wiring ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 223 of 421

D=27

Electrics

Seat Belt Pretensioner

050C Pretensioner Squib High Resistance 050D Pretensioner squib low resistance

050C will be logged if the resistance of the

pretensioner squib circuit rises above 4.5 ±0.5C2

050D will be logged if the resistance of the

pretensioner squib circuit falls below 1.4 ±0.4Q

Procedure

Read the warnings given at the start of this

pretensioner diagnostics section.

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 050C code is logged and note if the fault is

shown as internnittent. Note any other codes in the

DTC log and then clear ail codes.

Switch off the ignition and wait at least 10 minutes

for the pretensioner squib firing capacitors to fully

discharge before continuing with this procedure.

Disconnect the pretensioner squib connector at the

rearward harness. Disconnect the pretensioner

control module and temporarily cheat the squib

shorting link.

3.

Procedure

Read the warnings given at the start of this

pretensioner diagnostics section.

Connect the PDU to the lower diagnostic socket

and accessthe pretensioner control module. Verify

that an 050D code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes.

Switch off the ignition and wait at least 10 minutes

for the pretensioner squib firing capacitors to fully

discharge before continuing with this procedure.

Disconnect the pretensioner squib connector atthe

rearward harness. Disconnect the pretensioner

control module and temporarily cheat the squib

shorting link.

Note: The control module harness connector has a

shorting link which

short

circuits the squib

lines together

when the connector is displaced. Carefully insert a

suitable non-metallic

cheater to

remove

the short

circuit

between pins 11 and 12 before continuing with fault

diagnosis.

.j^ 'o o ob bo oooooooo

O O O

iV ^3 ^3 ^3 ^3 ^3 ^

lU Insert cheater here

Check the continuity of the squib feed and return

lines.

If any significant resistance is measured,

service the wiring as necessary.

Also check the condition of the connector pins for

damage or lack of tension and service

as

necessary.

If the circuit resistance is acceptable and the

connector pins are good, go to step 6.

If any defects are identified and serviced, go to step

7.

If the checks in step 4 are good, the high circuit

resistance must be in the pretensioner squib or in

thecontrol module. Replace the pretensioner squib

and reconnect all components.

Clearall logged DTCs from the pretensioner control

module and then test the vehicle.

If the 050C code is logged again, replace the

control module.

Note: The control module harness connector has a

shorting link which

short

circuits the squib

lines together

when the connector is displaced. Carefully insert a

suitable non-metallic

cheater to remove the

short circuit

between pins 11 and 12 before continuing with fault

diagnosis.

Insert cheater here

Check the continuity from the squib feed line to the

squib return line. With the shorting link cheated,

the resistance should be more than lOkQ. If the

resistance is less than 10kQ, service the wiring as

necessary.

Also check the connector pins for any damage

which could cause an unintentional short circuit.

If the checks in step 5 are good, the low circuit

resistance must be in the pretensioner squib or in

thecontrol module. Replace the pretensioner squib

and reconnect all components.

Clearall logged DTCs from the pretensioner control

module and then test the vehicle.

If the 050D code is logged again, replace the

control module.

September 1996 6-107

Page 225 of 421

Electrics

Seat Belt Pretensioner

Check the continuity of

the

line from pretensioner

control module pin 2 to instrument pack green

connector pin 2.

If continuity is approximately

OQ,

go to step 5.

If the line resistance

is

significantly greater

than

OQ,

service the wiring as necessary. Reconnect all

components and test the vehicle to ensure that the

problem is resolved.

Ifthe lamp

and

wiring

checks are

good,

the

fault lies

in the instrument pack or in the control module.

Replace the control module and retest. Ifthe fault

persists, replace the instrument

pack.

Reconnectall

components and test the vehicle to ensure that the

problem is resolved.

Pretensioner Control Module Internal

Faults

The following codes indicate internal faults within the

pretensioner control module.

0209 Safing sensor error

030A Temperature sensor error

0D13 Capacitor voltage error

0D14 Capacitor capacitance

0D09 Energy reserve switch

0D1E Energy shutdown switch

050E Seatbelt pretensioner switch error

0109 Accelerometer function

01OA Acceleration out of range

01 OB

Acceierometer offset

OAOC Analogue voltage error

090A EEPROM not programmed

0909 EEPROM checksum

090C RAM check error

060E Warning lamp driver error

0A09 Communications error

OAOA External watchdog error

OAOB External watchdog time out

020A Safing sensor not closed

If any of the above codes are logged, replace the

pretensioner control module.

September 1996 6-109

Page 396 of 421

^^2?

The Aston Martin Lagonda Diagnostic System

Users Guide

Airbag System Diagnostics

WARNING: Whilst it

is

completely safe to

access

and read the airbag diagnostic module memory at

the diagnostic socket, significant personal risks

exist in the performance of any other

tasks

on the

airbag system or components. Therefore all

workshop manual warnings must be read and all

safety procedures must be followed before, during

and on completion of any other practical work on

the airbag system.

System Description

The airbag system installation comprises:

Airbag Diagnostic Module

Driver and passenger airbag modules

Two front impact (crash) sensors

One 'safing' sensor

Dedicated wiring harness

SRS indicator/warning lamp

The system is designed to provide protection for both

driver and front seat passenger by automatically

deploying airbags in the event of a collision during

forward travel.

Intheeventof

a

collision, the crash and safing sensors

will operate, completing the firing circuit and causing

the airbags to inflate within 32 milliseconds. At least

one crash sensor and the safing sensor must operate to

fire the airbags.

Any faults in system components, installation or wiring

will be indicated by a flashing code on the SRS/

AIRBAG warning lamp. Fault code information may

also be monitored using the PDU or scan

tool.

A full description of the airbag system components is

included in the workshop manual.

Airbag Diagnostics

The Airbag Control Module indicates a fault by

transmitting a pulsed signal down the Airbag System

Failure line to flash the SRS/AIRBAC warning lamp.

The fault code is repeated continuously. If there are

two or more faults, the fault code with the highest

priority is transmitted first. The second fault code is

only transmitted when the first fault has been rectified.

TheSRS/AIRBAC warning lamp is also used to indicate

any problem in the seat belt pretensioner system (if

fitted). Flashing of the lamp indicates an airbag fault,

constant illumination of the lamp indicates a seat belt

pretensioner fault.

At the top left of the PDU screen there is a bullet mark

which indicates the current state of the Airbag System

Failure line. As a code is transmitted the bullet mark

can be seen to flash.The PDU reads the fault code, and

writes the code number and fault description to the

screen.

The PDU continues to monitor the transmitted

code.

If the transmitted code changes, the new code

number and description will appear below the first.

PMC Airbag

32 Drivers airbag circuit

shorted or open

o

when remedial action has been taken to correct a

fault, press the Clear Button to clear down the PDU

display. Then use the PDU to ensure that no faults are

reported.

A series of audible beeps, continuously transmitted by

the Airbag Diagnostic Module, indicates that there is

an Airbag System fault to report and that the Airbag

System Failure line

is

open circuit. The PDU is notable

to monitor the fault line in this situation as there is no

pull-up resistor, normally provided by a warning lamp

in the instrument pack.

Rapid continuous flashing of the Instrument Pack

Airbag Failure Lamp indicates that both front impact

sensors are disconnected. No fault code is reported on

the PDU, however on close inspection the bullet mark

can be seen to flicker.

