oil change ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 93 of 1771

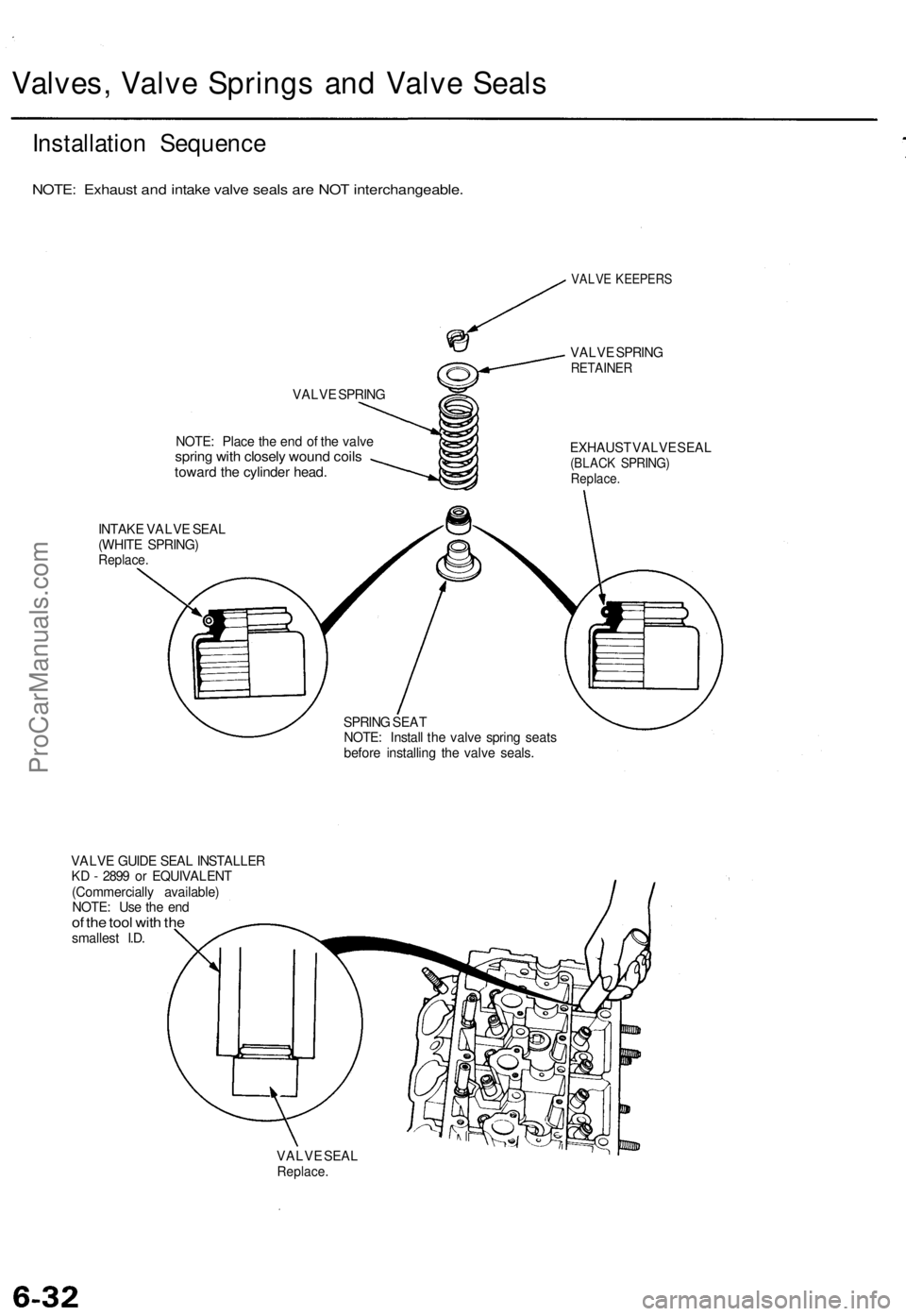

Valves, Valve Springs and Valve Seals

Installation Sequence

NOTE: Exhaust and intake valve seals are NOT interchangeable.

VALVE SPRING

NOTE: Place the end of the valve

spring with closely wound coils

toward the cylinder head.

INTAKE VALVE SEAL

(WHITE SPRING)

Replace.

VALVE KEEPERS

VALVE SPRING

RETAINER

EXHAUST VALVE SEAL

(BLACK SPRING)

Replace.

SPRING SEAT

NOTE: Install the valve spring seats

before installing the valve seals.

VALVE GUIDE SEAL INSTALLER

KD - 2899 or EQUIVALENT

(Commercially available)

NOTE: Use the end

of the tool with the

smallest I.D.

VALVE SEAL

Replace.ProCarManuals.com

Page 101 of 1771

Illustrated Inde x

(cont'd )

