Alfa Romeo 166 2006 Owner handbook (in English)

Manufacturer: ALFA ROMEO, Model Year: 2006, Model line: 166, Model: Alfa Romeo 166 2006Pages: 272, PDF Size: 4.17 MB

Page 161 of 272

160

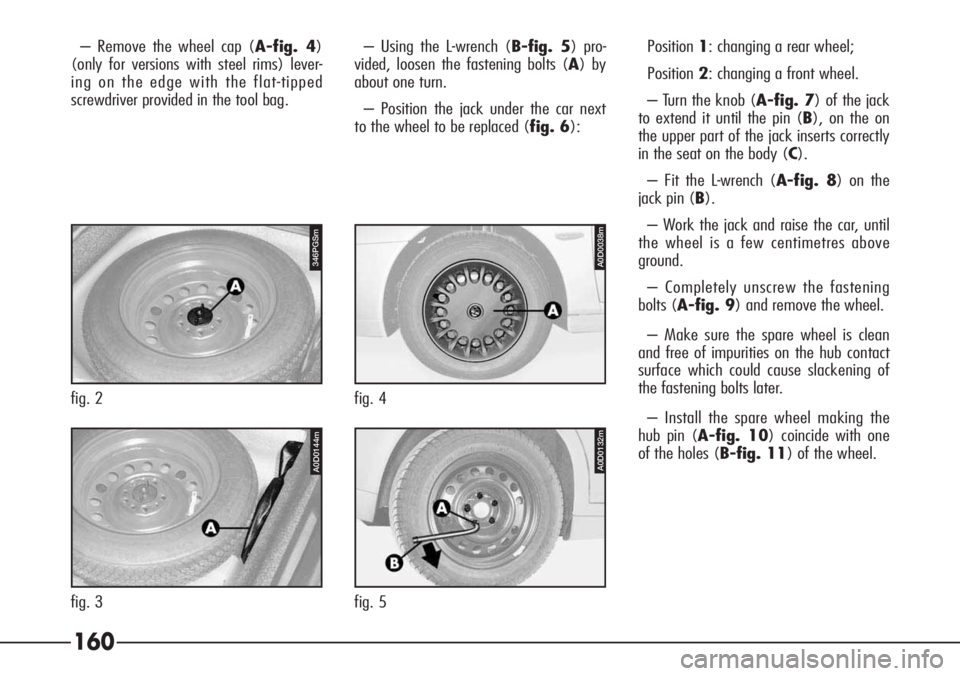

– Remove the wheel cap (A-fig. 4)

(only for versions with steel rims) lever-

ing on the edge with the flat-tipped

screwdriver provided in the tool bag.– Using the L-wrench (B-fig. 5) pro-

vided, loosen the fastening bolts (A) by

about one turn.

