turn signal ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 185 of 1771

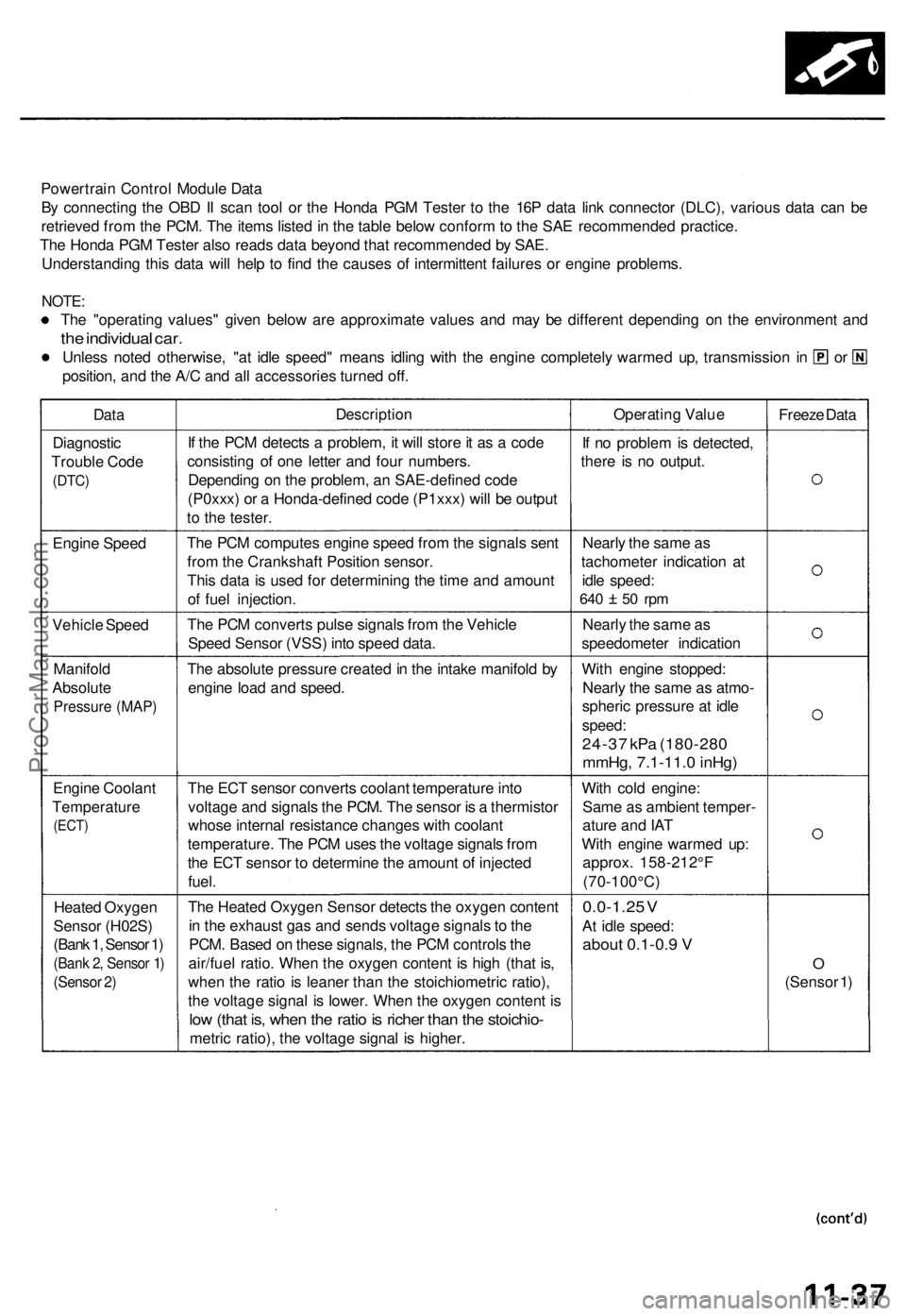

Powertrain Contro l Modul e Dat a

B y connectin g th e OB D II sca n too l o r th e Hond a PG M Teste r t o th e 16 P dat a lin k connecto r (DLC) , variou s dat a ca n b e

retrieve d fro m th e PCM . Th e item s liste d in th e tabl e belo w confor m to th e SA E recommende d practice .

Th e Hond a PG M Teste r als o read s dat a beyon d tha t recommende d b y SAE .

Understandin g thi s dat a wil l hel p t o fin d th e cause s o f intermitten t failure s o r engin e problems .

NOTE:

The "operatin g values " give n belo w ar e approximat e value s an d ma y b e differen t dependin g o n th e environmen t an d

the individua l car .

Unles s note d otherwise , "a t idl e speed " mean s idlin g wit h th e engine completel y warme d up , transmissio n i n o r

position , an d th e A/ C an d al l accessorie s turne d off .

Dat aDescriptio nOperating Valu e

Freeze Dat a

Diagnosti c

Troubl e Cod e

(DTC )

If th e PC M detect s a problem , i t wil l stor e it a s a cod e

consistin g o f on e lette r an d fou r numbers .

Dependin g o n th e problem , a n SAE-define d cod e

(P0xxx ) o r a Honda-define d cod e (P1xxx ) wil l b e outpu t

t o th e tester . I

f n o proble m is detected ,

ther e i s n o output .

Engin e Spee d Th

e PC M compute s engin e spee d fro m th e signal s sen t

fro m th e Crankshaf t Positio n sensor .

Thi s dat a is use d fo r determinin g th e tim e an d amoun t

o f fue l injection . Nearl

y th e sam e a s

tachomete r indicatio n a t

idl e speed :

640 5 0 rp m

Vehicl e Spee d Th

e PC M convert s puls e signal s fro m th e Vehicl e

Spee d Senso r (VSS ) int o spee d data . Nearl

y th e sam e a s

speedomete r indicatio n

Manifol d

Absolut e

Pressur e (MAP )

The absolut e pressur e create d in th e intak e manifol d b y

engin e loa d an d speed . Wit

h engin e stopped :

Nearl y th e sam e a s atmo -

spheri c pressur e a t idl e

speed :

24-37 kP a (180-28 0

mmHg, 7.1-11. 0 inHg )

Engin e Coolan t

Temperatur e

(ECT)

The EC T senso r convert s coolan t temperatur e int o

voltag e an d signal s th e PCM . Th e senso r i s a thermisto r

whos e interna l resistanc e change s wit h coolan t

temperature . Th e PC M use s th e voltag e signal s fro m

th e EC T senso r t o determin e th e amoun t o f injecte d

fuel . Wit

h col d engine :

Sam e a s ambien t temper -

atur e an d IA T

Wit h engin e warme d up :

approx . 158-212° F

(70-100°C )

Heate d Oxyge n

Senso r (H02S )

(Bank 1, Sensor 1)

(Ban k 2 , Senso r 1 )

(Senso r 2 )

Th e Heate d Oxyge n Senso r detect s th e oxyge n conten t

i n th e exhaus t ga s an d send s voltag e signal s to th e

PCM . Base d o n thes e signals , th e PC M control s th e

air/fue l ratio . Whe n th e oxyge n conten t i s hig h (tha t is ,

whe n th e rati o is leane r tha n th e stoichiometri c ratio) ,

th e voltag e signa l i s lower . Whe n th e oxyge n conten t i s

lo w (tha t is , whe n th e rati o is riche r tha n th e stoichio -

metric ratio) , th e voltag e signa l i s higher .

