Starting ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 187 of 421

^=2?

Electrics

Airbag System

Eye Protection

Chemical protective goggles are recommended

where there is a possibility of eye contact with the

propellant. Safety glasses with side shields are

recommended for all other operations.

Protective Clothing

Approved protective gloves, overalls and shoes/

boots should be worn.

Handling and Storage Precautions

Do not store airbag modules near live electrical

equipment or circuitry. Store in a dry environment

at ambient temperatures.

Good housekeeping and engineering practices

should be employed to prevent the generation and

accumulation of

dusts.

Store in compliance with all

local state and federal regulations.

Driver and Passenger Airbag Modules

Assembly/Removal/Service Instructions

WARNING: In the event of a vehicle impact where the

airbags and the seatbeltpretensioner (if fitted) are

deployed, the following actions MUST be

performed:

Check the condition of the seatbelts, steering

wheel,

steering column, all connections to airbags,

and the column switchgear connectors for integrity

and damage. If in any

doubt,

replace suspected

parts for new parts.

Replace both crash

sensors,

the

safing sensor

and

the seatbelt pretensioner module (if fitted).

On completion of all repair procedures, switch on

the ignition and check that the

Airbag/SRS

warning

light comes on when the ignition is switched on

and extinguishes after approximately six seconds

indicating satisfactory completion of the airbag

and pretensioner

system

self

tests.

WARNING: Before starting

work,

ensure

that the ignition

switch is in position 'O' and the ignition key is

removed.

Disconnect the battery negative lead

within 12 seconds of switching off the ignition to

prevent the alarm system triggering.

As the airbag control module is equipped with a

back-up power source and due to the risk of the

airbag being inadvertently deployed, wait one

minute or longer after disconnecting the battery

before starting work on the airbag module.

• Disconnectingthe battery negative cable cancels

the memory for the 'one-touch' window down

system and stops the vehicle clock. Reset the

window memory and the clock when work is

completed.

• Never use airbags from other vehicles, always

use new parts.

• After work is completed, reconnect the battery

and perform the airbag warning light check

• Never use electrical probes to check voltage or

electrical resistance of the airbag modules.

• Disconnect the airbag before carrying out any

work on, or in the vicinity of the module, or

when using electric welding equipment.

• Always ensure that the battery negative lead has

been disconnected for at least one minute before

commencing any removal procedure.

September 1996 6-71

Page 219 of 421

'^^

Electrics

Seat Belt Pretensioner

6.6.26.1

Pretensioner Control Module -

Renew

Read the warnings given in system fault strategy

and service instructions on the previous page before

starting the following procedure.

Procedure

1.

Disconnect the battery ground (black) lead and

wait at least 10 minutes for the pretensioner power

supply to fully discharge before working on the

pretensioner system.

Note:

The

vehicle battery must

be

disconnected within

12

seconds

of switching off

the

ignition to avoid the alarm

siren sounding.

2. Motor the right front seat to its rearmost position.

3. Remove the floor carpet and the ECU cover.

4.

Disconnect the pretensioner control module

connector (orange connector with black safety

clip).

5. Remove 3 flange screws securing the module,

noting the position of the earth strap.

6. Fit the new pretensioner control module with the

connector facing to the rear and secure with 3

flange screwsensuringthatthe earth strap is secured

with the outboard rear screw.

7. Connect the orange connector to the control

module.

8. RefitandsecuretheECU cover and the floor carpet.

9. Reconnect the battery ground (black)

lead.

Note:

The

vehicle clock and the window control unit will

need

resetting

after completion of this procedure.

10.

Switch on the ignition and check that the airbag

warni ng I ight comes on when the ign ition

is

switched

on and extinguishesafterapproximately sixseconds

indicating satisfactory completion of the

pretensioner and airbag system self tests.

6.6.24.1

Pretensioner Assembly Renew

Read the warnings given in system fault strategy

and service i nstruaions on the previous page before

starting the following procedure.

1.

2.

4.

Procedure

Motor the drivers seat to its rearmost position.

Disconnect the battery ground (black) lead and

wait at least 10 minutes for the pretensioner power

supply to fully discharge before working on the

pretensioner system.

Note: Disconnect the battery within 12 seconds of

switchingoffthe ignition to avoid the alarm siren sounding.

