door ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 9 of 421

[Em^^^?

Electrics

Repair Procedures

6.1.01

6.1.02

6.1.03

6.1.04

6.1.05

6.2.01

6.3.01

6.3.02

6.5.01

6.5.02

6.5.03

6.5.04

6.5.05

6.5.06

6.5.07

6.5.08

6.6.01

6.6.02

6.6.03

6.6.04

6.6.05

6.6.06

6.6.07

6.6.08

6.7.01

6.7.02

6.7.03

6.7.04

6.7.05

6.7.06

6.7.07

Headlamp Unit

Headlamp Alignment

Front Indicator/Parking Lamp Unit

Front Fog Lamp Assembly

Side Repeater Lamps

Windscreen Wiper Motor

Alternator

Starter Motor

Steering Wheel and Horn Switches

Column Switches

Ignition Switch

Instrument Panel

Radio

Air Conditioning and Switch Panel

Cruise Control, Window and Gearshift Switches

Seat Control Switch Panels

Front Interior Lamps

Rear Interior Lamps

Front Seat Removal

Front Seat Runner Assembly

Front Seat Rail Motor

Lumbar Support Motor

Seat Recline Motor

Seat Control Unit

Door Edge Lamps

Rear Lamp Cluster

Door Central Locking Motors

Door Window Motor

Door Mirror Assembly

Transmission Control Module - Renew (TCM)