0.0-1.2 5 V

A t idl e speed :

about 0.1-0. 9 V

O

(Senso r 1 )

ProCarManuals.com

Page 199 of 1771

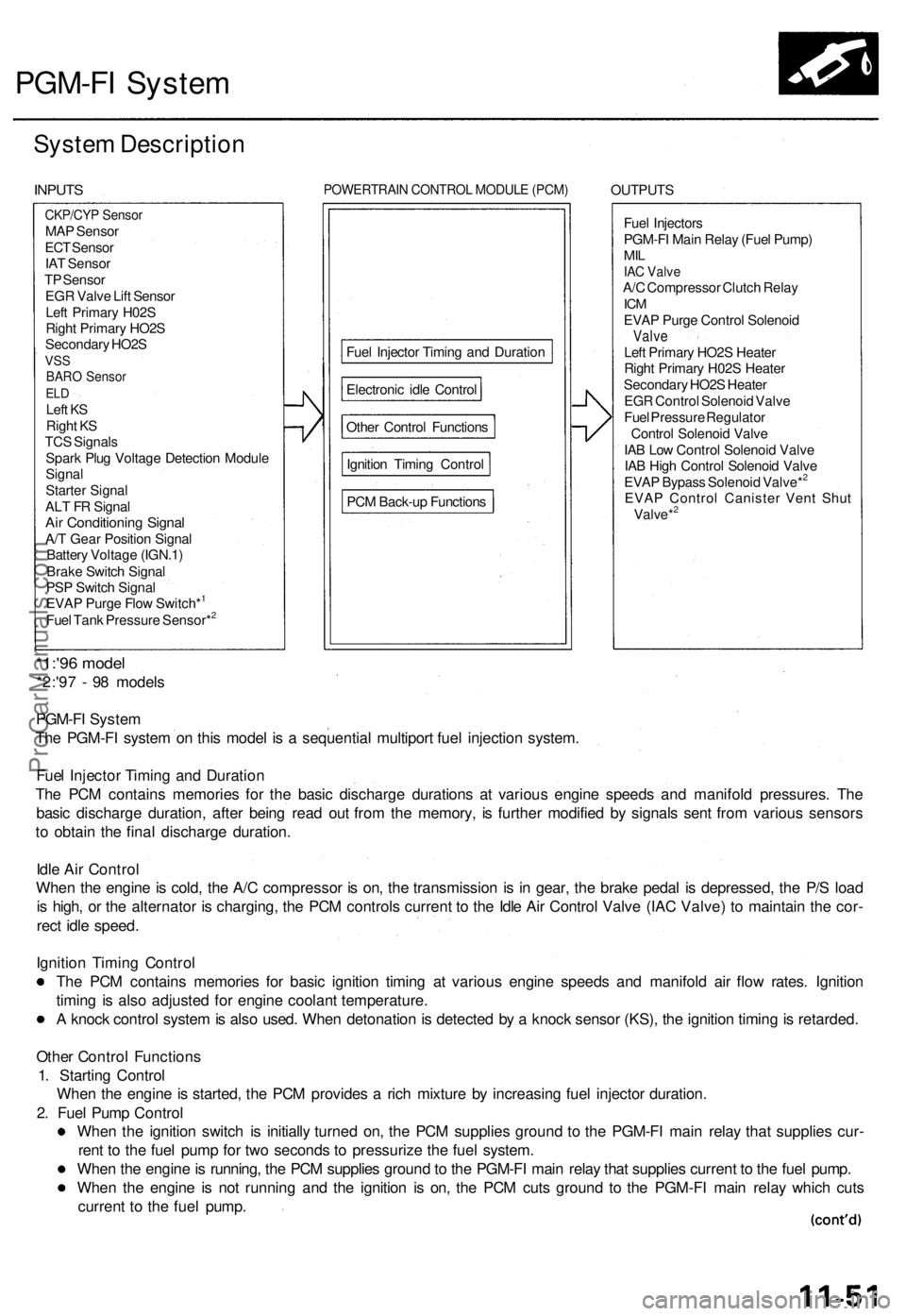

PGM-FI Syste m

System Descriptio n

INPUTS POWERTRAI N CONTRO L MODUL E (PCM ) OUTPUT S

Fue l Injector s

PGM-F I Mai n Rela y (Fue l Pump )

MILIAC Valv eA/C Compresso r Clutc h Rela yICMEVA P Purg e Contro l Solenoi dValveLeft Primar y HO2 S Heate r

Righ t Primar y H02 S Heate r

Secondar y HO2 S Heate r

EG R Contro l Solenoi d Valv e

Fue l Pressur e Regulato r

Contro l Solenoi d Valv e

IA B Lo w Contro l Solenoi d Valv e

IA B Hig h Contro l Solenoi d Valv e

EVA P Bypas s Solenoi d Valve*

2

EVA P Contro l Caniste r Ven t Shu t

Valve*2

*1:'9 6 mode l

*2:'97 - 9 8 model s

PGM-F I Syste m

Th e PGM-F I syste m o n thi s mode l i s a sequentia l multipor t fue l injectio n system .

Fue l Injecto r Timin g an d Duratio n

Th e PC M contain s memorie s fo r th e basi c discharg e duration s a t variou s engin e speed s an d manifol d pressures . Th e

basi c discharg e duration , afte r bein g rea d ou t fro m th e memory , i s furthe r modifie d b y signal s sen t fro m variou s sensor s

t o obtai n th e fina l discharg e duration .

Idl e Ai r Contro l

Whe n th e engin e is cold , th e A/ C compresso r i s on , th e transmissio n i s i n gear , th e brak e peda l i s depressed , th e P/ S loa d

i s high , o r th e alternato r i s charging , th e PC M control s curren t t o th e Idl e Ai r Contro l Valv e (IA C Valve ) t o maintai n th e cor -

rec t idl e speed .

Ignitio n Timin g Contro l

Th e PC M contain s memorie s fo r basi c ignitio n timin g a t variou s engin e speed s an d manifol d ai r flo w rates . Ignitio n

timin g i s als o adjuste d fo r engin e coolan t temperature .

A knoc k contro l syste m is als o used . Whe n detonatio n is detecte d b y a knoc k senso r (KS) , th e ignitio n timin g is retarded .

Othe r Contro l Function s

1 . Startin g Contro l

Whe n th e engin e is started , th e PC M provide s a ric h mixtur e b y increasin g fue l injecto r duration .

2 . Fue l Pum p Contro l

Whe n th e ignitio n switc h i s initiall y turne d on , th e PC M supplie s groun d t o th e PGM-F I mai n rela y tha t supplie s cur -

ren t t o th e fue l pum p fo r tw o second s t o pressuriz e th e fue l system .

Whe n th e engin e is running , th e PC M supplie s groun d to th e PGM-F I mai n rela y tha t supplie s curren t t o th e fue l pump .

Whe n th e engin e i s no t runnin g an d th e ignitio n i s on , th e PC M cut s groun d t o th e PGM-F I mai n rela y whic h cut s

curren t t o th e fue l pump .