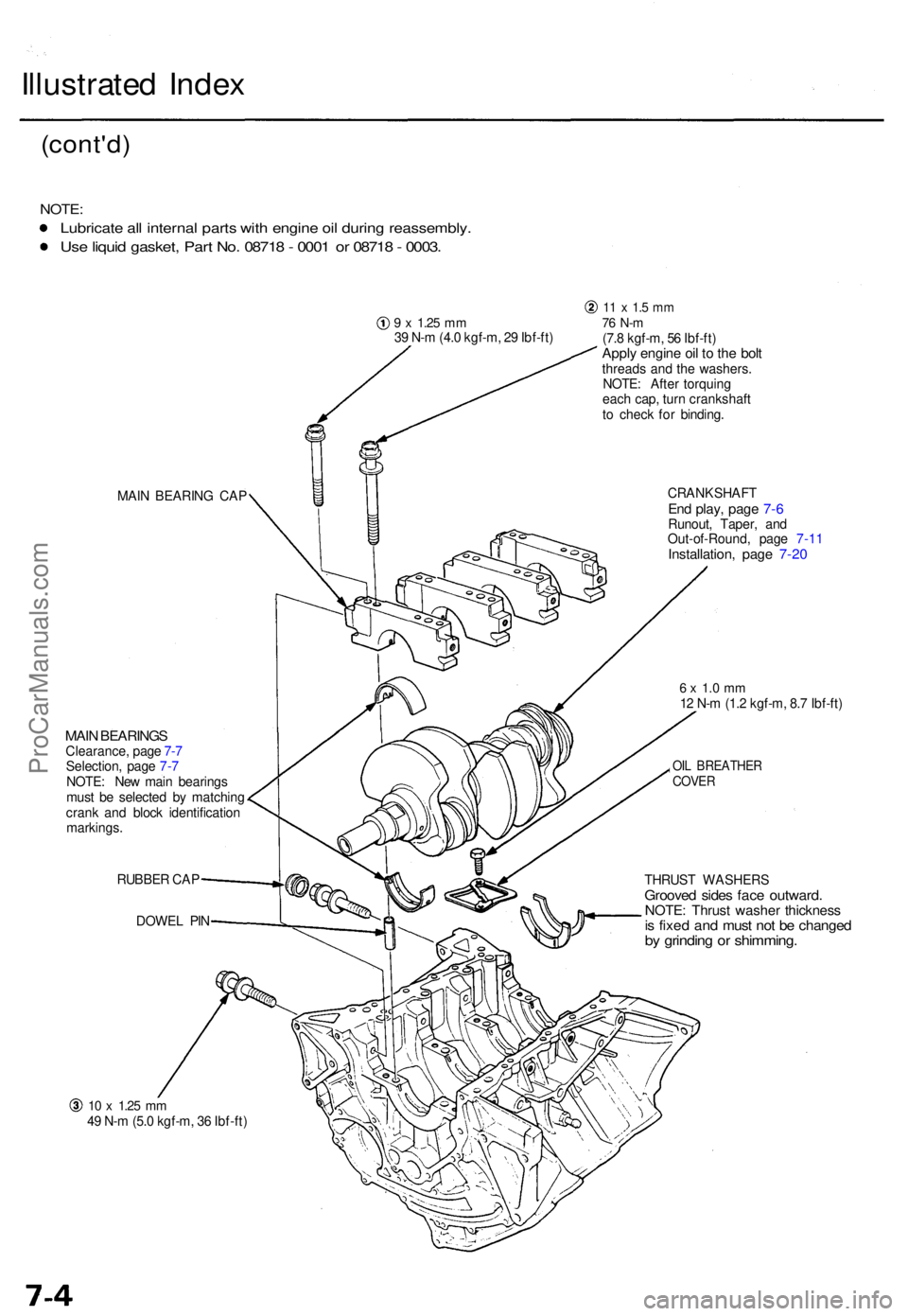

NOTE:

Lubricat e al l interna l part s wit h engin e oi l durin g reassembly .

Use liqui d gasket , Par t No . 0871 8 - 000 1 o r 0871 8 - 0003 .

9 x 1.2 5 mm39 N- m (4. 0 kgf-m , 2 9 Ibf-ft )

11 x 1. 5 m m76 N- m(7.8 kgf-m , 5 6 Ibf-ft )Apply engin e oi l t o th e bol tthread s an d th e washers .

NOTE : Afte r torquin g

eac h cap , tur n crankshaf t

t o chec k fo r binding .

MAI N BEARIN G CA P

MAIN BEARING SClearance , pag e 7- 7

Selection , pag e 7- 7

NOTE : Ne w mai n bearing s

mus t b e selecte d b y matchin g

cran k an d bloc k identificatio n

markings .

RUBBE R CA P

DOWE L PI N CRANKSHAF

T

End play , pag e 7- 6Runout , Taper , an d

Out-of-Round , pag e 7-1 1

Installation , pag e 7-2 0

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

OIL BREATHE RCOVER

THRUS T WASHER SGrooved side s fac e outward .NOTE: Thrus t washe r thicknes sis fixe d an d mus t no t b e change dby grindin g o r shimming .

10 x 1.2 5 mm49 N- m (5. 0 kgf-m , 3 6 Ibf-ft )

