low oil pressure ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 149 of 1954

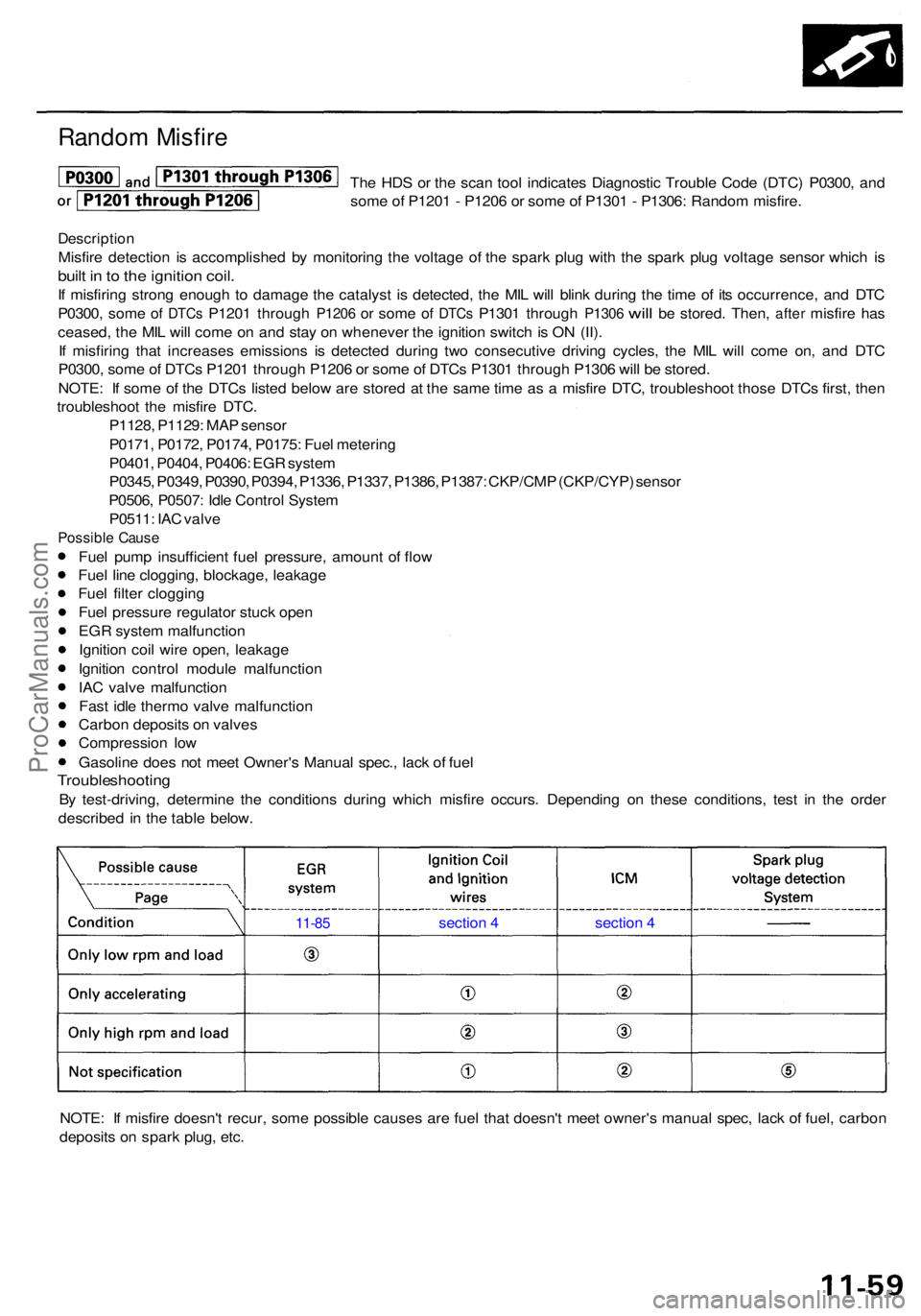

Random Misfir e

The HD S o r th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0300 , an d

som e o f P120 1 - P120 6 o r som e o f P130 1 - P1306 : Rando m misfire .

Descriptio n

Misfire detectio n i s accomplishe d b y monitorin g th e voltag e o f th e spar k plu g wit h th e spar k plu g voltag e senso r whic h i s

buil t i n to th e ignitio n coil .

If misfirin g stron g enoug h t o damag e th e catalys t i s detected , th e MI L wil l blin k durin g th e tim e o f it s occurrence , an d DT C

P0300 , som e

of DTC s P120 1 throug h P1206 or som e of DTC s P130 1 throug h P1306 will be stored . Then , after misfir e has

ceased , th e MI L wil l com e o n an d sta y o n wheneve r th e ignitio n switc h is O N (II) .

I f misfirin g tha t increase s emission s i s detecte d during two consecutiv e drivin g cycles , th e MI L wil l com e on , an d DT C

P0300 , som e o f DTC s P120 1 throug h P120 6 o r som e o f DTC s P130 1 throug h P130 6 wil l b e stored .

NOTE : I f som e o f th e DTC s liste d belo w ar e store d a t th e sam e tim e a s a misfir e DTC , troubleshoo t thos e DTC s first , the n

troubleshoo t th e misfir e DTC .

P1128 , P1129 : MA P senso r

P0171 , P0172 , P0174 , P0175 : Fue l meterin g

P0401 , P0404 , P0406 : EG R syste m

P0345 , P0349 , P0390 , P0394 , P1336 , P1337 , P1386 , P1387 : CKP/CM P (CKP/CYP ) senso r

P0506 , P0507 : Idl e Contro l Syste m

P0511 : IA C valv e

Possibl e Caus e

Fuel pum p insufficien t fue l pressure , amoun t o f flo w

Fue l lin e clogging , blockage , leakag e

Fue l filte r cloggin g

Fue l pressur e regulato r stuc k ope n

EG R syste m malfunctio n

Ignitio n coi l wir e open , leakag e

Ignitio n contro l modul e malfunctio n

IA C valv e malfunctio n

Fas t idl e therm o valv e malfunctio n

Carbo n deposit s o n valve s

Compressio n lo w

Gasolin e doe s no t mee t Owner' s Manua l spec. , lac k o f fue l

Troubleshootin g

By test-driving , determin e th e condition s during which misfir e occurs . Dependin g o n thes e conditions , tes t i n th e orde r

describe d i n th e tabl e below .

NOTE : I f misfir e doesn' t recur , som e possibl e cause s ar e fue l tha t doesn' t mee t owner' s manua l spec , lac k o f fuel , carbo n

deposit s o n spar k plug , etc .

11-8 5 sectio n 4 section 4

ProCarManuals.com

Page 492 of 1954

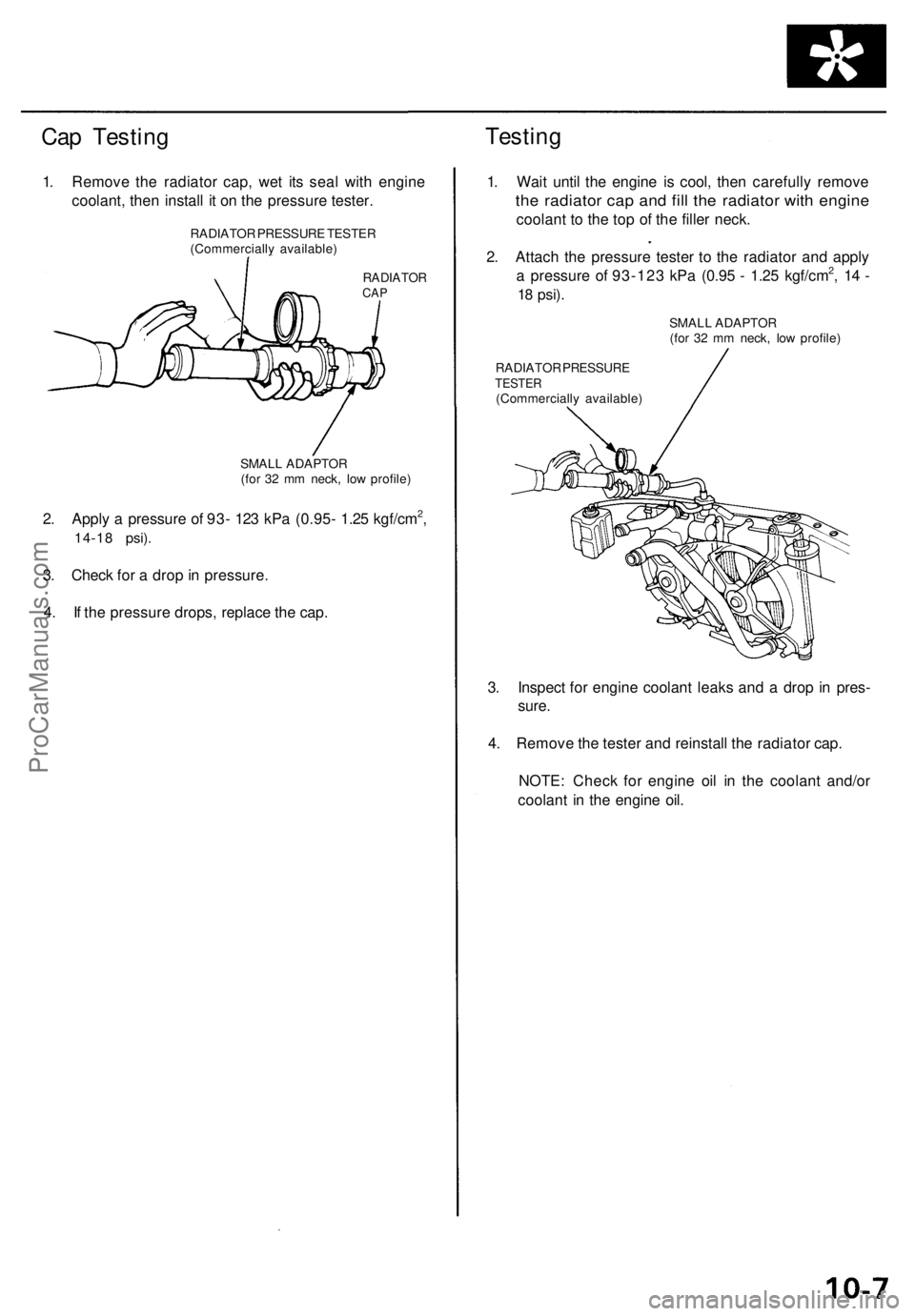

Cap Testing

Testing

1. Remove the radiator cap, wet its seal with engine

coolant, then install it on the pressure tester.

RADIATOR

CAP

2. Apply a pressure of 93- 123 kPa (0.95- 1.25 kgf/cm2,

14-18 psi).

3. Check for a drop in pressure.

4. If the pressure drops, replace the cap.

1. Wait until the engine is cool, then carefully remove

the radiator cap and fill the radiator with engine

coolant to the top of the filler neck.

2. Attach the pressure tester to the radiator and apply

a pressure of 93-123 kPa (0.95 - 1.25 kgf/cm2, 14 -

18

psi).

RADIATOR PRESSURE

TESTER

(Commercially available)

3. Inspect for engine coolant leaks and a drop in pres-

sure.

4. Remove the tester and reinstall the radiator cap.

NOTE: Check for engine oil in the coolant and/or

coolant in the engine oil.

RADIATOR PRESSURE TESTER

(Commercially available)

SMALL ADAPTOR

(for 32 mm neck, low profile)

SMALL ADAPTOR

(for 32 mm neck, low profile)ProCarManuals.com

Page 599 of 1954

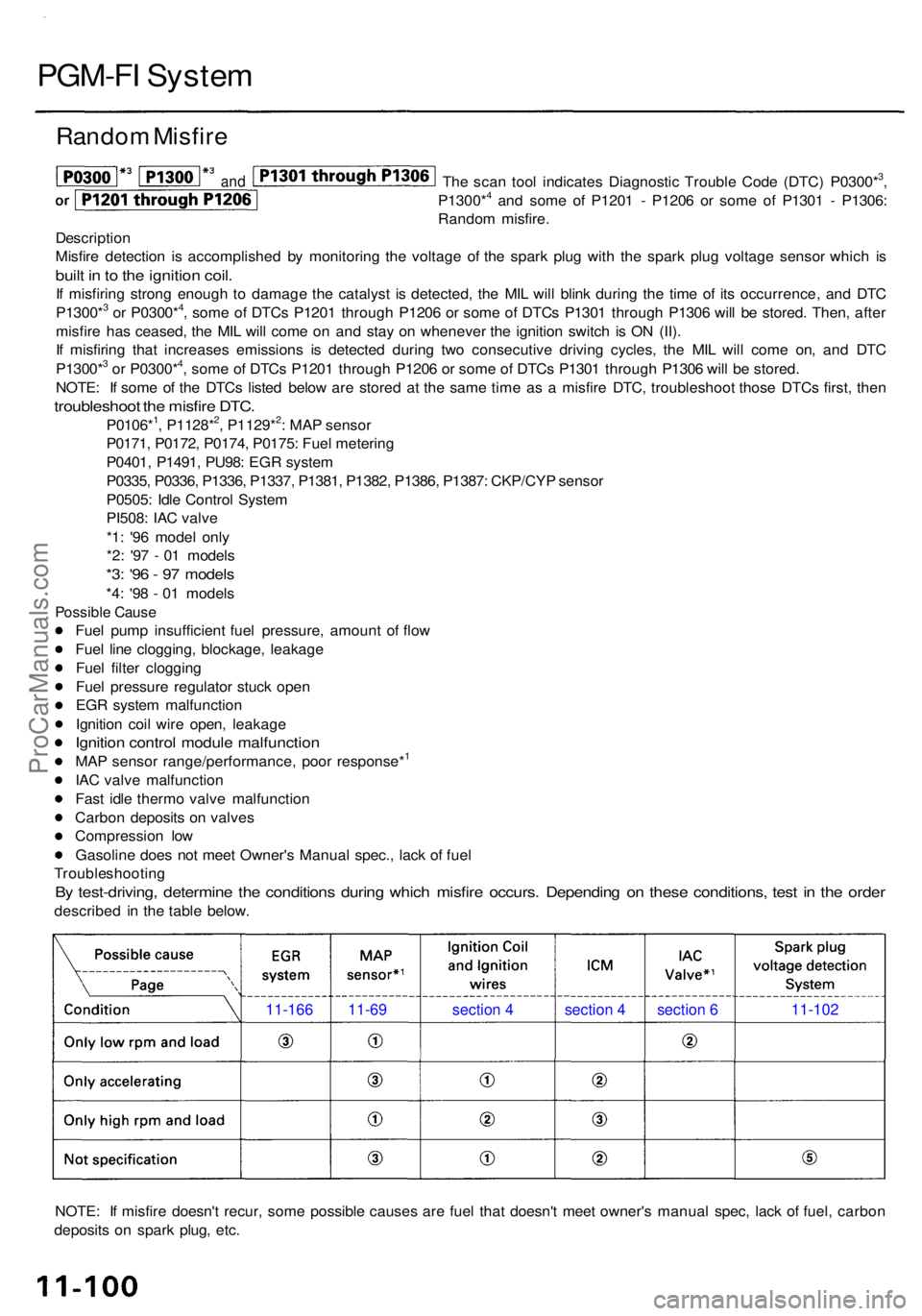

PGM-FI Syste m

Rando m Misfir e

The sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0300*3,

P1300*4 an d som e o f P120 1 - P120 6 o r som e o f P130 1 - P1306 :

Rando m misfire .

