battery ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 45 of 1771

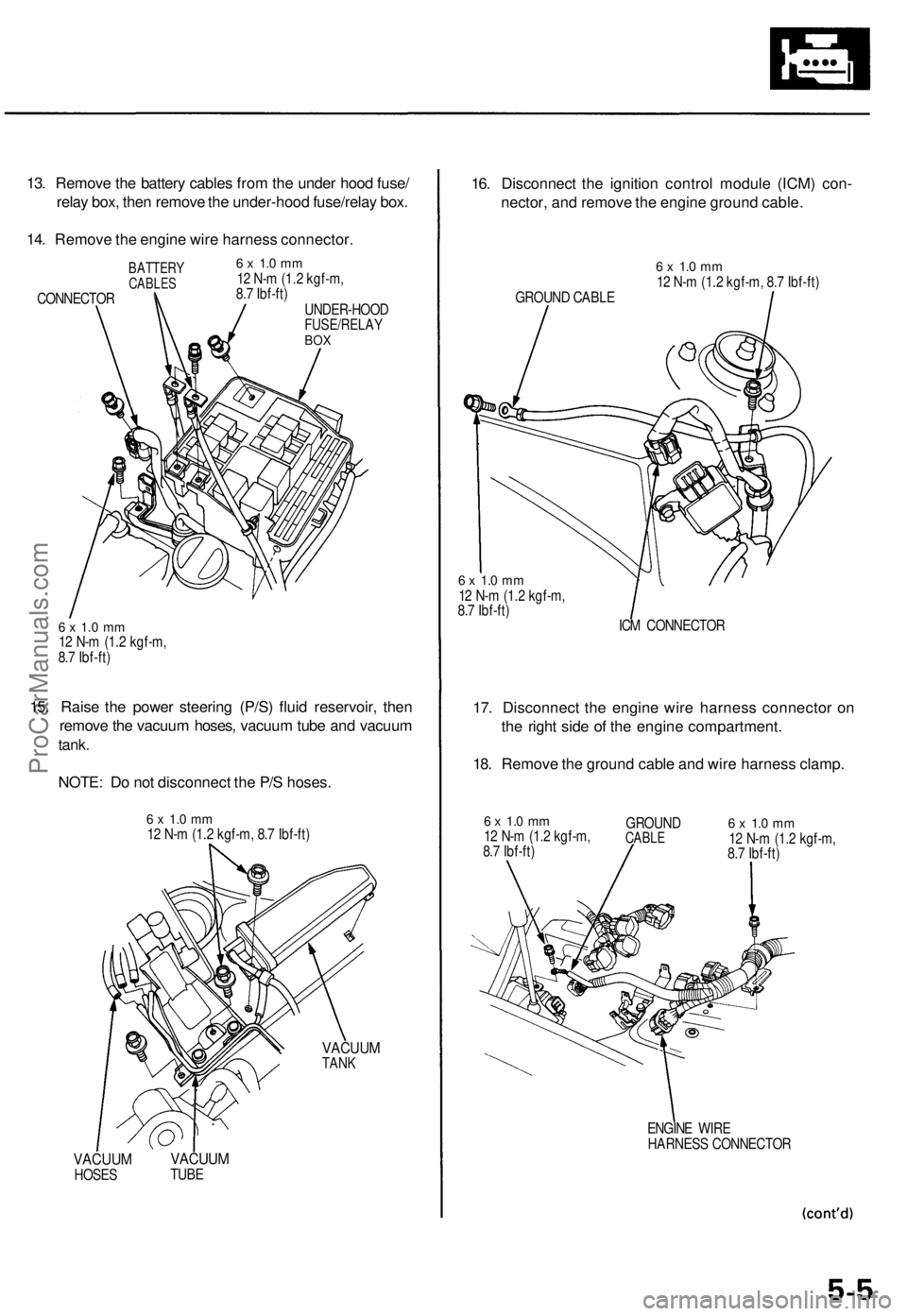

13. Remove the battery cables from the under hood fuse/

relay box, then remove the under-hood fuse/relay box.

14. Remove the engine wire harness connector.

BATTERY

CABLES

CONNECTOR

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

UNDER-HOOD

FUSE/RELAY

BOX

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

15. Raise the power steering (P/S) fluid reservoir, then

remove the vacuum hoses, vacuum tube and vacuum

tank.

NOTE: Do not disconnect the P/S hoses.

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

VACUUM

TANK

VACUUM

HOSES

VACUUM

TUBE

16. Disconnect the ignition control module (ICM) con-

nector, and remove the engine ground cable.

GROUND CABLE

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

ICM CONNECTOR

17. Disconnect the engine wire harness connector on

the right side of the engine compartment.