Barometric Pressure Sensor - Renew

6-3

6-3

6-4

6-4

6-4

6-5

6-5

6-6

6-6

6-6

6-7

6-7

6-8

6-8

6-9

6-9

6-10

6-10

6-10

6-11

6-11

6-12

6-12

6-12

6-12

6-13

6-13

6-14

6-15

6-16

6-17

April 1997 6-1

Page 20 of 421

Electrics

Lumbar Support, Recline Motor and Seat Control Unit - Removal Procedures

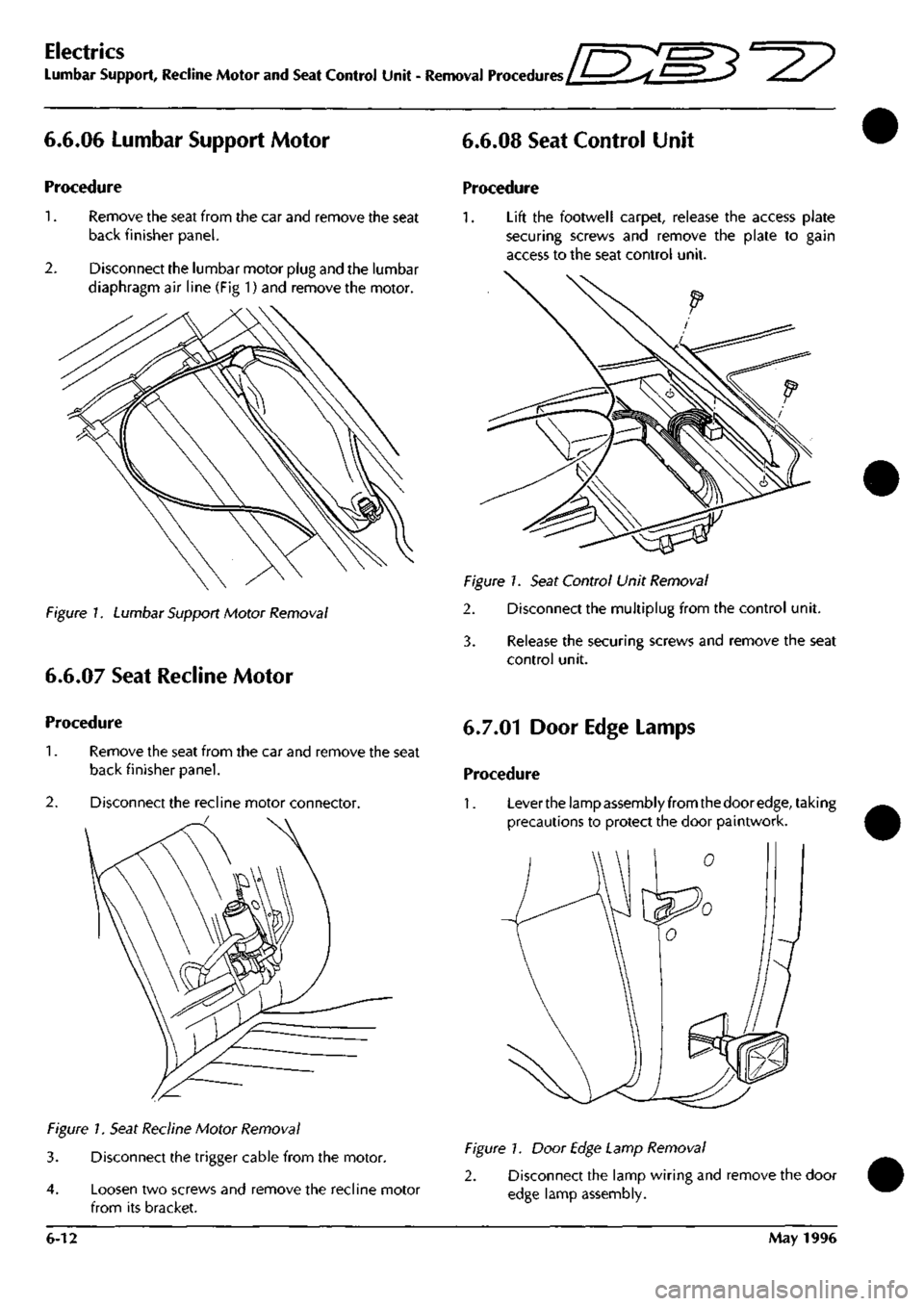

6.6.06 Lumbar Support Motor

Procedure

1.

Remove the seat from the car and remove the seat

back finisher panel.

2.

Disconnect the lumbar motor plug and the lumbar

diaphragm air line (Fig 1) and remove the motor.

Figure /. Lumbar Support Motor Removal

6.6.07 Seat Recline Motor

6.6.08 Seat Control Unit

Procedure

1.

Lift the footwell carpet, release the access plate

securing screws and remove the plate to gain

access to the seat control unit.

Figure 1. Seat Control Unit Removal

2. Disconnect the multiplug from the control unit.

3. Release the securing screws and remove the seat

control unit.

Procedure

1.

Remove the seat from the car and remove the seat

back finisher panel.

2.

Disconnect the recline motor connector.

Figure 1. Seat Recline Motor Removal

3. Disconnect the trigger cable from the motor.

4.

Loosen two screws and remove the recline motor

from its bracket.

6.7.01 Door Edge Lamps

Procedure

1.

Lever the lamp assembly from the door

edge,

taking

precautions to protect the door paintwork.

Figure 1. Door Edge Lamp Removal

2. Disconnect the lamp wiring and remove the door

edge lamp assembly.

6-12 May 1996

Page 21 of 421

3^?

