cooling ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 129 of 421

Electrics

Relay Location Index - 97 MY 5^^?

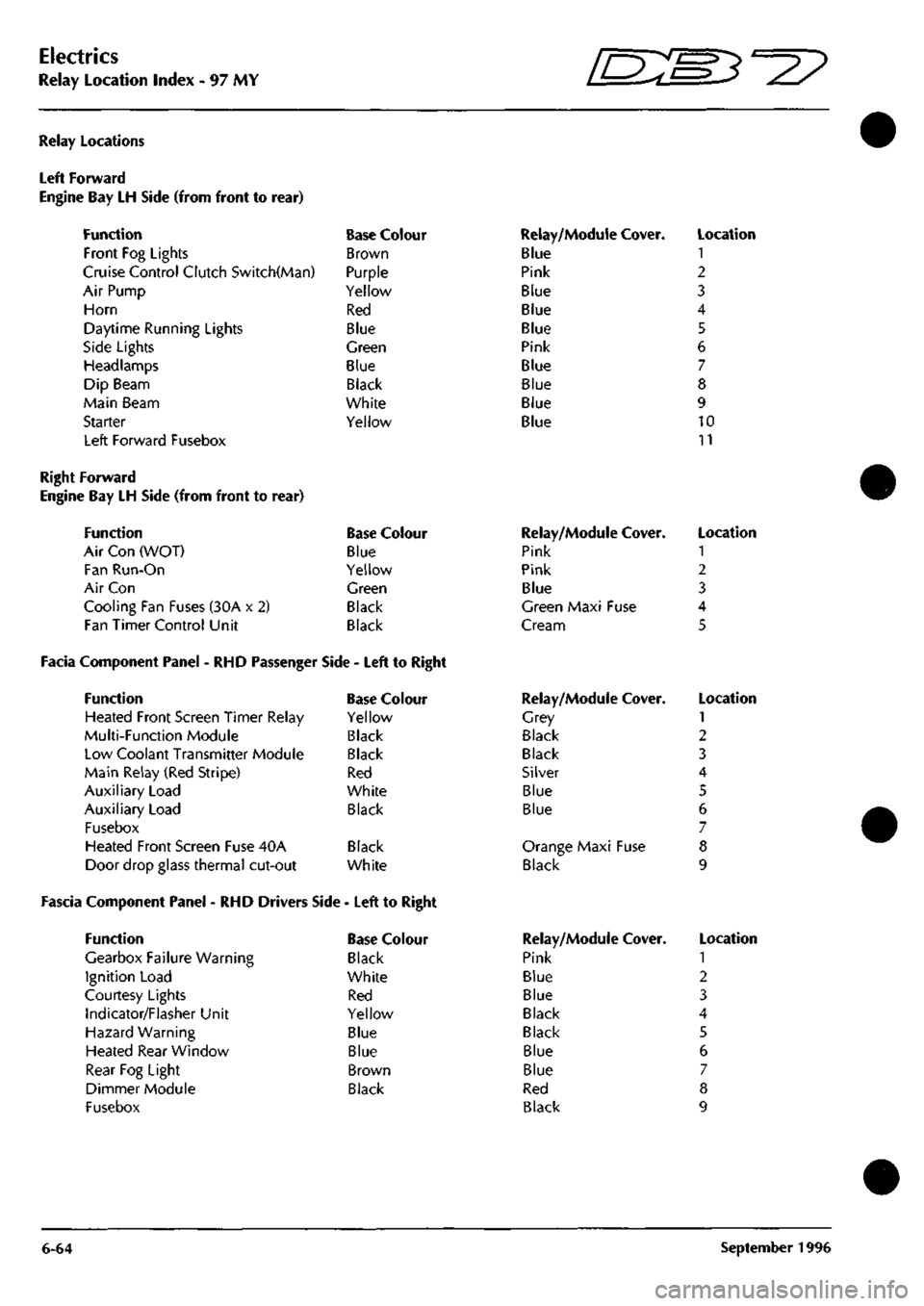

Relay Locations

Left Forward

Engine Bay LH Side (from front to

Function

Front Fog Lights

rear)

Cruise Control Clutch Switch(Man)

Air Pump

Horn

Daytime Running Lights

Side Lights

Headlamps

Dip Beam

Main Beam

Starter

Left Forward Fusebox

Base Colour

Brown

Purple

Yellow

Red

Blue

Green

Blue

Black

White

Yellow

Relay/Module Cover.

