power steering ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 309 of 1954

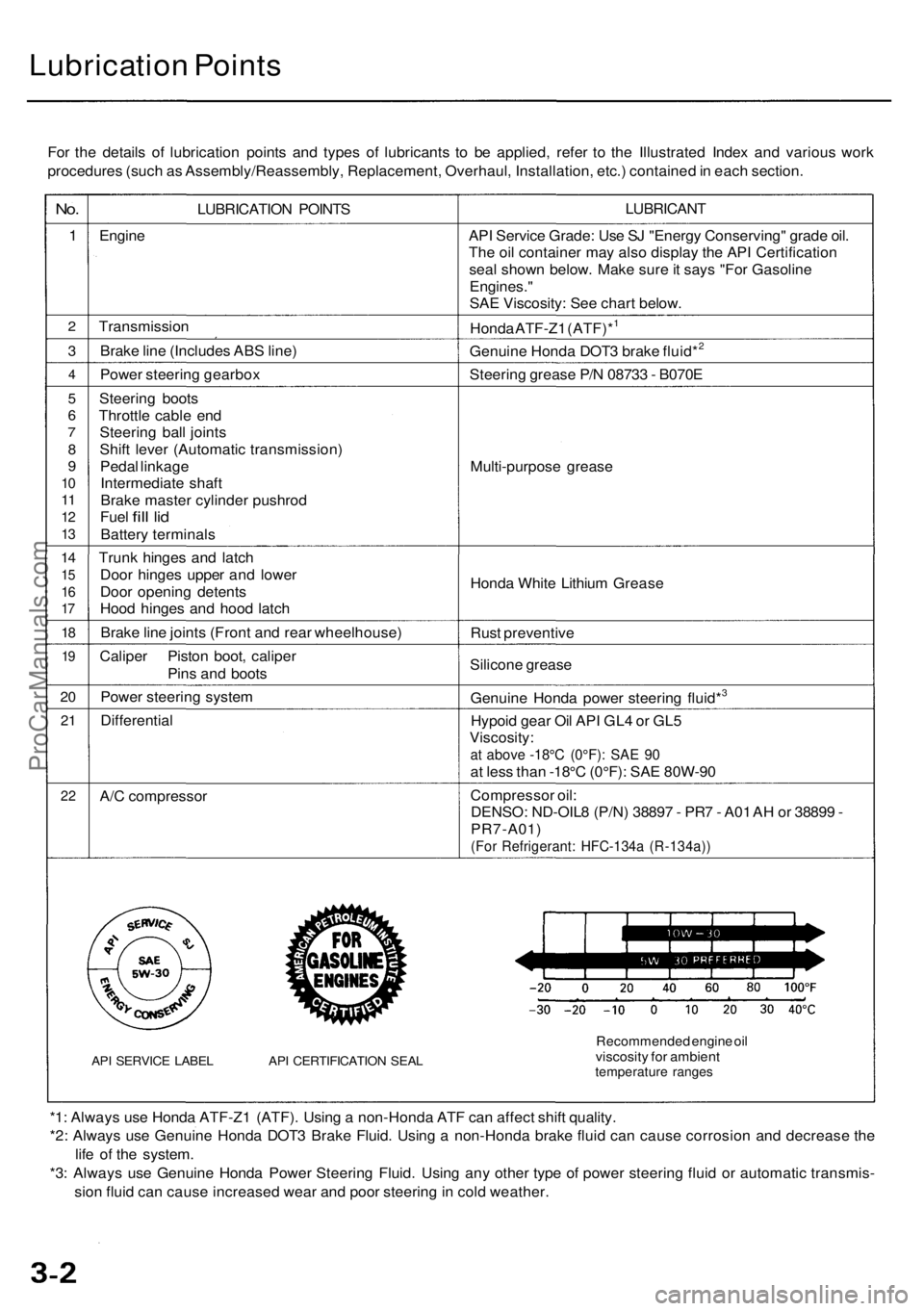

Lubrication Points

For the details of lubrication points and types of lubricants to be applied, refer to the Illustrated Index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

LUBRICATION POINTS

Engine

Transmission

Brake line (Includes ABS line)

Power steering gearbox

Steering boots

Throttle cable end

Steering ball joints

Shift lever (Automatic transmission)

Pedal linkage

Intermediate shaft

Brake master cylinder pushrod

Fuel

fill

lid

Battery terminals

Trunk hinges and latch

Door hinges upper and lower

Door opening detents

Hood hinges and hood latch

Brake line joints (Front and rear wheelhouse)

Caliper Piston boot, caliper

Pins and boots

Power steering system

Differential

A/C compressor

API SERVICE LABEL API CERTIFICATION SEAL

LUBRICANT

API Service Grade: Use SJ "Energy Conserving" grade oil.

The oil container may also display the API Certification

seal shown below. Make sure it says "For Gasoline

Engines."

SAE Viscosity: See chart below.

Honda ATF-Z1 (ATF)*1

Genuine Honda DOT3 brake fluid*2

Steering grease P/N 08733 - B070E

Multi-purpose grease

Honda White Lithium Grease

Rust preventive

Silicone grease

Genuine Honda power steering fluid*3

Hypoid gear Oil API GL4 or GL5

Viscosity:

at above -18°C (0°F): SAE 90

at less than -18°C (0°F): SAE 80W-90

Compressor oil:

DENSO: ND-OIL8 (P/N) 38897 - PR7 - A01 AH or 38899 -

PR7-A01)

(For Refrigerant: HFC-134a (R-134a))

Recommended engine oil

viscosity for ambient

temperature ranges

*1: Always use Honda ATF-Z1 (ATF). Using a non-Honda ATF can affect shift quality.

*2: Always use Genuine Honda DOT3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.