Descriptio n

Misfir e detectio n i s accomplishe d b y monitorin g th e voltag e o f th e spar k plu g wit h th e spar k plu g voltag e senso r whic h i s

buil t i n to th e ignitio n coil .

If misfirin g stron g enoug h t o damag e th e catalys t i s detected , th e MI L wil l blin k durin g th e tim e o f it s occurrence , an d DT C

P1300*3 o r P0300*4, som e o f DTC s P120 1 throug h P120 6 o r som e o f DTC s P130 1 throug h P130 6 wil l b e stored . Then , afte r

misfir e ha s ceased , th e MI L wil l com e o n an d sta y o n wheneve r th e ignitio n switc h i s O N (II) .

I f misfirin g tha t increase s emission s i s detecte d durin g tw o consecutiv e drivin g cycles , th e MI L wil l com e on , an d DT C

P1300*

3 o r P0300*4, som e o f DTC s P120 1 throug h P120 6 o r som e o f DTC s P130 1 throug h P130 6 wil l b e stored .

NOTE : I f som e o f th e DTC s liste d belo w ar e store d a t th e sam e tim e a s a misfir e DTC , troubleshoo t thos e DTC s first , the n

troubleshoo t th e misfir e DTC .

P0106*1, P1128*2, P1129*2: MA P senso r

P0171 , P0172 , P0174 , P0175 : Fue l meterin g

P0401 , P1491 , PU98 : EG R syste m

P0335 , P0336 , P1336 , P1337 , P1381 , P1382 , P1386 , P1387 : CKP/CY P senso r

P0505 : Idl e Contro l Syste m

PI508 : IA C valv e

*1 : '9 6 mode l onl y

*2 : '9 7 - 0 1 model s

*3: '9 6 - 9 7 model s

*4: '9 8 - 0 1 model s

Possibl e Caus e

Fuel pum p insufficien t fue l pressure , amoun t o f flo w

Fue l lin e clogging , blockage , leakag e

Fue l filte r cloggin g

Fue l pressur e regulato r stuc k ope n

EG R syste m malfunctio n

Ignitio n coi l wir e open , leakag e

Ignition contro l modul e malfunction

MA P senso r range/performance , poo r response*1

IA C valv e malfunctio n

Fas t idl e therm o valv e malfunctio n

Carbo n deposit s o n valve s

Compressio n lo w

Gasolin e doe s no t mee t Owner' s Manua l spec. , lac k o f fue l

Troubleshootin g

By test-driving , determin e th e condition s durin g whic h misfir e occurs . Dependin g o n thes e conditions , tes t i n th e orde r

describe d i n th e tabl e below .

NOTE : I f misfir e doesn' t recur , som e possibl e cause s ar e fue l tha t doesn' t mee t owner' s manua l spec , lac k o f fuel , carbo n

deposit s o n spar k plug , etc .