Blue

Pink

Blue

Blue

Blue

Pink

Blue

Blue

Blue

Blue

Location

1

2

3

4

5

6

7

8

9

10

11

Right Forward

Engine Bay LH Side (from front to rear)

Function Base Colour

Air Con (WOT) Blue

Fan Run-On Yellow

Air Con Green

Cooling Fan Fuses (30A x 2) Black

Fan Timer Control Unit Black

Facia Component Panel - RHD Passenger Side - Left to Right

Function Base Colour

Heated Front Screen Timer Relay Yellow

Multi-Function Module Black

Low Coolant Transmitter Module Black

Main Relay (Red Stripe) Red

Auxiliary Load White

Auxiliary Load Black

Fusebox

Heated Front Screen Fuse 40A Black

Door drop glass thermal cut-out White

Fascia Component Panel - RHD Drivers Side - Left to Right

Function

Gearbox Failure Warning

Ignition Load

Courtesy Lights

Indicator/Flasher Unit

Hazard Warning

Heated Rear Window

Rear Fog Light

Dimmer Module

Fusebox

Base Colour

Black

White

Red

Yellow

Blue

Blue

Brown

Black

Relay/Module

Pink

Pink

Blue

Cover.

Green Maxi Fuse

Cream

Relay/Module

Grey

Black

Black

Silver

Blue

Blue

Cover.

Orange Maxi Fuse

Black

Relay/Module

Pink

Blue

Blue

Black

Black

Blue

Blue

Red

Black

Cover.

Location

1

2

3

4

5

Location

1

2

3

4

5

6

7

8

9

Location

1

2

3

4

5

6

7

8

9

6-64 September 1996

Page 284 of 421

^^?

Air Conditioning

System Description

System Description

The in-car temperature and humidity are regulated by the electronically controlled air conditioning system. The

system comprises four subsystems:

• heater matrix, supplied with water from the engine cooling system

• refrigeration

• vacuum

• electronic control

Apart from the ambient temperature sensor and the aspirated in-car temperature sensor, most of the components

are housed in the air conditioning unit (Fig. 1) situated behind the dash board, or in the engine compartment.

Figure 1.

Key to Fig. 1 - Left Hand Air Conditioning Unit

1.

Upper feedback potentiometer

2.

Water temperature switch

3. Lower feedback potentiometer

4.

Vacuum valve block

5. Vacuum restrictor

6. Condensate drain tube

Figure 2.

Key to Fig. 2 - Right Hand Air Conditioning Unit

1.

Upper servo motor

2.

Electronic control module

3. Lower servo motor

4.

