lock ASTON MARTIN DB7 1997 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 334 of 421

^?

Air Conditioning Repair Procedures

upper/Lower Servo Feedback Potentiometer Renew

8.2.03.1

Upper Servo Feedback

Potentiometer Renewal

8.2.04.1

Lower Servo Feedback

Potentiometer Renew

1.

Disconnect the battery earth

lead.

2.

(On left hand cars) Remove the instrument paci<

and surround

trim.

2.

(On right hand cars) Remove the glove box

assembly.

3.

Remove the

securing screws

and

the potentiometer

assembly. Disconnect the electrical connector.

4.

Fitting a new potentiometer is the reverse of the

removal procedure.

1.

Disconnect the battery earth

lead.

2.

Un-clip and remove the left hand underscuttle

casing.

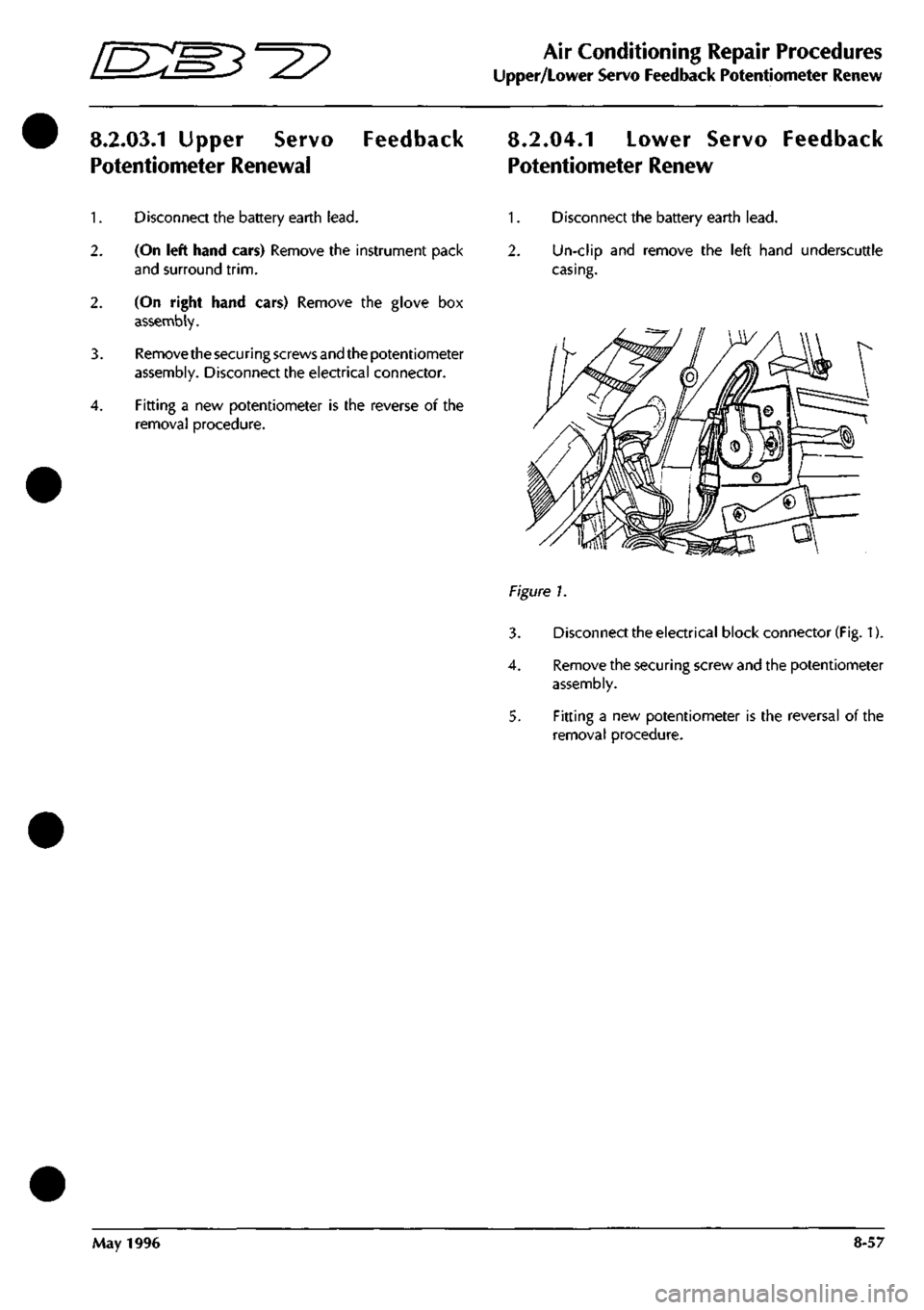

Figure 1.

3. Disconnect the electrical block connector

(Fig.

1).

4.

Remove the securing screw and the potentiometer

assembly.

5. Fitting a new potentiometer is the reversal of the

removal procedure.

May 1996 8-57

Page 335 of 421

Air Conditioning Repair Procedures

Upper/Lower Flap Motor Renew [EB^^^?

8.2.05.1 Upper Flap Motor Assembly

Renew

8.2.06.1 Lower Flap Motor Assembly

Renew

1.

Disconnect the battery earth

lead.

2.

Remove the electronic control module.

