belt ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 10 of 421

Electrics

Electrical Component Location and Wiring Information - Up to 97 MY

Component Index 6-19

Component Location Diagrams 6-23

Electronic Control Unit Location Diagram 6-38

Relay Panel, Fusebox and Earth Point Location Diagram 6-39

Loom Location Diagrams 6-40

Wiring Diagrams and Splice Lists 6-42

Electrical Component Location and Wiring Information - 97 MY

Component Index 6-43

Component Location Diagrams 6-47

Relay Location Diagrams 6-64

Wiring Diagrams and Splice Lists 6-68

Airbag System - Repair and Diagnostic Procedures 6-69

Seat Belt Pretensioner System - Repair and Diagnostic Procedures 6-101

Security System (Restricted Circulation) 6-111

PATS System (Restricted Circulation) 6-121

97.5 Model Year

6.6.03 Seat Removal (97.5 MY)

6.6.08 Seat Control Module (97.5 MY)

6-127

6-128

6-2 April! 997

Page 13 of 421

[EM^^^

Electrics

Wiper Motor / Alternator - Removal Procedures

6.2.01 Windscreen Wiper Motor 6.3.01 Alternator

Procedure

1.

Disconnect the battery.

2.

Disconnect the wiper motor multi-plug.

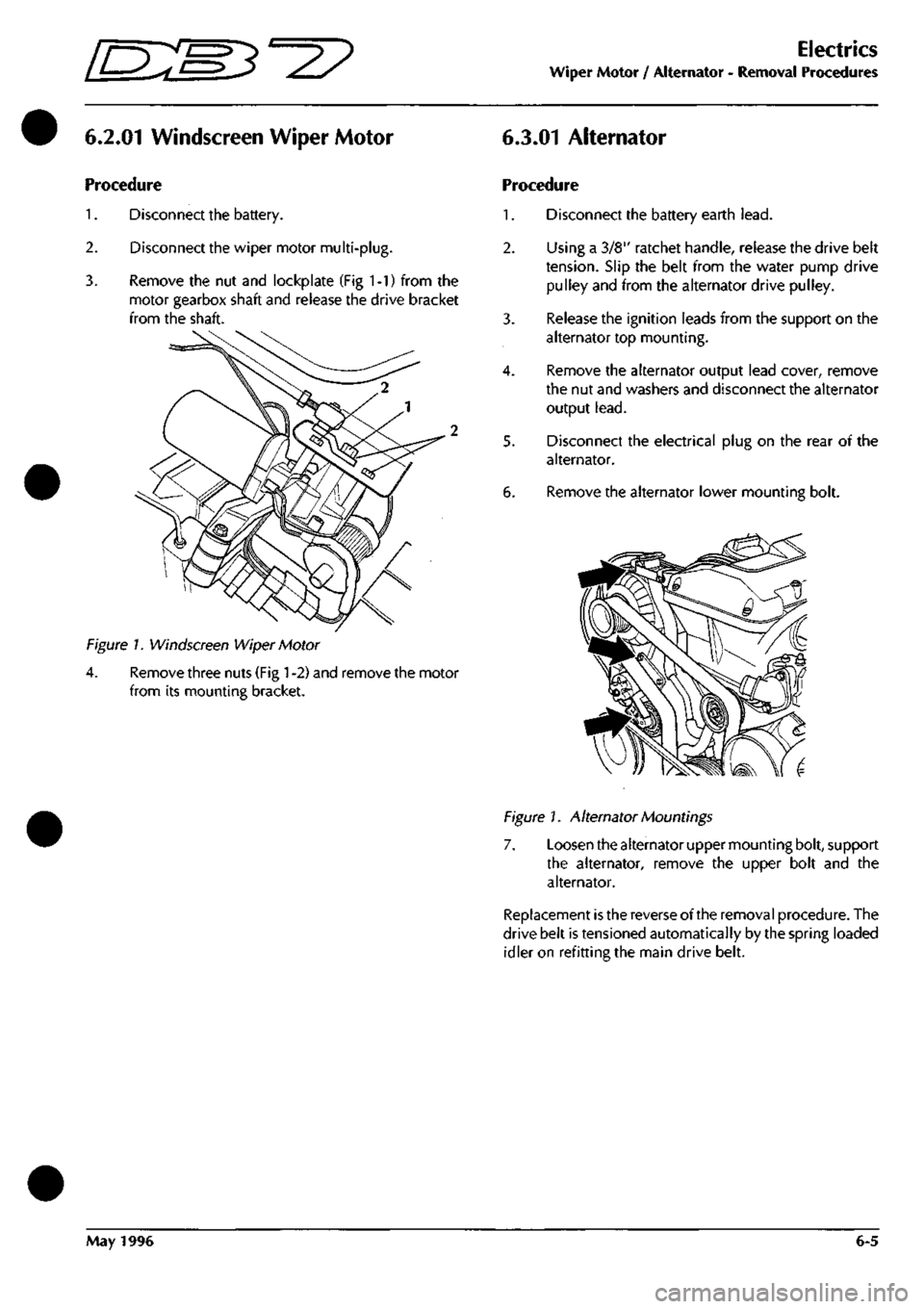

3. Remove the nut and lockplate (Fig 1-1) from the

motor gearbox shaft and release the drive bracket

from the shaft.

Figure 1. Windscreen Wiper Motor

4.

Remove three nuts (Fig

1

-2) and remove the motor

from its mounting bracket.

Procedure

1.

Disconnect the battery earth

lead.

2.

Using a 3/8" ratchet handle, release the drive belt

tension.

Slip the belt from the water pump drive

pulley and from the alternator drive pulley.

3. Release the ignition leads from the support on the

alternator top mounting.

4.