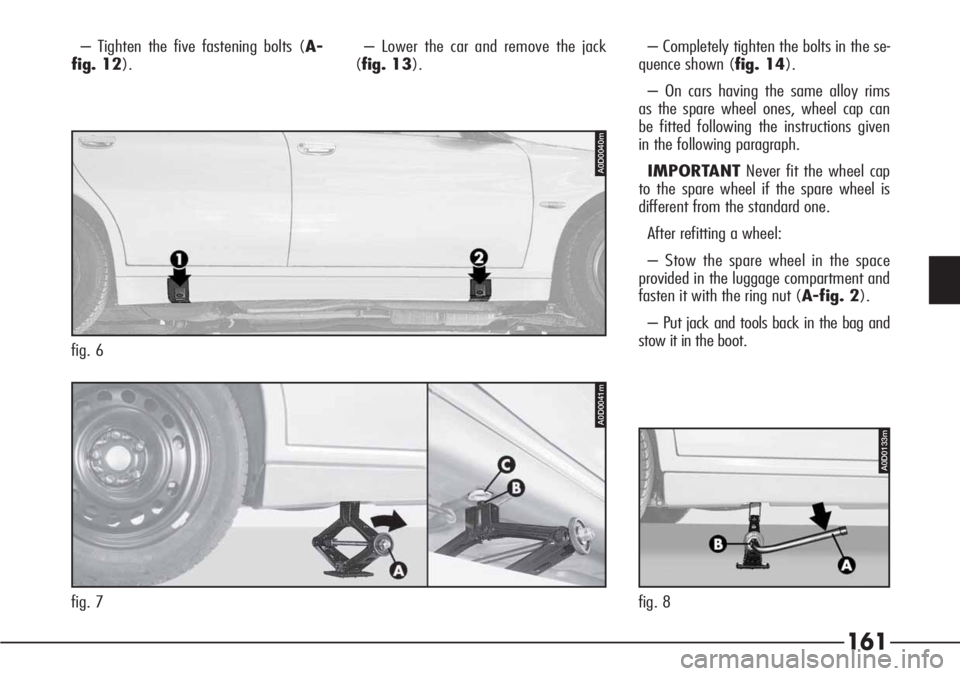

– Position the jack under the car next

to the wheel to be replaced (fig. 6):Position1: changing a rear wheel;

Position2: changing a front wheel.

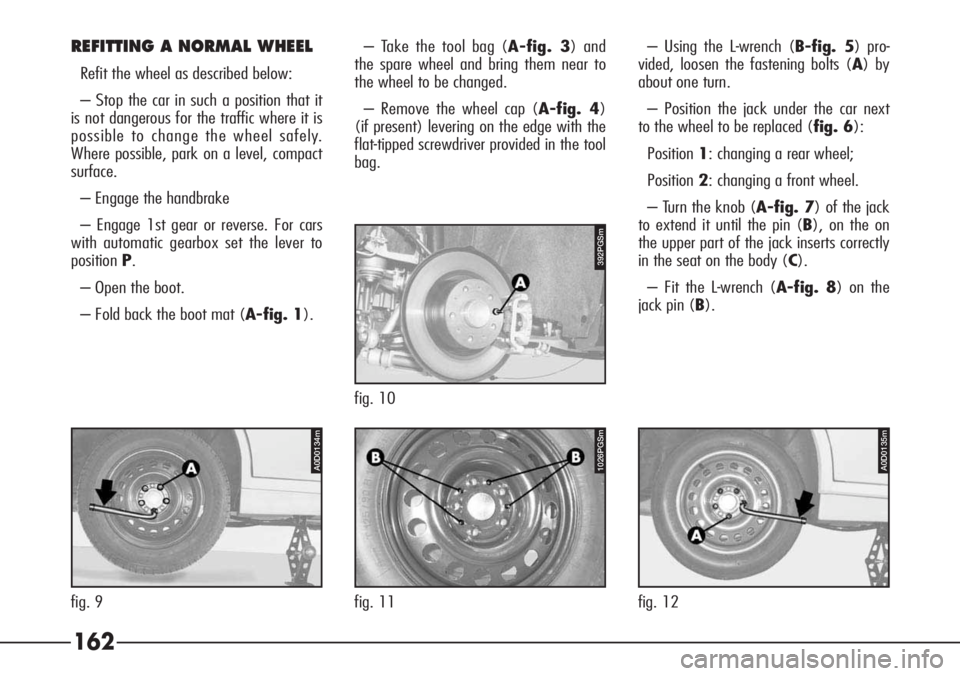

– Turn the knob (A-fig. 7) of the jack

to extend it until the pin (B), on the on

the upper part of the jack inserts correctly

in the seat on the body (C).