CKP/CY P Senso rMAP Senso r

EC T Senso r

IA T Senso r

T P Senso r

EG R Valv e Lif t Senso r

Lef t Primar y H02 S

Righ t Primar y HO2 S

Secondar y HO2 S

VSSBAR O Senso rELDLef t K S

Righ t K S

TC S Signal s

Spar k Plu g Voltag e Detectio n Modul e

Signa l

Starte r Signa l

AL T F R Signa l

Air Conditionin g Signa lA/T Gea r Positio n Signa l

Batter y Voltag e (IGN.1 )

Brak e Switc h Signa l

PS P Switc h Signa l

EVA P Purg e Flo w Switch*

1

Fue l Tan k Pressur e Sensor*2

PC M Back-u p Function s

Ignitio

n Timin g Contro l

Othe

r Contro l Function s

Electroni

c idl e Contro l

Fue

l Injecto r Timin g an d Duratio n

ProCarManuals.com

Page 200 of 1771

PGM-FI System

System Description (cont'd)

3. Fuel Cut-off Control

During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,000 rpm.

Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

4. A/C Compressor Clutch Relay .

When the PCM receives a demand for cooling from the air conditioning system, it delays the compressor from being

energized, and enriches the mixture to assure a smooth transition to the A/C mode.

5. Evaporative Emission (EVAP) Purge Control Solenoid Valve

'96 model: When the engine coolant temperature is below 158°F (70°C), the PCM controls the EVAP purge control

solenoid valve which cuts vacuum to the EVAP purge control canister diaphragm.

'97 - 98 models: When the engine coolant temperature is above 99°F (37°C), the PCM controls the EVAP purge control

solenoid valve which controls vacuum to the EVAP purge control canister.

6. Intake Air Bypass (IAB) Low Control Solenoid Valve, Intake Air Bypass (IAB) High Control Solenoid Valve

When engine speed is below 3,350 rpm, the IAB High Control Solenoid Valve and IAB Low Control Solenoid Valve are

activated by a signal from the PCM. Intake air flows through a long chamber path, increasing torque at low RPM.

When engine speed is 3,350 - 3,950 rpm, the IAB Low Control Solenoid Valve is deactivated by the PCM. Intake air

flows through a short chamber path, increasing mid-range torque.

When the engine rpm is above 3,950 rpm, the IAB Low Control Solenoid Valve and IAB High Control Solenoid Valve are

deactivated by the PCM. This creates a very short intake path and increases high-speed torque.

7. Exhaust Gas Recirculation (EGR) Control Solenoid Valve

When the EGR is required for control of oxides of nitrogen (NOx) emissions, the PCM controls the EGR control solenoid

valve which supplies regulated vacuum to the EGR valve.

ECM Fail-safe/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the PCM ignores that signal and assumes a pre-programmed

value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the PCM itself, the fuel injectors are controlled by a back-up circuit independent of the

system in order to permit minimal driving.

3. Self-diagnosis Function [Malfunction Indicator Lamp (MIL)]

When an abnormality occurs in a signal from a sensor, the PCM supplies ground for the MIL and stores the DTC in

erasable memory. When the ignition is initially turned on, the PCM supplies ground for the MIL for two seconds to

check the MIL bulb condition.

4. Two Driving Cycle Detection Method

To prevent false indications, the two driving cycle detection method is used for the H02S, fuel metering-related, idle

control system, ECT sensor, EGR system, TWC, EVAP control system and other self-diagnostic functions. When an

abnormality occurs, the PCM stores it in its memory. When the same abnormality recurs after the ignition switch is

turned OFF and ON (II) again, the PCM informs the driver by lighting the MIL.

However, to ease troubleshooting, this function is cancelled when you short the service check connector. The MIL will

then blink immediately when an abnormality occurs.ProCarManuals.com

Page 209 of 1771

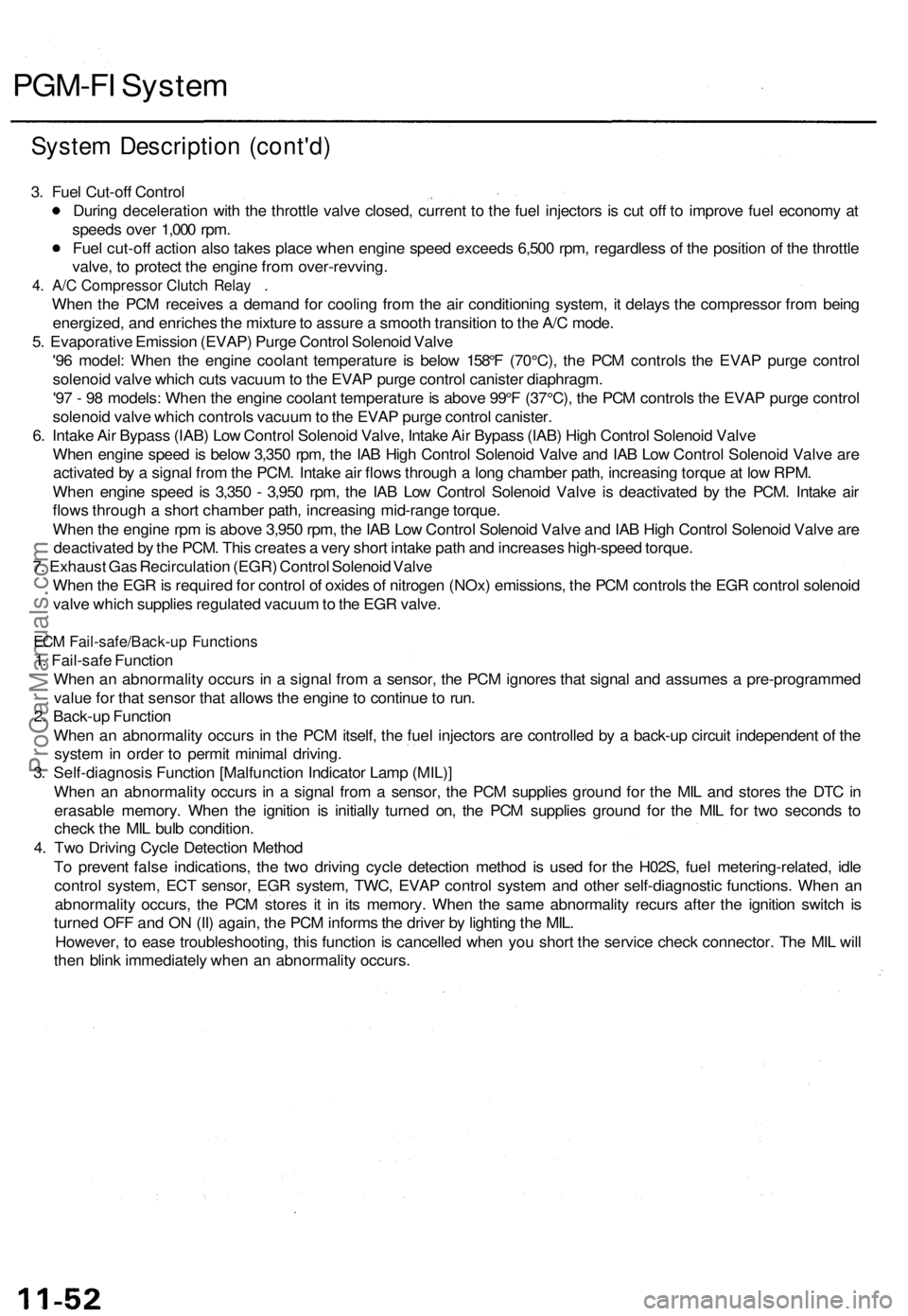

Idle Contro l Syste m

Alternato r (ALT ) F R Signa l

This signal s th e PC M whe n th e Alternato r (ALT ) i s charging .