ProCarManuals.com

Page 127 of 1771

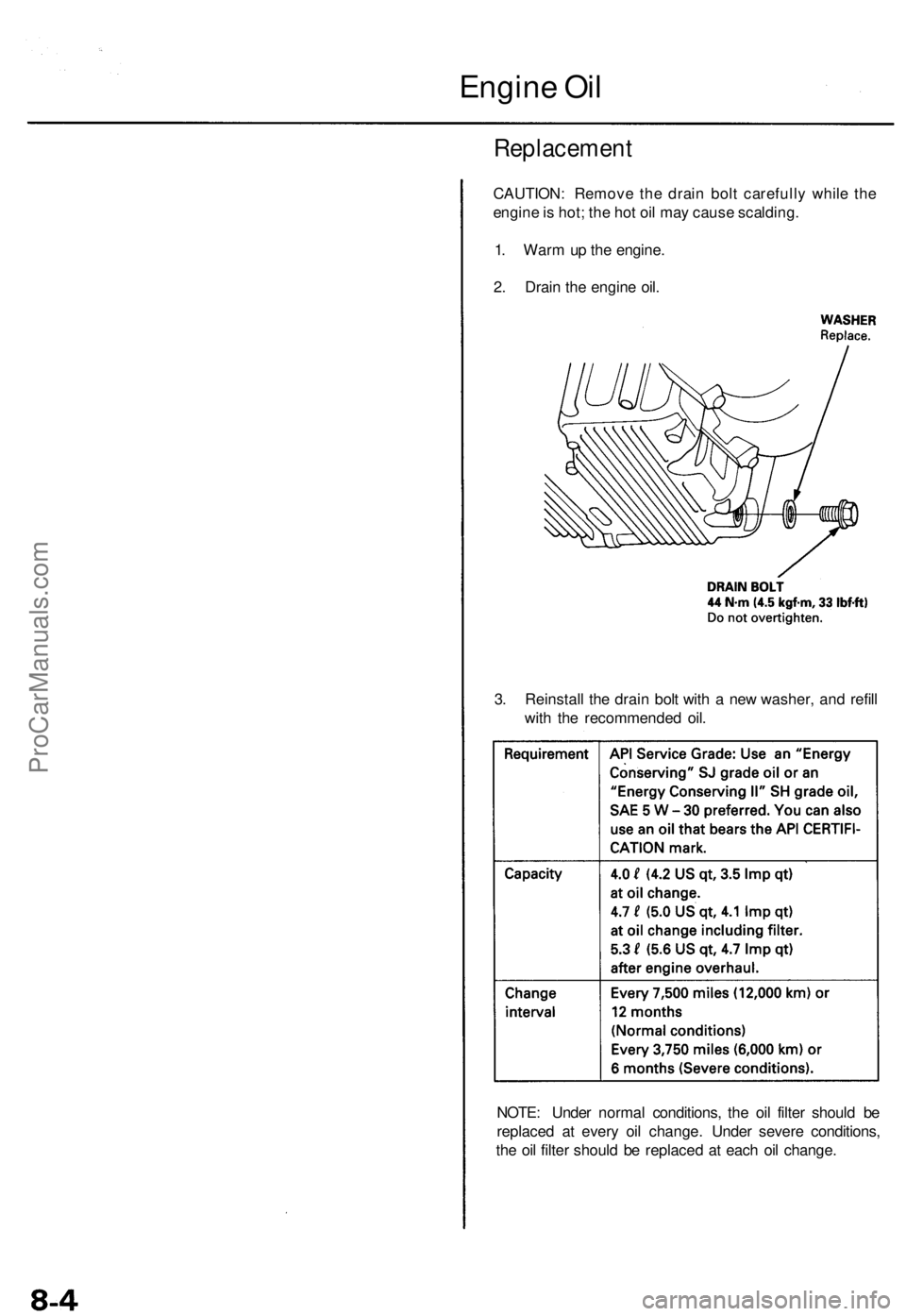

Engine Oi l

Replacemen t

CAUTION: Remov e th e drai n bol t carefull y whil e th e

engin e is hot ; th e ho t oi l ma y caus e scalding .

1 . War m u p th e engine .

2 . Drai n th e engin e oil .

3 . Reinstal l th e drai n bol t wit h a ne w washer , an d refil l

wit h th e recommende d oil .

NOTE : Unde r norma l conditions , th e oi l filte r shoul d b e

replace d a t ever y oi l change . Unde r sever e conditions ,

th e oi l filte r shoul d b e replace d a t eac h oi l change .

ProCarManuals.com

Page 434 of 1771

Maintenance

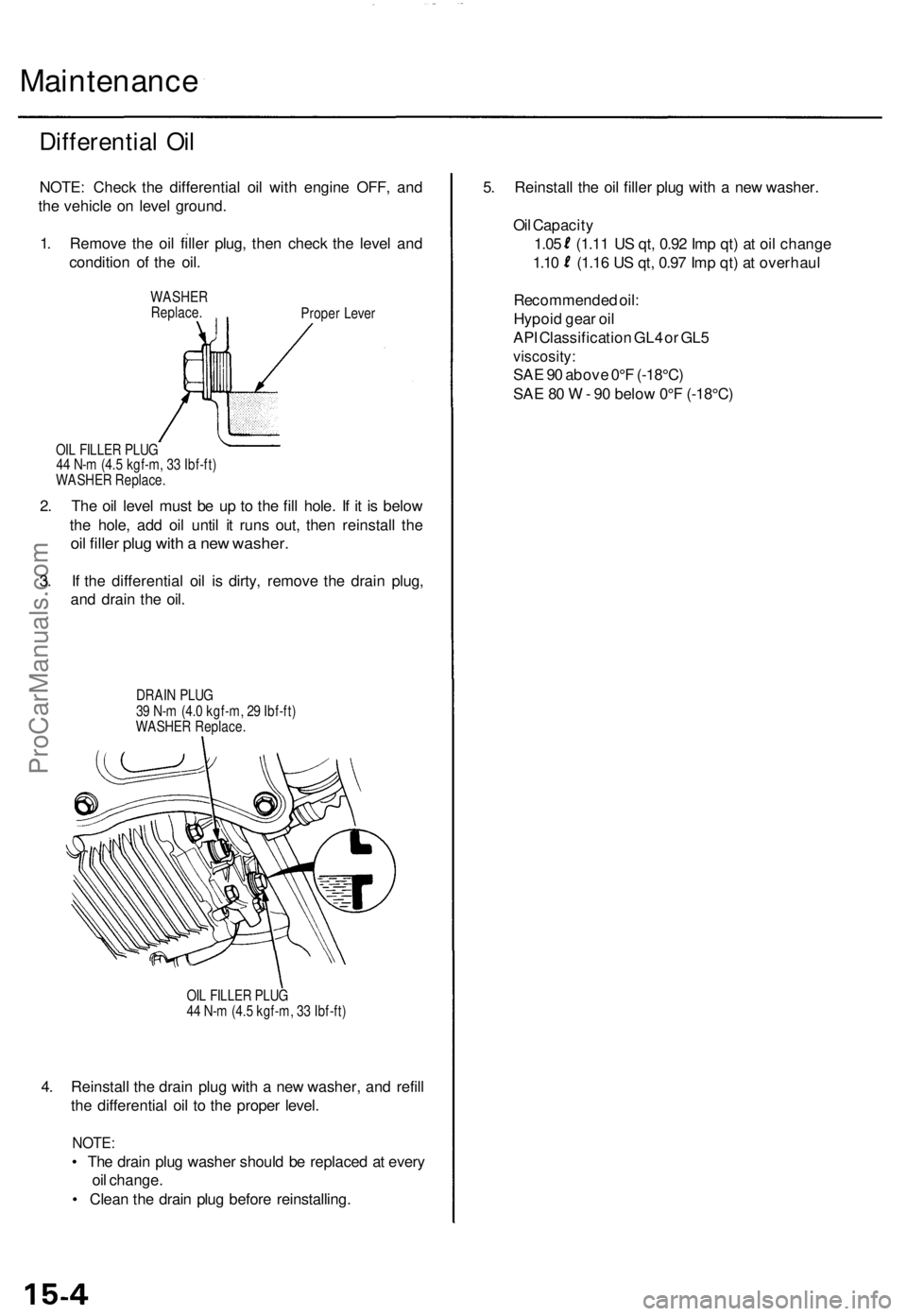

Differential Oi l

NOTE : Chec k th e differentia l oi l wit h engin e OFF , an d

th e vehicl e o n leve l ground .

1 . Remov e th e oi l fille r plug , the n chec k th e leve l an d

conditio n o f th e oil .

WASHERReplace .Proper Leve r

OI L FILLE R PLU G

4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

WASHE R Replace .

2. Th e oi l leve l mus t b e u p t o th e fil l hole . I f i t i s belo w

th e hole , ad d oi l unti l i t run s out , the n reinstal l th e

oil fille r plu g wit h a ne w washer .

3. I f th e differentia l oi l i s dirty , remov e th e drai n plug ,

an d drai n th e oil .

DRAI N PLU G

3 9 N- m (4. 0 kgf-m , 2 9 Ibf-ft )

WASHE R Replace .

