service ASTON MARTIN DB7 1997 Owner's Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 296 of 421

^2?

Air Conditioning

Electronic Control Module

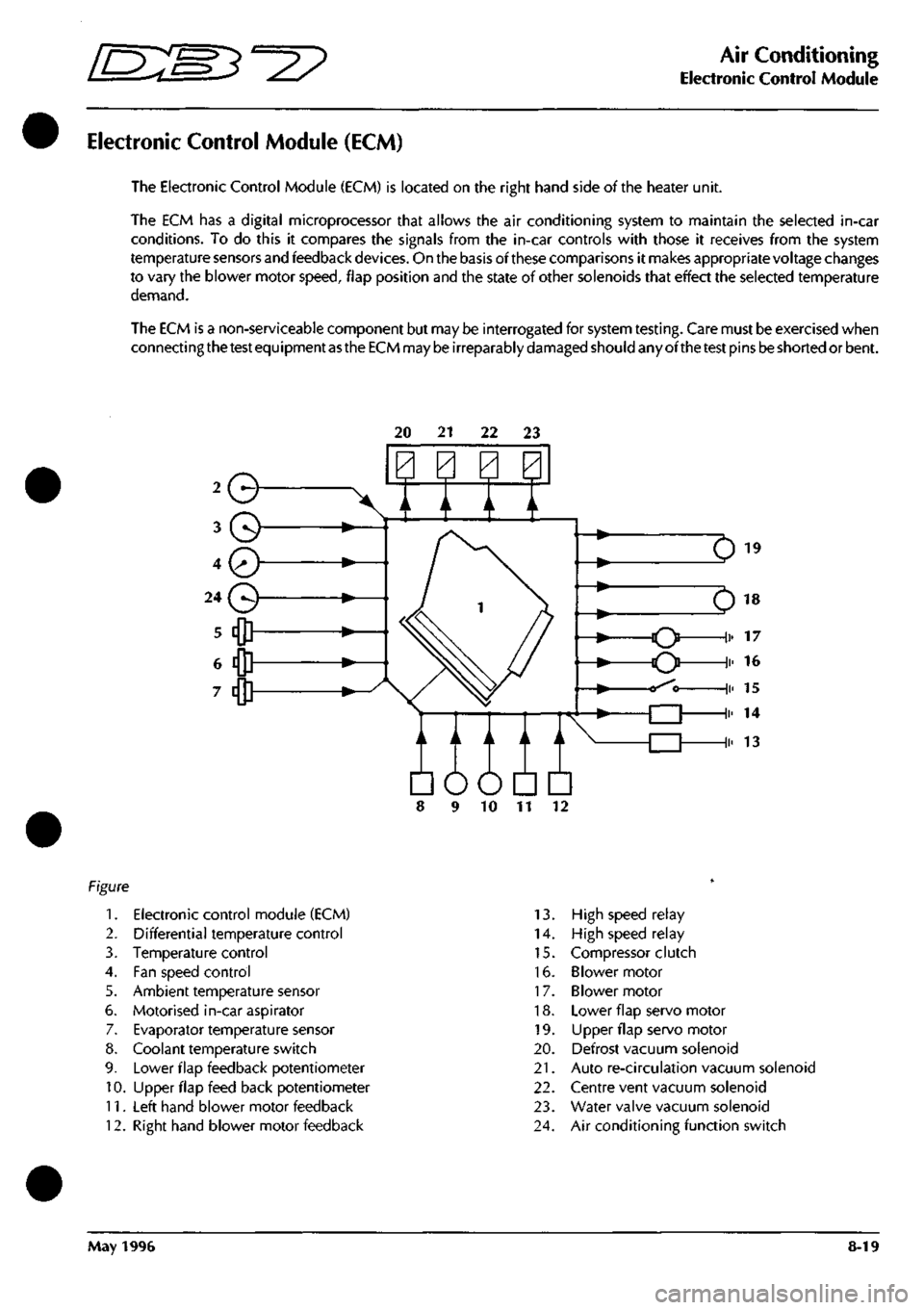

Electronic Control Module (ECM)

The Electronic Control Module (ECM) is located on the right hand side of the heater unit.

The ECM has a digital microprocessor that allows the air conditioning system to maintain the selected in-car

conditions. To do this it compares the signals from the in-car controls with those it receives from the system

temperature sensors and feedback

devices.

On the basis of these comparisons it makes appropriate voltage changes

to vary the blower motor

speed,

flap position and the state of other solenoids that effect the selected temperature

demand.

The ECM is a non-serviceable component but may be interrogated for system

testing.

Care must be exercised when

connecting

the test

equipment

as the ECM

may

be

irreparably

damaged

should any ofthe

test

pins

be

shorted or bent.

20 21 22 23

Q

A / A \/

Em

10 11

1.

Electronic control module (ECM)

2.

Differential temperature control

3. Temperature control

4.

Fan speed control

5. Ambient temperature sensor

6. Motorised in-car aspirator

7. Evaporator temperature sensor

8. Coolant temperature switch

9. Lower flap feedback potentiometer

10.