18. Remove the ground cable and wire harness clamp.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

GROUND

CABLE

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

ENGINE WIRE

HARNESS CONNECTORProCarManuals.com

Page 63 of 1771

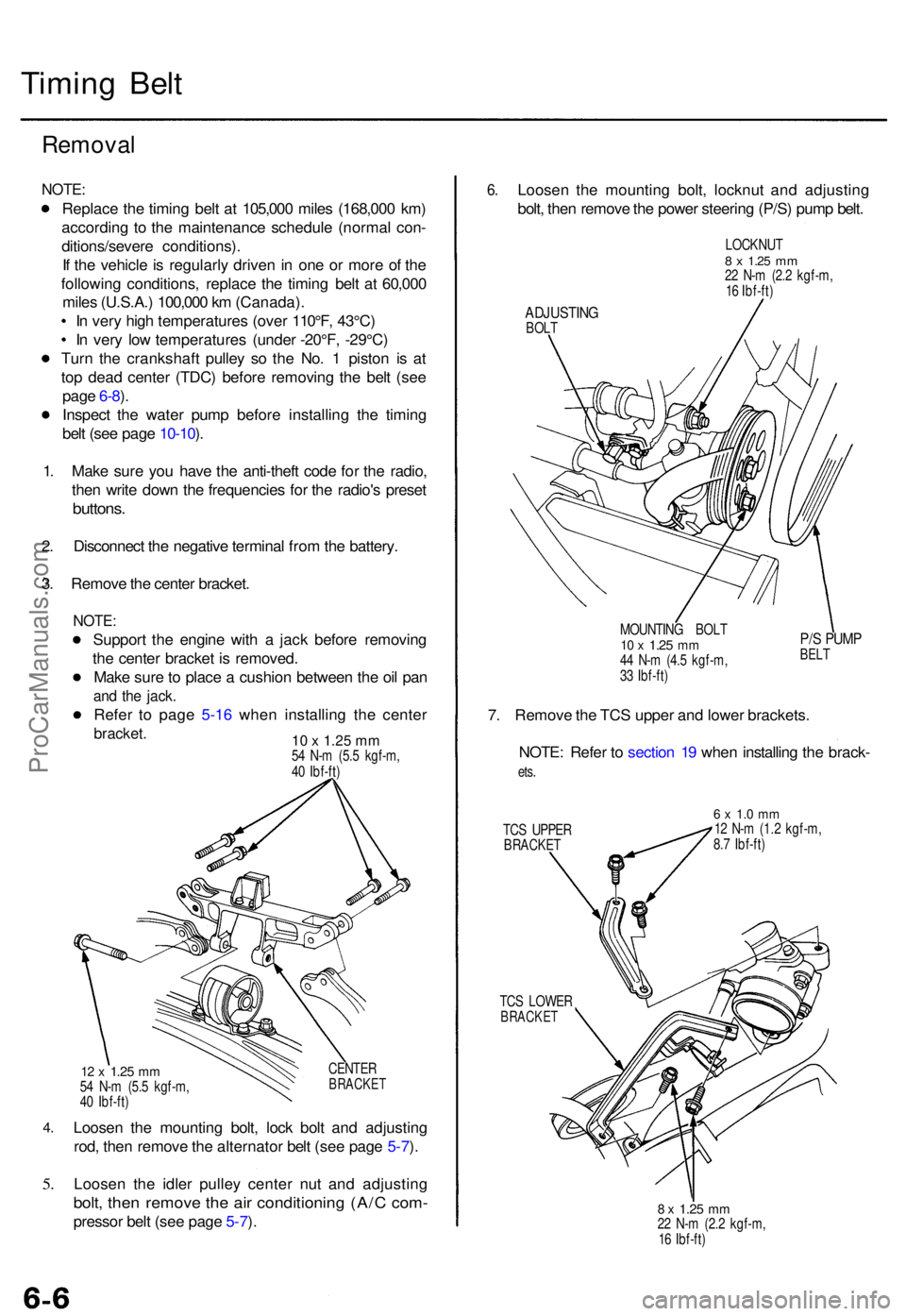

Timing Bel t

Remova l

NOTE:

Replac e th e timin g bel t a t 105,00 0 mile s (168,00 0 km )

accordin g t o th e maintenanc e schedul e (norma l con -

ditions/sever e conditions) .

I f th e vehicl e is regularl y drive n i n on e o r mor e o f th e

followin g conditions , replac e th e timin g bel t a t 60,00 0

mile s (U.S.A. ) 100,00 0 k m (Canada) .

I n ver y hig h temperature s (ove r 110°F , 43°C )

I n ver y lo w temperature s (unde r -20°F , -29°C )

Tur n th e crankshaf t pulle y s o th e No . 1 pisto n i s a t

to p dea d cente r (TDC ) befor e removin g th e bel t (se e

pag e 6-8 ).

Inspec t th e wate r pum p befor e installin g th e timin g

bel t (se e pag e 10-10 ).

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s prese t

buttons .

2. Disconnec t th e negativ e termina l fro m th e battery .

3 . Remov e th e cente r bracket .

NOTE:

Suppor t th e engin e wit h a jac k befor e removin g

th e cente r bracke t i s removed .

Mak e sur e to plac e a cushio n betwee n th e oi l pa n

and th e jack .

Refer t o pag e 5-1 6 whe n installin g th e cente r

bracket. 10 x 1.25 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

4.

5.

CENTE RBRACKE T12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

Loose n th e mountin g bolt , loc k bol t an d adjustin g

rod , the n remov e th e alternato r bel t (se e pag e 5-7 ).

Loose n th e idle r pulle y cente r nu t an d adjustin g

bolt, the n remov e th e ai r conditionin g (A/ C com -

presso r bel t (se e pag e 5-7 ).

6 .Loose n th e mountin g bolt , locknu t an d adjustin g

bolt , the n remov e th e powe r steerin g (P/S ) pum p belt .

LOCKNU T8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

ADJUSTIN GBOLT

MOUNTING BOL T

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

P/S PUM PBELT

7. Remov e th e TC S uppe r an d lowe r brackets .

NOTE : Refe r t o sectio n 1 9 whe n installin g th e brack -

ets.