Remove the pretensioner trim cover. Unbolt the

drivers seat. Tip the seat rearwards and disconnect

the seat and pretensioner squib connectors.

Release one bolt at the

base

of the seat belt

stal k

and

remove the pretensioner assembly.

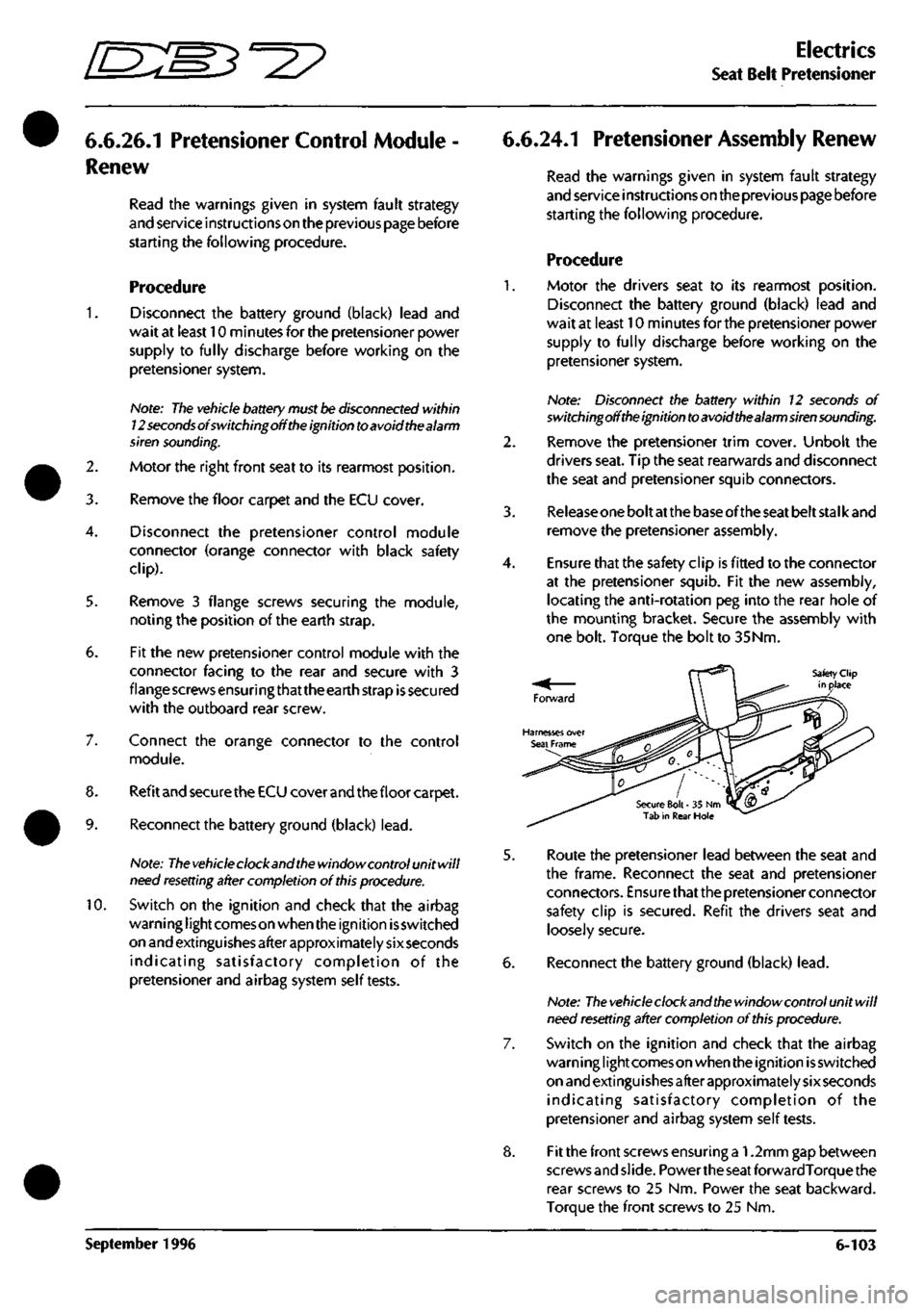

Ensure that the safety clip is fitted to the connector

at the pretensioner squib. Fit the new assembly,

locating the anti-rotation peg into the rear hole of

the mounting bracket. Secure the assembly with

one bolt. Torque the bolt to 35Nm.

Safety Clip in place

5. Route the pretensioner lead between the seat and

the frame. Reconnect the seat and pretensioner

connectors. Ensure that the pretensioner connector

safety clip is secured. Refit the drivers seat and

loosely secure.

6. Reconnect the battery ground (black)

lead.

Note:

The

vehicle clock and

the

window control unit will

need

resetting

after completion of this procedure.

7. Switch on the ignition and check that the airbag

warn i ng I ight comes on when the ignition

is

switched

on and extingu

ishes

after approximately six seconds

indicating satisfactory completion of the

pretensioner and airbag system self tests.

8. Fit the front screws ensuring a 1.2mm gap between

screws and slide. Power the seat forwardTorque the

rear screws to 25 Nm. Power the seat backward.

Torque the front screws to 25 Nm.

September 1996 6-103

Page 294 of 421

^=2?

Air Conditioning

System Trouble Shooting

System Trouble Shooting

There are five basic symptoms associated with air conditioning fault diagnosis. It is very important to identify the area of

concern before starting a rectification procedure. Spend time with your customer on problem identification, and use the

following trouble shooting guide.

The following conditions are not in order of priority.

No Cooling

1.

Is the electrical circuit to the compressor clutch functional?

2.

Is the electrical circuit to the blower motor(s) functional?

3. Slack or broken compressor drive belt.

4.

Compressor partially or completely seized.

5. Compressor shaft seal leak (see 9).

6. Compressor valve or piston damag^ (may be indicated by small variation between HIGH & LOW side pressures

relative to engine speed).

7. Broken refrigerant pipe (causing total loss of refrigerant).

8. Leak in system (causing total loss of refrigerant).

9. Blocked filter in the receiver drier.

10.

Evaporator sensor disconnected?

11.

Dual pressure switch faulty?

Note:

Should a

leak or low

refrigerant be established as

the

cause,

follow

the procedures

for

Recovery-Recycle

-Recharge,

and

observe all refrigerant and oil handling instructions.

insufficient Cooing

1.

Blower motor(s) sluggish.

2.

Restricted blower inlet or outlet passage

3. Blocked or partially restricted condenser matrix or fins.

4.

Blocked or partially restricted evaporator matrix.

5. Blocked or partially restricted filter in the receiver drier.

6. Blocked or partially restricted expansion valve.

7. Partially collapsed flexible pipe.

8. Expansion valve temperature sensor faulty (this sensor is integral with valve and is not serviceable).

9. Excessive moisture in the system.

10.

Air in the system.

11.

Low refrigerant charge.

May 1996 8-17

Page 307 of 421

Air Conditioning

System Fault Diagnosis ^=2?

