oil change ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 151 of 1954

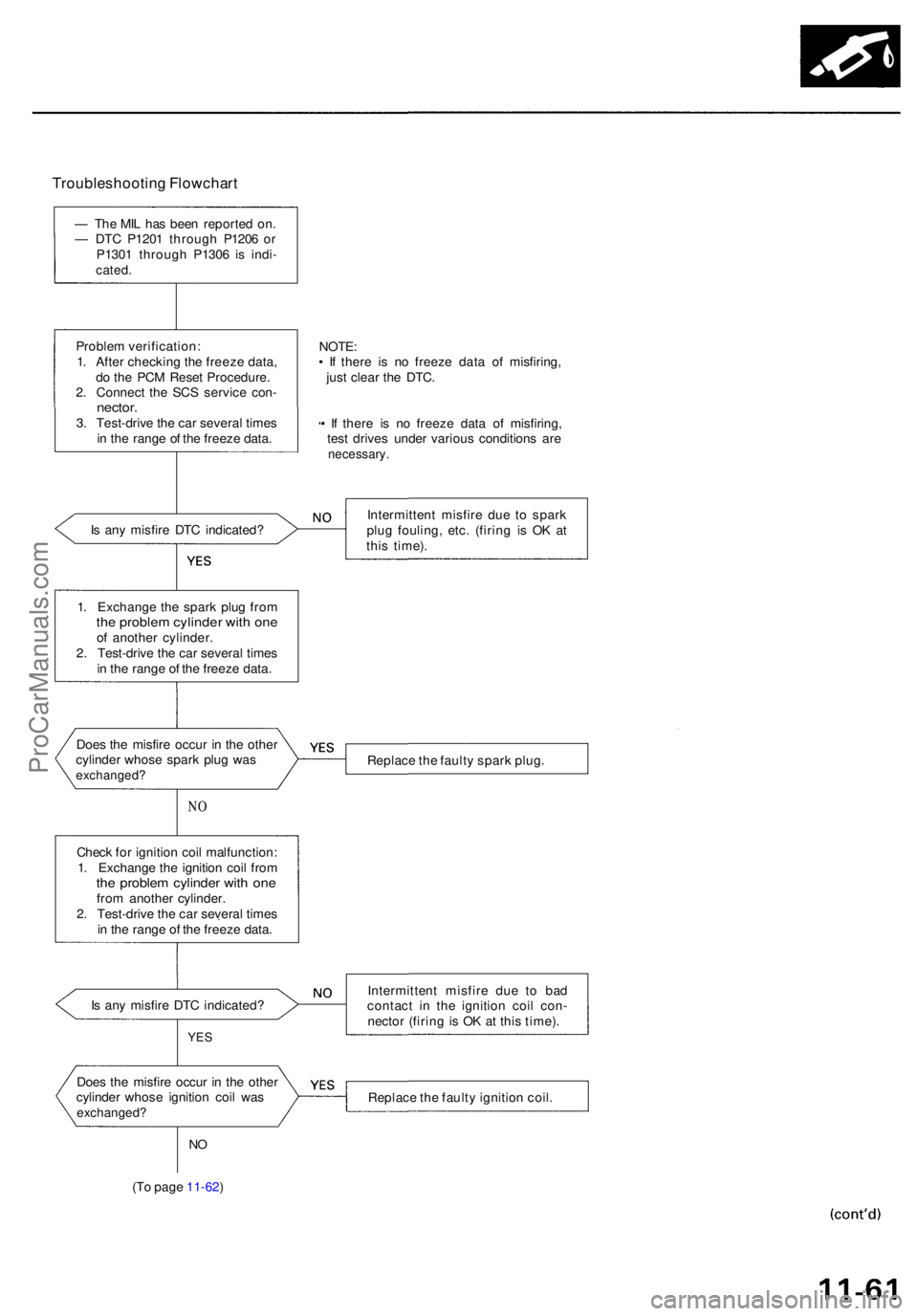

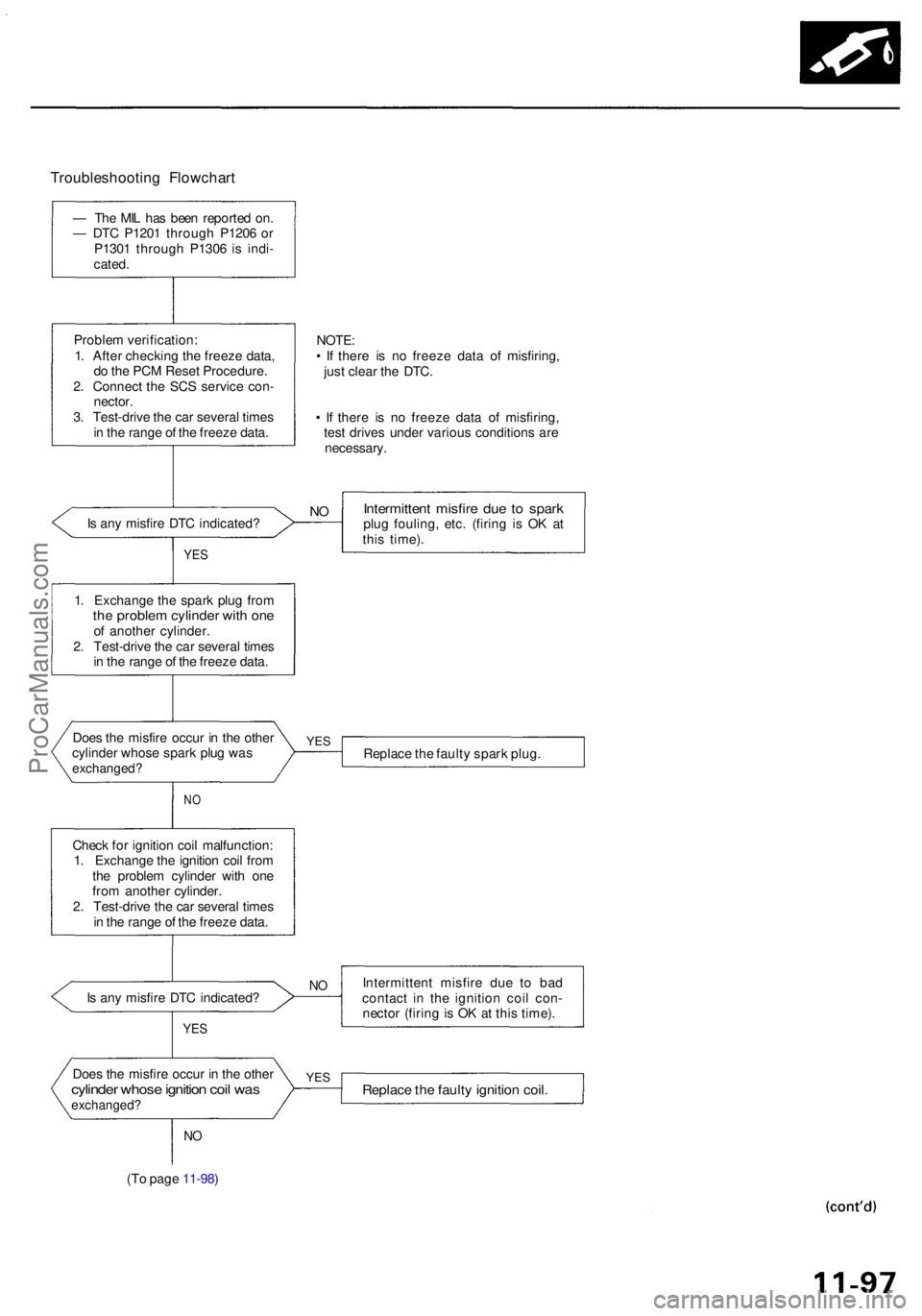

Troubleshooting Flowchar t

— Th e MI L ha s bee n reporte d on .