TC S UPPE RBRACKE T

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

TC S LOWE R

BRACKE T

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

ProCarManuals.com

Page 73 of 1771

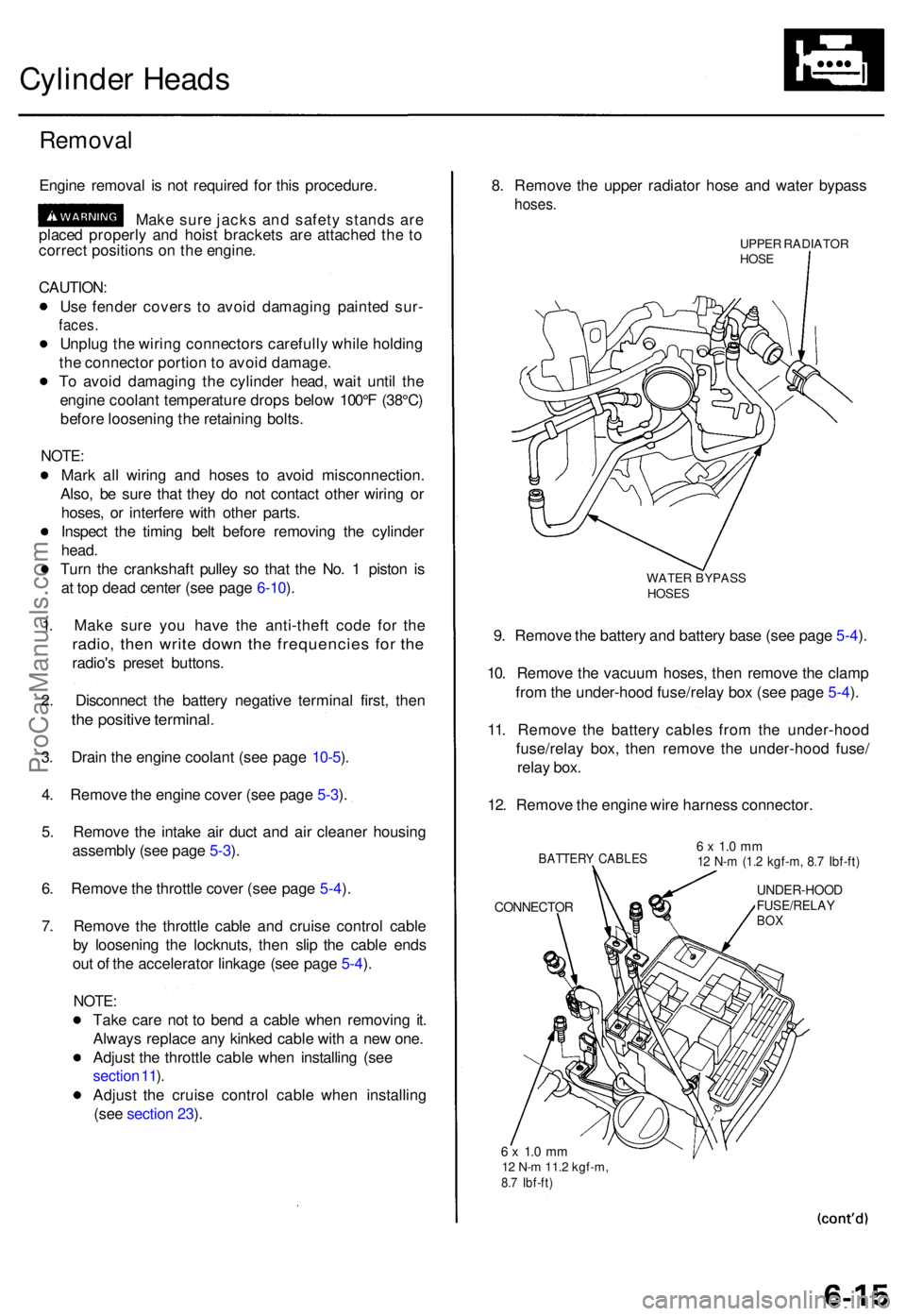

Cylinder Head s

Remova l

Engine remova l i s no t require d fo r thi s procedure .

Mak e sur e jack s an d safet y stand s ar e

place d properl y an d hois t bracket s ar e attache d th e t o

correc t position s o n th e engine .

CAUTION :

Us e fende r cover s t o avoi d damagin g painte d sur -

faces .

Unplu g th e wirin g connector s carefull y whil e holdin g

th e connecto r portio n to avoi d damage .

T o avoi d damagin g th e cylinde r head , wai t unti l th e

engin e coolan t temperatur e drop s belo w 100° F (38°C )

befor e loosenin g th e retainin g bolts .

NOTE :

Mark al l wirin g an d hose s t o avoi d misconnection .

Also , b e sur e tha t the y d o no t contac t othe r wirin g o r

hoses , o r interfer e wit h othe r parts .

Inspec t th e timin g bel t befor e removin g th e cylinde r

head .

Tur n th e crankshaf t pulle y s o tha t th e No . 1 pisto n i s

a t to p dea d cente r (se e pag e 6-10 ).

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e

radio , the n writ e dow n th e frequencie s fo r th e

radio' s prese t buttons .

2 . Disconnec t th e batter y negativ e termina l first , the n

the positiv e terminal .

3. Drai n th e engin e coolan t (se e pag e 10-5 ).

4 . Remov e th e engin e cove r (se e pag e 5-3 ).

5 . Remov e th e intak e ai r duc t an d ai r cleane r housin g

assembl y (se e pag e 5-3 ).

6 . Remov e th e throttl e cove r (se e pag e 5-4 ).

7 . Remov e th e throttl e cabl e an d cruis e contro l cabl e

b y loosenin g th e locknuts , the n sli p th e cabl e end s

ou t o f th e accelerato r linkag e (se e pag e 5-4 ).

NOTE :

Take car e no t t o ben d a cabl e whe n removin g it .

Alway s replac e an y kinke d cabl e wit h a ne w one .

Adjus t th e throttl e cabl e whe n installin g (se e

sectio n 11 ).

Adjus t th e cruis e contro l cabl e whe n installin g

(se e sectio n 23 ). 8

. Remov e th e uppe r radiato r hos e an d wate r bypas s

hoses.

UPPER RADIATO RHOSE

WATE R BYPAS SHOSES

9. Remov e th e batter y an d batter y bas e (se e pag e 5-4 ).

10 . Remov e th e vacuu m hoses , the n remov e th e clam p

fro m th e under-hoo d fuse/rela y bo x (se e pag e 5-4 ).

11 . Remov e th e batter y cable s fro m th e under-hoo d

fuse/rela y box , the n remov e th e under-hoo d fuse /

rela y box .

12 . Remov e th e engin e wir e harnes s connector .

BATTERY CABLE S

CONNECTO R

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

UNDER-HOO DFUSE/RELAYBOX

6 x 1. 0 m m12 N- m 11. 2 kgf-m ,8.7 Ibf-ft )