Electrics

Rear Lamp Cluster / Central Locking System / Door Lock Motors

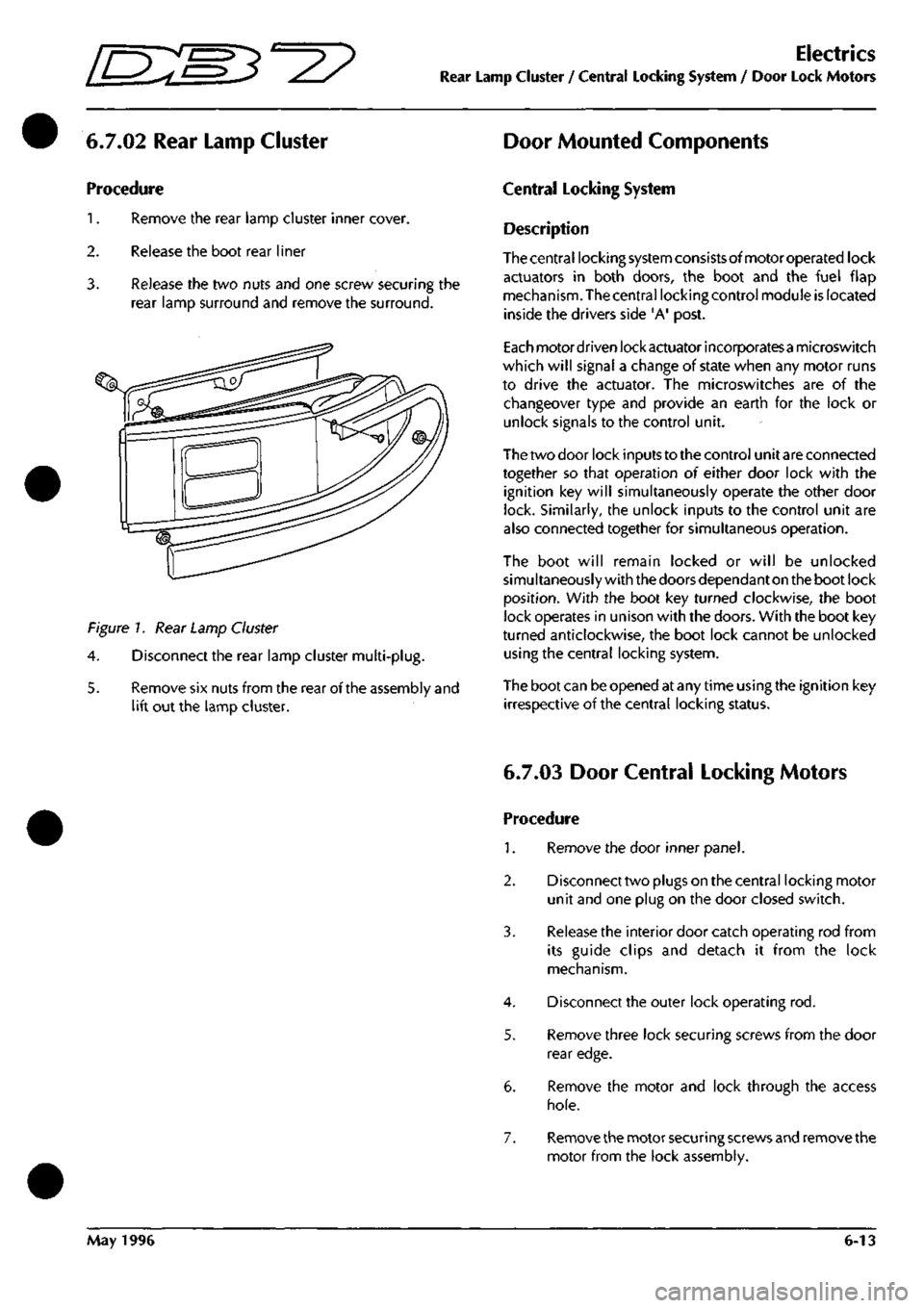

6.7.02 Rear Lamp Cluster Door Mounted Components

Procedure

1.

Remove the rear lamp cluster inner cover.

2.

Release the boot rear liner

3. Release the two nuts and one screw securing the

rear lamp surround and remove the surround.

Figure 7. Rear Lamp Cluster

4.

Disconnect the rear lamp cluster multi-plug.

5. Remove six nuts from the rear of the assembly and

lift out the lamp cluster.

Central Locking System

Description

Thecentral locking system consistsofmotoroperated lock

actuators in both doors, the boot and the fuel flap

mechanism. The central locking control module is located

inside the drivers side 'A' post.

Each motordriven lock actuator incorporatesa microswitch

which will signal a change of state when any motor runs

to drive the actuator. The microswitches are of the

changeover type and provide an earth for the lock or

unlock signals to the control unit.

The two door lock inputs to the control unit are connected

together so that operation of either door lock with the

ignition key will simultaneously operate the other door

lock. Similarly, the unlock inputs to the control unit are

also connected together for simultaneous operation.

The boot will remain locked or will be unlocked

simultaneously with the doors dependant on the boot lock

position.

With the boot key turned clockwise, the boot

lock operates in unison with the doors. With the boot key

turned anticlockwise, the boot lock cannot be unlocked

using the central locking system.

The boot can be opened at any time using the ignition key

irrespective of the central locking status.

6.7.03 Door Central Locking Motors

Procedure

1.

Remove the door inner panel.

2.

Disconnect two plugs on the central locking motor

unit and one plug on the door closed switch.

3. Release the interior door catch operating rod from

its guide clips and detach it from the lock

mechanism.

4.

Disconnect the outer lock operating rod.

5. Remove three lock securing screws from the door

rear edge.

6. Remove the motor and lock through the access

hole.

7. Remove the motor securing screws and remove the

motor from the lock assembly.

May 1996 6-13

Page 22 of 421

Electrics

Electric Windows - Fault Analysis / Window Motor Removal

[n:m3^^

Electric Windows

Description

Power to the window wind circuits is available

when the ignition switch is on and is supplied

through a thermal cut-out to the left and right

window switches. The switches are double pole

plus earth so that the current through a window

motor may be switched in either direction to raise

or lower the window.

DB7 uses frameless door windows which seal

against rubber strips around the body shell door

opening.

To avoid damaging these seals during

door opening, the door glass must be lowered

before the door can be opened. This function is

controlled by the window control units. The units

are mounted on the inside of each door frame and

will sense if a door handle is pulled to open the

door. Before releasing the door lock, the control

unit will drive the window wind motor briefly to

lower the door window glass down until it clears

the window seals. Similarly, after closing a door,

the window motor will be run to raise the door glass

to seat the glass against the body seals.

Fault Analysis Procedure

a) If a window fails to operate, check for fuse failure

and the connectors for poor or open contacts.

b) Check the thermal cut-out by shorting across it and

operating either window. If the windows operate

with the short

ci rcu

it but not without, the cut-out is

faulty.

c) With the ignition on, battery voltage should be

available between the inputterminalsof the switches

and chassis. Operate each switch and ensure that

battery voltage is available between the switch

output terminals and chassis.

d) Measure voltagefrom each switch inputterminalto

the switch earth return terminal. If no voltage is

measured,

the earth return line is open circuit.

e) Measure continuity through the wiring from the

switches to each motor. If continuity is correct,

remove the motor for bench testing.