Is ther e approx . 5 V ?

Chec k th e operatio n o f th e ALT :

1 . Tur n th e ignitio n switc h OFF .

2 . Reconnec t th e AL T GR N 4 P

connecto r t o th e ALT .

3 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n o

loa d (transmissio n in o r

position ) unti l th e radiato r fa n

come s on , the n le t i t idle .

4 . Measur e voltag e betwee n PC M

connecto r terminal s D 5 an d A26 .

Doe s th e voltag e decreas e whe n

headlight s an d rea r defogge r ar e

turne d on ?

Chec k fo r a n ope n in th e wir e (AL T

F line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e PC M connec -

tor D (22P) .4. Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

5 . Connec t th e AL T 4 P connecto r

termina l No . 2 to bod y groun d

with a jumpe r wire .6. Chec k fo r continuit y betwee n

bod y groun d an d PC M con -

necto r termina l D5 .

I s ther e continuity ?

Se e th e AL T inspectio n (se e

sectio n 23 ).

PC M CONNECTOR S

A (26P)D (22P )

LG1 (BRN/BLK )

Wire sid e o f femal e terminal s

Chec k fo r a shor t i n th e wir e (AL T

F line) :1. Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e PC M connecto r

D (22P) .4. Chec k fo r continuit y betwee n

bod y groun d an d PC M con -

necto r termina l D5 .

D (22P )

Is ther e continuity ? Repai

r shor t i n th e wir e betwee nthe PC M (D5 ) and th e ALT .

Substitut e a known-goo d PC M

an d recheck . I f prescribe d voltag e

i s no w available , replac e th e origi -

nal PCM .

ALT F R signa l i s OK .

ALT GR N 4P CONNECTO R (C129 )

JUMPE R WIR E

Wir e sid e o f femal e terminal s

Repai r ope n wir e betwee n th e

PC M (D5 ) and th e ALT .

Wire sid e o f femal e terminal s

PC

M CONNECTO R D (22P )

Chec

k fo r a shor t i n th e wir e (AL T

F line) :

1 . Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

2 . Tur n th e ignitio n switc h O N (II) .

3 . Measur e voltag e betwee n PC M

connecto r terminal s D 5 an d A26 .

Inspectio

n o f AL T F R Signal .

ProCarManuals.com

Page 291 of 1771

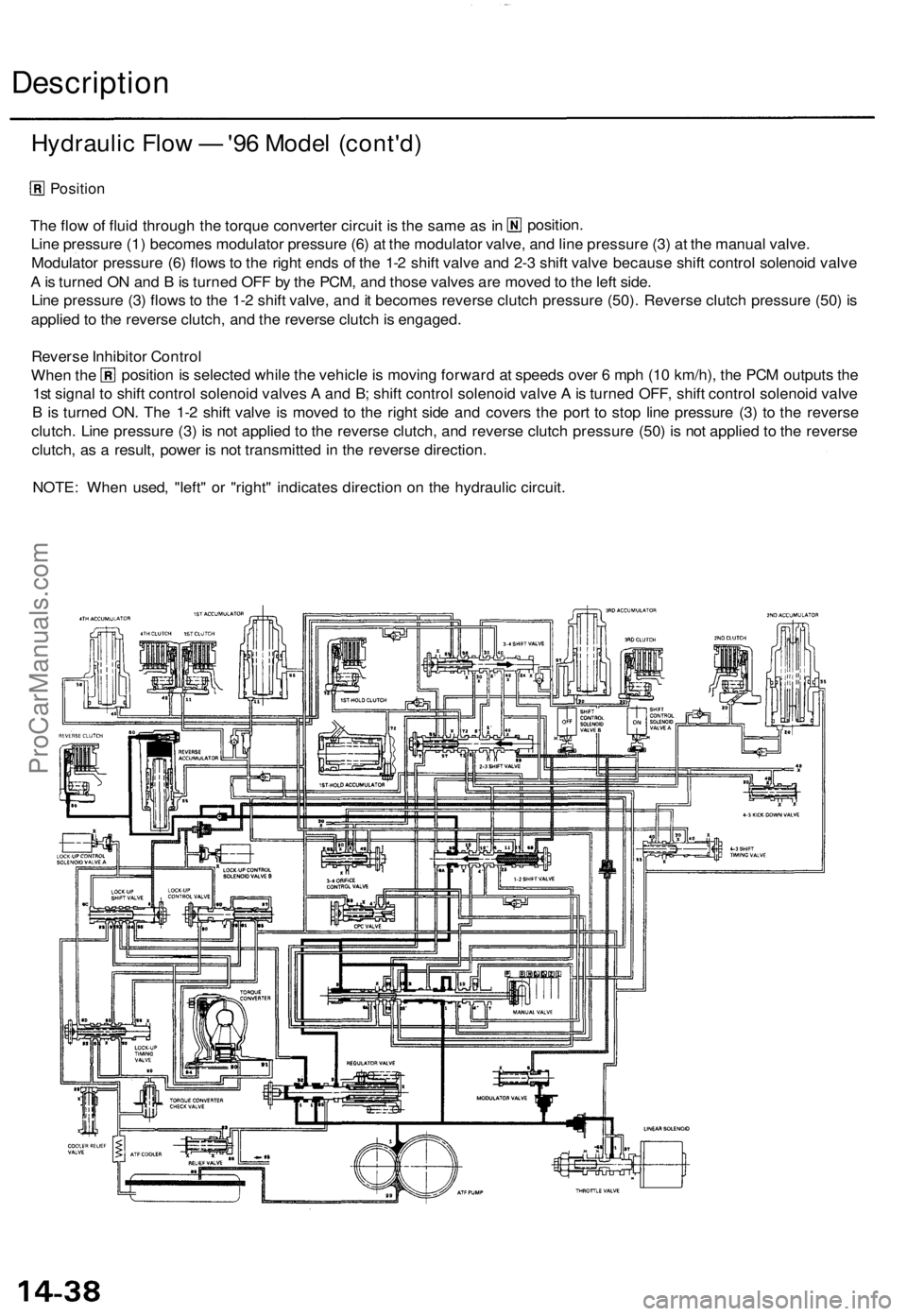

Description

Hydraulic Flow — '96 Model (cont'd)

Position

The flow of fluid through the torque converter circuit is the same as in

Line pressure (1) becomes modulator pressure (6) at the modulator valve, and line pressure (3) at the manual valve.

Modulator pressure (6) flows to the right ends of the 1-2 shift valve and 2-3 shift valve because shift control solenoid valve

A is turned ON and B is turned OFF by the PCM, and those valves are moved to the left side.

Line pressure (3) flows to the 1-2 shift valve, and it becomes reverse clutch pressure (50). Reverse clutch pressure (50) is

applied to the reverse clutch, and the reverse clutch is engaged.

position.

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit.