ProCarManuals.com

Page 188 of 1771

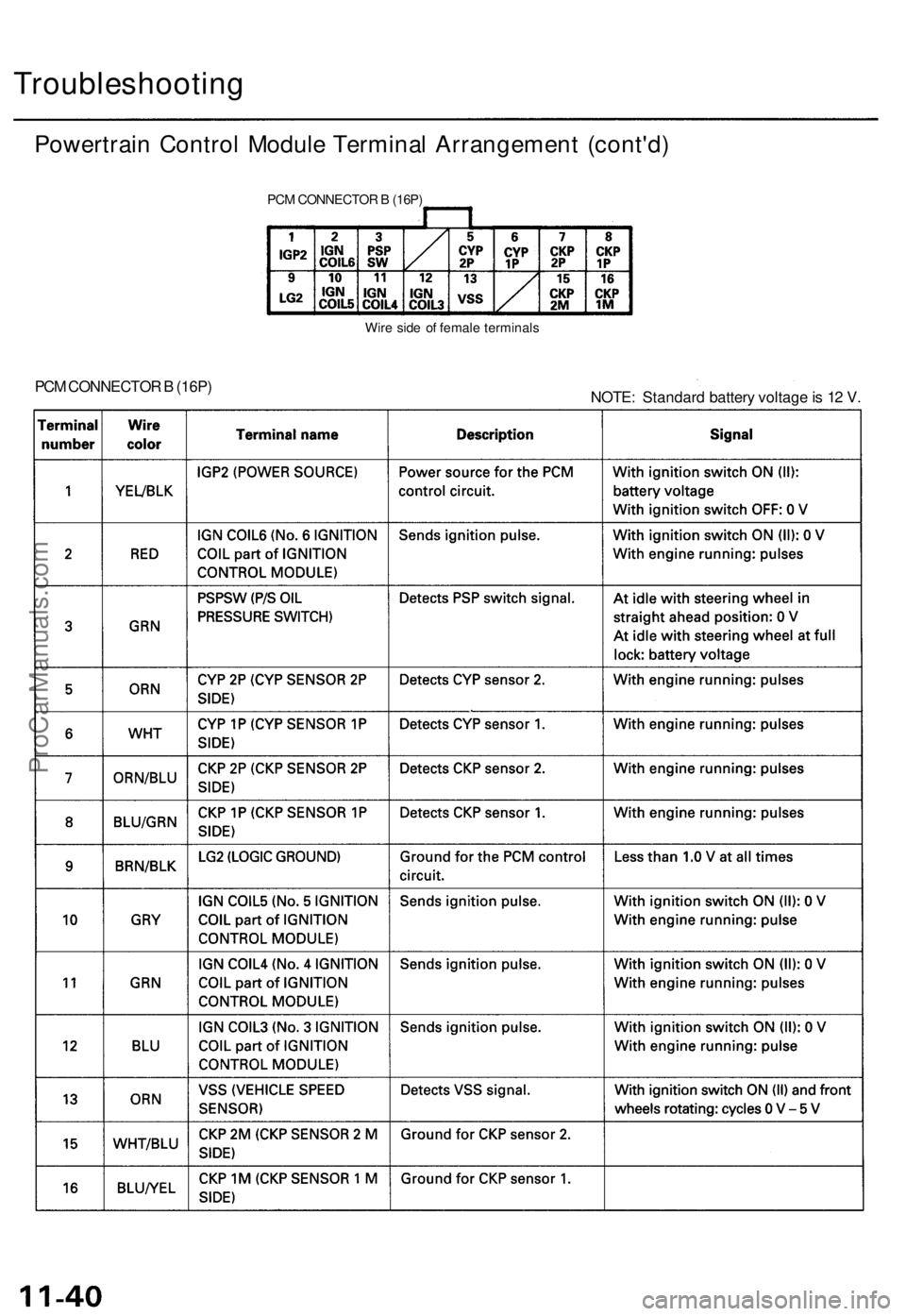

Troubleshooting

Powertrain Control Module Terminal Arrangement (cont'd)

PCM CONNECTOR B (16P)

Wire side of female terminals

PCM CONNECTOR B (16P)