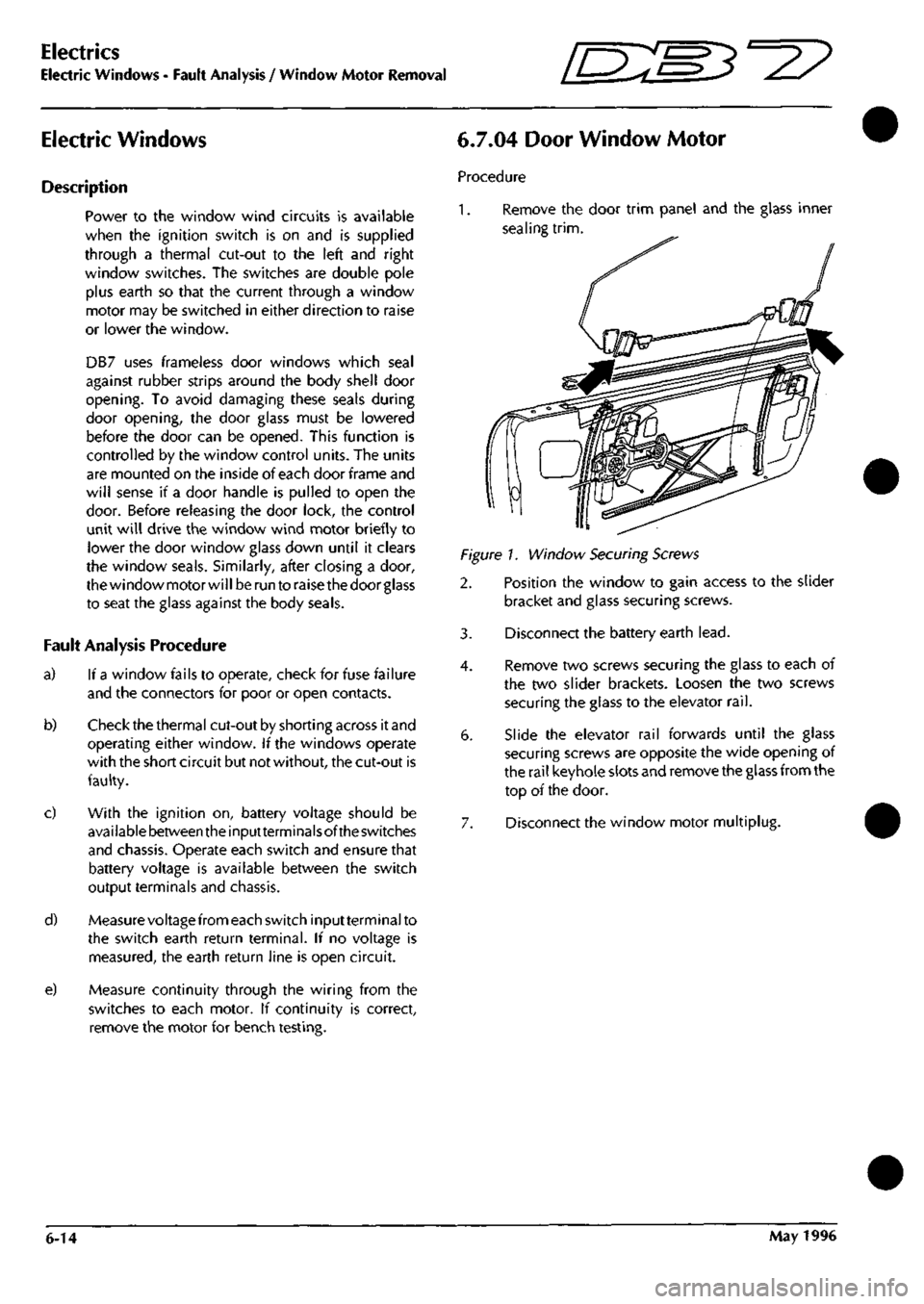

6.7.04 Door Window Motor

Procedure

1.

Remove the door trim panel and the glass inner

sealing

trim.

Figure!. Window Securing Screws

2. Position the window to gain access to the slider

bracket and glass securing screws.

3. Disconnect the battery earth

lead.

4.

Remove two screws securing the glass to each of

the two slider brackets. Loosen the two screws

securing the glass to the elevator

rail.

6. Slide the elevator rail forwards until the glass

securing screws are opposite the wide opening of

the rail keyhole slots and remove the glass from the

top of the door.

7. Disconnect the window motor multiplug.

6-14 May 1996

Page 23 of 421

in:s^^^

Electrics

Electric Door Mirrors

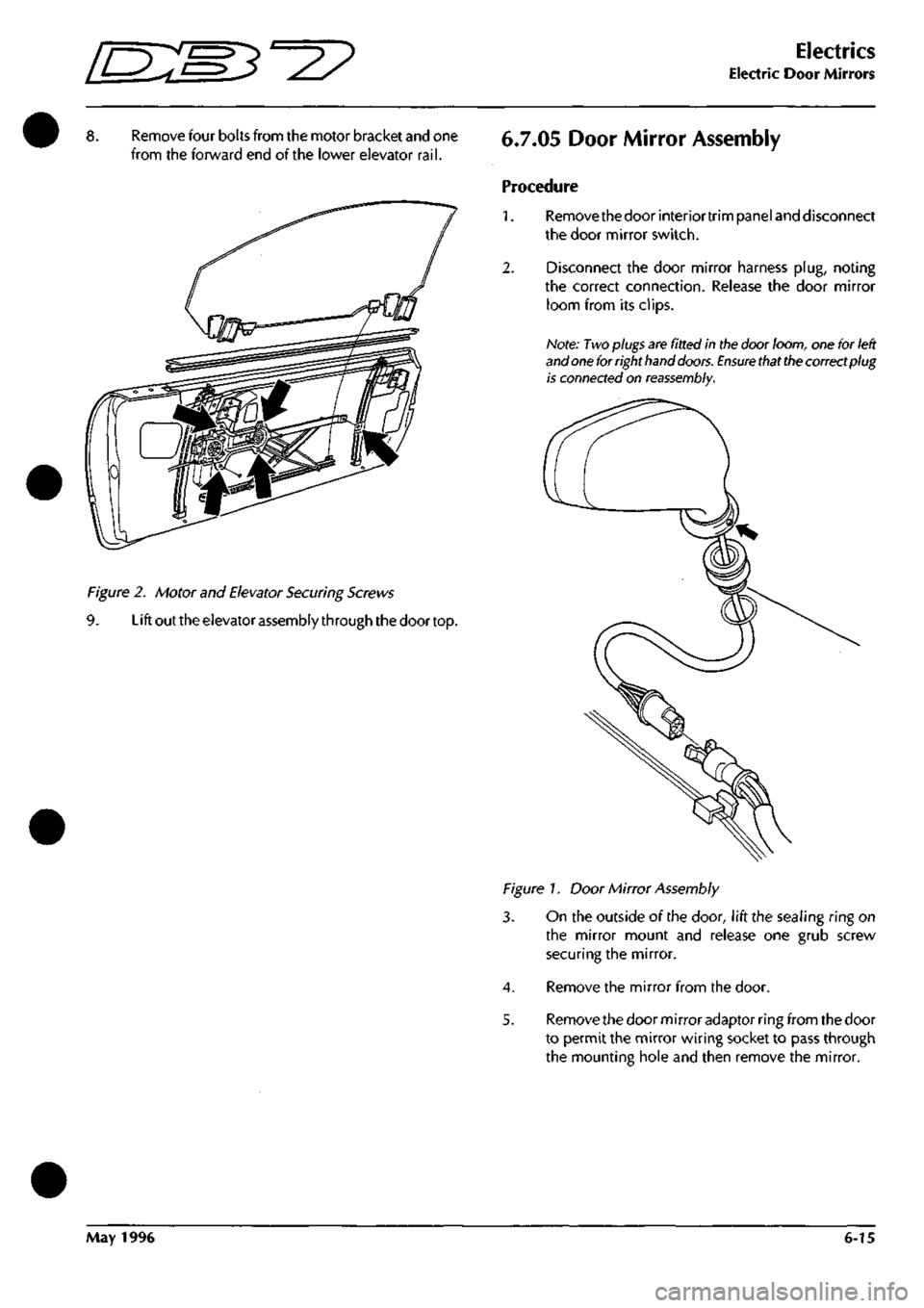

Remove four bolts from the motor bracket and one

from the forward end of the lower elevator

rail.

Figure 2. Motor and Elevator Securing Screws

9. Lift out the elevator assembly through the door top.

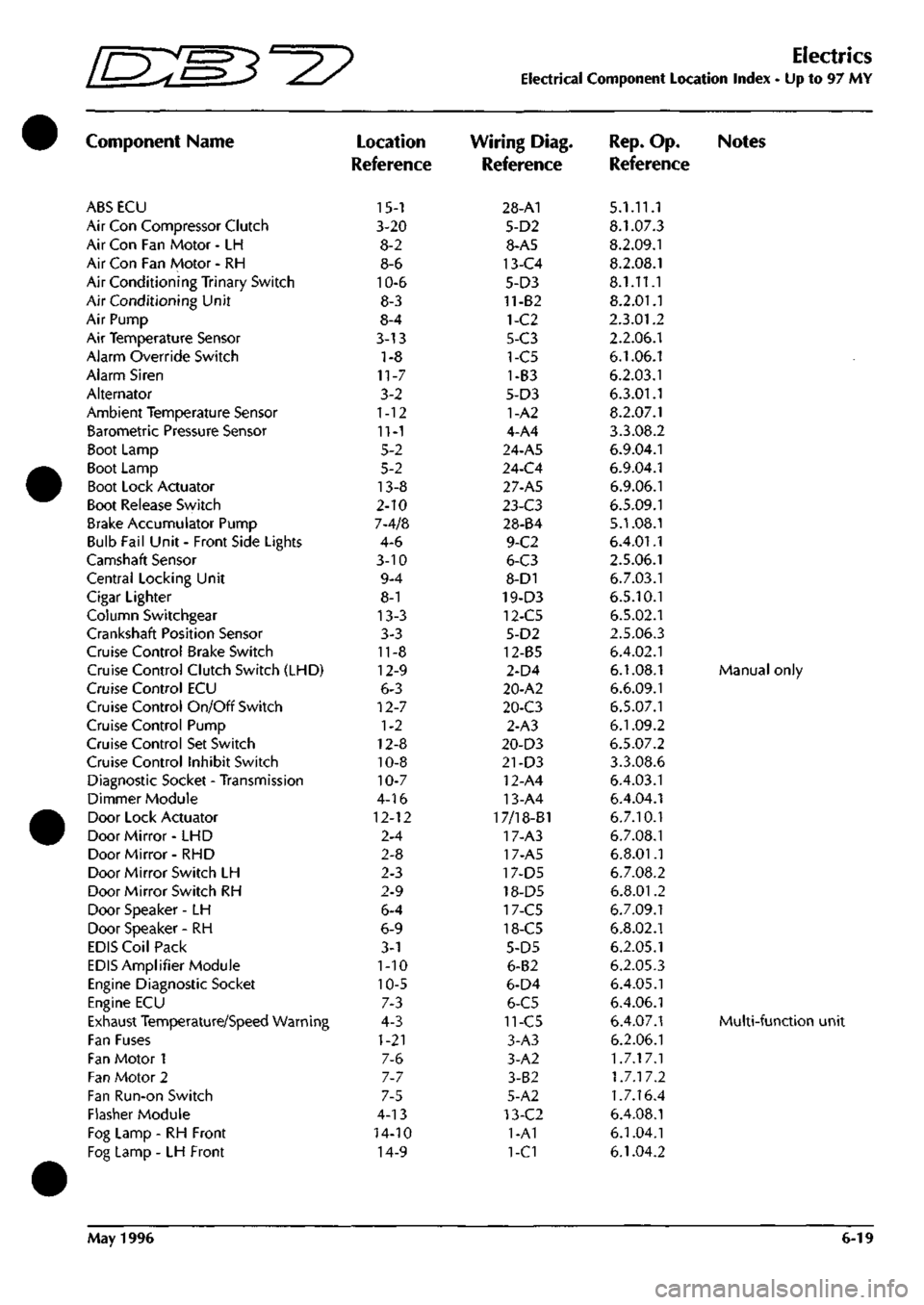

6.7.05 Door Mirror Assembly

Procedure

1.

2.

Removethe door interiortrim panel and disconnect

the door mirror switch.

Disconnect the door mirror harness

plug,

noting

the correct connection. Release the door mirror

loom from its clips.

Note:

Two

plugs are fitted in the door loom, one for left

and one for right hand

doors.

Ensure

that

the

correct plug

is connected on

reassembly.

Figure 7. Door Mirror Assembly

3. On the outside of the door, lift the sealing ring on

the mirror mount and release one grub screw

securing the mirror.

4.

Remove the mirror from the door.

5. Remove the door mirror adaptor ring from the door

to permit the mirror wiring socket to pass through

the mounting hole and then remove the mirror.

May 1996 6-15

Page 27 of 421

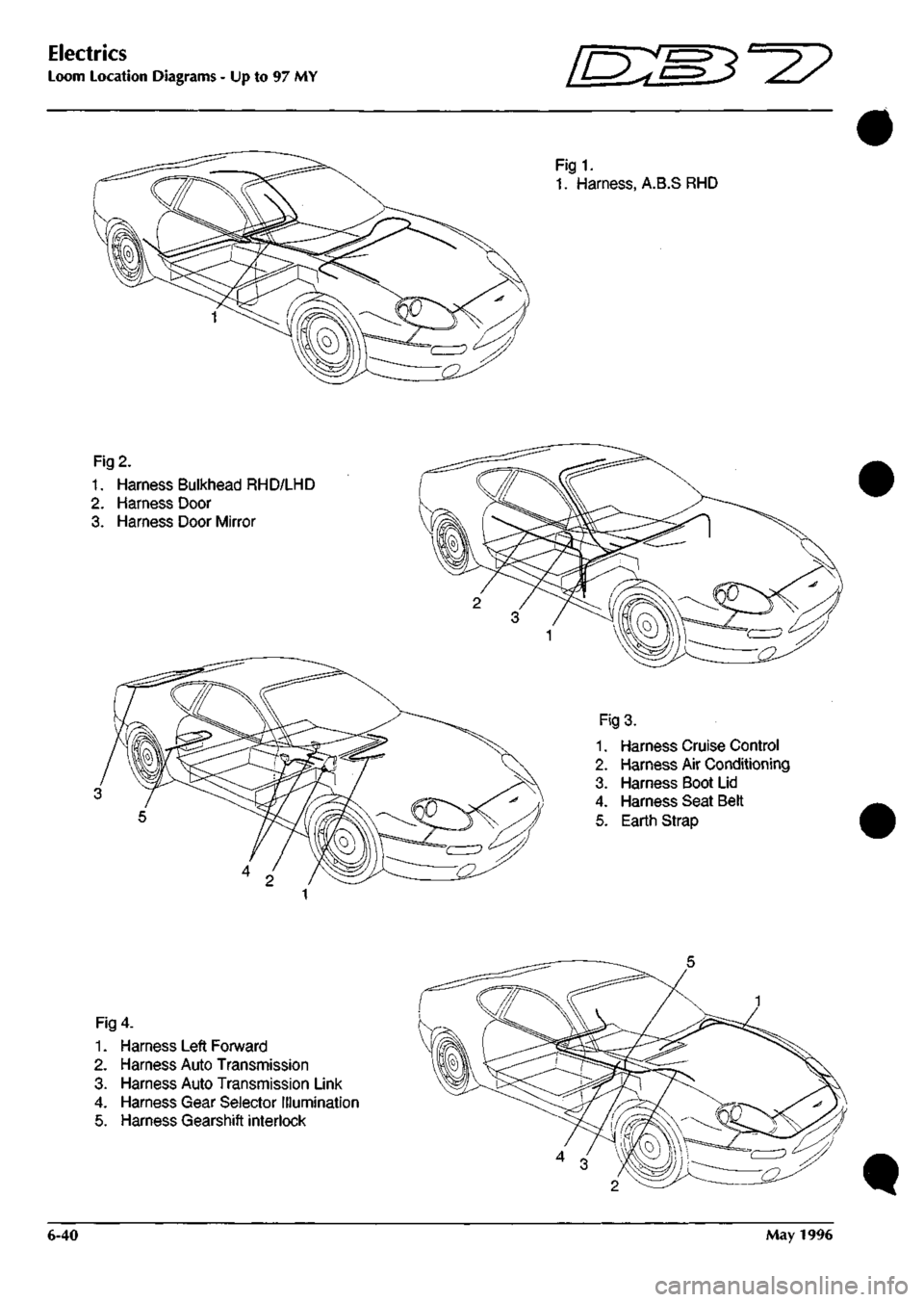

Electrics

Electrical Component Location Index - Up to 97 MY

Component Name

ABS ECU

Air Con Compressor Clutch

Air Con Fan Motor - LH

Air Con Fan Motor - RH

Air Conditioning Trinary Switch

Air Conditioning Unit

Air Pump

Air Temperature Sensor

Alarm Override Switch

Alarm Siren

Alternator

Ambient Temperature Sensor

Barometric Pressure Sensor

Boot Lamp

Boot Lamp

Boot Lock Actuator

Boot Release Switch

Brake Accumulator Pump

Bulb Fail Unit - Front Side Lights

Camshaft Sensor

Central Locking Unit

Cigar Lighter

Column Switchgear

Crankshaft Position Sensor

Cruise Control Brake Switch

Cruise Control Clutch Switch (LHD)

Cruise Control ECU

Cruise Control On/Off Switch

Cruise Control Pump

Cruise Control Set Switch

Cruise Control Inhibit Switch

Diagnostic Socket - Transmission

Dimmer Module

Door Lock Actuator

Door Mirror- LHD

Door Mirror- RHD

Door Mirror Switch LH

Door Mirror Switch RH

Door Speaker -LH

Door Speaker - RH

EDIS Coil Pack

EDIS Amplifier Module

Engine Diagnostic Socket

Engine ECU

Exhaust Temperature/Speed Warning

Fan Fuses

Fan Motor 1

Fan Motor 2

Fan Run-on Switch

Flasher Module

Fog Lamp - RH Front

Fog Lamp - LH Front

Location

Reference

15-1

3-20

8-2

8-6

10-6

8-3

8-4

3-13

1-8

11-7

3-2

1-12

11-1

5-2

5-2

13-8

2-10

7-4/8

4-6

3-10

9-4

8-1

13-3

3-3

11-8

12-9

6-3

12-7

1-2

12-8

10-8

10-7

4-16

12-12

2-4

2-8

2-3

2-9

6-4

6-9

3-1

1-10

10-5

7-3

4-3

1-21

7-6

7-7

7-5

4-13

14-10

14-9

Wiring Diag.

Reference

28-A1

5-D2

8-A5

13-C4

5-D3

11-82

1-C2

5-C3

1-C5

1-B3

5-D3

1-A2

4-A4

24-A5

24-C4

27-A5

l-i-C3

28-84

9-C2

6-C3

8-D1

19-D3

12-C5

5-D2

12-85

2-D4

20-A2

20-C3

2-A3

20-D3

21-D3

12-A4

13-A4

17/18-B1

17-A3

17-A5

17-D5

18-D5

17-C5

18-C5

5-D5

6-B2

6-D4

6-C5

11-C5

3-A3

3-A2

3-B2

5-A2

13-C2

1-A1

1-C1

Rep.

Op. Notes

Reference

5.1.11.1

8.1.07.3

8.2.09.1

8.2.08.1

8.1.11.1

8.2.01.1

2.3.01.2

2.2.06.1

6.1.06.1

6.2.03.1

6.3.01.1

8.2.07.1

3.3.08.2

6.9.04.1

6.9.04.1

6.9.06.1

6.5.09.1

5.1.08.1

6.4.01.1

2.5.06.1

6.7.03.1

6.5.10.1

6.5.02.1

2.5.06.3

6.4.02.1

6.1.08.1 Manual only

6.6.09.1

6.5.07.1

6.1.09.2

6.5.07.2

3.3.08.6

6.4.03.1

6.4.04.1

6.7.10.1

6.7.08.1

6.8.01.1

6.7.08.2

6.8.01.2

6.7.09.1

6.8.02.1

6.2.05.1

6.2.05.3

6.4.05.1

6.4.06.1

6.4.07.1 Multi-functio

6.2.06.1

1.7.17.1

1.7.17.2

1.7.16.4

6.4.08.1

6.1.04.1

6.1.04.2

May 1996 6-19

Page 48 of 421

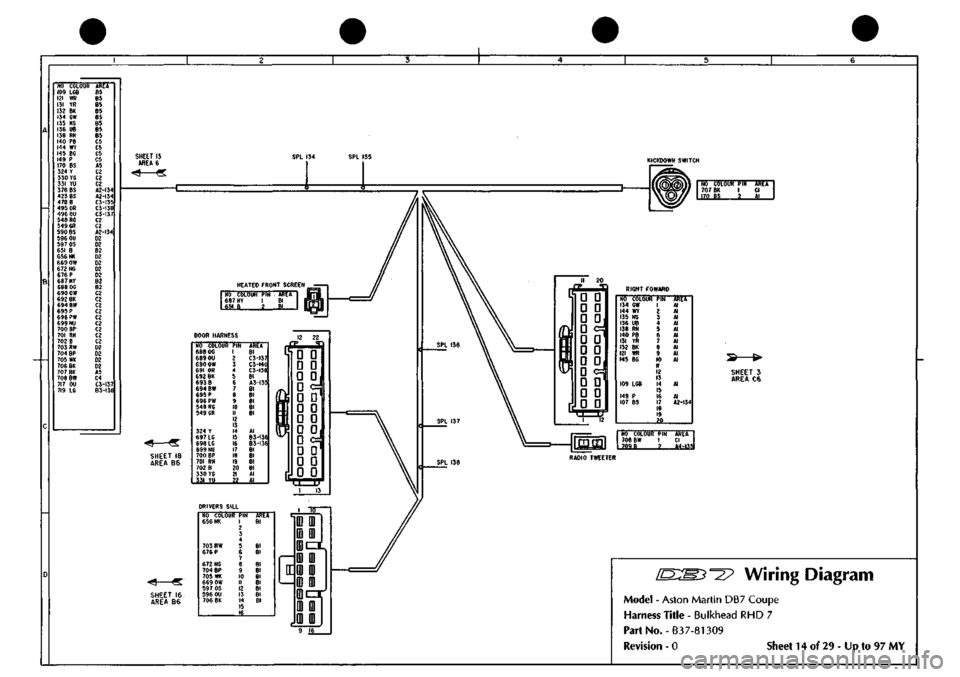

Electrics

Loom Location Diagrams - