coolant ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 4 of 421

Introduction

/^r"^^^^^3^

'"'P ?

Safety Precautions L —^ ^^—^

Safety Precautions "

All service workshops are a source of potential danger and repair work should only be performed by technically

trained staff following the procedures in this manual. A safety conscious approach to the performance of all service

procedures must be observed at all times. Statutory requirements governing all aspects of health and safety at work

including directives for the proper use of materials and equipment must be implemented.

The following contains a list of particular safety precautions which should be observed; it is not intended to be

exhaustive.

Air Conditioning System

Do not disconnect any air conditioning refrigerant system pipes unless trained and instructed to do

so.

The refrigerant

used can cause blindness if allowed to contact your eyes.

Chemical Handling and Storage

Chemicalsusedintheservicingofmotorvehiclesincludeacids,adhesives, antifreeze, brake fluids, coolants, grease,

oil,

paint, resin and solvents. Exposure to certain chemicals through direct contact or inhalation can be

fatal.

Potential hazards may also be present through the incorrect use, storage and handling of chemicals causing a fire

risk. The following precautions should be observed.

1.

Strictly adhere to handling and safety information found on containers and labels.

2.

Do not store chemicals in unlabelled or incorrectly labelled containers.

3. Containers used for storing chemicals should not be left

open;

there is a risk of

spilling,

or evaporation of fumes

which may be inflammable or toxic.

4.

Do not mix chemicals unless instructed to do so following manufacturers guidelines.

5. Do not inhale chemical materials to determine identity, they may be toxic.

6. Do not use petrol, kerosene, diesel

fuel,

gas oil, thinners or solvents for washing

skin.

7. Containers whose capacity is over 25 litres (5 gallons) require a bund wall in order to contain spillages.

8. Chemicals based on solvents such as paint should not be sprayed in a confined space; work areas used for

such operations should be well ventilated and fume extraction equipment should be utilised.

9. Ensure that adequate ventilation is provided when volatile de-greasing agents are being used.

WARNING: Fume extraction equipment must be in operation when

solvents

are

used

e.g.

trichloroethane, white

spirit, SBP3, methylene chloride, perchlorethylene.

WARNING: Do not smoke in the vicinity of volatile de-greasing agents.

10.

Avoid splashing the

skin,

eyes and clothing.

11.

Clean chemicals from the skin and clothing as soon as possible after soiling.

12.

Wear protective clothing such as goggles, non porous gloves and apron when hand

I

ing battery acid and other

corrosive and toxic substances.

iv April 1997

Page 28 of 421

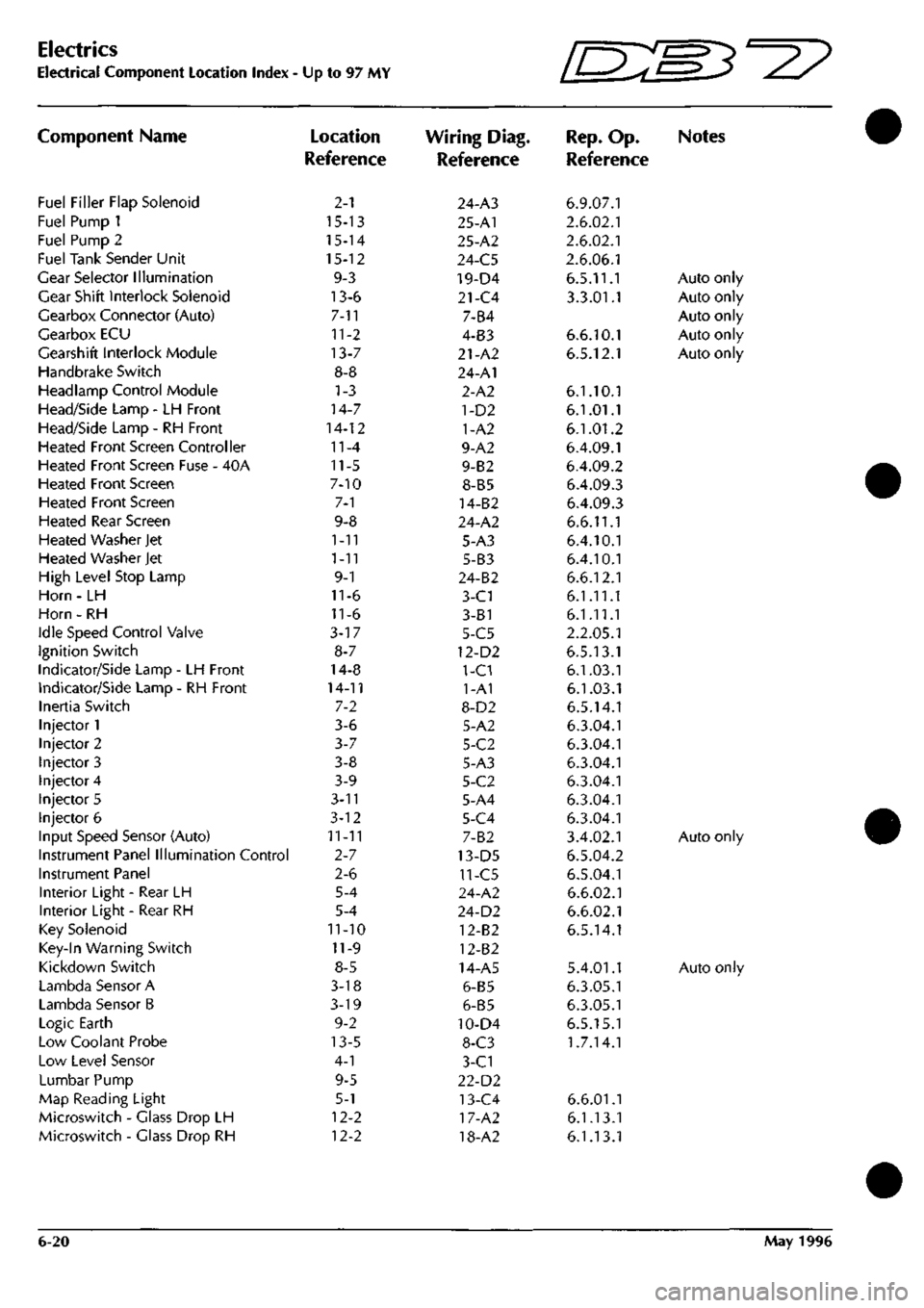

Electrics

Electrical Component Location Index •

Component Name

Fuel Filler Flap Solenoid

Fuel Pump 1

Fuel Pump 2

Fuel Tank Sender Unit

Gear Selector Illumination

Gear Shift Interlock Solenoid

Gearbox Connector (Auto)

Gearbox ECU

Gearshift Interlock Module

Handbrake Switch

Headlamp Control Module

Head/Side Lamp - LH Front

Head/Side Lamp - RH Front

Heated Front Screen Controller

Heated Front Screen Fuse - 40A

Heated Front Screen

Heated Front Screen

Heated Rear Screen

Heated Washer Jet

Heated Washer Jet

High Level Stop Lamp

Horn - LH

Horn - RH

Idle Speed Control Valve

Ignition Switch

Indicator/Side Lamp - LH Front

Indicator/Side Lamp - RH Front

Inertia Switch

Injector 1

Injector 2

Injector 3

Injector 4

Injector 5

Injector 6

Input Speed Sensor (Auto)

Instrument Panel Illumination Control

Instrument Panel

Interior Light - Rear LH

Interior Light - Rear RH

Key Solenoid

Key-In Warning Switch

Kickdown Switch

Lambda Sensor A

Lambda Sensor B

Logic Earth

Low Coolant Probe

Low Level Sensor

Lumbar Pump

Map Reading Light

Microswitch - Glass Drop LH

Microswitch - Glass Drop RH

Up to 97 MY

Location

Reference

2-1

15-13

15-14

15-12

9-3

13-6

7-11

11-2

13-7

8-8

1-3

14-7

14-12

11-4

11-5

7-10

7-1

9-8

1-11

1-11

9-1

11-6

11-6

3-17

8-7

14-8

14-11

7-2

3-6

3-7

3-8

3-9

3-n

3-12

11-11

2-7

2-6

5-4

5-4

11-10

11-9

8-5

3-18

3-19

9-2

13-5

4-1

9-5

5-1

12-2

12-2

Wiring Diag.

Reference

24-A3

25-A1

25-A2

24-C5

19-D4

21-C4

7-B4

4-B3

21-A2

24-A1

2-A2

1-D2

1-A2

9-A2

9-B2

8-B5

14-B2

24-A2

5-A3

5-B3

24-B2

3-C1

3-81

5-C5

12-D2

1-C1

1-A1

8-D2

5-A2

5-C2

5-A3

5-C2

5-A4

5-C4

7-B2

13-D5

11-C5

24-A2

24-D2

12-B2

12-B2

14-A5

6-B5

6-B5

10-D4

8-C3

3-C1

22-D2

13-C4

17-A2

18-A2

Ini^'

IL-^^'^

Rep.

Op.

Reference

6.9.07.1

2.6.02.1

2.6.02.1

2.6.06.1

6.5.11.1

3.3.01.1

6.6.10.1

6.5.12.1

6.1.10.1

6.1.01.1

6.1.01.2

6.4.09.1

6.4.09.2

6.4.09.3

6.4.09.3

6.6.11.1

6.4.10.1

6.4.10.1

6.6.12.1

6.1.11.1

6.1.11.1

2.2.05.1

6.5.13.1

6.1.03.1

6.1.03.1

6.5.14.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

6.3.04.1

3.4.02.1

6.5.04.2

6.5.04.1

6.6.02.1

6.6.02.1

6.5.14.1

5.4.01.1

6.3.05.1

6.3.05.1

6.5.15.1

1.7.14.1

6.6.01.1

6.1.13.1

6.1.13.1

W3^y

Notes

Auto only

Auto only

Auto only

Auto only

Auto only

Auto only

Auto only

6-20 May 1996

Page 55 of 421

NO COLOUR

PIN

116

NV I

I?

B ?

AREA A6

Si.

H6

COLOUR

fiN

ABEX"

125

N I

B3-23 12?

BY 2 SS_

NO

COLOUR

PIN

100

B I

101

PY ?

AREA B2-20 BI-19

HO

COLOUR

117

B

119

B

120

B

AREA

A2 A2

_«

NO COLOUR

PIN

ASET

103

B I CI

105

Py ' CI

NO COLOUR

PIN

102

B 1

103

B 1

lOfl

PT 2

105

PY 2

Ali^A B2-20

Bl

BI-19

fl

EARTH POINT

COOLANT

LOW

LEVEL SENSOR

AIR

CON

RELAY

l«

SPl

19

SPL

20

HO COLOUR

PIN

135

NS 65

136

UB 86

137

KB 87

87A

138

RH 3?

AREA

C6 C6

C3-22

..»,

.

NO COLOUR

PIH

133

P 85

140

PB 86

141

P 87

87A

14?

PY 30

AREA C4-24 ce C4-24

.BLI9..

NO COLOUR

PIH

115

N 85

143

BC 86

144

WY 87

S7A 110

WR 30

AREA 02 B4 C6

C2

NO COLOUR

PIK

146

RY 85

120

8 86

147 KB

87

129

UR 87A

130 BG

30

ARCA

A6 B2 C3-22 03 03 STARTER SOLENOID RELAY FAN

RUN ON

RELAY

NO COLOUR AREA 121

WR £5_

HO COLOUR 124

NG

146

RY

126

BY

116

NY

PIN 85 86 8/ 87A

55

AREA

A2 A5 A2

A2

NO COLOUR

PIH

123

NY 85

127

UN 86

148

KB 87

87A

lie

HY 30

AREA

B2 D3

C3-22

.^2...

l/

NO COLOUR

PIN

106

B I

W-S&

2_

AREA 82-21 C6 LOW LEVEL SENSOR

NO COLOUR PIN

ARET

I 110

WR 2 «4

STARTER MOTOR SOLENOID

NO COLOUR III

B

112

e

AREA B2-2I 82-20

SCREEN WASH PUMP

NO COLOUR

PIN

lOe

B 1

109

LCB 2

3 4

AR^A B2-2I C6 NO 113 114 l|^

COLOUR N N H

AlttA A2 B3-23

M

BATTERY

POSTL

NO COLOUR

133

B

134

aw

AREA B2-2I

J

RH

SIDE n REPEATER

NO COLOUR

PIN

131

YR I

132

BK 2

AREA ce C6 J CRUISE CONTROL ^ CLUTCH SWITCH

c

D:

r

ID ID

i D)

IDczt

mm

ffl

m

m m

ID Ul

ii=ir

i m

m ID

Trff'TsrawPir

134

OW

144

WY

135

NS

136

UB

138

RN

140

PB

IJI

YR

132

BK

121

WR

145

BC

109

LCB

149

P

107

BS

1 2 3 4 5 6 7 8 9

10

II 12 13 14 15 16 17 18 19

_.29

AREA

C4 A4 A3 A3 A5 A4 C4 C4 62 B4

01

C4-24

CI

NO COLOUR

PIN

127

UN 1

128

KB 2

129

UR 3

130

Bf. 4

AREA

AS

C3-22

A5

«5

SHEET

14

AREA

B4

SHEET

6

AREA

B3

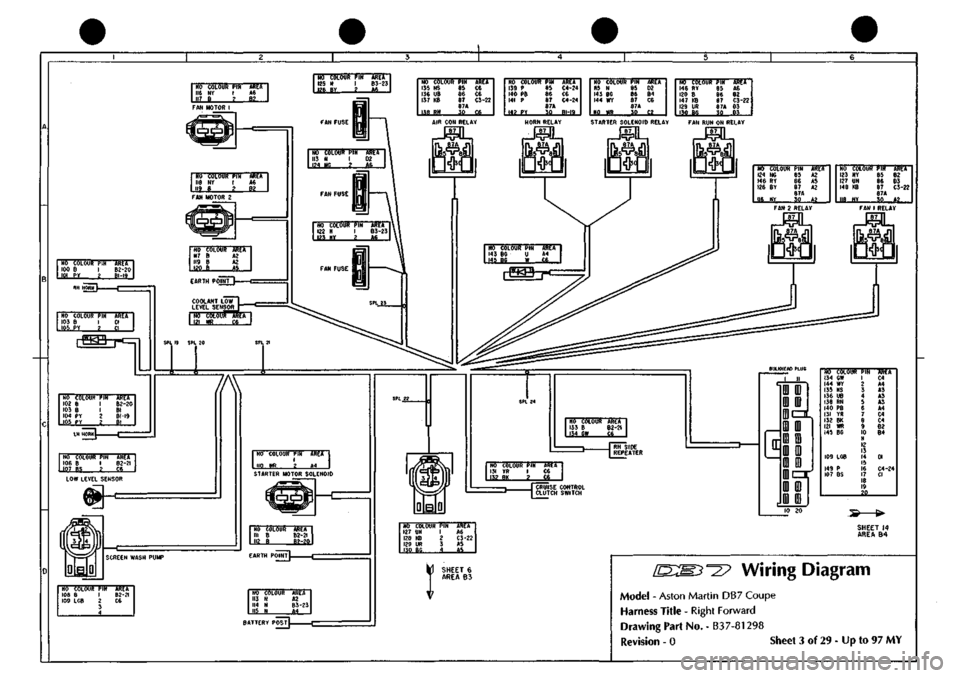

^27

Wiring Diagram

Model

-

Aston Martin DB7 Coupe

Harness

Title

-

Right Forward

Drawing

Part No.

-

B37-81298

Revision

- 0

Siieet

3 of

29

-

Up

to 97 MY

Page 108 of 421

^7

Electrics

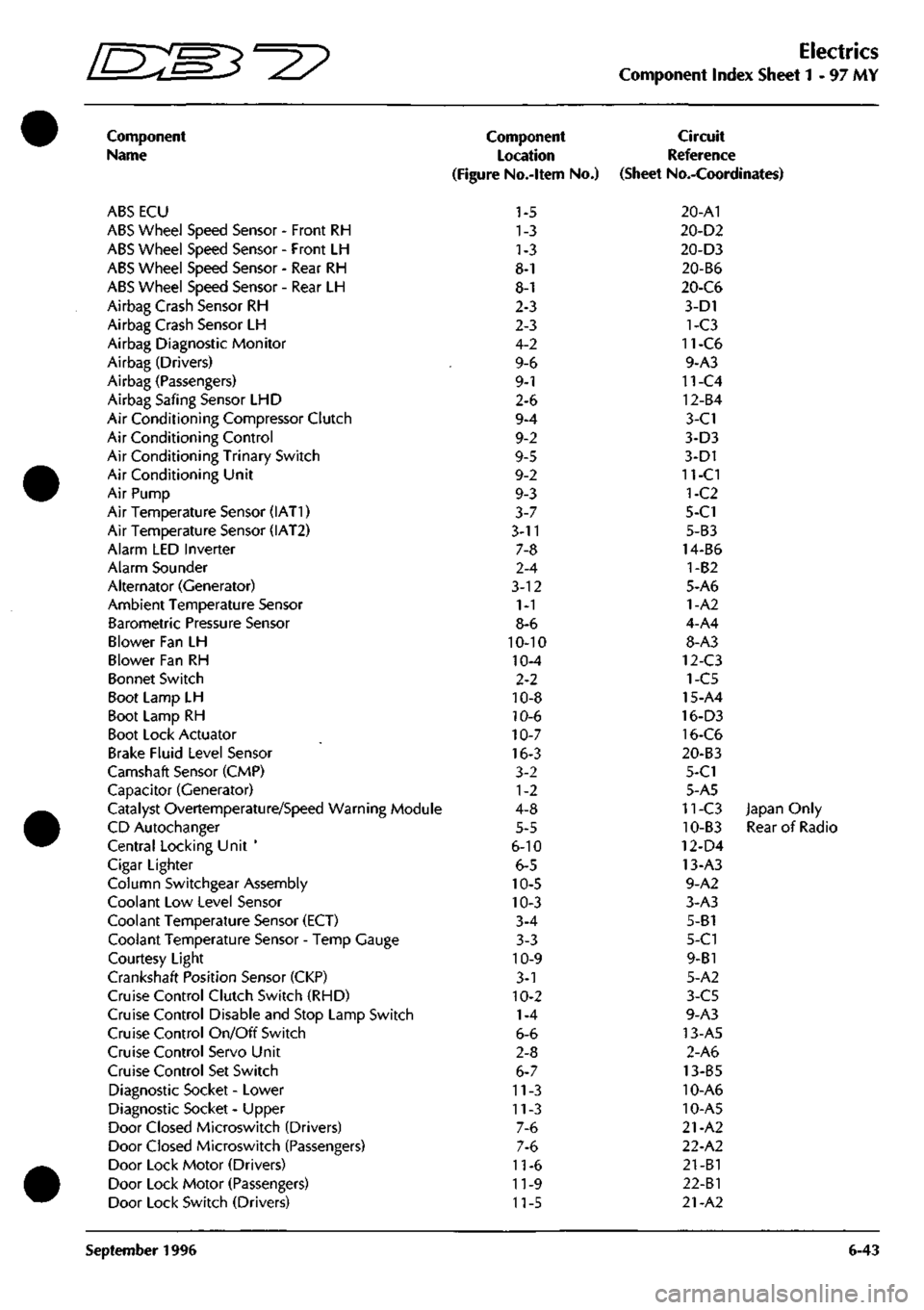

Component Index Sheet 1-97 MY

Component

Name

ABS ECU

ABS Wheel Speed Sensor - Front RH

ABS Wheel Speed Sensor - Front LH

ABS Wheel Speed Sensor - Rear RH

ABS Wheel Speed Sensor - Rear LH

Airbag Crash Sensor RH

Airbag Crash Sensor LH

Airbag Diagnostic Monitor

Airbag (Drivers)

Airbag (Passengers)

Airbag Safing Sensor LHD

Air Conditioning Compressor Clutch

Air Conditioning Control

Air Conditioning Trinary Switch

Air Conditioning Unit

Air Pump

Air Temperature Sensor (IAT1)

Air Temperature Sensor (IAT2)

Alarm LED Inverter

Alarm Sounder

Alternator (Generator)

Ambient Temperature Sensor

Barometric Pressure Sensor

Blower Fan LH

Blower Fan RH

Bonnet Switch

Boot Lamp LH

Boot Lamp RH

Boot Lock Actuator

Brake Fluid Level Sensor

Camshaft Sensor (CMP)

Capacitor (Generator)

Catalyst Overtemperature/Speed Warning Module

CD Autochanger

Central Locking Unit '

Cigar Lighter

Column Switchgear Assembly

Coolant Low Level Sensor

Coolant Temperature Sensor (ECT)

Coolant Temperature Sensor - Temp Gauge

Courtesy Light

Crankshaft Position Sensor (CKP)

Cruise Control Clutch Switch (RHD)

Cruise Control Disable and Stop Lamp Switch

Cruise Control On/Off Switch

Cruise Control Servo Unit

Cruise Control Set Switch

Diagnostic Socket - Lower

Diagnostic Socket - Upper

Door Closed Microswitch (Drivers)

Door Closed Microswitch (Passengers)

Door Lock Motor (Drivers)

Door Lock Motor (Passengers)

Door Lock Switch (Drivers)

Component

Location

(Figure No.-ltem No.)

1-5

1-3

1-3

8-1

8-1

2-3

2-3

4-2

9-6

9-1

2-6

9-4

9-2

9-5

9-2

9-3

3-7

3-11

7-8

2-4

3-12

1-1

8-6

10-10

10-4

2-2

10-8

10-6

10-7

16-3

3-2

1-2

4-8

5-5

6-10

6-5

10-5

10-3

3-4

3-3

10-9

3-1

10-2

1-4

6-6

2-8

6-7

11-3

11-3

7-6

7-6

11-6

11-9

11-5

Circuit

Reference

(Sheet No.-Coordinates)

20-A1

20-D2

20-D3

20-B6

20-C6

3-D1

1-C3

11-C6

9-A3

11-C4

12-B4

3-C1

3-D3

3-D1

11-CI

1-C2

5-C1

5-B3

14-B6

1-B2

5-A6

1-A2

4-A4

8-A3

12-C3

1-C5

15-A4

16-D3

16-C6

20-B3

5-C1

5-A5

11-C3 Japan Only

10-B3 Rear of Radio

12-D4

13-A3

9-A2

3-A3

5-B1

5-C1

9-B1

5-A2

3-C5

9-A3

13-A5

2-A6

13-B5

10-A6

10-A5

21-A2

22-A2

21-B1

22-Bl

21-A2

September 1996 6-43

Page 110 of 421

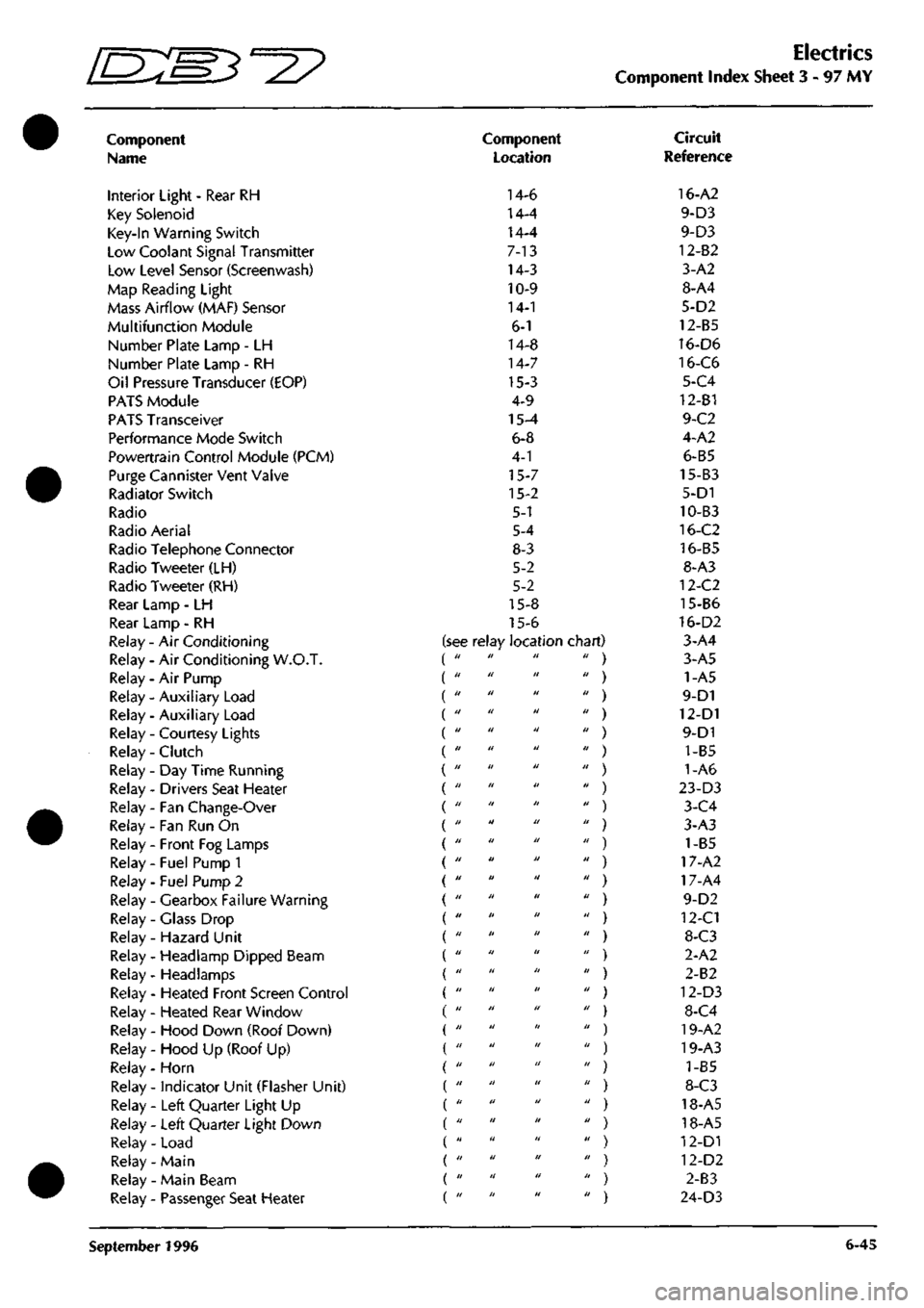

Electrics

Component Index Sheet 3 - 97

MY

Component

Name

Interior Light - Rear RH

Key Solenoid

Key-In Warning Switch

Low Coolant Signal Transmitter

Low Level Sensor (Screenwash)

Map Reading Light

Mass Airflow (MAF) Sensor

Multifunction Module

Number Plate Lamp - LH

Number Plate Lamp - RH

Oil Pressure Transducer (EOP)

PATS Module

PATS Transceiver

Performance Mode Switch

Powertrain Control Module (PCM)

Purge Cannister Vent Valve

Radiator Switch

Radio

Radio Aerial

Radio Telephone Connector

Radio Tweeter (LH)

Radio Tweeter (RH)

Rear Lamp - LH

Rear Lamp - RH

Relay - Air Conditioning

Relay - Air Conditioning W.O.T.

