check engine light ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 345 of 1954

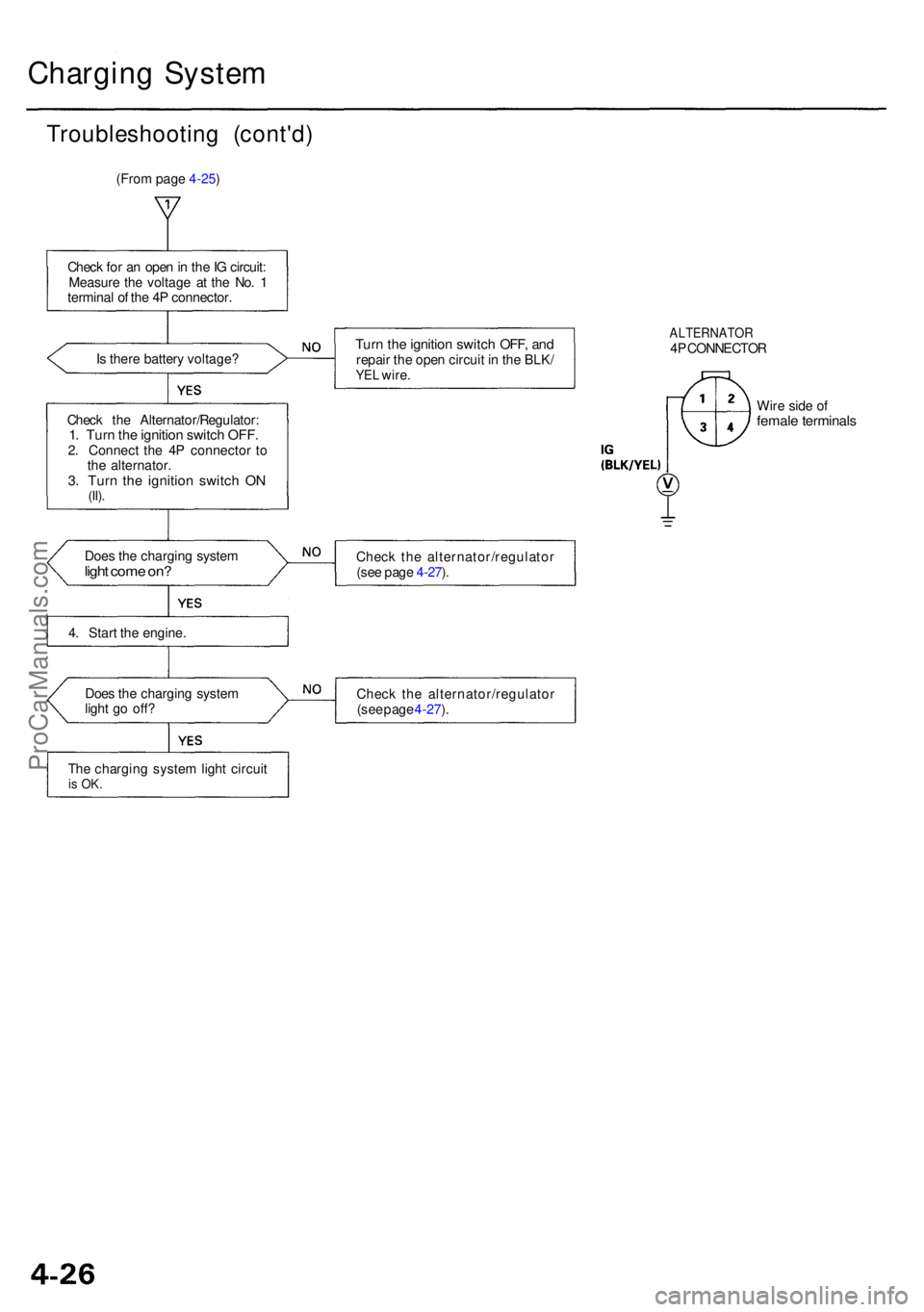

Charging Syste m

Troubleshootin g (cont'd )

(From page 4-25)

Chec k fo r a n ope n in th e IG circuit :

Measur e th e voltag e a t th e No . 1

termina l o f th e 4 P connector .

I s ther e batter y voltage ?

Chec k th e Alternator/Regulator :

1. Tur n th e ignitio n switc h OFF .2. Connec t th e 4 P connecto r t o

th e alternator .

3. Tur n th e ignitio n switc h O N(II).

Doe s th e chargin g syste mlight com e on ?

4. Star t th e engine .

Doe s th e chargin g syste m

ligh t g o off ?

Th e chargin g syste m ligh t circui t

is OK .

Turn th e ignitio n switc h OFF , an drepai r th e ope n circui t i n th e BLK /YEL wire .

ALTERNATO R4P CONNECTO R

Wir e sid e o f

femal e terminal s

Check th e alternator/regulato r

(se e pag e 4-27 ).

Chec k th e alternator/regulato r

(se e pag e 4-27 ).

