engine ALFA ROMEO STELVIO 2022 Repair Manual

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2022, Model line: STELVIO, Model: ALFA ROMEO STELVIO 2022Pages: 256, PDF Size: 10.17 MB

Page 126 of 256

STARTING AND OPERATING

124

REFUELING THE VEHICLE

Before refueling, make sure that the fuel type is

correct.

Also, stop the engine before refueling.

NOTE:

An inefficient catalytic converter leads to harmful

exhaust emissions, thus contributing to air pollu-

tion.

REFUELING CAPACITY

To ensure that you fill the tank completely, top off

twice after the first click of the fuel nozzle.

Further top-off could cause faults in the fuel

feeding system.

REFUELING PROCEDURE

The fuel filler door is unlocked when the central

door locking system is unlocked. It is automat -

ically locked when the central locking system is

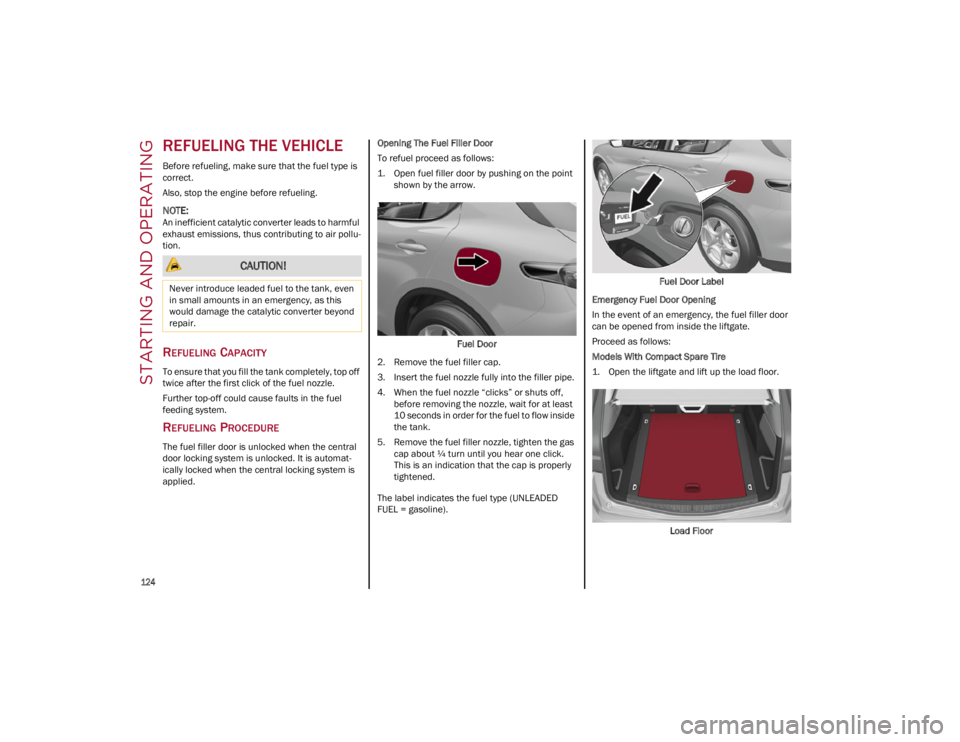

applied. Opening The Fuel Filler Door

To refuel proceed as follows:

1. Open fuel filler door by pushing on the point

shown by the arrow.

Fuel Door

2. Remove the fuel filler cap.

3. Insert the fuel nozzle fully into the filler pipe.

4. When the fuel nozzle “clicks” or shuts off, before removing the nozzle, wait for at least

10 seconds in order for the fuel to flow inside

the tank.

5. Remove the fuel filler nozzle, tighten the gas cap about ¼ turn until you hear one click.

This is an indication that the cap is properly

tightened.

