warning ASTON MARTIN DB7 1997 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 353 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions E:MB^^?

Introduction The Aston Martin Diagnostic System

This guide contains instructions for the installation

of the Portable Diagnostic Unit hardware in Aston

Martin Dealer workshops. To achieve maxinnum

benefit from the system, please follow the

instructions carefully. The following System

Diagram shows the principal system components

and panel details.

This introduction briefly describes the system and

its capabilities. This is followed by the Installation

and Power-Up procedures which give detailed

instruaions on how to start the system and access

the self-contained Interactive

Training

Programme.

The subsequent sections detail the fault diagnosis

and maintenance procedures.

WARNING:

The equipment must

only

be used by

trained

personnel.

Care should

be taken to use the

equipment in accordance with the operating

procedures.

Observe

all safety

warnings

in this

guide.

If any part of

the system is damaged do not

use it. Call your local CenRad

Service

Centre

immediately

for a

substitute

part.

Refer to

'Parts

Ordering'.

The Aston Martin Diagnostic System is a new

generation diagnostic

tool

which fulfils

a

number of

functions in aiding the technician to quickly and

accurately locate faults. The heart of the system is

the Portable Diagnostic

Unit,

a

lightweight powerful

computer/measurement system providing a step-

by-step user friendly interface for the technician.

PDU functions include:

Data Logger - The ability to monitor and record

control module signals even whilst the vehicle is

being driven.

On-Line Help-Containing detailed descriptions in

the

operation

ofthevehicleselectroniccomponents.

Vehicle Setup - The ability to setup various

adjustable parameters to their optimum settings.

Diagnostic Trouble Codes - The ability to extract

recorded fault information from the DB7's control

modules.

Each of

these

funaions is described in detail in the

PDU Users Guide.

WARNING: If

the system is used to measure high

voltages,

these voltages can appear on the pins of

other

connectors in

the

system.

Ensure

that socket

covers

are

fitted

on

unused

sockets.

Ensure

that all

connections

are

made

prior to

applying the high

voltage to

the

probes.

Do not

leave the equipment

unattended

in

this

state.

The maximum

voltage

that may be applied

between the

test

probes is 150

volts

AC or DC.

Radio Interference Statements

This digital apparatus does not exceed the Class A

limits for radio noiseemissionsfromdigital apparatus

as set

out

in

the radio interference regulations of the

Canadian Department of Communications.

This equipment has been tested and found to

comply with the limits for Class A digital device

pursuant to part 15 of the Federal Communications

Commission (FCC) rules. However, operation in

close proximity to domestic communication

equipment may cause interference. It is the

responsibility of the user to avoid or correct this

condition.

9-2 May 1996

Page 359 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions ^7

Base Station installation

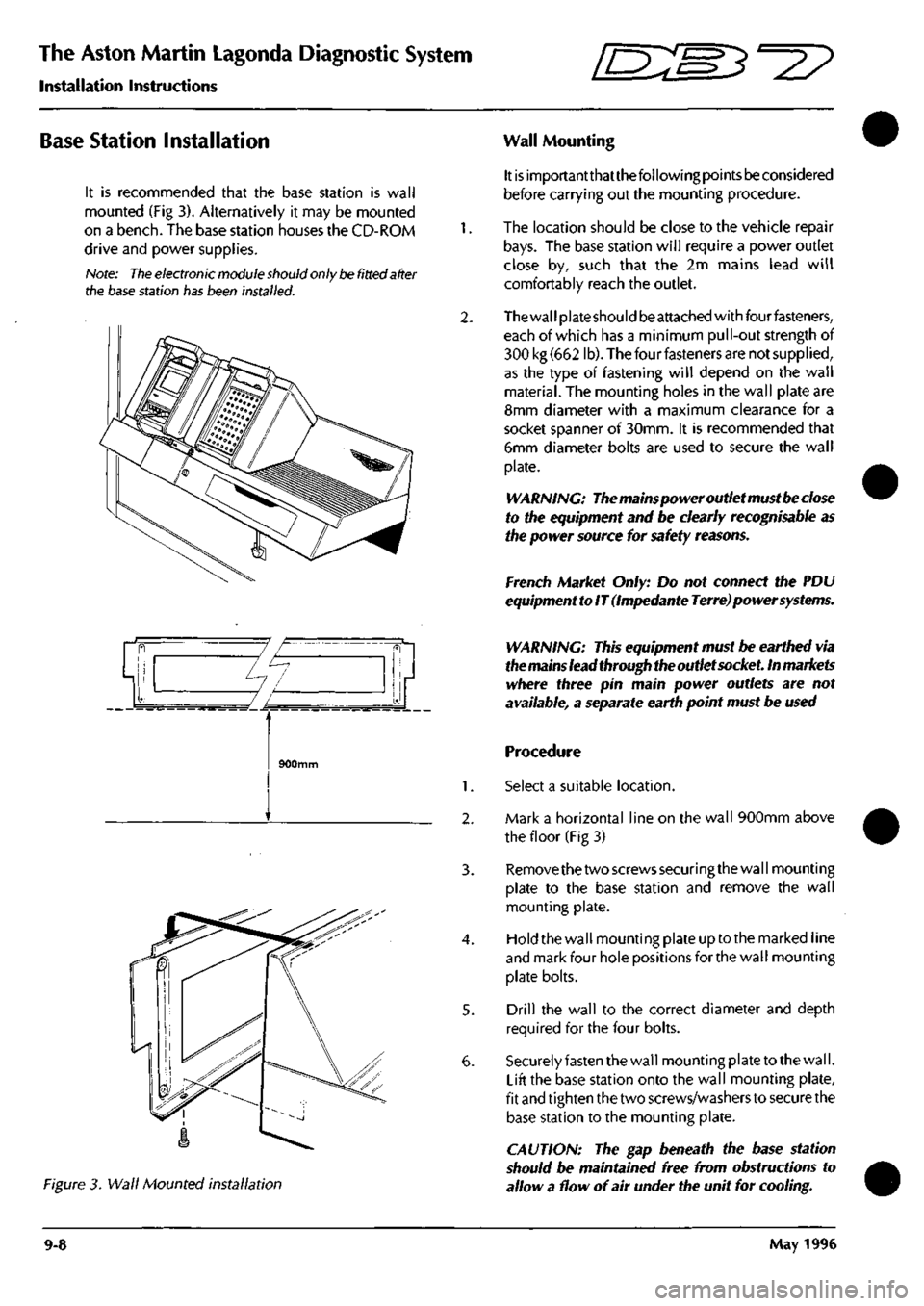

It is recommended that the base station is wall

mounted (Fig 3). Alternatively it may be mounted

on a bench. The base station houses the CD-ROM

drive and power supplies.