Evaporator sensor

5. Condensate drain tube

Special Servicing Tools and Equipment

1 PDU system

1 Charging station

1 Leak detector

1 Temperature test box

1 Sanden compressor service tool kit

1 CM Type compressor service tool kit

1 Digital voltmeter

1 Multimeter

May 1996 8-7

Page 286 of 421

^7

Air Conditioning

Temperature Distribution System

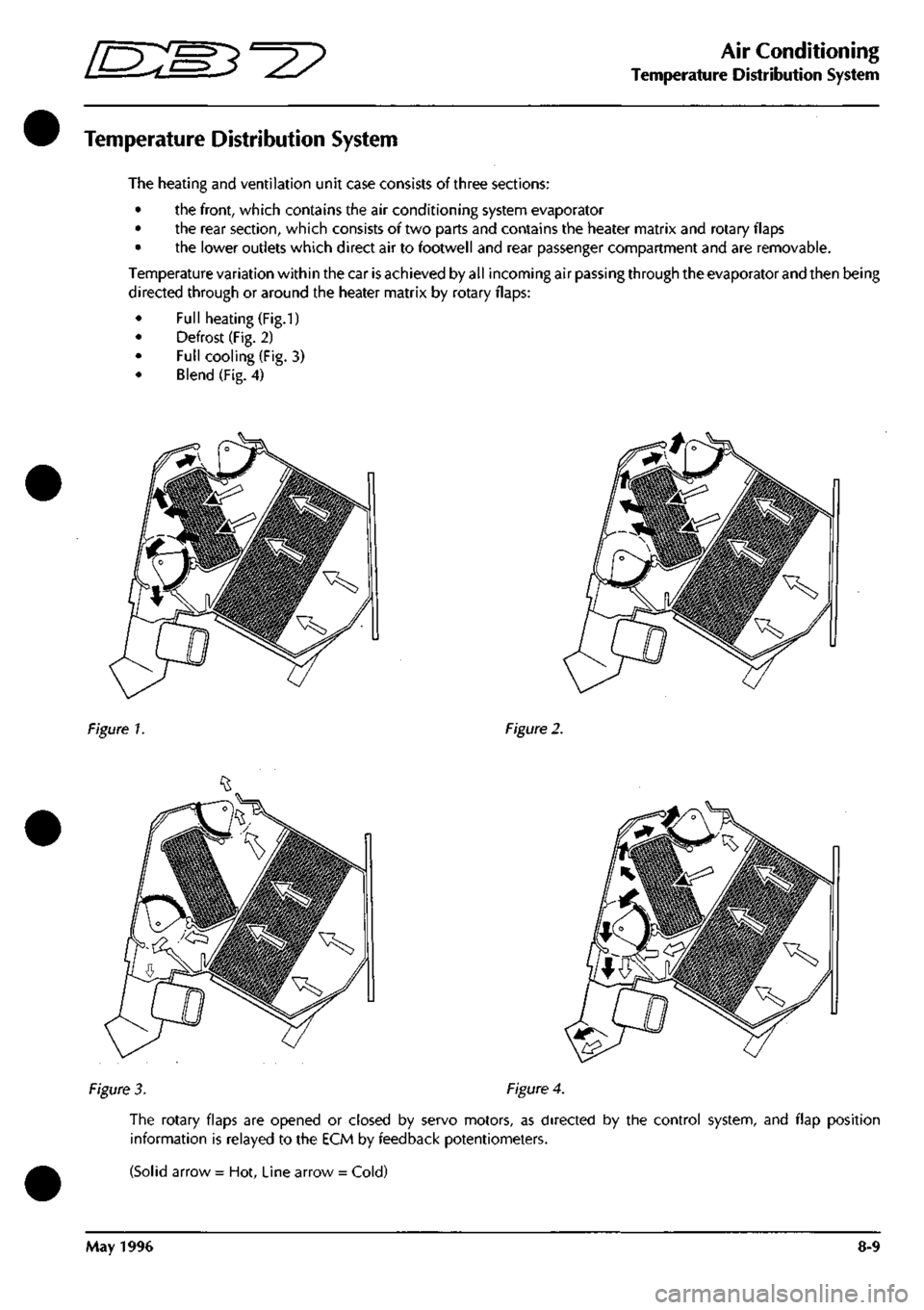

Temperature Distribution System

The heating and ventilation unit case consists of three sections:

• the front, which contains the air conditioning system evaporator

• the rear section, which consists of two parts and contains the heater matrix and rotary flaps

• the lower outlets which direct air to footwell and rear passenger compartment and are removable.

Temperature variation within the car

is

achieved by all incoming air passing through the evaporator and then being

directed through or around the heater matrix by rotary flaps:

• Full heating (Fig.1)

• Defrost (Fig. 2)

• Full cooling (Fig. 3)

Blend (Fig. 4)

Figure 1.

Figure

2.

Figure

3.

Figure

4.

The rotary flaps are opened or closed by servo motors, as directed by the control system, and flap position

information is relayed to the ECM by feedback potentiometers.

(Solid arrow = Hot, Line arrow = Cold)

May 1996 8-9

Page 288 of 421

^7

Air Conditioning

Temperature Distribution System

Air Conditioning Function Switch

When AC, DEM or Re-circulation ^v is selected the system engages the Air conditioning compressor using the

electromagnetic clutch. The in-car temperature is automatically corrected to the pre selected level by the system

sensors.

When MAN (manual mode) is selected it provides the operator selection of fan speed and in-car temperature

selection facilities. The in-car temperature is not thermostatically corrected to a predetermined level by the system

sensors.

When ECO is selected the system is in economy mode which allows the fan speed and heating levels to be selected

but gives no cooling. The air conditioning compressor is not engaged putting a minimum load on the engine.