Upper flap feed back potentiometer

11.

Left hand blower motor feedback

12.

Right hand blower motor feedback

13.

High speed relay

14.

High speed relay

15.

Compressor clutch

16.

Blower motor

17.

Blower motor

18.

Lower flap servo motor

19.

LIpper flap servo motor

20.

Defrost vacuum solenoid

21.

Auto re-circulation vacuum solenoid

22.

Centre vent vacuum solenoid

23.

Water valve vacuum solenoid

24.

Air conditioning function switch

May 1996 8-19

Page 314 of 421

^?

Air Conditioning

Sanden Compressor SD7H15

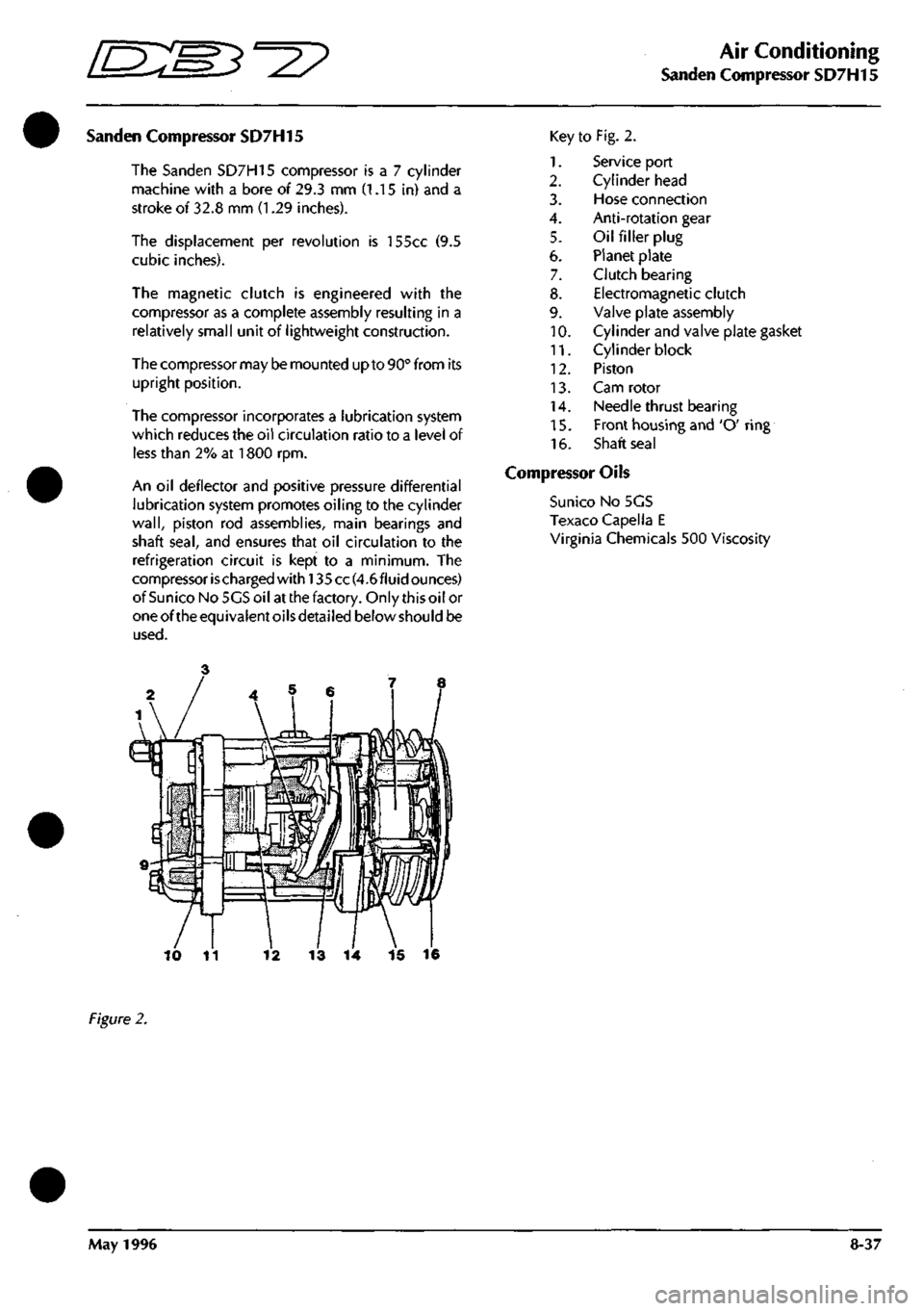

Sanden Compressor SD7H15

The Sanden SD7H15 compressor

is a 7

cylinder

machine with

a

bore

of

29.3

mm (1.15 in) and a

stroke

of

32.8

mm (1.29

inches).

The displacement

per

revolution

is

155cc

(9.5

cubic inches).

The magnetic clutch

is

engineered with

the

compressor

as a

complete assembly resulting

in a

relatively small unit

of

lightweight construction.