Note: The electronic module should only be fitted

after

the base station has been installed.

Wall Mounting

It

is

importantthatthefollowing points be considered

before carrying out the mounting procedure.

The location should be close to the vehicle repair

bays.

The base station will require a power outlet

close by, such that the 2m mains lead will

comfortably reach the outlet.

Thewall plate should be attached with fourfasteners,

each of which has a minimum pull-out strength of

300 kg (662 lb). Thefourfasteners are not supplied,

as the type of fastening will depend on the wall

material.

The mounting holes in the wall plate are

8mm diameter with a maximum clearance for a

socket spanner of 30mm. It is recommended that

6mm diameter bolts are used to secure the wall

plate.

WARNING: The mains power outlet must be dose

to the equipment and be clearly recognisable as

the power source for safety reasons.

French Market

Only:

Do not connect the PDU

equipment

to

IT(lmpedante Terre) power systems.

r

900mm

Figure 3. Wall Mounted installation

WARNING: This equipment must be earthed via

the

mains

lead through the outlet socket. In markets

where three pin main power outlets are not

available, a separate earth point must be used

Procedure

1.

Select a suitable location.

2.

Mark a horizontal line on the wall 900mm above

the floor (Fig 3)

3. Removethetwoscrewssecuringthewall mounting

plate to the base station and remove the wall

mounting plate.

4.

Holdthewall mounting plate up to the marked line

and mark four hole positions for the wall mounting

plate bolts.

5. Drill the wall to the correct diameter and depth

required for the four bolts.

6. Securely fasten the wall mounting plate to the

wall.

Lift the base station onto the wall mounting plate,

fit and tighten the two screws/washers to secure the

base station to the mounting plate.

CAUTION: The gap beneath the base station

should be maintained free from obstructions to

allow a flow of air under the unit for cooling.

9-8 May 1996

Page 360 of 421

^^?

The Aston Martin Lagonda Diagnostic System

I nstal lation I nstructions

Bench Mounting

The base station may also be mounted on a bench, which

must be in a safe position, stable and protected form

hazards and impacts. The base station must be mounted

at the back of the bench. 'Z' clips are provided for

permanent mounting. The bench surface must be kept free

from dust at all times.

CAUTION:

A gap under the base station must be

maintained free from obstructions to allow a flow of air

under the unit for cooling.

Electronic Module installation

WARNING: The base station electronic module must be

disconnected from the mains supply prior to installation/

removal from the base station assembly. DO NOT

reconnect to the mains supply until the module is safely

fitted into the base station. This unit must be earthed.

Note:

Users in North America are advised to replace the

ceramic mains fuse in the electronic module with theglass

fuse supplied.