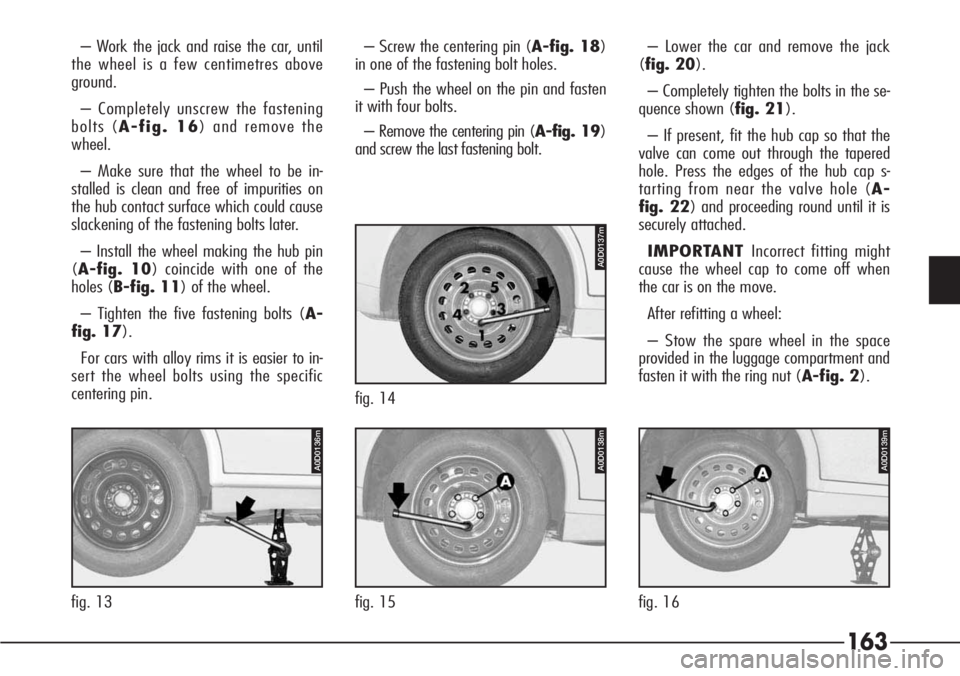

– Fit the L-wrench (A-fig. 8) on the

jack pin (B).

– Work the jack and raise the car, until

the wheel is a few centimetres above

ground.

– Completely unscrew the fastening

bolts (A-fig. 9) and remove the wheel.

– Make sure the spare wheel is clean

and free of impurities on the hub contact

surface which could cause slackening of

the fastening bolts later.

– Install the spare wheel making the

hub pin (A-fig. 10) coincide with one

of the holes (B-fig. 11) of the wheel.

A0D0038m

fig. 4

A0D0132m

fig. 5

346PGSm

fig. 2

A0D0144m

fig. 3

Page 162 of 272

161

– Tighten the five fastening bolts (A-

fig. 12).– Lower the car and remove the jack

(fig. 13).– Completely tighten the bolts in the se-

quence shown (fig. 14).

– On cars having the same alloy rims

as the spare wheel ones, wheel cap can

be fitted following the instructions given

in the following paragraph.

IMPORTANTNever fit the wheel cap

to the spare wheel if the spare wheel is

different from the standard one.

After refitting a wheel:

– Stow the spare wheel in the space

provided in the luggage compartment and

fasten it with the ring nut (A-fig. 2).

– Put jack and tools back in the bag and

stow it in the boot.

fig. 7

A0D0041m

fig. 6

A0D0040m

A0D0133m

fig. 8

Page 163 of 272

162

REFITTING A NORMAL WHEEL

Refit the wheel as described below:

– Stop the car in such a position that it

is not dangerous for the traffic where it is

possible to change the wheel safely.

Where possible, park on a level, compact

surface.

– Engage the handbrake

– Engage 1st gear or reverse. For cars

with automatic gearbox set the lever to

positionP.

– Open the boot.

– Fold back the boot mat (A-fig. 1).– Take the tool bag (A-fig. 3) and

the spare wheel and bring them near to

the wheel to be changed.

– Remove the wheel cap (A-fig. 4)

(if present) levering on the edge with the

flat-tipped screwdriver provided in the tool

bag.– Using the L-wrench (B-fig. 5) pro-

vided, loosen the fastening bolts (A) by

about one turn.

– Position the jack under the car next

to the wheel to be replaced (fig. 6):

Position1: changing a rear wheel;

Position2: changing a front wheel.

– Turn the knob (A-fig. 7) of the jack

to extend it until the pin (B), on the on

the upper part of the jack inserts correctly

in the seat on the body (C).

– Fit the L-wrench (A-fig. 8) on the

jack pin (B).

392PGSm

fig. 10

1026PGSm

fig. 11

A0D0134m

fig. 9

A0D0135m

fig. 12

Page 164 of 272

163

– Work the jack and raise the car, until

the wheel is a few centimetres above

ground.

– Completely unscrew the fastening

bolts (A-fig. 16) and remove the

wheel.

– Make sure that the wheel to be in-

stalled is clean and free of impurities on

the hub contact surface which could cause

slackening of the fastening bolts later.

– Install the wheel making the hub pin

(A-fig. 10) coincide with one of the

holes (B-fig. 11) of the wheel.