The compressor may be mounted up to 90° from

its

upright position.

The compressor incorporates

a

lubrication system

which reduces the

oil

circulation ratio

to a

level

of

less than

2% at 1800 rpm.

An

oil

deflector

and

positive pressure differential

lubrication system promotes oiling

to the

cylinder

wall,

piston

rod

assemblies, main bearings

and

shaft

seal,

and

ensures that

oil

circulation

to the

refrigeration circuit

is

kept

to a

minimum.

The

compressor ischarged

with!

35 cc(4.6fluid ounces)

ofSunico NoSGSoil at the factory. Only this oil

or

oneoftheequivalentoilsdetailed below should

be

used.

Key

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

to Fig. 2.

Service port

Cylinder head

Hose connection

Anti-rotation gear

Oil filler plug

Planet plate

Clutch bearing

Electromagnetic clutch

Valve plate assembly

Cylinder and valve plate gasket

Cylinder block

Piston

Cam rotor

Needle thrust bearing

Front housing and 'O' ring

Shaft seal

Compressor Oils

Suni

CO

No 5GS

Texaco Capella E

Virginia Chemicals 500 Viscosity

13

14 15 16

Figure

2.

May

1996

8-37

Page 315 of 421

Air Conditioning

Manifold Gauge Set 5=2?

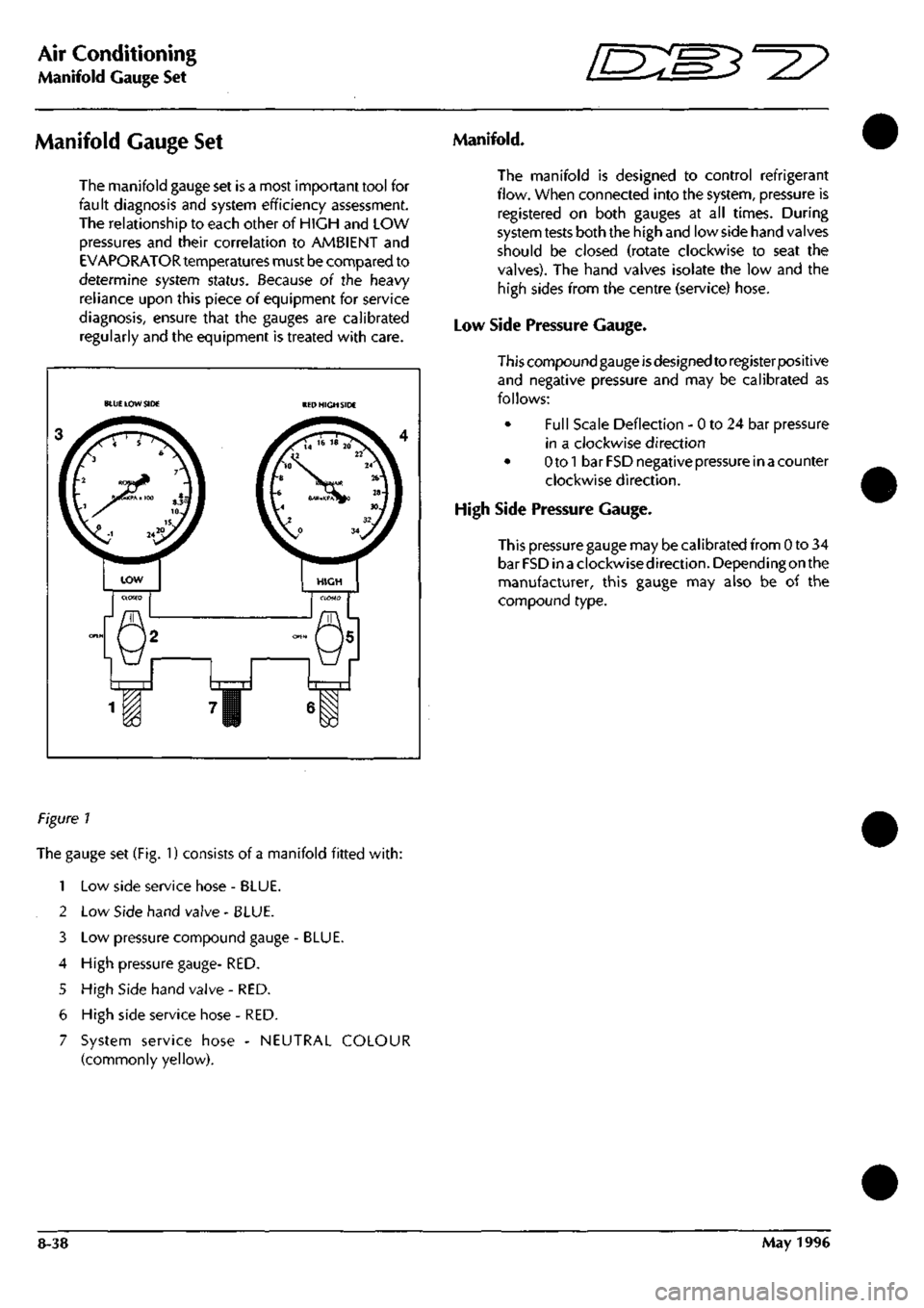

Manifold Gauge Set

The manifold gauge set is a most important tool for

fault diagnosis and system efficiency assessment.

The relationship to each other of HIGH and LOW

pressures and their correlation to AMBIENT and

EVAPORATOR temperatures must be compared to

determine system status. Because oi the heavy

reliance upon this piece of equipment for service

diagnosis, ensure that the gauges are calibrated

regularly and the equipment is treated with care.

BLUE LOW SIDE RED HIGH SIDE

LOW

m

m

Manifold.

The manifold is designed to control refrigerant

flow. When connected into the system, pressure is

registered on both gauges at all times. During

system tests both the high and low side hand valves

should be closed (rotate clockwise to seat the

valves). The hand valves isolate the low and the

high sides from the centre (service) hose.

Low Side Pressure Gauge.

This compound gauge

is

designed to register positive

and negative pressure and may be calibrated as

follows:

• Full Scale Deflection - 0 to 24 bar pressure

in a clockwise direction

• Otol bar FSD negative pressure in a counter

clockwise direction.

High Side Pressure Gauge.

This pressure gauge may be calibrated from 0 to 34

bar FSD inaclockwisedirection. Depending on the

manufacturer, this gauge may also be of the

compound type.

Figure 1

The gauge set (Fig. 1) consists of a manifold fitted

with:

1 Low side service hose - BLUE.

2 Low Side hand valve - BLUE.

3 Low pressure compound gauge - BLUE.

4 High pressure gauge- RED.

5 High Side hand valve - RED.

6 High side service hose - RED.

7 System service hose - NEUTRAL COLOUR

(commonly yellow).

8-38 May 1996

Page 352 of 421

^?

The Aston Martin Lagonda Diagnostic System

Contents

Installation Instructions

Introduaion 9-2

The Aston Martin Diagnostic System 9-2

Diagnostic System Cables 9-5

Base Station Installation 9-8

Problem Solving 9-16

Service Centres 9-21

Service and Maintenance 9-22

Technical Specifications 9-24

Operating Instructions

The Aston Martin Lagonda Diagnostic System 9-27

Software 9-29

Cable Setup 9-31

Diagnostic Sockets - 97 MY 9-31

Establishing Communications 9-32

System Menu Selections 9-32

PDU Use 9-32

Engine Diagnostics - 97 MY 9-33

Transmission Diagnostics 9-40

Climate Control Diagnostics 9-43

Anti-Lock Brakes Diagnostics 9-43

Passive Anti-Theft (PATS) Diagnostics 9-44

Airbag System Diagnostics 9-45

Seat Belt Pretensioner Diagnostics 9-47

Print Facility 9-49

Digital Multimeter 9-50

Diagnostic Trouble Codes 9-53

Datalogger 9-55

Datalogger Example 9-63

Training 9-66

OBD II Scan Tool 9-66

System Self Test 9-69

The Asterisk (*) Menu 9-69

System Setup 9-70

May 1996 9-1

Page 353 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions E:MB^^?

Introduction The Aston Martin Diagnostic System

This guide contains instructions for the installation

of the Portable Diagnostic Unit hardware in Aston

Martin Dealer workshops. To achieve maxinnum

benefit from the system, please follow the

instructions carefully. The following System

Diagram shows the principal system components

and panel details.

This introduction briefly describes the system and

its capabilities. This is followed by the Installation

and Power-Up procedures which give detailed

instruaions on how to start the system and access

the self-contained Interactive

Training

Programme.

The subsequent sections detail the fault diagnosis

and maintenance procedures.

WARNING:

The equipment must

only

be used by

trained

personnel.

Care should

be taken to use the

equipment in accordance with the operating

procedures.

Observe

all safety

warnings

in this

guide.

If any part of

the system is damaged do not

use it. Call your local CenRad

Service

Centre

immediately

for a

substitute

part.

Refer to

'Parts

Ordering'.

The Aston Martin Diagnostic System is a new

generation diagnostic

tool

which fulfils

a

number of

functions in aiding the technician to quickly and

accurately locate faults. The heart of the system is

the Portable Diagnostic

Unit,

a

lightweight powerful

computer/measurement system providing a step-

by-step user friendly interface for the technician.

PDU functions include:

Data Logger - The ability to monitor and record

control module signals even whilst the vehicle is

being driven.

On-Line Help-Containing detailed descriptions in

the

operation

ofthevehicleselectroniccomponents.

Vehicle Setup - The ability to setup various

adjustable parameters to their optimum settings.

Diagnostic Trouble Codes - The ability to extract

recorded fault information from the DB7's control

modules.

Each of

these

funaions is described in detail in the

PDU Users Guide.

WARNING: If

the system is used to measure high

voltages,

these voltages can appear on the pins of

other

connectors in

the

system.

Ensure

that socket

covers

are

fitted

on

unused

sockets.