ProCarManuals.com

Page 457 of 1954

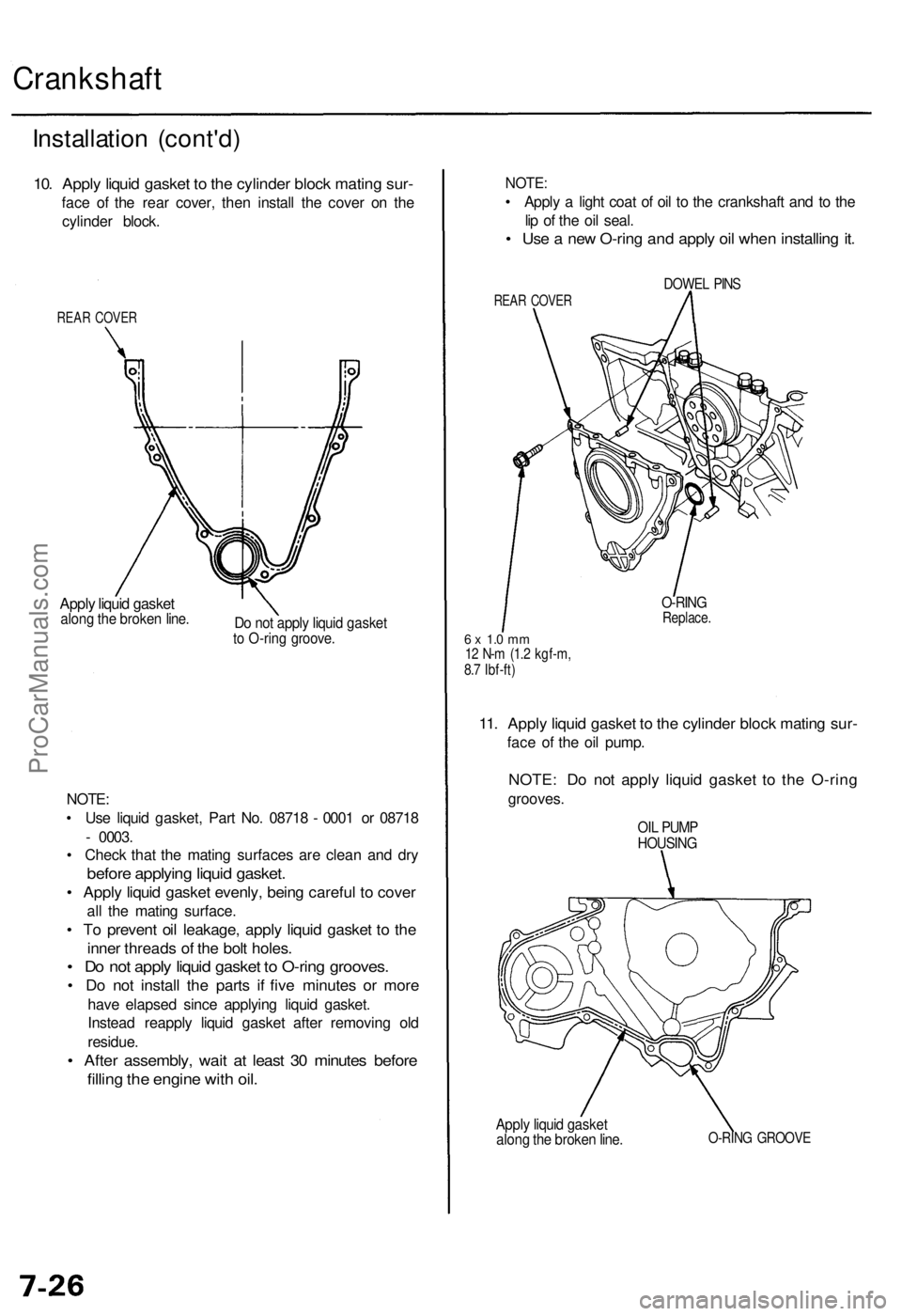

Crankshaft

Installation (cont'd)

10. Apply liquid gasket to the cylinder block mating sur-

face of the rear cover, then install the cover on the

cylinder block.

REAR COVER

Apply liquid gasket

along the broken line.

Do not apply liquid gasket

to O-ring groove.

NOTE:

• Use liquid gasket, Part No. 08718 - 0001 or 08718

- 0003.

• Check that the mating surfaces are clean and dry

before applying liquid gasket.

• Apply liquid gasket evenly, being careful to cover

all the mating surface.

• To prevent oil leakage, apply liquid gasket to the

inner threads of the bolt holes.

• Do not apply liquid gasket to O-ring grooves.

• Do not install the parts if five minutes or more

have elapsed since applying liquid gasket.

Instead reapply liquid gasket after removing old

residue.

• After assembly, wait at least 30 minutes before

filling the engine with oil.

Apply liquid gasket

along the broken line.

O-RING GROOVE

NOTE:

• Apply a light coat of oil to the crankshaft and to the

lip of the oil seal.

• Use a new O-ring and apply oil when installing it.

REAR COVER

DOWEL PINS

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

O-RING

Replace.

11. Apply liquid gasket to the cylinder block mating sur-

face of the oil pump.

NOTE: Do not apply liquid gasket to the O-ring

grooves.