The label indicates the fuel type (UNLEADED

FUEL = gasoline). Fuel Door Label

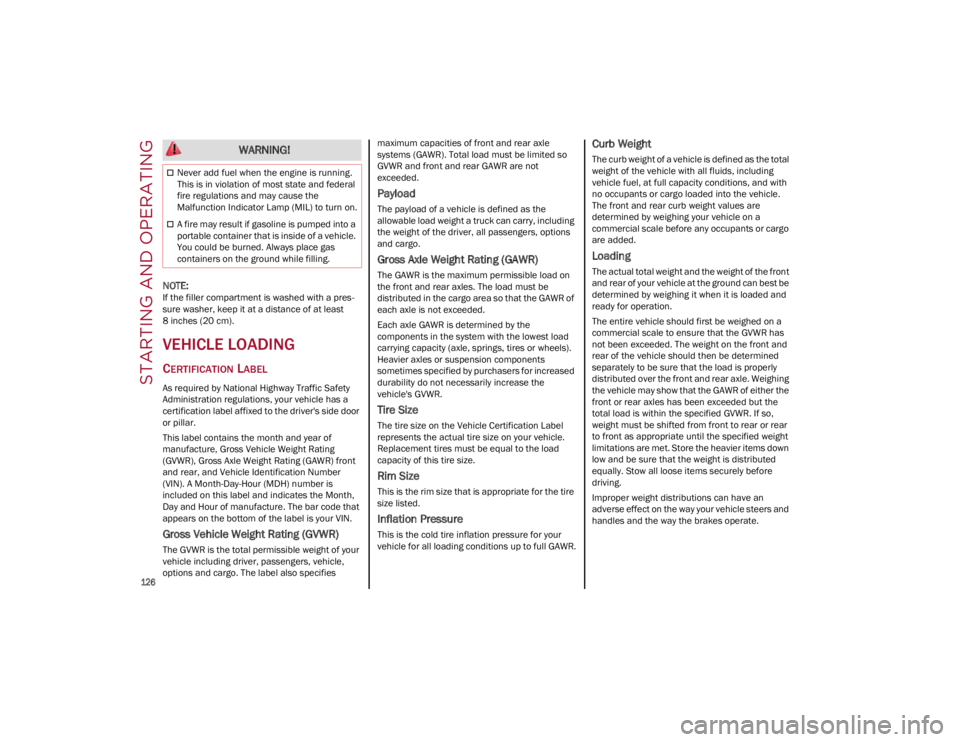

Emergency Fuel Door Opening

In the event of an emergency, the fuel filler door

can be opened from inside the liftgate.

Proceed as follows:

Models With Compact Spare Tire

1. Open the liftgate and lift up the load floor.

Load Floor

CAUTION!

Never introduce leaded fuel to the tank, even

in small amounts in an emergency, as this

would damage the catalytic converter beyond

repair.

22_GU_OM_EN_USC_t.book Page 124

Page 128 of 256

STARTING AND OPERATING

126

NOTE:

If the filler compartment is washed with a pres-

sure washer, keep it at a distance of at least

8 inches (20 cm).

VEHICLE LOADING

CERTIFICATION LABEL

As required by National Highway Traffic Safety

Administration regulations, your vehicle has a

certification label affixed to the driver's side door

or pillar.

This label contains the month and year of

manufacture, Gross Vehicle Weight Rating

(GVWR), Gross Axle Weight Rating (GAWR) front

and rear, and Vehicle Identification Number

(VIN). A Month-Day-Hour (MDH) number is

included on this label and indicates the Month,

Day and Hour of manufacture. The bar code that

appears on the bottom of the label is your VIN.

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies maximum capacities of front and rear axle

systems (GAWR). Total load must be limited so

GVWR and front and rear GAWR are not

exceeded.

Payload

The payload of a vehicle is defined as the

allowable load weight a truck can carry, including

the weight of the driver, all passengers, options

and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on

the front and rear axles. The load must be

distributed in the cargo area so that the GAWR of

each axle is not exceeded.

Each axle GAWR is determined by the

components in the system with the lowest load

carrying capacity (axle, springs, tires or wheels).

Heavier axles or suspension components

sometimes specified by purchasers for increased

durability do not necessarily increase the

vehicle's GVWR.

Tire Size

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire

size listed.

Inflation Pressure

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with

no occupants or cargo loaded into the vehicle.

The front and rear curb weight values are

determined by weighing your vehicle on a

commercial scale before any occupants or cargo

are added.

Loading

The actual total weight and the weight of the front

and rear of your vehicle at the ground can best be

determined by weighing it when it is loaded and

ready for operation.

The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has

not been exceeded. The weight on the front and

rear of the vehicle should then be determined

separately to be sure that the load is properly

distributed over the front and rear axle. Weighing

the vehicle may show that the GAWR of either the

front or rear axles has been exceeded but the

total load is within the specified GVWR. If so,

weight must be shifted from front to rear or rear

to front as appropriate until the specified weight

limitations are met. Store the heavier items down

low and be sure that the weight is distributed

equally. Stow all loose items securely before

driving.

Improper weight distributions can have an

adverse effect on the way your vehicle steers and

handles and the way the brakes operate.

Never add fuel when the engine is running.

This is in violation of most state and federal

fire regulations and may cause the

Malfunction Indicator Lamp (MIL) to turn on.

A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle.

You could be burned. Always place gas

containers on the ground while filling.

WARNING!