11-166 11-69 section 4 section 4 section 6 11-102

and

ProCarManuals.com

Page 1488 of 1954

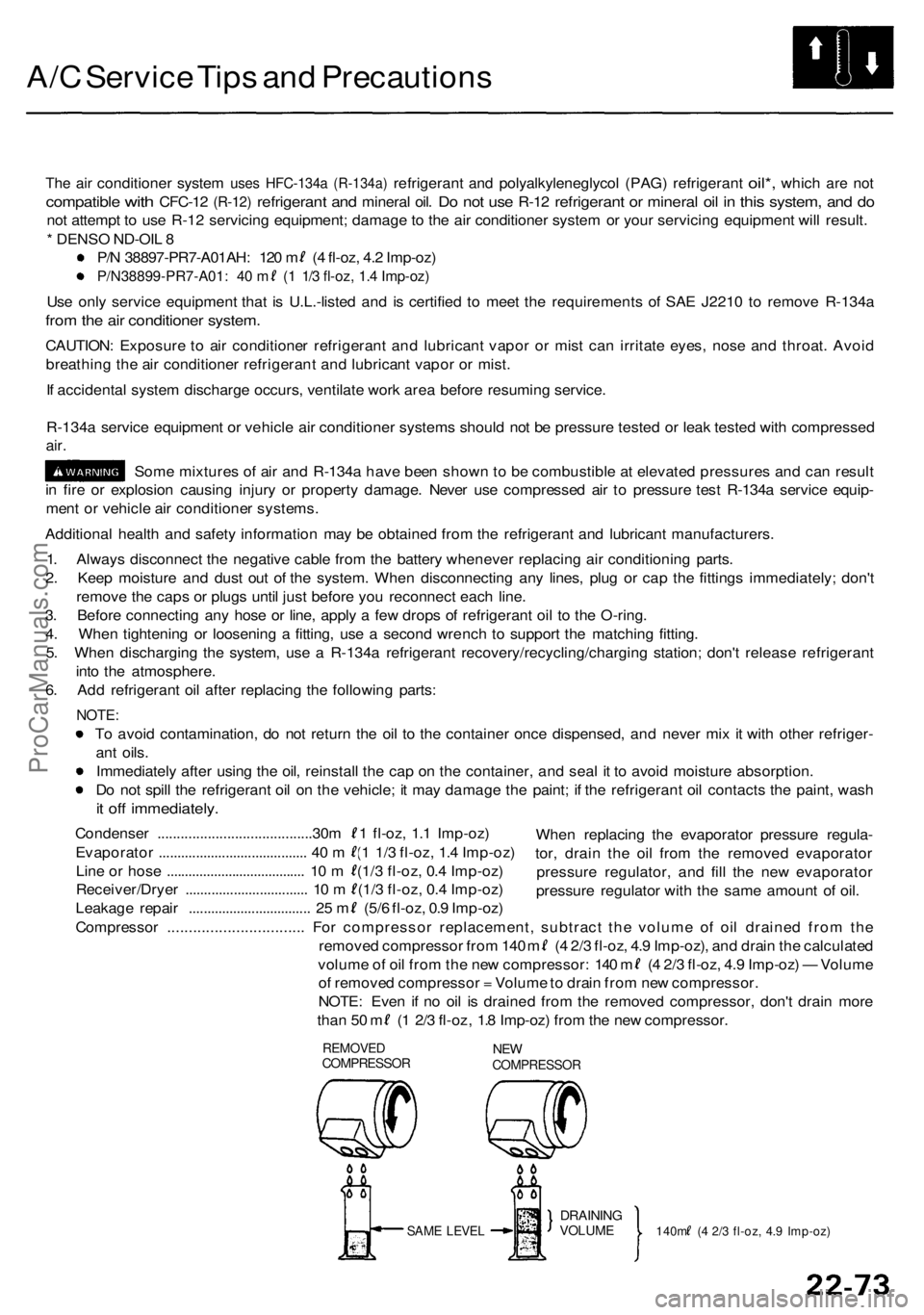

A/C Servic e Tip s an d Precaution s

The ai r conditione r syste m uses HFC-134 a (R-134a) refrigeran t and polyalkyleneglyco l (PAG ) refrigeran t oil*, whic h are no t

compatibl e with CFC-1 2 (R-12) refrigeran t and minera l oil . Do no t us e R-1 2 refrigeran t or minera l oil i n thi s system , and d o

no t attemp t t o us e R-1 2 servicin g equipment ; damag e to th e ai r conditione r syste m o r you r servicin g equipmen t wil l result .

* DENS O ND-OI L 8

P/ N 38897-PR7-A01AH : 12 0 m ( 4 fl-oz , 4. 2 Imp-oz )

P/N38899-PR7-A01 : 4 0 m ( 1 1/ 3 fl-oz , 1. 4 Imp-oz )

Use onl y servic e equipmen t tha t i s U.L.-liste d an d i s certifie d t o mee t th e requirement s o f SA E J221 0 t o remov e R-134 a

from th e ai r conditione r system .

CAUTION : Exposur e t o ai r conditione r refrigeran t an d lubrican t vapo r o r mis t ca n irritat e eyes , nos e an d throat . Avoi d

breathin g th e ai r conditione r refrigeran t an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k are a befor e resumin g service .

R-134 a servic e equipmen t o r vehicl e ai r conditione r system s shoul d no t b e pressur e teste d o r lea k teste d wit h compresse d

air.

Som e mixture s o f ai r an d R-134 a hav e bee n show n to b e combustibl e a t elevate d pressure s an d ca n resul t

i n fir e o r explosio n causin g injur y o r propert y damage . Neve r us e compresse d ai r t o pressur e tes t R-134 a servic e equip -

men t o r vehicl e ai r conditione r systems .

Additiona l healt h an d safet y informatio n ma y b e obtaine d fro m th e refrigeran t an d lubrican t manufacturers .

1 . Alway s disconnec t th e negativ e cabl e fro m th e batter y wheneve r replacin g ai r conditionin g parts .

2 . Kee p moistur e an d dus t ou t o f th e system . Whe n disconnectin g an y lines , plu g o r ca p th e fitting s immediately ; don' t

remov e th e cap s o r plug s unti l jus t befor e yo u reconnec t eac h line .

3 . Befor e connectin g an y hos e o r line , appl y a fe w drop s o f refrigeran t oi l t o th e O-ring .

4 . Whe n tightenin g o r loosenin g a fitting , us e a secon d wrenc h t o suppor t th e matchin g fitting .

5 . Whe n dischargin g th e system , us e a R-134 a refrigeran t recovery/recycling/chargin g station ; don' t releas e refrigeran t

int o th e atmosphere .

6 . Ad d refrigeran t oi l afte r replacin g th e followin g parts :

NOTE :

To avoi d contamination , d o no t retur n th e oi l t o th e containe r onc e dispensed , an d neve r mi x i t wit h othe r refriger -

an t oils .

Immediatel y afte r usin g th e oil , reinstal l th e ca p o n th e container , an d sea l i t t o avoi d moistur e absorption .

D o no t spil l th e refrigeran t oi l o n th e vehicle ; i t ma y damag e th e paint ; i f th e refrigeran t oi l contact s th e paint , was h

it of f immediately .

When replacin g th e evaporato r pressur e regula -

tor , drai n th e oi l fro m th e remove d evaporato r

pressur e regulator , an d fil l th e ne w evaporato r

pressur e regulato r wit h th e sam e amoun t o f oil .

Condense

r ........................................30 m ( 1 fl-oz , 1. 1 Imp-oz )

Evaporato r ....................................... . 4 0 m (1 1/ 3 fl-oz , 1. 4 Imp-oz )

Lin e o r hos e ..................................... . 1 0 m (1/ 3 fl-oz , 0. 4 Imp-oz )

Receiver/Drye r ................................ . 1 0 m (1/ 3 fl-oz , 0. 4 Imp-oz )

Leakage repai r ................................ . 2 5 m (5/ 6 fl-oz , 0. 9 Imp-oz )

Compresso r ............................... . Fo r compresso r replacement , subtrac t th e volum e o f oi l draine d fro m th e

remove d compresso r fro m 14 0 m ( 4 2/ 3 fl-oz , 4. 9 Imp-oz) , an d drai n th e calculate d

volume o f oi l fro m th e ne w compressor : 14 0 m ( 4 2/ 3 fl-oz , 4. 9 Imp-oz ) — Volum e

o f remove d compresso r = Volum e to drai n fro m ne w compressor .

NOTE : Eve n i f n o oi l i s draine d fro m th e remove d compressor , don' t drai n mor e

than 5 0 m ( 1 2/ 3 fl-oz , 1. 8 Imp-oz ) fro m th e ne w compressor .

REMOVEDCOMPRESSO RNEWCOMPRESSO R

SAME LEVE LDRAININ GVOLUME140m ( 4 2/ 3 fl-oz , 4. 9 Imp-oz )

