ARIEL ATOM 2 2006 Workshop Manual

Manufacturer: ARIEL, Model Year: 2006, Model line: ATOM 2, Model: ARIEL ATOM 2 2006Pages: 79, PDF Size: 2.5 MB

Page 51 of 79

45

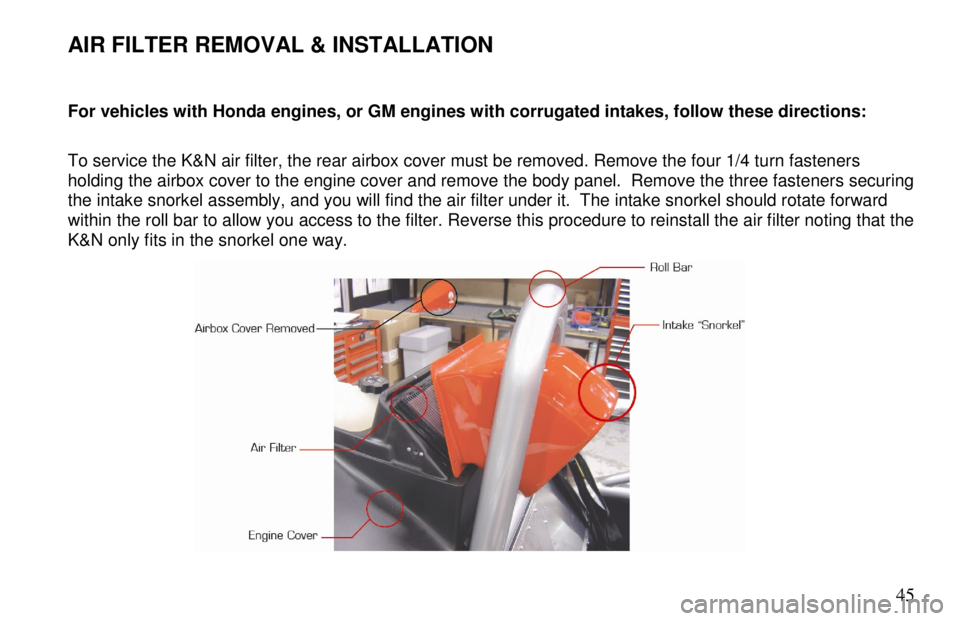

AIR FILTER REMOVAL & INSTALLATION

For vehicles with Honda engines, or GM engines with corrugated intakes, follow these directions:

To service the K&N air filter, the rear airbox cover m ust be removed. Remove the four 1/4 turn fasteners

holding the airbox cover to the engine cover and remo ve the body panel. Remove the three fasteners securing

the intake snorkel assembly, and you will find the air filter under it. The intake snorkel should rotate forward

within the roll bar to allow you access to the filter. Reverse this procedure to reinstall the air filter noti ng that the

K&N only fits in the snorkel one way.

Page 52 of 79

46

AIR FILTER REMOVAL & INSTALLATION (PLASTIC INTAKE)

If your car is equipped with a GM engine that was purch ased after November 2006, it may have a plastic intake

and require one additional step for removal.

Follow the previous instructions, and then remove the a ir filter retaining clip after the snorkel is removed. This

step will not require any tools.

NOTE: The Filtercharger® element must be cleaned and serviced with K&N cleaner and air filter oil per the

prescribed routine maintenance procedures as outlined in the product literature that accompanies the

Filtercharger®. For additional information, refer t o the K&N “Helpful Hints” document in your Owner’s Packet .

Page 53 of 79

47

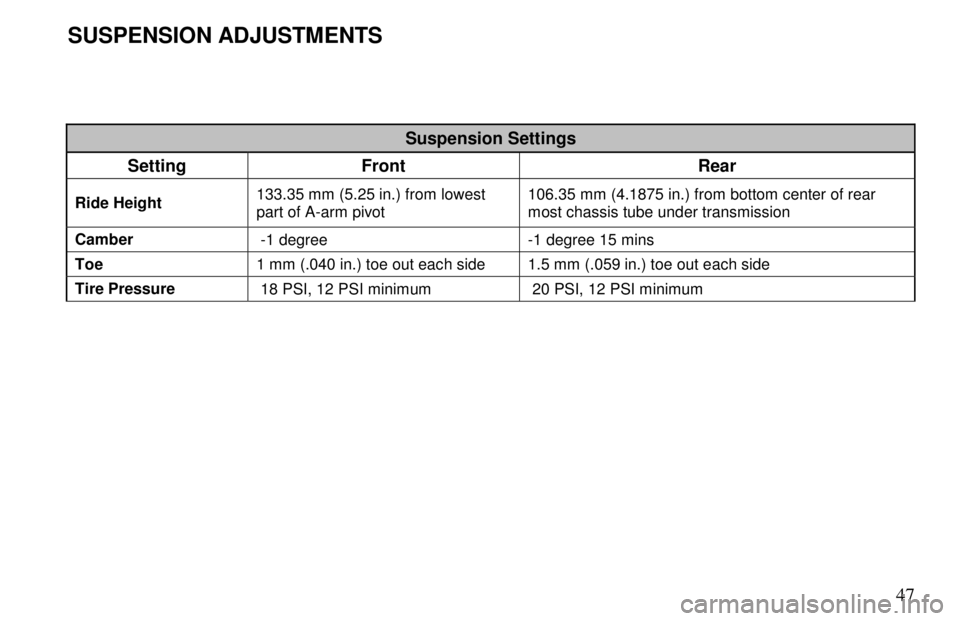

SUSPENSION ADJUSTMENTS

Suspension Settings

Setting Front Rear

Ride Height 133.35 mm (5.25 in.) from lowest

part of A-arm pivot 106.35 mm (4.1875 in.) from bottom center of rear

most chassis tube under transmission Camber

-1 degree -1 degree 15 mins Toe 1 mm (.040 in.) toe out each side 1.5 mm (.059 in.) toe out each side Tire Pressure

18 PSI, 12 PSI minimum 20 PSI, 12 PSI minimum

Page 54 of 79

48

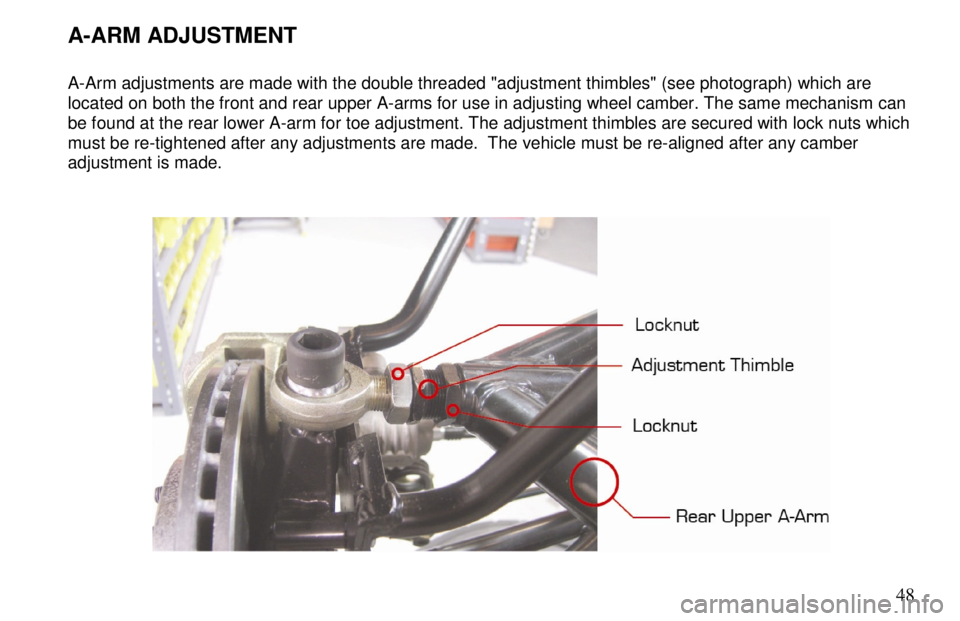

A-ARM ADJUSTMENT

A-Arm adjustments are made with the double threaded "adjustment thimbles" (see photograph) which are

located on both the front and rear upper A-arms for u se in adjusting wheel camber. The same mechanism can

be found at the rear lower A-arm for toe adjustment . The adjustment thimbles are secured with lock nuts whi ch

must be re-tightened after any adjustments are made. The vehicle must be re-aligned after any camber

adjustment is made.

Page 55 of 79

49

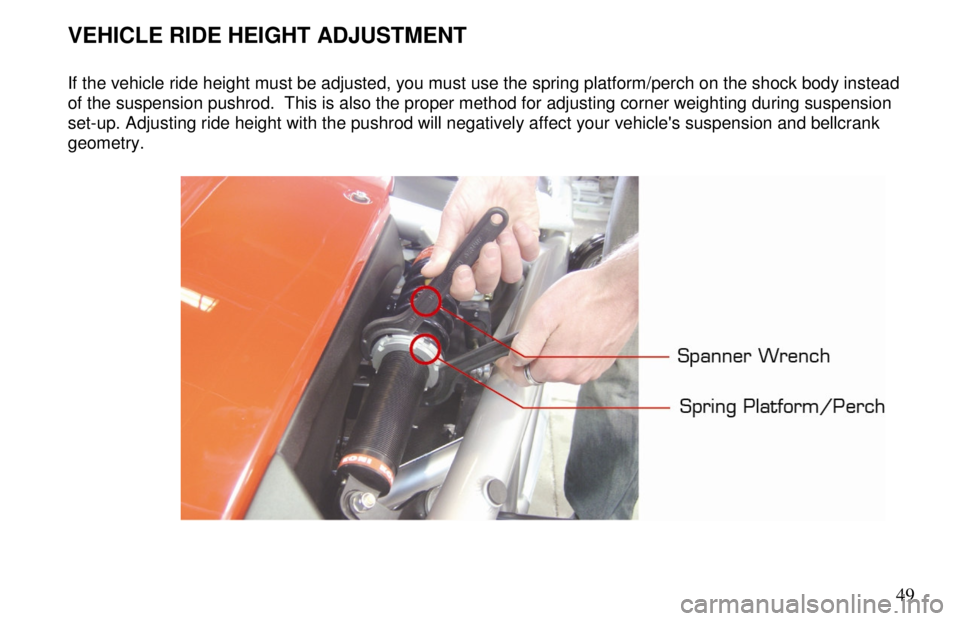

VEHICLE RIDE HEIGHT ADJUSTMENT

If the vehicle ride height must be adjusted, you must use the spring platform/perch on the shock body instead

of the suspension pushrod. This is also the proper method for adjusting corner weighting during suspension

set-up. Adjusting ride height with the pushrod will ne gatively affect your vehicle's suspension and bellcrank

geometry.

Page 56 of 79

50

DAMPER ADJUSTMENT

Your Ariel Atom comes with one of three damper options: (1) Rebound Adjustable, (2) Compression/Rebound

Adjustable, or (3) Compression/Rebound Dial Adjustable. Your vehicle will arrive to you with dampers set and

vehicle corner weighted from the factory. Adjusting t he suspension will require you to re-corner weight the

vehicle and should only be done for fine-tuning or pe rsonal driving preferences.

Page 57 of 79

51

SEAT ADJUSTMENTS

Your Atom comes with one of the following seating options:

Individual Seats

Individual seats are adjusted by a lever under the seat which allows the seat to move to the desired location.

Bench Seats

The bench seat is bolted to the frame with four bolts. There are four different seat locations. To remove the

bench seat, you will need a ratchet with either a 9/16 in. socket or a 5/16 in. Allen socket. Be sure the flat

washer is in place on the bolts before tightening so yo u do not damage the bench seat.

Page 58 of 79

52

TOW POINTS

The tow hooks are designed for track use only. If your car came equipped with tow hooks, they are the

recommended points to tow the vehicle. They should not be used as tie-down points, or to lift the vehicle.