OI L FILLE R PLU G

4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

4. Reinstal l th e drai n plu g wit h a ne w washer , an d refil l

th e differentia l oi l t o th e prope r level .

NOTE :

• Th e drai n plu g washe r shoul d b e replace d a t ever y

oi l change .

• Clea n th e drai n plu g befor e reinstalling . 5

. Reinstal l th e oi l fille r plu g wit h a ne w washer .

Oi l Capacit y

1.0 5 (1.1 1 U S qt , 0.9 2 Im p qt ) a t oi l chang e

1.10 (1.1 6 U S qt , 0.9 7 Im p qt ) a t overhau l

Recommende d oil :

Hypoi d gea r oi l

AP I Classificatio n GL 4 o r GL 5

viscosity :

SAE 9 0 abov e 0° F (-18°C )

SA E 8 0 W - 9 0 belo w 0° F (-18°C )

ProCarManuals.com

Page 778 of 1771

Illustrated Inde x

(cont'd )

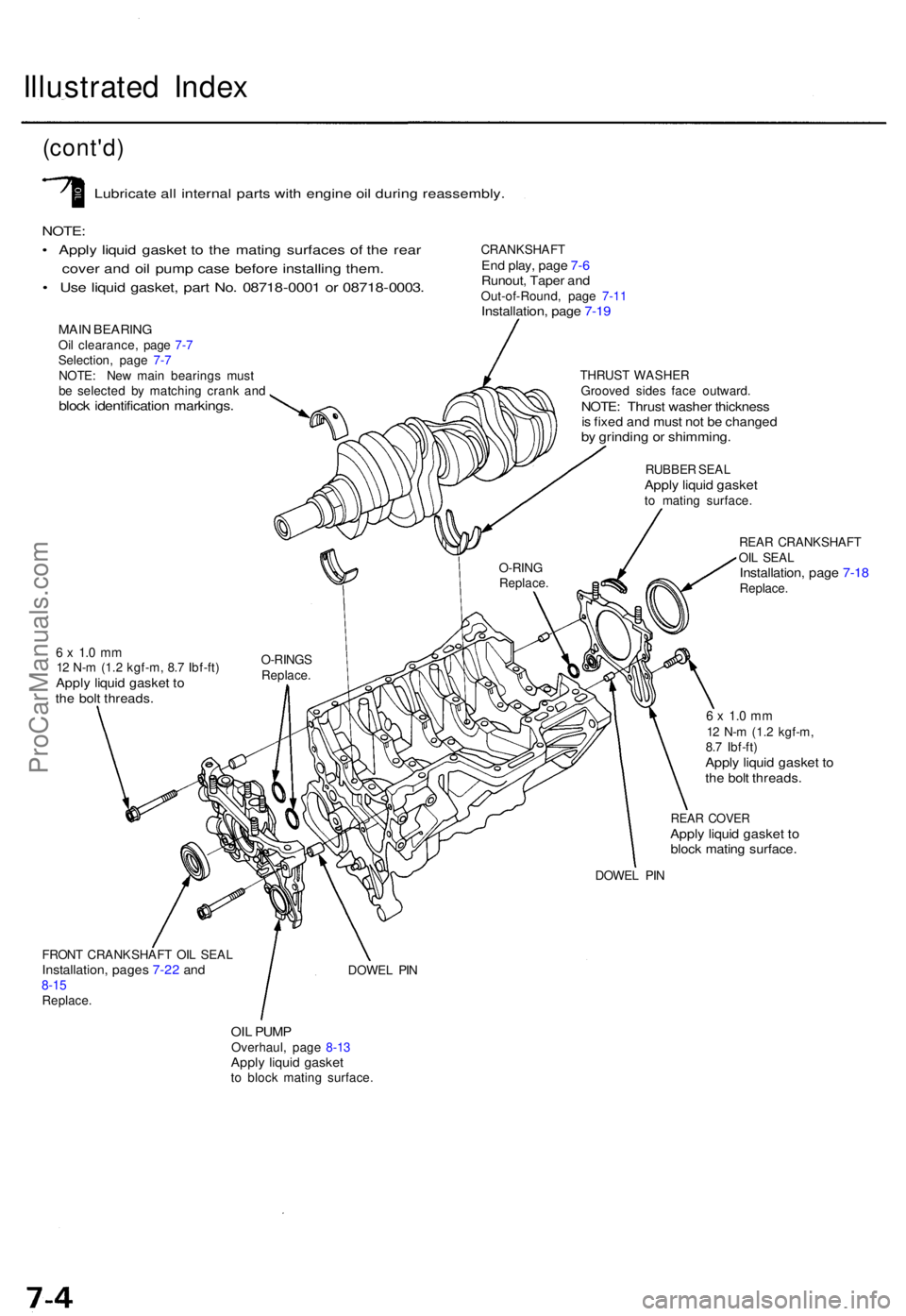

Lubricat e al l interna l part s wit h engin e oi l durin g reassembly .

NOTE:

• Appl y liqui d gaske t t o th e matin g surface s o f th e rea r

cove r an d oi l pum p cas e befor e installin g them .

• Us e liqui d gasket , par t No . 0871 8-000 1 o r 0871 8-0003 .

MAIN BEARIN GOil clearance , pag e 7- 7

Selection , pag e 7- 7

NOTE : Ne w mai n bearing s mus t

b e selecte d b y matchin g cran k an d

bloc k identificatio n markings .

CRANKSHAF TEnd play , pag e 7- 6Runout , Tape r an dOut-of-Round , pag e 7-1 1Installation , pag e 7-1 9

THRUS T WASHE R

Groove d side s fac e outward .

NOTE: Thrus t washe r thicknes sis fixe d an d mus t no t b e change dby grindin g o r shimming .

RUBBER SEA LApply liqui d gaske tto matin g surface .

REA R CRANKSHAF T

OI L SEA L

Installation , pag e 7-1 8Replace .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )Apply liqui d gaske t t oth e bol t threads .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

Apply liqui d gaske t t oth e bol t threads .

REAR COVE RApply liqui d gaske t t obloc k matin g surface .

DOWEL PI N

FRON T CRANKSHAF T OI L SEA L

Installation , page s 7-2 2 an d8-1 5Replace .

DOWEL PI N

OIL PUM POverhaul , pag e 8-1 3Appl y liqui d gaske tto bloc k matin g surface . O-RIN

G

Replace .

