compressor ASTON MARTIN DB7 1997 Owner's Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 311 of 421

Air Conditioning

Refrigeration /s:s^°27

Refrigeration

Safety Precautions

The air conditioning system is designed to use only

Refrigerant E134A (dichlorodifluoromethane). Extreme

care must betaken NOT to use

a

methylchloride refrigerant.

The chemical reaction between methylchloride and the

aluminium parts ofthe compressor results in the formation

ofproductswhich burn spontaneously on exposure toair,

or decompose with violence in the presence of moisture.

The suitable refrigerant is supplied under the following

names.

El 34A KLEA or equivalent

Warning: Take care when handling refrigerant. Serious

damage will occur if it is allowed to come into

contact with the eyes. Always wear with goggles

and gloves when working with refrigerant

First Aid

If refrigerant should come into contact with the

eyes or

skin,

splash the eyes or affected area with

cold water for several minutes. DO NOT RUB. As

soon as possible thereafter, obtain treatment from a

Doctor or an eye specialist.

Good Practice

1.

Protective sealing plugs must be fitted to all

disconnected pipes and units.

2.

Theprotectivesealingpiugsmustremain inposition

on ail replacement components and pipes until

immediately before assembly.

3. Any part arriving for assembly without sealing

plugs in position must be returned to the supplier as

defective.

4.

It is essential that a second backing spanner is

always used when tightening or loosening all joints.

This minimises distortion or strain on components

or connecting hoses.

5. Components must not be lifted by connecting

pipes,

hoses or capillary tubes.

6. Care must be taken not to damage fins on the

condenser or evaporator matrices. Any damage

must be rectified by the use of fin combs.

7. Before assembly oftube and hosejoints, use

a

small

amount of clean new refrigerant oil on the sealing

seat.

8. Refrigerant oil for any purpose must be kept very

clean and capped at all times. This prevents the oil

absorbing moisture.

9. Before assembly the condition of joints and flares

must be examined. Dirt and even minor damage

will cause leaks at the high pressure points

encountered in the system.

10.

Dirty end fitting can only be cleaned using a cloth

wetted with alcohol.

11.

Afterremovingsealingplugsand immediatelybefore

assembly, visually check the bore of pipes and

components. Where any dirt or moisture is

discovered,

the part must be rejected.

12. Ail components must be allowed to reach room

temperature before sealing plugs are removed.

This prevents condensation should the component

be cold initially.

13.

Before finally tightening hose connections ensure

that the hose lies in the correct position, is not

kinked or twisted and will not be trapped by

subsequent operations, e.g., refitting or closing

bonnet.

14.

Check that hoses are correctly fitted in clips or

straps.

15.

The compressor must be stored horizontally with

the sump down. It must not be rotated before fitting

and charging. Do not remove the shipping plate

until immediately before assembly. Always use

new "O" ring seals in those joints that incorporate

them.

"O" ring seals should be coated with

compressor oil before fitting.

16.

Components or hoses removed must be sealed

immediately after removal.

1 7. Afterthe system has been opened the receiver-drier

must be renewed.

18.

Before

testing,

run the engine until normal running

temperature is reached. This ensures that sufficient

vacuum is available for test. For cooling tests the

engine must be running for the compressor clutch

to operate.

8-34 May 1996

Page 312 of 421

'^T?

Air Conditioning

Compressors

Compressors

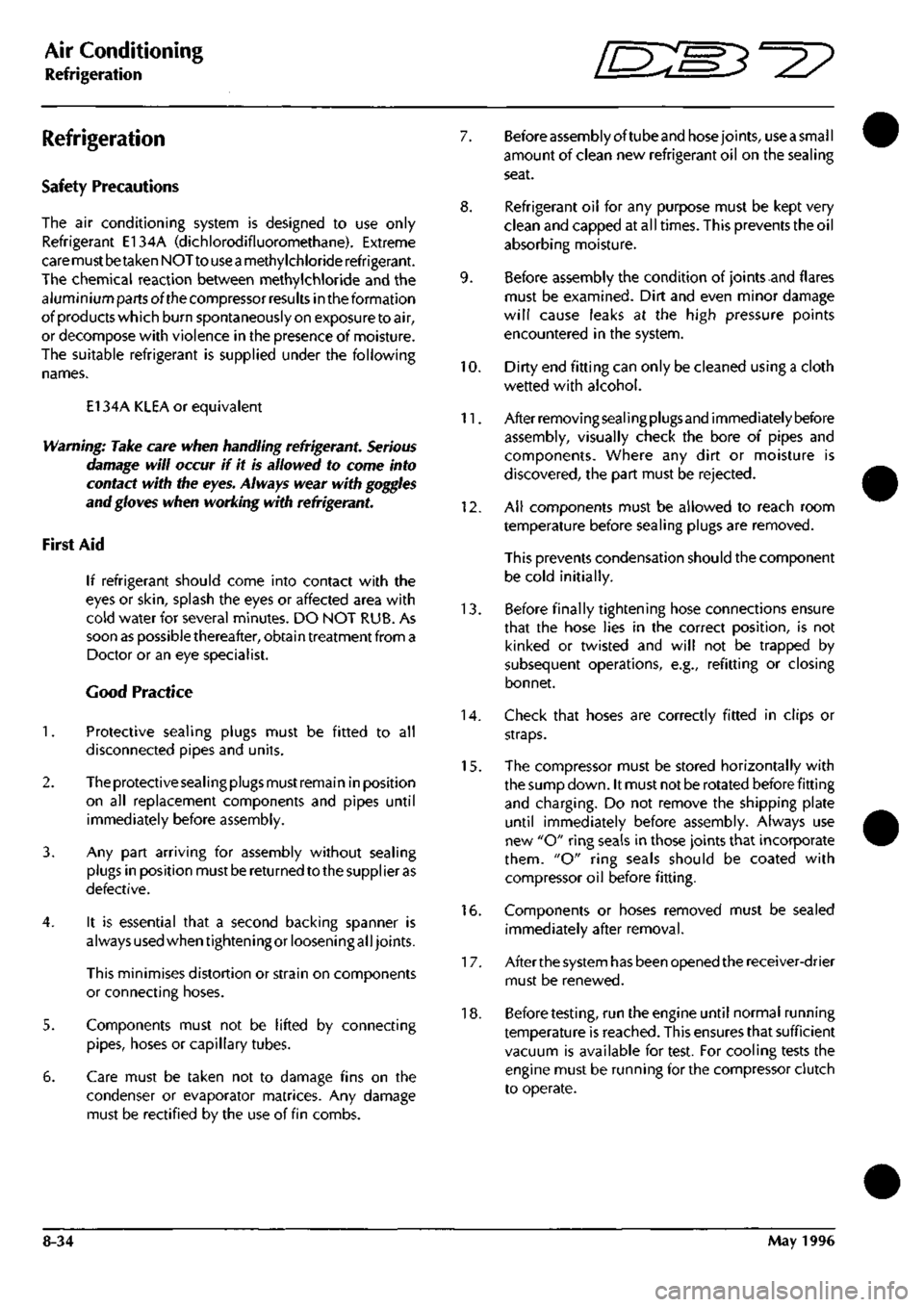

Compressor Clutch Control

The compressor

pu I

ley

is

driven continuously when

the engine is running. An electromagnetic clutch

allows the compressortobeengagedordisengaged.