3. Disconnect the motor block connector.

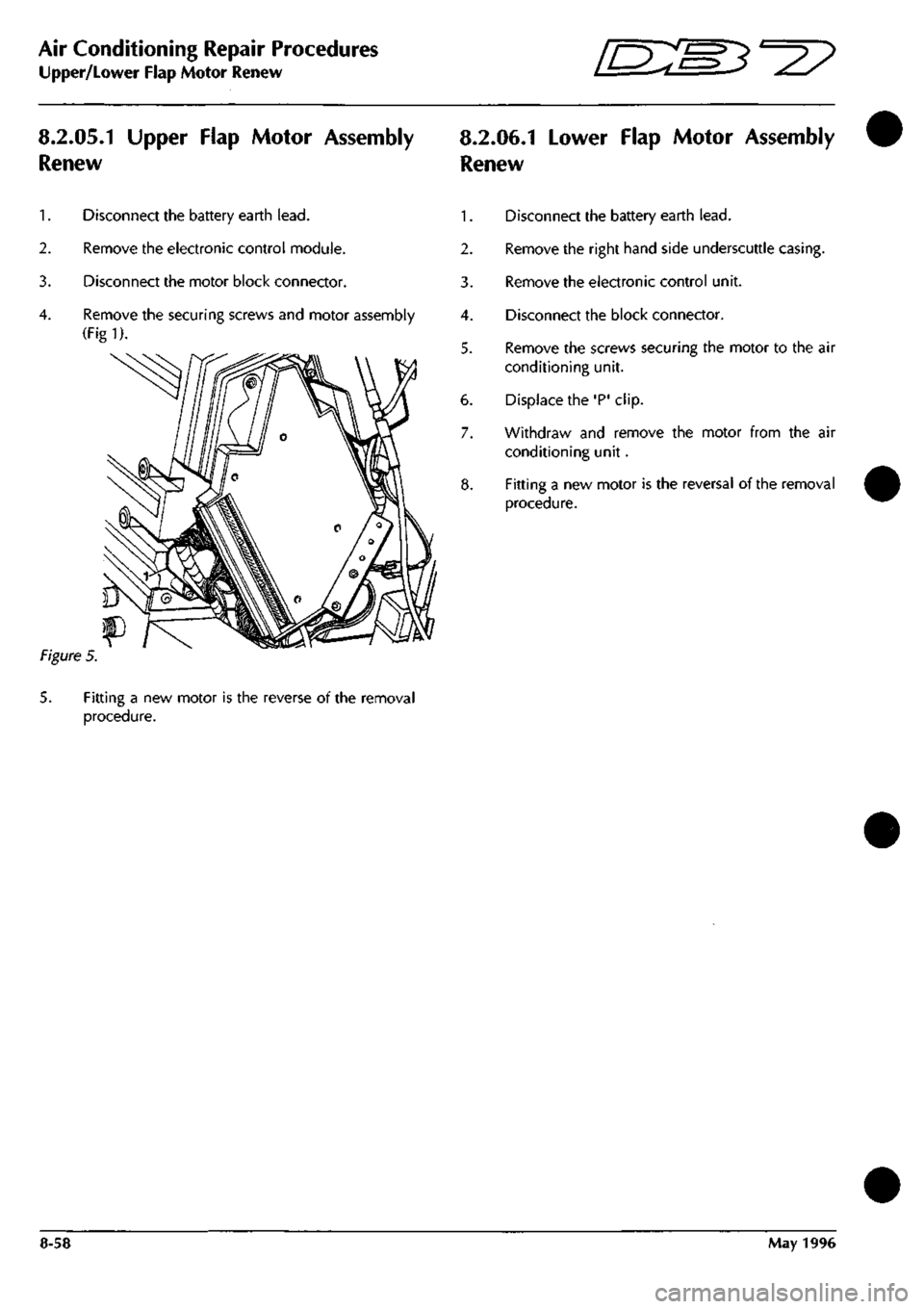

4.

Remove the securing screws and motor assembly

(Figl).

Figure

5.

5. Fitting a new motor is the reverse of the removal

procedure.

1.

Disconnect the battery earth

lead.

2.

Remove the right hand side underscuttle casing.

3. Remove the electronic control unit.

4.

Disconnect the block connector.

5. Remove the screws securing the motor to the air

conditioning unit.

6. Displace the'P'clip.

7. Withdraw and remove the motor from the air

conditioning unit.

8. Fitting a new motor is the reversal of the removal

procedure.

8-58 May 1996

Page 336 of 421

'nzm^=2?

Air Conditioning Repair Procedures

Blower Motor Renewal

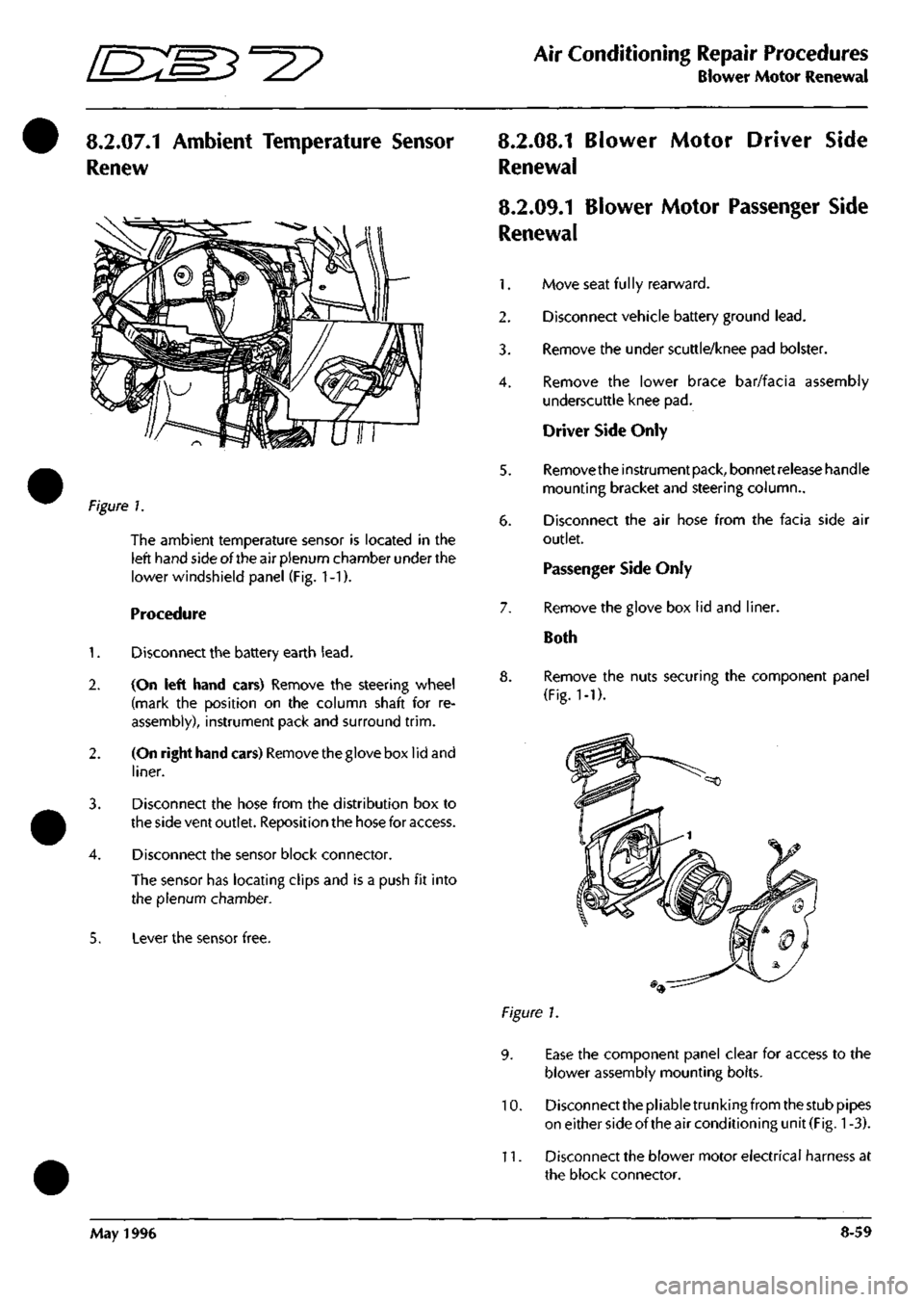

8.2.07.1 Ambient Temperature Sensor

Renew

?\gure

1.

The ambient temperature sensor is located in the

left hand side of the air plenum chamber under the

lower windshield panel (Fig. 1-1).

Procedure

1.

Disconnect the battery earth

lead.

2.

(On left hand cars) Remove the steering wheel

(mark the position on the column shaft for re

assembly), instrument pack and surround

trim.

2.

(On right hand cars) Removethegloveboxlidand

liner.

3. Disconnect the hose from the distribution box to

the side vent outlet. Reposition the hose for access.

4.

Disconnect the sensor block connector.

The sensor has locating clips and is a push fit into

the plenum chamber.

5. Lever the sensor free.

8.2.08.1 Blower Motor Driver Side

Renewal

8.2.09.1 Blower Motor Passenger Side

Renewal

1.

Move seat

fu 1

ly rearward.

2.

Disconnect vehicle battery ground

lead.

3. Remove the under scuttle/knee pad bolster.

4.

Remove the lower brace bar/facia assembly

underscuttle knee pad.

Driver Side Only

5. Removetheinstrumentpack, bonnetreieasehandle

mounting bracket and steering column..

6. Disconnect the air hose from the facia side air

outlet.

Passenger Side Only

7. Remove the glove box lid and liner.

Both

8. Remove the nuts securing the component panel

(Fig.

1-1).

Figure 1.

9. Ease the component panel clear for access to the

blower assembly mounting bolts.

10.

Disconnect the pliable trunking from the stub pipes

on either side of the air conditioning unit

(Fig.

1

-3).

11.

Disconnect the blower motor electrical harness at

the block connector.