Procedure

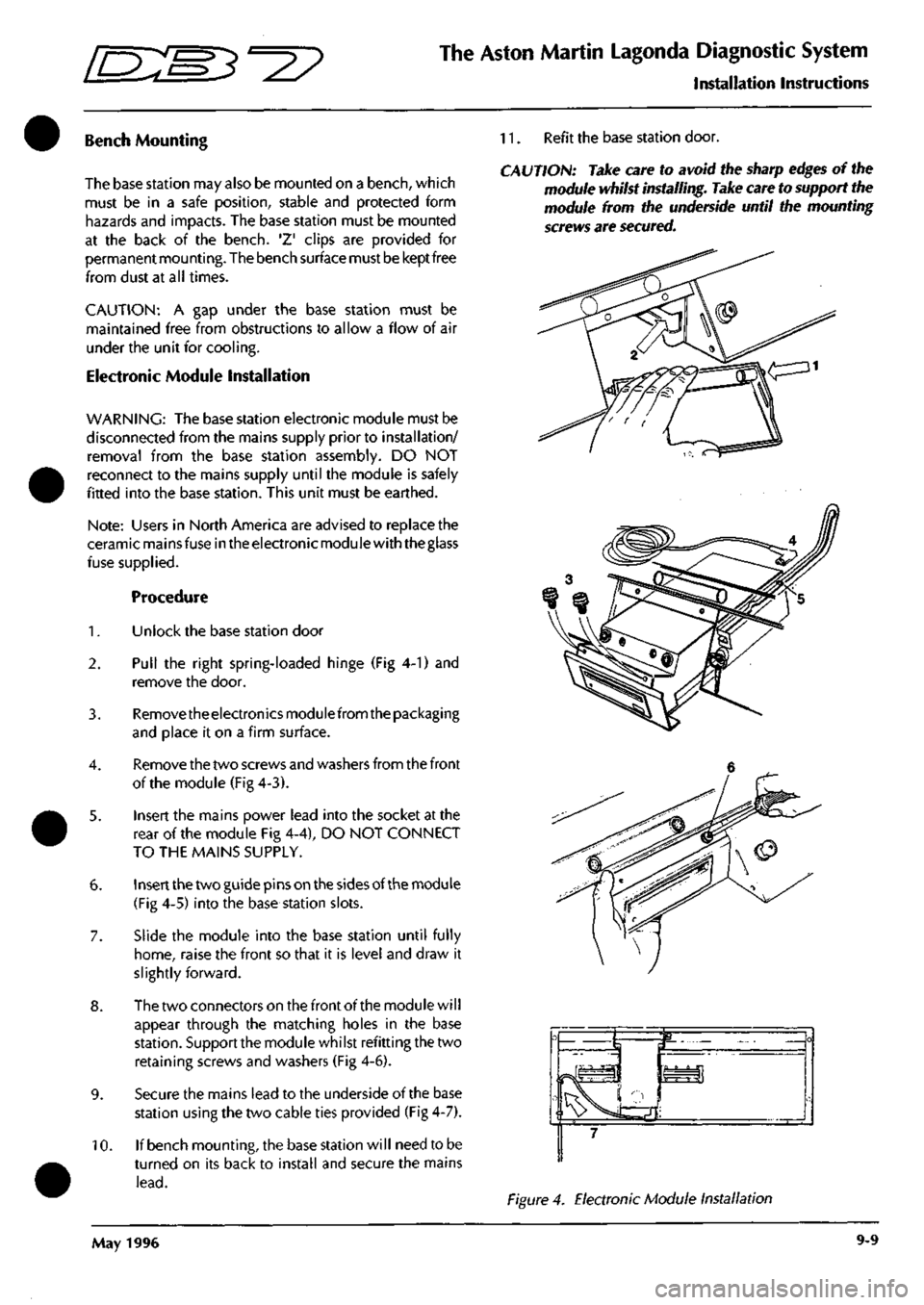

1.

Unlock the base station door

2.

Pull the right spring-loaded hinge (Fig 4-1) and

remove the door.

3. Removetheelectronicsmodulefrom the packaging

and place it on a firm surface.

4.

Remove the two screws and washers from the front

of the module (Fig 4-3).

5. Insert the mains power lead into the socket at the

rear of the module Fig 4-4), DO NOT CONNECT

TO THE MAINS SUPPLY.

6. Insert the two guide pins on the sides of the module

(Fig 4-5) into the base station slots.

7. Slide the module into the base station until fully

home,

raise the front so that it is level and draw it

slightly forward.

8. The two connectors on the front of the module will

appear through the matching holes in the base

station.

Support the module whilst refitting the two

retaining screws and washers (Fig 4-6).

9. Secure the mains lead to the underside of the base

station using the two cable ties provided (Fig 4-7).

10.

If bench mounting, the base station will need to be

turned on its back to install and secure the mains

lead.

11.

Refit the base station door.

CAUTION: Take care to avoid the sharp edges of the

module whilst installing. Take care to support the

module from the underside until the mounting

screws are secured.

Figure 4. Electronic Module Installation

May 1996 9-9

Page 373 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions ^=2?

Warranty

The Aston Martin Diagnostic System is covered by a one year warranty. Should any of the electrical components

fail during the warranty period, contact your local GenRad Service Centre for a replacement part. Note that the

warranty does not include physical damage.

Spare Parts

Refer to the Aston Martin Diagnostic System Users Guide for a full parts list. All spare parts should be obtained from

your local GenRad Service Centre who can advise you on current prices.

Servicing and Maintenance

CA UTION: With the exception of those parts listed in this section, there are no user serviceable parts within the

system. All servicing must be carried out by GenRad Service Centres.

Battery Testing.

The NICAD batteries fitted in the PDU are designed to be rechargeable and should normally last through many

recharge cycles. Battery life of three to five years can be expected. The capacity of new batteries improves after

several charging cycles. After extended use, they may require renewing. The following procedure will assist you to

determine when renewal is required. Do not use this procedure with new batteries or with a new PDU.

Testing Procedure

1.

Remove all cables from the PDU.

2.

Switch the PDU on and leave it until it switches off (the power on indicator will extinguish)

3. Connect the PDU to the base station for at least 12 hours charging.

4.

Remove all cables from the PDU, switch on the PDU and start timing.