OIL PUMP

HOUSINGProCarManuals.com

Page 728 of 1954

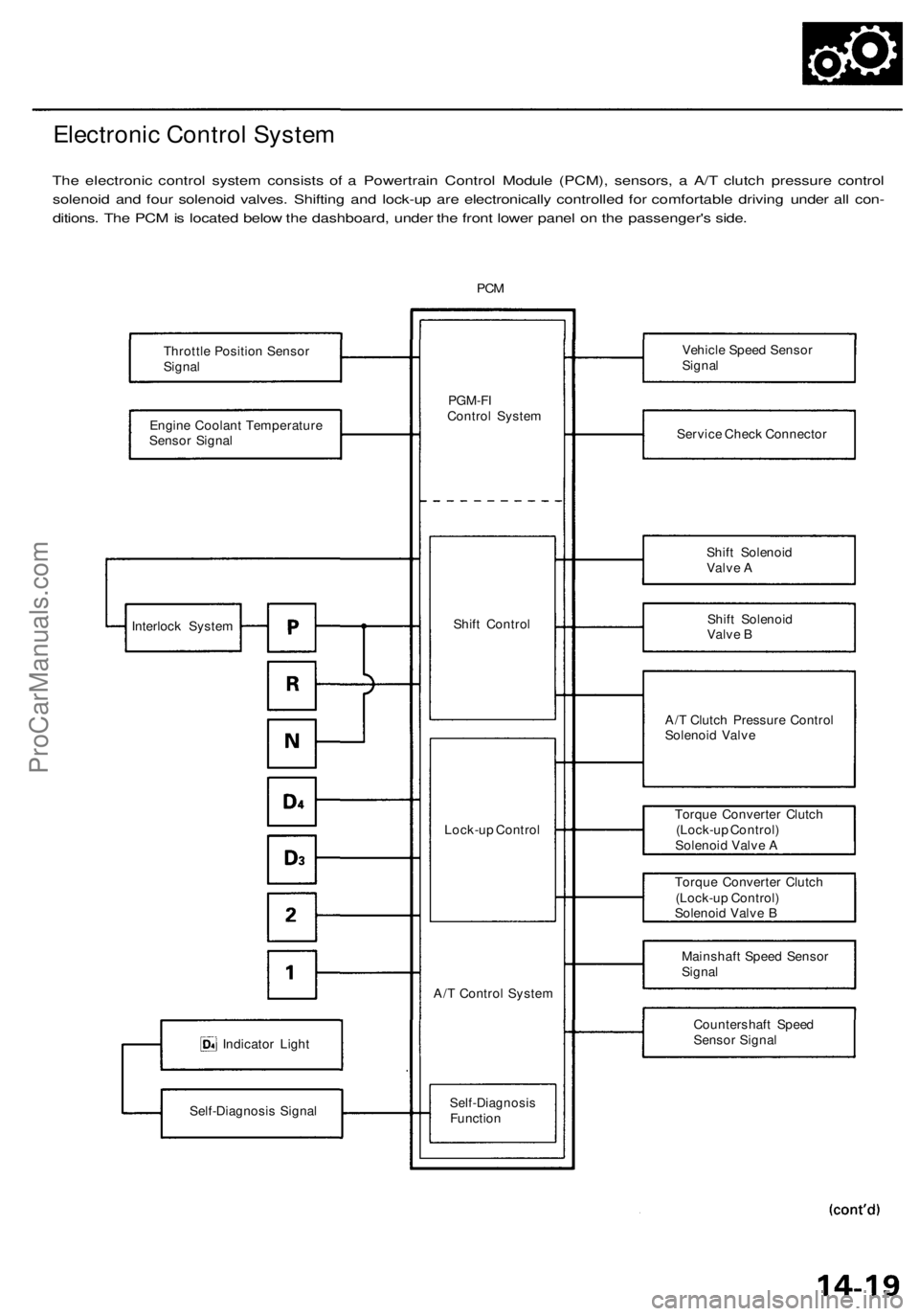

Electronic Control System

The electronic control system consists of a Powertrain Control Module (PCM), sensors, a A/T clutch pressure control

solenoid and four solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all con-

ditions. The PCM is located below the dashboard, under the front lower panel on the passenger's side.

PCM

Throttle Position Sensor

Signal

Engine Coolant Temperature

Sensor Signal

Indicator Light

Self-Diagnosis Signal

PGM-FI

Control System

Shift Control

Lock-up Control

A/T Control System

Self-Diagnosis

Function

Vehicle Speed Sensor

Signal

Service Check Connector

Shift Solenoid

Valve A

Shift Solenoid

Valve B

A/T Clutch Pressure Control

Solenoid Valve

Torque Converter Clutch

(Lock-up Control)

Solenoid Valve A

Torque Converter Clutch

(Lock-up Control)

Solenoid Valve B

Mainshaft Speed Sensor

Signal

Countershaft Speed

Sensor Signal

Interlock SystemProCarManuals.com

Page 802 of 1954

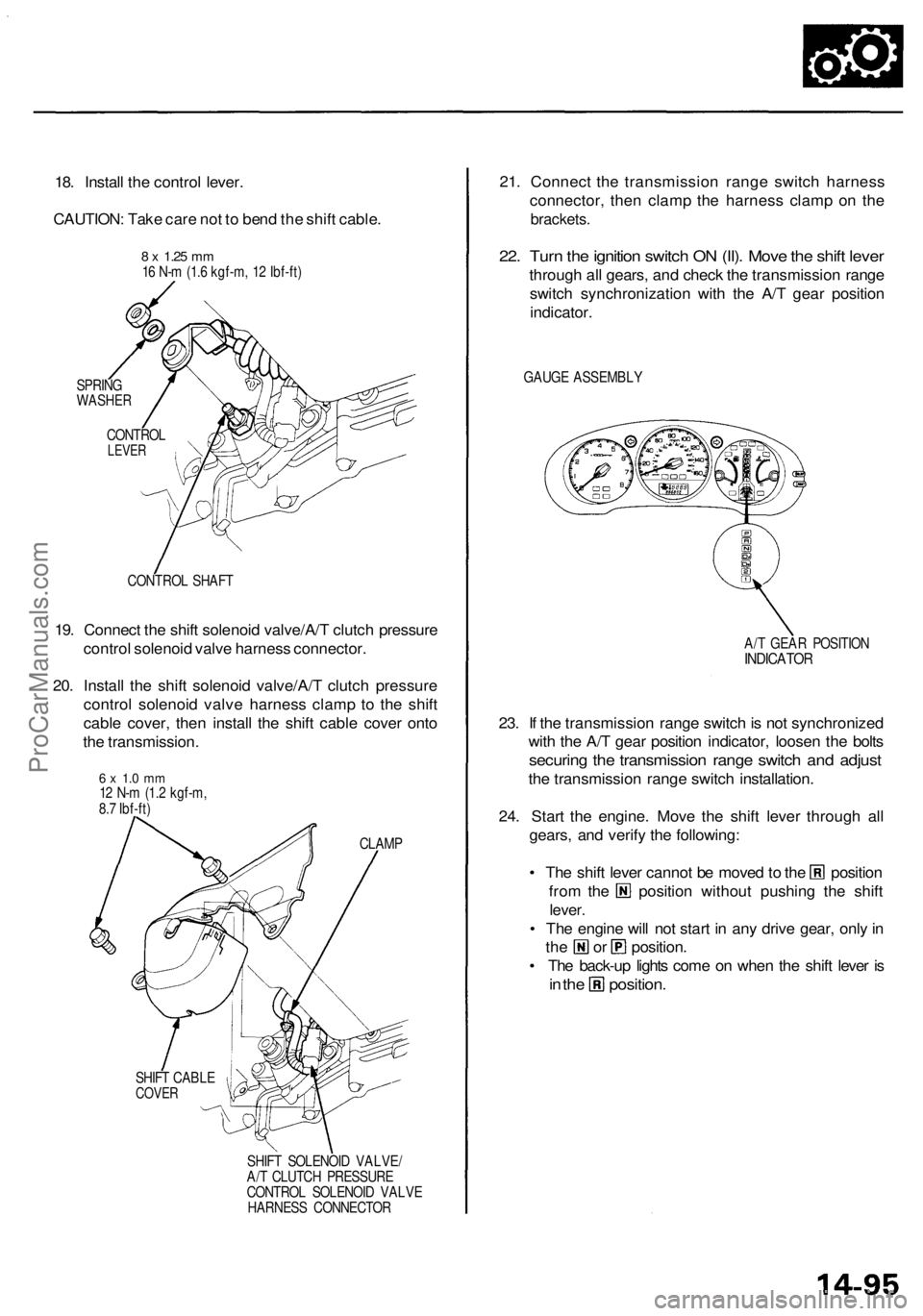

18. Install the control lever.

CAUTION: Take care not to bend the shift cable.