NOTE: Standard battery voltage is 12 V.ProCarManuals.com

Page 190 of 1771

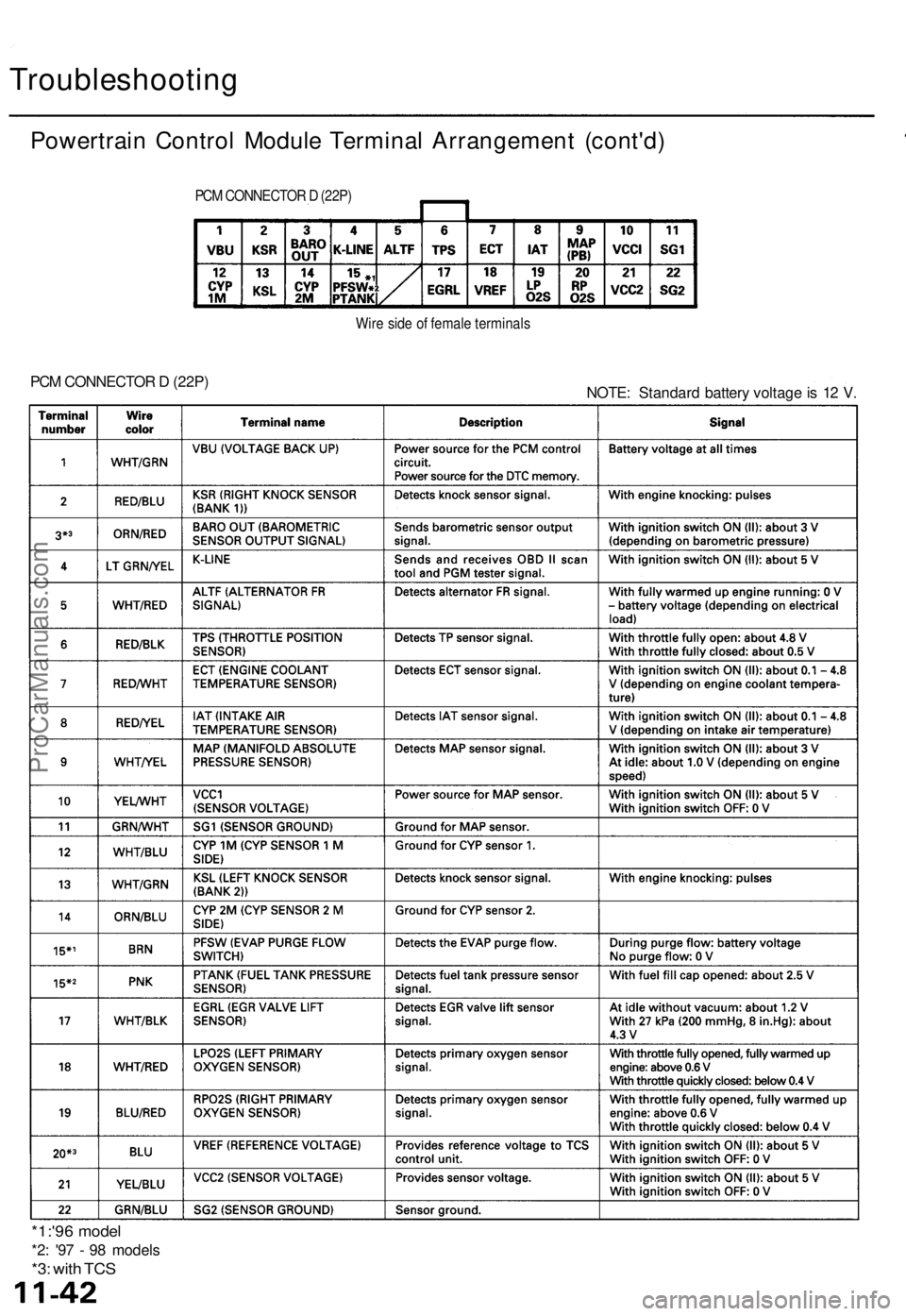

Troubleshooting

Powertrain Control Module Terminal Arrangement (cont'd)

PCM CONNECTOR D (22P)

Wire side of female terminals

PCM CONNECTOR D (22P)

NOTE: Standard battery voltage is 12 V.

*1:'96 model

*2: '97 - 98 models

*3: with TCSProCarManuals.com

Page 209 of 1771

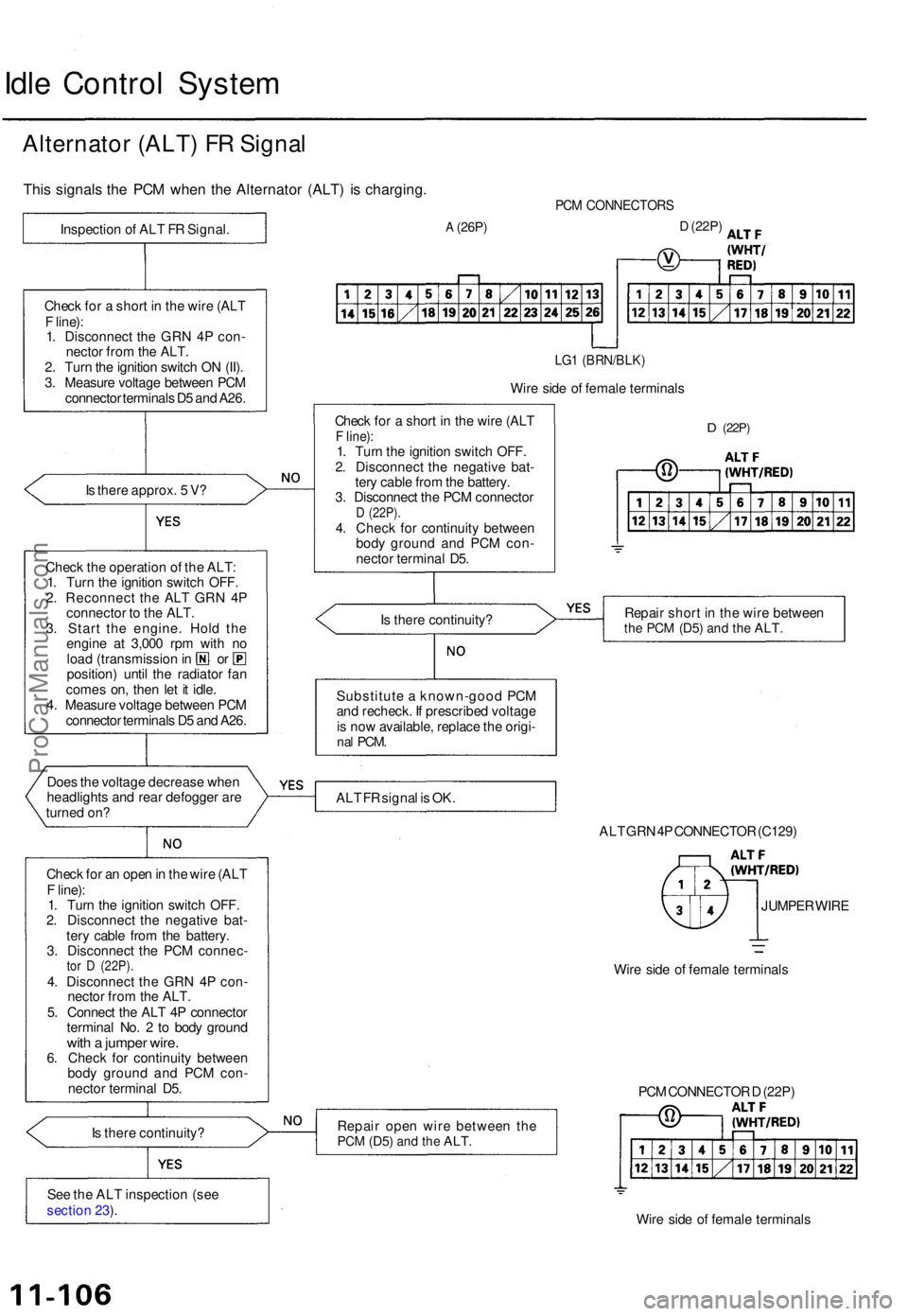

Idle Contro l Syste m

Alternato r (ALT ) F R Signa l

This signal s th e PC M whe n th e Alternato r (ALT ) i s charging .

Is ther e approx . 5 V ?

Chec k th e operatio n o f th e ALT :

1 . Tur n th e ignitio n switc h OFF .

2 . Reconnec t th e AL T GR N 4 P

connecto r t o th e ALT .

3 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n o

loa d (transmissio n in o r

position ) unti l th e radiato r fa n

come s on , the n le t i t idle .

4 . Measur e voltag e betwee n PC M

connecto r terminal s D 5 an d A26 .

Doe s th e voltag e decreas e whe n

headlight s an d rea r defogge r ar e

turne d on ?

Chec k fo r a n ope n in th e wir e (AL T

F line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e PC M connec -

tor D (22P) .4. Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

5 . Connec t th e AL T 4 P connecto r

termina l No . 2 to bod y groun d

with a jumpe r wire .6. Chec k fo r continuit y betwee n

bod y groun d an d PC M con -

necto r termina l D5 .