Ensure

that all

connections

are

made

prior to

applying the high

voltage to

the

probes.

Do not

leave the equipment

unattended

in

this

state.

The maximum

voltage

that may be applied

between the

test

probes is 150

volts

AC or DC.

Radio Interference Statements

This digital apparatus does not exceed the Class A

limits for radio noiseemissionsfromdigital apparatus

as set

out

in

the radio interference regulations of the

Canadian Department of Communications.

This equipment has been tested and found to

comply with the limits for Class A digital device

pursuant to part 15 of the Federal Communications

Commission (FCC) rules. However, operation in

close proximity to domestic communication

equipment may cause interference. It is the

responsibility of the user to avoid or correct this

condition.

9-2 May 1996

Page 361 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions

[ES^'^?

Powering-Up the Base Station

When first operating the System or when first using

a PDU fitted with substitute batteries, it will take up

to36 hourstoachievefull charge. Inthemeantime,

the PDU can be used whilst connected to the base

station or to the vehicle battery.

Vi/\RNmGS:

When using the system equipment, basic safety

precautions should always be followed, including:

Carefully read and follow all instructions.

Care should be taken as burns can occur from

touching hot parts.

Do not operate the appliance with a damaged

mains lead or if the appliance has been dropped or

damaged. Call your local GenRad Service Centre

immediately for a substitute

part.

Do not let the mains lead hang over the

edge

of the

table, bench or counter or come into contact with

hot manifolds or moving fan blades.

The Aston Martin Portable Diagnostic Unit

is

fitted with an

auto switching power supply suitable for voltage supplies

of 100 - 240 VAC 50 - 60 Hz. You need only check that

the power cord connector is of the correct type for your

power outlets.

1.

Connect the mains lead to the mains outlet.

2.

Check that the green indicator lamp above the base

station door is illuminated. If the green lamp does

not come on, see the problem solving section for

advice.

3. After a few seconds, during which the electronics

module completes its self-test, the red OK indicator

lamp should illuminate. If the red lamp does not

come on, see the problem solving section for

advice.

4.

Allow the base station electronics module to reach

working temperature. This will take approximately

BOminutes, after which time the base station will be

ready to accept the software on CD-ROM.

5. Slide the PDU into its carrying case and place the

associated cables and probes in the carrying case

compartments.