*3: Always use Genuine Honda Power Steering Fluid. Using any other type of power steering fluid or automatic transmis-

sion fluid can cause increased wear and poor steering in cold weather.ProCarManuals.com

Page 371 of 1954

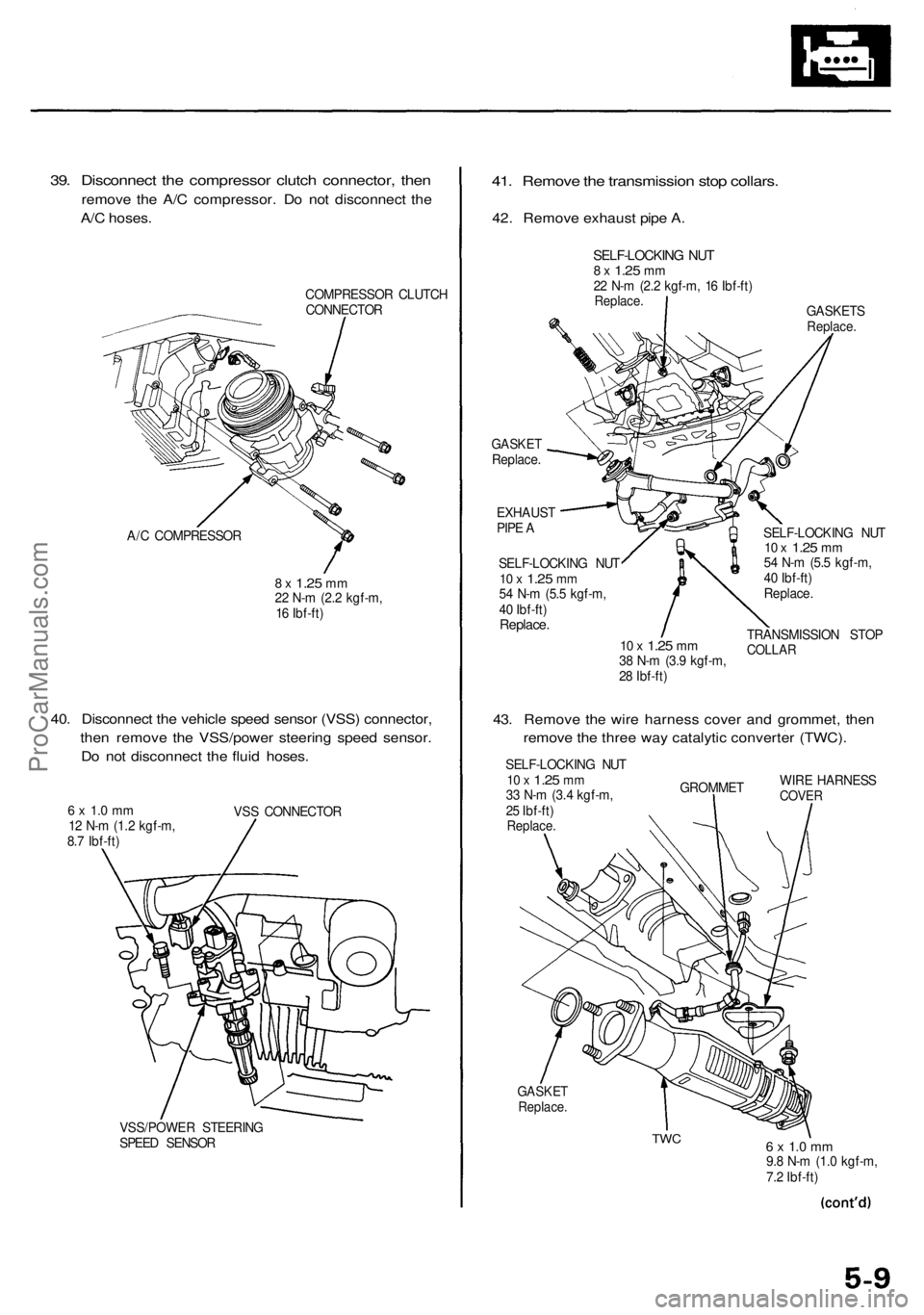

39. Disconnect the compressor clutch connector, then

remove the A/C compressor. Do not disconnect the

A/C hoses.

COMPRESSOR CLUTCH

CONNECTOR

A/C COMPRESSOR

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

40. Disconnect the vehicle speed sensor (VSS) connector,

then remove the VSS/power steering speed sensor.

Do not disconnect the fluid hoses.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

VSS CONNECTOR

VSS/POWER STEERING

SPEED SENSOR

41. Remove the transmission stop collars.

42. Remove exhaust pipe A.

GASKETS

Replace.

GASKET

Replace.

EXHAUST

PIPE A

SELF-LOCKING NUT

10 x

1.25

mm

54 N-m (5.5 kgf-m,

40 Ibf-ft)

Replace.

10 x

1.25

mm

38 N-m (3.9 kgf-m,

28 Ibf-ft)

SELF-LOCKING NUT

10 x

1.25

mm

54 N-m (5.5 kgf-m,

40 Ibf-ft)

Replace.

TRANSMISSION STOP

COLLAR

43. Remove the wire harness cover and grommet, then

remove the three way catalytic converter (TWC).

SELF-LOCKING NUT

10 x

1.25

mm

33 N-m (3.4 kgf-m,

25 Ibf-ft)

Replace.

GROMMET

WIRE HARNESS

COVER

GASKET

Replace.