22_GU_OM_EN_USC_t.book Page 126

Page 130 of 256

STARTING AND OPERATING

128

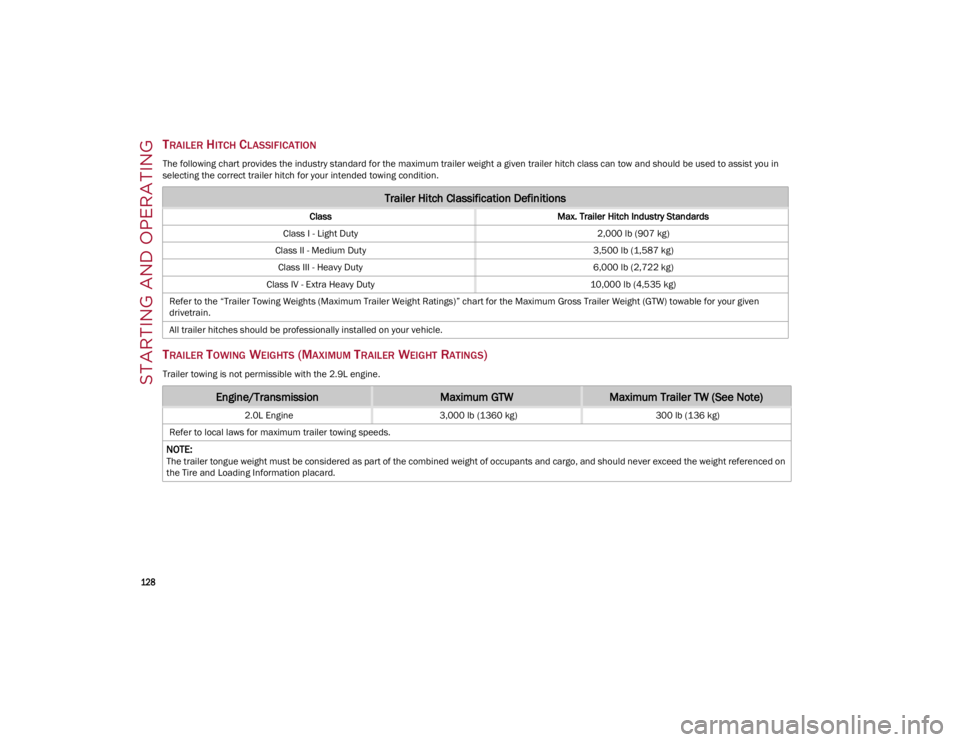

TRAILER HITCH CLASSIFICATION

The following chart provides the industry standard for the maximum trailer weight a given trailer hitch class can tow and should be used to assist you in

selecting the correct trailer hitch for your intended towing condition.

TRAILER TOWING WEIGHTS (MAXIMUM TRAILER WEIGHT RATINGS)

Trailer towing is not permissible with the 2.9L engine.

Trailer Hitch Classification Definitions

ClassMax. Trailer Hitch Industry Standards

Class I - Light Duty 2,000 lb (907 kg)

Class II - Medium Duty 3,500 lb (1,587 kg)

Class III - Heavy Duty 6,000 lb (2,722 kg)

Class IV - Extra Heavy Duty 10,000 lb (4,535 kg)

Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” chart for the Maximum Gross Trailer Weight (GTW) towable for your given

drivetrain.

All trailer hitches should be professionally installed on your vehicle.

Engine/TransmissionMaximum GTWMaximum Trailer TW (See Note)

2.0L Engine 3,000 lb (1360 kg) 300 lb (136 kg)

Refer to local laws for maximum trailer towing speeds.

NOTE:

The trailer tongue weight must be considered as part of the combined weight of occupants and cargo, and should never exceed the weight referenced on

the Tire and Loading Information placard.

22_GU_OM_EN_USC_t.book Page 128

Page 131 of 256

129

(Continued)

(Continued)

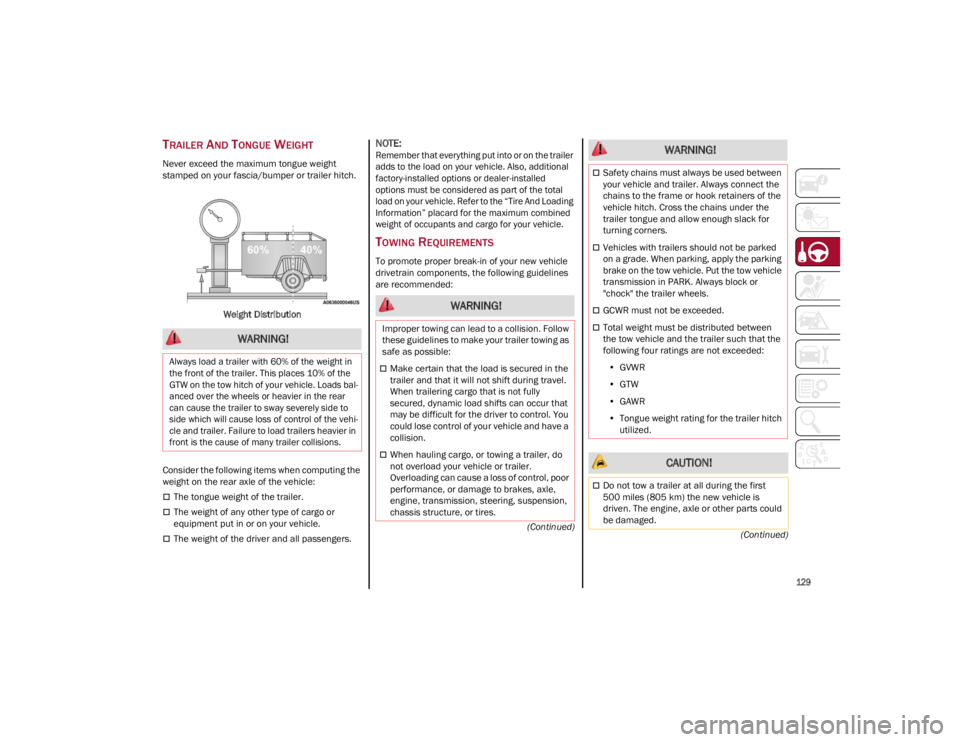

TRAILER AND TONGUE WEIGHT

Never exceed the maximum tongue weight

stamped on your fascia/bumper or trailer hitch.