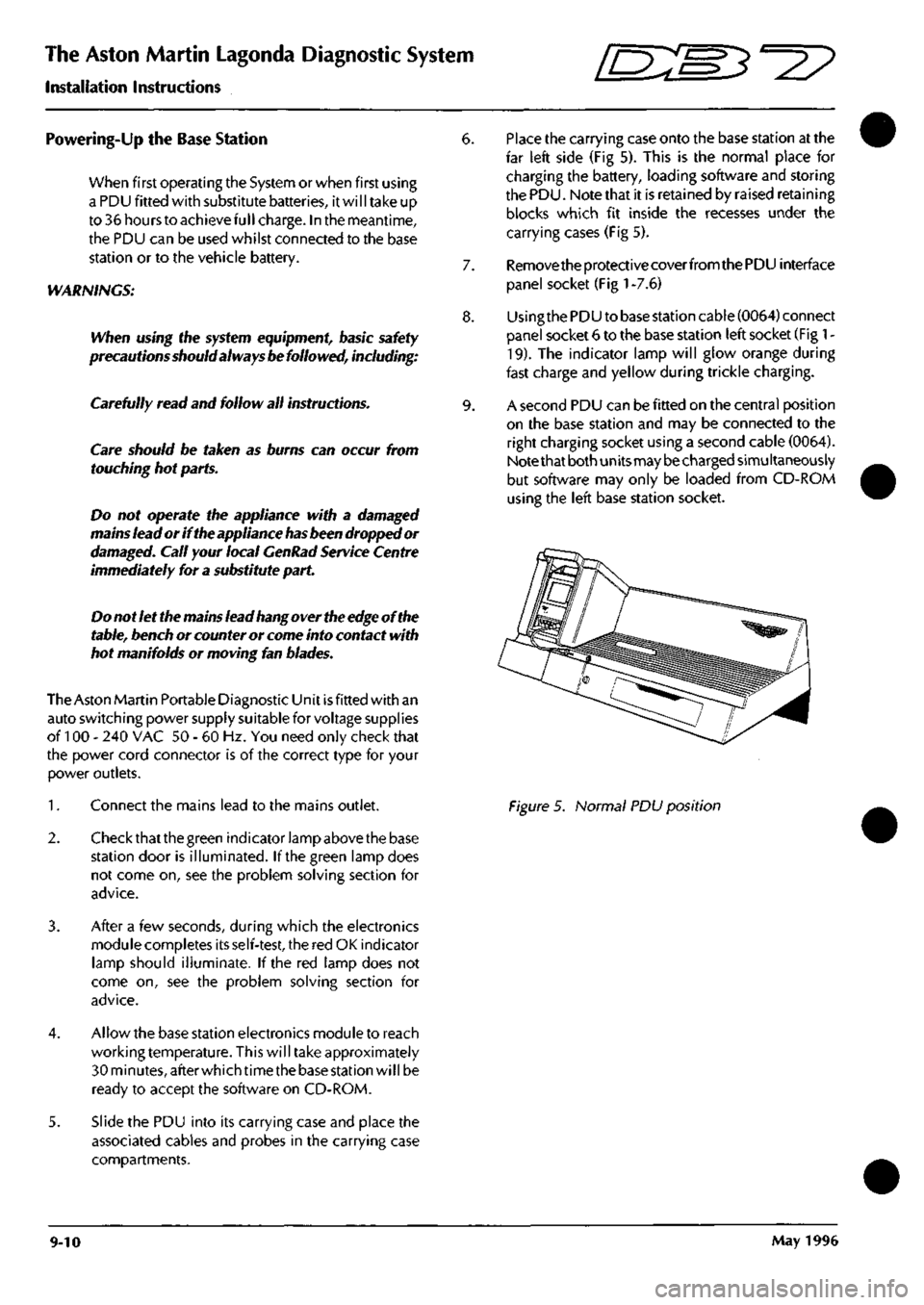

6. Place the carrying case onto the base station at the

far left side (Fig 5). This is the normal place for

charging the battery, loading software and storing

the PDU. Note that it is retained by raised retaining

blocks which fit inside the recesses under the

carrying cases (Fig 5).

7. Remove the protective coverfromthe PDU interface

panel socket (Fig

1

-7.6)

8. Usingthe PDU to base station cable (0064) connect

panel socket 6 to the base station left socket (Fig

1

-

19).

The indicator lamp will glow orange during

fast charge and yellow during trickle charging.

9. A second PDU can be fitted on the central position

on the base station and may be connected to the

right charging socket using a second cable (0064).

Note that both units may be charged simultaneously

but software may only be loaded from CD-ROM

using the left base station socket.

Figure 5. Normal PDU position

9-10 May 1996

Page 366 of 421

r^ ' ^ ^ The Aston Martin Lagonda Diagnostic System

Installation Instructions

Finishing the Test

When data analysis is finished, switch off the PDU

and disconnect it from the vehicle. Store the PDU

and cables in the carrying case and refit the case to

the base station.

Connect the PDU to the base station using cable

0064.

The base station will keep the PDU batteries

fully charged at all times (Fig 15).

Figure 15. PDU connected for recharging

Care of the Equipment

CAUTION: With the exception of those parts

referred to in the Servicing and Maintenance

section, there are no user serviceable parts. All

servicing must be carried out by GenRad Service

Centres.

Switch offthe power before cleaningtheequipment.

The Aston Martin Diagnostic System should only

be cleaned using a non-abrasive, mild cleaning

agent. Dust and other particles should be lightly

brushed from the surface before

cleaning.

Cleaning

agent should be applied to a soft lint-free cleaning

cloth and never directly to the unit. Do not soak the

cleaning cloth and take care not to allow cleaning

fluid to enter connectors.

CAUTION: Ifany liquid is spilt on theequipment,

switch off immediately.

Ensure

that the equipment

has

dried out completely before operating it again,

especially in connectors where fluid can lodge.

May 1996 9-15

Page 367 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions ^7

Problem Solving

CAUTION: If any part of the

system

is damaged, do not use it. Call your local GenRad Service Centre immediately for

a substitute

part.

Refer to 'Parts Ordering'.

CAUTION: With the exception of

those

parts referred to in the Servicing and Maintenance section, there are no user

serviceable parts. All servicing must be carried out by GenRad Service Centres.

PDU Self-Test

The system self test routine should be run periodically even if there are no apparent problems with the system.

Running the system self-test will identify any problems before they impact on productivity.

If it is suspected that the system is operating incorrectly, run the PDU system self test option on the main menu).

If the system self test will not run, or the PDU will not switch on, the instructions in this section must be followed

carefully.

If one of the fol lowing test steps advises you to order or fit a new part, make a note of the test step, part number and

description. Then follow the parts ordering procedure later in this section.

Stepi

Connect the mains power to the base station. Is the green base station indicator illuminated?

YES - Go to step 4

NO - Go to step 2

Step 2

Check the mains supply, then check the mains

lead.

Is

the mains lead faulty?

YES - Renew the mains

lead.