— DT C P120 1 throug h P120 6 o r

P130 1 throug h P130 6 i s indi -

cated .

Proble m verification :

1 . Afte r checkin g th e freez e data ,

d o th e PC M Rese t Procedure .

2 . Connec t th e SC S servic e con -

nector .3. Test-driv e th e ca r severa l time s

i n th e rang e o f th e freez e data .

I s an y misfir e DT C indicated ?

NO

Chec k fo r ignitio n coi l malfunction :

1 . Exchang e th e ignitio n coi l fro m

the proble m cylinde r wit h on efrom anothe r cylinder .

2 . Test-driv e th e ca r severa l time s

i n th e rang e o f th e freez e data .

I s an y misfir e DT C indicated ?

YES

NO

(T o pag e 11-62 )

NOTE:• I f ther e i s n o freez e dat a o f misfiring ,

jus t clea r th e DTC .

• I f ther e i s n o freez e dat a o f misfiring ,

tes t drive s unde r variou s condition s ar e

necessary .

Intermitten t misfir e du e t o spar k

plu g fouling , etc . (firin g i s O K a t

thi s time) .

Replac e th e fault y spar k plug .

Intermitten t misfir e du e t o ba d

contac t i n th e ignitio n coi l con -

necto r (firin g is O K a t thi s time) .

Replac e th e fault y ignitio n coil .

Doe

s th e misfir e occu r i n th e othe r

cylinde r whos e spar k plu g wa s

exchanged ?

Does th e misfir e occu r i n th e othe r

cylinde r whos e ignitio n coi l wa s

exchanged ?

1. Exchang e th e spar k plu g fro mthe proble m cylinde r wit h on eof anothe r cylinder .

2 . Test-driv e th e ca r severa l time s

i n th e rang e o f th e freez e data .

ProCarManuals.com

Page 421 of 1954

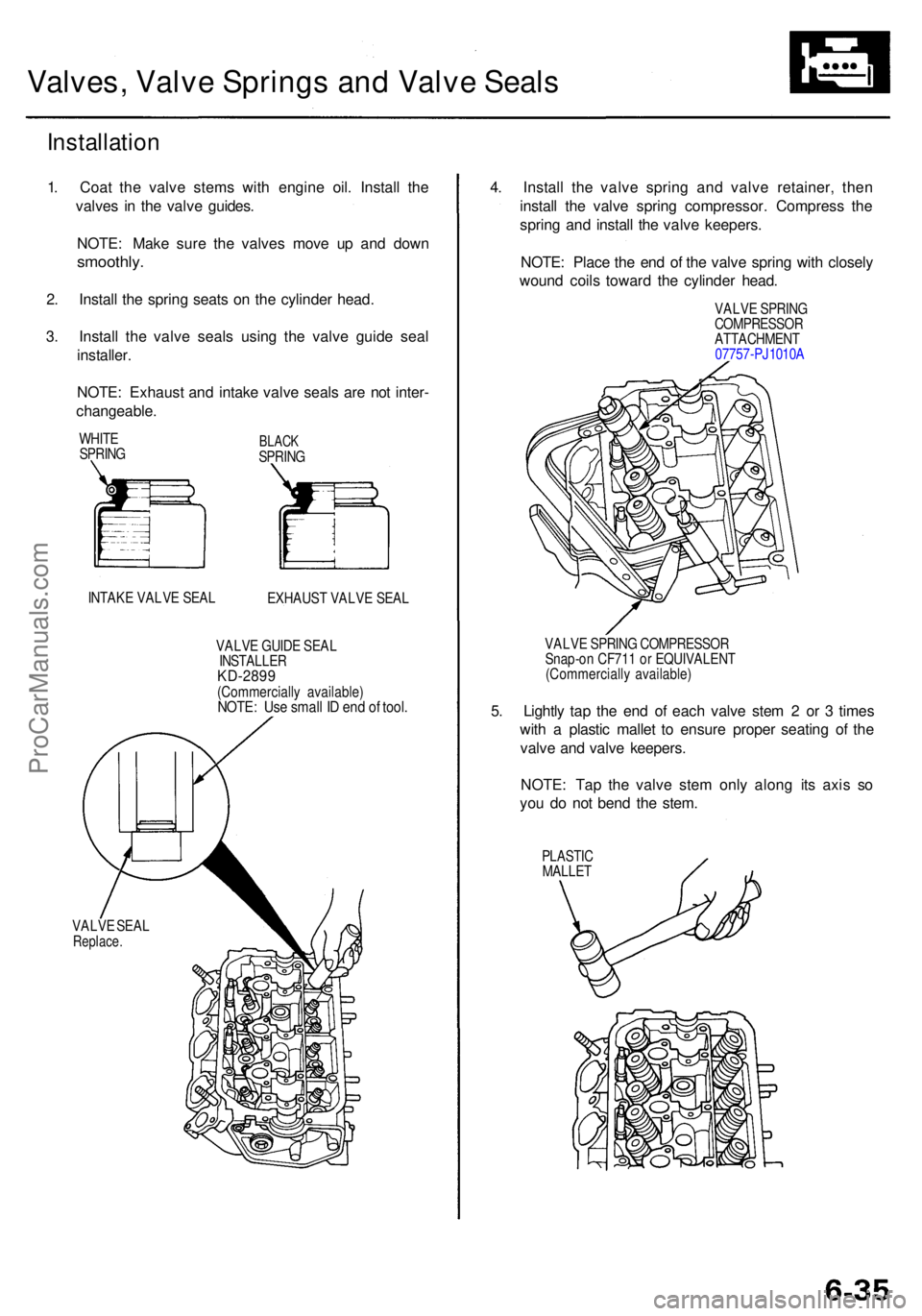

Valves, Valv e Spring s an d Valve Seals

Installatio n

1. Coa t th e valv e stem s wit h engin e oil . Instal l th e

valve s i n th e valv e guides .

