adjus t th e ja w spacin g b y turnin g th e

pressur e bolt .

NOTE : I f necessary , appl y penetratin g typ e lubrican t

to loose n the bal l joint . BALL JOIN T

HEX NU T('99 - 0 1 models )

5 4 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

COTTE RPINReplace .On reassembly ,

ben d th e cotte r pi n a s shown .

CASTL

E NU T

('9 6 - 9 8 models )

49 - 5 9 N- m(5. 0 - 6. 0 kgf-m ,36-43 Ibf-ft )

PRESSUR E BOL T

8 x 1 2 m mBOL T BRAK

E DIS C

ProCarManuals.com

Page 1036 of 1954

Front Suspensio n

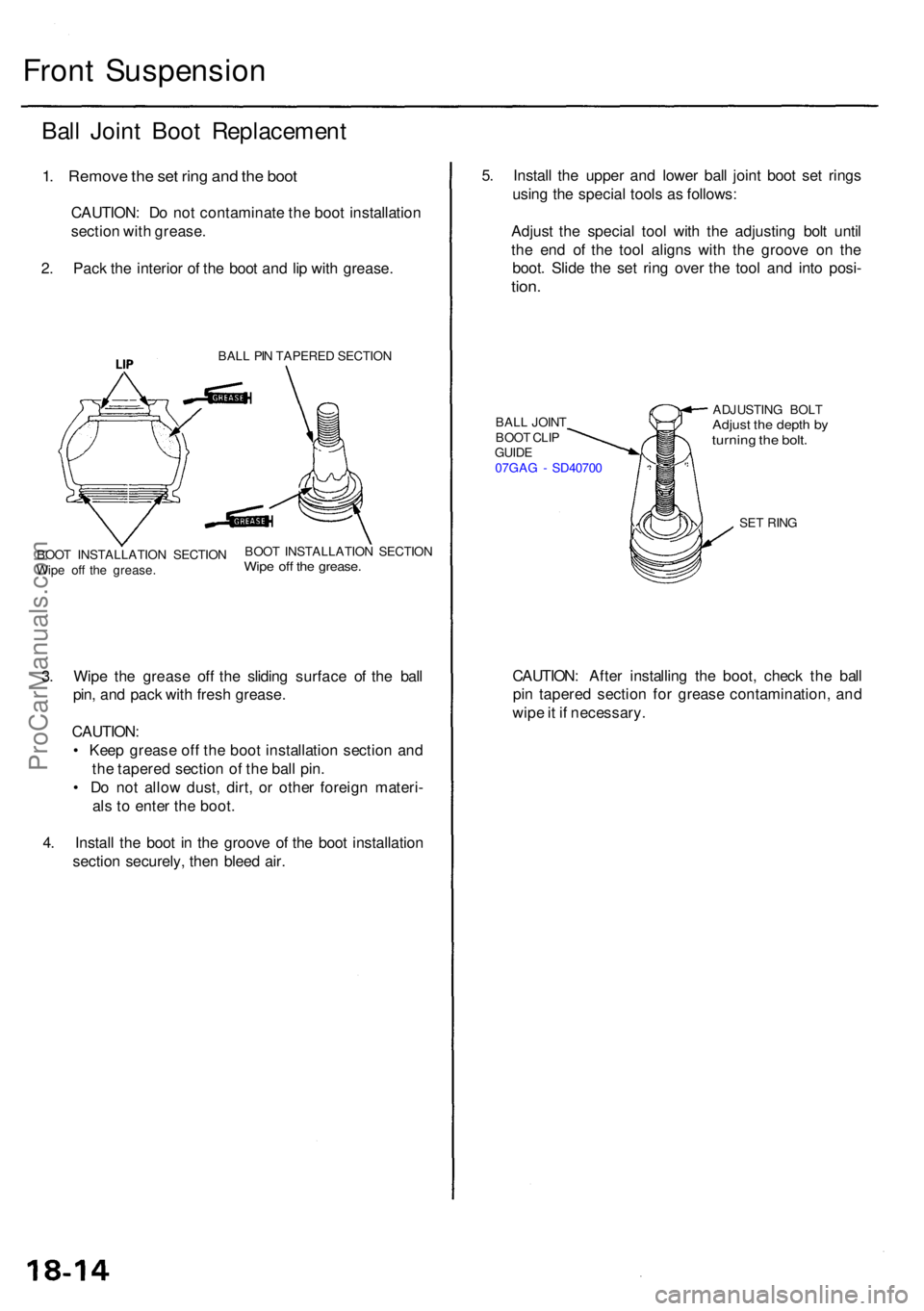

Ball Join t Boo t Replacemen t

1. Remov e th e se t rin g an d th e boo t

CAUTION : D o no t contaminat e th e boo t installatio n

sectio n wit h grease .

2 . Pac k th e interio r o f th e boo t an d li p wit h grease .

BALL PI N TAPERE D SECTIO N

3. Wip e th e greas e of f th e slidin g surfac e o f th e bal l

pin , an d pac k wit h fres h grease .

CAUTION :

• Kee p greas e of f th e boo t installatio n sectio n an d

th e tapere d sectio n o f th e bal l pin .