Reverse Inhibitor Control

When the

1st signal to shift control solenoid valves A and B; shift control solenoid valve A is turned OFF, shift control solenoid valve

B is turned ON. The 1-2 shift valve is moved to the right side and covers the port to stop line pressure (3) to the reverse

clutch. Line pressure (3) is not applied to the reverse clutch, and reverse clutch pressure (50) is not applied to the reverse

clutch, as a result, power is not transmitted in the reverse direction.

position is selected while the vehicle is moving forward at speeds over 6 mph (10 km/h), the PCM outputs theProCarManuals.com

Page 303 of 1771

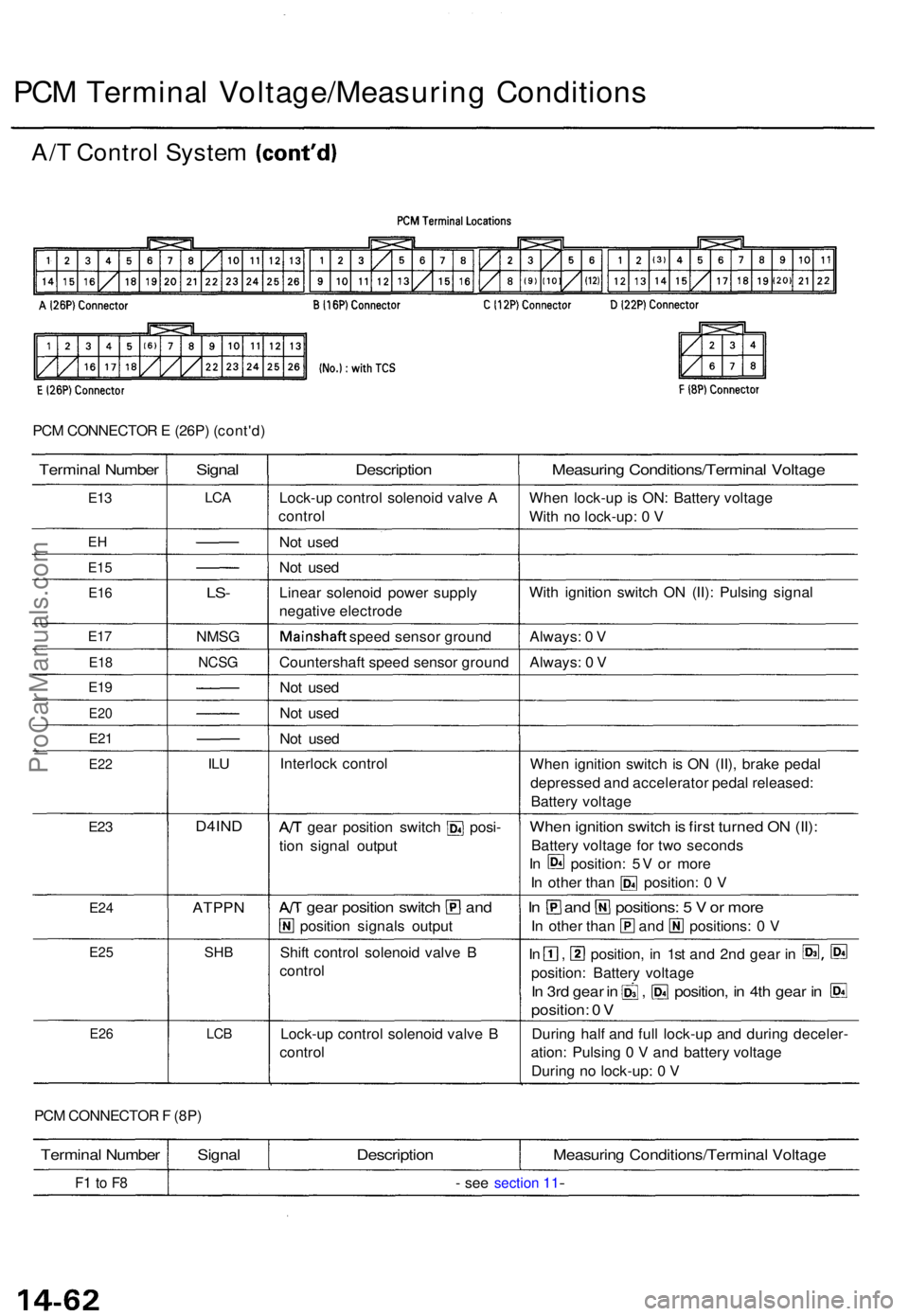

PCM CONNECTO R E (26P ) (cont'd )

Termina l Numbe r

E13

EH

E1 5

E16

E17

E1 8

E19

E2 0

E21

E2 2

E23

E2 4

E2 5

E2 6

Signa l

LCA

LS-

NMS G

NCSG

ILU

D4IN D

ATPP N

SHB

LCB

Descriptio n

Lock-up contro l solenoi d valv e A

contro l

No t use d

No t use d

Linea r solenoi d powe r suppl y

negativ e electrod e

Mainshaf t speed senso r groun d

Countershaf t spee d senso r groun d

No t use d

No t use d

No t use d

Interloc k contro l

A/T gea r positio n switc h posi -

tio n signa l outpu t

A/T gea r positio n switc h an d

positio n signal s outpu t

Shif t contro l solenoi d valv e B

contro l

Lock-u p contro l solenoi d valv e B

contro l

Measurin g Conditions/Termina l Voltag e

When lock-u p is ON : Batter y voltag e

Wit h n o lock-up : 0 V

Wit h ignitio n switc h O N (II) : Pulsin g signa l

Always : 0 V

Always : 0 V

Whe n ignitio n switc h i s O N (II) , brak e peda l

depresse d an d accelerato r peda l released :

Batter y voltag e

When ignitio n switc h is firs t turne d O N (II) :

Batter y voltag e fo r tw o second s

In position : 5 V o r mor e

In othe r tha n position : 0 V

In an d positions : 5 V or mor e

In othe r tha n an d positions : 0 V

In , position , i n 1s t an d 2n d gea r i n S3 , @

position : Batter y voltag e

In 3r d gea r i n , position , i n 4t h gea r i n E

position : 0 V

Durin g hal f an d ful l lock-u p an d durin g deceler -

ation : Pulsin g 0 V an d batter y voltag e

Durin g n o lock-up: 0 V

PC M CONNECTO R F (8P )

Termina l Numbe r

F1 t o F 8

Signa lDescriptio nMeasuring Conditions/Termina l Voltag e

- se e section 11-

A/ T Contro l Syste m (cont'd )