I s ther e continuity ?

Se e th e AL T inspectio n (se e

sectio n 23 ).

PC M CONNECTOR S

A (26P)D (22P )

LG1 (BRN/BLK )

Wire sid e o f femal e terminal s

Chec k fo r a shor t i n th e wir e (AL T

F line) :1. Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e PC M connecto r

D (22P) .4. Chec k fo r continuit y betwee n

bod y groun d an d PC M con -

necto r termina l D5 .

D (22P )

Is ther e continuity ? Repai

r shor t i n th e wir e betwee nthe PC M (D5 ) and th e ALT .

Substitut e a known-goo d PC M

an d recheck . I f prescribe d voltag e

i s no w available , replac e th e origi -

nal PCM .

ALT F R signa l i s OK .

ALT GR N 4P CONNECTO R (C129 )

JUMPE R WIR E

Wir e sid e o f femal e terminal s

Repai r ope n wir e betwee n th e

PC M (D5 ) and th e ALT .

Wire sid e o f femal e terminal s

PC

M CONNECTO R D (22P )

Chec

k fo r a shor t i n th e wir e (AL T

F line) :

1 . Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

2 . Tur n th e ignitio n switc h O N (II) .

3 . Measur e voltag e betwee n PC M

connecto r terminal s D 5 an d A26 .

Inspectio

n o f AL T F R Signal .

ProCarManuals.com

Page 210 of 1771

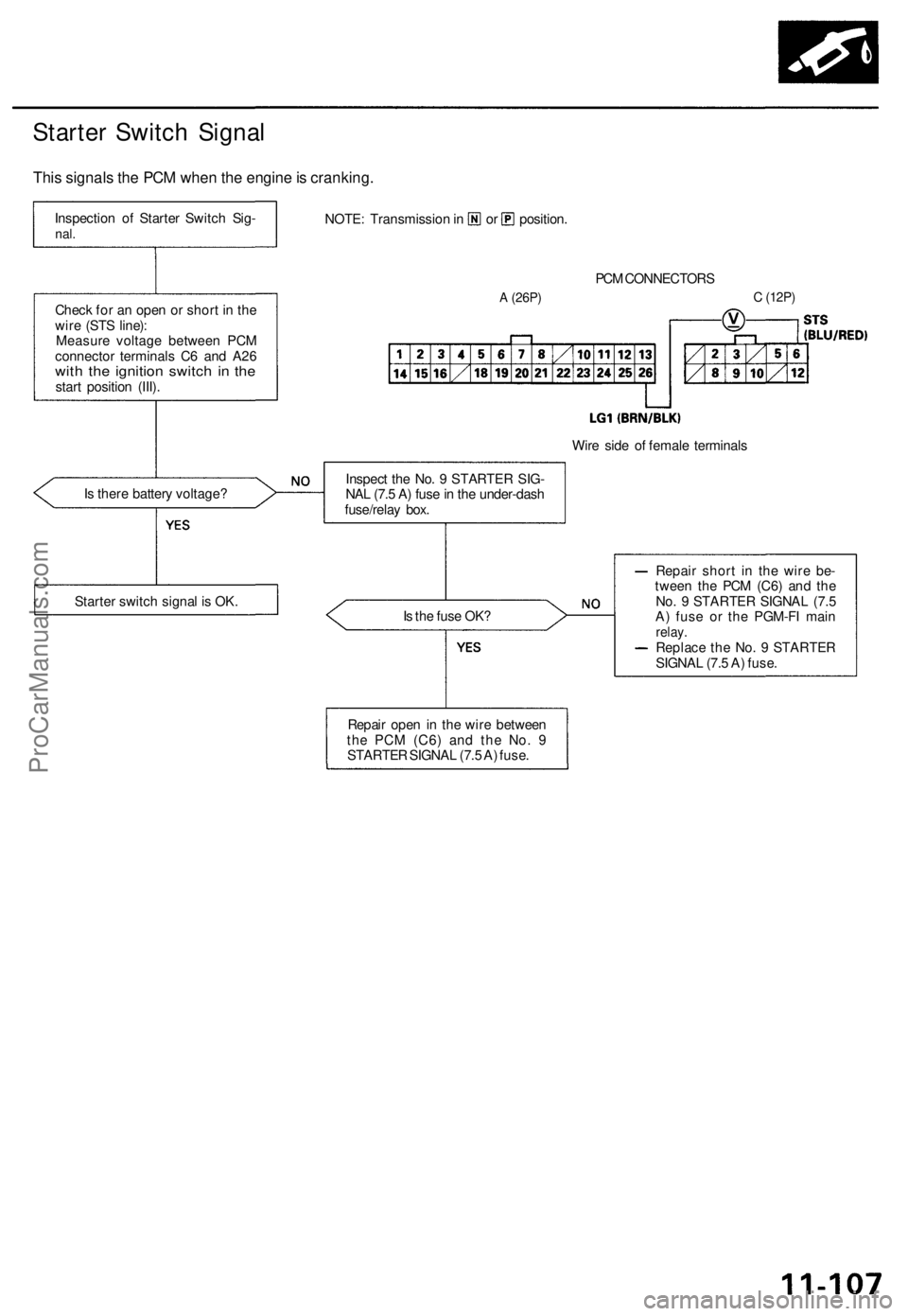

Starter Switch Signal

This signals the PCM when the engine is cranking.

PCM CONNECTORS

A

(26P)

C

(12P)

Wire side of female terminals

Is there battery voltage?

Is the fuse OK?

Repair short in the wire be-

tween the PCM (C6) and the

No. 9 STARTER SIGNAL (7.5

A) fuse or the PGM-FI main

relay.

Replace the No. 9 STARTER

SIGNAL (7.5 A) fuse.

Repair open in the wire between

the PCM

(C6)

and the No. 9

STARTER SIGNAL (7.5 A) fuse.

Starter switch signal is OK.

Inspect the No. 9 STARTER SIG-

NAL (7.5 A) fuse in the under-dash

fuse/relay box.

Check for an open or short in the

wire (STS line):

Measure voltage between PCM

connector terminals C6 and A26

with the ignition switch in the

start position (III).

Inspection of Starter Switch Sig-

nal.