Weight Distribution

Consider the following items when computing the

weight on the rear axle of the vehicle:

The tongue weight of the trailer.

The weight of any other type of cargo or

equipment put in or on your vehicle.

The weight of the driver and all passengers.

NOTE:Remember that everything put into or on the trailer

adds to the load on your vehicle. Also, additional

factory-installed options or dealer-installed

options must be considered as part of the total

load on your vehicle. Refer to the “Tire And Loading

Information” placard for the maximum combined

weight of occupants and cargo for your vehicle.

TOWING REQUIREMENTS

To promote proper break-in of your new vehicle

drivetrain components, the following guidelines

are recommended:

WARNING!

Always load a trailer with 60% of the weight in

the front of the trailer. This places 10% of the

GTW on the tow hitch of your vehicle. Loads bal -

anced over the wheels or heavier in the rear

can cause the trailer to sway severely side to

side which will cause loss of control of the vehi -

cle and trailer. Failure to load trailers heavier in

front is the cause of many trailer collisions.

WARNING!

Improper towing can lead to a collision. Follow

these guidelines to make your trailer towing as

safe as possible:

Make certain that the load is secured in the

trailer and that it will not shift during travel.

When trailering cargo that is not fully

secured, dynamic load shifts can occur that

may be difficult for the driver to control. You

could lose control of your vehicle and have a

collision.

When hauling cargo, or towing a trailer, do

not overload your vehicle or trailer.

Overloading can cause a loss of control, poor

performance, or damage to brakes, axle,

engine, transmission, steering, suspension,

chassis structure, or tires.

Safety chains must always be used between

your vehicle and trailer. Always connect the

chains to the frame or hook retainers of the

vehicle hitch. Cross the chains under the

trailer tongue and allow enough slack for

turning corners.

Vehicles with trailers should not be parked

on a grade. When parking, apply the parking

brake on the tow vehicle. Put the tow vehicle

transmission in PARK. Always block or

"chock" the trailer wheels.

GCWR must not be exceeded.

Total weight must be distributed between

the tow vehicle and the trailer such that the

following four ratings are not exceeded:

• GVWR

• GTW

• GAWR

• Tongue weight rating for the trailer hitch

utilized.

CAUTION!

Do not tow a trailer at all during the first

500 miles (805 km) the new vehicle is

driven. The engine, axle or other parts could

be damaged.

WARNING!

22_GU_OM_EN_USC_t.book Page 129

Page 132 of 256

STARTING AND OPERATING

130

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h)

when towing while using a full size spare tire.

Proper tire inflation pressures are essential to

the safe and satisfactory operation of your

vehicle.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer.

Replacing tires with a higher load carrying

capacity will not increase the vehicle's GVWR

and GAWR limits.

For proper tire inflation procedures

Ú

page 216.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake

system or vacuum system of your vehicle with

that of the trailer. This could cause inadequate

braking and possible personal injury.

An electronically actuated trailer brake

controller is required when towing a trailer with

electronically actuated brakes. When towing a

trailer equipped with a hydraulic surge

actuated brake system, an electronic brake

controller is not required.

Trailer brakes are recommended for trailers

over 1,000 lb (453 kg) and required for trailers

in excess of 2,000 lb (907 kg).

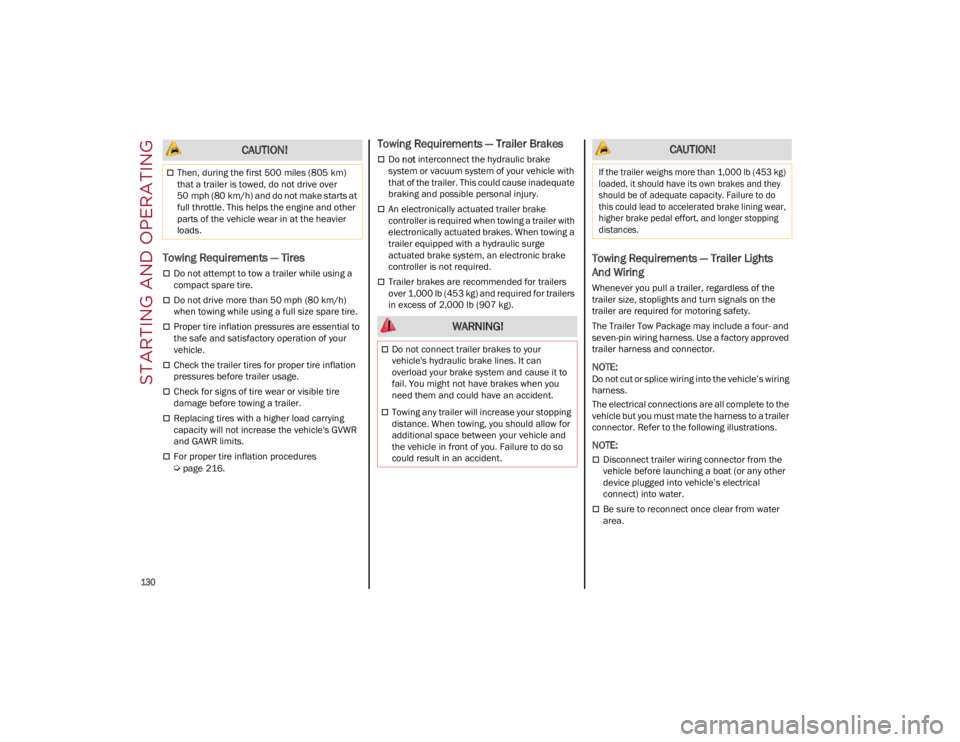

Towing Requirements — Trailer Lights

And Wiring

Whenever you pull a trailer, regardless of the

trailer size, stoplights and turn signals on the

trailer are required for motoring safety.

The Trailer Tow Package may include a four- and

seven-pin wiring harness. Use a factory approved

trailer harness and connector.

NOTE:

Do not cut or splice wiring into the vehicle’s wiring

harness.

The electrical connections are all complete to the

vehicle but you must mate the harness to a trailer

connector. Refer to the following illustrations.

NOTE:

Disconnect trailer wiring connector from the

vehicle before launching a boat (or any other

device plugged into vehicle’s electrical

connect) into water.

Be sure to reconnect once clear from water

area.

Then, during the first 500 miles (805 km)

that a trailer is towed, do not drive over

50 mph (80 km/h) and do not make starts at

full throttle. This helps the engine and other

parts of the vehicle wear in at the heavier

loads.

CAUTION!

WARNING!

Do not connect trailer brakes to your

vehicle's hydraulic brake lines. It can

overload your brake system and cause it to

fail. You might not have brakes when you

need them and could have an accident.

Towing any trailer will increase your stopping

distance. When towing, you should allow for

additional space between your vehicle and

the vehicle in front of you. Failure to do so

could result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lb (453 kg)

loaded, it should have its own brakes and they

should be of adequate capacity. Failure to do

this could lead to accelerated brake lining wear,

higher brake pedal effort, and longer stopping

distances.

22_GU_OM_EN_USC_t.book Page 130

Page 133 of 256

131

Four-Pin Connector

Seven-Pin Connector

TOWING TIPS

Before setting out on a trip, practice turning,

stopping, and backing up the trailer in an area

located away from heavy traffic.

Automatic Transmission

Select the DRIVE range when towing. The

transmission controls include a drive strategy to

avoid frequent shifting when towing. However, if

frequent shifting does occur while in DRIVE, you

can use the AutoStick shift control to manually

select a lower gear.

NOTE:

Using a lower gear while operating the vehicle

under heavy loading conditions will improve

performance and extend transmission life by

reducing excessive shifting and heat buildup. This

action will also provide better engine braking.

Cruise Control — If Equipped

Do not use on hilly terrain or with heavy loads.

When using the Cruise Control, if you

experience speed drops greater than 10 mph

(16 km/h), disengage until you can get back to

cruising speed.

Use Cruise Control in flat terrain and with light

loads to maximize fuel efficiency.

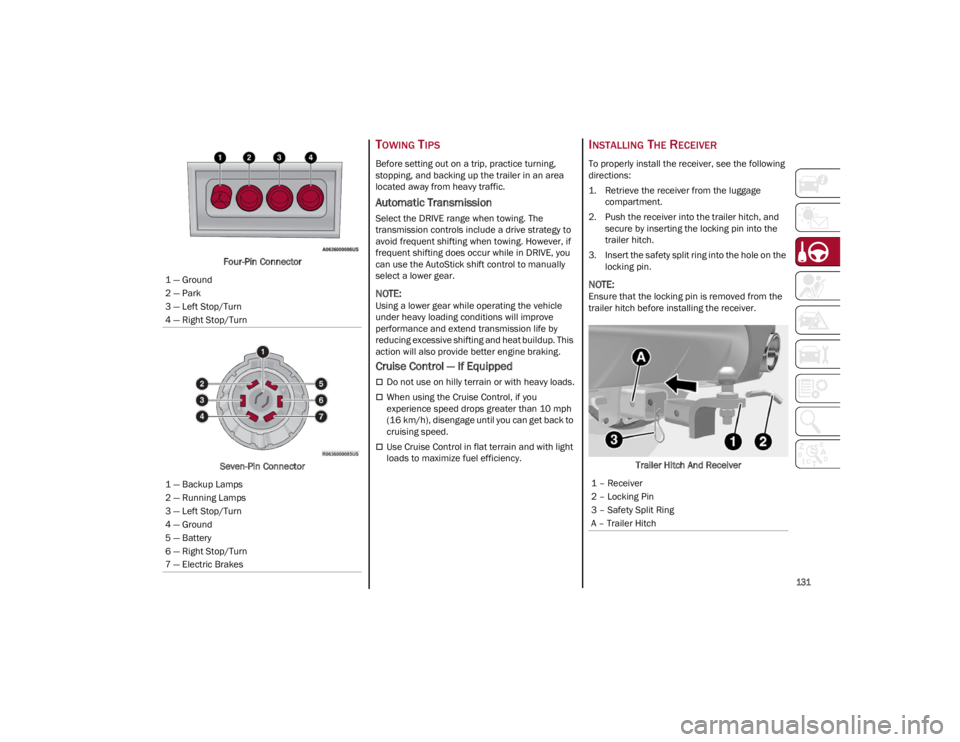

INSTALLING THE RECEIVER

To properly install the receiver, see the following

directions:

1. Retrieve the receiver from the luggage compartment.

2. Push the receiver into the trailer hitch, and secure by inserting the locking pin into the

trailer hitch.