TWC

6 x 1.0 mm

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

SELF-LOCKING NUT

8 x

1.25

mm

22 N-m (2.2 kgf-m, 16 Ibf-ft)

Replace.ProCarManuals.com

Page 989 of 1954

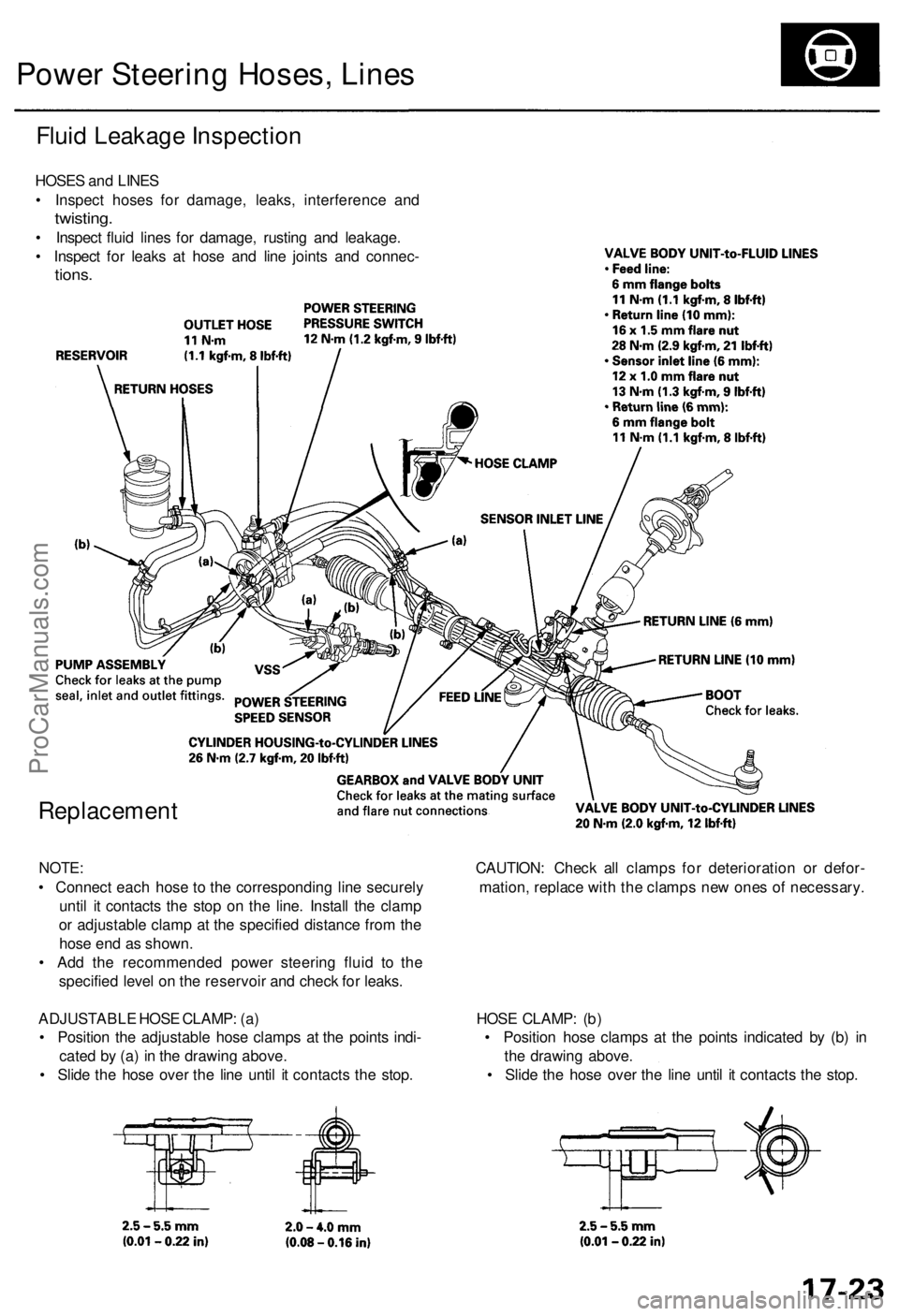

Power Steering Hoses, Lines

Fluid Leakage Inspection

HOSES and LINES

• Inspect hoses for damage, leaks, interference and

twisting.

• Inspect fluid lines for damage, rusting and leakage.

• Inspect for leaks at hose and line joints and connec-

tions.

Replacement

NOTE: CAUTION: Check all clamps for deterioration or defor-

• Connect each hose to the corresponding line securely mation, replace with the clamps new ones of necessary.

until it contacts the stop on the line. Install the clamp

or adjustable clamp at the specified distance from the

hose end as shown.

• Add the recommended power steering fluid to the

specified level on the reservoir and check for leaks.

ADJUSTABLE HOSE CLAMP: (a) HOSE CLAMP: (b)

• Position the adjustable hose clamps at the points indi- • Position hose clamps at the points indicated by (b) in

cated by (a) in the drawing above. the drawing above.

• Slide the hose over the line until it contacts the stop. • Slide the hose over the line until it contacts the stop.ProCarManuals.com