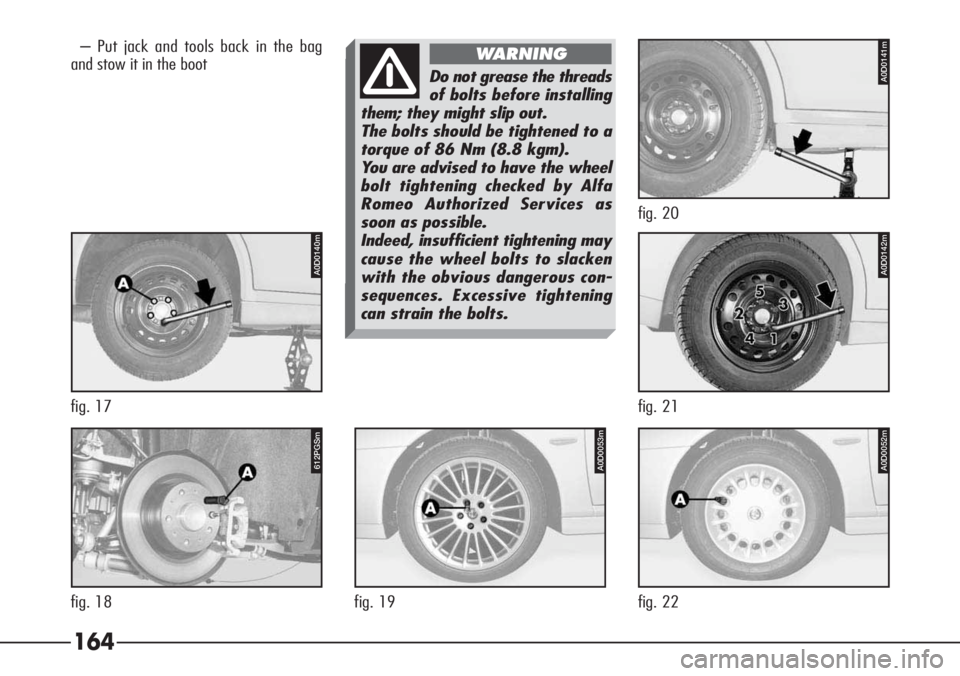

– Tighten the five fastening bolts (A-

fig. 17).

For cars with alloy rims it is easier to in-

sert the wheel bolts using the specific

centering pin.– Screw the centering pin (A-fig. 18)

in one of the fastening bolt holes.

– Push the wheel on the pin and fasten

it with four bolts.

– Remove the centering pin (A-fig. 19)

and screw the last fastening bolt.– Lower the car and remove the jack

(fig. 20).

– Completely tighten the bolts in the se-

quence shown (fig. 21).

– If present, fit the hub cap so that the

valve can come out through the tapered

hole. Press the edges of the hub cap s-

tarting from near the valve hole (A-

fig. 22) and proceeding round until it is

securely attached.

IMPORTANT Incorrect fitting might

cause the wheel cap to come off when

the car is on the move.

After refitting a wheel:

– Stow the spare wheel in the space

provided in the luggage compartment and

fasten it with the ring nut (A-fig. 2).

A0D0139m

fig. 16

A0D0138m

fig. 15

A0D0136m

fig. 13

A0D0137m

fig. 14

Page 165 of 272

164

– Put jack and tools back in the bag

and stow it in the boot

Do not grease the threads

of bolts before installing

them; they might slip out.

The bolts should be tightened to a

torque of 86 Nm (8.8 kgm).

You are advised to have the wheel

bolt tightening checked by Alfa

Romeo Authorized Services as

soon as possible.

Indeed, insufficient tightening may

cause the wheel bolts to slacken

with the obvious dangerous con-

sequences. Excessive tightening

can strain the bolts.

WARNING

A0D0053m

fig. 19

A0D0052m

fig. 22

612PGSm

fig. 18

A0D0140m

fig. 17

A0D0142m

fig. 21

A0D0141m

fig. 20

Page 166 of 272

165

GENERAL INSTRUCTIONS

– When a light is not working check

that the corresponding fuse is intact be-

fore replacing the bulb.

– For the location of fuses, refer to the

paragraph “In the event of a burnt fuse”

in this chapter.

– Before changing a bulb check the

contacts for oxidation.

– Burnt bulbs must be replaced with

others of the same type and power.