O-RINGS

Replace .

ProCarManuals.com

Page 806 of 1771

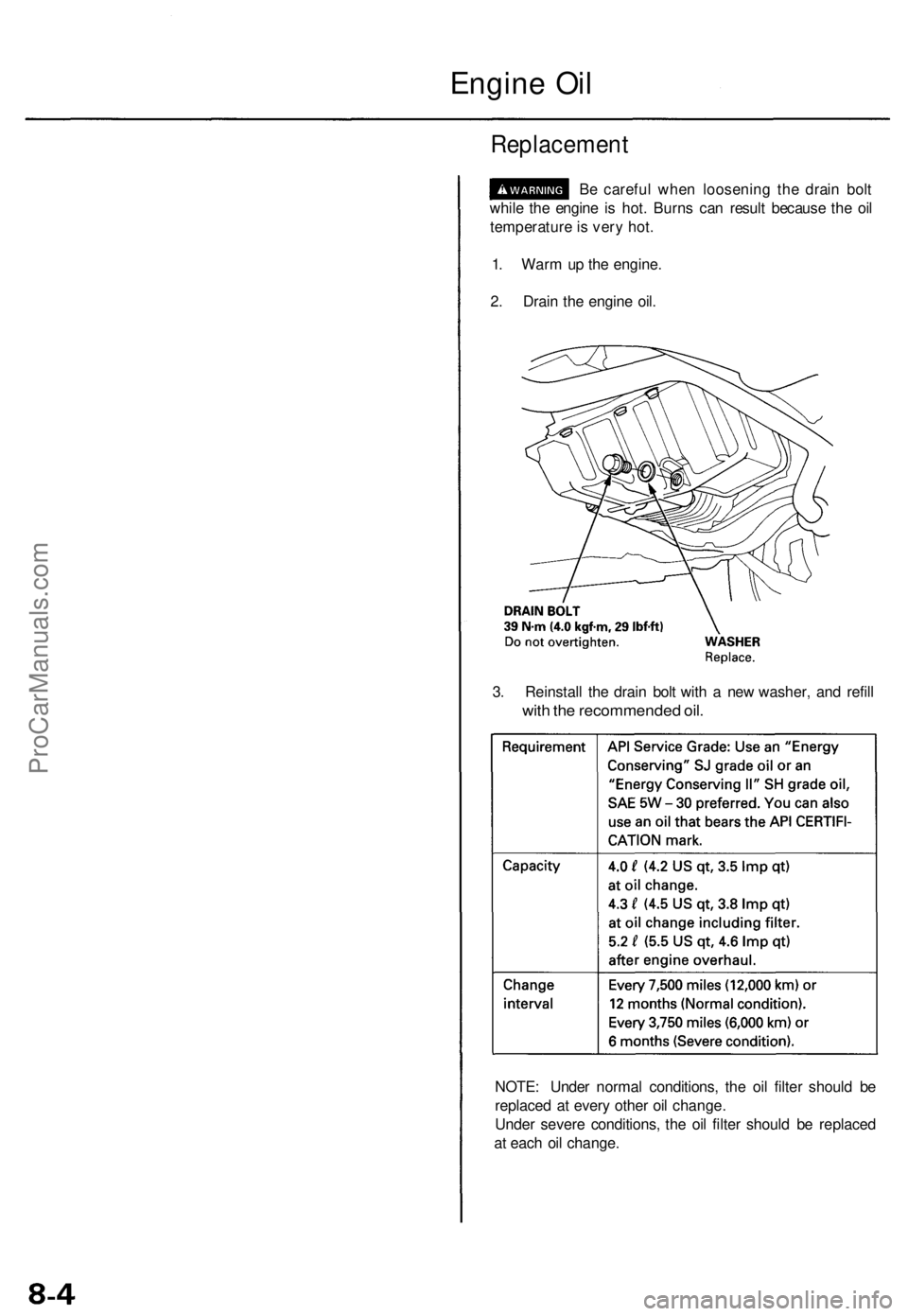

NOTE: Unde r norma l conditions , th e oi l filte r shoul d b e

replace d a t ever y othe r oi l change .

Unde r sever e conditions , th e oi l filte r shoul d b e replace d

a t eac h oi l change .

Replacemen t

Be carefu l whe n loosenin g th e drai n bol t

whil e th e engin e i s hot . Burn s ca n resul t becaus e th e oi l

temperatur e is ver y hot .

1 . War m u p th e engine .

2 . Drai n th e engin e oil .

3 . Reinstal l th e drai n bol t wit h a ne w washer , an d refil l

with th e recommende d oil .