Relay - Air Pump

Relay - Auxiliary Load (

Relay - Auxiliary Load (

Relay - Courtesy Lights (

Relay - Clutch (

Relay-Day Time Running (

Relay - Drivers Seat Heater (

Relay - Fan Change-Over (

Relay - Fan Run On

Relay - Front Fog Lamps

Relay - Fuel Pump 1

Relay - Fuel Pump 2

Relay - Gearbox Failure Warning

Relay - Glass Drop

Relay - Hazard Unit

Relay - Headlamp Dipped Beam

Relay- Headlamps

Relay - Heated Front Screen Control

Relay - Heated Rear Window

Relay - Hood Down (Roof Down)

Relay - Hood Up (Roof Up)

Relay - Horn

Relay - indicator Unit (Flasher Unit)

Relay - Left Quarter Light Up

Relay - Left Quarter Light Down

Relay - Load

Relay- Main

Relay - Main Beam

Relay - Passenger Seat Heater

Component

Location

14-6

14-4

14-4

7-13

14-3

10-9

14-1

6-1

14-8

14-7

15-3

4-9

15-4

6-8

4-1

15-7

15-2

5-1

5-4

8-3

5-2

5-2

15-8

15-6

see relay location chart) di II II II

II II II II

II II II II

11 II II II

II II II II

II II II II

II II II II

II II II II

II II II II

11 II II II

II II II II

II II II II

II II It II

II II II II

11 II II II

II II II II

II II II II

II II II II

II II II II

II It II II

II II II II

11 II II II

II II II II

11 II II II

11 II II II

II II II II

II II II II

II II II II

II II II II

II II II II

Circuit

Reference

16-A2

9-D3

9-D3

12-82

3-A2

8-A4

5-D2

12-B5

16-D6

16-C6

5-C4

12-B1

9-C2

4-A2

6-B5

15-B3

5-D1

10-B3

16-C2

16-B5

8-A3

12-C2

15-B6

16-D2

3-A4

3-A5

1-A5

9-D1

12-D1

9-D1

1-B5

1-A6

23-D3

3-C4

3-A3

) 1-B5

) 17-A2

) 17-A4

9-D2

) 12-C1

) 8-C3

2-A2

) 2-B2

) 12-D3

) 8-C4

) 19-A2

) 19-A3

) 1-85

) 8-C3

) 18-A5

) 18-A5

) 12-D1

) 12-D2

) 2-83

) 24-D3

September 1996 6-45

Page 129 of 421

Electrics

Relay Location Index - 97 MY 5^^?

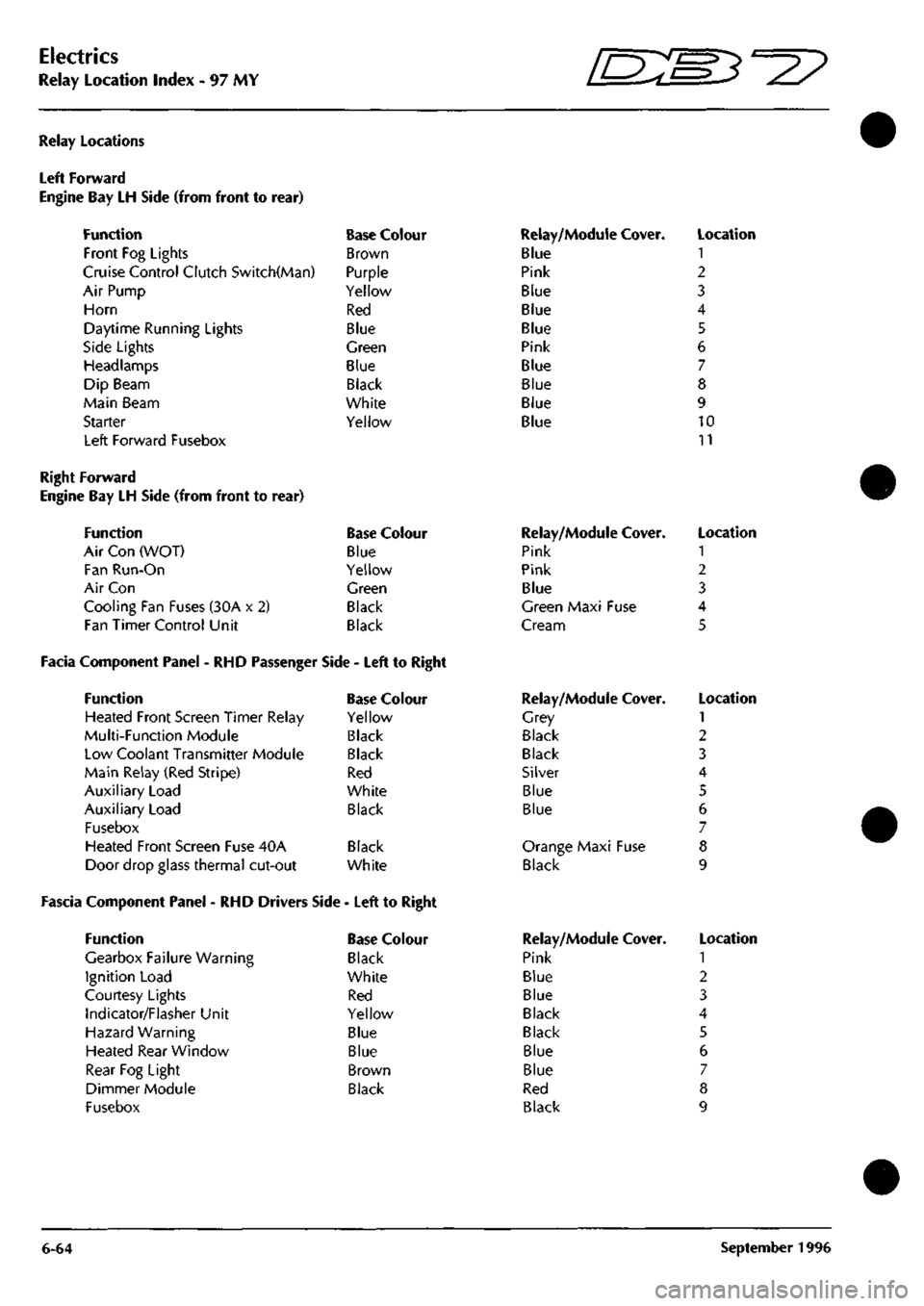

Relay Locations

Left Forward

Engine Bay LH Side (from front to

Function

Front Fog Lights

rear)

Cruise Control Clutch Switch(Man)

Air Pump

Horn

Daytime Running Lights

Side Lights

Headlamps

Dip Beam

Main Beam

Starter

Left Forward Fusebox

Base Colour

Brown

Purple

Yellow

Red

Blue

Green

Blue

Black

White

Yellow

Relay/Module Cover.