Remove the alternator output lead cover, remove

the nut and washers and disconnect the alternator

output

lead.

5. Disconnect the electrical plug on the rear of the

alternator.

6. Remove the alternator lower mounting bolt.

Figure 1. Alternator Mountings

7. Loosen the alternator upper mounting bolt, support

the alternator, remove the upper bolt and the

alternator.

Replacement is the reverse of the removal procedure. The

drive belt is tensioned automatically by the spring loaded

idler on refitting the main drive belt.

May 1996 6-5

Page 19 of 421

Em3^^

Electrics

Front Seat Runner and Rail Motor - Removal Procedures

6.6.04 Front Seat Runner Assembly

Procedure

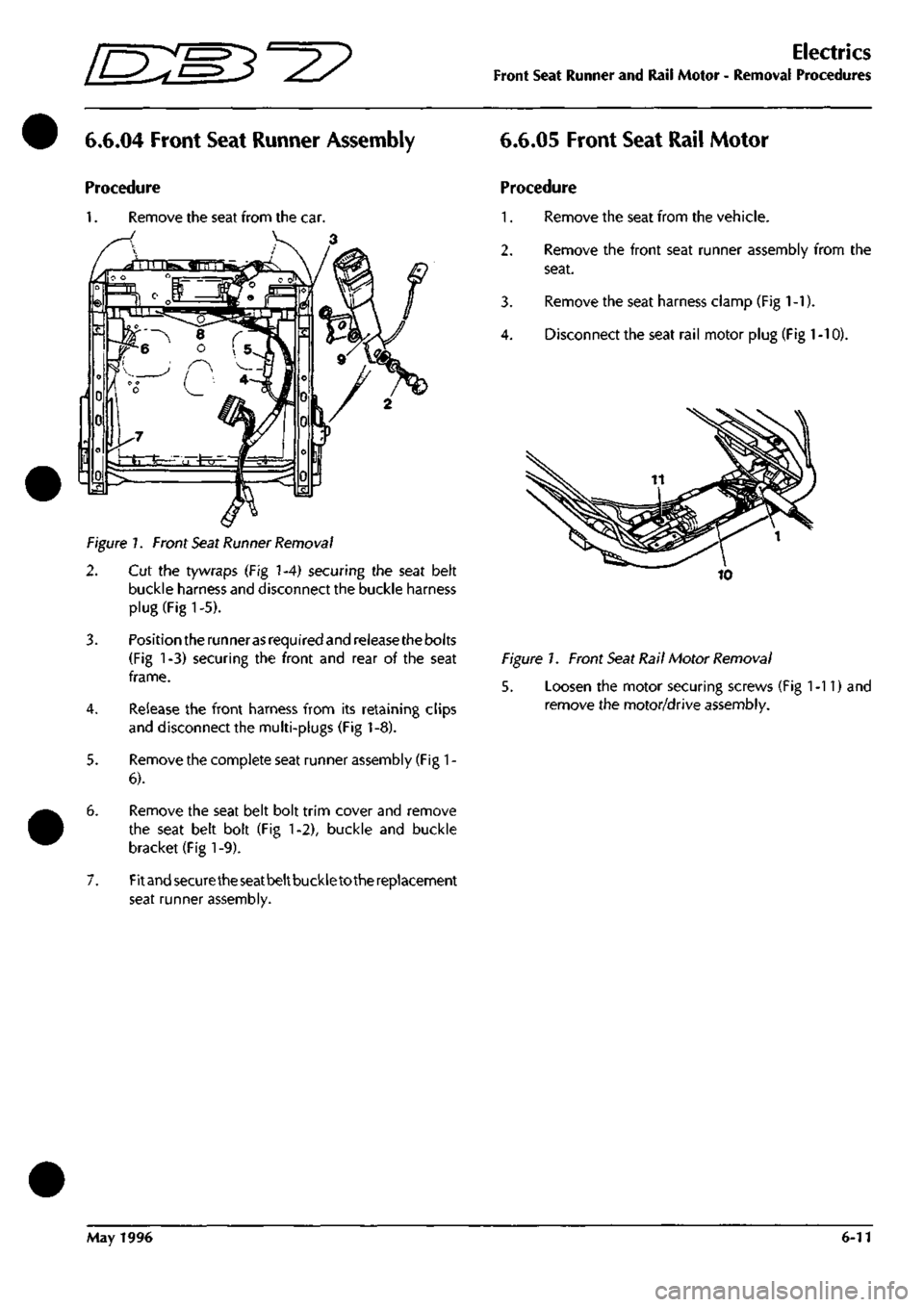

1.

Remove the seat from the car.

7>

Figure 1. Front Seat Runner Removal

2. Cut the tywraps (Fig 1-4) securing the seat belt

buckle harness and disconnect the buckle harness

plug (Fig 1-5).

3. Position the runneras required and release the bolts

(Fig 1-3) securing the front and rear of the seat

frame.

4.

Release the front harness from its retaining clips

and disconnect the multi-plugs (Fig 1-8).

5. Remove the complete seat runner assembly (Fig

1

-

6).

6. Remove the seat belt bolt trim cover and remove

the seat belt bolt (Fig 1-2), buckle and buckle

bracket (Fig 1-9).

7. Fitandsecuretheseatbeltbuckletothereplacement

seat runner assembly.

6.6.05 Front Seat Rail Motor

Procedure

1.

Remove the seat from the vehicle.

2.

Remove the front seat runner assembly from the

seat.

3. Remove the seat harness clamp (Fig

1

-1).

4.

Disconnect the seat rail motor plug (Fig

1

-10).

Figure 1. Front Seat Rail Motor Removal

5. Loosen the motor securing screws (Fig 1-11) and

remove the motor/drive assembly.

May 1996 6-11

Page 30 of 421

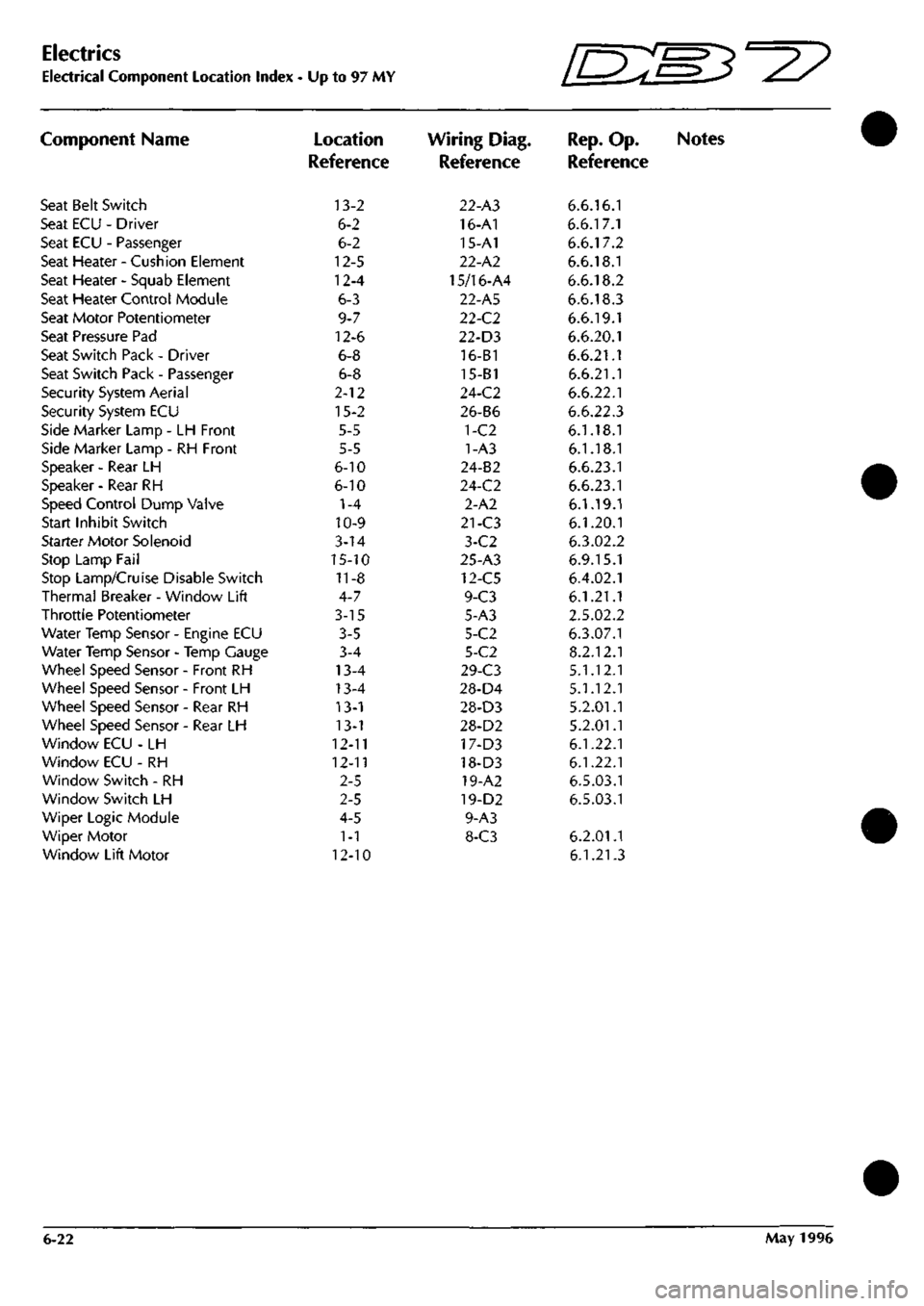

Electrics

Electrical Component Location Index - Up to 97 MY

Component Name

Seat Belt Switch

Seat ECU - Driver

Seat ECU - Passenger

Seat Heater - Cushion Element

Seat Heater - Squab Element

Seat Heater Control Module

Seat Motor Potentiometer

Seat Pressure Pad

Seat Switch Pack - Driver

Seat Switch Pack - Passenger

Security System Aerial

Security System ECU

Side Marker Lamp - LH Front

Side Marker Lamp - RH Front

Speaker - Rear LH

Speaker - Rear RH

Speed Control Dump Valve

Start Inhibit Switch

Starter Motor Solenoid

Stop Lamp Fail

Stop Lamp/Cruise Disable Switch

Thermal Breaker - Window Lift

Throttle Potentiometer

Water Temp Sensor - Engine ECU

Water Temp Sensor - Temp Gauge

Wheel Speed Sensor - Front RH

Wheel Speed Sensor - Front LH

Wheel Speed Sensor - Rear RH

Wheel Speed Sensor - Rear LH

Window ECU - LH

Window ECU - RH

Window Switch - RH

Window Switch LH

Wiper Logic Module

Wiper Motor

Window Lift Motor

Location

Reference

13-2

6-2

6-2

12-5

12-4

6-3

9-7

12-6

6-8

6-8

2-12

15-2

5-5

5-5

6-10

6-10

1-4

10-9

3-14

15-10

11-8

4-7

3-15

3-5

3-4

13-4

13-4

13-1

13-1

12-11

12-11

2-5

2-5

4-5

1-1

12-10

Wiring Diag.