PCM Termina l Voltage/Measurin g Condition s

ProCarManuals.com

Page 310 of 1771

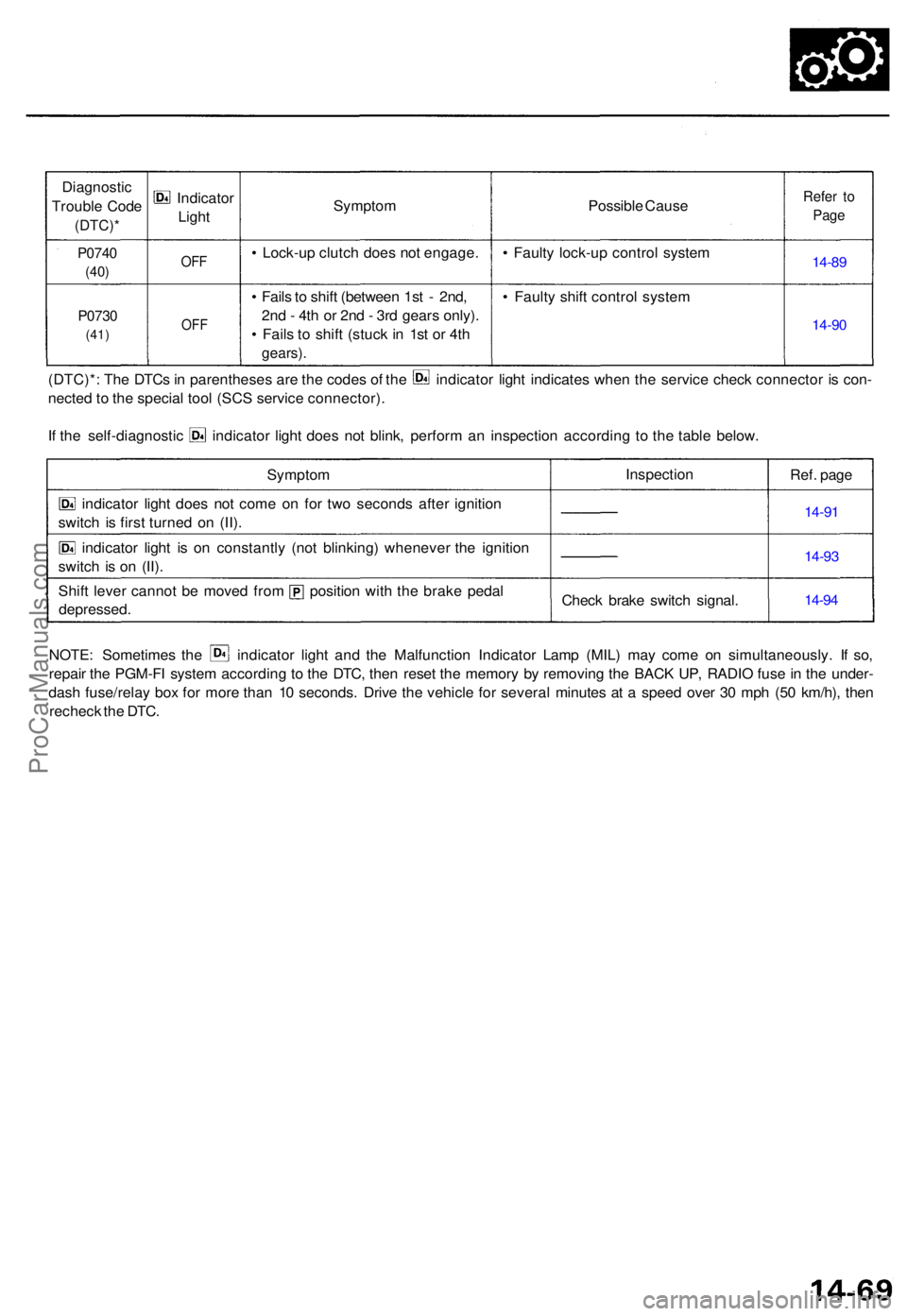

Diagnostic

Troubl e Cod e

(DTC) *

P0740

(40)

P073 0

(41)

Indicato r

Ligh t

OFF

OF F

Sympto m

• Lock-u p clutc h doe s no t engage .

• Fail s to shif t (betwee n 1s t - 2nd ,

2n d - 4t h o r 2n d - 3r d gear s only) .

• Fail s t o shif t (stuc k i n 1s t o r 4t h

gears) .

Possibl e Caus e

• Fault y lock-u p contro l syste m

• Fault y shif t contro l syste mRefer t o

Pag e

14-8 9

14-9 0

(DTC)* : Th e DTC s in parenthese s ar e th e code s o f th e indicato r ligh t indicate s whe n th e servic e chec k connecto r i s con -

necte d t o th e specia l too l (SC S servic e connector) .

If th e self-diagnosti c indicato r ligh t doe s no t blink , perfor m a n inspectio n accordin g t o th e tabl e below .

Sympto m

indicato r ligh t doe s no t com e o n fo r tw o second s afte r ignitio n

switc h i s firs t turne d o n (II) .

indicato r ligh t i s o n constantl y (no t blinking ) wheneve r th e ignitio n

switc h i s o n (II) .

Shif t leve r canno t b e move d fro m positio n wit h th e brak e peda l

depressed . Inspectio

n

Chec k brak e switc h signal . Ref.

page

14-9 1

14-9 3

14-9 4

NOTE : Sometime s th e indicato r ligh t an d th e Malfunctio n Indicato r Lam p (MIL ) ma y com e o n simultaneously . I f so ,

repai r th e PGM-F I syste m accordin g t o th e DTC , the n rese t th e memor y b y removin g th e BAC K UP , RADI O fus e in th e under -

das h fuse/rela y bo x fo r mor e tha n 1 0 seconds . Driv e th e vehicl e fo r severa l minute s a t a spee d ove r 3 0 mp h (5 0 km/h) , the n

rechec k th e DTC .

ProCarManuals.com

Page 512 of 1771

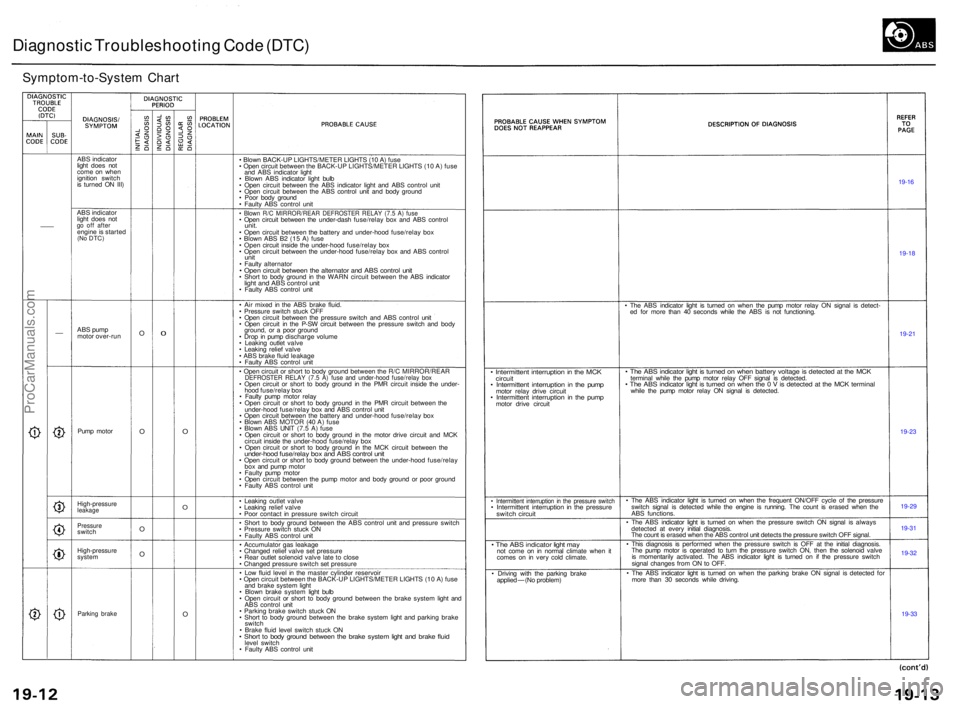

Diagnostic Troubleshootin g Cod e (DTC )