NO - Go to step 3

Step 3

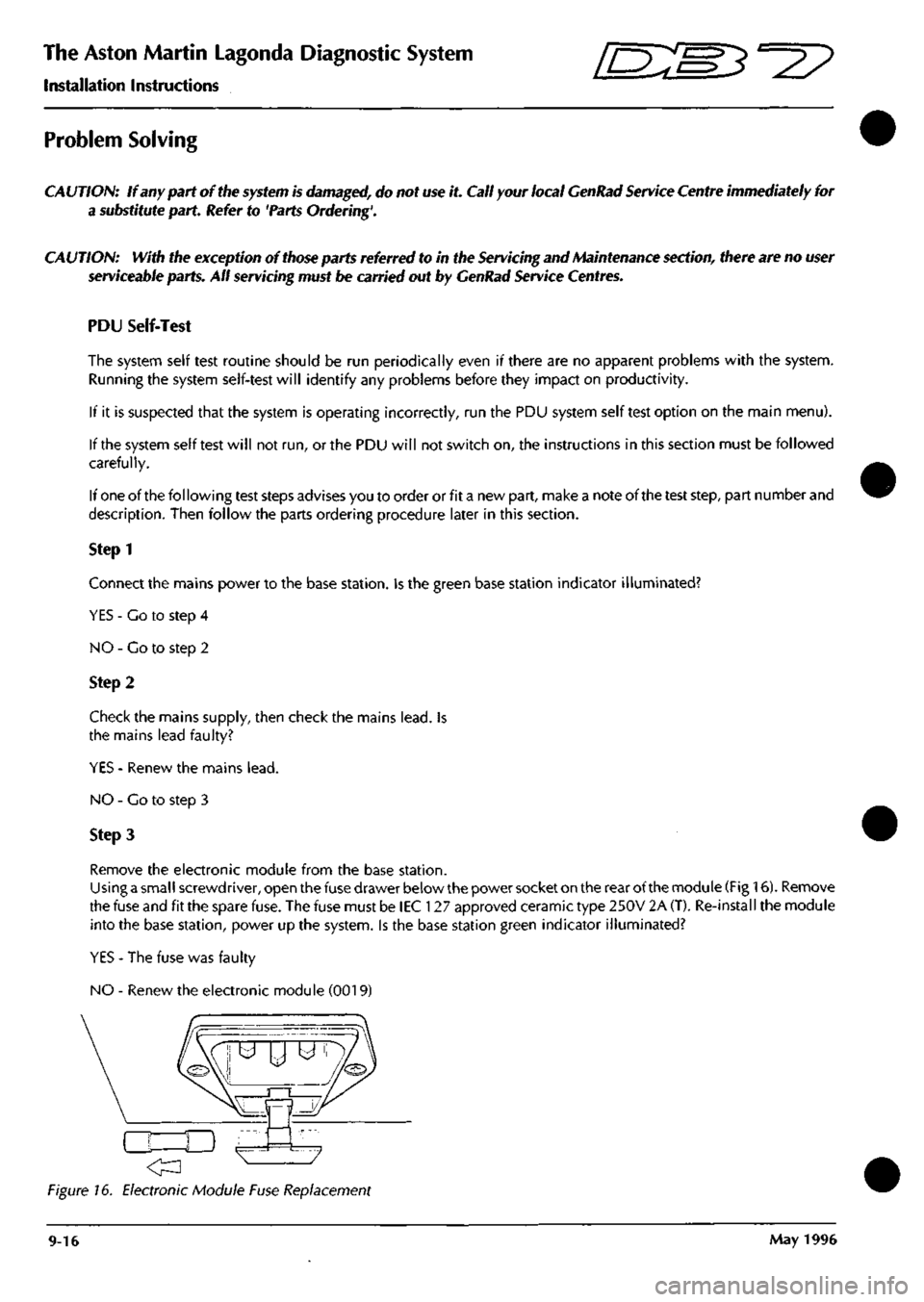

Remove the electronic module from the base station.

Using a small screwdriver, open the fuse drawer below the power socket on the rear of the module (Fig 16). Remove

the fuse and fit the spare fuse. The fuse must be lEC 127 approved ceramic type 250V 2A (T). Re-install the module

into the base station, power up the system. Is the base station green indicator illuminated?

YES - The fuse was faulty

NO - Renew the electronic module (0019)