Reference

22-A3

16-A1

15-A1

22-A2

15/16-A4

22-A5

22-C2

22-D3

16-B1

15-B1

24-C2

26-B6

1-C2

1-A3

24-B2

24-C2

2-A2

21-C3

3-C2

25-A3

12-C5

9-C3

5-A3

5-C2

5-C2

29-C3

28-D4

28-D3

28-D2

17-D3

18-D3

19-A2

19-D2

9-A3

8-C3

Rep.

Op.

Reference

6.6.16.1

6.6.17.1

6.6.17.2

6.6.18.1

6.6.18.2

6.6.18.3

6.6.19.1

6.6.20.1

6.6.21.1

6.6.21.1

6.6.22.1

6.6.22.3

6.1.18.1

6.1.18.1

6.6.23.1

6.6.23.1

6.1.19.1

6.1.20.1

6.3.02.2

6.9.15.1

6.4.02.1

6.1.21.1

2.5.02.2

6.3.07.1

8.2.12.1

5.1.12.1

5.1.12.1

5.2.01.1

5.2.01.1

6.1.22.1

6.1.22.1

6.5.03.1

6.5.03.1

6.2.01.1

6.1.21.3

Notes

6-22 May 1996

Page 93 of 421

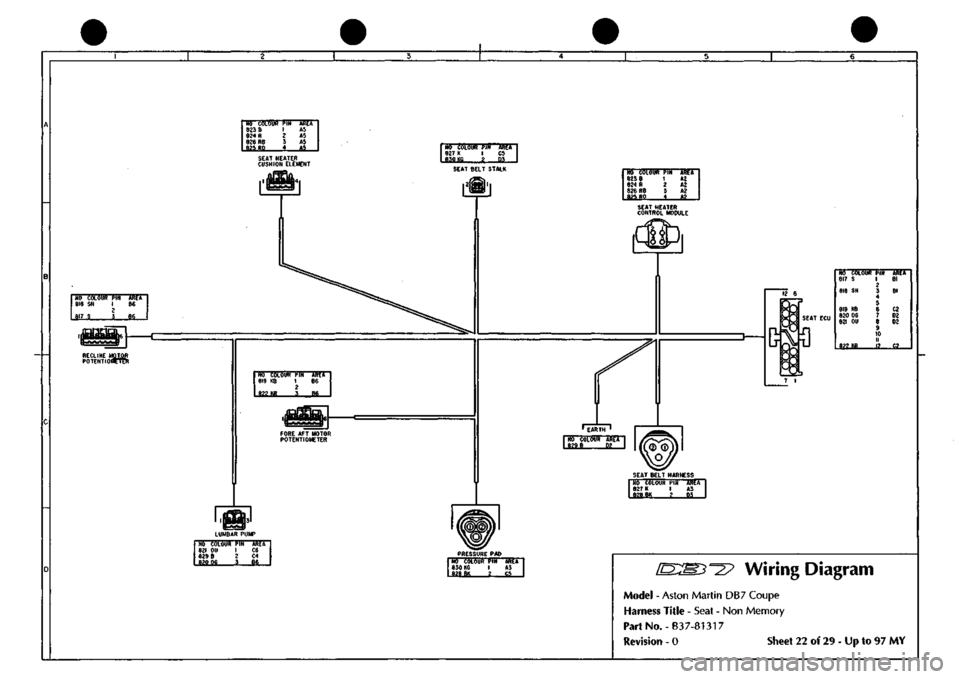

N6

WLdUlt PIN 823 8 I 824

R

2 826

R8

3 825

RO

1

Mi AS AJ AJ A5 SEAT HEATER CUSHION ELEMENT

NO COLOUR PIN 827

K

I 630 KG g

MET CS

SEAT BELT STALK NO COLOUR I^IN 823 8 1 824

R

2 826

R8

3 a?f,

RO

4

HdU A2 A2 A2

AJ

„

SEAT HEATER CONTROL MODULE

NO COLOUR

PIN

AREA 818

SN 1 B6

2 817

S 3 86

>iinBBU|6

RECLINE MOTOR POTENTIOBPTn!

NO COLOUI 817

S

818

SN

819

KB

820

06

821

OU

m

m

TUT 1 2

5 6 7

• li 12

-KKtr Bl

Bl

02 D2 02

C2

SEAT BELT HARNESS NO COLOUR

PIN 827 K 1 828

BK

2

ASA A3

ti

NO COLOUR

PIN

ARET

821

OU I C6

829

8 2 C4

620 06

I SSi.

PRESSURE

PAD

NO COLOUR

PIN

830 K6

I £iiM 2

AREA A3 i5_

[D:My^^2?

Wiring Diagram

Model - Aston Martin DB7 Coupe

Harness Title - Seat - Non Memory

PartNo.-B37-81317

Revision - 0 Sheet 22 of 29 - Up to 97 MY

Page 95 of 421

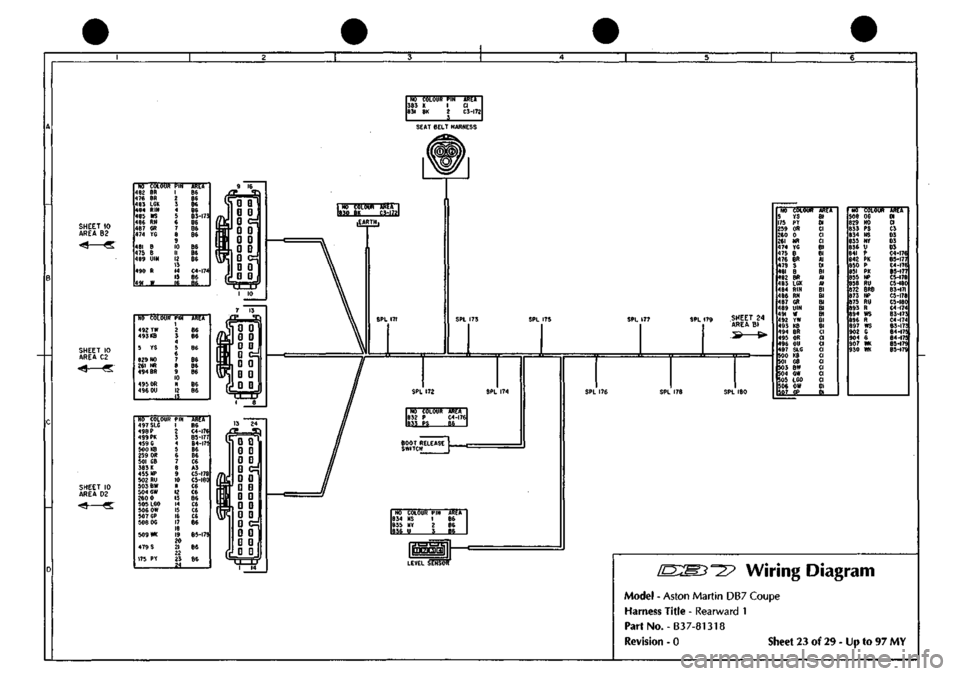

wmm-m—im: 383 K I a S3I BK 2 C3-I72 i

SHEET 10 AREA B2

NO

iii.m

M 482 BR 476 BR 483 LCK 484 RIN 483 WS 486 RN 487 GR 474 YG

481 B 475 B 489 UIN

490 R

49r W

1 2 3 4 3 6 7 8 9 10 II 12 13 14 15

...If...

mi B6 B6 B6 B6 B3-I73 86 86 86

86 B6 86

C4-I74 86 B6

NO COLOUR

492

YW

493 KB

5 YS

829

NO

261 NR 494 BR

495 OR 496 OU

PIN

2 3 4 5 6 7 8 9 10 II 12

.1?..

AitU

86 B6

B6

86 B6 86

86 B6

NO COLOUF 497 SLO 498 P 499 PK 459 0 500 KB 259

OR

SOI GB 383 K 455 NP 502

RU

503 BW 504

OW

260 0 505 LCO 506

OW

507

OP

508 015

509 WK

479

S

175 PY

PIN 1 2 3 4 5 6 7 8 9 10 II 1? 13 14 15 16 17 18 19 20 21 2? 23 21

AREA 86 C4-I76 85-177

84-17;

B6 B6 C6 A3 C5-I78 c5-ieo C6 C6 86 C6 C6 C6 86

85-179

86

86

SEAT BELT HARNESS

NO COLOUR PIN 834 NS 1 835 NY 2 836 U 3

AREA B6 B6 B6

NO COLOUR 5 YS 175 PY 259 OR 260 0 261 NR 474 YG 475 8 476 BR 479 S 481 8 482 BR 483 LGK 484 RIN 486 RN 487 6R 489 UIN 491 W 492 YW 493 KB 494 BR 495 OR 496 OU 497 SLG 500 KB 501 08 503 BW 504 «W 505 LGO 506 OW 507 GP

AREA Bl 01 CI CI CI Bl 81 Al 01 81 Al AI 81 81 81 81 81 Bl 81 CI CI CI CI CI CI a CI CI 01 Dl

NO 508 S?9 833 834 833 836 R4I 842 850 851 B55 838 872 873 875 893 894 896

89'

902 904 907 930

COLOUR OG NO PS NS NY U P PK P PK NP RU 8RD NP RU R WS R WS G 6 WK WK

arr a a C3 D3 D3 03 04-176 85-177 04-176 85-177 C5-I78 C5-I8C 83-171 05-178 C5-I8C C4-I74

83-17!

C4-I74

83-17!

B4-I7S

84-17!