• D o no t allo w dust , dirt , o r othe r foreig n materi -

al s to ente r th e boot .

4 . Instal l th e boo t i n th e groov e o f th e boo t installatio n

sectio n securely , the n blee d air . 5

. Instal l th e uppe r an d lowe r bal l join t boo t se t ring s

usin g th e specia l tool s a s follows :

Adjus t th e specia l too l wit h th e adjustin g bol t unti l

th e en d o f th e too l align s wit h th e groov e o n th e

boot . Slid e th e se t rin g ove r th e too l an d int o posi -

tion.

BAL L JOIN T

BOO T CLI P

GUID E

07GA G - SD4070 0 ADJUSTIN

G BOL TAdjust th e dept h b yturnin g th e bolt .

SET RIN G

CAUTION : Afte r installin g th e boot , chec k th e bal l

pi n tapere d sectio n fo r greas e contamination , an d

wip e it i f necessary .

BOOT INSTALLATIO N SECTIO N

Wip e of f th e grease . BOO

T INSTALLATIO N SECTIO NWipe of f th e grease .

ProCarManuals.com

Page 1037 of 1954

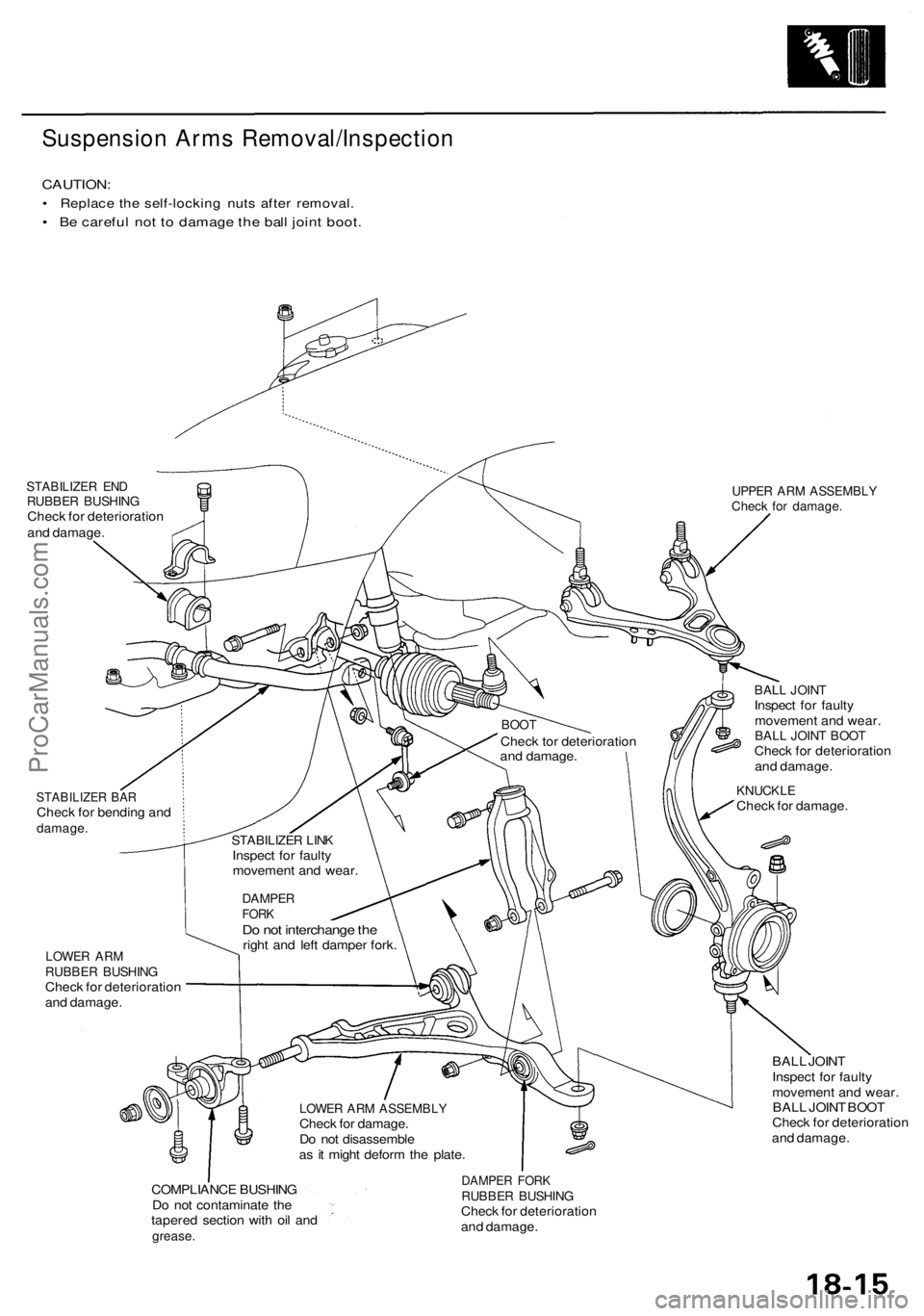

Suspension Arms Removal/Inspection

CAUTION:

• Replace the self-locking nuts after removal.