ProCarManuals.com

Page 1490 of 1954

A/C System Service

Recovery

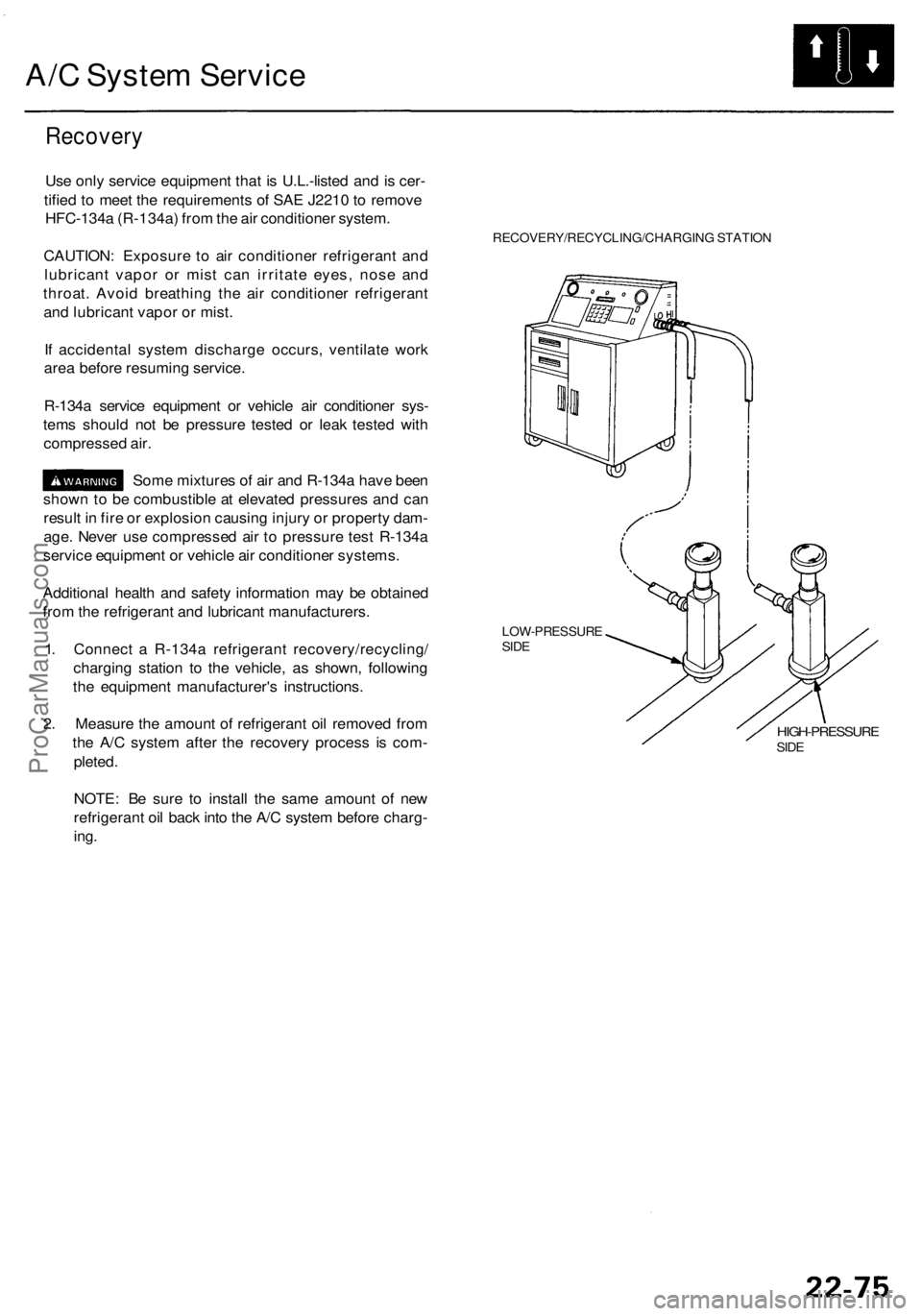

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritate eyes, nose and

throat. Avoid breathing the air conditioner refrigerant

and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have been

shown to be combustible at elevated pressures and can

result in fire or explosion causing injury or property dam-

age. Never use compressed air to pressure test R-134a

service equipment or vehicle air conditioner systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. Connect a R-134a refrigerant recovery/recycling/

charging station to the vehicle, as shown, following

the equipment manufacturer's instructions.

2. Measure the amount of refrigerant oil removed from

the A/C system after the recovery process is com-

pleted.