Page 994 of 1954

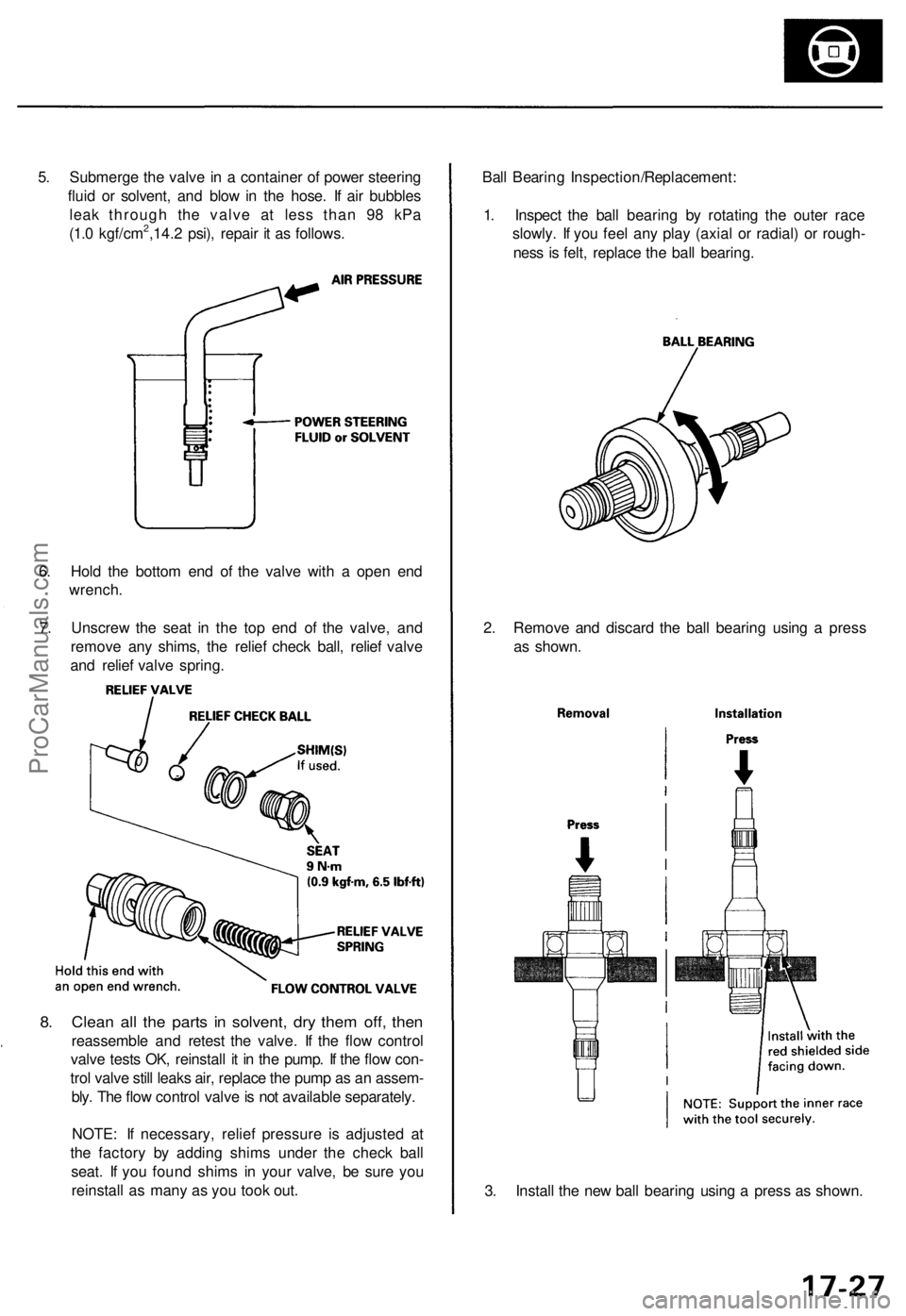

5. Submerge the valve in a container of power steering

fluid or solvent, and blow in the hose. If air bubbles

leak through the valve at less than 98 kPa

(1.0 kgf/cm2,14.2 psi), repair it as follows.

6. Hold the bottom end of the valve with a open end

wrench.

7. Unscrew the seat in the top end of the valve, and

remove any shims, the relief check ball, relief valve

and relief valve spring.

8. Clean all the parts in solvent, dry them off, then

reassemble and retest the valve. If the flow control

valve tests OK, reinstall it in the pump. If the flow con-

trol valve still leaks air, replace the pump as an assem-

bly. The flow control valve is not available separately.

NOTE: If necessary, relief pressure is adjusted at

the factory by adding shims under the check ball

seat. If you found shims in your valve, be sure you

reinstall as many as you took out.

3. Install the new ball bearing using a press as shown.

2. Remove and discard the ball bearing using a press

as shown.

Ball Bearing Inspection/Replacement:

1. Inspect the ball bearing by rotating the outer race

slowly. If you feel any play (axial or radial) or rough-

ness is felt, replace the ball bearing.ProCarManuals.com

Page 1000 of 1954

Power Steering Gearbox

Removal (cont'd)

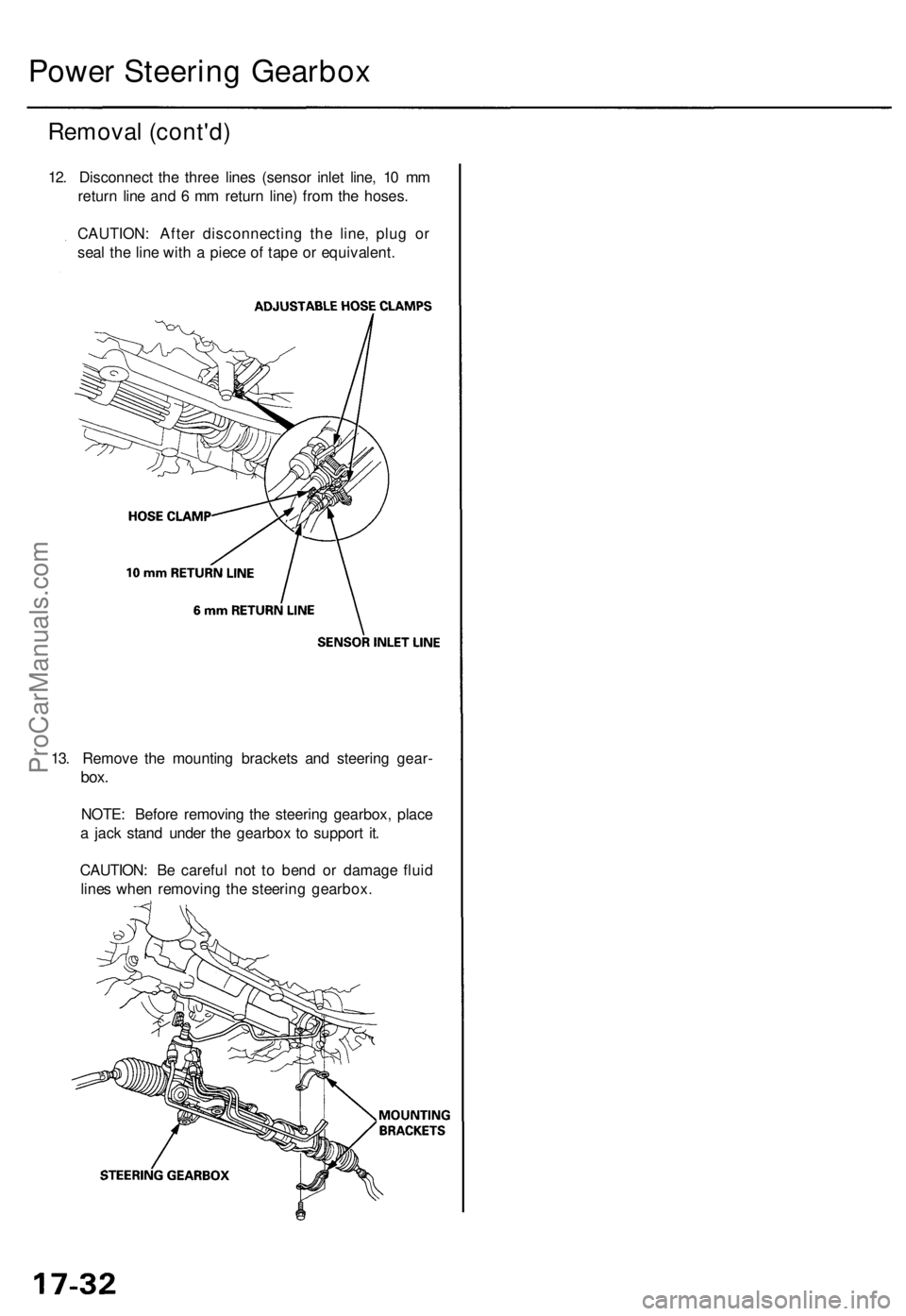

12. Disconnect the three lines (sensor inlet line, 10 mm

return line and 6 mm return line) from the hoses.