• Be careful not to damage the ball joint boot.

STABILIZER END

RUBBER BUSHING

Check for deterioration

and damage.

UPPER ARM ASSEMBLY

Check for damage.

STABILIZER BAR

Check for bending and

damage.

BALL JOINT

Inspect for faulty

movement and wear.

BALL JOINT BOOT

Check for deterioration

and damage.

KNUCKLE

Check for damage.

LOWER ARM

RUBBER BUSHING

Check for deterioration

and damage.

BALL JOINT

Inspect for faulty

movement and wear.

BALL JOINT BOOT

Check for deterioration

and damage.

COMPLIANCE BUSHING

Do not contaminate the

tapered section with oil and

grease.

DAMPER FORK

RUBBER BUSHING

Check for deterioration

and damage.

LOWER ARM ASSEMBLY

Check for damage.

Do not disassemble

as it might deform the plate.

DAMPER

FORK

Do not interchange the

right and left damper fork.

STABILIZER LINK

Inspect for faulty

movement and wear.

BOOT

Check tor deterioration

and damage.ProCarManuals.com

Page 1043 of 1954

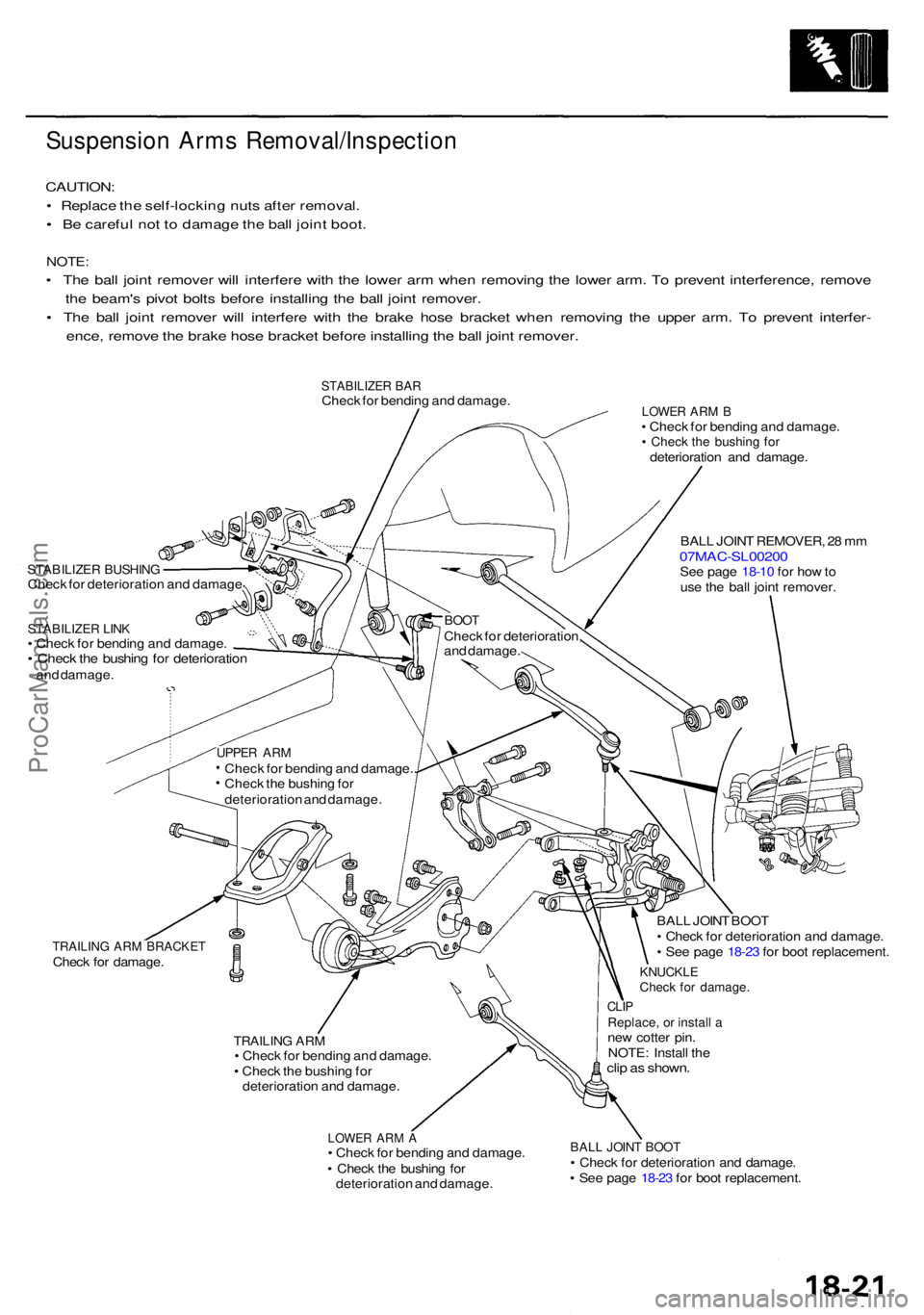

Suspension Arm s Removal/Inspectio n

CAUTION:

• Replac e th e self-lockin g nut s afte r removal .