Engin e Oi l

ProCarManuals.com

Page 1095 of 1771

Maintenance

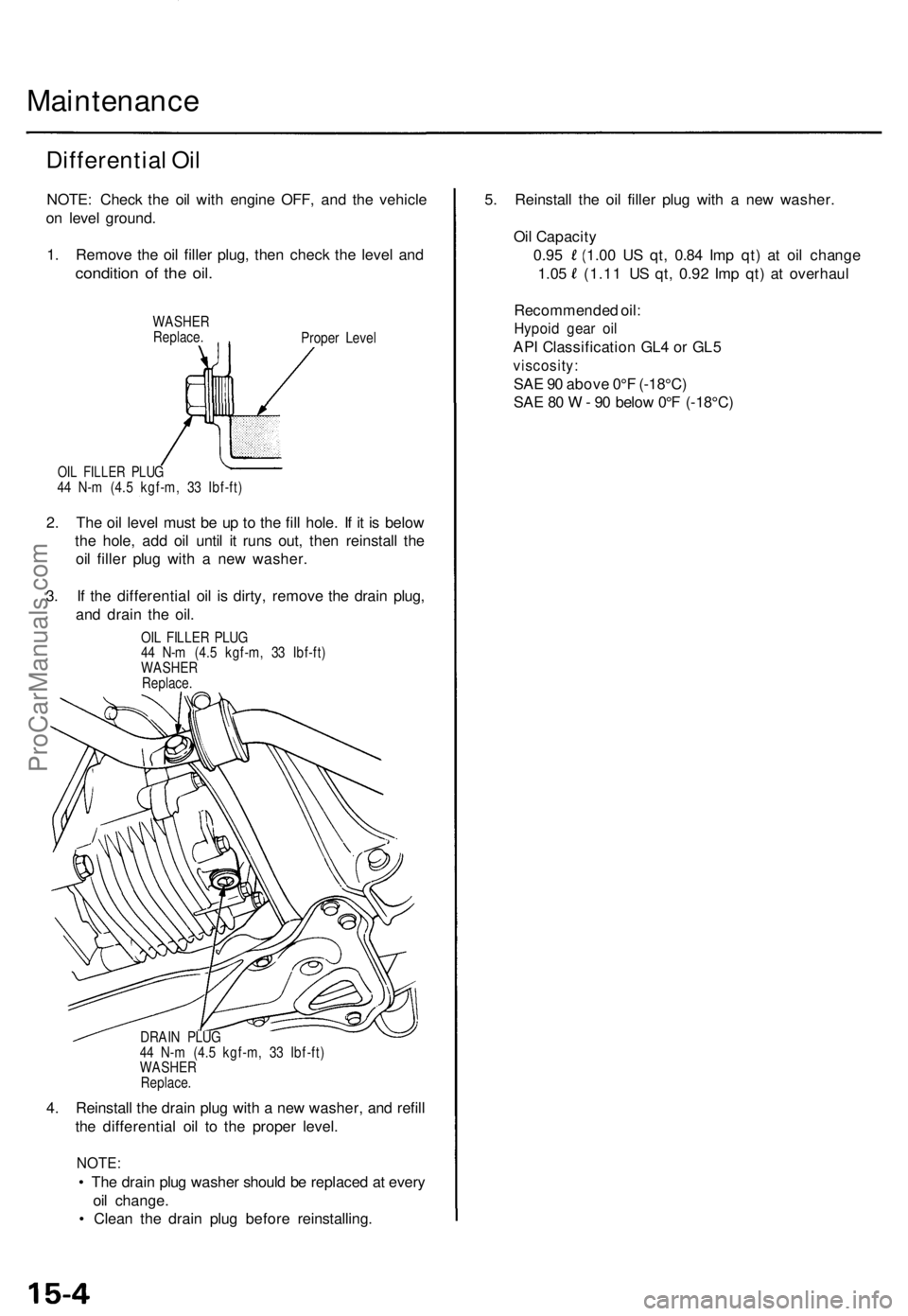

Differential Oi l

NOTE : Chec k th e oi l wit h engin e OFF , an d th e vehicl e

o n leve l ground .

1 . Remov e th e oi l fille r plug , the n chec k th e leve l an d

conditio n o f th e oil .

WASHE R

Replace .

Proper Leve l

OIL FILLE R PLU G44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

2. Th e oi l leve l mus t b e u p t o th e fil l hole . I f i t i s belo w

th e hole , ad d oi l unti l i t run s out , the n reinstal l th e

oi l fille r plu g wit h a ne w washer .

3 . I f th e differentia l oi l i s dirty , remov e th e drai n plug ,

an d drai n th e oil .

OIL FILLE R PLU G

4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

WASHE R

Replace .

DRAI N PLU G

4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

WASHE R

Replace .

4. Reinstal l th e drai n plu g wit h a ne w washer , an d refil l

th e differentia l oi l t o th e prope r level .

NOTE :

• Th e drai n plu g washe r shoul d b e replace d a t ever y

oi l change .

• Clea n th e drai n plu g befor e reinstalling . 5

. Reinstal l th e oi l fille r plu g wit h a ne w washer .

Oi l Capacit y

0.9 5 (1.0 0 U S qt , 0.8 4 Im p qt) at oi l chang e

1.05 (1.1 1 U S qt , 0.9 2 Im p qt ) a t overhau l

Recommende d oil :

Hypoi d gea r oi l

AP I Classificatio n GL 4 o r GL 5

viscosity :

SAE 9 0 abov e 0°F (-18°C )

SA E 8 0 W - 9 0 belo w 0° F (-18°C )