May 1996 8-59

Page 340 of 421

^>

Air Conditioning Repair Procedures

Electronic Control Module/Vacuum Solenoid Renewal

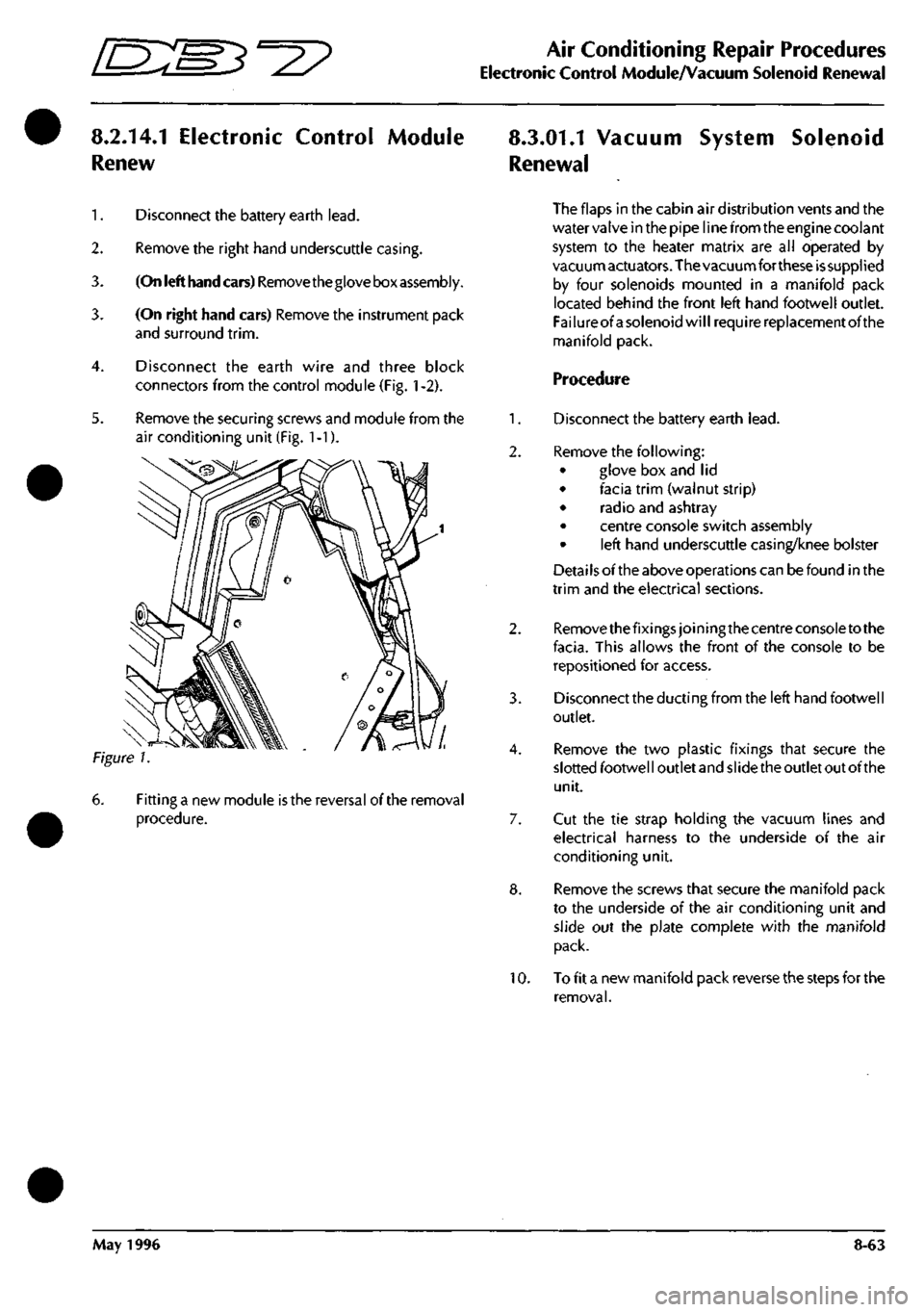

8.2.14.1 Electronic Control Module

Renew

8.3.01.1 Vacuum System Solenoid

Renewal

1.

Disconnect the battery earth

lead.

2.

Remove the right hand underscuttle casing.

3. (On left hand cars) Removethe glove box assembly.

3. (On right hand cars) Remove the instrument pack

and surround

trim.

4.

Disconnect the earth wire and three block

connectors from the control module (Fig.

1

-2).

5. Remove the securing screws and module from the

air conditioning unit (Fig. 1-1).

Fitting a new module

is

the reversal of the removal

procedure.

The flaps in the cabin air distribution vents and the

water valve in the pipe line from the engine coolant

system to the heater matrix are all operated by

vacuumactuators.The vacuumfor these issupplied

by four solenoids mounted in a manifold pack

located behind the front left hand footwell outlet.

Failureof a solenoid will require replacement of the

manifold pack.

Procedure

1.

Disconnect the battery earth

lead.

2.

Remove the following:

• glove box and lid

• facia trim (walnut strip)

• radio and ashtray

• centre console switch assembly

• left hand underscuttle casing/knee bolster

Detai

Is

ofthe above operations can be found in the

trim and the electrical sections.

2.

Remove thefixings joining the centre console to the

facia.

This allows the front of the console to be

repositioned for access.

3. Disconnect the ducting from the left hand footwell

outlet.

4.

Remove the two plastic fixings that secure the

slotted footwel

I

outlet and

si

ide the outlet out ofthe

unit.

7. Cut the tie strap holding the vacuum lines and

electrical harness to the underside of the air

conditioning unit.

8. Remove the screws that secure the manifold pack

to the underside of the air conditioning unit and

slide out the plate complete with the manifold

pack.

10.

To fit a new manifold pack reverse the steps for the

removal.

May 1996 8-63

Page 352 of 421

^?

The Aston Martin Lagonda Diagnostic System

Contents

Installation Instructions

Introduaion 9-2

The Aston Martin Diagnostic System 9-2

Diagnostic System Cables 9-5

Base Station Installation 9-8

Problem Solving 9-16

Service Centres 9-21

Service and Maintenance 9-22

Technical Specifications 9-24

Operating Instructions

The Aston Martin Lagonda Diagnostic System 9-27

Software 9-29

Cable Setup 9-31

Diagnostic Sockets - 97 MY 9-31

Establishing Communications 9-32

System Menu Selections 9-32

PDU Use 9-32

Engine Diagnostics - 97 MY 9-33

Transmission Diagnostics 9-40

Climate Control Diagnostics 9-43

Anti-Lock Brakes Diagnostics 9-43

Passive Anti-Theft (PATS) Diagnostics 9-44

Airbag System Diagnostics 9-45

Seat Belt Pretensioner Diagnostics 9-47

Print Facility 9-49

Digital Multimeter 9-50

Diagnostic Trouble Codes 9-53

Datalogger 9-55

Datalogger Example 9-63

Training 9-66

OBD II Scan Tool 9-66

System Self Test 9-69

The Asterisk (*) Menu 9-69

System Setup 9-70

May 1996 9-1

Page 354 of 421

'=^

The Aston Martin Lagonda Diagnostic System

Installation Instructions

12 10

19 22 21 20

VIA A / /^^>^ I B T

A-XA^I'A® QA

13

16

18 29

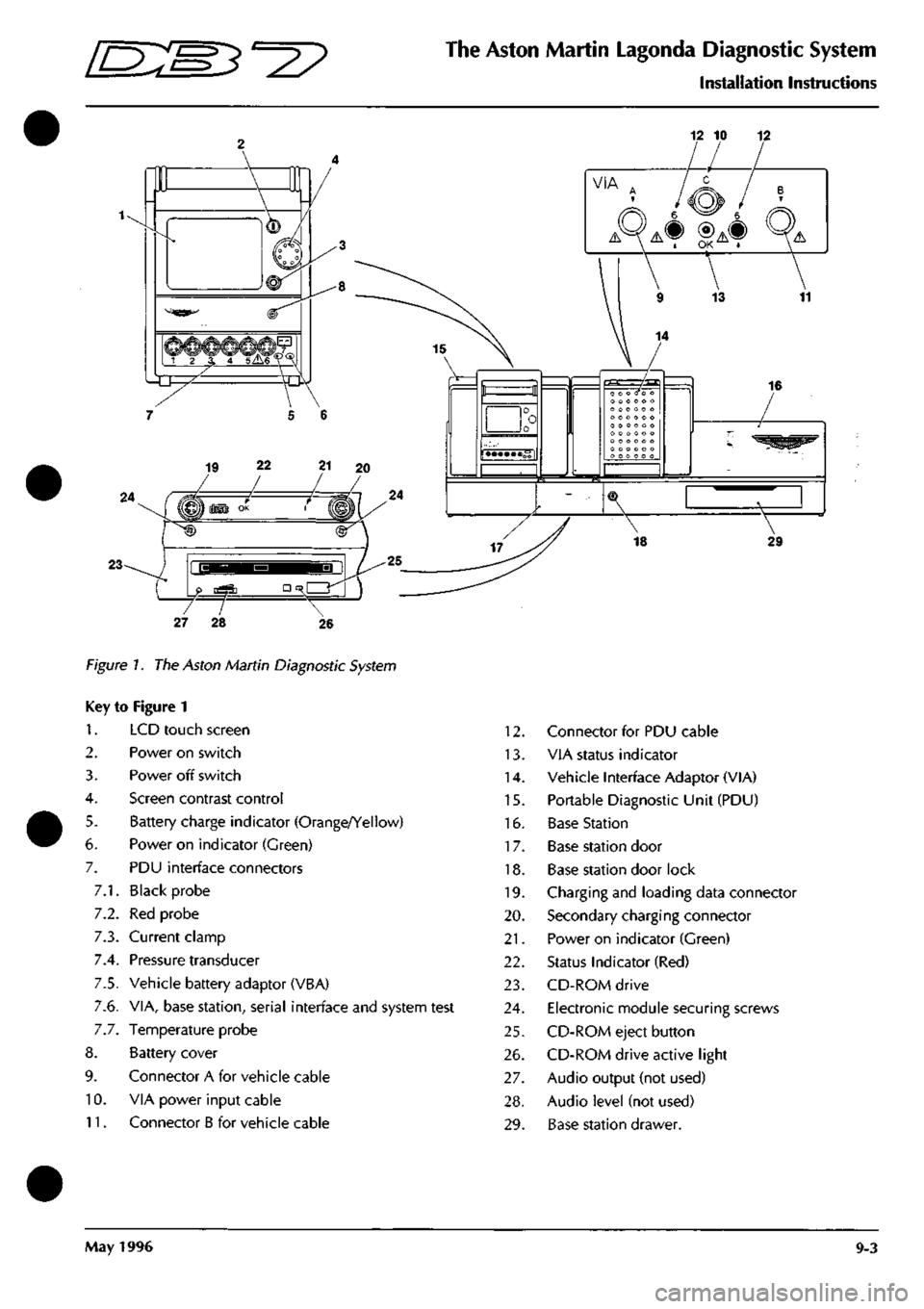

Figure 7. The Aston Martin Diagnostic System

Key to Figure 1

1.

2.

3.

4.

5.

6.

7.

7.1.

7.2.

7.3.

7.4.

7.5.

7.6.

7.7.

8.

9.

10.

11.

LCD touch screen

Power on switch

Power off switch

Screen contrast control

Battery charge indicator (Orange/Yellow)

Power on indicator (Green)

PDU interface connectors

Black probe

Red probe

Current clamp

Pressure transducer

Vehicle battery adaptor (VBA)

VIA, base station, serial interface and system test

Temperature probe

Battery cover

Connector A for vehicle cable

VIA power input cable

Connector B for vehicle cable

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

Connector for PDU cable

VIA status indicator

Vehicle Interface Adaptor (VIA)

Portable Diagnostic Unit (PDU)

Base Station

Base station door

Base station door lock

Charging and loading data connector

Secondary charging connector

Power on indicator (Green)

Status Indicator (Red)

CD-ROM drive

Electronic module securing screws

CD-ROM eject button

CD-ROM drive active light

Audio output (not used)

Audio level (not used)

Base station drawer.

May 1996 9-3

Page 357 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions mm^^?

Diagnostic System Cables

311

^ri M

r 1

3130-0030-01 VIA-PDU Cable

^

ctfa

3130-0778-00-B Anti-Lock Brakes

3130-0064-01 Base Station-PDU Cable

3130-0475-00 Test Probes

VBA

3130-0024-01 Vehicle Battery Adapti

3130-0764-00 Road Test Ext Cable

9-6 May 1996

Page 360 of 421

^^?

The Aston Martin Lagonda Diagnostic System

I nstal lation I nstructions

Bench Mounting

The base station may also be mounted on a bench, which

must be in a safe position, stable and protected form

hazards and impacts. The base station must be mounted

at the back of the bench. 'Z' clips are provided for

permanent mounting. The bench surface must be kept free

from dust at all times.

CAUTION:

A gap under the base station must be

maintained free from obstructions to allow a flow of air

under the unit for cooling.