Symptom-to-Syste m Char t

ABS indicato r

ligh t doe s no t

com e o n whe n

ignitio n switc h

i s turne d O N III )

AB S indicato r

ligh t doe s no t

go of f afte rengin e is starte d(No DTC )

ABS pum p

moto r over-ru n

Pum p moto r

High-pressur eleakage

Pressur eswitch

High-pressur esystem

Parkin g brak e

O

O

O

O0

O

O

O

• Blow n BACK-U P LIGHTS/METE R LIGHT S (1 0 A ) fus e

• Ope n circui t betwee n th e BACK-U P LIGHTS/METE R LIGHT S (1 0 A ) fus e

an d AB S indicato r ligh t

• Blow n AB S indicato r ligh t bul b

• Ope n circui t betwee n th e AB S indicato r ligh t an d AB S contro l uni t

• Ope n circui t betwee n th e AB S contro l uni t an d bod y groun d

• Poo r bod y groun d

• Fault y AB S contro l uni t

• Blow n R/ C MIRROR/REA R DEFROSTE R RELA Y (7. 5 A ) fus e• Ope n circui t betwee n th e under-das h fuse/rela y bo x an d AB S contro lunit.• Ope n circui t betwee n th e batter y an d under-hoo d fuse/rela y bo x

• Blow n AB S B 2 (1 5 A ) fus e

• Ope n circui t insid e th e under-hoo d fuse/rela y bo x

• Ope n circui t betwee n th e under-hoo d fuse/rela y bo x an d AB S contro l

unit• Fault y alternato r• Ope n circui t betwee n th e alternato r an d AB S contro l uni t• Shor t t o bod y groun d i n th e WAR N circui t betwee n th e AB S indicato rlight an d AB S contro l uni t• Fault y AB S contro l uni t

• Ai r mixe d i n th e AB S brak e fluid .

• Pressur e switc h stuc k OF F

• Ope n circui t betwee n th e pressur e switc h an d AB S contro l uni t

• Ope n circui t i n th e P-S W circui t betwee n th e pressur e switc h an d bod y

ground , o r a poo r groun d

• Dro p in pum p discharg e volum e

• Leakin g outle t valv e

• Leakin g relie f valv e

• AB S brak e flui d leakag e

• Fault y AB S contro l uni t

• Ope n circui t o r shor t t o bod y groun d betwee n th e R/ C MIRROR/REA R

DEFROSTER RELA Y (7. 5 A ) fus e an d under-hoo d fuse/rela y bo x• Ope n circui t o r shor t t o bod y groun d i n th e PM R circui t insid e th e under -

hoo d fuse/rela y bo x

• Fault y pum p moto r rela y

• Ope n circui t o r shor t t o bod y groun d i n th e PM R circui t betwee n th e

under-hoo d fuse/rela y bo x an d AB S contro l uni t

• Ope n circui t betwee n th e batter y an d under-hoo d fuse/rela y bo x

• Blow n AB S MOTO R (4 0 A ) fus e

• Blow n AB S UNI T (7. 5 A ) fus e

• Ope n circui t o r shor t t o bod y groun d i n th e moto r driv e circui t an d MC K

circui t insid e th e under-hoo d fuse/rela y bo x

• Ope n circui t o r shor t t o bod y groun d i n th e MC K circui t betwee n th e

under-hoo d fuse/rela y bo x an d AB S contro l uni t• Ope n circui t o r shor t t o bod y groun d betwee n th e under-hoo d fuse/rela y

bo x an d pum p moto r

• Fault y pum p moto r

• Ope n circui t betwee n th e pum p moto r an d bod y groun d o r poo r groun d

• Fault y AB S contro l uni t

• Leakin g outle t valv e

• Leakin g relie f valv e

• Poo r contac t i n pressur e switc h circui t

• Shor t t o bod y groun d betwee n th e AB S contro l uni t an d pressur e switc h

• Pressure switch stuc k O N

• Fault y AB S contro l uni t

• Accumulato r ga s leakag e

• Change d relie f valv e se t pressur e

• Rea r outle t solenoi d valv e lat e t o clos e

• Change d pressur e switc h se t pressur e

• Lo w flui d leve l i n th e maste r cylinde r reservoi r

• Ope n circui t betwee n th e BACK-U P LIGHTS/METE R LIGHT S (1 0 A ) fus e

an d brak e syste m ligh t

• Blow n brak e syste m ligh t bul b

• Ope n circui t o r shor t t o bod y groun d betwee n th e brak e syste m ligh t an d

AB S contro l uni t

• Parkin g brak e switc h stuc k O N

• Shor t t o bod y groun d betwee n th e brak e syste m ligh t an d parkin g brak e

switc h

• Brak e flui d leve l switc h stuc k O N

• Shor t t o bod y groun d betwee n th e brak e syste m ligh t an d brak e flui dleve l switc h

• Fault y AB S contro l uni t

• Intermitten t interruptio n in th e MC Kcircui t• Intermitten t interruptio n in th e pum pmotor rela y driv e circui t• Intermitten t interruptio n i n th e pum pmotor driv e circui t

• Intermitten t interruptio n i n th e pressur e switc h• Intermitten t interruptio n i n th e pressur eswitch circui t

• Th e AB S indicato r ligh t ma ynot com e o n i n norma l climat e whe n i t

come s o n i n ver y col d climate .

• Drivin g wit h th e parkin g brak e

applie d — (No problem ) •

Th e AB S indicato r ligh t i s turne d o n whe n th e pum p moto r rela y O N signa l i s detect -

e d fo r mor e tha n 4 0 second s whil e th e AB S i s no t functioning .

• Th e AB S indicato r ligh t i s turne d o n whe n batter y voltag e is detecte d a t th e MC Ktermina l whil e th e pum p moto r rela y OF F signa l i s detected .• Th e AB S indicato r ligh t i s turne d o n whe n th e 0 V is detecte d a t th e MC K termina lwhile th e pum p moto r rela y O N signa l i s detected .

• Th e AB S indicato r ligh t i s turne d o n whe n th e frequen t ON/OF F cycl e o f th e pressur e

switc h signa l i s detecte d whil e th e engin e i s running . Th e coun t i s erase d whe n th e

AB S functions .

• Th e AB S indicato r ligh t i s turne d o n whe n th e pressur e switc h O N signa l i s alway s

detecte d a t ever y initia l diagnosis .

Th e coun t i s erase d whe n th e AB S contro l uni t detect s th e pressur e switc h OF F signal .

• Thi s diagnosi s i s performe d whe n th e pressur e switc h i s OF F a t th e initia l diagnosis .

Th e pum p moto r i s operate d t o tur n th e pressur e switc h ON , the n th e solenoi d valv e

i s momentaril y activated . Th e AB S indicato r ligh t i s turne d o n i f th e pressur e switc h

signa l change s fro m O N to OFF .

• Th e AB S indicato r ligh t i s turne d o n whe n th e parkin g brak e O N signa l i s detecte d fo r

mor e tha n 3 0 second s whil e driving .

19-16

19-1 8

19-2 1

19-2 3

19-2 9

19-3 1

19-3 2

19-3 3

ProCarManuals.com

Page 522 of 1771

Troubleshooting Precautions

ABS Indicator Light

1. If the system is OK, the ABS indicator light goes off two seconds after turning the ignition switch ON (II) without start-

ing the engine. After starting the engine, the ABS indicator light comes on again and goes off after two seconds. This

occurs because the ABS control unit is activated by the IG2 power source.