ProCarManuals.com

Page 1326 of 1771

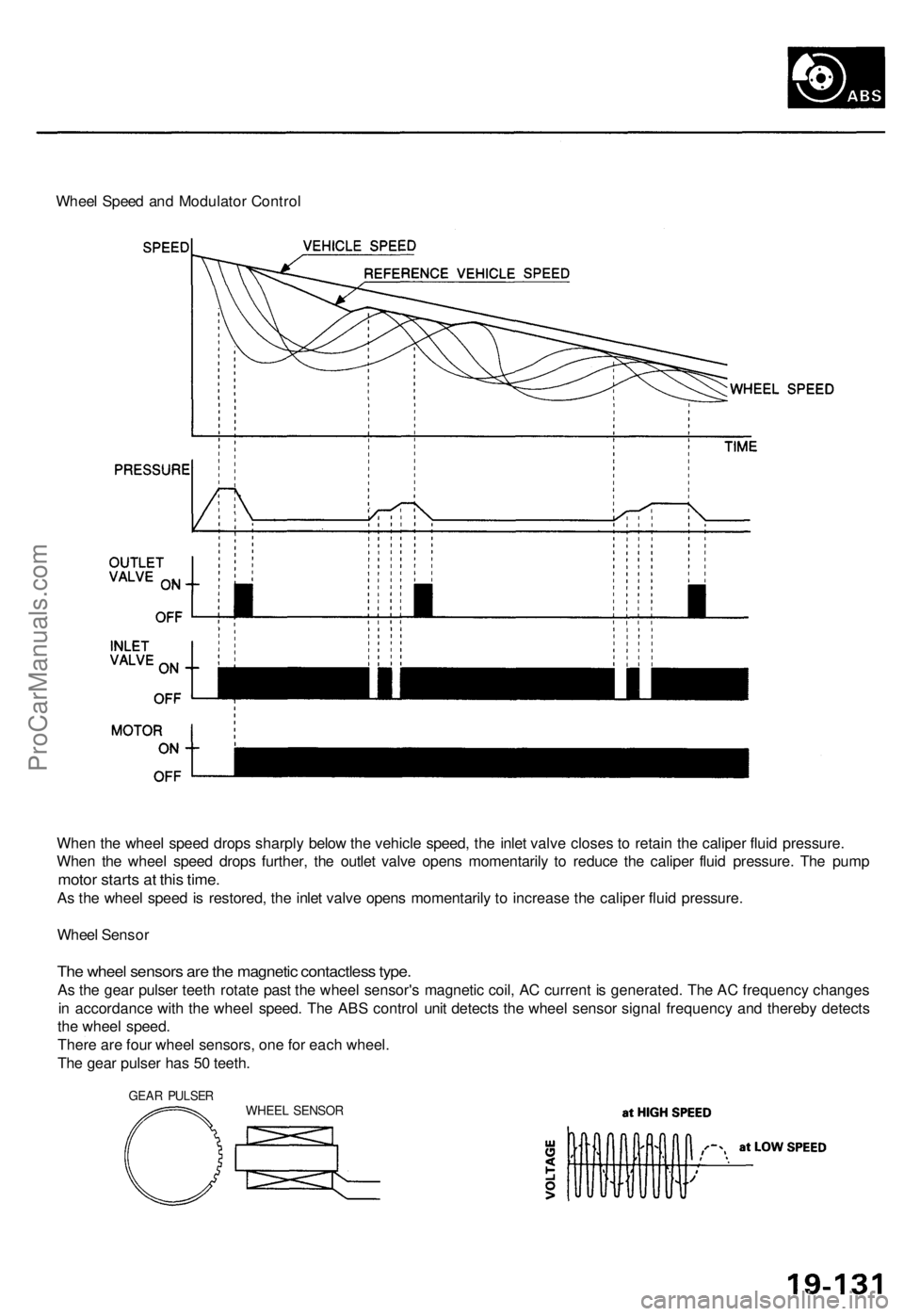

Wheel Speed and Modulator Control

When the wheel speed drops sharply below the vehicle speed, the inlet valve closes to retain the caliper fluid pressure.

When the wheel speed drops further, the outlet valve opens momentarily to reduce the caliper fluid pressure. The pump

motor starts at this time.

As the wheel speed is restored, the inlet valve opens momentarily to increase the caliper fluid pressure.

Wheel Sensor

The wheel sensors are the magnetic contactless type.

As the gear pulser teeth rotate past the wheel sensor's magnetic coil, AC current is generated. The AC frequency changes

in accordance with the wheel speed. The ABS control unit detects the wheel sensor signal frequency and thereby detects

the wheel speed.

There are four wheel sensors, one for each wheel.

The gear pulser has 50 teeth.

GEAR PULSER

WHEEL SENSORProCarManuals.com

Page 1493 of 1771

Description

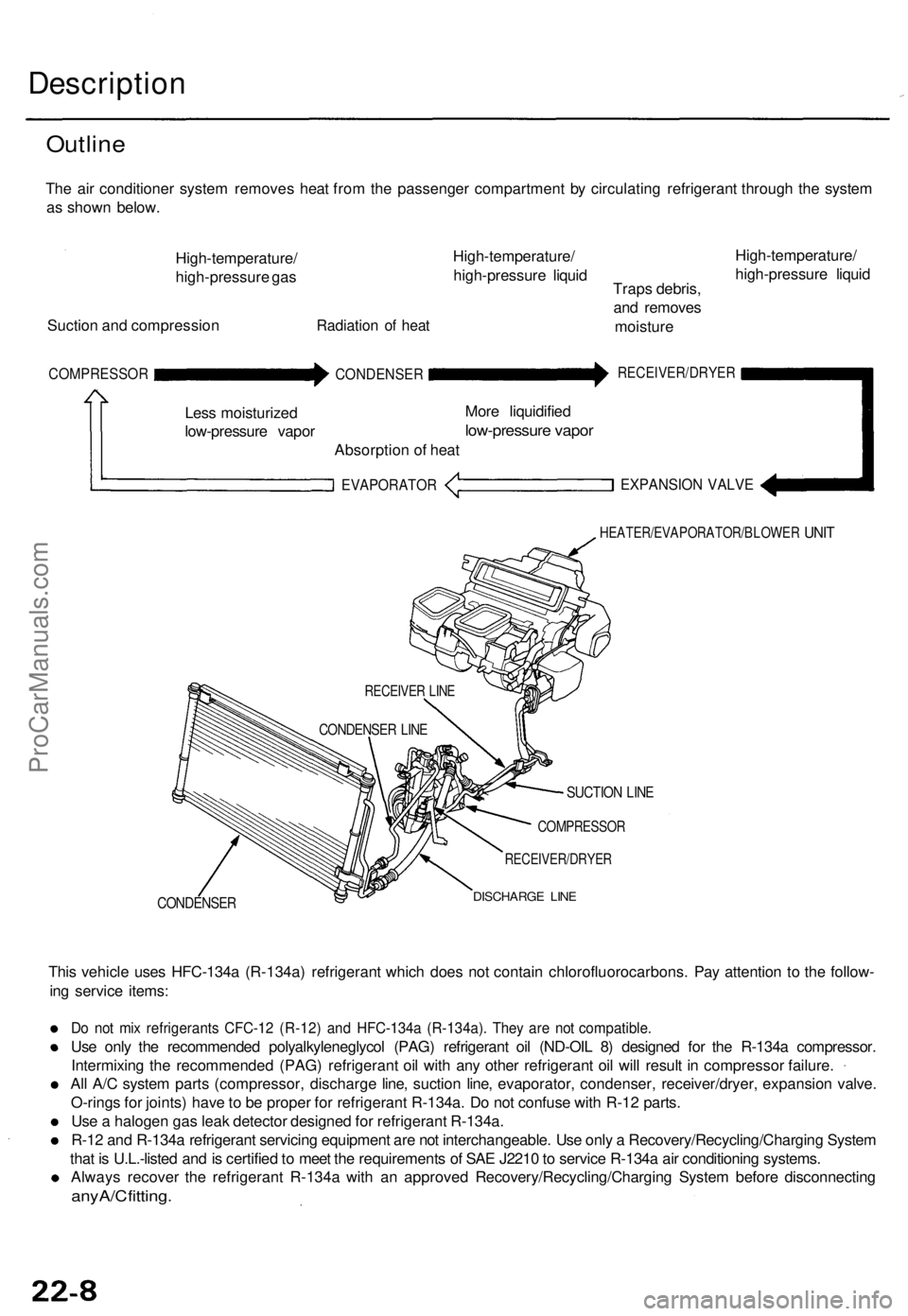

Outline

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the system

as shown below.