NOTE : Mak e sur e th e valve s mov e u p an d dow n

smoothly .

2. Instal l th e sprin g seat s o n th e cylinde r head .

3 . Instal l th e valv e seal s usin g th e valv e guid e sea l

installer .

NOTE : Exhaus t an d intak e valv e seal s ar e no t inter -

changeable .

WHITE

SPRIN GBLACKSPRIN G

INTAK E VALV E SEA L

EXHAUST VALV E SEA L

VALV E GUID E SEA L

INSTALLE RKD-2899(Commerciall y available )NOTE: Us e smal l I D en d o f tool .

VALV E SEA LReplace .

4. Instal l th e valv e sprin g an d valv e retainer , the n

instal l th e valv e sprin g compressor . Compres s th e

sprin g an d instal l th e valv e keepers .

NOTE : Plac e th e en d o f th e valv e sprin g wit h closel y

woun d coil s towar d th e cylinde r head .

VALV E SPRIN GCOMPRESSO RATTACHMENT

0775 7-PJ1010 A

VALV E SPRIN G COMPRESSO R

Snap-o n CF71 1 o r EQUIVALEN T

(Commerciall y available )

5. Lightl y ta p th e en d o f eac h valv e ste m 2 or 3 time s

wit h a plasti c malle t t o ensur e prope r seatin g o f th e

valv e an d valv e keepers .

NOTE : Ta p th e valv e ste m onl y alon g it s axi s s o

yo u d o no t ben d th e stem .

PLASTI CMALLET

ProCarManuals.com

Page 432 of 1954

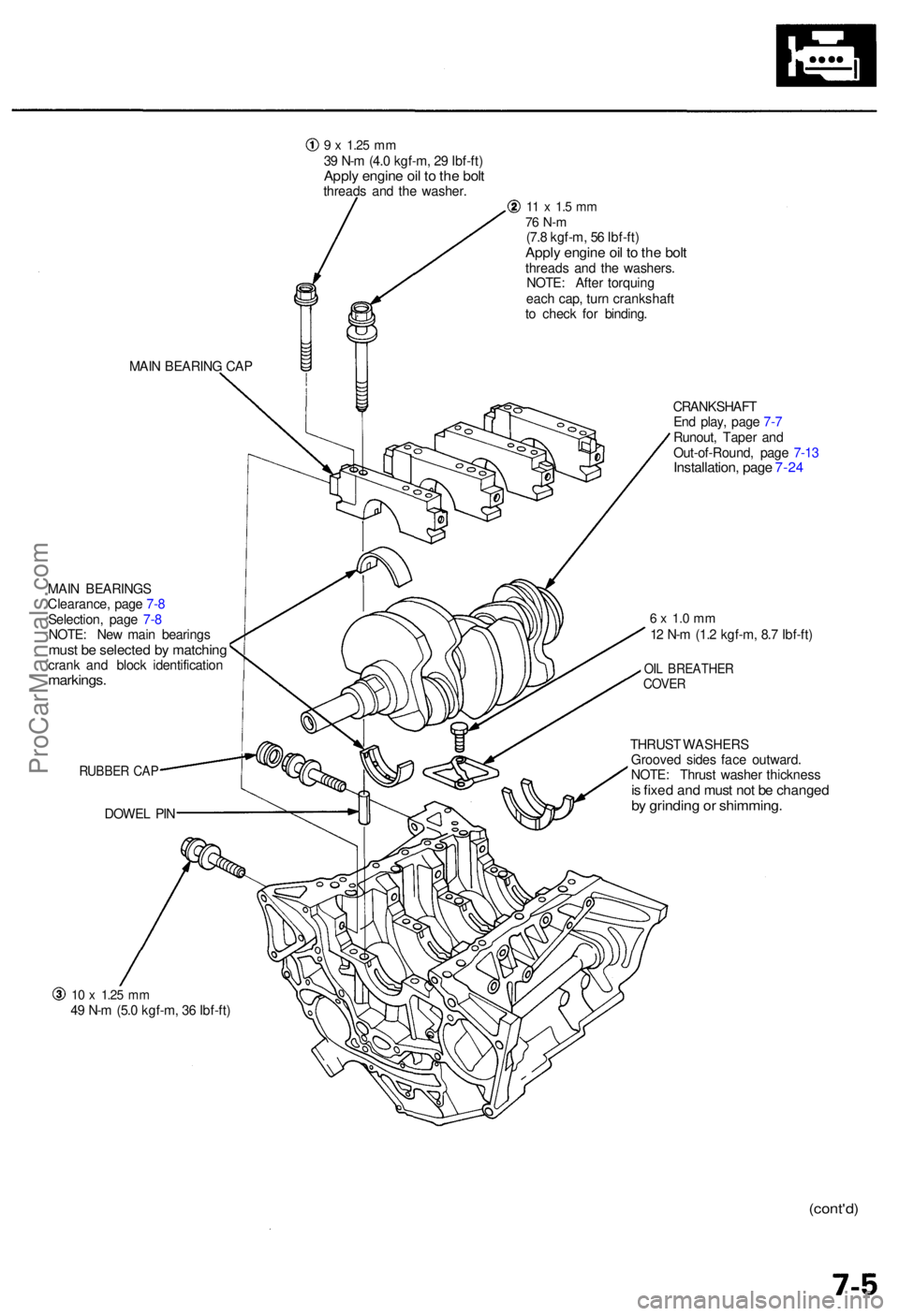

10 x 1.2 5 mm49 N- m (5. 0 kgf-m , 3 6 Ibf-ft )

9 x 1.2 5 mm39 N- m (4. 0 kgf-m , 2 9 Ibf-ft )Apply engin e oi l t o th e bol tthread s an d th e washer .11 x 1. 5 m m76 N- m(7.8 kgf-m , 5 6 Ibf-ft )Apply engin e oi l t o th e bol tthread s an d th e washers .

NOTE : Afte r torquin g

eac h cap , tur n crankshaf t

t o chec k fo r binding .

CRANKSHAF T

En d play , pag e 7- 7

Runout , Tape r an d

Out-of-Round , pag e 7-1 3

Installation , pag e 7-2 4

MAI N BEARIN G CA P

MAI N BEARING S

Clearance , pag e 7- 8

Selection , pag e 7- 8

NOTE : Ne w mai n bearing s

must b e selecte d b y matchin gcrank an d bloc k identificatio nmarkings.

RUBBER CA P

DOWE L PI N

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

OIL BREATHE RCOVER

THRUS T WASHER S

Groove d side s fac e outward .

NOTE : Thrus t washe r thicknes s

is fixe d an d mus t no t b e change dby grindin g o r shimming .