• B e carefu l no t t o damag e th e bal l join t boot .

NOTE :

• Th e bal l join t remove r wil l interfer e wit h th e lowe r ar m whe n removin g th e lowe r arm . T o preven t interference , remov e

th e beam' s pivo t bolt s befor e installin g th e bal l join t remover .

• Th e bal l join t remove r wil l interfer e wit h th e brak e hos e bracke t whe n removin g th e uppe r arm . T o preven t interfer -

ence , remov e th e brak e hos e bracke t befor e installin g th e bal l join t remover .

STABILIZE R BA RChec k fo r bendin g an d damage .

STABILIZE R BUSHIN GCheck fo r deterioratio n an d damag e

STABILIZE R LIN K• Chec k fo r bendin g an d damage .• Chec k th e bushin g fo r deterioratio nand damage .

LOWER AR M B• Chec k fo r bendin g an d damage .• Chec k th e bushin g fo rdeterioratio n an d damage .

BAL L JOIN T REMOVER , 2 8 m m

07MAC-SL0020 0See pag e 18-1 0 fo r ho w to

us e th e bal l join t remover .

TRAILING AR M BRACKE TCheck fo r damage .

TRAILING AR M• Chec k fo r bendin g an d damage .

• Chec k th e bushin g fo r

deterioratio n an d damage .

LOWER AR M A• Chec k fo r bendin g an d damage .

• Chec k th e bushin g fo r

deterioratio n an d damage . BAL

L JOIN T BOO T

• Chec k fo r deterioratio n an d damage .

• Se e pag e 18-2 3 fo r boo t replacement .

KNUCKLECheck fo r damage .

CLIPReplace , o r instal l ane w cotte r pin .

NOTE : Instal l th e

clip a s shown .

BALL JOIN T BOO T• Chec k fo r deterioratio n an d damage .

• Se e pag e 18-2 3 fo r boo t replacement .

BOOTChec k fo r deterioration ,

an d damage .

UPPER AR MChec k fo r bendin g an d damage. .

Chec k th e bushin g fo r

deterioratio n an d damage .

ProCarManuals.com

Page 1045 of 1954

Rear Dampe r

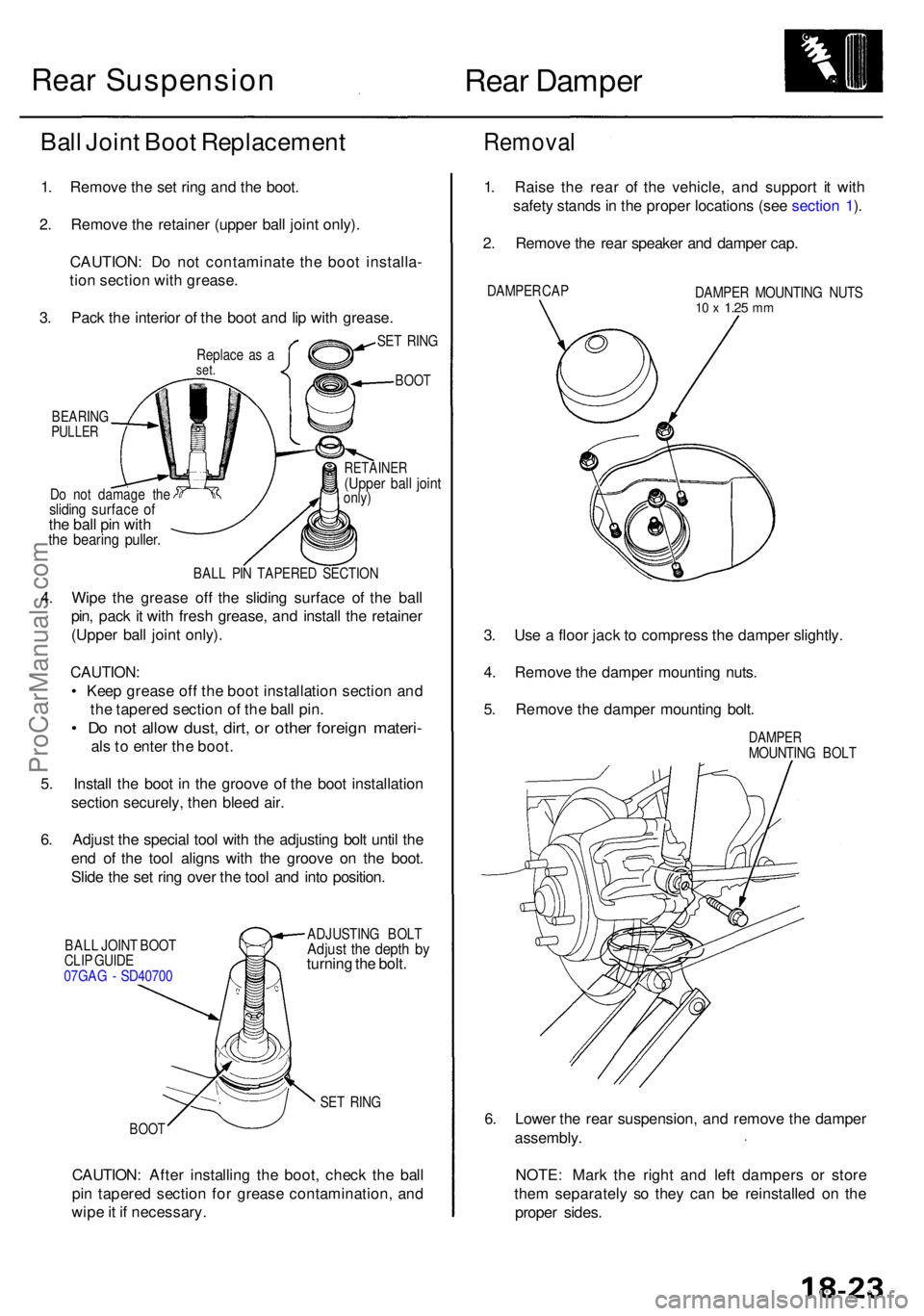

Do no t damag e th eslidin g surfac e o fthe bal l pi n wit hthe bearin g puller .

RETAINE R(Upper bal l join tonly)

BAL L PI N TAPERE D SECTIO N

4. Wip e th e greas e of f th e slidin g surfac e o f th e bal l

pin , pac k i t wit h fres h grease , an d instal l th e retaine r

(Uppe r bal l join t only) .

CAUTION :

• Kee p greas e of f th e boo t installatio n sectio n an d

th e tapere d sectio n o f th e bal l pin .

• D o no t allo w dust , dirt , o r othe r foreig n materi -

als to ente r th e boot .

5 . Instal l th e boo t i n th e groov e o f th e boo t installatio n

sectio n securely , the n blee d air .

6 . Adjus t th e specia l too l wit h th e adjustin g bol t unti l th e

en d o f th e too l align s wit h th e groov e o n th e boot .

Slid e th e se t rin g ove r th e too l an d int o position .

BALL JOIN T BOO T

CLI P GUID E

07GA G - SD4070 0 ADJUSTIN

G BOL TAdjust th e dept h b yturnin g th e bolt .

SET RIN G

BOO T

CAUTION : Afte r installin g th e boot , chec k th e bal l

pi n tapere d sectio n fo r greas e contamination , an d

wip e it i f necessary .

Removal

1. Rais e th e rea r o f th e vehicle , an d suppor t i t wit h

safet y stand s in th e prope r location s (se e sectio n 1 ).

2 . Remov e th e rea r speake r an d dampe r cap .

DAMPE R CA P

DAMPER MOUNTIN G NUT S10 x 1.2 5 mm

3. Us e a floo r jac k t o compres s th e dampe r slightly .

4 . Remov e th e dampe r mountin g nuts .

5 . Remov e th e dampe r mountin g bolt .

DAMPE RMOUNTIN G BOL T

6. Lowe r th e rea r suspension , an d remov e th e dampe r

assembly .

NOTE : Mar k th e righ t an d lef t damper s o r stor e

the m separatel y s o the y can be reinstalle d o n th e

prope r sides .

SET RIN G

BOO T

Ball Join t Boo t Replacemen t

1. Remov e th e se t rin g an d th e boot .

2 . Remov e th e retaine r (uppe r bal l join t only) .

CAUTION : D o no t contaminat e th e boo t installa -

tio n sectio n wit h grease .

3 . Pac k th e interio r o f th e boo t an d li p wit h grease .

Replace a s aset .

BEARIN GPULLER

Rear Suspension

ProCarManuals.com

Page 1050 of 1954

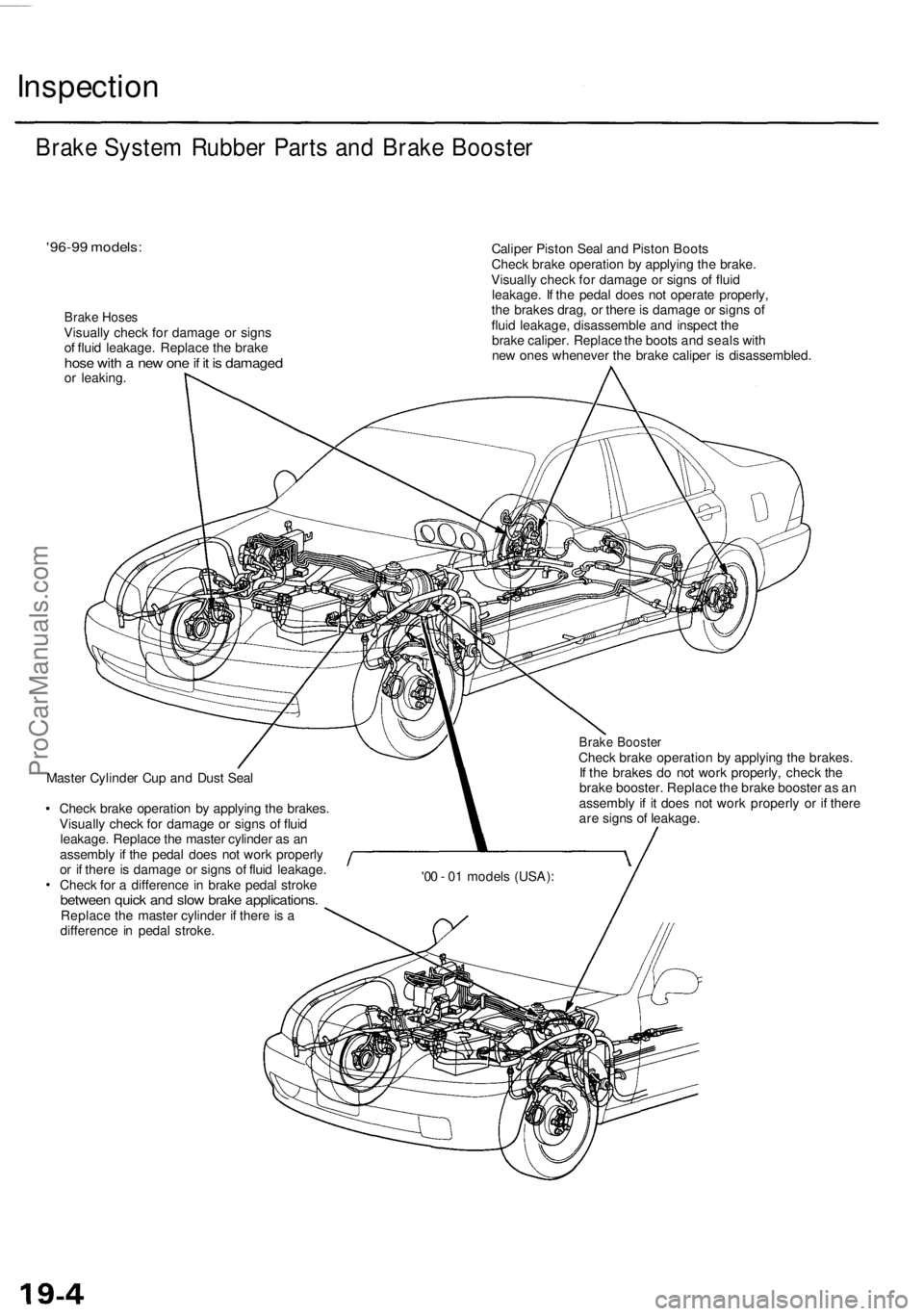

Inspection

'96-99 models:

Brake Hoses

Visually check for damage or signs

of fluid leakage. Replace the brake

hose with a new one if it is damaged

or leaking.

Caliper Piston Seal and Piston Boots

Check brake operation by applying the brake.

Visually check for damage or signs of fluid

leakage. If the pedal does not operate properly,

the brakes drag, or there is damage or signs of

fluid leakage, disassemble and inspect the

brake caliper. Replace the boots and seals with

new ones whenever the brake caliper is disassembled.

Master Cylinder Cup and Dust Seal

Check brake operation by applying the brakes.

Visually check for damage or signs of fluid

leakage. Replace the master cylinder as an

assembly if the pedal does not work properly

or if there is damage or signs of fluid leakage.

Check for a difference in brake pedal stroke

between quick and slow brake applications.

Replace the master cylinder if there is a

difference in pedal stroke.

Brake Booster

Check brake operation by applying the brakes.

If the brakes do not work properly, check the

brake booster. Replace the brake booster as an

assembly if it does not work properly or if there

are signs of leakage.

Brake System Rubber Parts and Brake Booster

'00 - 01 models (USA):ProCarManuals.com

Page 1056 of 1954

Front Brak e Pad s

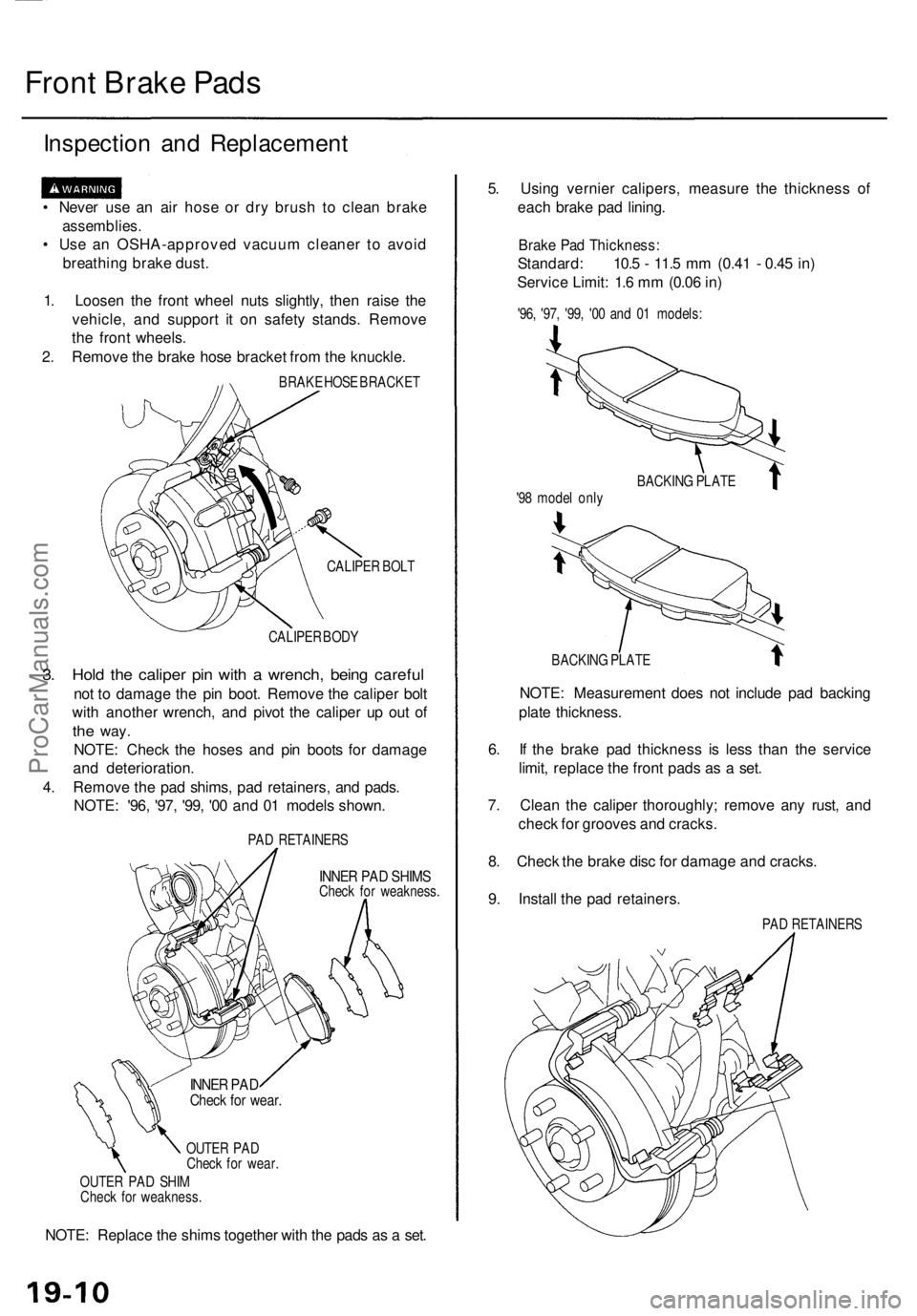

Inspectio n an d Replacemen t

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brake

assemblies .

• Us e a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

1 . Loose n th e fron t whee l nut s slightly , the n rais e th e

vehicle , an d suppor t i t o n safet y stands . Remov e

th e fron t wheels .

2 . Remov e th e brak e hos e bracke t fro m th e knuckle .

BRAKE HOS E BRACKE T

CALIPE R BOL T

CALIPE R BOD Y

3. Hol d th e calipe r pi n wit h a wrench , bein g carefu l

not t o damag e th e pi n boot . Remov e th e calipe r bol t

wit h anothe r wrench , an d pivo t th e calipe r u p ou t o f

the way .

NOTE : Chec k th e hose s an d pi n boot s fo r damag e

an d deterioration .

4 . Remov e th e pa d shims , pa d retainers , an d pads .

NOTE : '96 , '97 , '99 , '0 0 an d 0 1 model s shown .

PAD RETAINER S

INNER PA D SHIM SCheck fo r weakness .

OUTE R PA D

Chec k fo r wear .

OUTE R PA D SHI M

Chec k fo r weakness .

NOTE: Replac e th e shim s togethe r wit h th e pad s a s a set . 5

. Usin g vernie r calipers , measur e th e thicknes s of

eac h brak e pa d lining .

Brake Pa d Thickness :

Standard: 10. 5 - 11. 5 m m (0.4 1 - 0.4 5 in )

Servic e Limit : 1. 6 m m (0.0 6 in )

'96 , '97 , '99 , '0 0 an d 0 1 models :

BACKIN G PLAT E

NOTE: Measuremen t doe s no t includ e pa d backin g

plat e thickness .

6 . I f th e brak e pa d thicknes s i s les s tha n th e servic e

limit , replac e th e fron t pad s a s a set .

7 . Clea n th e calipe r thoroughly ; remov e an y rust , an d

chec k fo r groove s an d cracks .

8 . Chec k th e brak e dis c fo r damag e an d cracks .

9 . Instal l th e pa d retainers .

PAD RETAINER S

BACKIN

G PLAT E

'9 8 mode l onl y

INNE R PA DChec k fo r wear .