– Always check the height of the head-

light beam after changing a bulb to en-

sure they are safe.

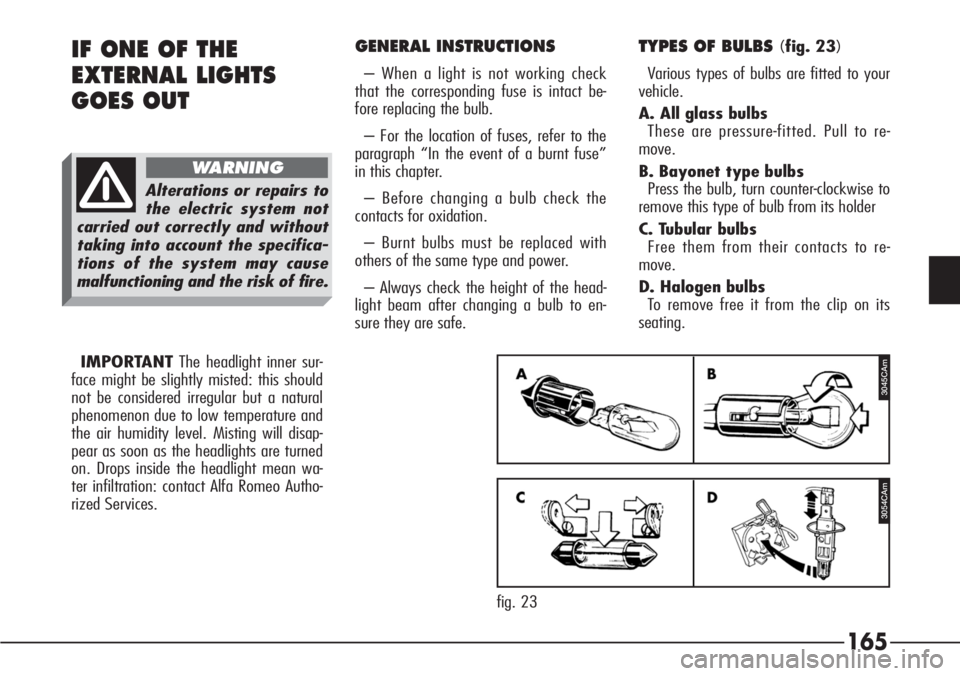

TYPES OF BULBS (fig. 23)

Various types of bulbs are fitted to your

vehicle.

A. All glass bulbs

These are pressure-fitted. Pull to re-

move.

B. Bayonet type bulbs

Press the bulb, turn counter-clockwise to

remove this type of bulb from its holder

C. Tubular bulbs

Free them from their contacts to re-

move.

D. Halogen bulbs

To remove free it from the clip on its

seating.IF ONE OF THE

EXTERNAL LIGHTS

GOES OUT

Alterations or repairs to

the electric system not

carried out correctly and without

taking into account the specifica-

tions of the system may cause

malfunctioning and the risk of fire.

WARNING

3045CAm

3054CAm

fig. 23 IMPORTANTThe headlight inner sur-

face might be slightly misted: this should

not be considered irregular but a natural

phenomenon due to low temperature and

the air humidity level. Misting will disap-

pear as soon as the headlights are turned

on. Drops inside the headlight mean wa-

ter infiltration: contact Alfa Romeo Autho-

rized Services.