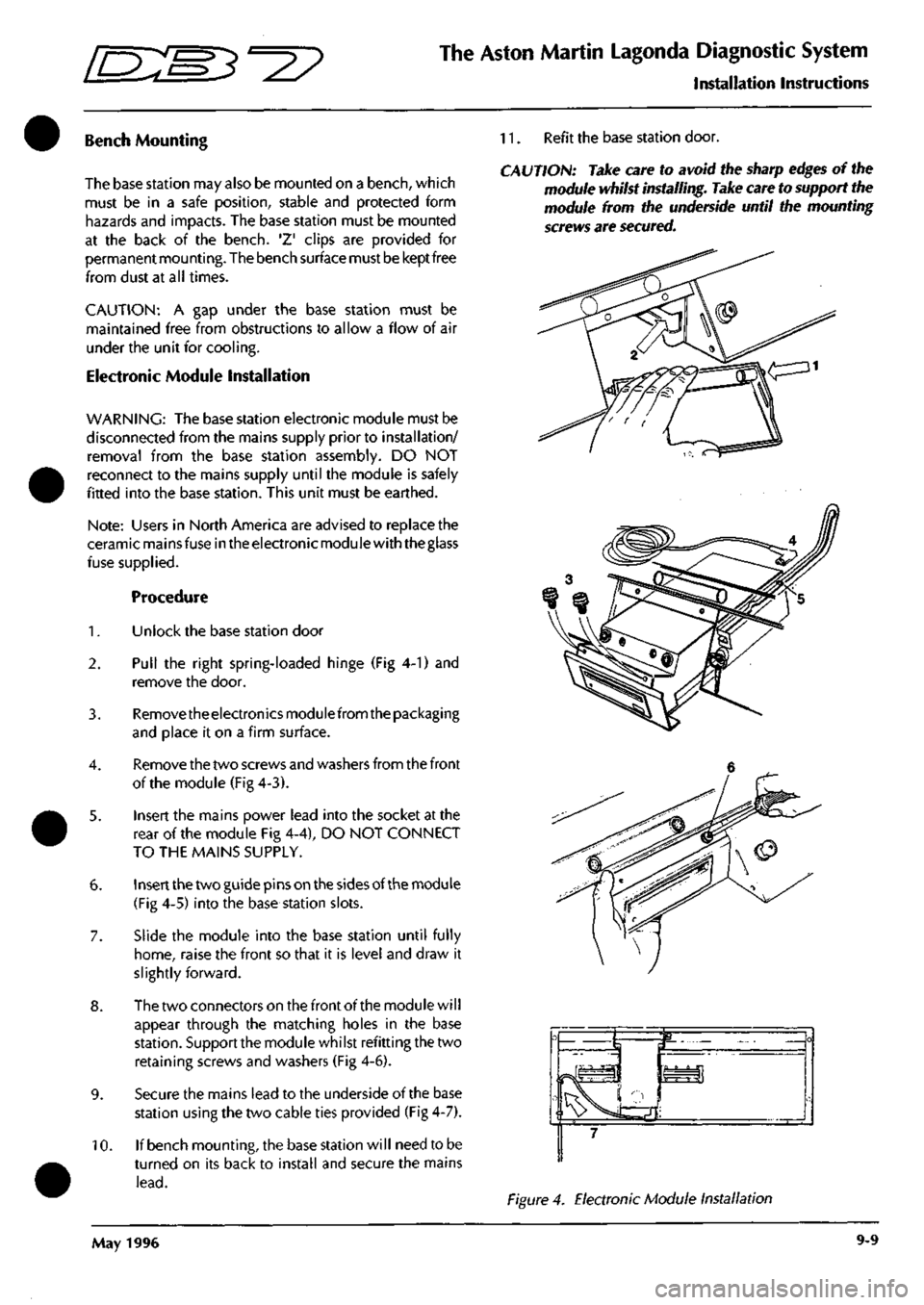

Electronic Module installation

WARNING: The base station electronic module must be

disconnected from the mains supply prior to installation/

removal from the base station assembly. DO NOT

reconnect to the mains supply until the module is safely

fitted into the base station. This unit must be earthed.

Note:

Users in North America are advised to replace the

ceramic mains fuse in the electronic module with theglass

fuse supplied.

Procedure

1.

Unlock the base station door

2.

Pull the right spring-loaded hinge (Fig 4-1) and

remove the door.

3. Removetheelectronicsmodulefrom the packaging

and place it on a firm surface.

4.

Remove the two screws and washers from the front

of the module (Fig 4-3).

5. Insert the mains power lead into the socket at the

rear of the module Fig 4-4), DO NOT CONNECT

TO THE MAINS SUPPLY.

6. Insert the two guide pins on the sides of the module

(Fig 4-5) into the base station slots.

7. Slide the module into the base station until fully

home,

raise the front so that it is level and draw it

slightly forward.

8. The two connectors on the front of the module will

appear through the matching holes in the base

station.

Support the module whilst refitting the two

retaining screws and washers (Fig 4-6).

9. Secure the mains lead to the underside of the base

station using the two cable ties provided (Fig 4-7).

10.

If bench mounting, the base station will need to be

turned on its back to install and secure the mains

lead.

11.

Refit the base station door.

CAUTION: Take care to avoid the sharp edges of the

module whilst installing. Take care to support the

module from the underside until the mounting

screws are secured.

Figure 4. Electronic Module Installation

May 1996 9-9

Page 361 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions

[ES^'^?

Powering-Up the Base Station

When first operating the System or when first using

a PDU fitted with substitute batteries, it will take up

to36 hourstoachievefull charge. Inthemeantime,

the PDU can be used whilst connected to the base

station or to the vehicle battery.