SPRING

WASHER

CONTROL SHAFT

19. Connect the shift solenoid valve/A/T clutch pressure

control solenoid valve harness connector.

20. Install the shift solenoid valve/A/T clutch pressure

control solenoid valve harness clamp to the shift

cable cover, then install the shift cable cover onto

the transmission.

CLAMP

SHIFT CABLE

COVER

SHIFT SOLENOID VALVE/

A/T CLUTCH PRESSURE

CONTROL SOLENOID VALVE

HARNESS CONNECTOR

21. Connect the transmission range switch harness

connector, then clamp the harness clamp on the

brackets.

22. Turn the ignition switch ON (II). Move the shift lever

through all gears, and check the transmission range

switch synchronization with the A/T gear position

indicator.

GAUGE ASSEMBLY

A/T GEAR POSITION

INDICATOR

23. If the transmission range switch is not synchronized

with the A/T gear position indicator, loosen the bolts

securing the transmission range switch and adjust

the transmission range switch installation.

24. Start the engine. Move the shift lever through all

gears, and verify the following:

• The shift lever cannot be moved to the position

from the position without pushing the shift

lever.

• The engine will not start in any drive gear, only in

the or position.

• The back-up lights come on when the shift lever is

in the position.

8 x

1.25

mm

16 N-m (1.6 kgf-m, 12 Ibf-ft)

CONTROL

LEVER

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)ProCarManuals.com

Page 1051 of 1954

Inspection and Adjustment

Brake Pedal

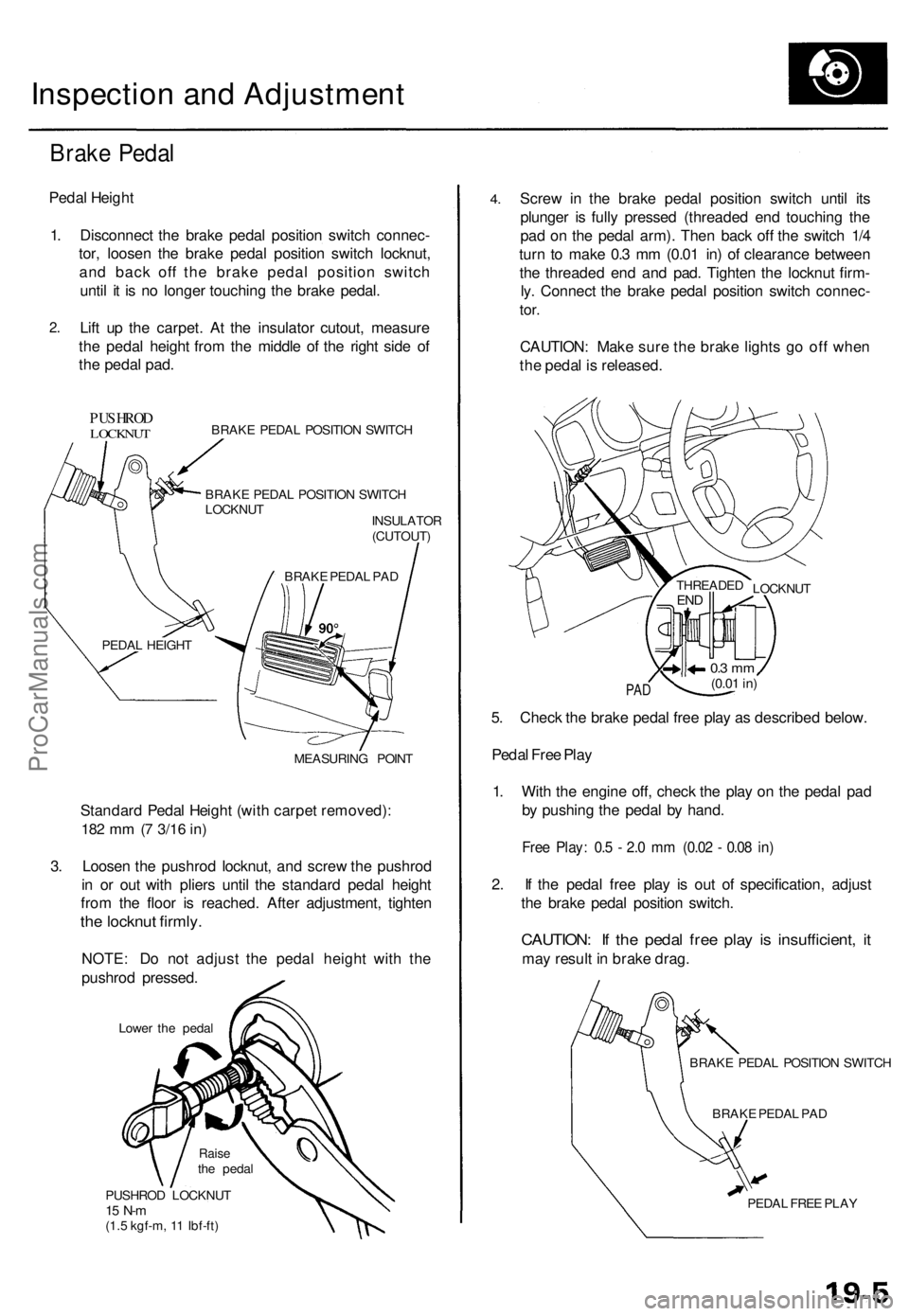

Pedal Height

1. Disconnect the brake pedal position switch connec-

tor, loosen the brake pedal position switch locknut,

and back off the brake pedal position switch

until it is no longer touching the brake pedal.

2.