Page 167 of 272

166

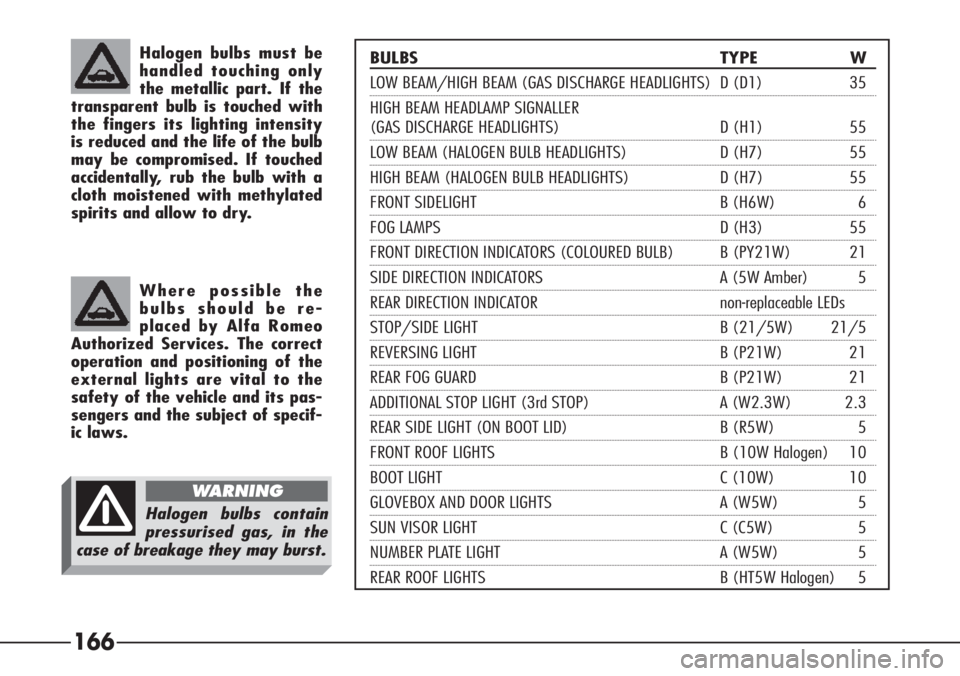

BULBS TYPE W

LOW BEAM/HIGH BEAM (GAS DISCHARGE HEADLIGHTS) D (D1) 35

HIGH BEAM HEADLAMP SIGNALLER

(GAS DISCHARGE HEADLIGHTS) D (H1) 55

LOW BEAM (HALOGEN BULB HEADLIGHTS) D (H7) 55

HIGH BEAM (HALOGEN BULB HEADLIGHTS) D (H7) 55

FRONT SIDELIGHT B (H6W) 6

FOG LAMPS D (H3) 55

FRONT DIRECTION INDICATORS (COLOURED BULB) B (PY21W) 21

SIDE DIRECTION INDICATORS A (5W Amber) 5

REAR DIRECTION INDICATOR non-replaceable LEDs

STOP/SIDE LIGHT B (21/5W) 21/5

REVERSING LIGHT B (P21W) 21

REAR FOG GUARD B (P21W) 21

ADDITIONAL STOP LIGHT (3rd STOP) A (W2.3W) 2.3

REAR SIDE LIGHT (ON BOOT LID) B (R5W) 5

FRONT ROOF LIGHTS B (10W Halogen) 10

BOOT LIGHT C (10W) 10

GLOVEBOX AND DOOR LIGHTS A (W5W) 5

SUN VISOR LIGHT C (C5W) 5

NUMBER PLATE LIGHT A (W5W) 5

REAR ROOF LIGHTS B (HT5W Halogen) 5

Halogen bulbs must be

handled touching only

the metallic part. If the

transparent bulb is touched with

the fingers its lighting intensity

is reduced and the life of the bulb

may be compromised. If touched

accidentally, rub the bulb with a

cloth moistened with methylated

spirits and allow to dry.

Where possible the

bulbs should be re-

placed by Alfa Romeo

Authorized Services. The correct

operation and positioning of the

external lights are vital to the

safety of the vehicle and its pas-

sengers and the subject of specif-

ic laws.

Halogen bulbs contain

pressurised gas, in the

case of breakage they may burst.