September 1996 9-45

Page 402 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

Operation

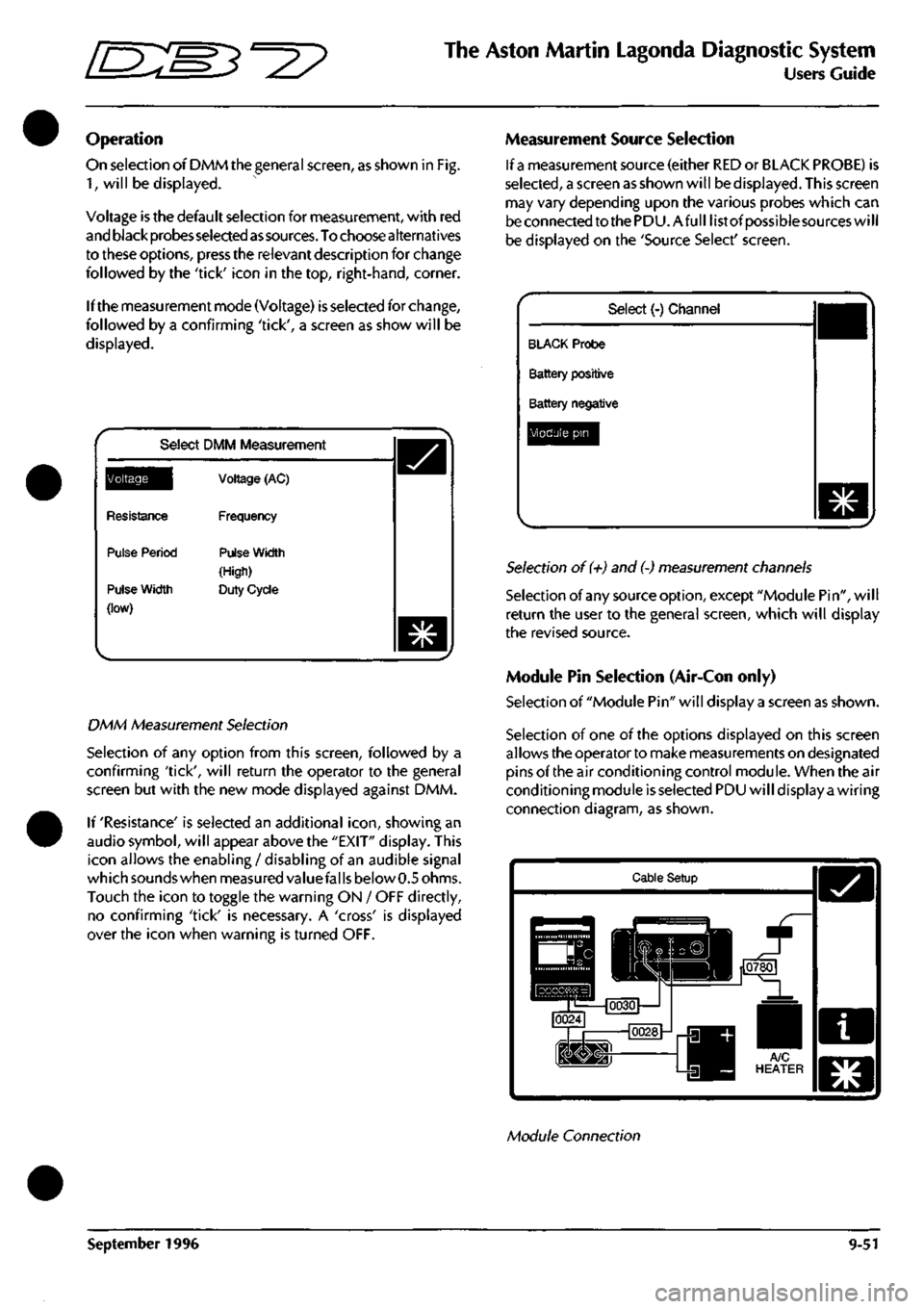

On selection of DMM the general screen, as shown in Fig.

1,

will be displayed.

Voltage is the default selection for measurement, with red

and black probes selected

as

sources.

To choose alternatives

to these options, press the relevant description for change

followed by the 'tick' icon in the top, right-hand, corner.

If the measurement mode (Voltage) is selected for change,

followed by a confirming 'tick', a screen as show will be

displayed.

Select DMM Measurement

^Q^||[

Resistance

Pulse Period

Pulse Width

(low)

Voltage (AC)

Frequency

Pulse Width

(High)

Duty Cycle

DMM Measurement Selection

Selection of any option from this screen, followed by a

confirming 'tick', will return the operator to the general

screen but with the new mode displayed against DMM.

If 'Resistance' is selected an additional

icon,

showing an

audio symbol, will appear above the "EXIT" display. This

icon allows the enabling / disabling of an audible signal

which sounds when measured valuefal

Is

below 0.5 ohms.

Touch the icon to toggle the warning ON / OFF directly,

no confirming 'tick' is necessary. A 'cross' is displayed

over the icon when warning is turned OFF.

Measurement Source Selection

If

a

measurement source (either RED or BLACK PROBE) is

selected,

a screen as shown will be displayed. This screen

may vary depending upon the various probes which can

be connected to the PDU.Afull list of possiblesources will

be displayed on the 'Source Select' screen.

Select (-) Channel

BLACK Probe

Battery positive

Battery negative

Module pin

Selection of (+) and (-) measurement channels

Selection of any source option, except "Module Pin", will

return the user to the general screen, which will display

the revised source.

Module Pin Selection (Air-Con only)

Selection of "Module Pin" will display a screen as shown.

Selection of one of the options displayed on this screen

allows the operator to make measurements on designated

pins of the air conditioning control module. When the air

conditioning module is selected PDU will display a wiring

connection diagram, as shown.

Cable Setup

Module Connection

September 1996 9-51

Page 403 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide [S:S3^2?

The PDU will then check the cable connections. Until all

connections are correct, the PDU will not allow progression

beyond this

screen.

Pressingthe'asterisk'icon and selecting

abort returns the operator to the general screen if an

incorrect system has been chosen.

If selection and wiring are correct a numeric keypad will

be displayed. The operator can nowenterapin numberto

be tested, using this keypad.