5. If the PDU switches off in less than 30 minutes, the batteries should be renewed.

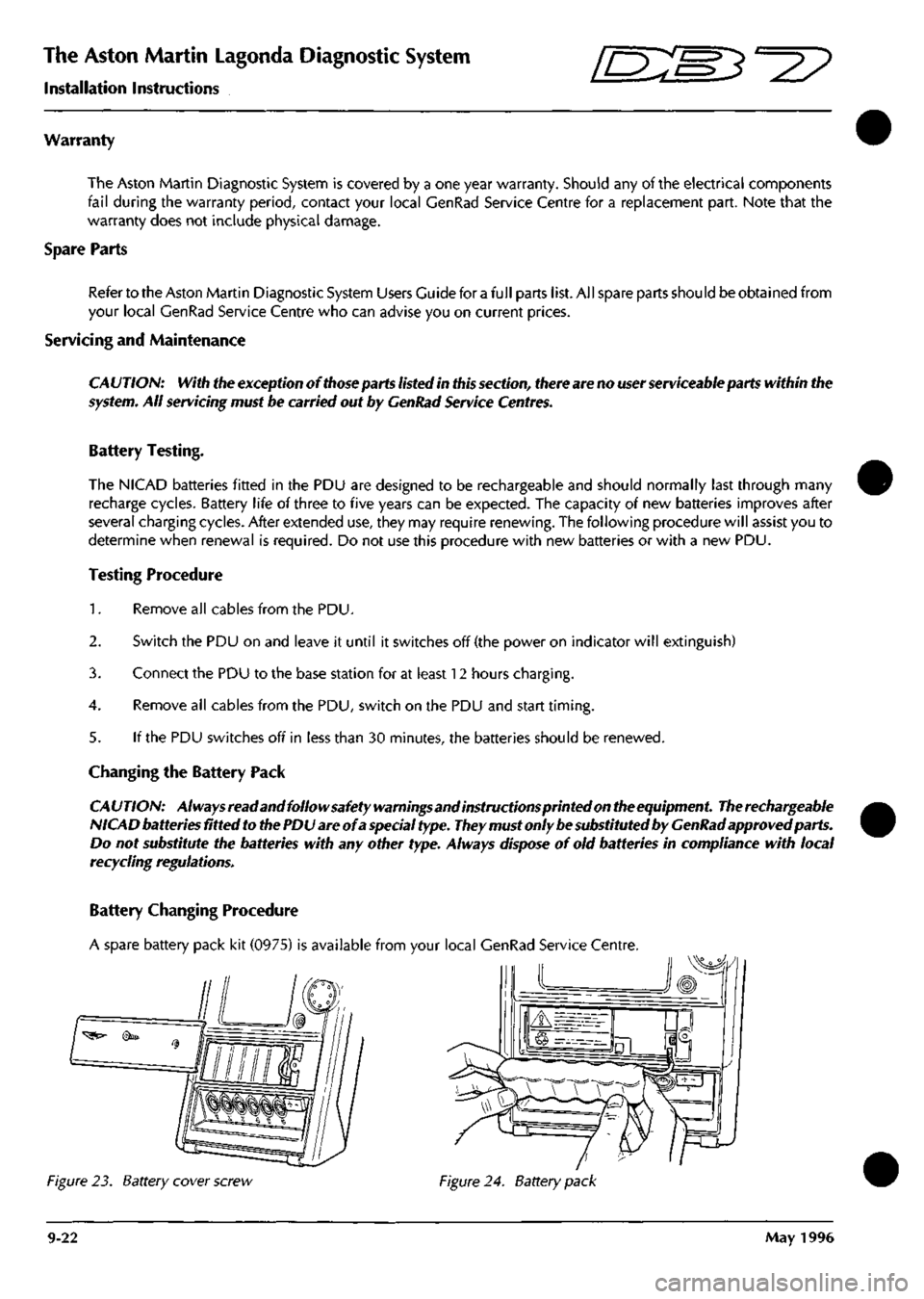

Changing the Battery Pack

CAUTION: Always read and follow safety warnings and instructions printed on the equipment. The rechargeable

NICAD batteries fitted to the PDU are of a special type. They must only be substituted by GenRad approved parts.

Do not substitute the batteries with any other type. Always dispose of old batteries in compliance with local

recycling regulations.

Battery Changing Procedure

A spare battery pack kit (0975) is available from your local GenRad Service Centre.

Figure 23. Battery cover screw Figure 24. Battery pack

9-22 May 1996

Page 384 of 421

^27

The Aston Martin Lagonda Diagnostic System

Users Guide

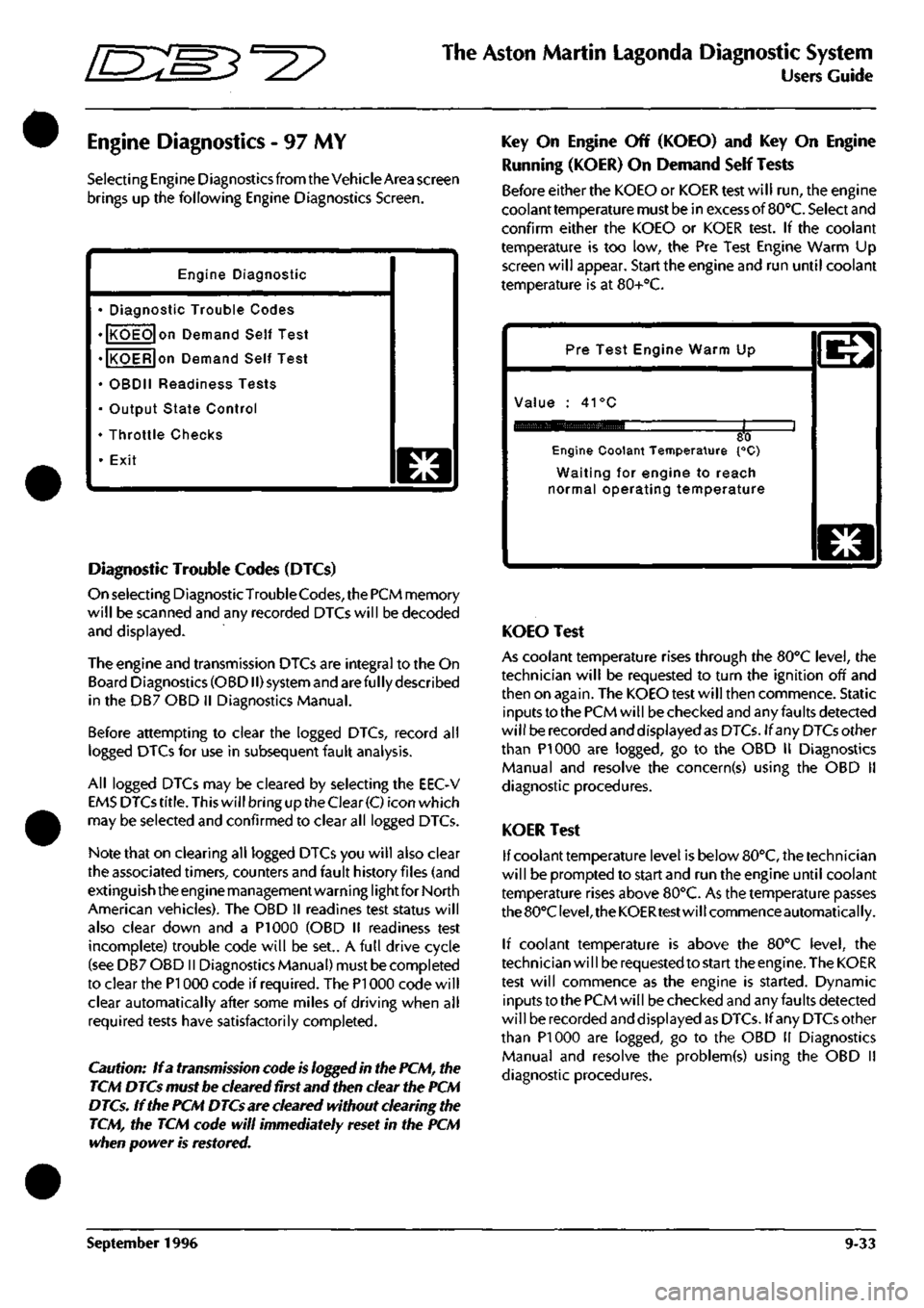

Engine Diagnostics - 97 MY

Selecting Engine Diagnostics from the Vehicle Area screen

brings up the following Engine Diagnostics Screen.

Engine Diagnostic

• Diagnostic Trouble Codes

• KOEO on Demand Self Test

• KOER on Demand Self Test

• OBDII Readiness Tests

• Output State Control

• Throttle Checks

• Exit

o

Diagnostic Trouble Codes (DTCs)

On selecting DiagnosticTrouble

Codes,

the PCM memory

will be scanned and any recorded DTCs will be decoded

and displayed.

The engine and transmission DTCs are integral to the On

Board Diagnostics (OBDII) system and are ful ly described

in the DB7 OBD II Diagnostics Manual.

Before attempting to clear the logged DTCs, record all

logged DTCs for use in subsequent fault analysis.

All logged DTCs may be cleared by selecting the EEC-V

EMS DTCs

title.

This will bring up the Clear

(C)

icon which

may be selected and confirmed to clear all logged DTCs.

Note that on clearing all logged DTCs you will also clear

the associated timers, counters and fault history files (and

extinguish the engine management warning lightfor North

American vehicles). The OBD II readines test status will

also clear down and a PI 000 (OBD II readiness test

incomplete) trouble code will be set.. A full drive cycle

(see DB7 OBD II Diagnostics Manual) must be completed

to clear the PI 000 code if required. The PI 000 code will

clear automatically after some miles of driving when all

required tests have satisfactorily completed.

Caution: If a transmission code is logged in the PCM, the

TCM DTCs must be cleared first and then clear the PCM

DTCs. If the PCM DTCs are cleared without clearing the

TCM, the TCM code will immediately reset in the PCM

when power is restored.

Key On Engine Off (KOEO) and Key On Engine

Running (KOER) On Demand Self Tests

Before either the KOEO or KOER test will run, the engine

coolant temperature must be in excess of

BO'C.

Select and

confirm either the KOEO or KOER test. If the coolant

temperature is too low, the Pre Test Engine Warm Up

screen will appear. Start the engine and run until coolant

temperature is at 80+°C.

Pre Test Engine Warm Up

Value : 41°C

80 Engine Coolant Temperature {°C)

Waiting for engine to reach

normal operating temperature

o

KOEO Test

As coolant temperature rises through the BO'C level, the

technician will be requested to turn the ignition off and

then on again. The KOEO test will then commence. Static

inputs to the PCM will be checked and any faults detected

will be recorded and displayed as DTCs. If any DTCs other

than PI 000 are logged, go to the OBD II Diagnostics

Manual and resolve the concern(s) using the OBD 11

diagnostic procedures.

KOER Test

If coolant temperature level is below 80°C, the technician

will be prompted to start and run the engine until coolant

temperature rises above 80°C. As the temperature passes

the 80°C

level,

the KOERtest will commence automatically.

If coolant temperature is above the 80°C level, the

technician wi

11

be requested to start the engine. The KOER

test will commence as the engine is started. Dynamic

inputs to the PCM will be checked and any faults detected

will be recorded and displayed as DTCs. If any DTCs other

than PI 000 are logged, go to the OBD 11 Diagnostics

Manual and resolve the problem(s) using the OBD II

diagnostic procedures.

September 1996 9-33

Page 394 of 421

^?