CAUTION: After disconnecting the line, plug or

seal the line with a piece of tape or equivalent.

13. Remove the mounting brackets and steering gear-

box.

NOTE: Before removing the steering gearbox, place

a jack stand under the gearbox to support it.

CAUTION: Be careful not to bend or damage fluid

lines when removing the steering gearbox.ProCarManuals.com

Page 1001 of 1954

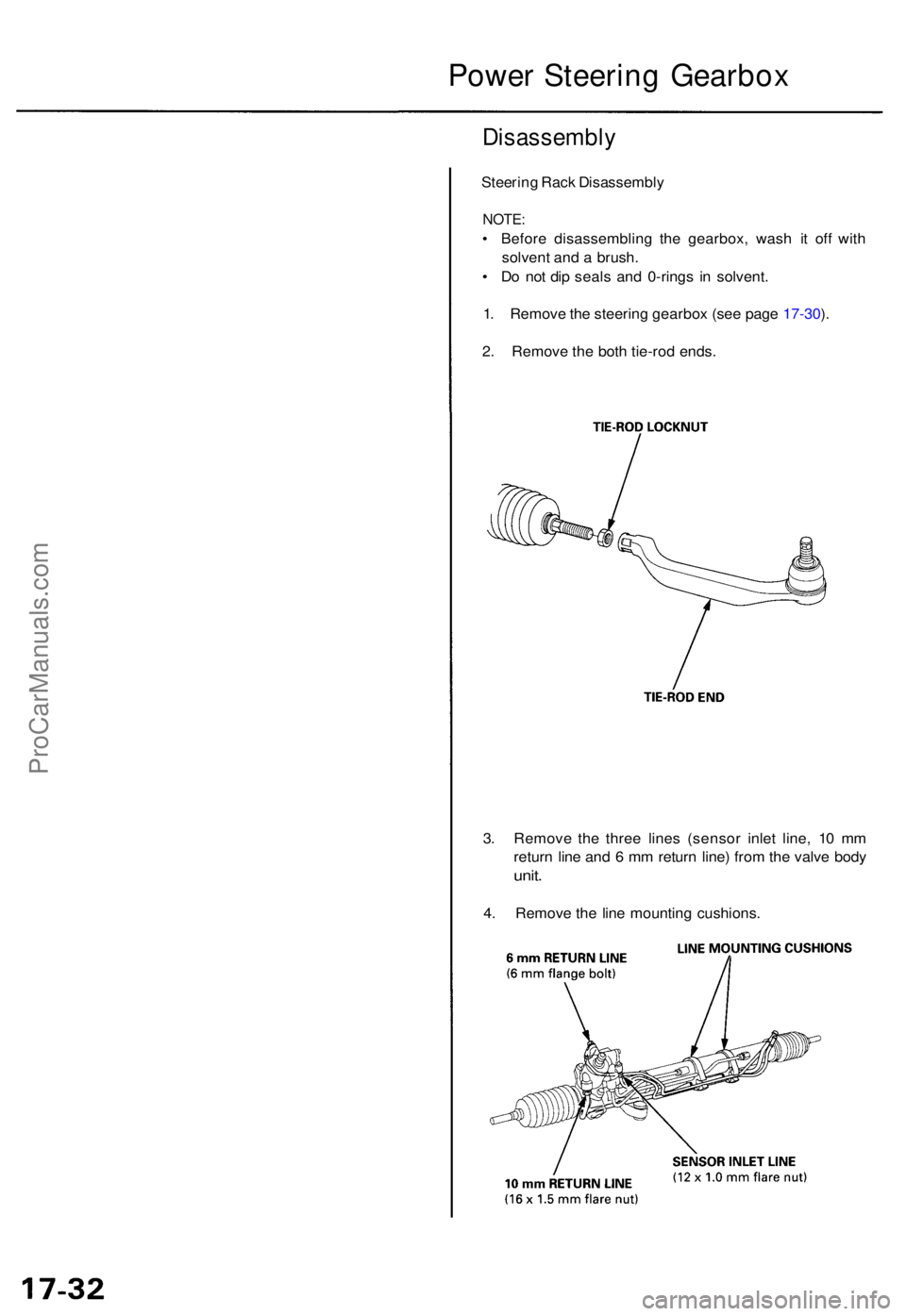

Disassembly

Steering Rac k Disassembl y

NOTE:

• Befor e disassemblin g th e gearbox , was h i t of f wit h

solven t an d a brush .

• D o no t di p seal s an d 0-ring s i n solvent .

1 . Remov e th e steerin g gearbo x (se e pag e 17-30 ).

2 . Remov e th e bot h tie-ro d ends .

3 . Remov e th e thre e line s (senso r inle t line , 1 0 m m

retur n lin e an d 6 m m retur n line ) fro m th e valv e bod y

unit.