When manual re-circulation is selected the blower flaps are closed and only that air which is in the vehicle is re

circulated.

When the ignition is turned off the blower flaps revert to the fresh air position.

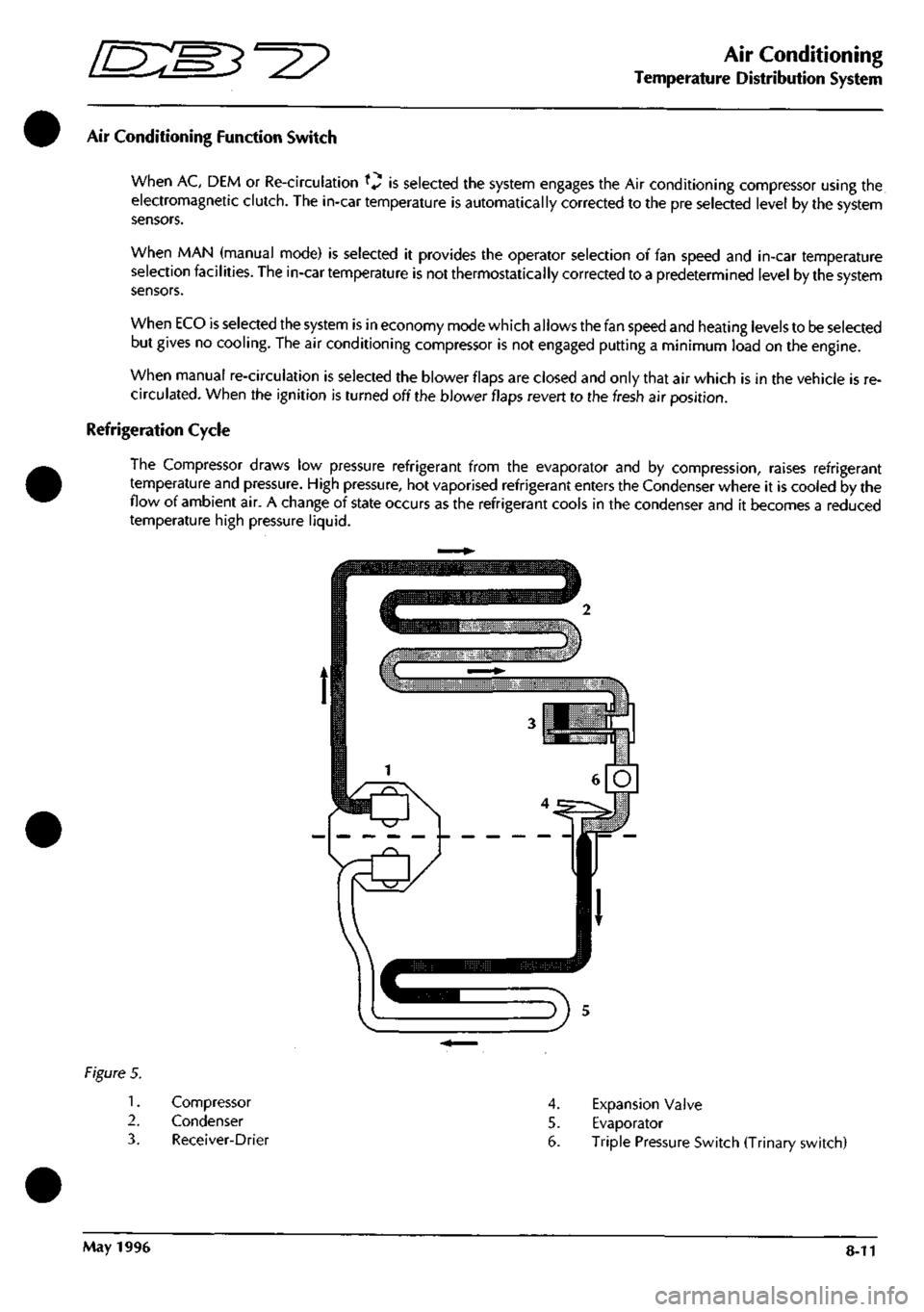

Refrigeration Cycle

The Compressor draws low pressure refrigerant from the evaporator and by compression, raises refrigerant

temperature and pressure. High pressure, hot vaporised refrigerant enters the Condenser where it is cooled by the

flow of ambient air. A change of state occurs as the refrigerant cools in the condenser and it becomes a reduced

temperature high pressure liquid.