Lift up the carpet. At the insulator cutout, measure

the pedal height from the middle of the right side of

the pedal pad.

PUSHROD

LOCKNUT

BRAKE PEDAL POSITION SWITCH

BRAKE PEDAL POSITION SWITCH

LOCKNUT

INSULATOR

(CUTOUT)

MEASURING POINT

Standard Pedal Height (with carpet removed):

182 mm (7

3/16

in)

3. Loosen the pushrod locknut, and screw the pushrod

in or out with pliers until the standard pedal height

from the floor is reached. After adjustment, tighten

the locknut firmly.

NOTE: Do not adjust the pedal height with the

pushrod pressed.

Lower the pedal

PUSHROD LOCKNUT

15 N-m

(1.5 kgf-m, 11 Ibf-ft)

4.

Screw in the brake pedal position switch until its

plunger is fully pressed (threaded end touching the

pad on the pedal arm). Then back off the switch 1/4

turn to make 0.3 mm (0.01 in) of clearance between

the threaded end and pad. Tighten the locknut firm-

ly. Connect the brake pedal position switch connec-

tor.

CAUTION: Make sure the brake lights go off when

the pedal is released.

PAD

5. Check the brake pedal free play as described below.

Pedal Free Play

1. With the engine off, check the play on the pedal pad

by pushing the pedal by hand.

Free Play: 0.5 - 2.0 mm (0.02 - 0.08 in)

2. If the pedal free play is out of specification, adjust

the brake pedal position switch.

CAUTION: If the pedal free play is insufficient, it

may result in brake drag.

BRAKE PEDAL POSITION SWITCH

BRAKE PEDAL PAD

PEDAL FREE PLAY

LOCKNUT

THREADED

END

0.3 mm

(0.01

in)

BRAKE PEDAL PAD

PEDAL HEIGHT

Raise

the pedalProCarManuals.com

Page 1084 of 1954

Troubleshooting Precautions

ABS Indicator Light:

The ABS indicator light comes on for 3 seconds and then goes off when the control unit detects no problem during the ini-

tial diagnosis right after the engine starts. However, the ABS indicator light can stay on for up to 40 seconds when the

control unit starts to check for pump overrun, etc. during the initial diagnosis. The ABS indicator light comes on, and the

ABS control unit memorizes the diagnostic trouble code (DTC) under certain conditions.

The parking brake is applied for more than 30 seconds while the vehicle is being driven. (DTC 2-1)

The transmission downshifted excessively. (DTC 4-1, 4-2)

The vehicle loses traction, and the front wheels spin for more than 1 minute when starting from a stuck condition on a

muddy, snowy, or sandy road. (DTC 4-8)

Tire adhesion is lost due to excessive cornering speed. (DTC 5, 5-4, 5-8)

The vehicle is driven on an extremely rough road. (DTC 8-1)

The vehicle is interfered by strong radio waves (noise), for example, illegal radio, etc. (DTC 8-2)

NOTE: If there is any trouble in the system, the ABS indicator light comes on during driving.

Diagnostic Trouble Code (DTC):

When the control unit detects a problem and the ABS indicator light comes on, the control unit memorizes the DTC.

The control unit has three memory registers. When a problem occurs, the control unit stores the DTC in the first memory

register. If another problem occurs, or the same problem occurs again, the control unit moves the first DTC to the next

memory register, and stores the second DTC in the first register. If there's a third problem occurrence, the two existing

DTCs are moved up one register, and the third DTC is stored in the first register. If problems continue to occur, the oldest

problem is moved out of the last register and lost, and the most recent problem is stored in the first register. When the

same problem occurs three times, the same DTC is stored in all memory registers. (Refer to the Symptom-to-System

Chart for diagnostic period.)

The most recent DTC is indicated first, and the oldest DTC is indicated last.

The DTCs are erased from the control unit when the ABS control unit +B2 power supply or connector is disconnected.

The control unit's memory can be erased by disconnecting the ABS B2 fuse for more than 3 seconds.

Self-diagnosis:

There are three self-diagnoses described below.

Initial diagnosis: Performed right after the engine starts until the ABS indicator light goes off.

Regular diagnosis: Continuously performed (under some conditions) after the ABS indicator light goes off until the

engine stops.

Individual part/system diagnosis: Diagnosis about a specific part/system under its operating conditions.

The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

Turns the ABS indicator light ON.

Turns the front and rear fail-safe relays off.

Stops the ABS control.

Stops the ABS pump. (The pump may work under some conditions.)

After the DTC is stored in the control unit, the CPU stops self-diagnosis.ProCarManuals.com