Figure 16. Electronic Module Fuse Replacement

9-16 May 1996

Page 370 of 421

^^

The Aston Martin Lagonda Diagnostic System

Installation Instructions

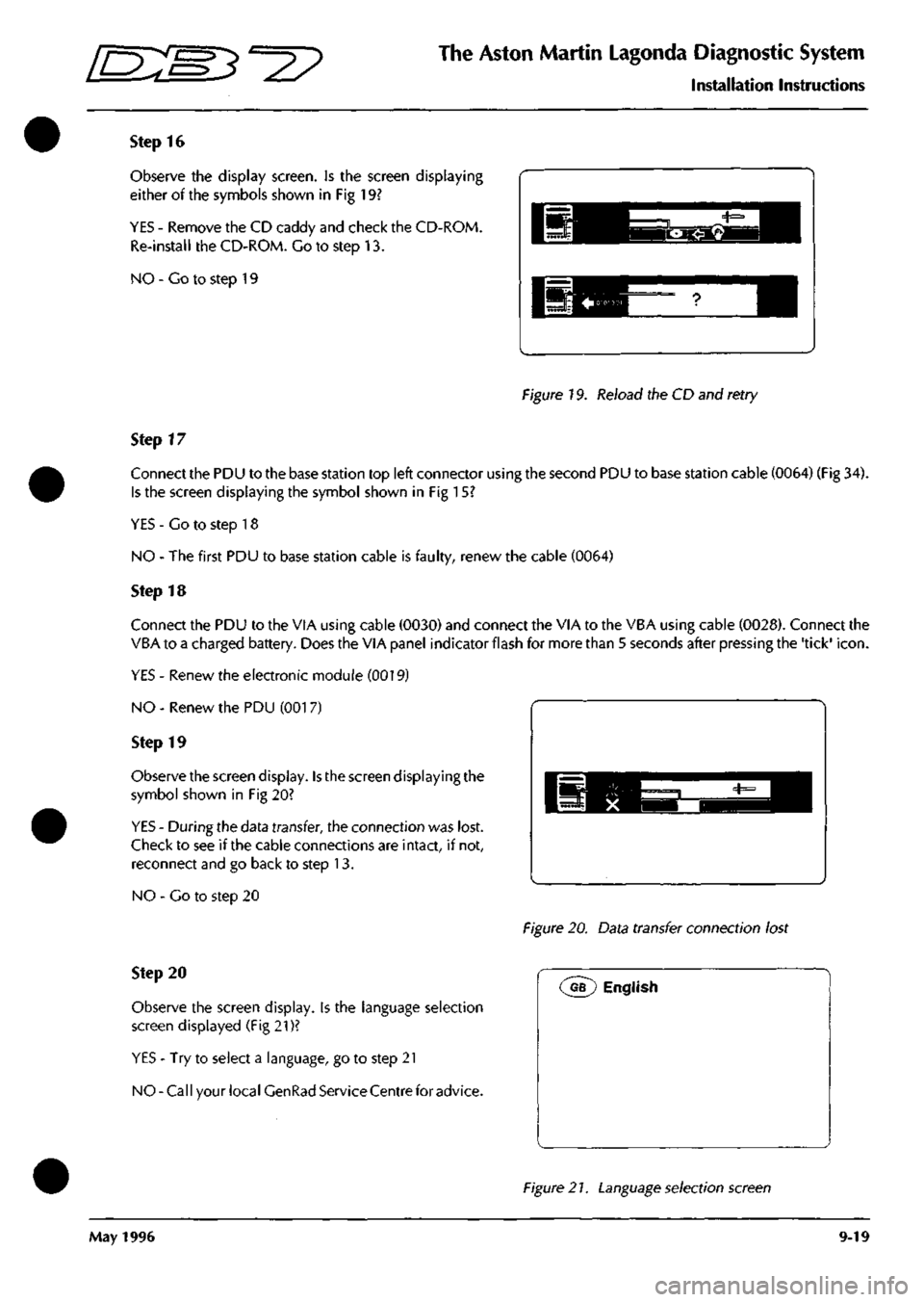

Step 16

Observe the display screen. Is the screen displaying

either of the symbols shown in Fig 19?

YES - Remove the CD caddy and check the CD-ROM.

Re-install the CD-ROM. Go to step 13.

NO - Co to step 19

Figure 19. Reload the CD and retry

Step 17

Connect the PDU to the base station top left connector using the second PDU to base station cable (0064) (Fig 34).

Is the screen displaying the symbol shown in Fig 15?

YES - Go to step 18

NO - The first PDU to base station cable is faulty, renew the cable (0064)

Step 18

Connect the PDU to the VIA using cable (0030) and connect the VIA to the VBA using cable (0028). Connect the

VBA to a charged battery. Does the VIA panel indicator flash for more than 5 seconds after pressing the 'tick'

icon.

YES - Renew the electronic module (0019)

NO - Renew the PDU (001 7)

Step 19

Observe the screen display. Is the screen displaying the

symbol shown in Fig 20?

YES - During the data transfer, the connection was lost.

Check to see if the cable connections are intact, if not,

reconnect and go back to step 13.

NO - Go to step 20

Figure 20. Data transfer connection lost

Step 20

Observe the screen display, is the language selection

screen displayed (Fig 21)?

YES - Try to select a language, go to step 21

NO-Call your local GenRad Service Centre for advice.

(^G?) English

Figure 2

7.

Language selection screen

May 1996 9-19

Page 371 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions =27

step 21

Observe the screen display. Is the system loading from the CD-ROM?

YES - Go to step 13.

NO - Renew the PDU (001 7).

Parts Ordering

Before calling GenRad, it is essential that the system self test is run from the main menu. If the system self test will

not run or the PDU does not switch on, follow the Problem Solving procedures.

The system self test option will identify any fau It and display a fault code on the PDU screen. This fault code number

must be recorded. When in contact with your local GenRad Service Centre, they will require this number in order

to send the correct substitute parts.

Before calling the GenRad Service Centre, please have the following information available.

Dealer Name and Address

Name of the contact at that address

PDU Serial Number (base station LHS - Fig 22)

Fault Code, Component Name and Serial Number as given on the PDU screen during self test.

Ifthe system self test will not run, GenRad will require the name and part number ofthe component identified during

he Problem Solving Procedures.

Figure 22. Diagnostic System Serial Number

9-20 May 1996