The clutch is energised by battery supply voltage

when the clutch relay RF3 is closed by a signal from

the ECM (pin 21) via the engine management

system.

6^

o>o 1

4

Figure 1

Figure 2

Key to Fig. 2

1.

2.

3.

4.

5.

Condenser

Clutch relay supply

Compressor clutch

HSLP switch

Protection diode

Earth-ground

Key to Fig. 1

1.

+ve battery supply

2.

Clutch relay

3. Compressor clutch

4.

Pin 20 ECM supply to clutch relay solenoid

5. Earth-Ground

6. Earth-Ground

Trinary Switch

High Side Low Pressure Switch

The high side low pressure switch (HSLP) is

connected in the earth-ground return lead of the

compressor clutch

coil.

The switch is a function of

the trinary switch and monitors the pressure on the

high side of the refrigeration system. If the pressure

drops below 25 psi (+ 5 psi) the contacts open to de-

energise the clutch coil and disengage the clutch.

Low pressure occurs when there is a fault in the

system,

and the HSLP switch contacts remain open

until the fault has been rectified.

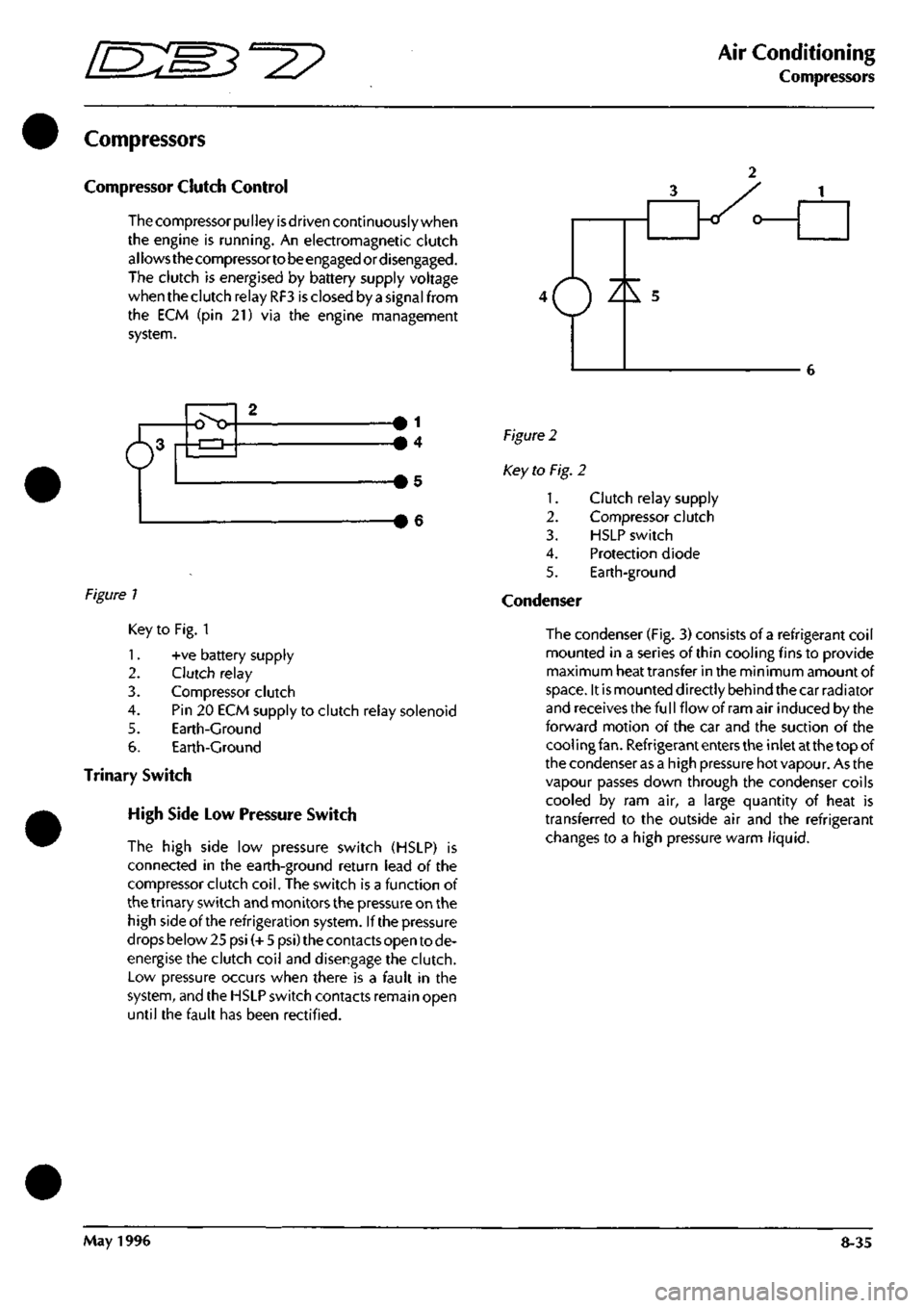

The condenser (Fig, 3) consists of a refrigerant coil

mounted in a series of thin cooling fins to provide

maximum heat transfer in the minimum amount of

space.

It is mounted directly behind the car radiator

and receives the fu

11

flow of ram air induced by the

forward motion of the car and the suction of the

cool ing

fan.

Refrigerant enters the inlet at the top of

the condenser as a high pressure hot vapour. As the

vapour passes down through the condenser coils

cooled by ram air, a large quantity of heat is

transferred to the outside air and the refrigerant

changes to a high pressure warm liquid.