85-179 B5-I79

Wiring Diagram

Model - Aston Martin DB7 Coupe

Harness Title - Rearward 1

PartNo.-B37-81318

Revision - 0 Sheet 23 of 29 - Up to 97 MY

Page 111 of 421

Electrics

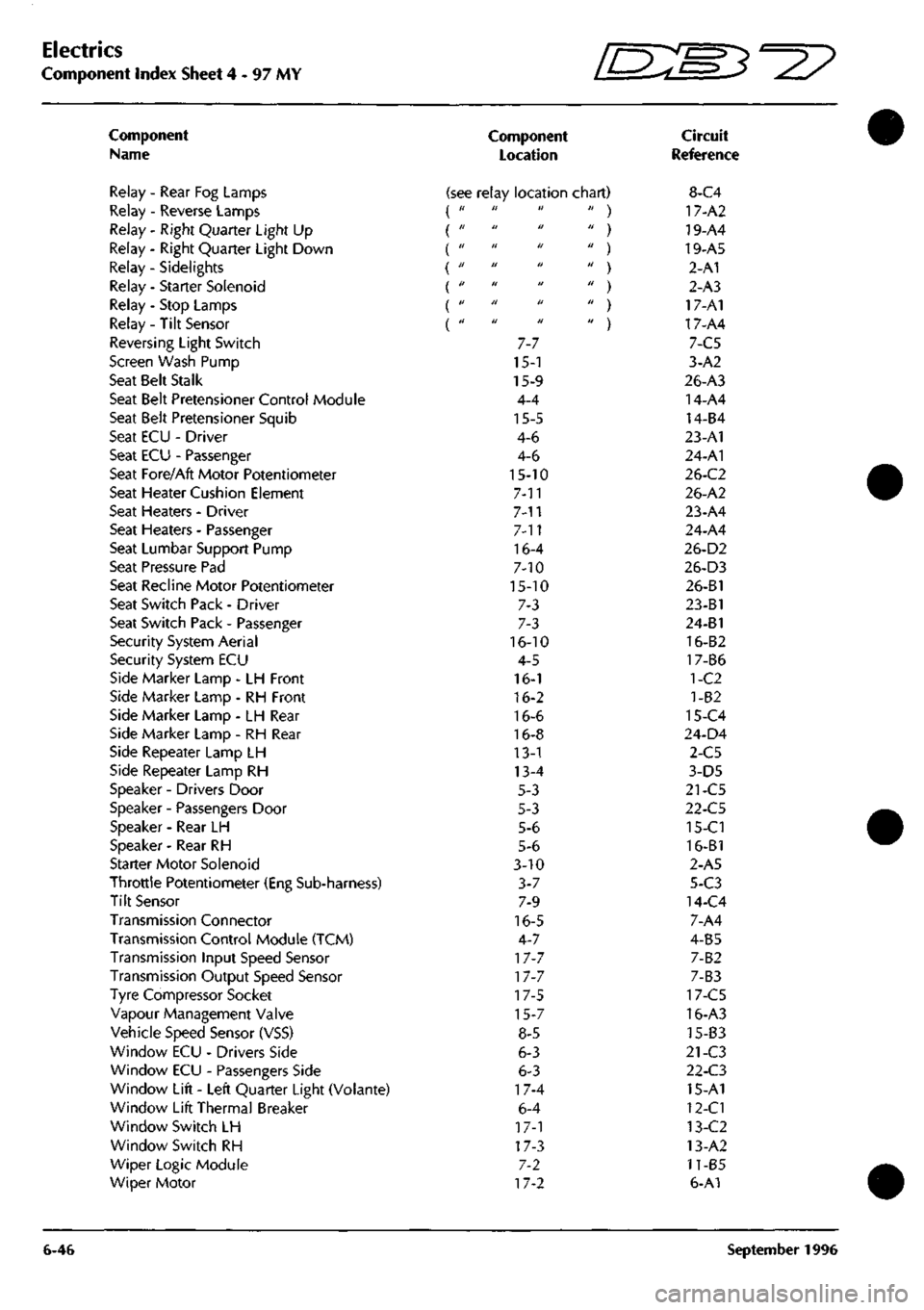

Component Index Sheet 4-97 MY ^7

Component

Name

Relay - Rear Fog Lamps

Relay - Reverse Lamps

Relay - Right Quarter Light Up

Relay - Right Quarter Light Down

Relay - Sidelights {

Relay - Starter Solenoid

Relay - Stop Lamps

Relay- Tilt Sensor

Reversing Light Switch

Screen Wash Pump

Seat Belt Stalk

Seat Belt Pretensioner Control Module

Seat Belt Pretensioner Squib

Seat ECU - Driver

Seat ECU - Passenger

Seat Fore/Aft Motor Potentiometer

Seat Heater Cushion Element

Seat Heaters - Driver

Seat Heaters - Passenger

Seat Lumbar Support Pump

Seat Pressure Pad

Seat Recline Motor Potentiometer

Seat Switch Pack - Driver

Seat Switch Pack - Passenger

Security System Aerial

Security System ECU

Side Marker Lamp - LH Front

Side Marker Lamp - RH Front

Side Marker Lamp - LH Rear

Side Marker Lamp - RH Rear

Side Repeater Lamp LH

Side Repeater Lamp RH

Speaker - Drivers Door

Speaker - Passengers Door

Speaker - Rear LH

Speaker - Rear RH

Starter Motor Solenoid

Throttle Potentiometer (Eng Sub-harness)

Tilt Sensor

Transmission Connector

Transmission Control Module (TCM)

Transmission Input Speed Sensor

Transmission Output Speed Sensor

Tyre Compressor Socket

Vapour Management Valve

Vehicle Speed Sensor (VSS)

Window ECU - Drivers Side

Window ECU - Passengers Side

Window Lift - Left Quarter Light (Volante)