Blue

Pink

Blue

Blue

Blue

Pink

Blue

Blue

Blue

Blue

Location

1

2

3

4

5

6

7

8

9

10

11

Right Forward

Engine Bay LH Side (from front to rear)

Function Base Colour

Air Con (WOT) Blue

Fan Run-On Yellow

Air Con Green

Cooling Fan Fuses (30A x 2) Black

Fan Timer Control Unit Black

Facia Component Panel - RHD Passenger Side - Left to Right

Function Base Colour

Heated Front Screen Timer Relay Yellow

Multi-Function Module Black

Low Coolant Transmitter Module Black

Main Relay (Red Stripe) Red

Auxiliary Load White

Auxiliary Load Black

Fusebox

Heated Front Screen Fuse 40A Black

Door drop glass thermal cut-out White

Fascia Component Panel - RHD Drivers Side - Left to Right

Function

Gearbox Failure Warning

Ignition Load

Courtesy Lights

Indicator/Flasher Unit

Hazard Warning

Heated Rear Window

Rear Fog Light

Dimmer Module

Fusebox

Base Colour

Black

White

Red

Yellow

Blue

Blue

Brown

Black

Relay/Module

Pink

Pink

Blue

Cover.

Green Maxi Fuse

Cream

Relay/Module

Grey

Black

Black

Silver

Blue

Blue

Cover.

Orange Maxi Fuse

Black

Relay/Module

Pink

Blue

Blue

Black

Black

Blue

Blue

Red

Black

Cover.

Location

1

2

3

4

5

Location

1

2

3

4

5

6

7

8

9

Location

1

2

3

4

5

6

7

8

9

6-64 September 1996

Page 131 of 421

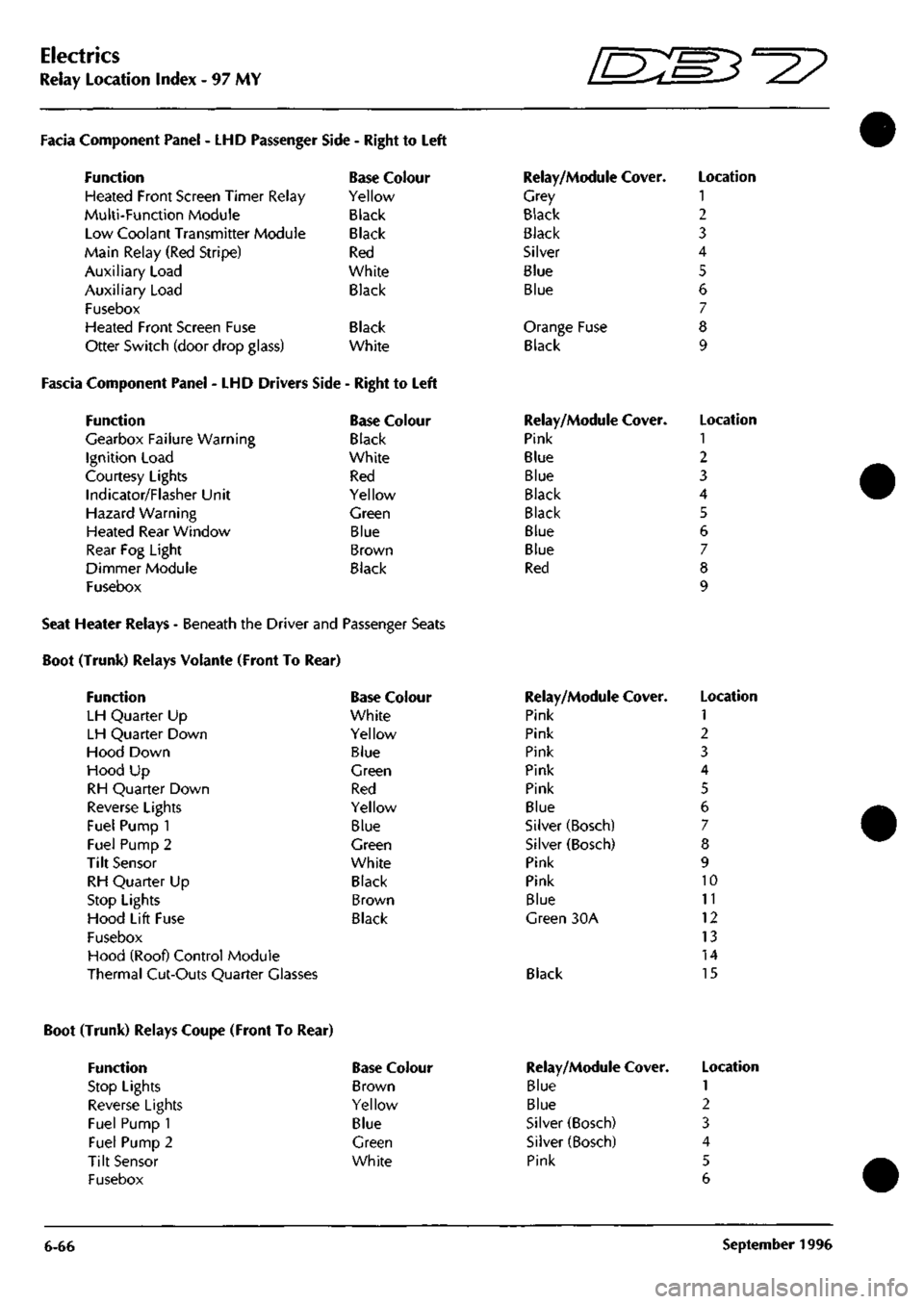

Electrics

Relay Location Index - 97 MY

D^^

Facia Component Panel

- LHD

Passenger

Function

Heated Front Screen Timer Relay

Multi-Function Module

Low Coolant Transmitter Module

Main Relay (Red Stripe)

Auxiliary Load

Auxiliary Load

Fusebox

Heated Front Screen Fuse

Otter Switch (door drop glass)

Side

-

Right

to

Left

Base Colour

Yellow

Black

Black

Red

White

Black

Black

White

Fascia Component Panel

- LHD

Drivers Side

-

Right

to

Left

Function

Gearbox Failure Warning

Ignition Load

Courtesy Lights

Indicator/Flasher Unit

Hazard Warning

Heated Rear Window

Rear

Fog

Light

Dimmer Module

Fusebox

Base Colour

Black

White

Red

Yellow

Green

Blue

Brown

Black

Relay/Module Cover.

Grey

Black

Black

Silver

Blue

Blue

Orange Fuse

Black

Relay/Module Cover.