ProCarManuals.com

Page 1057 of 1954

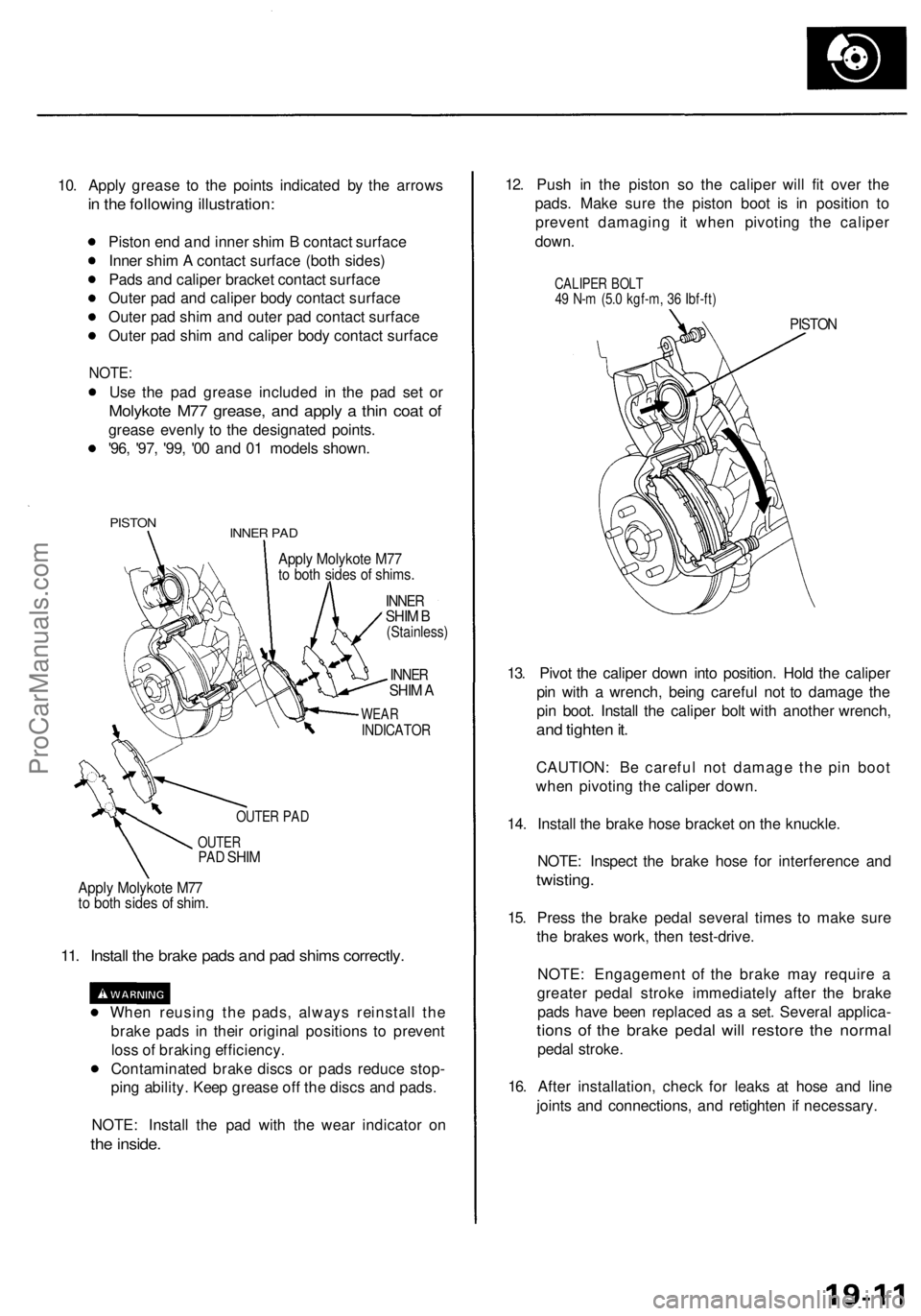

10. Apply grease to the points indicated by the arrows

in the following illustration:

Piston end and inner shim B contact surface

Inner shim A contact surface (both sides)

Pads and caliper bracket contact surface

Outer pad and caliper body contact surface

Outer pad shim and outer pad contact surface

Outer pad shim and caliper body contact surface

NOTE:

Use the pad grease included in the pad set or

Molykote M77 grease, and apply a thin coat of

grease evenly to the designated points.

'96, '97, '99, '00 and 01 models shown.

PISTON

INNER PAD

Apply Molykote M77

to both sides of shims.

INNER

SHIM B

(Stainless)

INNER

SHIM A

WEAR

INDICATOR

OUTER PAD

OUTER

PAD

SHIM

Apply Molykote M77

to both sides of shim.

11. Install the brake pads and pad shims correctly.

When reusing the pads, always reinstall the

brake pads in their original positions to prevent

loss of braking efficiency.

Contaminated brake discs or pads reduce stop-

ping ability. Keep grease off the discs and pads.

NOTE: Install the pad with the wear indicator on

the inside.

12. Push in the piston so the caliper will fit over the

pads. Make sure the piston boot is in position to

prevent damaging it when pivoting the caliper

down.

CALIPER BOLT

49 N-m (5.0 kgf-m, 36 Ibf-ft)

PISTON

13. Pivot the caliper down into position. Hold the caliper

pin with a wrench, being careful not to damage the

pin boot. Install the caliper bolt with another wrench,

and tighten it.

CAUTION: Be careful not damage the pin boot

when pivoting the caliper down.

14. Install the brake hose bracket on the knuckle.

NOTE: Inspect the brake hose for interference and

twisting.

15. Press the brake pedal several times to make sure

the brakes work, then test-drive.

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normal

pedal stroke.

16. After installation, check for leaks at hose and line

joints and connections, and retighten if necessary.ProCarManuals.com