3. Insert the safety split ring into the hole on the locking pin.

NOTE:

Ensure that the locking pin is removed from the

trailer hitch before installing the receiver.

Trailer Hitch And Receiver

1 — Ground

2 — Park

3 — Left Stop/Turn

4 — Right Stop/Turn

1 — Backup Lamps

2 — Running Lamps

3 — Left Stop/Turn

4 — Ground

5 — Battery

6 — Right Stop/Turn

7 — Electric Brakes

1 – Receiver

2 – Locking Pin

3 – Safety Split Ring

A – Trailer Hitch

22_GU_OM_EN_USC_t.book Page 131

Page 134 of 256

STARTING AND OPERATING

132

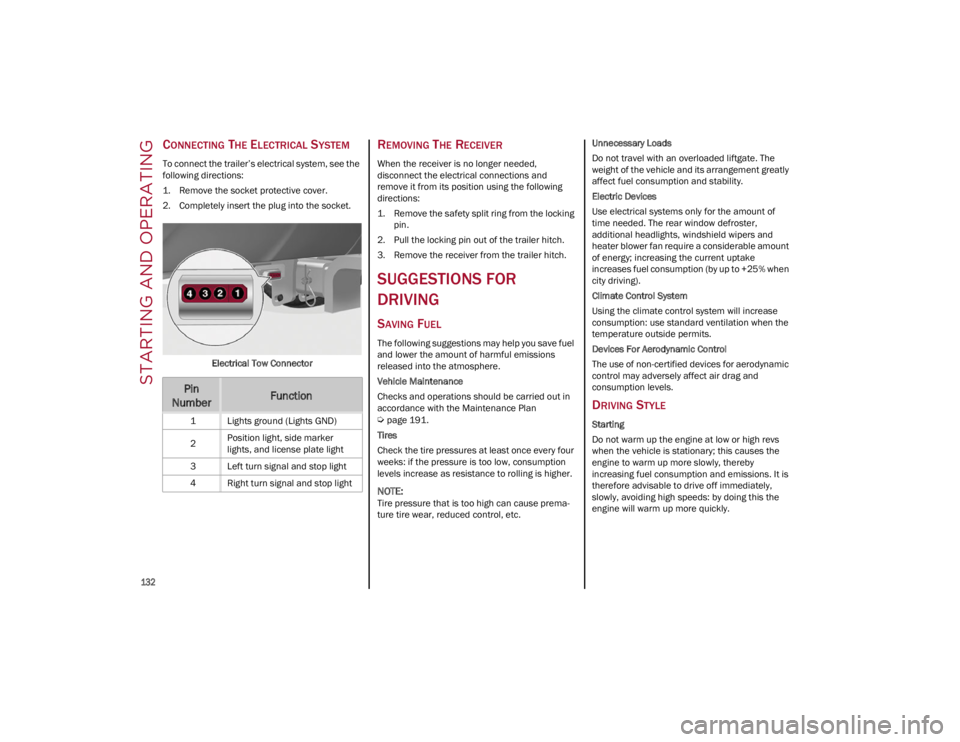

CONNECTING THE ELECTRICAL SYSTEM

To connect the trailer’s electrical system, see the

following directions:

1. Remove the socket protective cover.

2. Completely insert the plug into the socket.Electrical Tow Connector

REMOVING THE RECEIVER

When the receiver is no longer needed,

disconnect the electrical connections and

remove it from its position using the following

directions:

1. Remove the safety split ring from the locking pin.

2. Pull the locking pin out of the trailer hitch.

3. Remove the receiver from the trailer hitch.

SUGGESTIONS FOR

DRIVING

SAVING FUEL

The following suggestions may help you save fuel

and lower the amount of harmful emissions

released into the atmosphere.

Vehicle Maintenance

Checks and operations should be carried out in

accordance with the Maintenance Plan

Ú

page 191.

Tires

Check the tire pressures at least once every four

weeks: if the pressure is too low, consumption

levels increase as resistance to rolling is higher.

NOTE:

Tire pressure that is too high can cause prema -

ture tire wear, reduced control, etc. Unnecessary Loads

Do not travel with an overloaded liftgate. The

weight of the vehicle and its arrangement greatly

affect fuel consumption and stability.

Electric Devices

Use electrical systems only for the amount of

time needed. The rear window defroster,

additional headlights, windshield wipers and

heater blower fan require a considerable amount

of energy; increasing the current uptake

increases fuel consumption (by up to +25% when

city driving).

Climate Control System

Using the climate control system will increase

consumption: use standard ventilation when the

temperature outside permits.

Devices For Aerodynamic Control

The use of non-certified devices for aerodynamic

control may adversely affect air drag and

consumption levels.

DRIVING STYLE

Starting

Do not warm up the engine at low or high revs

when the vehicle is stationary; this causes the

engine to warm up more slowly, thereby

increasing fuel consumption and emissions. It is

therefore advisable to drive off immediately,

slowly, avoiding high speeds: by doing this the

engine will warm up more quickly.