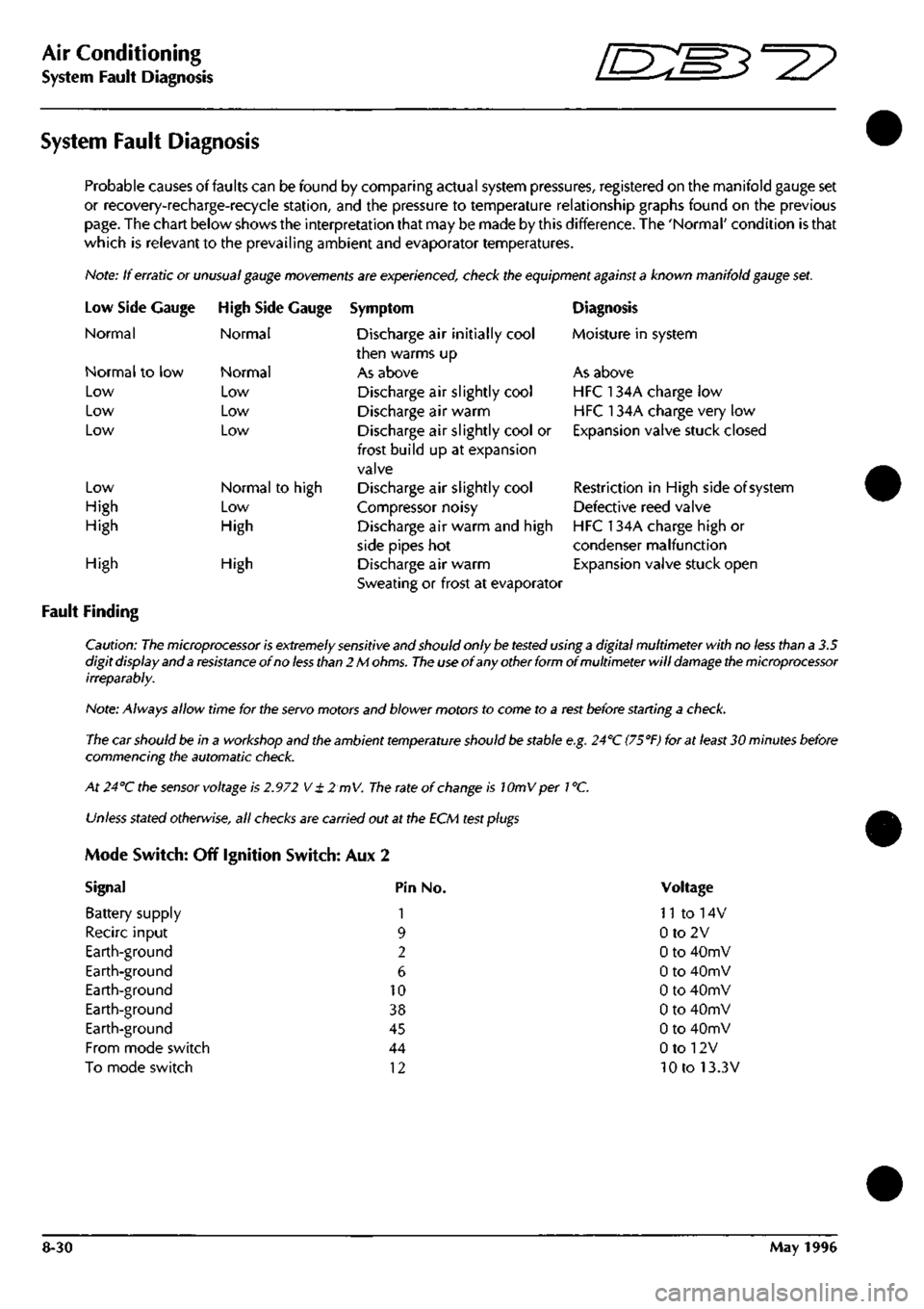

System Fault Diagnosis

Probable causes of faults can be found by comparing actual system pressures, registered on the manifold gauge set

or recovery-recharge-recycie station, and the pressure to temperature relationship graphs found on the previous

page.

The chart below shows the interpretation that may be made by this difference. The 'Normal' condition is that

which is relevant to the prevailing ambient and evaporator temperatures.

Note: If erratic or

unusual gauge movements

are experienced, check the equipment

against a

known manifold

gauge

set.

Low Side

Normal

Gauge

Normal to low

Low

Low

Low

Low

High

High

High Side Gauge

Normal

Normal

Low

Low

Low

Normal to high

Low

High

High

Fault Finding

High

Symptom

Discharge air initially cool

then warms up

As above

Discharge air slightly cool

Discharge air warm

Discharge air slightly cool or

frost build up at expansion

valve

Discharge air slightly cool

Compressor noisy

Discharge air warm and high

side pipes hot

Discharge air warm

Sweating or frost at evaporator

Diagnosis

Moisture in system

As above

HFC 134A charge low

HFC 134A charge very low

Expansion valve stuck closed

Restriction in High side of system

Defective reed valve

HFC 134A charge high or

condenser malfunction

Expansion valve stuck open

Caution:

The microprocessor is extremely sensitive

and should only

be tested

using

a

digital multimeter with no

less

than a 3.5

digit display and a

resistance

of no

less than

2 M

ohms.

The use

of any other form of multimeter will

damage the microprocessor

irreparably.

Note: Always allow time for the

servo

motors and blower motors to come to a

rest

before starting a

check.

The car should be in a workshop and the ambient

temperature

should

be

stable

e.g.

24''C

(75°F)

for at

least

30 minutes before

commencing the automatic

check.