Page 1087 of 1954

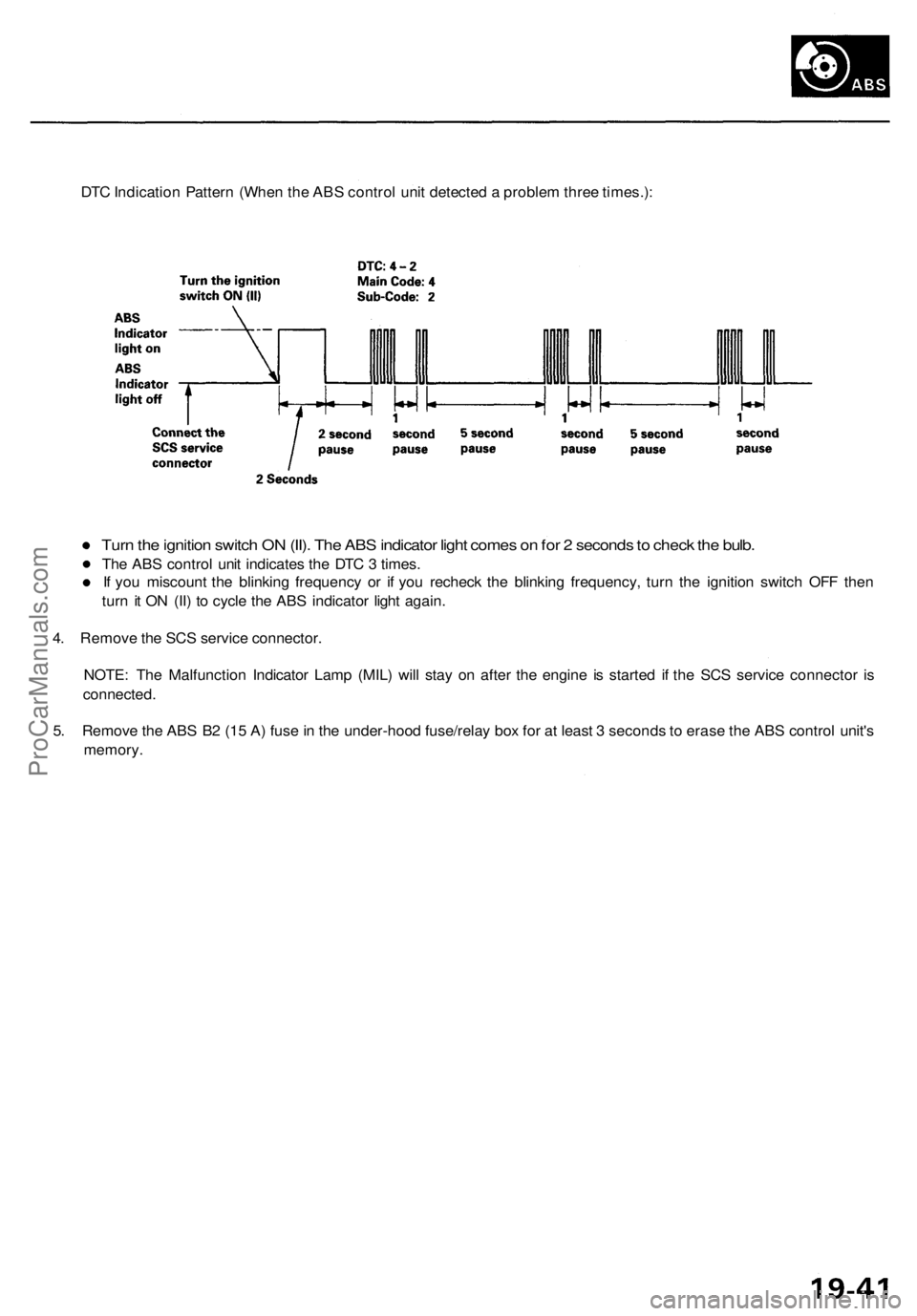

DTC Indication Pattern (When the ABS control unit detected a problem three times.):

Turn the ignition switch ON (II). The ABS indicator light comes on for 2 seconds to check the bulb.

The ABS control unit indicates the DTC 3 times.

If you miscount the blinking frequency or if you recheck the blinking frequency, turn the ignition switch OFF then

turn it ON (II) to cycle the ABS indicator light again.

4. Remove the SCS service connector.

NOTE: The Malfunction Indicator Lamp (MIL) will stay on after the engine is started if the SCS service connector is

connected.

5. Remove the ABS B2 (15 A) fuse in the under-hood fuse/relay box for at least 3 seconds to erase the ABS control unit's

memory.ProCarManuals.com

Page 1091 of 1954

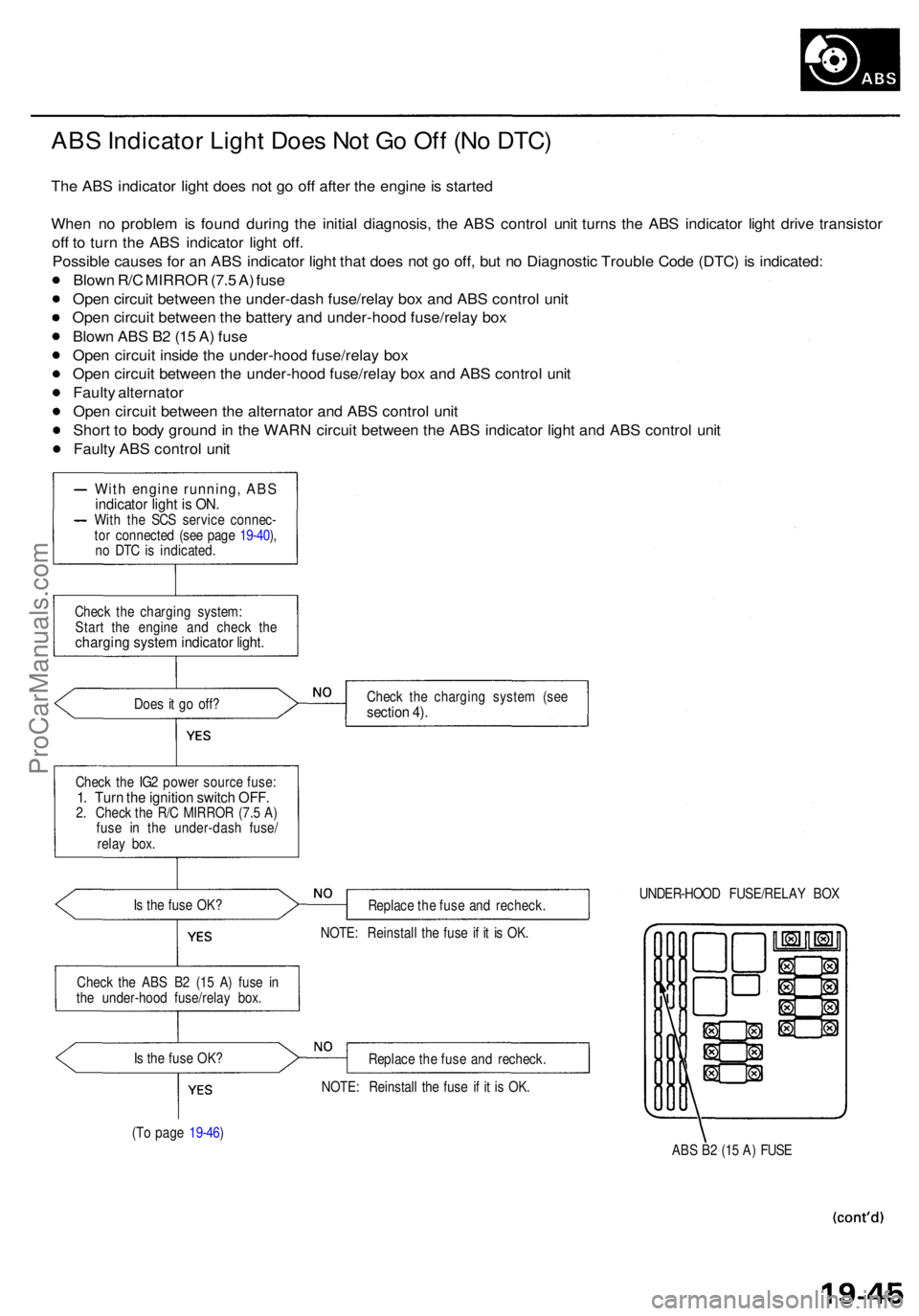

ABS Indicato r Ligh t Doe s No t G o Of f (N o DTC )