Figure 5.

1.

2.

3.

Compressor

Condenser

Receiver-Drier

4.

Expansion Valve

5. Evaporator

6. Triple Pressure Switch (Trinary switch)

May 1996 8-11

Page 289 of 421

Air Conditioning //~-->> ^/zz:^^ • ^ ^

General Svstem Procedures ' —"^ ^ '^ General System Procedures

From the condenser the liquid passes into the Receiver-Drier which has three functions:

• Storage vessel for varying system refrigerant demands.

• Filter to remove system contaminants.

• Moisture removal via the desiccant.

With the passage through the receiver-drier completed the, still high pressure liquid refrigerant, enters the Expansion

Valve where it is metered through a controlled orifice which has the effect of reducing the pressure and temperature.

The refrigerant, now in a cold atomised state, flows into the Evaporator and cools the air which is passing through

the matrix.

As heat is absorbed by the refrigerant it once again changes state, into a vapour, and returns to the compressor for

the cycle to be repeated (Fig. 5).

There is an automatic safety valve incorporated in the compressor which operates should the system pressure be

in excess of

41

bar. The valve re-seats when the pressure drops below 35 bar.

Note: The division of HIGH and LOW side is simply the

system pressure

differential created by the

compressor

discharge

(pressure),

suction

(inlet)

ports and

the

relative inlet and outlet

ports

of the

expansion

valve.

This

differential is critical to

system

fault

diagnosis

and efficiency checks.

System Protection

The trinary pressure switch, located in the liquid line, cuts electrical power to the compressor clutch if the system

pressure is outside of the range of 2 Bar

(1

st Function) to 27 Bar (2nd Function). The third function is to switch on

the cooling fans when pressure exceeds 20 bar.

General System Procedures

Leak Test

Faults associated with low refrigerant charge weight and low pressure may be caused by leakage. Leaks traced to

mechanical connections may be caused by torque relaxation or joint face contamination. Evidence of oil around

such areas is an indicator of leakage. When checking for non visible leaks use only a dedicated Refrigerant El 34A

electronic analyser and apply the probe all round the joint connection. Should a leak be traced to a joint, check that

the fixing is secured to the correct tightening torque before any other action is taken.

Do not forget to check the compressor shaft seal and evaporator.

Note: Never

use

a dedicated

CFC 12

or

naiced

flame type

analyser.

Charge Recovery (System Depressurisation)

The process of refrigerant recovery depends on the basic characteristics of your chosen recovery-recycle-recharge

equipment, therefore, follow the manufacturers instructions carefully. Remember that compressor oil may be drawn

out of the system by this process, take note of the quantity recovered so that it may be replaced.

CAUTION: Observe all relevant safety requirements.

• Do not vent refrigerant directly to atmosphere and always use approved recovery-recycle-recharge

equipment.

• Wear suitable eye and skin protection.

• Do not mix the refrigerant with CFC 12.

• Take note of the amount of recovered refrigerant, it indica

tes the

state of the

system

and

thus the

magnitude

of any problem.

8-12 May 1996

Page 293 of 421

Air Conditioning //—^ ^ci^^ • ^ ^

Fnnrtlnn;il fhprk I *-/ -^ r <

Procedure Normal System Reaction

16.

Select ECO Blower flaps revert to fresh air position

17.

Select AC Engine revs change then stabilise

18.

Select fan speed 3 Small increase in fan speed

19.

Select fan speed 2 Fan speed lower

Centre vent and dash end cold

footwell cool

20.

Select MAX temperature

allow in-car temperature to stabilise Hot air from footwell,

(Passenger side underscuttle panel must be in place) warm from dash end

21.

Select MIN temperature and mid face level System goes to full cooling automatically

Cold air from all vent except from screen vent

Centre vent open

Blower at re-circulation

22.

Select DEMIST and full heat Demist vents open, centre vent closes and

blower flaps revert to fresh air position

System check now complete System good.

Note: A small amount of air will bleed from the

ends

of the

demist-defrost vents

in all

cases,

but there should be no leak along

the length of the vents.

8-16 May 1996

Page 294 of 421

^=2?

Air Conditioning

System Trouble Shooting

System Trouble Shooting

There are five basic symptoms associated with air conditioning fault diagnosis. It is very important to identify the area of

concern before starting a rectification procedure. Spend time with your customer on problem identification, and use the

following trouble shooting guide.

The following conditions are not in order of priority.

No Cooling

1.

Is the electrical circuit to the compressor clutch functional?

2.

Is the electrical circuit to the blower motor(s) functional?

3. Slack or broken compressor drive belt.

4.

Compressor partially or completely seized.

5. Compressor shaft seal leak (see 9).

6. Compressor valve or piston damag^ (may be indicated by small variation between HIGH & LOW side pressures

relative to engine speed).

7. Broken refrigerant pipe (causing total loss of refrigerant).

8. Leak in system (causing total loss of refrigerant).

9. Blocked filter in the receiver drier.

10.

Evaporator sensor disconnected?

11.

Dual pressure switch faulty?

Note:

Should a

leak or low

refrigerant be established as

the

cause,

follow

the procedures

for

Recovery-Recycle

-Recharge,

and

observe all refrigerant and oil handling instructions.

insufficient Cooing

1.

Blower motor(s) sluggish.

2.

Restricted blower inlet or outlet passage

3. Blocked or partially restricted condenser matrix or fins.

4.

Blocked or partially restricted evaporator matrix.

5. Blocked or partially restricted filter in the receiver drier.

6. Blocked or partially restricted expansion valve.

7. Partially collapsed flexible pipe.

8. Expansion valve temperature sensor faulty (this sensor is integral with valve and is not serviceable).

9. Excessive moisture in the system.

10.

Air in the system.

11.

Low refrigerant charge.

May 1996 8-17

Page 295 of 421

Air Conditioning

/J=y>f^^^

—p )

System Trouble Shooting

12.

Compressor clutch slipping.

13.

Blower flaps or distribution vents closed or partially seized.

14.

Water valve not closed.

15.

Evaporator sensor detached from evaporator.

Intermittent Cooling

Is the electrical circuit to the compressor clutch consistent?

2.

Is the electrical circuit to the blower motor(s) consistent?

3. Compressor clutch slipping.

4.

Faulty air distribution flap potentiometer or motor.

5. Motorised in-car aspirator or evaporator temperature sensor faulty, causing temperature variations.

6. Blocked or partially restricted evaporator or condenser.

Noisy System

1.

Loose or damaged compressor drive belt.

2.

Loose or damaged compressor mountings.

3. Compressor oil level low, look for evidence of leakage.

4.

Compressor damage caused by low oil level or internal debris.

5. Blower(s) motor(s) noisy.

6. Excessive refrigerant charge, witnessed by vibration and 'thumping' in the high pressure line (may be indicated by

high HIGH & high LOW side pressures).

7. Low refrigerant charge causing 'hissing' at the expansion valve (may be indicated by low HIGH side pressure).

8. Excessive moisture in the system causing expansion valve noise.

Note;

Electrical faults

may

be more rapidly traced using PDU.

Insufficient Heating

1.

Water valve stuck in the closed position.

2.

Motorised in-car aspirator seized.

3. Blend flaps stuck or seized.

4.

Blocked or restricted blower inlet or outlet.

5. Low coolant level.

6. Blower fan speed low.

7. Coolant thermostat faulty or seized open.

8-18 May 1996

Page 299 of 421

Air Conditioning

In Car Controls '^^

Air Conditioning Function Switch

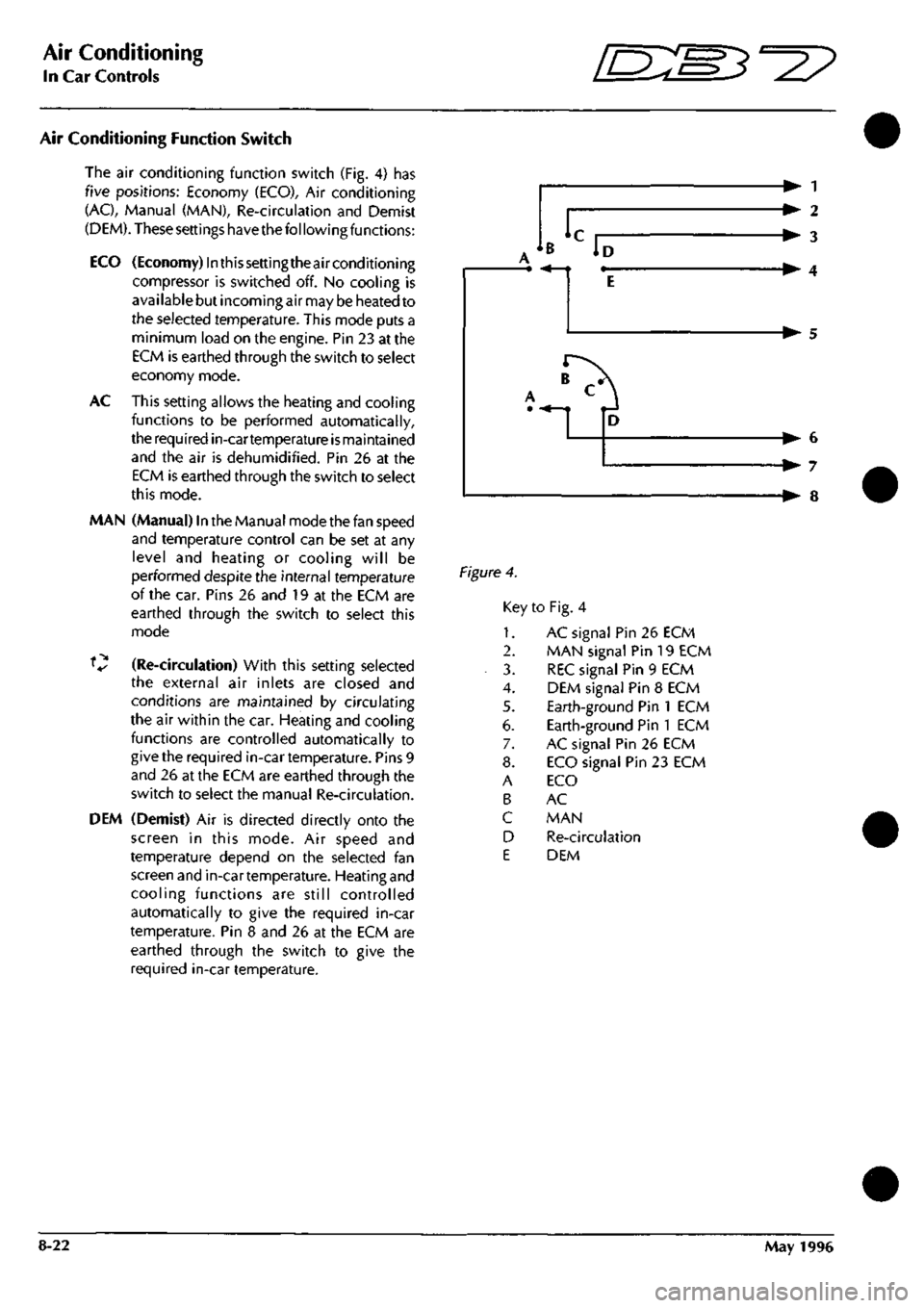

The air conditioning function switch (Fig. 4) has

five positions: Economy (ECO), Air conditioning

(AC),

Manual (MAN), Re-circulation and Demist

(DEM). These settings have thefol lowing functions:

ECO (Economy) Inthissettingtheairconditioning

compressor is switched off. No cooling is

available but incoming air may be heated to

the selected temperature. This mode puts a

minimum load on the engine. Pin 23 at the

ECM is earthed through the switch to select

economy mode.

AC This setting allows the heating and cooling

functions to be performed automatically,

the required in-cartemperature

is

maintained

and the air is dehumidified. Pin 26 at the

ECM is earthed through the switch to select

this mode.

MAN (Manual) In the Manual mode the fan speed

and temperature control can be set at any

level and heating or cooling will be

performed despite the internal temperature

of the car. Pins 26 and 19 at the ECM are

earthed through the switch to select this

mode

V (Re-circulation) With this setting selected

the external air inlets are closed and

conditions are maintained by circulating

the air within the car. Heating and cooling

functions are controlled automatically to

give the required in-cartemperature. Pins 9

and 26 at the ECM are earthed through the

switch to select the manual Re-circulation.

DEM (Demist) Air is directed directly onto the

screen in this mode. Air speed and

temperature depend on the selected fan

screen and in-cartemperature. Heating and

cooling functions are still controlled

automatically to give the required in-car

temperature. Pin 8 and 26 at the ECM are

earthed through the switch to give the

required in-car temperature.

B

liD^

-• 1

-• 2

-• 3

-• 4

-• 5

,'^

1 -• 6

-• 7

-• 8

Figure 4.

Key to Fig. 4

1.

AC signal Pin 26 ECM

2.

MAN signal Pin 19 ECM

3. REC signal Pin 9 ECM

4.

DEM signal Pin 8 ECM

5. Earth-ground Pin 1 ECM

6. Earth-ground Pin 1 ECM

7. AC signal Pin 26 ECM

8. ECO signal Pin 23 ECM

A ECO

B AC

C MAN

D Re-circulation

E DEM

8-22 May 1996

Page 311 of 421

Air Conditioning

Refrigeration /s:s^°27

Refrigeration

Safety Precautions

The air conditioning system is designed to use only

Refrigerant E134A (dichlorodifluoromethane). Extreme

care must betaken NOT to use

a

methylchloride refrigerant.

The chemical reaction between methylchloride and the

aluminium parts ofthe compressor results in the formation

ofproductswhich burn spontaneously on exposure toair,

or decompose with violence in the presence of moisture.

The suitable refrigerant is supplied under the following

names.

El 34A KLEA or equivalent

Warning: Take care when handling refrigerant. Serious

damage will occur if it is allowed to come into

contact with the eyes. Always wear with goggles

and gloves when working with refrigerant

First Aid

If refrigerant should come into contact with the

eyes or

skin,

splash the eyes or affected area with

cold water for several minutes. DO NOT RUB. As

soon as possible thereafter, obtain treatment from a

Doctor or an eye specialist.

Good Practice

1.

Protective sealing plugs must be fitted to all

disconnected pipes and units.

2.

Theprotectivesealingpiugsmustremain inposition

on ail replacement components and pipes until

immediately before assembly.

3. Any part arriving for assembly without sealing

plugs in position must be returned to the supplier as

defective.

4.

It is essential that a second backing spanner is

always used when tightening or loosening all joints.

This minimises distortion or strain on components

or connecting hoses.

5. Components must not be lifted by connecting

pipes,

hoses or capillary tubes.

6. Care must be taken not to damage fins on the

condenser or evaporator matrices. Any damage

must be rectified by the use of fin combs.

7. Before assembly oftube and hosejoints, use

a

small

amount of clean new refrigerant oil on the sealing

seat.

8. Refrigerant oil for any purpose must be kept very

clean and capped at all times. This prevents the oil

absorbing moisture.

9. Before assembly the condition of joints and flares

must be examined. Dirt and even minor damage

will cause leaks at the high pressure points

encountered in the system.

10.

Dirty end fitting can only be cleaned using a cloth

wetted with alcohol.

11.

Afterremovingsealingplugsand immediatelybefore

assembly, visually check the bore of pipes and

components. Where any dirt or moisture is

discovered,

the part must be rejected.

12. Ail components must be allowed to reach room

temperature before sealing plugs are removed.

This prevents condensation should the component

be cold initially.

13.

Before finally tightening hose connections ensure

that the hose lies in the correct position, is not

kinked or twisted and will not be trapped by

subsequent operations, e.g., refitting or closing

bonnet.

14.

Check that hoses are correctly fitted in clips or

straps.

15.

The compressor must be stored horizontally with

the sump down. It must not be rotated before fitting

and charging. Do not remove the shipping plate

until immediately before assembly. Always use

new "O" ring seals in those joints that incorporate

them.

"O" ring seals should be coated with

compressor oil before fitting.

16.

Components or hoses removed must be sealed

immediately after removal.

1 7. Afterthe system has been opened the receiver-drier

must be renewed.

18.

Before

testing,

run the engine until normal running

temperature is reached. This ensures that sufficient

vacuum is available for test. For cooling tests the

engine must be running for the compressor clutch

to operate.

8-34 May 1996