(cont'd)

ProCarManuals.com

Page 465 of 1954

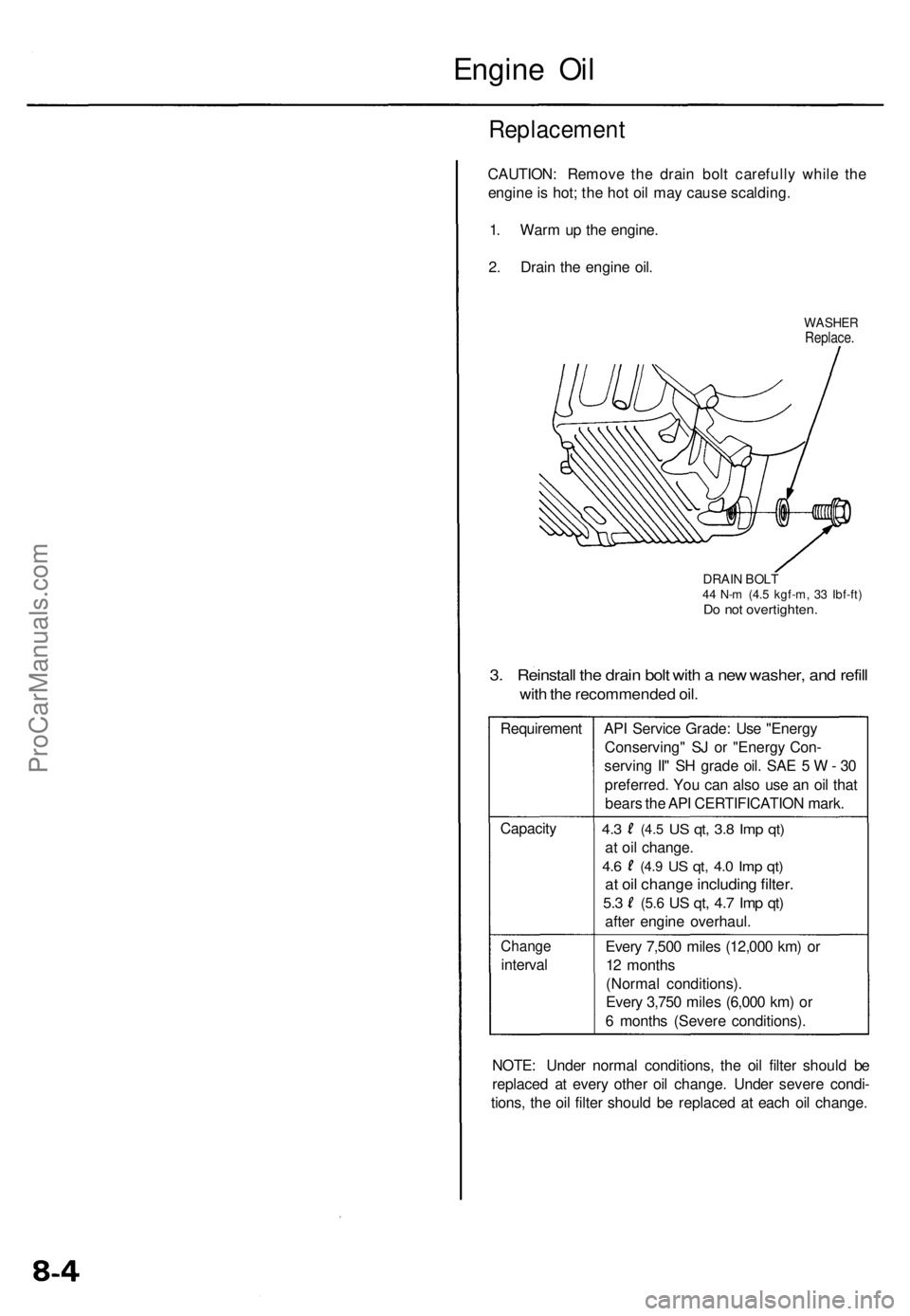

Engine Oi l

Replacemen t

CAUTION: Remov e th e drai n bol t carefull y whil e th e

engin e is hot ; th e ho t oi l ma y caus e scalding .

1 . War m u p th e engine .

2 . Drai n th e engin e oil .

WASHE RReplace.

DRAIN BOL T44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )Do no t overtighten .

3. Reinstal l th e drai n bol t wit h a ne w washer , an d refil l

with th e recommende d oil .

Requiremen tAPI Servic e Grade : Us e "Energ y

Conserving " S J o r "Energ y Con -

servin g II " S H grad e oil . SA E 5 W - 30

preferred . Yo u ca n als o us e a n oi l tha t

bear s th e AP I CERTIFICATIO N mark .

Capacit y

4.3 (4. 5 US qt , 3. 8 Im p qt )

at oi l change .

4.6 (4. 9 US qt , 4. 0 Im p qt )

at oi l chang e includin g filter .

5.3 (5. 6 US qt , 4. 7 Im p qt )

afte r engin e overhaul .

Change

interval Ever

y 7,50 0 mile s (12,00 0 km ) o r

1 2 month s

(Norma l conditions) .

Ever y 3,75 0 mile s (6,00 0 km ) o r

6 month s (Sever e conditions) .

NOTE : Unde r norma l conditions , th e oi l filte r shoul d b e

replace d a t ever y othe r oi l change . Unde r sever e condi -

tions , th e oi l filte r shoul d b e replace d a t eac h oi l change .

ProCarManuals.com

Page 596 of 1954

Troubleshooting Flowchar t

— Th e MI L ha s bee n reporte d on .

— DT C P120 1 throug h P120 6 o r

P130 1 throug h P130 6 i s indi -

cated .

Proble m verification :

1 . Afte r checkin g th e freez e data ,

d o th e PC M Rese t Procedure .

2 . Connec t th e SC S servic e con -

nector .

3 . Test-driv e th e ca r severa l time s

i n th e rang e o f th e freez e data .

I s an y misfir e DT C indicated ?

Doe s th e misfir e occu r i n th e othe r

cylinde r whos e spar k plu g wa s

exchanged ?

NO

Chec k fo r ignitio n coi l malfunction :

1 . Exchang e th e ignitio n coi l fro m

th e proble m cylinde r wit h on e

fro m anothe r cylinder .

2 . Test-driv e th e ca r severa l time s

i n th e rang e o f th e freez e data .

I s an y misfir e DT C indicated ?

YES

Doe s th e misfir e occu r i n th e othe rcylinde r whos e ignitio n coi l wa sexchanged ?

NO

(T o pag e 11-98 )

NOTE :• I f ther e i s n o freez e dat a o f misfiring ,

jus t clea r th e DTC .

• I f ther e i s n o freez e dat a o f misfiring ,

tes t drive s unde r variou s condition s ar e

necessary .

Intermittent misfir e du e t o spar kplug fouling , etc . (firin g i s O K a t

thi s time) .

Replac e th e fault y spar k plug .

Intermitten t misfir e du e t o ba d

contac t i n th e ignitio n coi l con -

necto r (firin g is O K a t thi s time) .