The Aston Martin Lagonda Diagnostic System

Users Guide

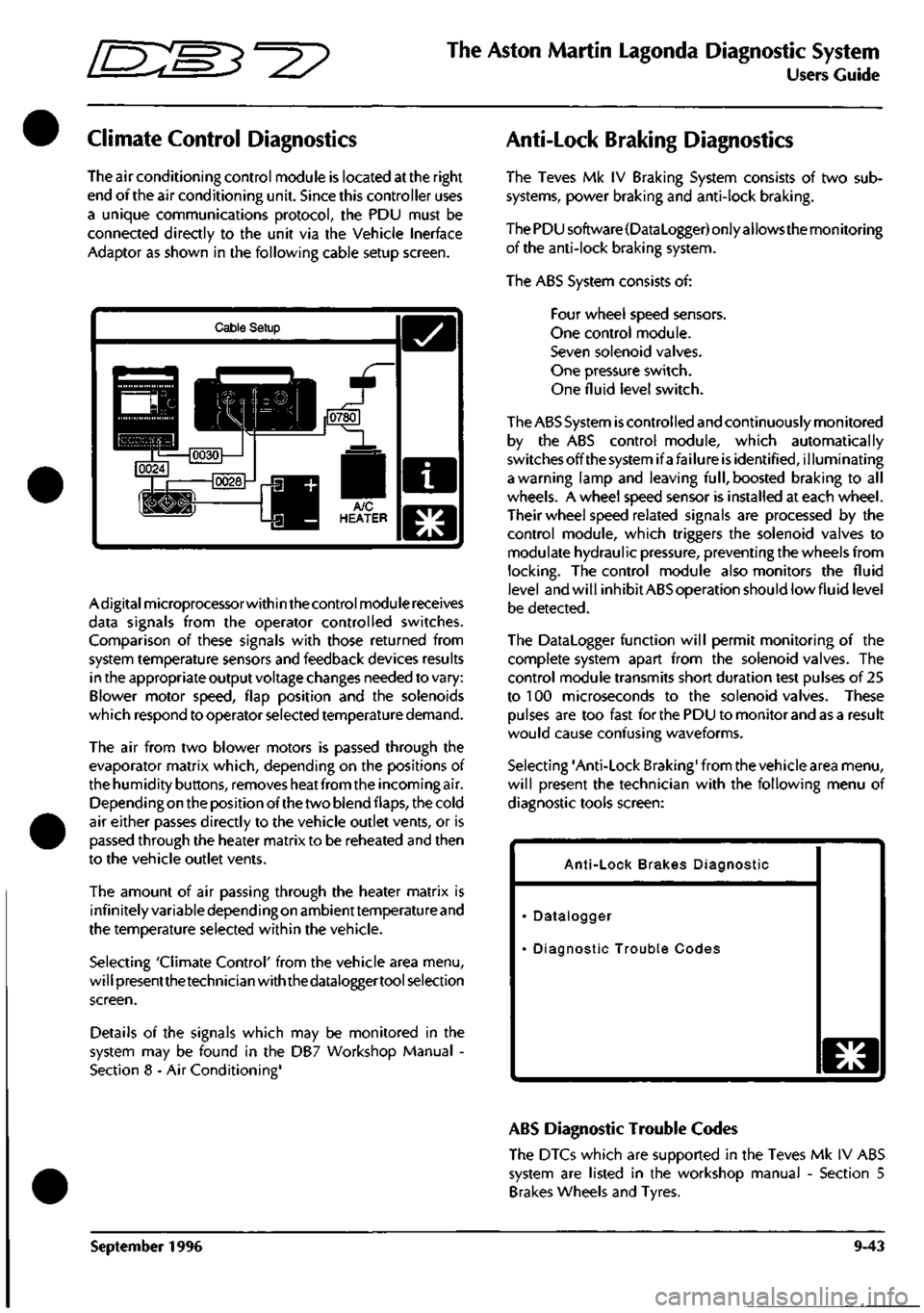

Climate Control Diagnostics

The air conditioning control module is located at the right

end of the air conditioning unit. Since this controller uses

a unique communications protocol, the PDU must be

connected directly to the unit via the Vehicle Inerface

Adaptor as shown in the following cable setup screen.

Cable Setup

Adigitalmicroprocessorwithin the control module receives

data signals from the operator controlled switches.

Comparison of these signals with those returned from

system temperature sensors and feedback devices results

in the appropriate output voltage changes needed to vary:

Blower motor speed, flap position and the solenoids

which respond to operator selected temperature demand.

The air from two blower motors is passed through the

evaporator matrix which, depending on the positions of

the humidity buttons, removes heat from the incoming air.

Dependingon the position of the two blend flaps, the cold

air either passes directly to the vehicle outlet vents, or is

passed through the heater matrix to be reheated and then

to the vehicle outlet vents.

The amount of air passing through the heater matrix is

infinitely variable depending on ambienttemperature and

the temperature selected within the vehicle.

Selecting 'Climate Control' from the vehicle area menu,

will presentthetechnician with the dataloggertool selection

screen.

Details of the signals which may be monitored in the

system may be found in the DB7 Workshop Manual -

Section 8 - Air Conditioning'

Anti-Lock Braking Diagnostics

The Teves Mk IV Braking System consists of two sub

systems, power braking and anti-lock braking.

The PDU software(DataLogger) only allows the monitoring

of the anti-lock braking system.

The ABS System consists of:

Four wheel speed sensors.

One control module.

Seven solenoid valves.

One pressure switch.

One fluid level switch.

The ABS System

is

controlled and continuously monitored

by the ABS control module, which automatically

switchesoffthesystemifafailure is identified, illuminating

a warning lamp and leaving

full,

boosted braking to all

wheels. A wheel speed sensor is installed at each wheel.

Their wheel speed related signals are processed by the

control module, which triggers the solenoid valves to

modulate hydraulic pressure, preventing the wheels from

locking.

The control module also monitors the fluid

level and will inhibit ABS operation should lowfluid level

be detected.

The Datalogger function will permit monitoring of the

complete system apart from the solenoid valves. The

control module transmits short duration test pulses of 25

to 100 microseconds to the solenoid valves. These

pulses are too fast for the PDU to monitor and as a result

would cause confusing waveforms.

Selecting 'Anti-Lock Braking' from the vehicle area menu,

will present the technician with the following menu of

diagnostic tools screen:

Anti-Lock Brakes Diagnostic

Datalogger

Diagnostic Trouble Codes

o

ABS Diagnostic Trouble Codes

The DTCs which are supported in the Teves Mk IV ABS

system are listed in the workshop manual - Section 5

Brakes Wheels and Tyres.

September 1996 9-43

Page 396 of 421

^^2?

The Aston Martin Lagonda Diagnostic System

Users Guide

Airbag System Diagnostics

WARNING: Whilst it

is

completely safe to

access

and read the airbag diagnostic module memory at

the diagnostic socket, significant personal risks

exist in the performance of any other

tasks

on the

airbag system or components. Therefore all

workshop manual warnings must be read and all

safety procedures must be followed before, during

and on completion of any other practical work on

the airbag system.

System Description

The airbag system installation comprises:

Airbag Diagnostic Module

Driver and passenger airbag modules

Two front impact (crash) sensors

One 'safing' sensor

Dedicated wiring harness

SRS indicator/warning lamp

The system is designed to provide protection for both

driver and front seat passenger by automatically

deploying airbags in the event of a collision during

forward travel.

Intheeventof

a

collision, the crash and safing sensors

will operate, completing the firing circuit and causing

the airbags to inflate within 32 milliseconds. At least

one crash sensor and the safing sensor must operate to

fire the airbags.

Any faults in system components, installation or wiring

will be indicated by a flashing code on the SRS/

AIRBAG warning lamp. Fault code information may

also be monitored using the PDU or scan

tool.

A full description of the airbag system components is

included in the workshop manual.

Airbag Diagnostics

The Airbag Control Module indicates a fault by

transmitting a pulsed signal down the Airbag System

Failure line to flash the SRS/AIRBAC warning lamp.

The fault code is repeated continuously. If there are

two or more faults, the fault code with the highest

priority is transmitted first. The second fault code is

only transmitted when the first fault has been rectified.