Pin

Numeric Keypad

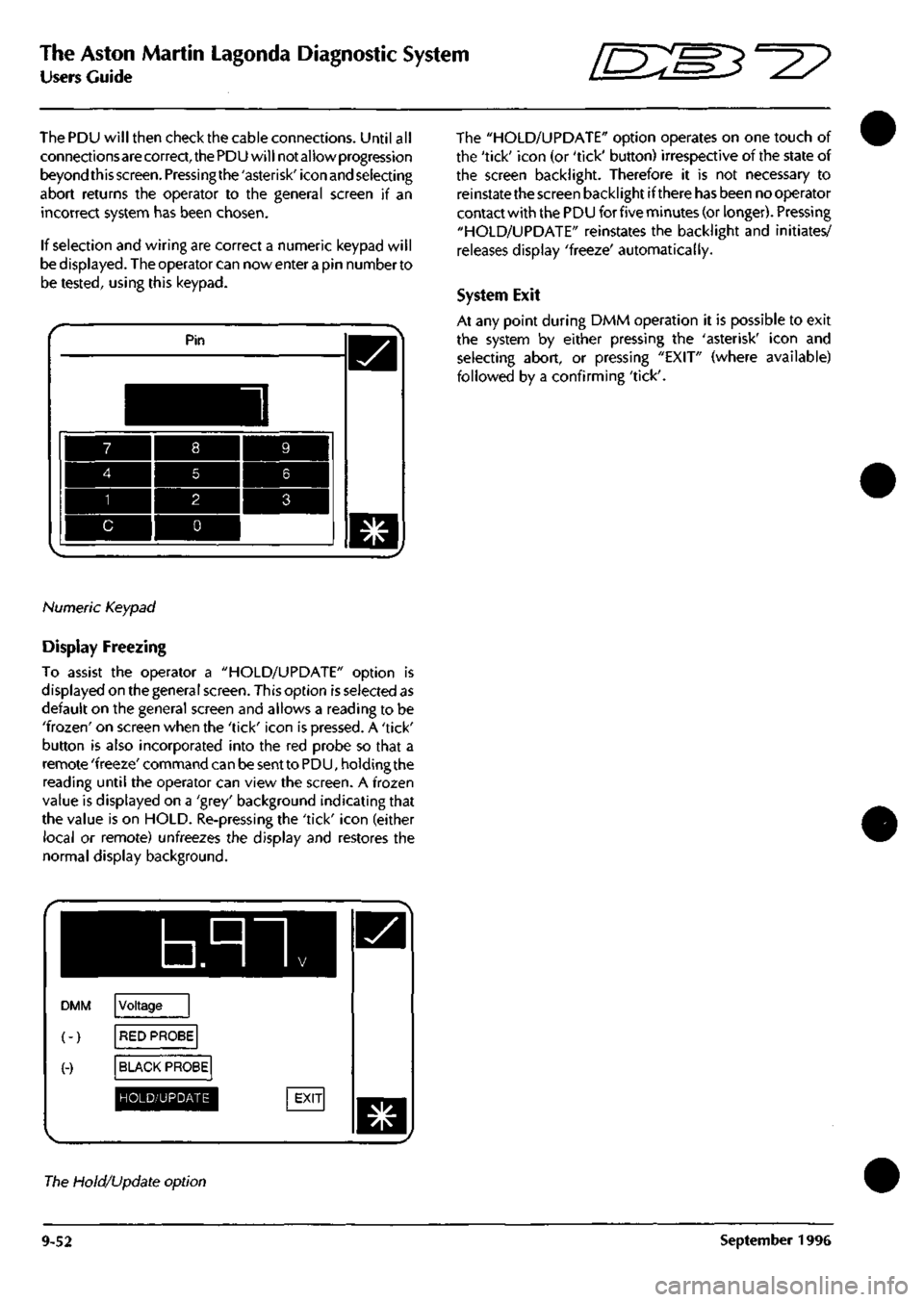

Display Freezing

To assist the operator a "HOLD/UPDATE" option is

displayed on the general screen. This option is selected as

default on the general screen and allows a reading to be

'frozen'

on screen when the 'tick' icon is pressed. A 'tick'

button is also incorporated into the red probe so that a

remote 'freeze' command can be sent to PDU, holding the

reading until the operator can view the screen. A frozen

value is displayed on a 'grey' background indicating that

the value is on HOLD. Re-pressing the 'tick' icon (either

local or remote) unfreezes the display and restores the

normal display background.

b.nn

DMM

(-)

(-)

Voltage

RED PROBE

BLACK PROBE

HOLD/UPDATE

The "HOLD/UPDATE" option operates on one touch of

the 'tick' icon (or 'tick' button) irrespective of the state of

the screen backlight. Therefore it is not necessary to

reinstate the screen backlight if there has been no operator

contact with the PDU for five minutes (or longer). Pressing

"HOLD/UPDATE" reinstates the backlight and initiates/

releases display 'freeze' automatically.

System Exit

At any point during DMM operation it is possible to exit

the system by either pressing the 'asterisk' icon and

selecting abort, or pressing "EXIT" (where available)

followed by a confirming 'tick'.

The Hold/Update option

9-52 September 1996