2. The ABS indicator light comes on when the ABS control unit detects a problem in the system. However, even though

the system is normal, the ABS indicator light comes on, too, under the following conditions. To determine the actual

cause of problem, question the customer about the problem, talking the following conditions into consideration.

Only drive wheels rotate

One wheel stuck of drive wheels

Vehicle spin

ABS operate condition continue for long time

Signal disturbance

3. When a problem is detected and the ABS indicator light comes on, there are cases when the indicator light stays on

until the ignition switch is turned OFF, and cases when the indicator light goes off automatically when the system

returns normal. For the DTC 61 and 62, the indicator light goes off automatically when the system returns normal. For

all other codes, the indicator light stays on until the ignition switch is turned OFF.

4. For DTCs 12, 14, 16, 18, 21, 22, 23, 24, 51, 52 and 53, the indicator light goes off when the vehicle is driven again and

the signals are OK after the ignition switch is turned from OFF to ON (II). However, if the DTC is erased, the CPU is

reset and the indicator light goes off right after the engine is started if the signals are OK.

Diagnostic Trouble Code (DTC)

1. The DTC is not memorized if the CPU cannot be activated or the CPU fails and the indicator light comes on.

2. The memory can hold any number of DTCs. However, when the same DTC is detected more than once, the later one

is written over the old one. Therefore, when the same problem is detected repeatedly, it is memorized as one DTC.

3. The DTCs are indicated in the order of ascending number, not in the order they occur.

4. The DTCs are memorized in the EEPROM (non-volatile memory). Therefore, the memorized DTCs cannot be canceled

by disconnecting the battery. Perform the specified procedures to erase the DTCs.

Self-diagnosis

1. The

self-diagnosis

can be

classified

into

two

categories.

• Initial diagnosis: Performed right after the engine starts and until the ABS indicator light goes off.

• Regular diagnosis: Performed right after the initial diagnosis until the ignition switch is turned OFF.

2. When a problem is detected by self-diagnosis, the system

• Turns the ABS indicator light ON

• Memorizes the DTC

• Turns the fail-safe relay OFF

• Stops ABS controlProCarManuals.com

Page 530 of 1771

Construction and Function

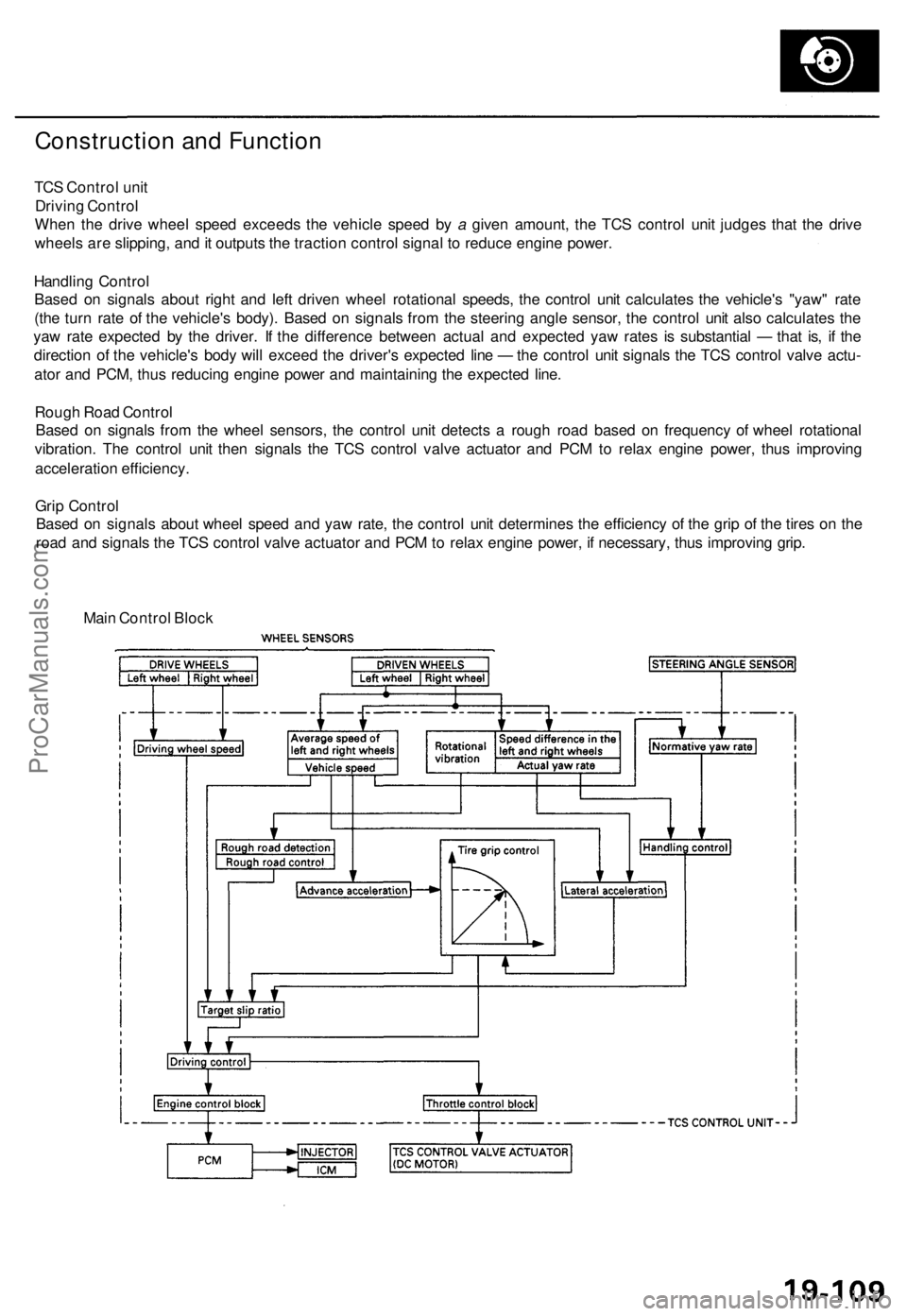

TCS Control unit

Driving Control

When the drive wheel speed exceeds the vehicle speed by a given amount, the TCS control unit judges that the drive

wheels are slipping, and it outputs the traction control signal to reduce engine power.

Handling Control

Based on signals about right and left driven wheel rotational speeds, the control unit calculates the vehicle's "yaw" rate

(the turn rate of the vehicle's body). Based on signals from the steering angle sensor, the control unit also calculates the

yaw rate expected by the driver. If the difference between actual and expected yaw rates is substantial — that is, if the

direction of the vehicle's body will exceed the driver's expected line — the control unit signals the TCS control valve actu-

ator and PCM, thus reducing engine power and maintaining the expected line.

Rough Road Control

Based on signals from the wheel sensors, the control unit detects a rough road based on frequency of wheel rotational

vibration. The control unit then signals the TCS control valve actuator and PCM to relax engine power, thus improving

acceleration efficiency.

Grip Control

Based on signals about wheel speed and yaw rate, the control unit determines the efficiency of the grip of the tires on the

road and signals the TCS control valve actuator and PCM to relax engine power, if necessary, thus improving grip.

Main Control BlockProCarManuals.com