RECOVERY/RECYCLING/CHARGING STATION

LOW-PRESSURE

SIDE

HIGH-PRESSURE

SIDE

NOTE: Be sure to install the same amount of new

refrigerant oil back into the A/C system before charg-

ing.ProCarManuals.com

Page 1493 of 1954

A/C Syste m Servic e

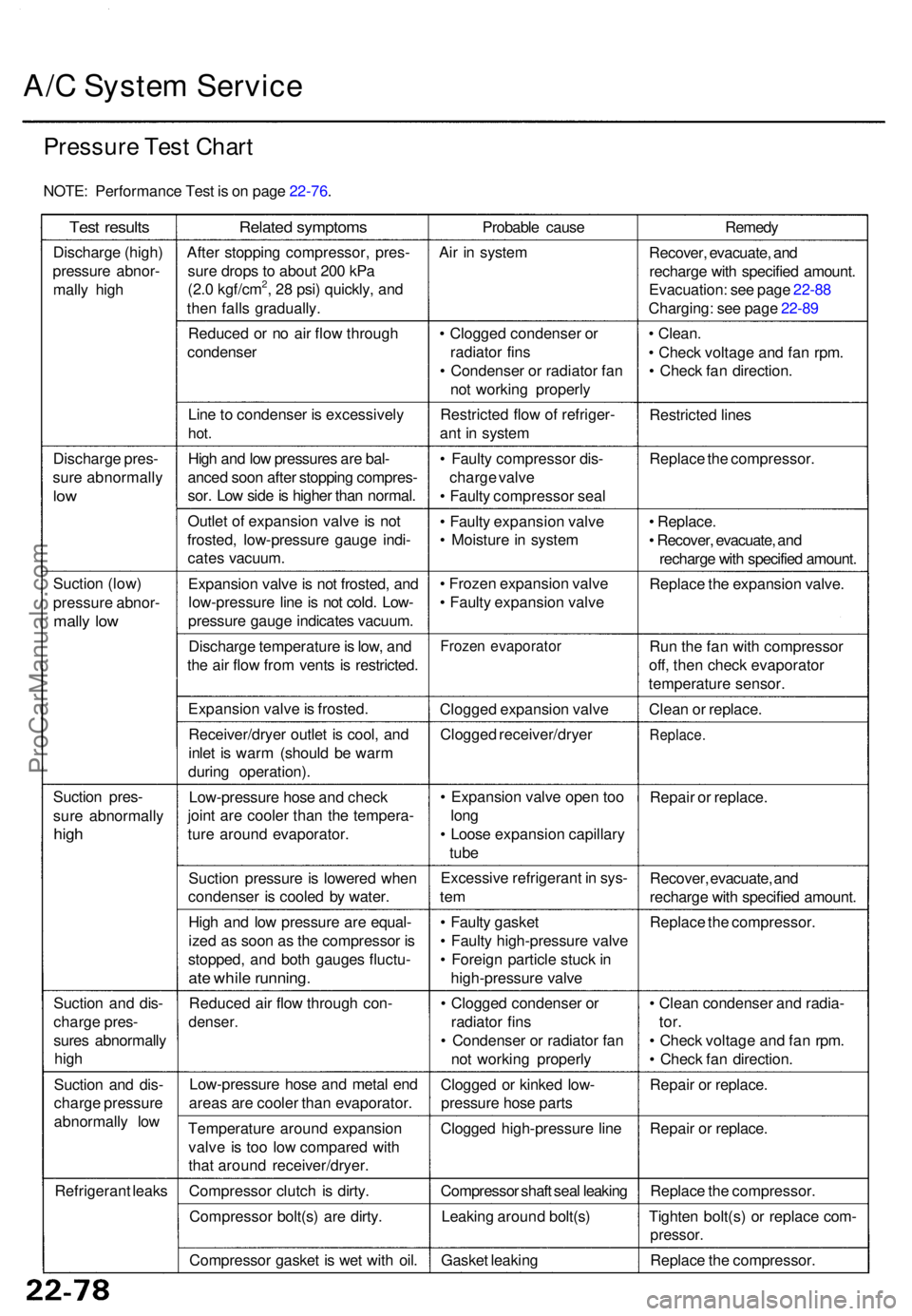

Pressur e Tes t Char t

NOTE : Performanc e Tes t i s o n pag e 22-76 .

Test result s

Discharg e (high )

pressur e abnor -

mall y hig h

Discharg e pres -

sur e abnormall y

low

Suctio n (low )

pressur e abnor -

mally lo w

Suctio n pres -

sur e abnormall y

high

Suctio n an d dis -

charg e pres -

sure s abnormall y

hig h

Suctio n an d dis -

charg e pressur e

abnormall y lo w

Refrigeran t leak s

Relate d symptom s

After stoppin g compressor , pres -

sur e drop s t o abou t 20 0 kP a

(2. 0 kgf/cm

2, 2 8 psi ) quickly , an d

the n fall s gradually .

Reduce d o r n o ai r flo w throug h

condense r

Lin e to condense r i s excessivel y

hot.

Hig h an d lo w pressure s ar e bal -

ance d soo n afte r stoppin g compres -

sor . Lo w sid e is highe r tha n normal .

Outle t o f expansio n valv e is no t

frosted , low-pressur e gaug e indi -

cate s vacuum .

Expansio n valv e is no t frosted , an d

low-pressur e lin e is no t cold . Low -

pressur e gaug e indicate s vacuum .

Discharg e temperatur e is low , an d

th e ai r flo w fro m vent s i s restricted .

Expansio n valv e is frosted .

Receiver/drye r outle t i s cool , an d

inle t i s war m (shoul d b e war m

durin g operation) .

Low-pressur e hos e an d chec k

join t ar e coole r tha n th e tempera -

tur e aroun d evaporator .

Suctio n pressur e is lowere d whe n

condense r i s coole d b y water .

Hig h an d lo w pressur e ar e equal -

ize d a s soo n a s th e compresso r i s

stopped , an d bot h gauge s fluctu -

ate whil e running .

Reduce d ai r flo w throug h con -

denser .

Low-pressur e hos e an d meta l en d

area s ar e coole r tha n evaporator .

Temperatur e aroun d expansio n

valv e i s to o lo w compare d wit h

tha t aroun d receiver/dryer .

Compresso r clutc h i s dirty .

Compresso r bolt(s ) ar e dirty .

Compresso r gaske t i s we t wit h oil . Probabl

e caus e

Ai r i n syste m

• Clogge d condense r o r

radiato r fin s

• Condense r o r radiato r fa n

no t workin g properl y

Restricte d flo w o f refriger -

an t i n syste m

• Fault y compresso r dis -

charg e valv e

• Fault y compresso r sea l

• Fault y expansio n valv e

• Moistur e in syste m

• Froze n expansio n valv e

• Fault y expansio n valv e

Froze n evaporato r

Clogged expansio n valv e

Clogge d receiver/drye r

• Expansio n valv e ope n to o

lon g

• Loos e expansio n capillar y

tub e

Excessiv e refrigeran t i n sys -

tem

• Fault y gaske t

• Fault y high-pressur e valv e

• Foreig n particl e stuc k in

high-pressur e valv e

• Clogge d condense r o r

radiato r fin s

• Condense r o r radiato r fa n

no t workin g properl y

Clogge d o r kinke d low -

pressur e hos e part s

Clogge d high-pressur e lin e

Compresso r shaf t sea l leakin g

Leakin g aroun d bolt(s )

Gaske t leakin g Remed

y

Recover , evacuate , an d

recharg e wit h specifie d amount .

Evacuation : se e pag e 22-8 8

Charging : se e pag e 22-8 9

• Clean .

• Chec k voltag e an d fa n rpm .

• Chec k fa n direction .

Restricte d line s

Replac e th e compressor .

• Replace .

• Recover , evacuate , an d

recharg e wit h specifie d amount .

Replac e th e expansio n valve .

Ru n th e fa n wit h compresso r

off , the n chec k evaporato r

temperatur e sensor .

Clea n o r replace .

Replace .

Repair o r replace .

Recover , evacuate , an d

recharg e wit h specifie d amount .

Replac e th e compressor .

• Clea n condense r an d radia -

tor.

• Chec k voltag e an d fa n rpm .

• Chec k fa n direction .

Repai r o r replace .

Repai r o r replace .

Replac e th e compressor .

Tighte n bolt(s ) o r replac e com -

pressor .

Replace th e compressor .

ProCarManuals.com