May 1996 8-35

Page 313 of 421

Air Conditioning

Compressors ^?

Evaporator

Figure 3.

Receiver-Drier

The receiver drier (Fig. 1) accepts high pressure

warm refrigerant liquid from the condenser and

del ivers it via an expansion valve to the evaporator.

It contains a quantity of molecular sieve desiccant

to remove moisture from the refrigerant, and

a

fi Iter

to removecontaminants.lt also

a

providesa reservoir

of refrigerant for the evaporator under varying

operating conditions.

The evaporator consists of a refrigerant coil mounted

in a series of thin fins to provide a maximum

amount of heat transfer in a minimum amount of

space.

It is housed in the air conditioning unit and

all air entering the system passes across its

coil.

The evaporator receives refrigerant from the

thermostatic expansion valve as a low pressure

cold atomised liquid. As this cold liquid passes

through the evaporator coils, it absorbs heat from

the surrounding air and changes into

a

low pressure

warm vapour.

Expansion Valve

The expansion valve is the dividing point between

the high and low pressure sides of the system. It

automatically meters high pressure, warm liquid

refrigerant via a metering orifice into the low

pressure, cold side of the evaporator matrix. The

valve senses outlet pipe temperature, inlet pipe

pressure and regulates the flow of refrigerant into

the evaporator to ensure that only vaporised

refrigerant appears at the outlet.

Figure 1.

8-36 May 1996

Page 314 of 421

^?

Air Conditioning

Sanden Compressor SD7H15

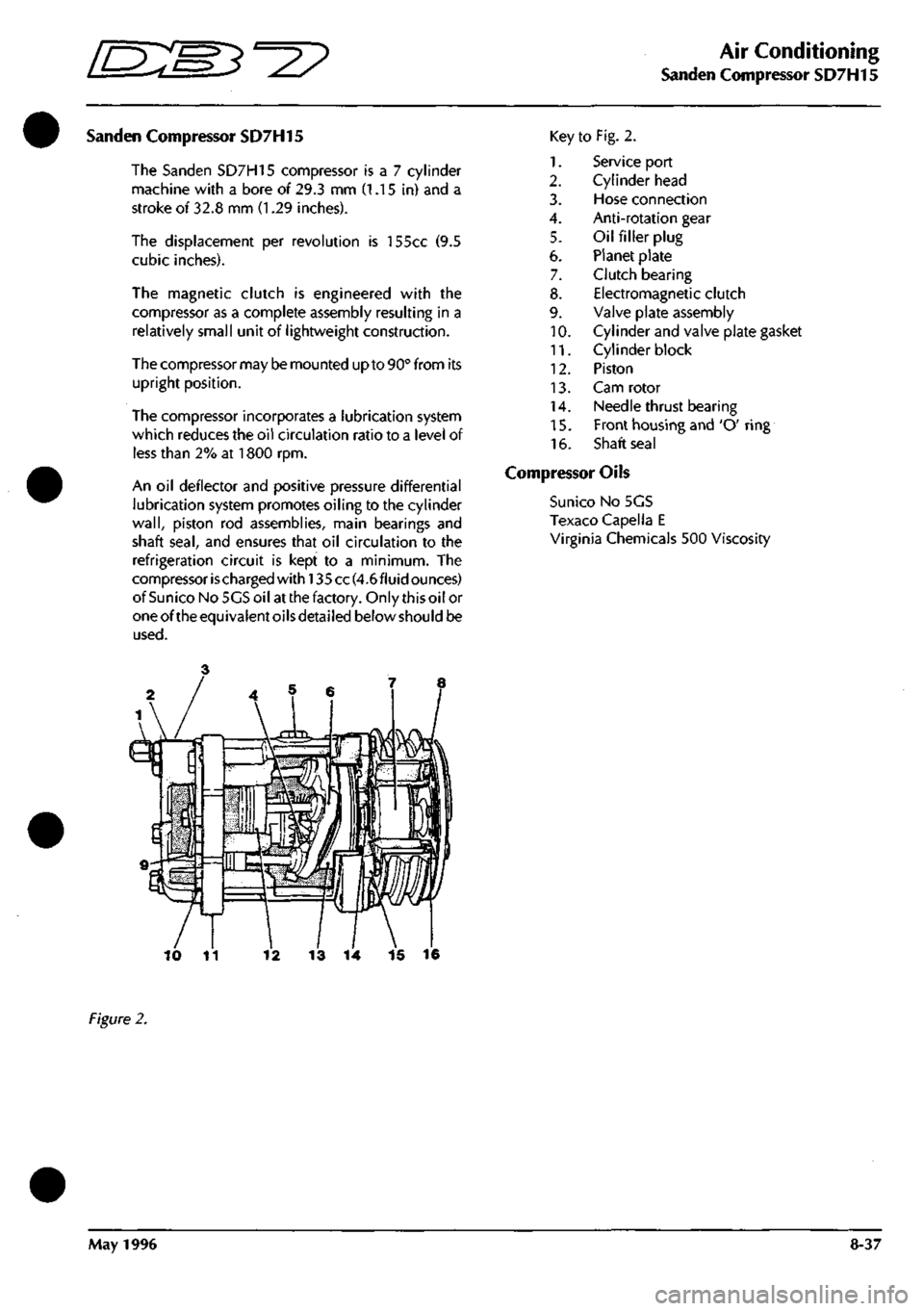

Sanden Compressor SD7H15

The Sanden SD7H15 compressor

is a 7

cylinder

machine with

a

bore

of

29.3

mm (1.15 in) and a

stroke

of

32.8

mm (1.29

inches).

The displacement

per

revolution

is

155cc

(9.5

cubic inches).

The magnetic clutch

is

engineered with

the

compressor

as a

complete assembly resulting

in a

relatively small unit

of

lightweight construction.

The compressor may be mounted up to 90° from

its

upright position.

The compressor incorporates

a

lubrication system

which reduces the

oil

circulation ratio

to a

level

of

less than

2% at 1800 rpm.

An

oil

deflector

and

positive pressure differential

lubrication system promotes oiling

to the

cylinder

wall,

piston

rod

assemblies, main bearings

and

shaft

seal,

and

ensures that

oil

circulation

to the

refrigeration circuit

is

kept

to a

minimum.

The

compressor ischarged

with!

35 cc(4.6fluid ounces)

ofSunico NoSGSoil at the factory. Only this oil

or

oneoftheequivalentoilsdetailed below should

be

used.

Key

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

to Fig. 2.

Service port

Cylinder head

Hose connection

Anti-rotation gear

Oil filler plug

Planet plate

Clutch bearing

Electromagnetic clutch

Valve plate assembly

Cylinder and valve plate gasket

Cylinder block

Piston

Cam rotor

Needle thrust bearing

Front housing and 'O' ring

Shaft seal

Compressor Oils

Suni

CO

No 5GS

Texaco Capella E

Virginia Chemicals 500 Viscosity

13

14 15 16

Figure

2.

May

1996

8-37

Page 316 of 421

^=2?

Air Conditioning

System Checking with the Manifold Gauge Set

System Checking with the Manifold

Gauge Set

Connecting the Manifold Gauge Set

Caution: Only use hoses with connectors which are

dedicated to HFC 134A charge ports.

Attachmentofthehosequick release connectors to

the high and low side

system

ports

is

straightforward,

provided that the high and low valves are closed

and the system is NOT operational.

Assessment ofthe system's operating system can be

carried out by using the facilities ofthe Recovery-

Recharging-Recycling station. Follow the

manufacturer's instructions carefully and closely

observe the safety procedures.

Warning: Under no circumstances should the connections

be made with the

system

in operation or the

valves

open. Should the valves be open and a vacuum

pump or refrigerant container attached, an

explosion could occur

as

a result of high pressure

refrigerant being forced back into the vacuum

pump or container.

Stabilising the System

Accurate test gauge data can be attained only if the

system temperatures and pressures are stabilised.

Ensure that equipment and its hoses cannot come

into contact with moving parts or heat sources.

It is recommended that a free standing air mover is

placed in front of the vehicle to provide mass air

flow through the condenser-cooling system.

Checking Procedure

Connecting the Gauge Set.

A test hose connected to the fitting directly under

the low side gauge is used to connect the low side

ofthe test manifold into the low side ofthe system,

and a similar connection is found on the high side.

When connecting the gauge manifold set to the air

cond ition i ng system an access va Ive core removi ng

tool is available for connecting the test hoses to the

high and low sides ofthe system.

Using the valve removing tool it enables the valve

core to be removed and held back inside the tool

eliminating restrictions and, thereby, providing a

full flow of refrigerant.

Warning: Do not open the high side hand valve while the

air conditioning system is in operation because,

high pressure refrigerant will be forced through

the high side gauge and to the refrigerant container,

if it is attached.

This

could cause the container to

rupture or the fitting at the safety container valve

to burst resulting in damage and personal injury.

1.

With theengineswitched off, remove the protective

caps from the schraeder valves.

2.

Fit the access valve removal tool to the schraeder

valves. Ensure that both the manifold hand valves

are in the closed position.

3. Connect the high pressure manifold gauge hose (to

the high pressure side of the air conditioning side of

the system (high side is always the line from the

compressor to the condenser). Connect the low

pressure or compound gauge hose to the low

pressure side ofthe air conditioning system.

4.

Using the access valve removal tool loosen and

screw out the valve cores.

1.

Start the engine and allow it to attain normal

working temperature then set it at fast idle (typically

1200 to ISOOrpm).

2.

Select full air conditioning performance.

3. With all temperatures and pressures stable or

displaying symptoms of faults, begin relevant test

procedures.

May 1996 8-39

Page 318 of 421

=2?

Air Conditioning

System Checking with the Manifold Gauge Set

Pressure Temperature Relationship.

Note:

Pressures

shown are under exact conditions

(see

test

conditions) and

are

not

necessary

true for every

car

checked.

Ambient Temperature is given as the air

surrounding the

condenser

and

is

taken 5 cm in front of

the

condenser.

Test Conditions.

Use a large fan to substitute for normal ram air through the

condenser. Engine adjusted to fast idle speed.

All conditions equivalent to 30 m.p.h. or 48 km/h.

Ambient

Evaporator

Temp °C

16

18

21

24

27

29

32

35

38

41

43

46

49

High

Pressure

Gauge

Reading

Ibf/in2

95-115

105-125

115-125

130-150

1

50-170

165-185

175-195

185-205

210-230

230-250

250-270

265-285

280-310

Low

Pressure

Gauge

Reading

Ibf/in2

10

12

4

16

18

20

22

24

26

28

30

35

40

45

50

55

60

65

70

Ten

-16

-14

-12

-10

-8

-6

-5

-4

-3

-1

0

2

5

9

11

14

17

19

21

Normal operating ambient temperature range is:

-24 to 43°C.

Normal operating evaporator temperature range

is:-12toO°C.

Under normal running conditions system pressure

should be, as follows:

Lowside:1.05to2.10kgf/cm21.034to2.06bar15

to 30 ibf/in2

High side: 13.00 to 14.40 kgf/cm2 12.75 to 14.34

bar185to205lbf/in2

Manifold Gauge Set Check Procedures

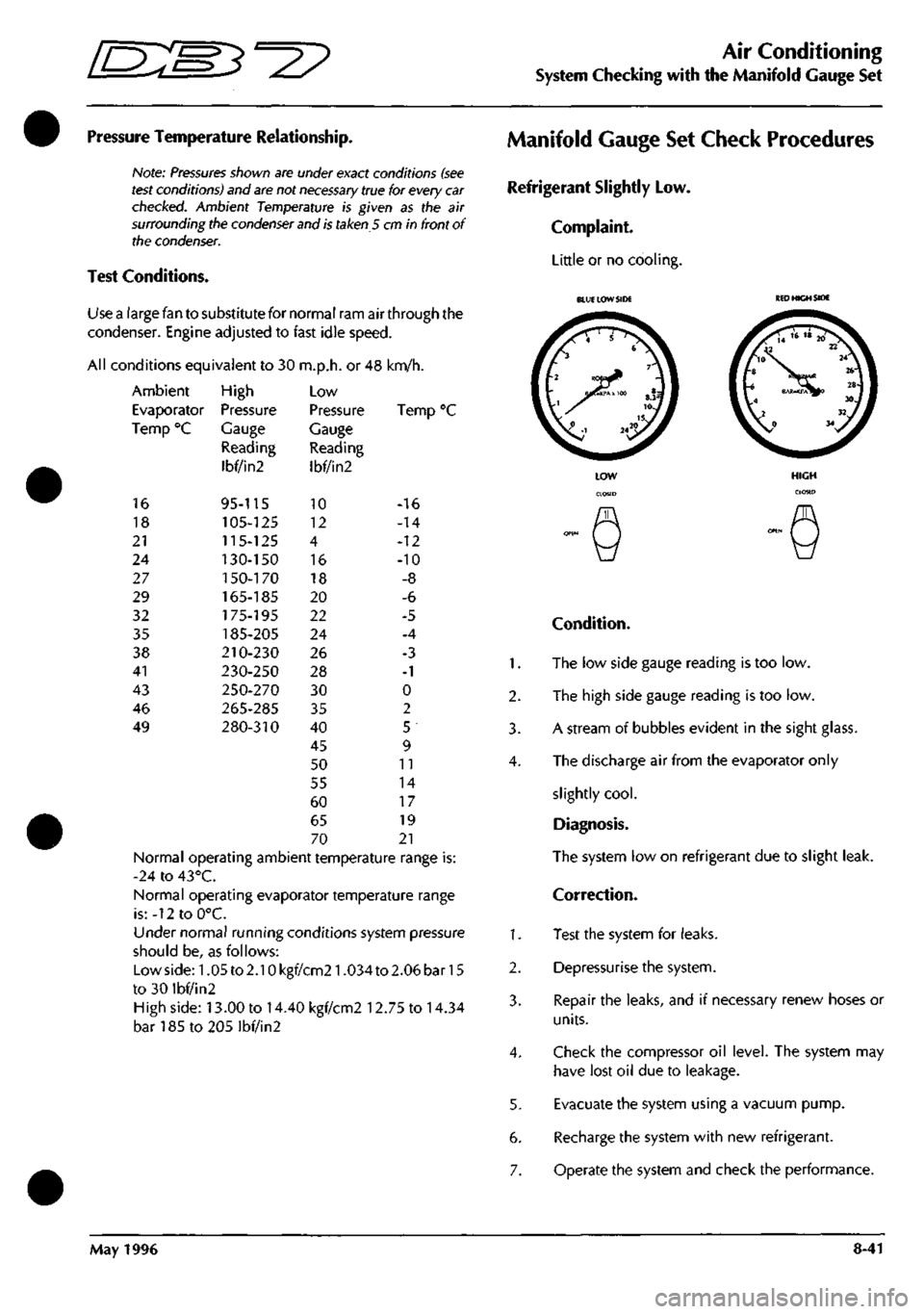

Refrigerant Slightly Low.

Complaint.

Little or no cooling.

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

7.

BLUE LOW SIDE

KED

HIGH SIDE

Condition.

The low side gauge reading is too low.

The high side gauge reading is too low.

A stream of bubbles evident in the sight glass.

The discharge air from the evaporator only

slightly

cool.

Diagnosis.

The system low on refrigerant due to slight leak.

Correction.

Test the system for leaks.

Depressurise the system.

Repair the leaks, and if necessary renew hoses or

units.

Check the compressor oil level. The system may

have lost oil due to leakage.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

Operate the system and check the performance.

May 1996 8-41

Page 319 of 421

Air Conditioning

System Checking with the Manifold Gauge Set [n::S3^^?

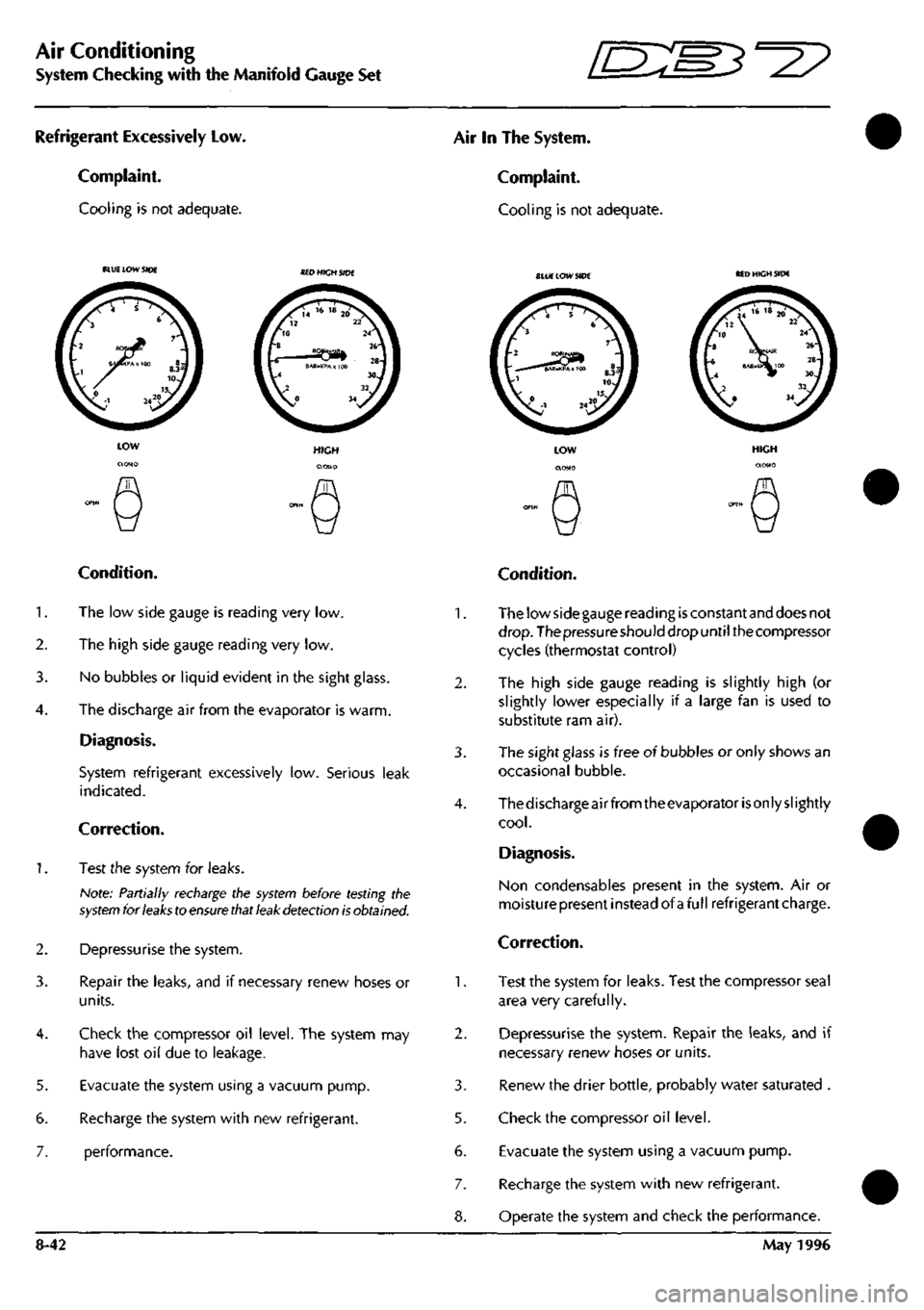

Refrigerant Excessively Low.

Complaint.

Cooling is not adequate.

Air In The System.

Complaint.

Cooling is not adequate.

BLU£ LOW SIDE SlUE LOW SIDE MD HIGH SIDE

5.

6.

7.

Condition.

1.

The low side gauge is reading very low.

2.

The high side gauge reading very low.

3. No bubbles or liquid evident in the sight glass.

4.

The discharge air from the evaporator is warm.

Diagnosis.

System refrigerant excessively low. Serious leak

indicated.

Correction.

1.

Test the system for leaks.

Note: Partially recharge the

system

before testing the

system

for

leaks

to

ensure that leak detection is

obtained.

Depressurise the system.

Repair the leaks, and if necessary renew hoses or

units.

Check the compressor oil level. The system may

have lost oil due to leakage.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

performance.

2.

3.

5.

6.

7.

8-42

Condition.

The low side gauge reading

is

constant and does not

drop.

The pressure should drop until the compressor

cycles (thermostat control)

The high side gauge reading is slightly high (or

slightly lower especially if a large fan is used to

substitute ram air).

The sight glass is free of bubbles or only shows an

occasional bubble.

Thedischarge air from theevaporator

is

only slightly

cool.

Diagnosis.

Non condensables present in the system. Air or

moisturepresent instead of afullrefrigerantcharge.

Correction.

Test the system for leaks. Test the compressor seal

area very carefully.

Depressurise the system. Repair the leaks, and if

necessary renew hoses or units.

Renew the drier bottle, probably water saturated .

Check the compressor oil level.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

Operate the system and check the performance.

May 1996

Page 320 of 421

^2?

Air Conditioning

System Checking with the Manifold Gauge Set

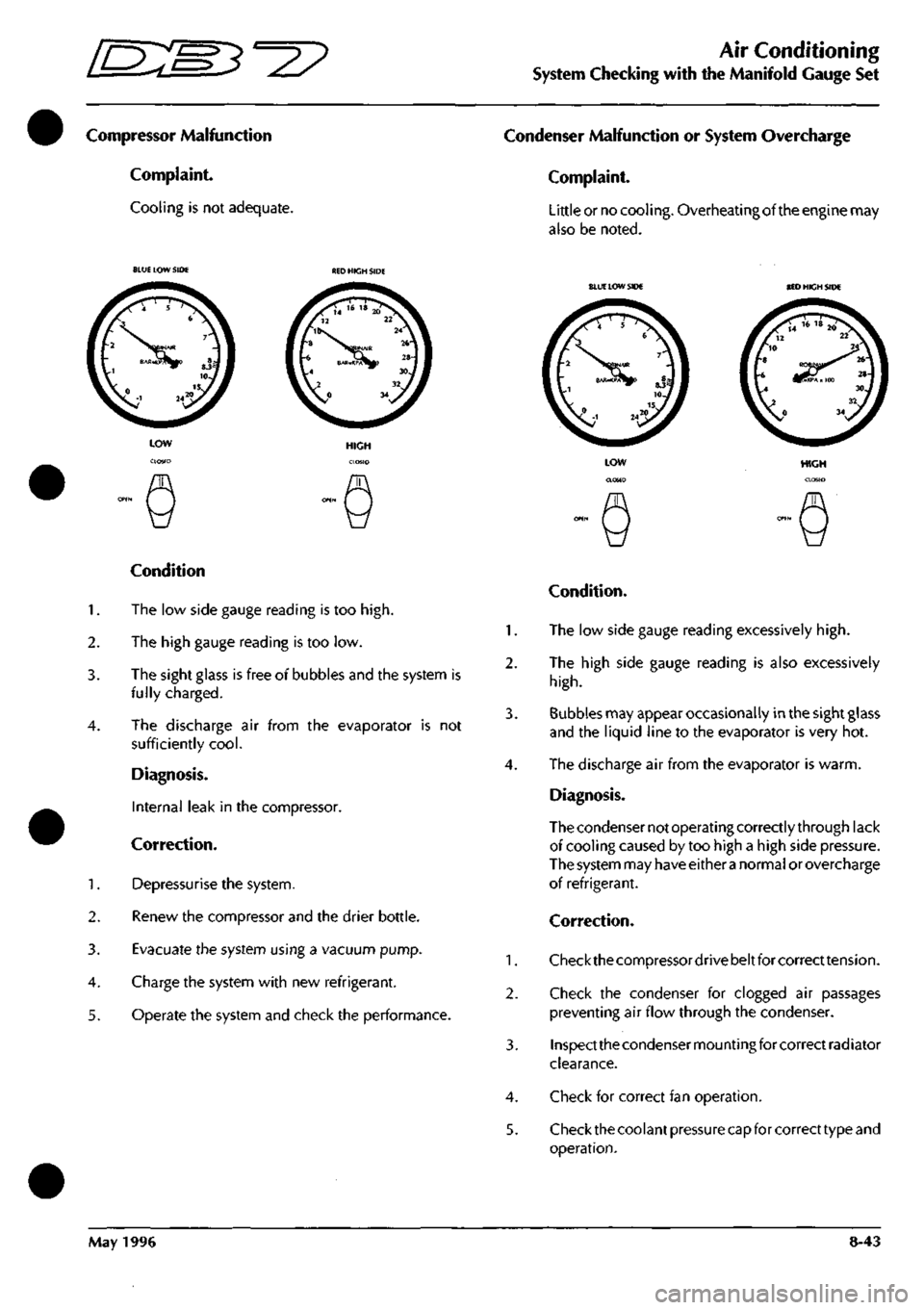

Compressor Malfunction

Complaint.

Cooling is not adequate.

Condenser Malfunction or System Overcharge

Complaint.

Little or no cooling. Overheating of the engine may

also be noted.

BLUE LOW SIDE

BLUE

LOW SIDE BED HICH SIDE

Condition

1.

The low side gauge reading is too

high.

2.

The high gauge reading is too low.

3. The sight glass is free of bubbles and the system is

fully charged.