4. Remov e th e lin e mountin g cushions .

Power Steerin g Gearbo x

ProCarManuals.com

Page 1190 of 1954

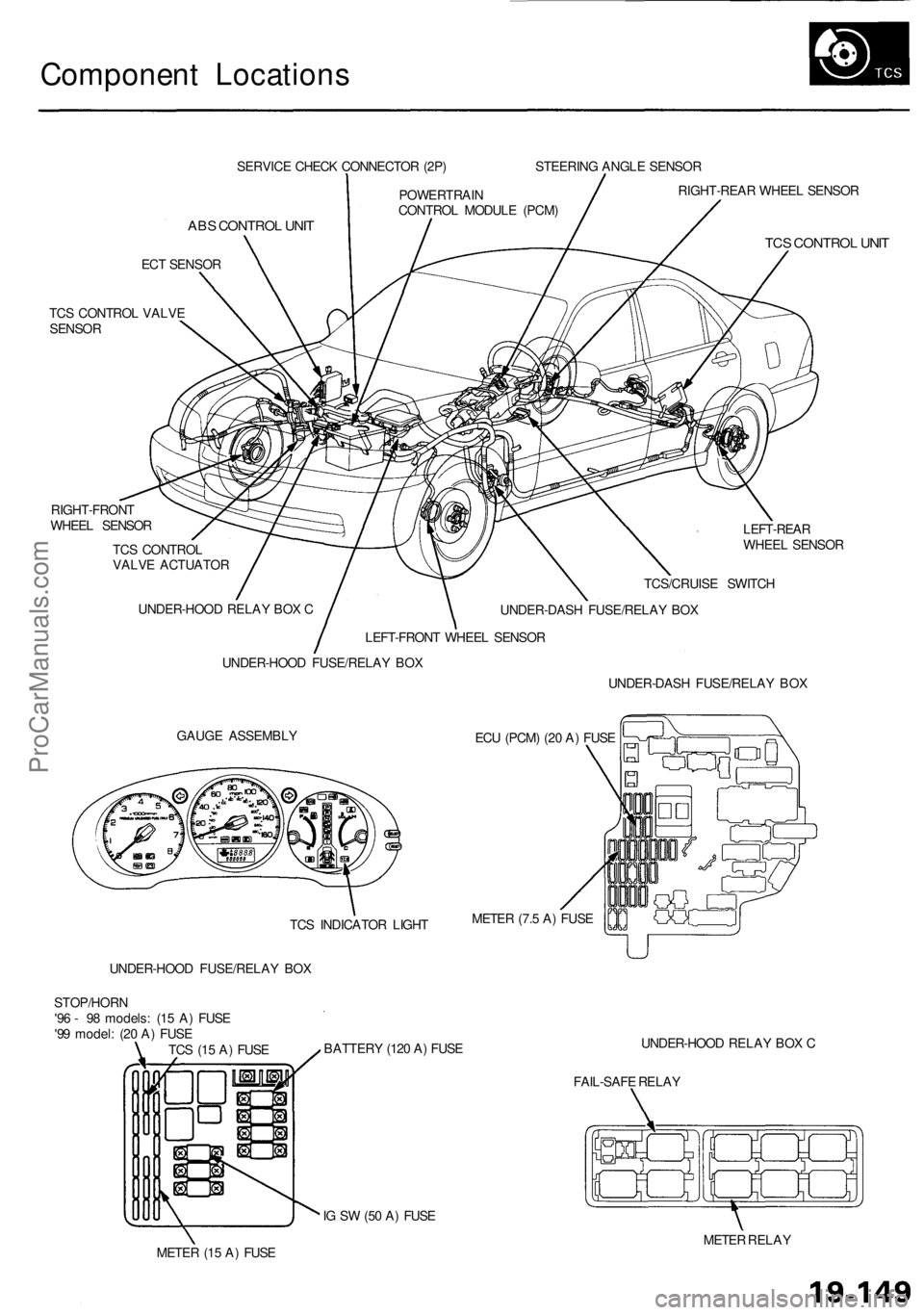

Component Locations

SERVICE CHECK CONNECTOR (2P)

ABS CONTROL UNIT

ECT SENSOR

TCS CONTROL VALVE

SENSOR

RIGHT-FRONT

WHEEL SENSOR

TCS CONTROL

VALVE ACTUATOR

LEFT-REAR

WHEEL SENSOR

GAUGE ASSEMBLY

ECU (PCM) (20 A) FUSE

UNDER-HOOD FUSE/RELAY BOX

BATTERY (120 A) FUSE

UNDER-HOOD RELAY BOX C

FAIL-SAFE RELAY

IG SW (50 A) FUSE

METER (15 A) FUSE

METER RELAY

TCS (15 A) FUSE

STOP/HORN

'96 - 98 models: (15 A) FUSE

'99 model: (20 A) FUSE

UNDER-HOOD FUSE/RELAY BOX

UNDER-HOOD RELAY BOX C

LEFT-FRONT WHEEL SENSOR

POWERTRAIN

CONTROL MODULE (PCM)