NOTE: Transmission in or position.ProCarManuals.com

Page 235 of 1771

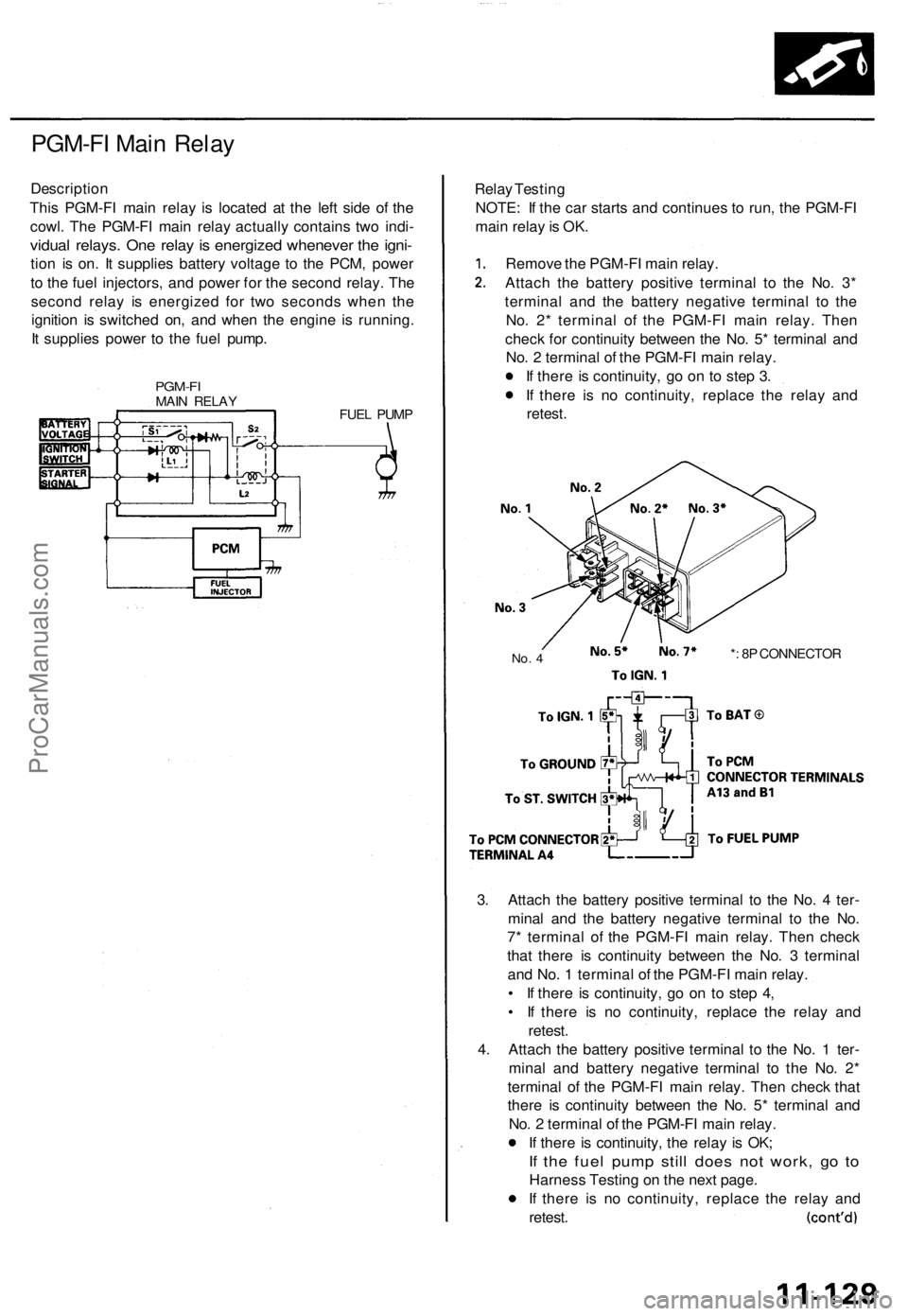

PGM-FI Main Relay

Description

This PGM-FI main relay is located at the left side of the

cowl. The PGM-FI main relay actually contains two indi-

vidual relays. One relay is energized whenever the igni-

tion is on. It supplies battery voltage to the PCM, power

to the fuel injectors, and power for the second relay. The

second relay is energized for two seconds when the

ignition is switched on, and when the engine is running.

It supplies power to the fuel pump.

PGM-FI

MAIN RELAY

FUEL PUMP

Relay Testing

NOTE: If the car starts and continues to run, the PGM-FI

main relay is OK.

Remove the PGM-FI main relay.

Attach the battery positive terminal to the No. 3*

terminal and the battery negative terminal to the

No. 2* terminal of the PGM-FI main relay. Then

check for continuity between the No. 5* terminal and

No. 2 terminal of the PGM-FI main relay.

If there is continuity, go on to step 3.

If there is no continuity, replace the relay and

retest.

No. 4

*: 8P CONNECTOR

3. Attach the battery positive terminal to the No. 4 ter-

minal and the battery negative terminal to the No.

7* terminal of the PGM-FI main relay. Then check

that there is continuity between the No. 3 terminal

and No. 1 terminal of the PGM-FI main relay.

• If there is continuity, go on to step 4,

• If there is no continuity, replace the relay and

retest.

4. Attach the battery positive terminal to the No. 1 ter-

minal and battery negative terminal to the No. 2*

terminal of the PGM-FI main relay. Then check that

there is continuity between the No. 5* terminal and

No. 2 terminal of the PGM-FI main relay.

If there is continuity, the relay is OK;

If the fuel pump still does not work, go to

Harness Testing on the next page.