Window Lift Thermal Breaker

Window Switch LH

Window Switch RH

Wiper Logic Module

Wiper Motor

6-46

Component

Location

Circuit

Reference

(see relay location chart) 8-C4 it ti It

II H U

tl 11 U

a II 11

II II II

II Ji II

II II II

7-7

15-1

15-9

4-4

15-5

4-6

4-6

15-10

7-11

7-n

7-11

16-4

7-10

15-10

7-3

7-3

16-10

4-5

16-1

16-2

16-6

16-8

13-1

13-4

5-3

5-3

5-6

5-6

3-10

3-7

7-9

16-5

4-7

17-7

17-7

17-5

15-7

8-5

6-3

6-3

17-4

6-4

17-1

17-3

7-2

17-2

' ) 17-A2

' ) 19-A4

' ) 19-A5

' ) 2-A1

' ) 2-A3

' ) 17-A1

' ) 17-A4

7-C5

3-A2

26-A3

14-A4

14-B4

23-A1

24-A1

26-C2

26-A2

23-A4

24-A4

26-D2

26-D3

26-B1

23-B1

24-B1

16-B2

17-B6

1-C2

1-82

15-C4

24-D4

2-C5

3-D5

21-C5

22-C5

15-Cl

16-B1

2-A5

5-C3

14-C4

7-A4

4-B5

7-B2

7-B3

17-C5

16-A3

15-B3

21-C3

22-C3

15-A1

12-Cl

13-C2

13-A2

11-B5

6-A1

September 1996

Page 160 of 421

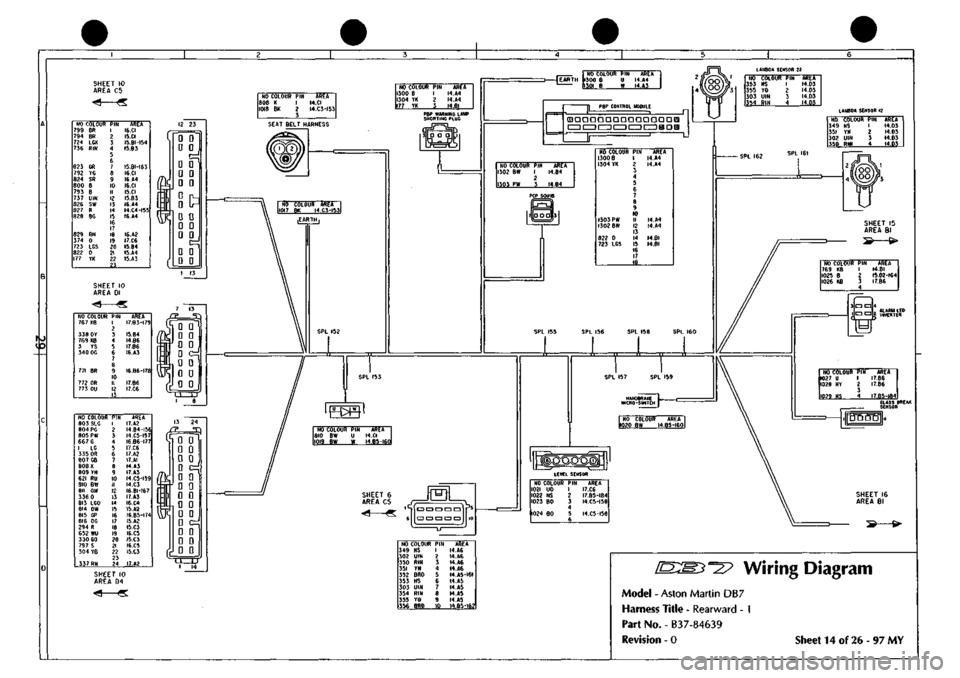

SHEET 10 AREA C5 NO COLOUR PIN AREA 808 K I I4.CI 1018 BK 2 I4.C3-I53 3

NO COLOUR PIN AREA 1300 B I I4.A4 1304 rK 2 I4.A4 177 YK 3 I4.BI

NO COLOUF 799 BR 794 BR 724 LCK 736 RIN

823 GR 792 YG 824 SR 800 B 793 B 757 UIN 826 SW 827 R 828 80

629 RN 374 0 723 LGS 822 0 177 YK

PIN 1 2 3 4 5 6 7 8 9 10 II 1? 13 14 IS 16 17 m 19 20 21 22 23

AREA le.ci I5.CI 15.81-154 15.63

15.81-163 16.CI I6.A4 I6.CI I5.CI I5.B3 16.A4 I4.C4-155 I6.A4

I6.A2 I7C6 15.84 IS.A4 I5.A3

12 23

Cool

!f

f;

w

(

D Dj

D

a]

Q

D

I

a D

St

' D D

a

D

a

D

M

In

D

D

D

D

SEAT BELT HARNESS

SHEET 10 AREA Dl

NO COLOUR 767

KB

338

OY

769

KB

3 YS 340 OG

771 BR

772 OR 773 OU

PIN 1 2 3 4 5 6 7 8 9 10 11 12 13

AREA I7.B3-I79

I5.B4 I4.B6 I7.B6 I6.A3

16.86-178

I7.B6 I7.C6

NO COLOUf 803 SLG 804 PG 805 PW 667 G 1 LG 335 OR 807 CB 808 X 809 YN 621 RU 810 BW 811 OW 336 0 813 LGO 814 OW 815 GP eie OG 294

R

652

WU

330 GO 797 S 304

YB

337 RN

PIN 1 2 3 4 5 6 7 8 9 10 II P? 13 14 15 16 17 18 19 20 21 22 23 24

AREA I7.A2 I4.B4-I56 I4.C5-I57 I6.B6-177 I7.C6 I7A2 I7.AI I4.A3 I7.A3 I4.C5-I59 I4.C3 16.81-167 I7.A3 I6.C4 I5.A2 I6.B5-I74 I5.A2 I5.C3 I6.C5 I5.C3 I6.C5 I5.C3

17A2 SHEET 10 AREA D4

NO COLOUR PIN 1300 B U 1301 B W

AREA 14.A4 I4.A3

PBP CONTROL MODULE

LAMBDA SENSOf? 22 NO 353 355 303 354

COLOUR NS YO UIN RIN

PIN 1 ? 3 4

AREA 14.03 14.03 14.D3 I4.D3

CDDDDDnaDDDDDDDH

cziizz)cr3cz]ciDEinBnn

LAM8DA SENSOR 12 NO 349 351 302 350

COLOUR NS YN UIN RIN

PIN 1 2 3 4

AREA 14.03 I4.D5 I4.D3 14.05

NO COLOUR PIN AREA 1302

BW

I 14.64 2 1303 PW 3 I4.B4

PCP SQUIB

NO COLOUr 1500 B 1304 YK

1303 PW 1302 BW

822 0 723 LGS

PIN 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

AREA I4.A4 I4.A4

I4.A4 I4.A4

I4.BI 14 .Bl

LEVEL SENSOR NO COLOUR 1021 UO 1022 NS 1023 BO

1024 BO

PIN 1 2 3 4 5 6

AREA I7.C6 I7.B5-I84 I4.C5-I58

I4.C5-156

NO COLOUf 349 NS 502 UIN 350 RIN 351 YN 552 BRO 353 NS 303 UIN 554 RIN 355 YO 356 BRO

PIN 1 2 i 4 5 6 7 8 9 10

AREA I4.A6 l4.Ae I4.A6 l4.Ae I4.A5-I6I I4.A5 I4.A5 I4.A5 14.A5 14.B5-I62

Wiring Diagram

Model - Aston Martin DB7

Harness Title - Rearward - 1

Part No. - B37-84639

Revision - 0 Sheet 14 of 26-97 MY

Page 187 of 421

^=2?