Page 59 of 79

53

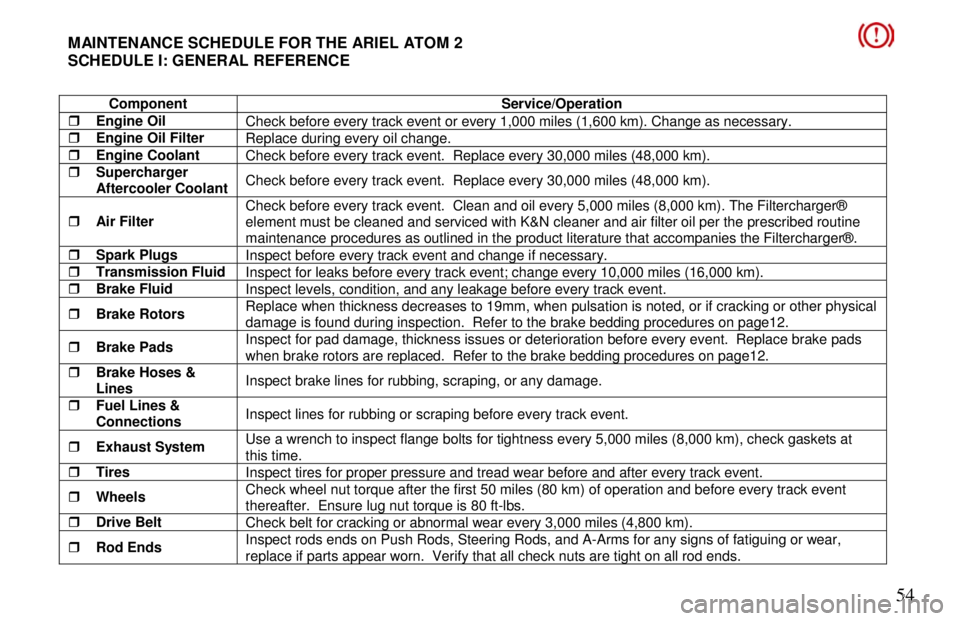

MAINTENANCE SCHEDULES

The following schedules describe the maintenance require d for your Atom. Your vehicle is dependent on these

services to retain its safety and dependability. Refer to the Fluid Level/Fluid Type sections on pages 35-36

and the Replacement Part sections on pages 59-62 for qu antities and product types. Refer to the specific

component sections for locations, descriptions and/or accessing instructions.

Schedule I: General Reference

Refer to this schedule as an overall guide for perfor ming specific operations at specific mileage intervals.

Schedule II: Before Every Track Event

Follow the steps in this schedule before every track even t. Follow this schedule in conjunction with the other

schedules.

Schedule III: Initial 50 Miles (80 km)

Follow the steps in this schedule immediately following the initial 50 miles (80 km) of driving your vehicle.

Schedule IV: Initial 300 Miles (480 km)

Follow the steps in this schedule immediately following the initial 300 miles (480 km) of driving your vehicle.

Schedule V: Every 1,000 Miles (1,600 km)

Refer to this schedule at every 1,000 mile (1,600 km) interval of driving your vehicle.

Follow this schedule in

conjunction with schedules I & II.

Page 60 of 79

54

MAINTENANCE SCHEDULE FOR THE ARIEL ATOM 2

SCHEDULE I: GENERAL REFERENCE

Component Service/Operation

� Engine Oil

Check before every track event or every 1,000 miles (1,600 km). Change as necessary. � Engine Oil Filter

Replace during every oil change. � Engine Coolant

Check before every track event. Replace every 30,0 00 miles (48,000 km). � Supercharger

Aftercooler Coolant Check before every track event. Replace every 30,0

00 miles (48,000 km). � Air Filter Check before every track event. Clean and oil ever

y 5,000 miles (8,000 km). The Filtercharger®

element must be cleaned and serviced with K&N clean er and air filter oil per the prescribed routine

maintenance procedures as outlined in the product l iterature that accompanies the Filtercharger®. � Spark Plugs

Inspect before every track event and change if nece ssary. � Transmission Fluid

Inspect for leaks before every track event; change every 10,000 miles (16,000 km). � Brake Fluid

Inspect levels, condition, and any leakage before e very track event. � Brake Rotors Replace when thickness decreases to 19mm, when puls

ation is noted, or if cracking or other physical

damage is found during inspection. Refer to the br ake bedding procedures on page12. � Brake Pads Inspect for pad damage, thickness issues or deterio

ration before every event. Replace brake pads

when brake rotors are replaced. Refer to the brake bedding procedures on page12. � Brake Hoses &

Lines Inspect brake lines for rubbing, scraping, or any d

amage. � Fuel Lines &

Connections Inspect lines for rubbing or scraping before every

track event. � Exhaust System Use a wrench to inspect flange bolts for tightness

every 5,000 miles (8,000 km), check gaskets at

this time. � Tires

Inspect tires for proper pressure and tread wear be fore and after every track event. � Wheels Check wheel nut torque after the first 50 miles (80

km) of operation and before every track event

thereafter. Ensure lug nut torque is 80 ft-lbs. � Drive Belt

Check belt for cracking or abnormal wear every 3,00 0 miles (4,800 km). � Rod Ends Inspect rods ends on Push Rods, Steering Rods, and

A-Arms for any signs of fatiguing or wear,

replace if parts appear worn. Verify that all chec k nuts are tight on all rod ends.