WARNING

Page 168 of 272

167

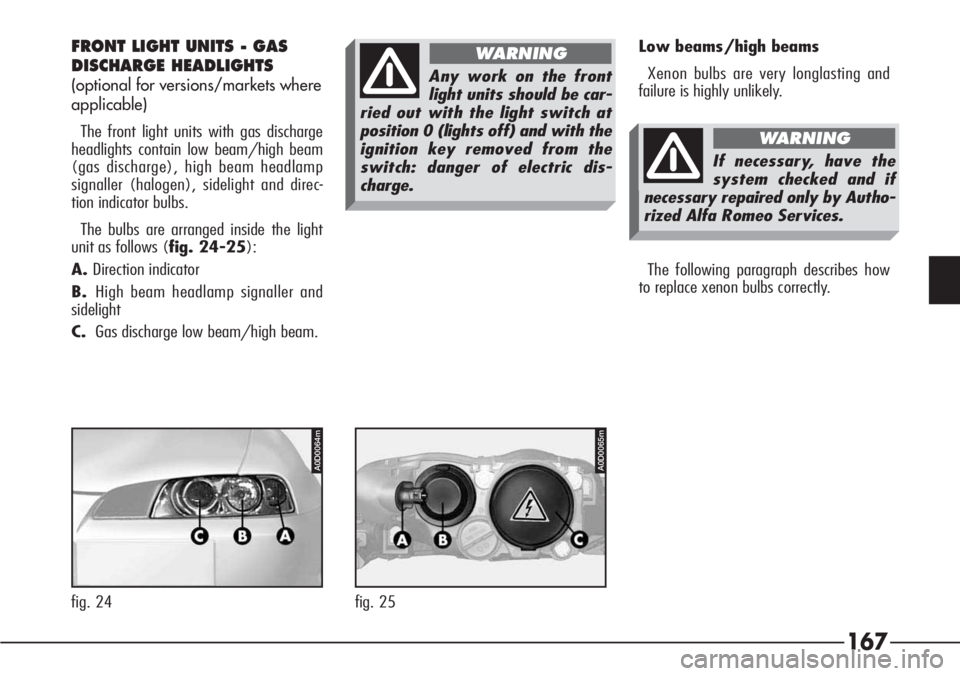

FRONT LIGHT UNITS - GAS

DISCHARGE HEADLIGHTS

(optional for versions/markets where

applicable)

The front light units with gas discharge

headlights contain low beam/high beam

(gas discharge), high beam headlamp

signaller (halogen), sidelight and direc-

tion indicator bulbs.

The bulbs are arranged inside the light

unit as follows (fig. 24-25):

A.Direction indicator

B.High beam headlamp signaller and

sidelight

C.Gas discharge low beam/high beam.Low beams/high beams

Xenon bulbs are very longlasting and

failure is highly unlikely.

The following paragraph describes how

to replace xenon bulbs correctly.

Any work on the front

light units should be car-

ried out with the light switch at

position 0 (lights off) and with the

ignition key removed from the

switch: danger of electric dis-

charge.

WARNING

If necessary, have the

system checked and if

necessary repaired only by Autho-

rized Alfa Romeo Services.

WARNING

A0D0064m

fig. 24

A0D0065m

fig. 25

Page 169 of 272

168

To replace the bulb (Type D – D1,

35W):

– Remove the engine compartment cov-

er after turning the fastening pins.

– Remove the rubber cap (A-fig. 26)

by pulling the tab (B).– Release the clip (C- fig. 27).

– Remove the bulb (D- fig. 28) and

disconnect the snap-fitted connector (E).– Fit connector to new bulb.

– Fit the bulb in the headlight reflector

making the notch coincide with the corre-

sponding groove.

– Lock the bulb with the clip.

– Fit the rubber cap.

– Refit the engine compartment cover

and fasten turning the fastening pins. Xenon bulbs may only

be touched on the metal

part. If the glass bulb is

touched by the fingers, clean it

carefully with a clean cloth

moistened with methylated spirit

and allow to dry before refitting

the bulb.

Any work on the front

light units should be car-

ried out with the light switch at

position 0 (lights off) and with the

ignition key removed from the

switch: danger of electric dis-

charge.

WARNING

A0D0056m

fig. 26

A0D0057m

fig. 27

A0D0058m

fig. 28

Page 170 of 272

169

High beam headlamp signaller

To replace the bulb (Type D – H1,

55W):

– Remove the engine compartment cov-

er after turning the fastening pins.

– Turn counter-clockwise and remove

the direction indicator bulb holder (A-

fig. 29), without disconnecting the con-

nector to widen the working space.

– Remove the rubber cap (B) by

pulling the tab (C).– Disconnect the snap-fitted connector

(D- fig. 30) and release clip (E).

– Remove the bulb (F- fig. 31).– Fit new bulb in the headlight reflector

making the notches coincide with the cor-

responding grooves.

– Lock the bulb with the clip.

– Fit the connector to the bulb.

– Fit the rubber cap.

– Fit the direction indicator bulb holder

and lock it by turning it clockwise.

– Refit the engine compartment cover

and secure it by turning the fastening

pins.

A0D0059m

fig. 29

A0D0060m

fig. 30

A0D0061m

fig. 31