High-temperature/

high-pressure gas

Suction and compression

Radiation of heat

High-temperature/

high-pressure liquid

Traps debris,

and removes

moisture

High-temperature/

high-pressure liquid

COMPRESSOR

Less moisturized

low-pressure vapor

CONDENSER

Absorption of heat

EVAPORATOR

More liquidified

low-pressure vapor

RECEIVER/DRYER

EXPANSION VALVE

HEATER/EVAPORATOR/BLOWER

UNIT

CONDENSER

SUCTION LINE

COMPRESSOR

RECEIVER/DRYER

DISCHARGE LINE

This vehicle uses HFC-134a (R-134a) refrigerant which does not contain chlorofluorocarbons. Pay attention to the follow-

ing service items:

Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a). They are not compatible.

Use only the recommended polyalkyleneglycol (PAG) refrigerant oil (ND-OIL 8) designed for the R-134a compressor.

Intermixing the recommended (PAG) refrigerant oil with any other refrigerant oil will result in compressor failure.

All A/C system parts (compressor, discharge line, suction line, evaporator, condenser, receiver/dryer, expansion valve.

O-rings for joints) have to be proper for refrigerant R-134a. Do not confuse with R-12 parts.

Use a halogen gas leak detector designed for refrigerant R-134a.

R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a Recovery/Recycling/Charging System

that is U.L.-listed and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning systems.

Always recover the refrigerant R-134a with an approved Recovery/Recycling/Charging System before disconnecting

any A/C fitting.

RECEIVER LINE

CONDENSER LINEProCarManuals.com

Page 1525 of 1771

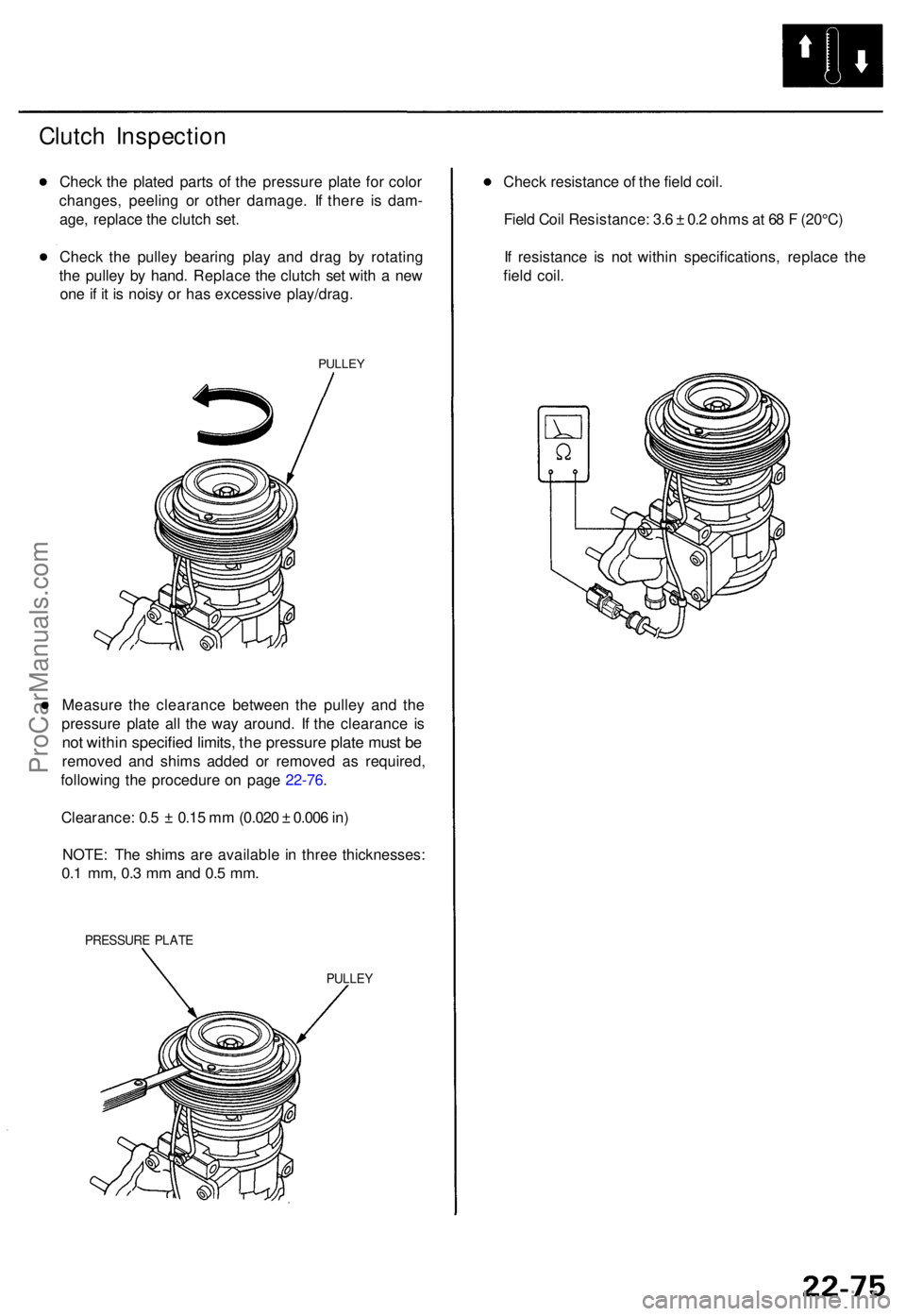

Clutch Inspectio n

Check th e plate d part s o f th e pressur e plat e fo r colo r

changes , peelin g o r othe r damage . I f ther e i s dam -

age , replac e th e clutc h set .

Chec k th e pulle y bearin g pla y an d dra g b y rotatin g

th e pulle y b y hand . Replac e th e clutc h se t wit h a ne w

on e if i t i s nois y o r ha s excessive play/drag.

PULLEY

Measur e th e clearanc e betwee n th e pulle y an d th e

pressur e plat e al l th e wa y around . I f th e clearanc e i s

no t withi n specifie d limits , th e pressur e plat e mus t b e

remove d an d shim s added or remove d a s required ,

followin g th e procedur e o n pag e 22-76 .

Clearance : 0. 5 ± 0.1 5 m m (0.02 0 ± 0.00 6 in )

NOTE : Th e shim s ar e availabl e i n thre e thicknesses :

0.1 mm , 0. 3 m m an d 0. 5 mm .

PRESSUR E PLAT E

PULLE Y

Check resistanc e o f th e fiel d coil .

Fiel d Coi l Resistance : 3. 6 ± 0. 2 ohm s a t 6 8 F (20°C )

I f resistanc e i s no t withi n specifications , replac e th e

fiel d coil .

ProCarManuals.com