STEERING ANGLE SENSOR

RIGHT-REAR WHEEL SENSOR

TCS CONTROL UNIT

TCS/CRUISE SWITCH

UNDER-DASH FUSE/RELAY BOX

UNDER-DASH FUSE/RELAY BOX

METER (7.5 A) FUSE

TCS INDICATOR LIGHTProCarManuals.com

Page 1191 of 1954

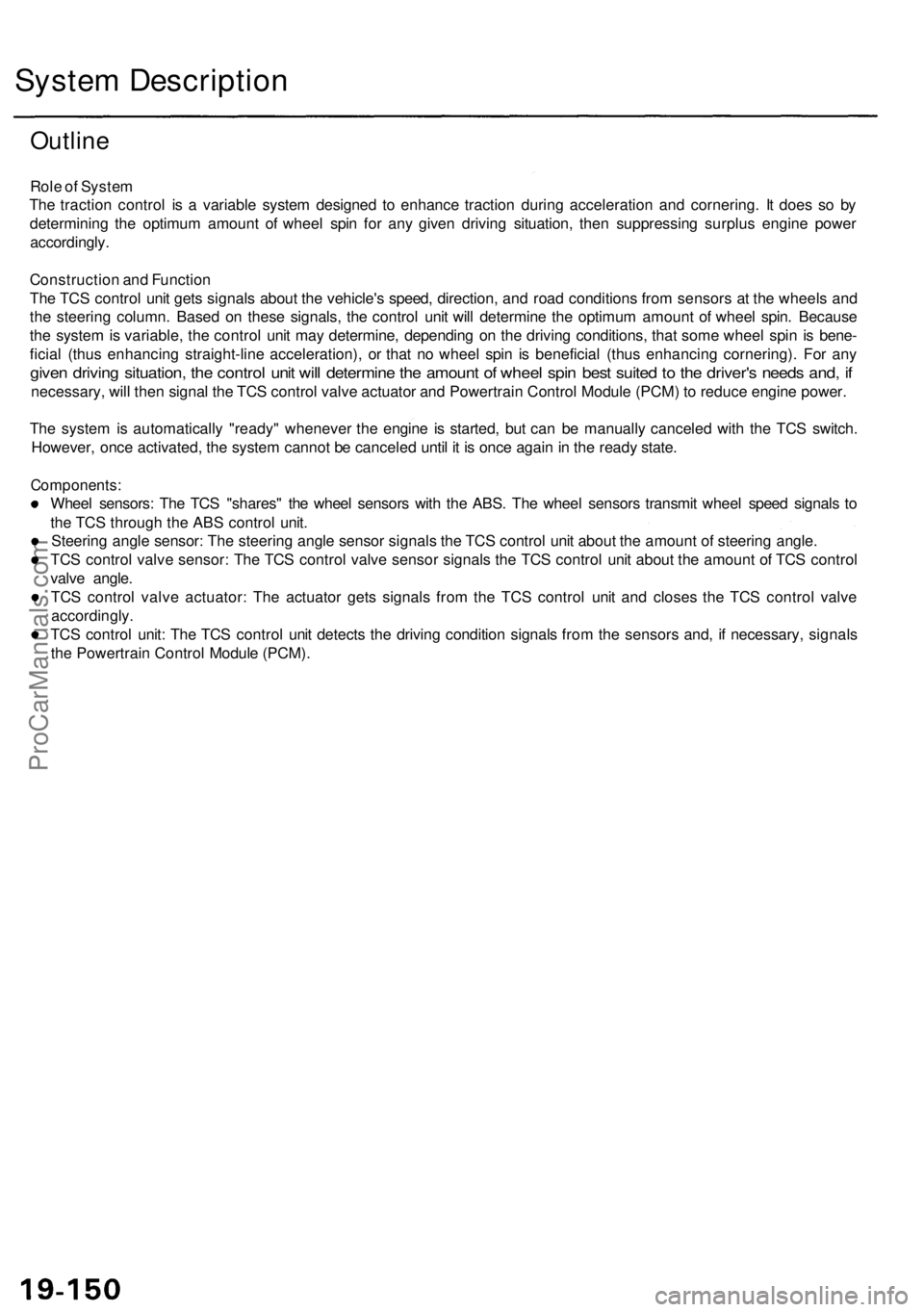

System Description

Outline

Role of System

The traction control is a variable system designed to enhance traction during acceleration and cornering. It does so by

determining the optimum amount of wheel spin for any given driving situation, then suppressing surplus engine power

accordingly.

Construction and Function

The TCS control unit gets signals about the vehicle's speed, direction, and road conditions from sensors at the wheels and

the steering column. Based on these signals, the control unit will determine the optimum amount of wheel spin. Because

the system is variable, the control unit may determine, depending on the driving conditions, that some wheel spin is bene-

ficial (thus enhancing straight-line acceleration), or that no wheel spin is beneficial (thus enhancing cornering). For any

given driving situation, the control unit will determine the amount of wheel spin best suited to the driver's needs and, if

necessary, will then signal the TCS control valve actuator and Powertrain Control Module (PCM) to reduce engine power.

The system is automatically "ready" whenever the engine is started, but can be manually canceled with the TCS switch.

However, once activated, the system cannot be canceled until it is once again in the ready state.

Components:

Wheel sensors: The TCS "shares" the wheel sensors with the ABS. The wheel sensors transmit wheel speed signals to

the TCS through the ABS control unit.

Steering angle sensor: The steering angle sensor signals the TCS control unit about the amount of steering angle.

TCS control valve sensor: The TCS control valve sensor signals the TCS control unit about the amount of TCS control

valve angle.

TCS control valve actuator: The actuator gets signals from the TCS control unit and closes the TCS control valve

accordingly.

TCS control unit: The TCS control unit detects the driving condition signals from the sensors and, if necessary, signals