Replac e th e fault y ignitio n coil .

YES

NO

YE S

1. Exchang e th e spar k plu g fro mthe proble m cylinde r wit h on eof anothe r cylinder .

2 . Test-driv e th e ca r severa l time s

i n th e rang e o f th e freez e data .

YES

NO

ProCarManuals.com

Page 614 of 1954

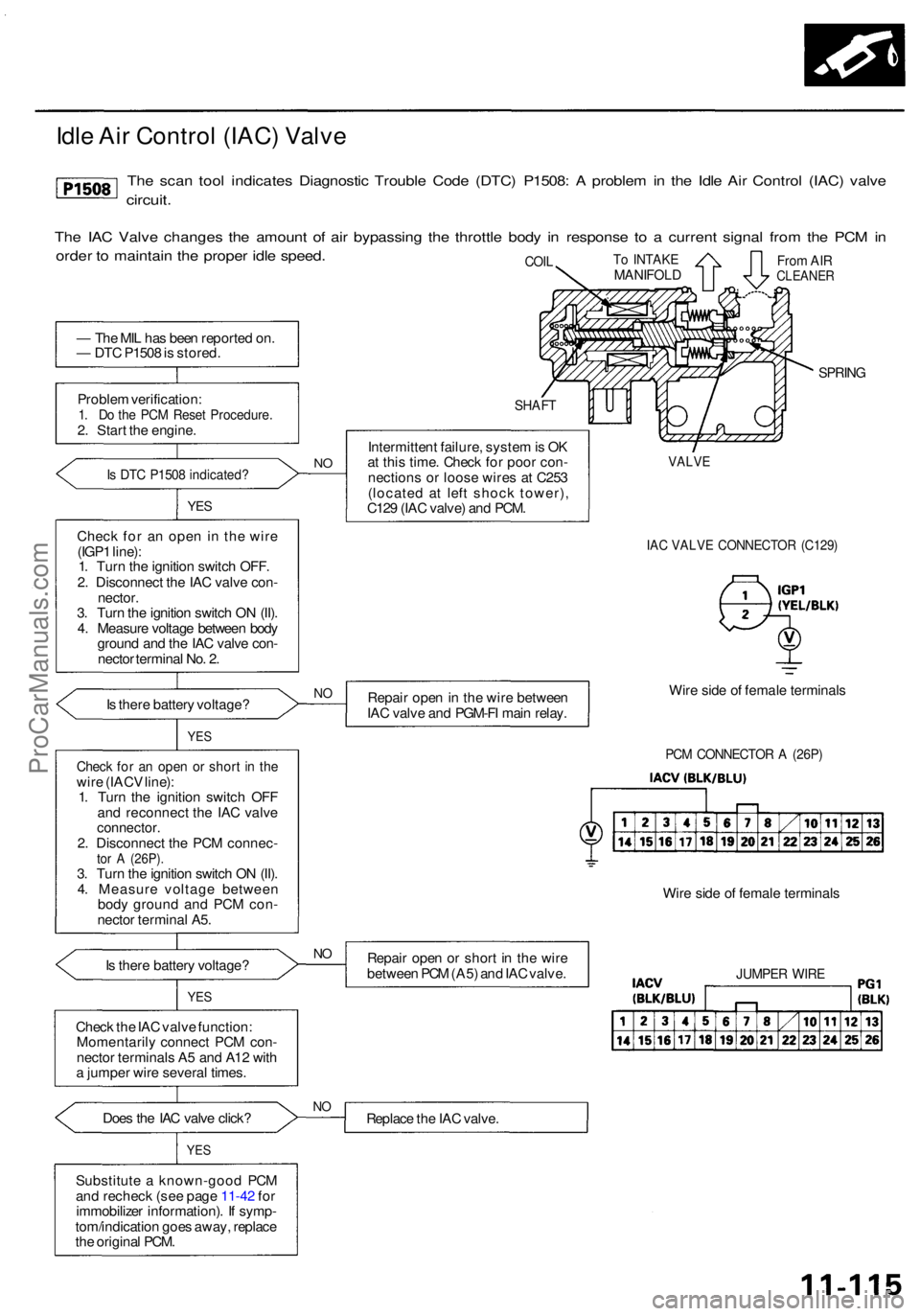

— Th e MI L ha s bee n reporte d on .

— DT C P150 8 is stored .

Proble m verification :

1. D o th e PC M Rese t Procedure .2. Star t th e engine .

Is DT C P150 8 indicated ?

YES

Chec k fo r a n ope n i n the wire

(IGP 1 line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e IA C valv e con -

nector .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Measur e voltag e betwee n bod y

groun d an d th e IA C valv e con -

necto r termina l No . 2 .

I s ther e batter y voltage ?

I s ther e batter y voltage ?

YES

Chec k th e IA C valv e function :

Momentaril y connec t PC M con -

necto r terminal s A 5 an d A1 2 wit h

a jumpe r wire severa l times .

Doe s th e IA C valv e click ?

YES

Substitut e a known-goo d PC M

an d rechec k (se e pag e 11-42 fo r

immobilize r information) . I f symp -

tom/indicatio n goe s away , replac e

th e origina l PCM .

SHAF T

Intermitten t failure , syste m is O K

a t thi s time . Chec k fo r poo r con -

nection s o r loos e wire s a t C25 3

(locate d a t lef t shoc k tower) ,

C12 9 (IA C valve ) an d PCM .

SPRIN G

IAC VALV E CONNECTO R (C129 )

Repair ope n in th e wir e betwee n

IA C valv e an d PGM-F I mai n relay . Wir

e sid e o f femal e terminal s

PCM CONNECTO R A (26P )

Repai r ope n o r shor t i n th e wir e

betwee n PC M (A5 ) an d IA C valve . Wir

e sid e o f femal e terminal sJUMPER WIR E

Replac e th e IA C valve .NO

NO

Chec k fo r a n ope n o r shor t i n th ewir e (IAC V line) :

1 . Tur n th e ignitio n switc h OF F

an d reconnec t th e IA C valv e

connector .2. Disconnec t th e PC M connec -tor A (26P) .3. Tur n th e ignitio n switc h O N (II) .

4 . Measur e voltag e betwee n

bod y groun d an d PC M con -

necto r termina l A5 .

NO

YE S

VALV E

To INTAK EMANIFOL DFrom AI RCLEANE RCOIL

NO

Idl e Ai r Contro l (IAC ) Valv e

The sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1508 : A proble m in th e Idl e Ai r Contro l (IAC ) valv e

circuit .

The IA C Valv e change s th e amoun t o f ai r bypassin g th e throttl e bod y i n respons e t o a curren t signa l fro m th e PC M in

orde r t o maintai n th e prope r idl e speed .

ProCarManuals.com

Page 915 of 1954

Maintenance

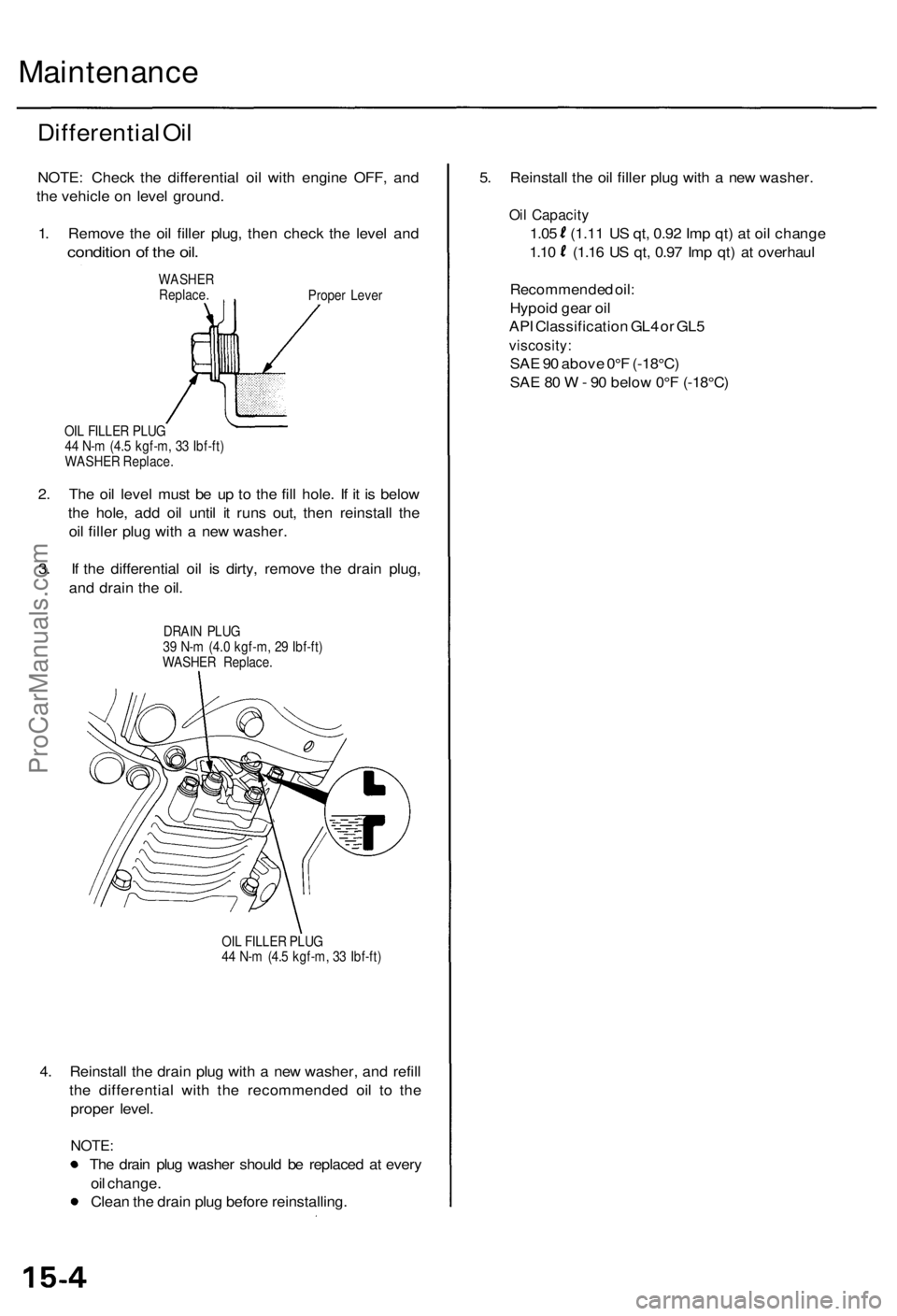

Differential Oil

NOTE: Check the differential oil with engine OFF, and

the vehicle on level ground.

1. Remove the oil filler plug, then check the level and

condition of the oil.

WASHER

Replace.

Proper Lever

OIL FILLER PLUG

44 N-m (4.5 kgf-m, 33 Ibf-ft)

WASHER Replace.

2. The oil level must be up to the fill hole. If it is below

the hole, add oil until it runs out, then reinstall the

oil filler plug with a new washer.

3. If the differential oil is dirty, remove the drain plug,

and drain the oil.

DRAIN PLUG

39 N-m (4.0 kgf-m, 29 Ibf-ft)

WASHER Replace.

OIL FILLER PLUG

44 N-m (4.5 kgf-m, 33 Ibf-ft)

4. Reinstall the drain plug with a new washer, and refill

the differential with the recommended oil to the

proper level.

NOTE:

The drain plug washer should be replaced at every

oil change.

Clean the drain plug before reinstalling.

5. Reinstall the oil filler plug with a new washer.

Oil Capacity

1.05 (1.11 US qt, 0.92 Imp qt) at oil change

1.10 (1.16 US qt, 0.97 Imp qt) at overhaul

Recommended oil:

Hypoid gear oil

API Classification GL4 or GL5

viscosity:

SAE 90 above 0°F (-18°C)

SAE 80 W - 90 below 0°F (-18°C)ProCarManuals.com

Page 1037 of 1954

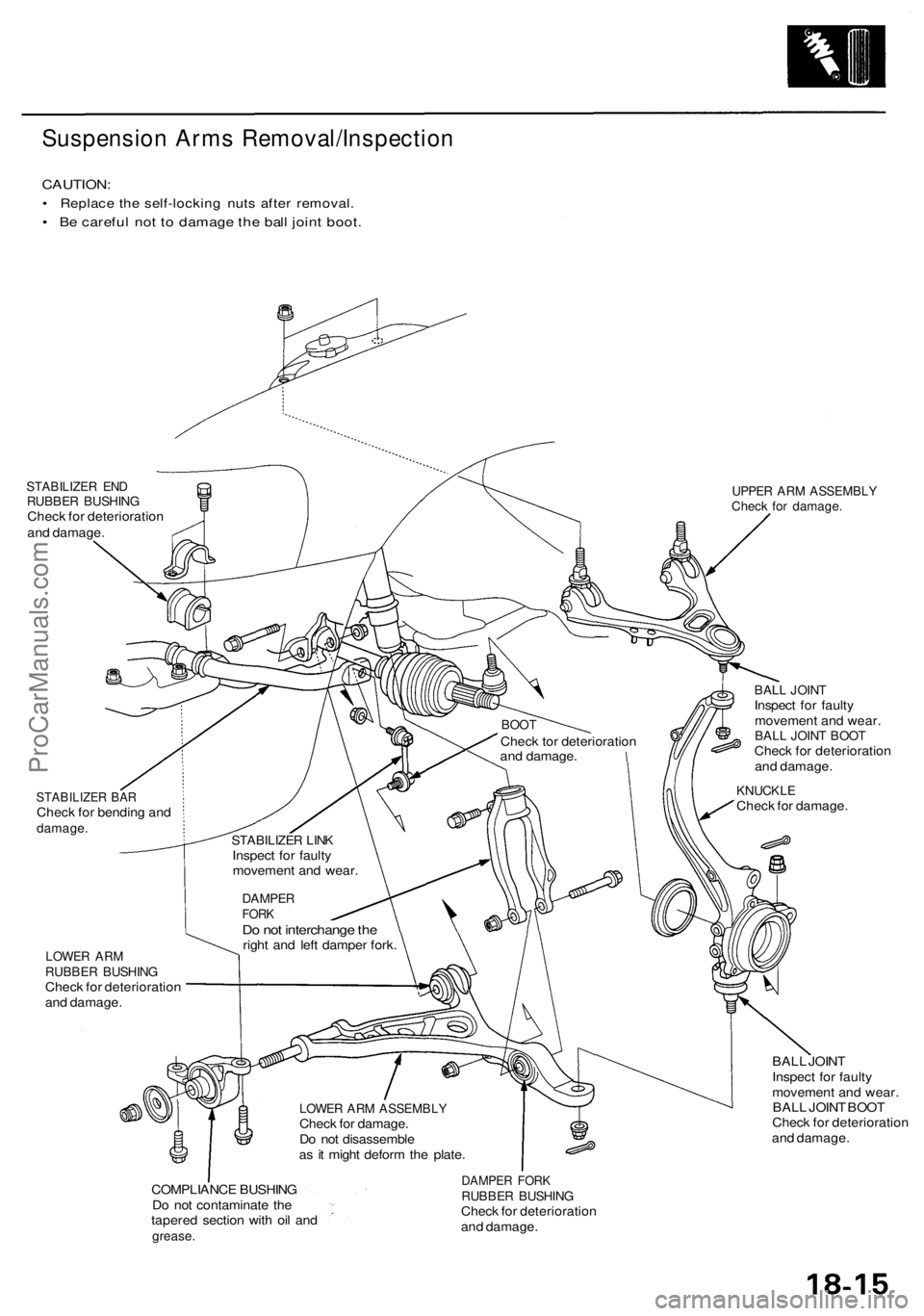

Suspension Arms Removal/Inspection

CAUTION:

• Replace the self-locking nuts after removal.

• Be careful not to damage the ball joint boot.

STABILIZER END

RUBBER BUSHING

Check for deterioration

and damage.

UPPER ARM ASSEMBLY

Check for damage.

STABILIZER BAR

Check for bending and

damage.

BALL JOINT

Inspect for faulty

movement and wear.

BALL JOINT BOOT

Check for deterioration

and damage.

KNUCKLE

Check for damage.

LOWER ARM

RUBBER BUSHING

Check for deterioration

and damage.

BALL JOINT

Inspect for faulty

movement and wear.

BALL JOINT BOOT

Check for deterioration

and damage.

COMPLIANCE BUSHING

Do not contaminate the

tapered section with oil and

grease.

DAMPER FORK

RUBBER BUSHING

Check for deterioration

and damage.

LOWER ARM ASSEMBLY

Check for damage.

Do not disassemble

as it might deform the plate.

DAMPER

FORK

Do not interchange the

right and left damper fork.

STABILIZER LINK

Inspect for faulty

movement and wear.

BOOT

Check tor deterioration

and damage.ProCarManuals.com

Page 1156 of 1954

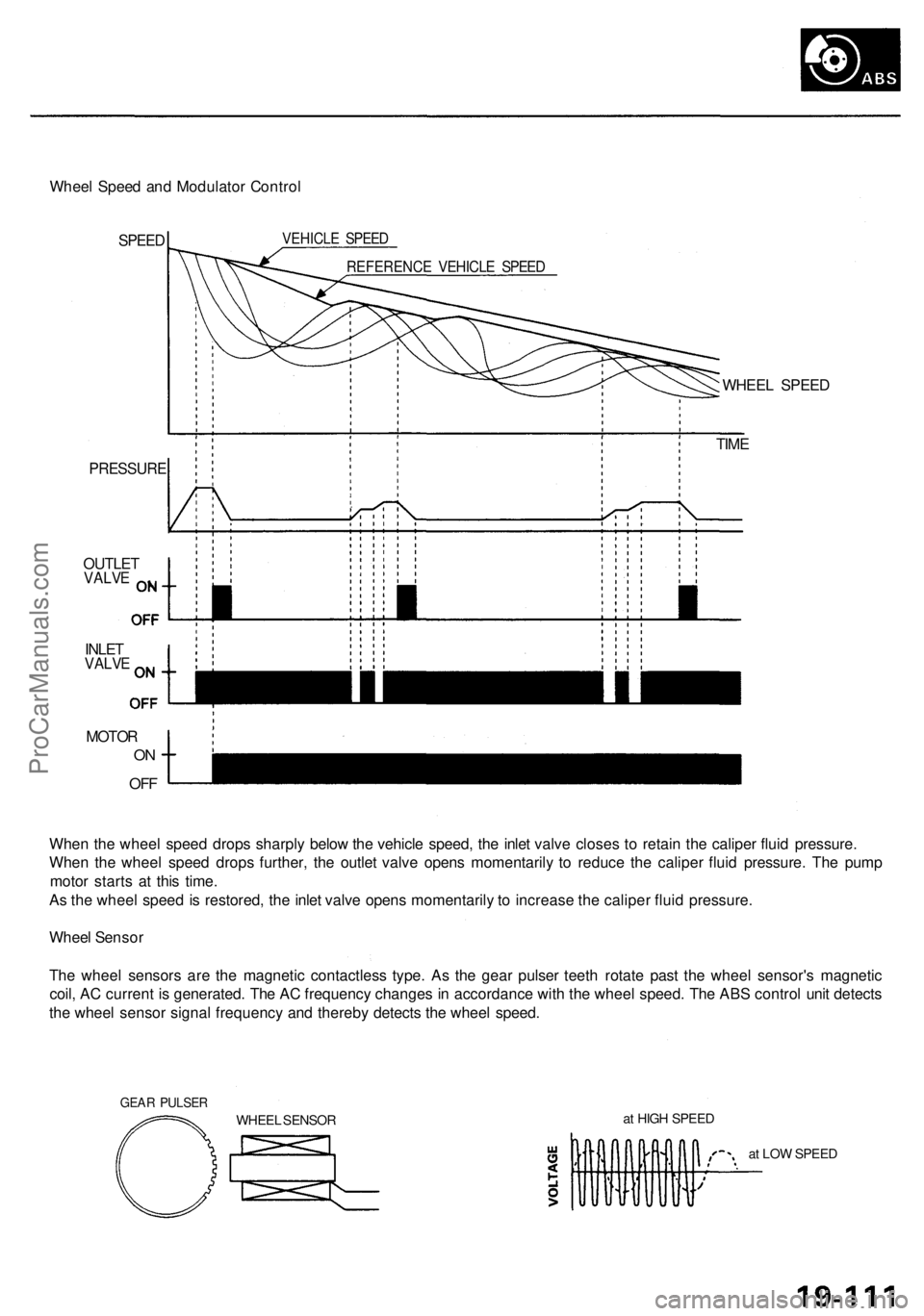

Wheel Spee d an d Modulato r Contro l

SPEED VEHICL E SPEE D

REFERENC E VEHICL E SPEE D

PRESSUR E

OUTLETVALVE

INLETVALV E

MOTO R

ON

OF F

WHEE L SPEE D

TIM E

Whe n th e whee l spee d drop s sharpl y belo w th e vehicl e speed , th e inle t valv e close s t o retai n th e calipe r flui d pressure .

Whe n th e whee l spee d drop s further , th e outle t valv e open s momentaril y t o reduc e th e calipe r flui d pressure . Th e pum p

moto r start s a t thi s time .

A s th e whee l spee d i s restored , th e inle t valv e open s momentaril y t o increas e th e calipe r flui d pressure .

Whee l Senso r

Th e whee l sensor s ar e th e magneti c contactles s type . A s th e gea r pulse r teet h rotat e pas t th e whee l sensor' s magnetic

coil , A C curren t i s generated . Th e A C frequenc y change s i n accordanc e wit h th e whee l speed . Th e AB S contro l uni t detect s

th e whee l senso r signa l frequenc y an d thereb y detect s th e whee l speed .

GEAR PULSE R

WHEEL SENSO R a

t HIG H SPEE D

at LO W SPEE D

ProCarManuals.com

Page 1497 of 1954

Compressor

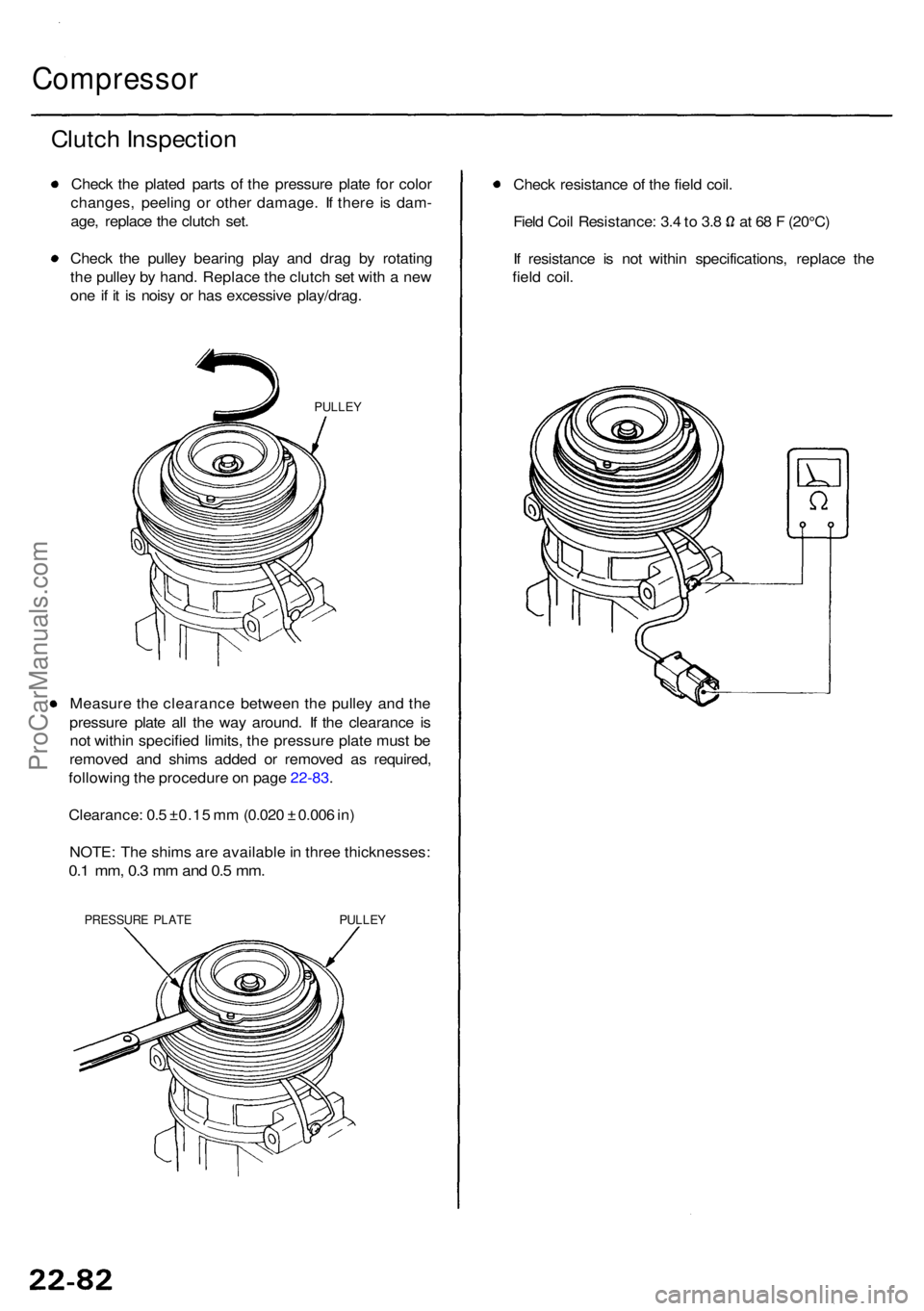

Clutch Inspectio n

Check th e plate d part s o f th e pressur e plat e fo r colo r

changes , peelin g o r othe r damage . I f ther e i s dam -

age , replac e th e clutc h set .

Chec k th e pulle y bearin g pla y an d dra g b y rotatin g

th e pulle y b y hand . Replac e th e clutc h se t wit h a ne w

on e if i t i s nois y o r ha s excessiv e play/drag .

PULLEY

Measur e th e clearanc e betwee n th e pulle y an d th e

pressur e plat e al l th e wa y around . I f th e clearanc e i s

no t withi n specifie d limits , th e pressur e plat e mus t b e

remove d an d shim s adde d o r remove d a s required ,

followin g th e procedur e o n pag e 22-83 .

Clearance : 0. 5 ±0.1 5 m m (0.02 0 ± 0.00 6 in )

NOTE : Th e shim s ar e availabl e in thre e thicknesses :

0.1 mm , 0. 3 m m an d 0. 5 mm .

PRESSUR E PLAT EPULLE Y

Check resistanc e o f th e fiel d coil .

Field Coi l Resistance : 3. 4 to 3. 8 a t 6 8 F (20°C )

I f resistanc e i s no t withi n specifications , replac e th e

fiel d coil .

ProCarManuals.com