Pin

NumberFunction

1 Lights ground (Lights GND)

2 Position light, side marker

lights, and license plate light

3 Left turn signal and stop light

4 Right turn signal and stop light

22_GU_OM_EN_USC_t.book Page 132

Page 135 of 256

133

Unnecessary Actions

Avoid revving up when starting at traffic lights or

before stopping the engine. This action is

unnecessary and causes increased fuel

consumption and pollution.

Gear Selection

Use a high gear when traffic and road conditions

allow it. Using a low gear for faster acceleration

will increase fuel consumption. Improper use of a

high gear increases consumption, emissions and

engine wear.

Maximum Speed

Fuel consumption considerably increases as

speed increases. Maintain a constant speed,

avoiding unnecessary braking and acceleration,

which cost in terms of both fuel consumption and

emissions.

Acceleration

Accelerating violently severely affects consumption

and emissions: acceleration should be gradual and

should not exceed the maximum torque.

CONDITIONS OF USE

Cold Starting

Short trips and frequent cold starts will not allow

the engine to reach optimum operating

temperature. This results in a significant increase

in consumption levels (from +15 to +30% in city

driving) and emissions.

Traffic And Road Conditions

High fuel consumption is caused by heavy traffic,

for instance when traveling in traffic with frequent

use of low gears or in cities with many traffic

lights. Winding mountain roads and rough road

surfaces also adversely affect consumption.Stops In Traffic

During prolonged stops (e.g. railway crossings),

turn off the engine.

PERFORMANCE — QUADRIFOGLIO

This vehicle is equipped with an engine capable

of delivering exceptionally fast acceleration and

speed:

Peak power: 505 HP at 6,500 RPM.

Peak torque: 443 ft-lb at 2,500–5,000 RPM.

Top speed: 176 mph (283 km/h).

Acceleration from 0 to 60 mph (0 to 100 km/h):

3.6 seconds.

For safe driving, it is essential, particularly during

the first days of use, to get to know the car by

driving carefully and gradually discovering its

performance.

Brakes

The car braking system may be available with four

carbon ceramic material brake discs, one on

each wheel.

In order to guarantee the maximum braking

capacity for the first use, Alfa Romeo performs a

"run-in" procedure for discs and pads directly at

the factory.

The use of carbon ceramic material brake discs

guarantees braking features (better

deceleration/pedal load ratio, braking distances,

fading resistance) proportional to the dynamic

features of the car in addition to considerably

decreasing the unsprung component weight.

The materials used and the structural features of

the system could generate unusual noises which

have absolutely no adverse effect on correct

operation and reliability of the braking system. Greater pressure may need to be applied to the

brake pedal the first time to keep the same

braking capacities in presence of condensation

or salt on the braking surfaces, for example after

washing or if the car is not used for a long time.

NOTE:

Given the high technological level of this system,

any servicing on it must be performed by an

authorized dealer which exclusively has the skills

needed for the repair and maintenance opera

-

tions.

In case of intensive, high-performance use of the

car, have the efficiency of the carbon ceramic

material braking system inspected as shown on

the Maintenance Plan at an authorized dealer.

Driving On Race Tracks

Before driving on a track using a racing style, it is

necessary to:

Attend a race track driving course.

Check the liquid levels in the engine

compartment

Ú

page 191.

Have the car inspected at an authorized

dealer.

Remember that the car was not designed to be

driven exclusively on the race track and that this

use increases stress and component wear.

NOTE:

Quadrifoglio front brakes are equipped with

Non-Asbestos Organic (NAO) type pads. These

pads are NOT suitable for high thermal loads (for

example track use). If you plan to use vehicle on

a track it is recommended to use the optional

CCM Brakes (Carbon Ceramic Brake disc).

22_GU_OM_EN_USC_t.book Page 133

Page 138 of 256

136

(Continued)

DYNAMIC STEERING TORQUE (DST)

S

YSTEM

DST uses the integration of the Electronic

Stability Control (ESC) system with the electric

power steering to increase the safety level of the

whole vehicle.

In critical situations (e.g. braking on surfaces with

different grip conditions), the ESC system

influences the steering through the DST function

to implement an additional torque contribution

on the steering wheel in order to suggest the

most correct maneuver to the driver.

The coordinated action of the brakes and

steering increases the safety and control of the

vehicle.

NOTE:

The DST feature is only meant to help the driver

realize the correct course of action through small

torques on the steering wheel, which means the

effectiveness of the DST feature is highly depen -

dent on the driver’s sensitivity and overall reac -

tion to the applied torque. It is very important to

realize that this feature will not steer the vehicle,

meaning the driver is still responsible for steering

the vehicle.

DRIVE TRAIN CONTROL (DTC) SYSTEM

Some models of this vehicle are equipped with an

All-Wheel Drive (AWD) system, which offers an

optimal drive for countless driving conditions and

road surfaces. The system reduces tire slipping to

a minimum, automatically redistributing the

torque to the front and rear wheels as needed. To maximize fuel savings, the vehicle with AWD

automatically passes to Rear-Wheel Drive (RWD)

when the road and environmental conditions are

such that they wouldn't cause the tires to slip.

When the road and environmental conditions

require better traction, the vehicle automatically

switches to AWD mode.

NOTE:

There may be a brief delay in shifting to AWD

mode after a tire slipping event occurs.

If the system failure symbol switches on, after

starting the engine or while driving, it means

that the AWD system is not working properly. If

the warning message activates frequently, it is

recommended to carry out the maintenance

operations.

ELECTRONIC STABILITY CONTROL (ESC)

S

YSTEM

The ESC system improves the directional control

and stability of the vehicle in various driving

conditions.

The ESC system corrects the vehicle’s understeer

and oversteer, distributing the brake force on the

appropriate wheels. The torque supplied by the

engine can also be reduced in order to maintain

control of the vehicle.

The ESC system uses sensors installed on the

vehicle to determine the path that the driver

intends to follow and compares it with the

vehicle’s effective path. When the real path

deviates from the desired path, the ESC system

intervenes to counter the vehicle’s oversteer or

understeer.

Oversteer occurs when the vehicle is turning

more than it should according to the angle of

the steering wheel.

Understeer occurs when the vehicle is turning

less than it should according to the angle of

the steering wheel.

System Intervention

The intervention of the system is indicated by the

flashing of the ESC Warning Light on the

instrument panel, to inform the driver that the

vehicle stability and grip are critical.

WARNING!

Electronic Stability Control (ESC) cannot

prevent the natural laws of physics from

acting on the vehicle, nor can it increase the

traction afforded by prevailing road

conditions. ESC cannot prevent accidents,

including those resulting from excessive

speed in turns, driving on very slippery

surfaces, or hydroplaning. ESC also cannot

prevent accidents resulting from loss of

vehicle control due to inappropriate driver

input for the conditions. Only a safe,

attentive, and skillful driver can prevent

accidents. The capabilities of an ESC

equipped vehicle must never be exploited in

a reckless or dangerous manner which could

jeopardize the user’s safety or the safety of

others.

22_GU_OM_EN_USC_t.book Page 136

SAFETY

Page 140 of 256

SAFETY

138

NOTE:

If the vehicle’s speed exceeds 6 mph (10 km/h),

but remains below 37 mph (60 km/h) and the

accelerator pedal is released, as soon as the

vehicle gets close to the set speed the HDC

system will automatically brake to keep the

vehicle at the set speed.

The driver can cancel HDC system intervention at

any time by pressing the accelerator pedal.

System Deactivation

The HDC system will be deactivated, but remain

available, if any of the following conditions are

met:

The vehicle is traveling on a downhill slope

with a gradient less than 8%, on a level

surface, or on an uphill grade.

PARK (P) mode is engaged.

Disabling The System

The system is disabled if any of the following

conditions are met:

The HDC switch is pressed.

Cruise Control/Adaptive Cruise Control is

activated.

A vehicle speed of 37 mph (60 km/h) is

exceeded.

System deactivation is shown by the icon on

the display turning off.

HILL START ASSIST (HSA) SYSTEM

HSA is an integral part of the Electronic Stability

Control (ESC) system that facilitates starting on

slopes, activating automatically in the following

cases:

Uphill: the vehicle is stationary on a road with

a gradient higher than 5%, the engine is

running, the brake is pressed, and the

transmission is in NEUTRAL (N) or a gear other

than REVERSE (R) is engaged.

Downhill: the vehicle is stationary on a road

with a gradient higher than 5%, the engine is

running, the brake is pressed, and the

transmission is in REVERSE.

When starting to move forward from a complete

stop, the ESC system control unit maintains the

braking pressure on the wheels until the engine

torque necessary for starting is reached, or in any

case for a maximum of two seconds, allowing

your right foot to be moved easily from the brake

pedal to the accelerator.

The system will automatically deactivate after

two seconds without starting, gradually releasing

the braking pressure. During this release stage, it

is possible to hear a typical mechanical brake

release noise, indicating the imminent

movement of the vehicle.

PANIC BRAKE ASSIST (PBA) SYSTEM

The PBA system is designed to improve the

vehicle’s braking capacity during emergency

braking.

The system detects emergency braking by

monitoring the speed and force with which the

brake pedal is pressed, and consequently applies

the optimal brake pressure. This can reduce the

braking distance; the PBA system therefore

complements the ABS.

Maximum assistance from the PBA system is

obtained by pressing the brake pedal very

quickly. In addition, the brake pedal should be

pressed continuously during braking, avoiding

intermittent presses, to get the most out of the

system. Do not reduce pressure on the brake

pedal until braking is no longer necessary.

WARNING!

HDC is only intended to assist the driver in

controlling vehicle speed when descending

hills. The driver must remain attentive to the

driving conditions and is responsible for main -

taining a safe vehicle speed.

WARNING!

There may be situations where the Hill Start

Assist (HSA) will not activate and slight rolling

may occur, such as on minor hills or with a

loaded vehicle, or while pulling a trailer. HSA is

not a substitute for active driving involvement.

It is always the driver’s responsibility to be

attentive to distance to other vehicles, people,

and objects, and most importantly brake oper -

ation to ensure safe operation of the vehicle

under all road conditions. Your complete

attention is always required while driving to

maintain safe control of your vehicle. Failure to

follow these warnings can result in a collision

or serious personal injury.

22_GU_OM_EN_USC_t.book Page 138