Vi/\RNmGS:

When using the system equipment, basic safety

precautions should always be followed, including:

Carefully read and follow all instructions.

Care should be taken as burns can occur from

touching hot parts.

Do not operate the appliance with a damaged

mains lead or if the appliance has been dropped or

damaged. Call your local GenRad Service Centre

immediately for a substitute

part.

Do not let the mains lead hang over the

edge

of the

table, bench or counter or come into contact with

hot manifolds or moving fan blades.

The Aston Martin Portable Diagnostic Unit

is

fitted with an

auto switching power supply suitable for voltage supplies

of 100 - 240 VAC 50 - 60 Hz. You need only check that

the power cord connector is of the correct type for your

power outlets.

1.

Connect the mains lead to the mains outlet.

2.

Check that the green indicator lamp above the base

station door is illuminated. If the green lamp does

not come on, see the problem solving section for

advice.

3. After a few seconds, during which the electronics

module completes its self-test, the red OK indicator

lamp should illuminate. If the red lamp does not

come on, see the problem solving section for

advice.

4.

Allow the base station electronics module to reach

working temperature. This will take approximately

BOminutes, after which time the base station will be

ready to accept the software on CD-ROM.

5. Slide the PDU into its carrying case and place the

associated cables and probes in the carrying case

compartments.

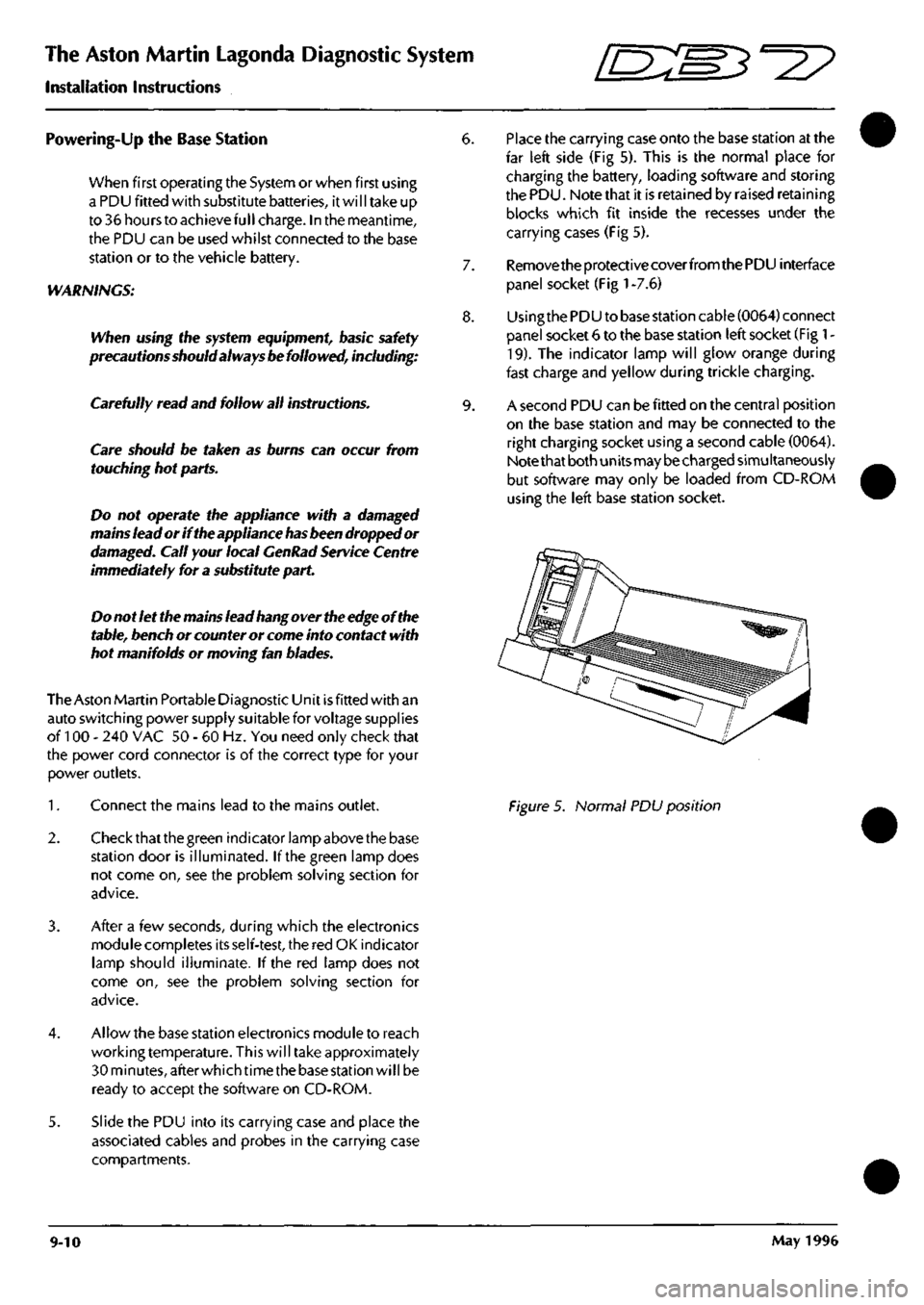

6. Place the carrying case onto the base station at the

far left side (Fig 5). This is the normal place for

charging the battery, loading software and storing

the PDU. Note that it is retained by raised retaining

blocks which fit inside the recesses under the

carrying cases (Fig 5).

7. Remove the protective coverfromthe PDU interface

panel socket (Fig

1

-7.6)

8. Usingthe PDU to base station cable (0064) connect

panel socket 6 to the base station left socket (Fig

1

-

19).

The indicator lamp will glow orange during

fast charge and yellow during trickle charging.