Electrics

Airbag System

Eye Protection

Chemical protective goggles are recommended

where there is a possibility of eye contact with the

propellant. Safety glasses with side shields are

recommended for all other operations.

Protective Clothing

Approved protective gloves, overalls and shoes/

boots should be worn.

Handling and Storage Precautions

Do not store airbag modules near live electrical

equipment or circuitry. Store in a dry environment

at ambient temperatures.

Good housekeeping and engineering practices

should be employed to prevent the generation and

accumulation of

dusts.

Store in compliance with all

local state and federal regulations.

Driver and Passenger Airbag Modules

Assembly/Removal/Service Instructions

WARNING: In the event of a vehicle impact where the

airbags and the seatbeltpretensioner (if fitted) are

deployed, the following actions MUST be

performed:

Check the condition of the seatbelts, steering

wheel,

steering column, all connections to airbags,

and the column switchgear connectors for integrity

and damage. If in any

doubt,

replace suspected

parts for new parts.

Replace both crash

sensors,

the

safing sensor

and

the seatbelt pretensioner module (if fitted).

On completion of all repair procedures, switch on

the ignition and check that the

Airbag/SRS

warning

light comes on when the ignition is switched on

and extinguishes after approximately six seconds

indicating satisfactory completion of the airbag

and pretensioner

system

self

tests.

WARNING: Before starting

work,

ensure

that the ignition

switch is in position 'O' and the ignition key is

removed.

Disconnect the battery negative lead

within 12 seconds of switching off the ignition to

prevent the alarm system triggering.

As the airbag control module is equipped with a

back-up power source and due to the risk of the

airbag being inadvertently deployed, wait one

minute or longer after disconnecting the battery

before starting work on the airbag module.

• Disconnectingthe battery negative cable cancels

the memory for the 'one-touch' window down

system and stops the vehicle clock. Reset the

window memory and the clock when work is

completed.

• Never use airbags from other vehicles, always

use new parts.

• After work is completed, reconnect the battery

and perform the airbag warning light check

• Never use electrical probes to check voltage or

electrical resistance of the airbag modules.

• Disconnect the airbag before carrying out any

work on, or in the vicinity of the module, or

when using electric welding equipment.

• Always ensure that the battery negative lead has

been disconnected for at least one minute before

commencing any removal procedure.

September 1996 6-71

Page 196 of 421

Electrics

Airbag System ^2?

6.4.21.4

Airbag Disarming/Arming

Procedures

WARNINGS AND CAUTIONS:

WARNINGS:

Disarm the airbags by disconnecting the battery

ground (black)

lead,

waiting one minute and then

removing the airbag modules before servicing of

any airbag or steering column component.

After disconnecting the battery ground

lead,

allow

a minimum of one minute delay for the back-up

power supply to discharge before servicing the

airbag system.

The system components are non-serviceable, if

faults are

suspected,

change components for new

items

only.

Failure to observe the above procedures may

result in accidental deployment of the airbags.

Always wear safety

glasses

when working on airbag

equipped vehicles.

Personnel carrying an airbag module must ensure

that the module and trim cover are pointing away

from the

body.

When positioning on a bench or

work surface, ensure that the airbag module and

trim cover face upwards to limit motion on

accidental deployment.

Always wear

gloves

when handling deployed airbag

modules. Deposits of sodium hydroxide may be

presenton the module surface. If sodium hydroxide

contacts any area of the skin, wash the affected

area immediately with mild soap and

water.

Dispose of the deployed airbag using the correct

procedures referred to in this section.

Cautions:

When scrapping vehicles,

ensure

that the

airbags

have

been deployed (see

Scrapping Vehicles

with Live

Airbags).

If a component

has been

renewed and the fault

does

not

clear,

refit the original item and repeat the diagnostic

procedure.

After

servicing,

repeatthe diagnostic

procedures

to ensure

correct

system

operation.

Renew

the airbag module if the surrounding trim

panels

are

damaged.

Do not attempt to repaint trim covers as

paint may

damage

cover material.

Disarming the Airbags

3.

4.

WARNING: Carry out the following disarming

procedure before attempting any work on the

vehicles electrical

systems.

Note: The battery ground (black) lead must be

disconnected within 12 seconds of switching off the

ignition to avoid the alarm siren sounding.

Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

Remove the drivers side airbag module and replace

it with an airbag simulatorfrom the simulator kit (Pt

No.

43.27028).

Remove the passengers airbag module and replace

it with an airbag simulator from the simulator kit.

Reconnect the battery ground.

Rearming the Airbags

WARNING: Carry out the following procedure to

rearm and check the airbags after completing all

work on the vehicles electrical

systems.

Note: The vehicle battery

must be

disconnected within

12

seconds

of switching off

the

ignition

to

avoid the alarm

siren sounding.

^. Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

2.

Removethedriverssideairbagsimulatorand replace

it with the drivers airbag module. Secure the airbag

module with the two captive torx screws.

3. Remove the passengers side airbag simulator and

replace it with the passenger side airbag module.

Secure the module with four nuts and washers.

Close the passenger side airbag door.

4.

Reconnect the battery ground.

5. Switch on the ignition and check for correct

indications from the SRS/AIRBAG warning light.

TheSRS/AIRBAC lamp should come on after

a

brief

delay and remain on for approximately six seconds

during the airbag system self check. The lamp will

extinguish upon satisfactory completion of the self

check, or will flash a diagnostic code if an airbag

system fault is detected. Continuous illumination of

the warning lamp may indicate a seatbelt

pretensioner fault

Note:

Reset the

clock and window

ECUs

on completion.

6-80 September 1996