TheSRS/AIRBAC warning lamp is also used to indicate

any problem in the seat belt pretensioner system (if

fitted). Flashing of the lamp indicates an airbag fault,

constant illumination of the lamp indicates a seat belt

pretensioner fault.

At the top left of the PDU screen there is a bullet mark

which indicates the current state of the Airbag System

Failure line. As a code is transmitted the bullet mark

can be seen to flash.The PDU reads the fault code, and

writes the code number and fault description to the

screen.

The PDU continues to monitor the transmitted

code.

If the transmitted code changes, the new code

number and description will appear below the first.

PMC Airbag

32 Drivers airbag circuit

shorted or open

o

when remedial action has been taken to correct a

fault, press the Clear Button to clear down the PDU

display. Then use the PDU to ensure that no faults are

reported.

A series of audible beeps, continuously transmitted by

the Airbag Diagnostic Module, indicates that there is

an Airbag System fault to report and that the Airbag

System Failure line

is

open circuit. The PDU is notable

to monitor the fault line in this situation as there is no

pull-up resistor, normally provided by a warning lamp

in the instrument pack.

Rapid continuous flashing of the Instrument Pack

Airbag Failure Lamp indicates that both front impact

sensors are disconnected. No fault code is reported on

the PDU, however on close inspection the bullet mark

can be seen to flicker.

September 1996 9-45

Page 398 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

Seat Belt Pretensioner Diagnostics

(where fitted)

Description

The DB7 seat belt pretensioner system operates the

drivers seat belt pretensioner in conjunction with the

Airbag system. The seat belt pretensioner control

module is located underthe right hand seat, beside the

seat control module.

The pretensioner control module calculates changes

in vehicle speed using an input signal from an

accelerometer. When a collision is detected (Rapid

reduction in vehicle speed) the pretensioner charge is

fired using electrical energy stored in a capacitor

within the pretensioner control module. Firing of the

pretensioner charge applies additional tension to the

drivers seat belt.

The airbag and seat belt pretensioner systems share the

SRS (Airbag) warning lamp. Any fault detected by the

pretensioner control module is indicated by constant

illumination ofthe

SRS

(Airbag) warning

lamp.

Flashing

of the SRS warning lamp indicates a fault in the airbag

system.

Should both systems develop faults, the pretensioner

system will permanently illuminate the warning lamp.

This would mask the airbag system warning indication.

Therefore, rectify the pretensioner fault and then retest

for faults in the airbag system

The pretensioner control module can log up to 10

diagnostic trouble codes together with a time since

each fault was alerted to the driver. Each fault will be

identified as 'Permanent' or 'Intermittent' on the PDU

diagnostic trouble codes screen.

System Connections

The Autoliv RC5 Pretensioner Control Module has an

18 pin connector featuring six shorting bridges. The

mating halves ofthe connector may be securely locked

using a double mechanical locking system.

The following pins on the control module connector

are used in the Aston Martin seat belt pretensioner

system:

Pin 1

Pin 2

Pin n

Pin 12

Pin 14

Pin 15

Case

September 1996

Ground

SRS/Airbag Warning Lamp

Drivers airbag positive

Drivers airbag negative

Serial communications

12 volt positive feed

Ground

System Fault Strategy

No single fault may cause an unexpected deployment.

The controller will supervise the airbag/pretensioner

electrical system in order to warn the driver should a

fault occur. Any fault detected by the self diagnostics

shall cause the airbag warning lamp to be activated,

and in some cases the pretensioner control module to

enter shutdown mode. In shutdown mode, the energy

ofthe reserve capacitors shall be discharged to avoid

unintended deployment.

As the ignition is switched on, the pretensioner

controller will directly discharge theenergy capacitors.

When the start up procedure is completed without

detecting any faults, the converter will be activated

allowing the capacitors to be

charged.

The system shall

be fully active within 11 seconds after switching the

ignition on providing that no faults are detected.

All system faults monitored by the controller are filtered

in software to avoid fault warnings due to transient

electrical disturbances.

If a fault which could lead to inadvertent deployment

bedetectedbythemicroprocessor,asoftwareshutdown

will be generated. However, a leakage to an earth or

positive potential in the pretensioner output circuit

shall not cause the controller to enter shutdown mode.

If

a

permanent short of the ignition transistor occurs, a

shutdown shall be generated by the hardware circuit.

If a shutdown occurs, the system shall be unable to

deploy the pretensioner after a period of

3

seconds (i.e.

capacitors discharged to under minimum deployment

voltage).

WARNING: To avoid the possibility of personal

injury caused by accidental deployment of the

pretensioner, disconnect the vehicle battery and

wait at least 10 minutes for all voltages to fully

discharge before working on the pretensioner

system. This covers the possibility of the normal

capacitor discharge circuits being inopera tive and

failing to discharge the capacitor when instructed

to do so.

If the module enters shutdown mode, all diagnostic

functions are stopped, but the communications link

remains active. A fault code corresponding to the

cause of the problem may be read by the PDU.

9-47

Page 399 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^?

Seatbelt Pretensioner Diagnostic Trouble Codes

050A Pretensioner squib leak to battery positive

050B Pretensioner squib leak to ground

050C Pretensioner squib high resistance

050D Pretensioner squib low resistance

0D13 Capacitor voltage error

0D14 Capacitor capacitance

0D09 Energy reserve switch

0D1E Energy shutdown switch

050E Seatbelt pretensioner switch error

0109 Accelerometer function

01OA Acceleration out of range

01

OB Accelerometer offset

0209 Safing sensor error

030A Temperature sensor error

060C Warning lamp short circuit

060D Warning lamp open circuit

060E Warning lamp driver error

OAOC Analogue voltage error

0A09 Communications error

090A EEPROM not programmed

0909 EEPROM checksum

OAOA External watchdog error

OAOB External watchdog time out

020A Safing sensor not closed

090C RAM check error

9-48 September 1996

Page 401 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^=2?