4.

The discharge air from the evaporator is not

sufficiently

cool.

Diagnosis.

Internal leak in the compressor.

Correction.

1.

Depressurise the system.

2.

Renew the compressor and the drier bottle.

3. Evacuate the system using a vacuum pump.

4.

Charge the system with new refrigerant.

5. Operate the system and check the performance.

HIGH

Condition.

1.

The low side gauge reading excessively

high.

2.

The high side gauge reading is also excessively

high.

3. Bubbles may appear occasionally in the sight glass

and the liquid line to the evaporator is very hot.

4.

The discharge air from the evaporator is warm.

Diagnosis.

The condenser not operating correctly through lack

of cooling caused by too high a high side pressure.

The system may have either

a

normal or overcharge

of refrigerant.

Correction.

1.

Checkthecompressordrivebeltforcorrecttension.

2.

Check the condenser for clogged air passages

preventing air flow through the condenser.

3. Inspect the condenser mounting for correct radiator

clearance.

4.

Check for correct fan operation.

5. Check the coolant pressure capfor correct type and

operation.

May 1996 8-43

Page 323 of 421

Air Conditioning

System Checking with the Manifold Gauge Set ^^?

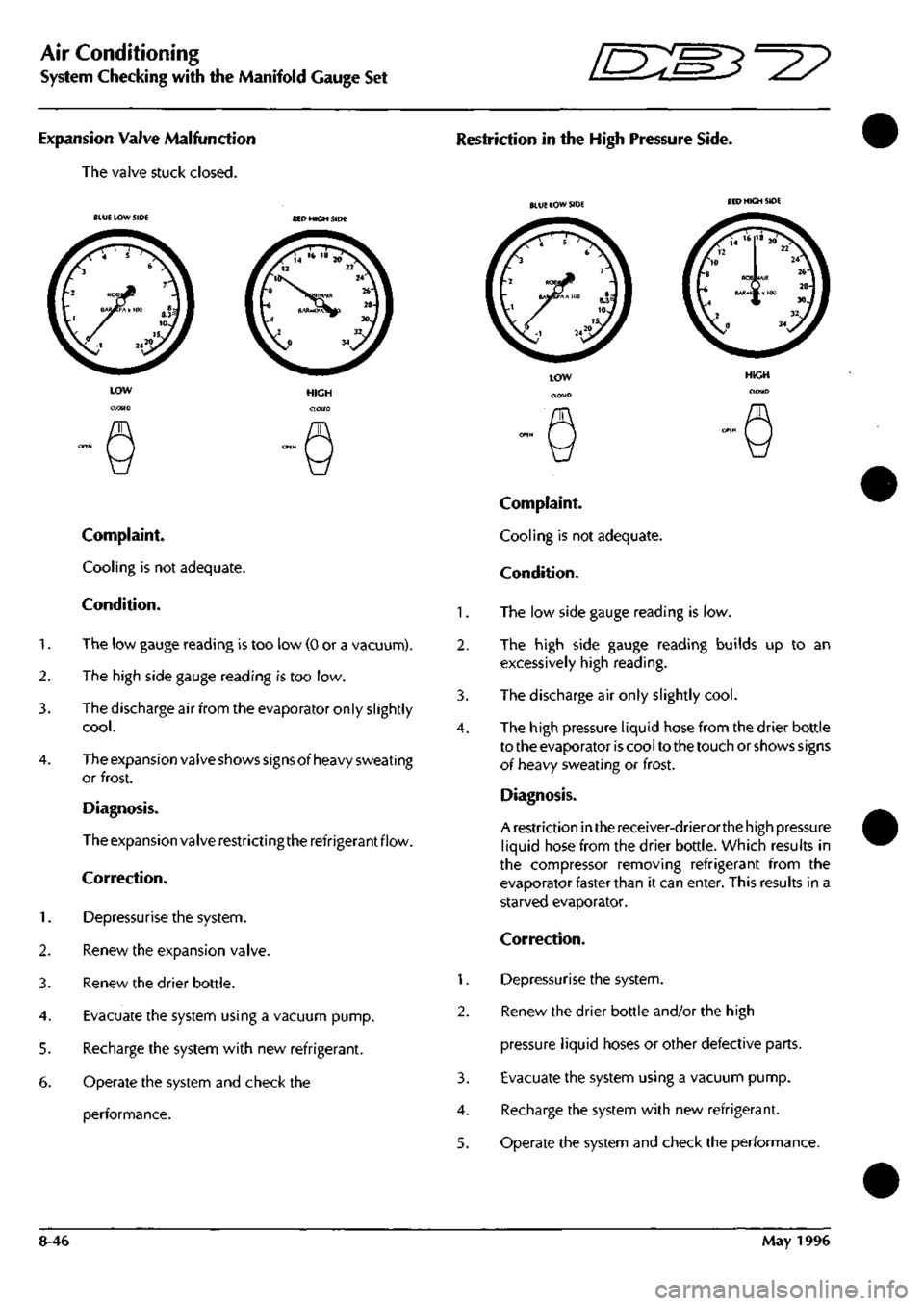

Expansion Valve Malfunction

The valve stuck closed.

Restriction in the High Pressure Side.

BLUE LOW SIDE SED HIGH SIDE

Complaint.

Cooling is not adequate.

Condition.

1.

The low gauge reading is too low (0 or a vacuunn).

2.

The high side gauge reading is too low.

3. The discharge air from the evaporator only slightly

cool.

4.

The expansion valve shows signs of heavy sweating

or frost.

Diagnosis.

The expansion valve restrictingthe refrigerant flow.

Correction.

1.

Depressurise the system.

2.

Renew the expansion valve.

3. Renew the drier bottle.

4.

Evacuate the system using a vacuum pump.

5. Recharge the system with new refrigerant.

6. Operate the system and check the

performance.

1.

2.

3.

4.

1.

2.

3.

4.

5.

BLUE LOW SIDE

Complaint.

Cooling is not adequate.

Condition.

The low side gauge reading is low.

The high side gauge reading builds up to an

excessively high reading.

The discharge air only slightly

cool.

The high pressure liquid hose from the drier bottle

to the evaporator is cool to the touch or shows signs

oi heavy sweating or frost.

Diagnosis.

A restriction in the receiver-drier orthe high pressure

liquid hose from the drier bottle. Which results in

the compressor removing refrigerant from the

evaporator faster than it can enter. This results in a

starved evaporator.