If there is no continuity, replace the relay and

retest.ProCarManuals.com

Page 332 of 1771

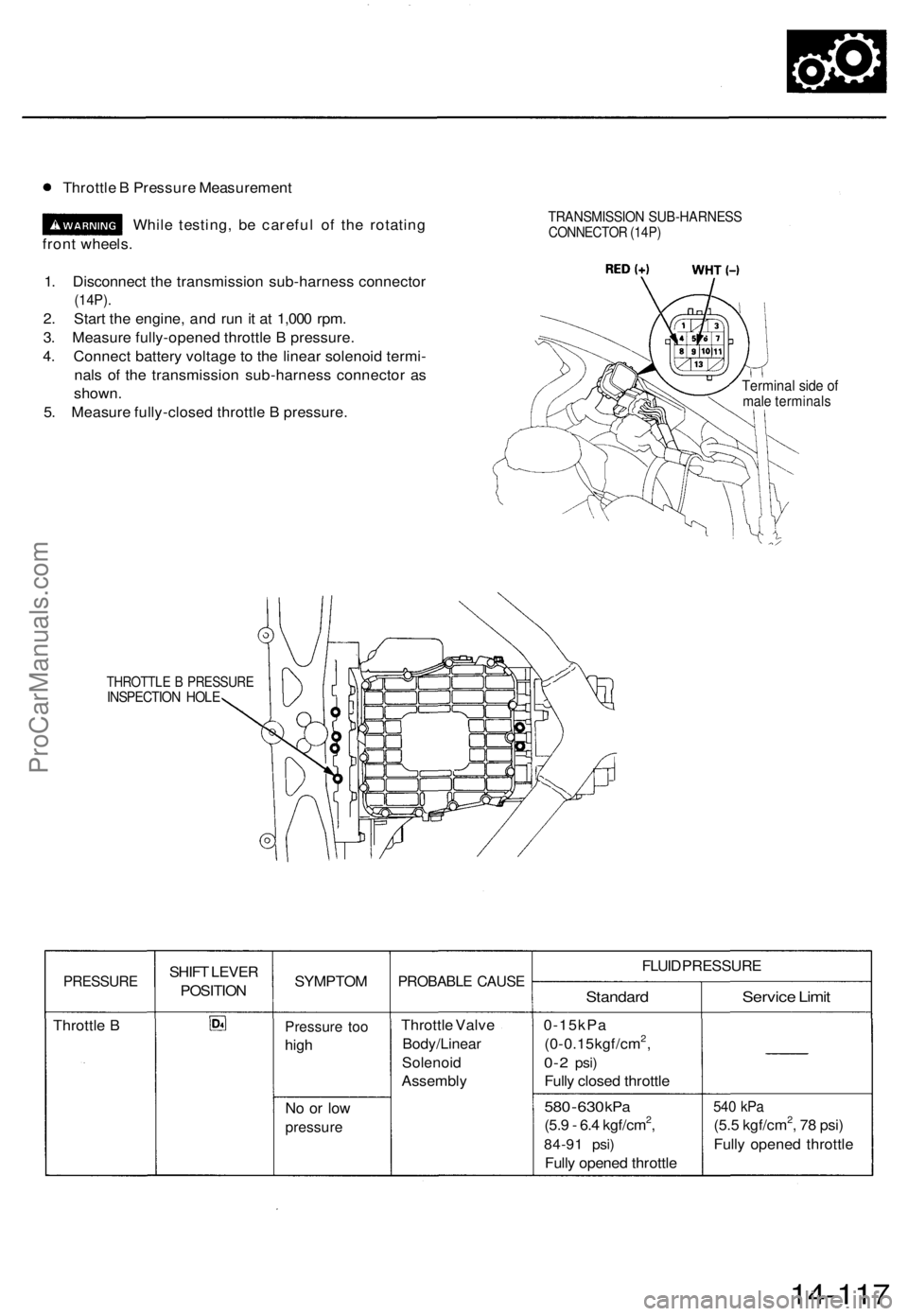

Throttle B Pressure Measurement

While testing, be careful of the rotating

front wheels.

1. Disconnect the transmission sub-harness connector

(14P).

2. Start the engine, and run it at 1,000 rpm.

3. Measure fully-opened throttle B pressure.

4. Connect battery voltage to the linear solenoid termi-

nals of the transmission sub-harness connector as

shown.

5. Measure fully-closed throttle B pressure.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)

Terminal side of

male terminals

THROTTLE B PRESSURE

INSPECTION HOLE

PRESSURE

Throttle B

SHIFT LEVER

POSITION

SYMPTOM

Pressure too

high

No or low

pressure

PROBABLE CAUSE

Throttle Valve

Body/Linear

Solenoid

Assembly

FLUID PRESSURE

Standard

0-15kPa

(0-0.15kgf/cm2,

0-2

psi)

Fully closed throttle

580

-

630

kPa

(5.9 - 6.4 kgf/cm2,

84-91 psi)

Fully opened throttle

Service Limit

540 kPa

(5.5 kgf/cm2, 78 psi)

Fully opened throttle

14-117ProCarManuals.com

Page 334 of 1771

![ACURA TL 1995 Service Repair Manual

6. Disconnect the transmission sub-harness connector (14P).

7. Start the engine, and run it at 2,000 rpm.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)

8. Shift to the [HI or [P] position, and measure ACURA TL 1995 Service Repair Manual

6. Disconnect the transmission sub-harness connector (14P).

7. Start the engine, and run it at 2,000 rpm.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)

8. Shift to the [HI or [P] position, and measure](/img/32/56993/w960_56993-333.png)

6. Disconnect the transmission sub-harness connector (14P).

7. Start the engine, and run it at 2,000 rpm.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)

8. Shift to the [HI or [P] position, and measure line pressure at fully-opened throttle.

9. Connect battery voltage to the linear solenoid terminals of the transmission sub-harness connector as shown.

10. Measure line pressure at fully-closed throttle.

If line pressure is out of specification, check and repair the probable cause in the table below.

PRESSURE

Line

SHIFT LEVER

POSITION

or

SYMPTOM

No (or

low)

line pressure

PROBABLE CAUSE

Torque converter,

ATF pump, pres-

sure regulator.

torque converter

check valve

FLUID PRESSURE

Standard

520 kPa

(5.3 kgf/cm2, 75 psi)

Fully closed throttle

|

910 kPa

(9.3 kgf/cm2, 130 psi)

Fully opened throttle

Service Limit

500 kPa

(5.1 kgf/cm2, 73 psi)

Fully closed throttle

790 kPa

(8.1 kgf/cm2, 120 psi)

Fully opened throttle

11. Stop the engine, and connect the transmission sub-harness connector (14P).

12. Disconnect the special tool from line pressure inspection hole, and connect the special tool to each inspection hole.

13. Start the engine, and run it at 2,000 rpm.

(cont'd)ProCarManuals.com