the Powertrain Control Module (PCM).ProCarManuals.com

Page 1192 of 1954

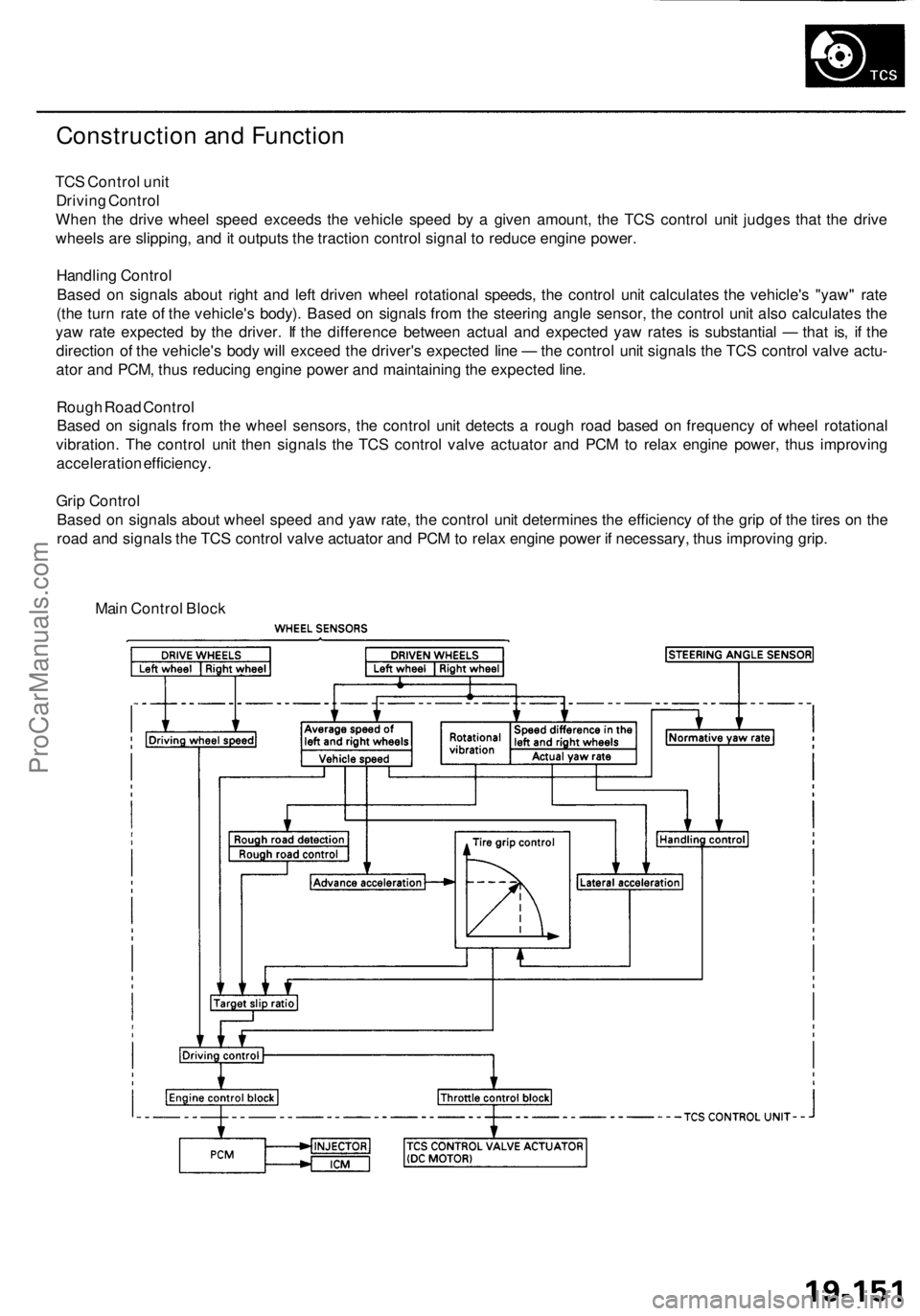

Construction and Function

TCS Control unit

Driving Control

When the drive wheel speed exceeds the vehicle speed by a given amount, the TCS control unit judges that the drive

wheels are slipping, and it outputs the traction control signal to reduce engine power.

Handling Control

Based on signals about right and left driven wheel rotational speeds, the control unit calculates the vehicle's "yaw" rate

(the turn rate of the vehicle's body). Based on signals from the steering angle sensor, the control unit also calculates the

yaw rate expected by the driver. If the difference between actual and expected yaw rates is substantial — that is, if the

direction of the vehicle's body will exceed the driver's expected line — the control unit signals the TCS control valve actu-

ator and PCM, thus reducing engine power and maintaining the expected line.

Rough Road Control

Based on signals from the wheel sensors, the control unit detects a rough road based on frequency of wheel rotational

vibration. The control unit then signals the TCS control valve actuator and PCM to relax engine power, thus improving

acceleration efficiency.

Grip Control

Based on signals about wheel speed and yaw rate, the control unit determines the efficiency of the grip of the tires on the

road and signals the TCS control valve actuator and PCM to relax engine power if necessary, thus improving grip.

Main Control BlockProCarManuals.com

Page 1196 of 1954

TCS CONTROL UNIT 20P CONNECTOR

Wire side of female terminals

VB: Battery Voltage

Terminal

number

1

2

4

5

6

9

10

11

12

13

14

15

16

17

20

Wire

color

BLK/YEL

GRN/RED

BLU

PNK/BLU

BLK/WHT

BLK

BRN/WHT

GRN/WHT

BLU

GRN/ORN

BLK/ORN

BRN/BLK

WHT/BLU

BLU/GRY

GRN

BRN

Terminal sign

(Terminal name)

IG1

(Ignition 1)

PARK

(Parking)

SCS

(Service check

signal)

STR-GND

(Steering ground)

AT-SHIFT

(AT shift)

FSR

(Fail-safe relay)

PMG

(Power motor

Ground)

VPM

(Voltage power

motor)

STOP

(Stop)

NEP (Engine

speed pulse)

BARO

(Barometric)

TC-FC

(Traction control

fuel cut)

LG2

(Logic ground 2)

STR-VCC (Steer-

ing power supply)

WARN2

(Warning 2)

SH-MOT

(Shield motor)

MOT +

(Motor +)

MOT-

(Motor -)

Description

Detects ignition switch

IG1 signal

Detects parking brake

switch signal

Detects service check

connector signal

(Diagnostic trouble

code indication)

Ground for the steering

angle sensor

Detects A/T shift posi-

tion signal

Drives fail-safe relay

Power ground for the

TCS control valve

actuator motor

Power source for the

TCS control valve

actuator motor

Detects brake pedal

position switch signal

Detects engine speed

signal

Detects barometric

sensor signal

TCS Fl, Fuel cut

(torque down) signal

Ground for the logic

circuit

Power source for the

steering angle sensor

Drives TCS indicator light

(The indicator light comes

on by the self-bias)

Shield for the TCS con-

trol valve actuator motor

Drives TCS control

valve actuator motor

Drives TCS control

valve actuator motor

Measurement

terminals

1-GND

2

3-GND

4-GND

5-GND

6-GND

9-GND

10-GND

11-GND

12-GND

13-GND

14-GND

15-GND

16-GND

17-GND

19-20

20-19

Voltage

Conditions

(Ignition Switch ON (II))

Depress the parking

brake pedal.

Release the parking

brake pedal.

SCS service connector

connected.

SCS service connector

disconnected.

Shift the transmission

to position, then

start the engine.

Start the engine.

Start the engine.

Brake pedal depressed.

Brake pedal released.

Engine idling

TCS is functioning,

(maximum fuel cut)

TCS is not functioning.

Indicator light ON

Indicator light OFF

TCS is functioning.

TCS is not functioning.

TCS is functioning.

TCS is not functioning.

Output

voltage

VB

Below 0.6 V

VB

0V

5V

Below 0.3V

About 4V

(5V 0V)

VB

1.5V

Below 0.3 V

0V

VB

VB

0V

About 6V

(12V

0V)

About 3 V

About 1.5V

About 4.5 V

(5 V,

PWM)

Below 0.3V

About 5 V

About 2 V

VB

VB

0V

VB

0VProCarManuals.com