The AB S indicato r ligh t doe s no t g o of f afte r th e engine is starte d

Whe n n o proble m is foun d durin g th e initia l diagnosis , th e AB S contro l uni t turn s th e AB S indicato r ligh t driv e transisto r

of f t o tur n th e AB S indicato r ligh t off .

Possibl e cause s fo r a n AB S indicato r ligh t tha t doe s no t g o off , bu t n o Diagnosti c Troubl e Cod e (DTC ) i s indicated :

Blow n R/ C MIRRO R (7. 5 A ) fus e

Ope n circui t betwee n th e under-das h fuse/rela y bo x an d AB S contro l uni t

Ope n circui t betwee n th e batter y an d under-hoo d fuse/rela y bo x

Blow n AB S B 2 (1 5 A ) fus e

Ope n circui t insid e th e under-hoo d fuse/rela y bo x

Ope n circui t betwee n th e under-hoo d fuse/rela y bo x an d AB S contro l uni t

Fault y alternato r

Ope n circui t betwee n th e alternato r an d AB S contro l uni t

Shor t t o bod y groun d in th e WAR N circui t betwee n th e AB S indicator light an d AB S contro l uni t

Fault y AB S contro l uni t

Wit h engin e running , AB Sindicato r ligh t i s ON .With th e SC S servic e connec -

to r connecte d (se e pag e 19-40 ),

n o DT C is indicated .

Chec k th e chargin g system :

Star t th e engin e an d chec k th e

chargin g syste m indicato r light .

Does i t g o off ?

Chec k th e IG 2 powe r sourc e fuse :

1. Tur n th e ignitio n switc h OFF .2. Chec k th e R/ C MIRRO R (7. 5 A )

fus e i n th e under-das h fuse /

rela y box .

I s th e fus e OK ?

Chec k th e AB S B 2 (1 5 A ) fus e i n

th e under-hoo d fuse/rela y box .

I s th e fus e OK ?

(T o pag e 19-46 ) Chec

k th e chargin g syste m (se e

sectio n 4) .

Replac e th e fus e an d recheck . UNDER-HOO

D FUSE/RELA Y BO X

NOTE : Reinstal l th e fus e i f i t i s OK .

Replac e th e fus e an d recheck .

NOTE : Reinstal l th e fus e i f i t i s OK .

ABS B 2 (1 5 A ) FUS E

ProCarManuals.com

Page 1196 of 1954

TCS CONTROL UNIT 20P CONNECTOR

Wire side of female terminals

VB: Battery Voltage

Terminal

number

1

2

4

5

6

9

10

11

12

13

14

15

16

17

20

Wire

color

BLK/YEL

GRN/RED

BLU

PNK/BLU

BLK/WHT

BLK

BRN/WHT

GRN/WHT

BLU

GRN/ORN

BLK/ORN

BRN/BLK

WHT/BLU

BLU/GRY

GRN

BRN

Terminal sign

(Terminal name)

IG1

(Ignition 1)

PARK

(Parking)

SCS

(Service check

signal)

STR-GND

(Steering ground)

AT-SHIFT

(AT shift)

FSR

(Fail-safe relay)

PMG

(Power motor

Ground)

VPM

(Voltage power

motor)

STOP

(Stop)

NEP (Engine

speed pulse)

BARO

(Barometric)

TC-FC

(Traction control

fuel cut)

LG2

(Logic ground 2)

STR-VCC (Steer-

ing power supply)

WARN2

(Warning 2)

SH-MOT

(Shield motor)

MOT +

(Motor +)

MOT-

(Motor -)

Description

Detects ignition switch

IG1 signal

Detects parking brake

switch signal

Detects service check

connector signal

(Diagnostic trouble

code indication)

Ground for the steering

angle sensor

Detects A/T shift posi-

tion signal

Drives fail-safe relay

Power ground for the

TCS control valve

actuator motor

Power source for the

TCS control valve

actuator motor

Detects brake pedal

position switch signal

Detects engine speed

signal

Detects barometric

sensor signal

TCS Fl, Fuel cut

(torque down) signal

Ground for the logic

circuit

Power source for the

steering angle sensor

Drives TCS indicator light

(The indicator light comes

on by the self-bias)

Shield for the TCS con-

trol valve actuator motor

Drives TCS control

valve actuator motor

Drives TCS control

valve actuator motor

Measurement

terminals

1-GND

2

3-GND

4-GND

5-GND

6-GND

9-GND

10-GND

11-GND

12-GND

13-GND

14-GND

15-GND

16-GND

17-GND

19-20

20-19

Voltage

Conditions

(Ignition Switch ON (II))

Depress the parking

brake pedal.

Release the parking

brake pedal.

SCS service connector

connected.

SCS service connector

disconnected.

Shift the transmission

to position, then

start the engine.

Start the engine.

Start the engine.

Brake pedal depressed.

Brake pedal released.

Engine idling

TCS is functioning,

(maximum fuel cut)

TCS is not functioning.

Indicator light ON

Indicator light OFF

TCS is functioning.

TCS is not functioning.

TCS is functioning.

TCS is not functioning.