At 24°C the

sensor

voltage is

2.972

V

± 2 mV.

The

rate of

change

is lOmVper

1

°C.

Unless

stated

otherwise,

all

checks

are carried out at the ECM

test plugs

Mode Switch: Off Ignition Switch: Aux 2

Signal Pin No.

Battery supply 1

Recirc input 9

Earth-ground 2

Earth-ground 6

Earth-ground 10

Earth-ground 38

Earth-ground 45

From mode switch 44

To mode switch 12

Voltage

n to 14v

0to2V

0 to 40mV

0 to 40mV

0 to 40mV

0 to 40mV

0 to 40mV

0 to 12V

10 to 13.3V

8-30 May 1996

Page 325 of 421

Air Conditioning

Refrigerant Recovery and Recycling ^=2?

Recovery Procedure

Hote:

Run the

air-conditioning

system

for

a

few

minutes

before starting the

recovery

procedure as

this will

enable

more refrigerant to be recovered. Turn the

system

off

before

starting

the procedure.

1.

Attach the red (high side) hose oftheunittothe high

side fitting of the system on the vehicle then fit the

blue (low side) fitting to the low side on the vehicle.

Note: Make sure that the Air conditioning

system

has

pressure in it before beginning the recovery

process;

if

there is no

system

pressure there is no refrigerant to

recover.

Also

make sure that the

oil

drain

valve

is

closed.

2. Open both the high and low side valves on the

control panel.

3. Open the red CAS (vapour) valve and the blue

LIQUID valve on the tank.

4.

Turn on the MAIN POWER switch.

5. Press the RECOVERY key on the key-pad. The

display shows that the unit in the RECOVER mode

and AUTOMATIC cycle. After the compressor starts

the display shows the weight of refrigerant being

recovered.

The compressor shuts off automatically

when the recovery is complete and the display

shows the message 'CPL' and the final weight of the

recovered refrigerant.

6. Wait for five minutes and watch the manifold

gauges for a rise above 0. If a rise occurs press the

HOLD/CONT key. Repeat as needed until the

system pressure holds for two minutes.

Note: Drain the oil

separator

after

each

job.

7. Slowly open the oil drain valve and drain the oil

into the oil catch bottle. When all the recovered oil

has completely drained close the valve.

8. Replace oil lost during the recovery procedure by

measuringthe amount of oil inthe catch bottle and

adding the same amount of new oil to the system.

Note:

Dispose

of the

recovered

oil in an approved way.

9. When the recovery tank is full the compressor is

shut off and the display shows the message FULL.

Evacuating and Recycling the Refrigerant

1.

Open the red (high side) and the blue (low side)

valves on the unit and open the red GAS (vapour)

valve and the blue LIQUID valve on the tank.

2.

Enter the required time using the key-pad, press

enter,thedisplayshowstheenteredtime in minutes.

3. Start the vacuum pump by pressing the VACUUM

KEY again. The recycling process begins

approximately five seconds after the vacuum pump

starts and the message RECYCLE is displayed.

Note: If the vacuum pump

has

run for ten hours or

over

without an oil change the

message

OIL

flashes

on the

display.

Change

the pump oil and

then press

the

SHIFT/

RESET key and

the

zero key to

reset the

oil

change

timer

to zero.

The digital display counts down the evacuation

time.

4.

Check for non-condensibles after five minutes

recycling.

Ifthegauge needles are more than lOpsi

apart purge the non-condensibles from the tank by

open

i ng

the purge valve on the back of the

un

it and

continue to bleed until both needles show the same

reading.

The vacuum sequence continues until the

programmed time has elapsed at which point the

message CPL is displayed.

5. If the moisture indicator turns green recharge with

refrigerant.

or

5. If the moisture indicator has not turned green

replace the unit's filter-drier, which is probably

saturated.

Note:

Pressing

any key at this point allows the next

function to be

accessed.

To recycle the refrigerant only without pulling a

vacuum for an indefinite period of time press the

SHIFT/RESET key and the RECYCLE key on the key

pad.

Press the SHIFT/RESET key to cancel.

For vacuum only press the SHIFT/RESET key and

the ENTER key and then press

"1".

Run the vacuum

pump as long as required and then press

"1"

or

press SHIFT/RESET to cancel.

8-48 May 1996