Printer Use Digital Multimeter

Print Trace

The Trace Buffer is used to record technician use of the

PDU.As the diagnostics are executed, the following

information is written to trace:

Screen Title

Menu options selected

Operator questions selected

Operator actions

Control module information

Test limits and results

P codes detected by the DTC monitor

Snapshot data from the datalogger

OBD II freeze frame data

Set up the printer and load with paper. Select Print

Trace and confirm the selection. All recorded

information in the above list will be printed.

Printtrace is supported in English, French, German and

Italian.

Print Screen

The Print Screen function dumps a bitmap image of the

current screen display to the printer. This function is

particularly useful for recordingdata such as waveforms

captured by the datalogger application.

The print screen function is supported in English,

French,

German, Italian and Japanese.

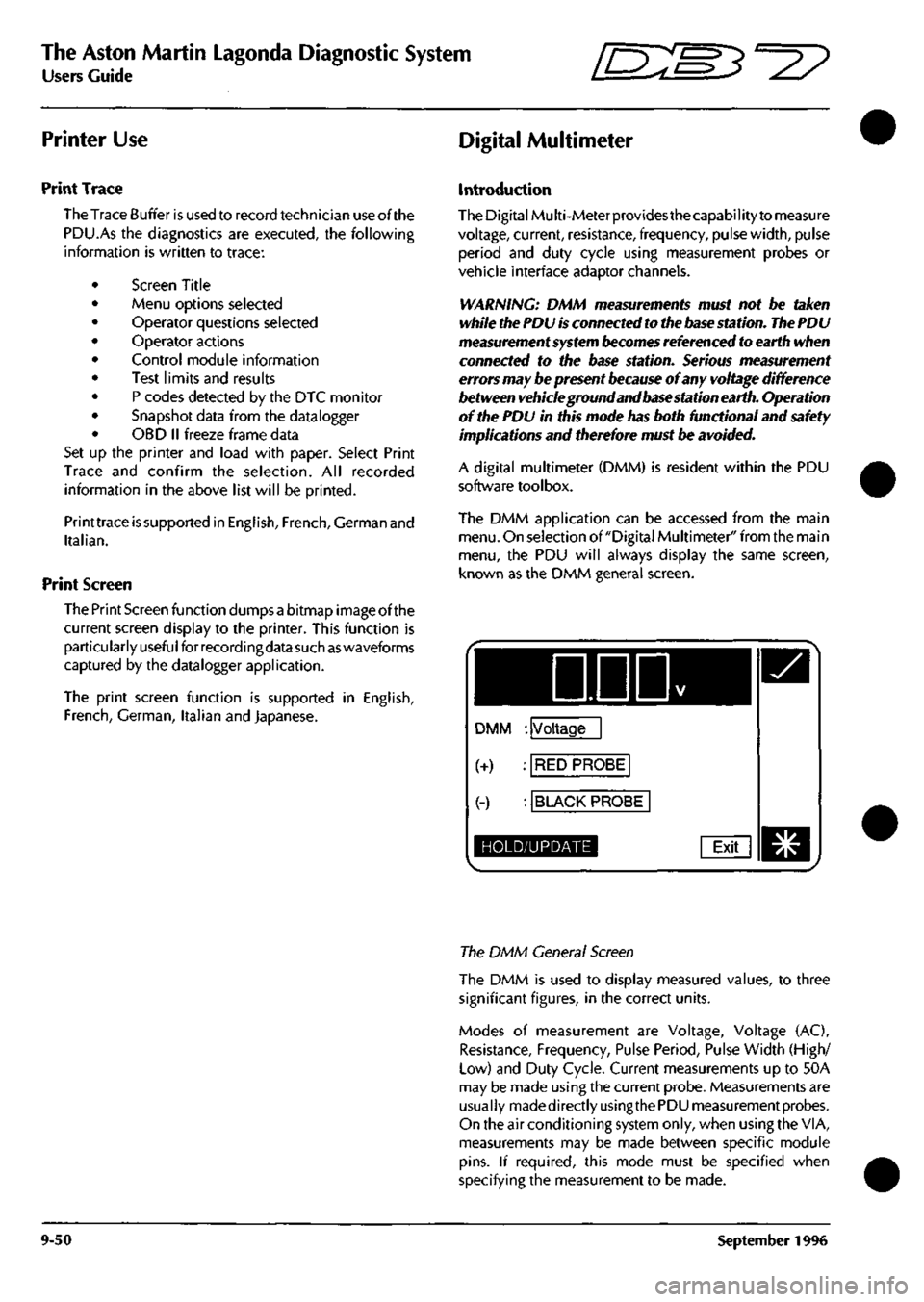

Introduction

The Digital Multi-Meterprovidesthecapability to measure

voltage, current, resistance, frequency, pulse width, pulse

period and duty cycle using measurement probes or

vehicle interface adaptor channels.

WARNING: DMM measurements must not be taken

while the PDU

is

connected to the

base

station. The PDU

measurement system

becomes

referenced to earth when

connected to the base station. Serious measurement

errors may be present

because

of any voltage difference

between vehicle ground and base station earth. Operation

of the PDU in this mode has both functional and safety

implications and therefore must be

avoided.

A digital multimeter (DMM) is resident within the PDU

software toolbox.

The DMM application can be accessed from the main

menu.

On selection of "Digital Multimeter" from the main

menu,

the PDU will always display the same screen,

known as the DMM general screen.

DDD

DMM : Voltage

(+) : RED PROBE

(-) : BLACK PROBE

HOLD/UPDATE Exit

The DMM General Screen

The DMM is used to display measured values, to three

significant figures, in the correct units.

Modes of measurement are Voltage, Voltage (AC),

Resistance, Frequency, Pulse Period, Pulse Width (High/

Low) and Duty Cycle. Current measurements up to 50A

may be made using the current probe. Measurements are

usually madedirectlyusingthe PDU measurement probes.

On the air conditioning system only, when using the VIA,

measurements may be made between specific module

pins.

If required, this mode must be specified when

specifying the measurement to be made.

9-50 September 1996