Pink

Blue

Blue

Black

Black

Blue

Blue

Red

Location

1

2

3

4

5

6

7

8

9

Location

1

2

3

4

5

6

7

8

9

Seat Heater Relays - Beneath the Driver and Passenger Seats

Boot (Trunk) Relays Volante (Front To Rear)

Function

LH Quarter

Up

LH Quarter Down

Hood Down

Hood

Up

RH Quarter Down

Reverse Lights

Fuel Pump

1

Fuel Pump

2

Tilt Sensor

RH Quarter

Up

Stop Lights

Hood Lift Fuse

Fusebox

Hood (Roof) Control Module

Thermal Cut-Outs Quarter Glasses

Base Colour

White

Yellow

Blue

Green

Red

Yellow

Blue

Green

White

Black

Brown

Black

Relay/Module Cover.

Pink

Pink

Pink

Pink

Pink

Blue

Silver (Bosch)

Silver (Bosch)

Pink

Pink

Blue

Green

30A

Black

Location

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Boot (Trunk) Relays Coupe (Front To Rear)

Function

Stop Lights

Reverse Lights

Fuel Pump 1

Fuel Pump 2

Tilt Sensor

Fusebox

Base Colour

Brown

Yellow

Blue

Green

White

6-66

Relay/Module

Blue

Blue

Silver (Bosch)

Silver (Bosch)

Pink

Cover. Location

1

2

3

4

5

6

September

1996

Page 295 of 421

Air Conditioning

/J=y>f^^^

—p )

System Trouble Shooting

12.

Compressor clutch slipping.

13.

Blower flaps or distribution vents closed or partially seized.

14.

Water valve not closed.

15.

Evaporator sensor detached from evaporator.

Intermittent Cooling

Is the electrical circuit to the compressor clutch consistent?

2.

Is the electrical circuit to the blower motor(s) consistent?

3. Compressor clutch slipping.

4.

Faulty air distribution flap potentiometer or motor.

5. Motorised in-car aspirator or evaporator temperature sensor faulty, causing temperature variations.

6. Blocked or partially restricted evaporator or condenser.

Noisy System

1.

Loose or damaged compressor drive belt.

2.

Loose or damaged compressor mountings.

3. Compressor oil level low, look for evidence of leakage.

4.

Compressor damage caused by low oil level or internal debris.

5. Blower(s) motor(s) noisy.

6. Excessive refrigerant charge, witnessed by vibration and 'thumping' in the high pressure line (may be indicated by

high HIGH & high LOW side pressures).

7. Low refrigerant charge causing 'hissing' at the expansion valve (may be indicated by low HIGH side pressure).

8. Excessive moisture in the system causing expansion valve noise.

Note;

Electrical faults

may

be more rapidly traced using PDU.

Insufficient Heating

1.

Water valve stuck in the closed position.

2.

Motorised in-car aspirator seized.

3. Blend flaps stuck or seized.

4.

Blocked or restricted blower inlet or outlet.

5. Low coolant level.

6. Blower fan speed low.

7. Coolant thermostat faulty or seized open.

8-18 May 1996

Page 296 of 421

^2?

Air Conditioning

Electronic Control Module

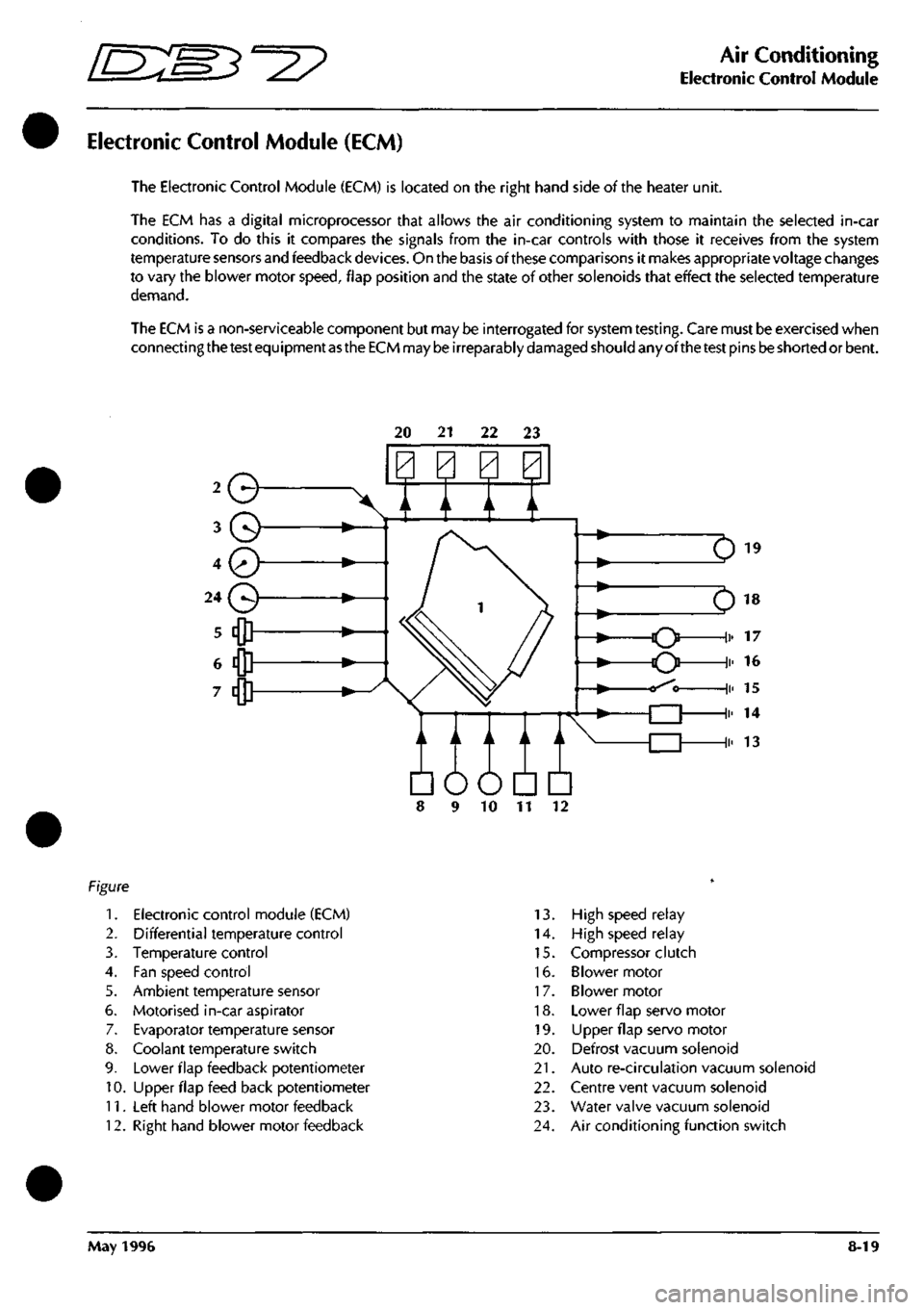

Electronic Control Module (ECM)

The Electronic Control Module (ECM) is located on the right hand side of the heater unit.

The ECM has a digital microprocessor that allows the air conditioning system to maintain the selected in-car

conditions. To do this it compares the signals from the in-car controls with those it receives from the system

temperature sensors and feedback

devices.