9. A second PDU can be fitted on the central position

on the base station and may be connected to the

right charging socket using a second cable (0064).

Note that both units may be charged simultaneously

but software may only be loaded from CD-ROM

using the left base station socket.

Figure 5. Normal PDU position

9-10 May 1996

Page 362 of 421

'D::B^^?

The Aston Martin Lagonda Diagnostic System

Installation Instructions

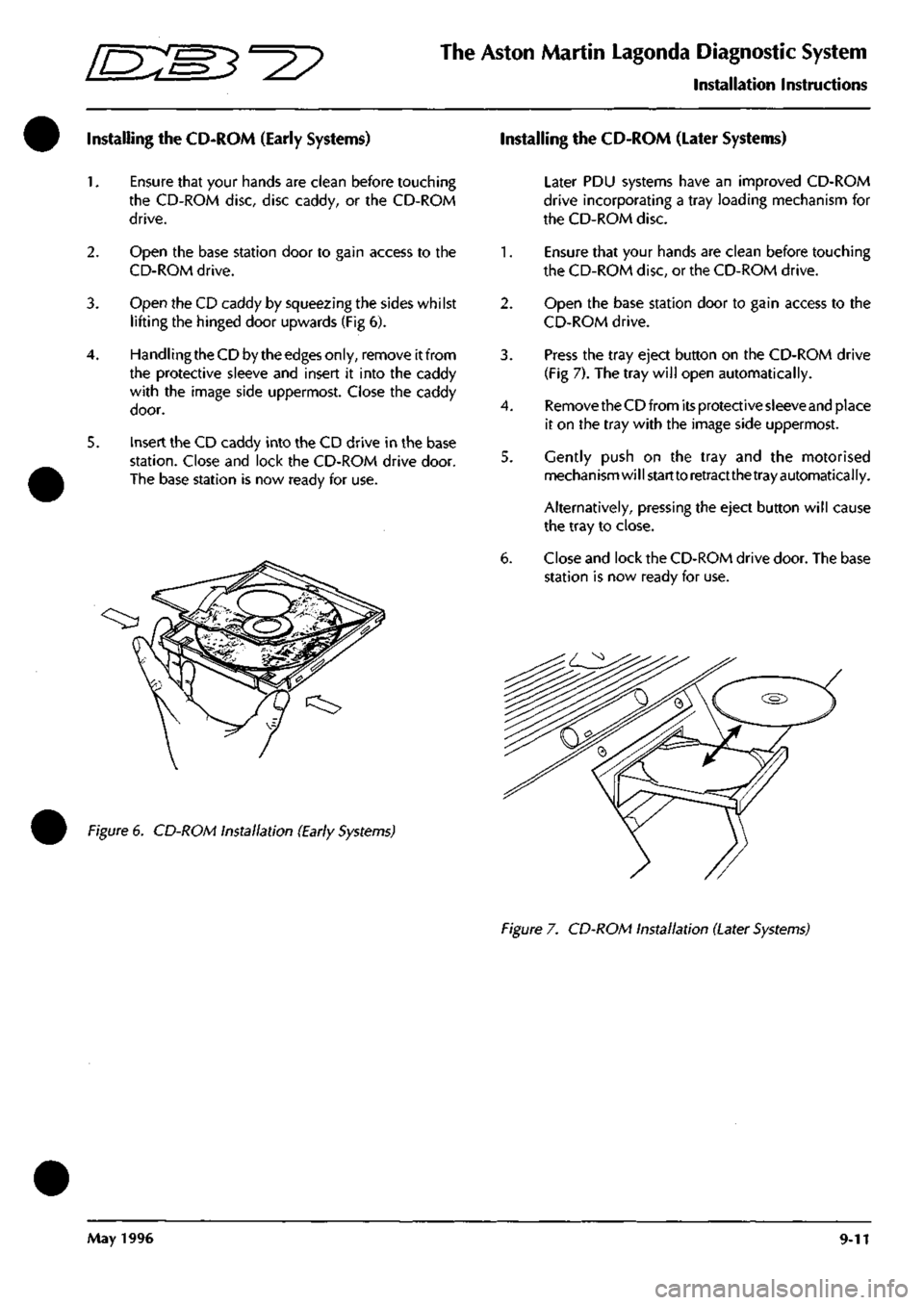

Installing the CD-ROM (Early Systems) Installing the CD-ROM (Later Systems)

2.

3.

5.

Ensure that your hands are clean before touching

the CD-ROM disc, disc caddy, or the CD-ROM

drive.

Open the base station door to gain access to the

CD-ROM drive.

Open the CD caddy by squeezing the sides whilst

lifting the hinged door upwards (Fig 6).

Handling the CD by the edges only, remove it from

the protective sleeve and insert it into the caddy

with the image side uppermost. Close the caddy

door.

Insert the CD caddy into the CD drive in the base

station.

Close and lock the CD-ROM drive door.

The base station is now ready for use.

Figure 6. CD-ROM Installation (Early Systems)

Later PDU systems have an improved CD-ROM

drive incorporating a tray loading mechanism for

the CD-ROM disc.

1.

Ensure that your hands are clean before touching

the CD-ROM disc, or the CD-ROM drive.

2.

Open the base station door to gain access to the

CD-ROM drive.

3. Press the tray eject button on the CD-ROM drive

(Fig 7). The tray will open automatically.

4.

Remove the CD from its protective sleeve and place

it on the tray with the image side uppermost.

5. Gently push on the tray and the motorised

mechanism will start to retractthe tray automatically.

Alternatively, pressing the eject button will cause

the tray to close.

6. Close and lock the CD-ROM drive door. The base

station is now ready for use.

Figure 7. CD-ROM Installation (Later Systems)

May 1996 9-11