Output

voltage

VB

Below 0.6 V

VB

0V

5V

Below 0.3V

About 4V

(5V 0V)

VB

1.5V

Below 0.3 V

0V

VB

VB

0V

About 6V

(12V

0V)

About 3 V

About 1.5V

About 4.5 V

(5 V,

PWM)

Below 0.3V

About 5 V

About 2 V

VB

VB

0V

VB

0VProCarManuals.com

Page 1212 of 1954

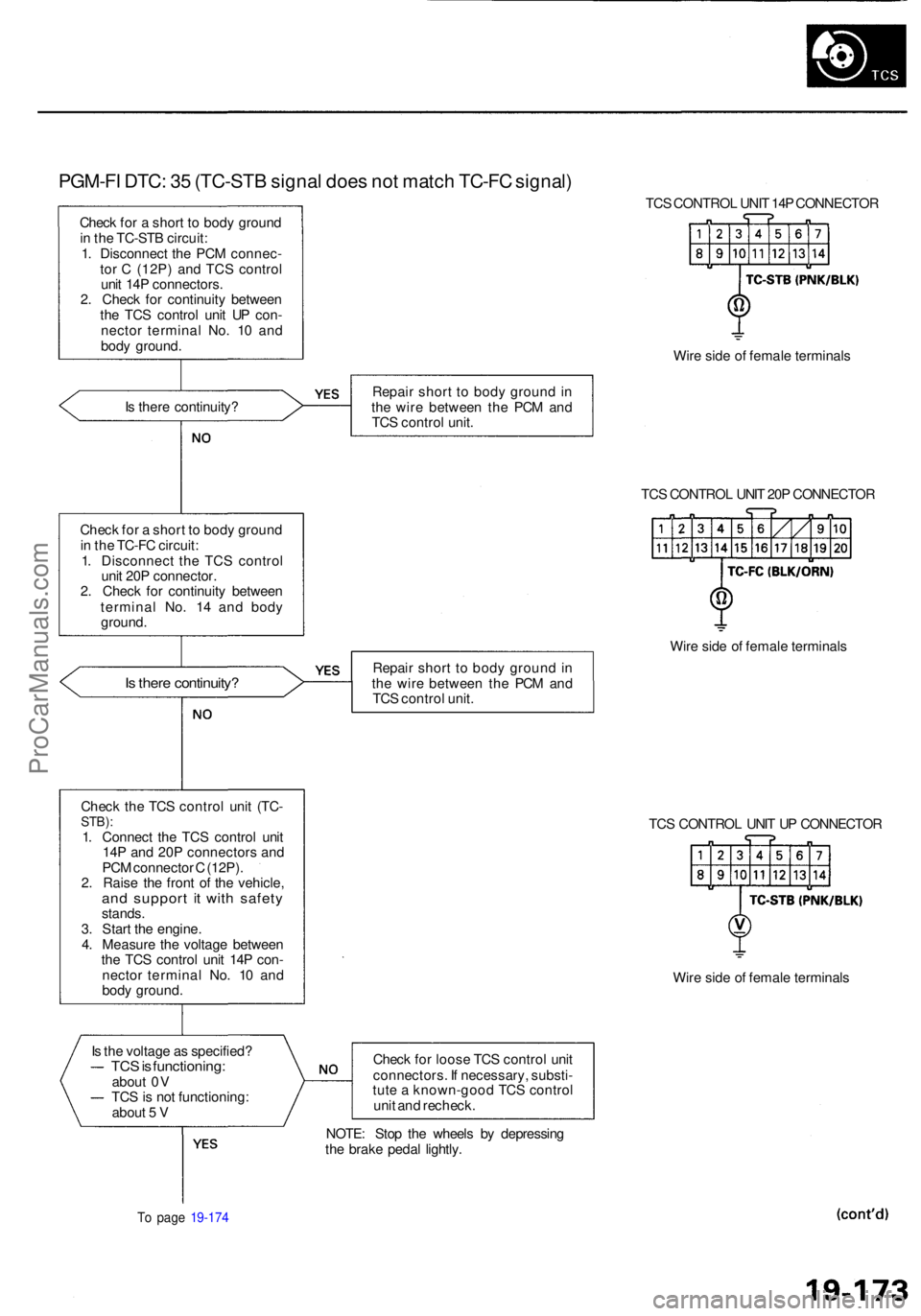

PGM-FI DTC : 3 5 (TC-ST B signa l doe s no t matc h TC-F C signal )

Check fo r a shor t t o bod y groun d

i n th e TC-ST B circuit :

1 . Disconnec t th e PC M connec -

to r C (12P ) an d TC S contro l

uni t 14 P connectors .

2 . Chec k fo r continuit y betwee n

th e TC S contro l uni t U P con -

necto r termina l No . 1 0 an d

bod y ground . TC

S CONTRO L UNI T 14 P CONNECTO R

Wir e sid e o f femal e terminal s

I s ther e continuity ? Repai

r shor t t o bod y groun d in

th e wir e betwee n th e PC M an d

TC S contro l unit .

TCS CONTRO L UNI T 20 P CONNECTO R

Chec k fo r a shor t t o bod y groun d

i n th e TC-F C circuit :

1 . Disconnec t th e TC S contro l

uni t 20 P connector .

2 . Chec k fo r continuit y betwee n

termina l No . 1 4 an d bod y

ground .

Is ther e continuity ?Repair shor t t o bod y groun d in

th e wir e betwee n th e PC M an d

TC S contro l unit . Wir

e sid e o f femal e terminal s

Chec k th e TC S contro l uni t (TC -

STB) :1. Connec t th e TC S contro l uni t

14 P an d 20 P connector s an d

PC M connecto r C (12P) .

2 . Rais e th e fron t o f th e vehicle ,

and suppor t i t wit h safet ystands.

3 . Star t th e engine .

4 . Measur e th e voltag e betwee n

th e TC S contro l uni t 14 P con -

necto r termina l No . 1 0 an d

bod y ground . TC

S CONTRO L UNI T U P CONNECTO R

Wir e sid e o f femal e terminal s

I s th e voltag e a s specified ?

TCS is functioning :about 0 V

TC S is no t functioning :

abou t 5 V Chec

k fo r loos e TC S contro l uni t

connectors . I f necessary , substi -

tut e a known-goo d TC S contro l

uni t an d recheck .

To pag e 19-17 4

NOTE : Sto p th e wheel s b y depressin g

th e brak e peda l lightly .

ProCarManuals.com