On the basis of these comparisons it makes appropriate voltage changes

to vary the blower motor

speed,

flap position and the state of other solenoids that effect the selected temperature

demand.

The ECM is a non-serviceable component but may be interrogated for system

testing.

Care must be exercised when

connecting

the test

equipment

as the ECM

may

be

irreparably

damaged

should any ofthe

test

pins

be

shorted or bent.

20 21 22 23

Q

A / A \/

Em

10 11

1.

Electronic control module (ECM)

2.

Differential temperature control

3. Temperature control

4.

Fan speed control

5. Ambient temperature sensor

6. Motorised in-car aspirator

7. Evaporator temperature sensor

8. Coolant temperature switch

9. Lower flap feedback potentiometer

10.

Upper flap feed back potentiometer

11.

Left hand blower motor feedback

12.

Right hand blower motor feedback

13.

High speed relay

14.

High speed relay

15.

Compressor clutch

16.

Blower motor

17.

Blower motor

18.

Lower flap servo motor

19.

LIpper flap servo motor

20.

Defrost vacuum solenoid

21.

Auto re-circulation vacuum solenoid

22.

Centre vent vacuum solenoid

23.

Water valve vacuum solenoid

24.

Air conditioning function switch

May 1996 8-19

Page 305 of 421

Air Conditioning

Vacuum System •^^

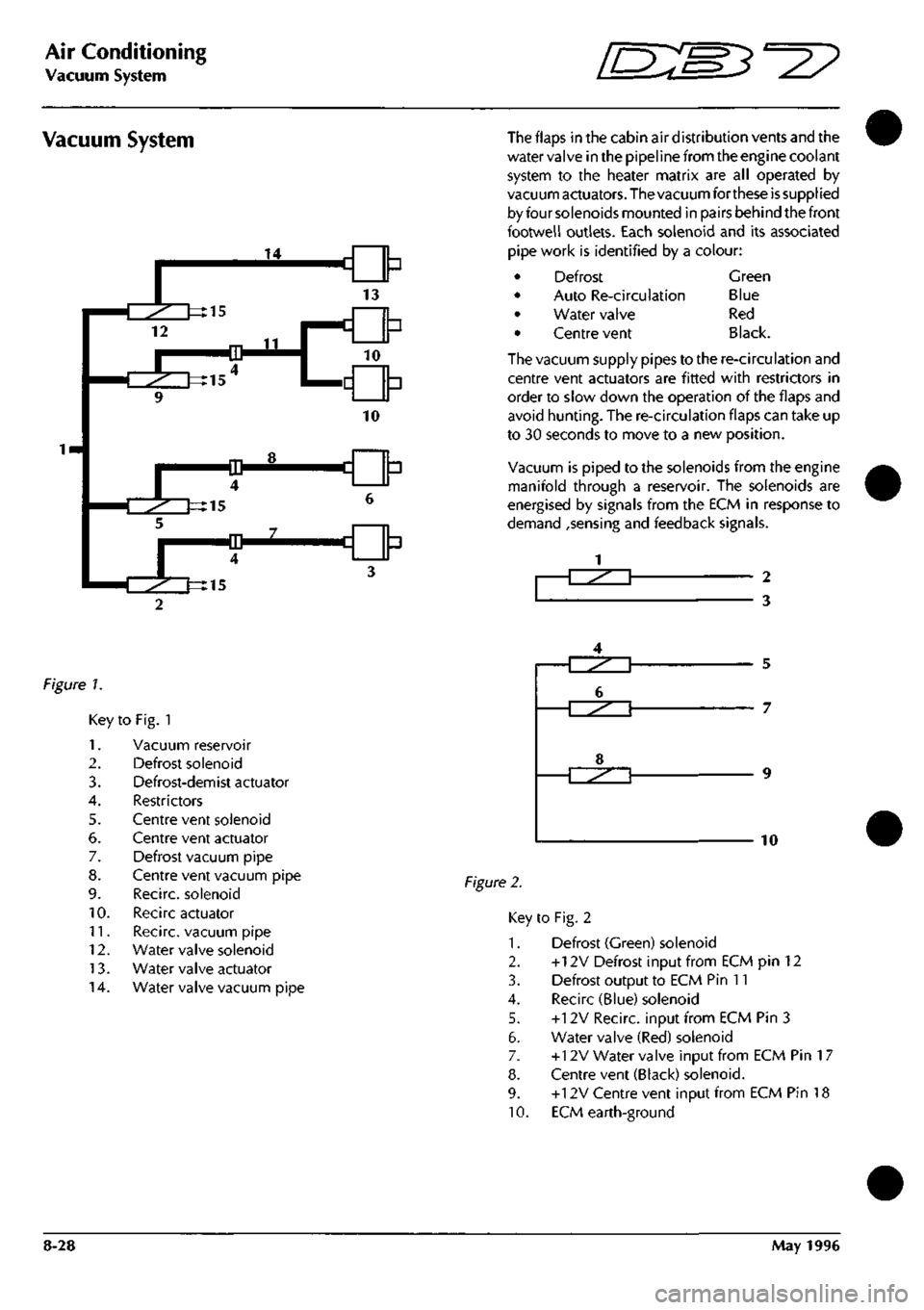

Vacuum System The flaps in the cabin air distribution vents and the

water valve in the pipeline from the engine coolant

system to the heater matrix are all operated by

vacuum actuators. The vacuum forthese

is

supplied

by four solenoids mounted in pairs behind the front

footwell outlets. Each solenoid and its associated

pipe work is identified by a colour:

Defrost

Auto Re-circulation

Water valve

Centre vent

Green

Blue

Red

Black.

The vacuum supply pipes to the re-circulation and

centre vent actuators are fitted with restrictors in

order to slow down the operation of the flaps and

avoid hunting. The re-circulation flaps can take up

to 30 seconds to move to a new position.

Vacuum is piped to the solenoids from the engine

manifold through a reservoir. The solenoids are

energised by signals from the ECM in response to

demand ,sensing and feedback signals.

-T^^^T 2

3

figure 7.

Key

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

to Fig. 1

Vacuum reservoir

Defrost solenoid

Defrost-demist actuator

Restrictors

Centre vent solenoid

Centre vent actuator

Defrost vacuum pipe

Centre vent vacuum pipe

Recirc. solenoid

Recirc actuator

Recirc. vacuum pipe

Water valve solenoid

Water valve actuator

Water valve vacuum pipe

Figure 2.

5

7

10

Key to Fig. 2

1.

Defrost (Green) solenoid

2.

+12V Defrost Input from ECM pin 12

3. Defrost output to ECM Pin 11

4.

Recirc (Blue) solenoid

5. +12V Recirc. input from ECM Pin 3

6. Water valve (Red) solenoid

7. +12V Water valve input from ECM Pin

1

7

8. Centre vent (Black) solenoid.

9. +12V Centre vent input from ECM Pin 18

10.

ECM earth-ground

8-28 May 1996