Correction.

Depressurise the system.

Renew the drier bottle and/or the high

pressure liquid hoses or other defective parts.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

Operate the system and check the performance.

8-46 May 1996

Page 324 of 421

^?

Air Conditioning

Torque Settings / Depressurising the System

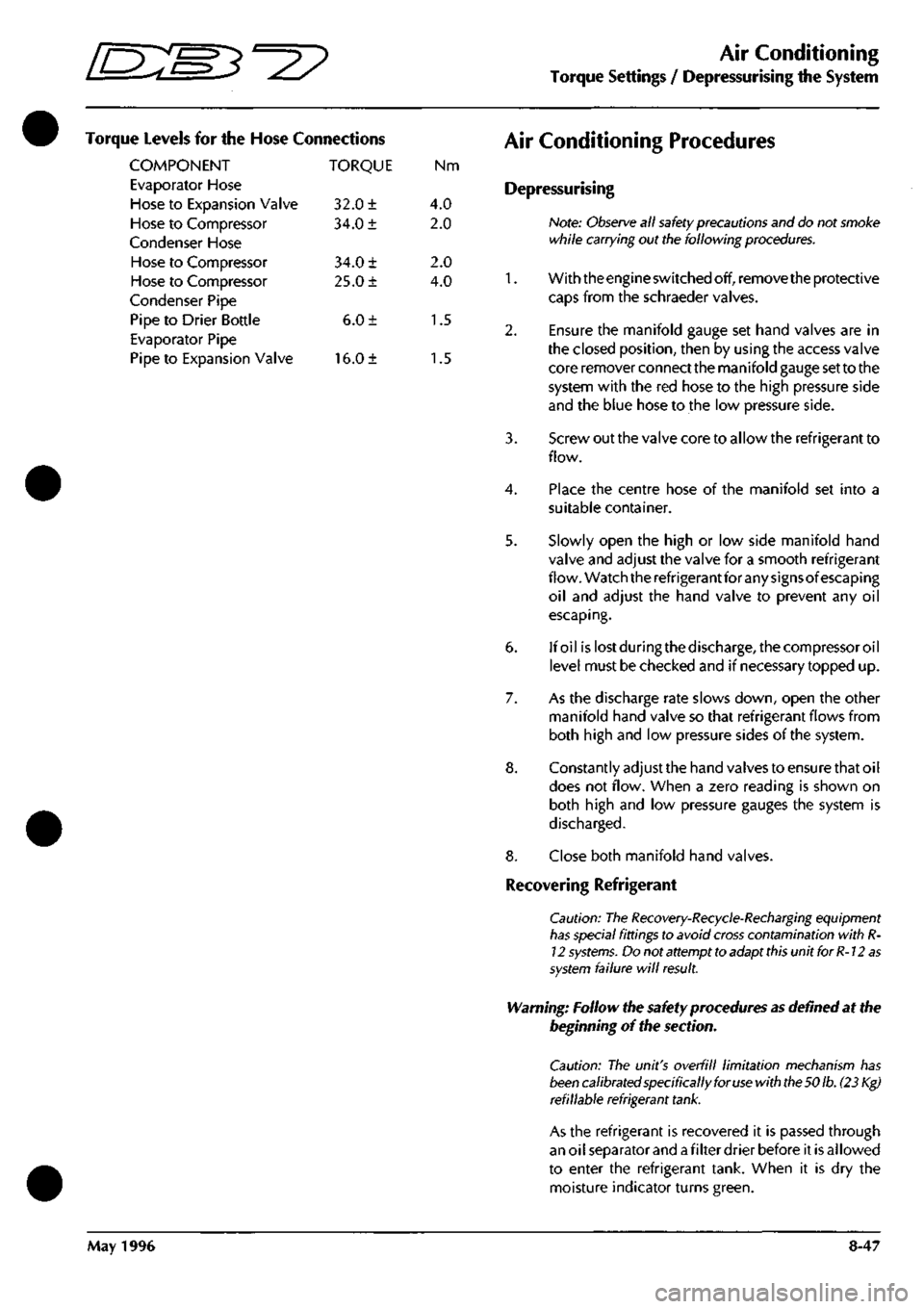

Torque Levels for the Hose Connections

COMPONENT TORQUE Nm

Evaporator Hose

Hose to Expansion Valve 32.0 ± 4.0

Hose to Compressor 34.0 ± 2.0

Condenser Hose

Hose to Compressor 34.0 ± 2.0

Hose to Compressor 25.0 ± 4.0

Condenser Pipe

Pipe to Drier Bottle 6.0 ± 1.5

Evaporator Pipe

Pipe to Expansion Valve 16.0 ± 1.5

Air Conditioning Procedures

Depressurising

Note:

Observe

all

safety

precautions and do not smoke

while carrying out the following

procedures.

1.

With the engine switched off, remove the protective

caps from the schraeder valves.

2.

Ensure the manifold gauge set hand valves are in

the closed position, then by using the access valve

core remover connect the manifold gauge set to the

system with the red hose to the high pressure side

and the blue hose to the low pressure side.

3. Screw out the valve core to allow the refrigerant to

flow.

4.

Place the centre hose of the manifold set into a

suitable container.

5. Slowly open the high or low side manifold hand

valve and adjust the valve for a smooth refrigerant

flow. Watch the refrigerant for any signsof escaping

oil and adjust the hand valve to prevent any oil

escaping.

6. If oil islostduringthedischarge,thecompressoroil

level must be checked and if necessary topped up.

7. As the discharge rate slows down, open the other

manifold hand valve so that refrigerant flows from

both high and low pressure sides of the system.

8. Constantly adjust the hand valves to ensure that oil

does not flow. When a zero reading is shown on

both high and low pressure gauges the system is

discharged.

8. Close both manifold hand valves.

Recovering Refrigerant

Caution: The

Recovery-Recycle-Recharging

equipment

has

special fittings to avoid

cross

contamination with

R-

12

systems.

Do not attempt to adapt

this

unit for

R-12

as

system

failure will

result.

Warning: Follow the safety procedures

as

defined at the

beginning of the section.

Caution: The unit's overfill limitation mechanism has

been

calibrated specifically for

use

with

the 50

lb.

(23 Kg)

refillable refrigerant

tank.

As the refrigerant is recovered it is passed through

an oil separator and

a

filter drier before it is allowed

to enter the refrigerant tank. When it is dry the

moisture indicator turns green.

May 1996 8-47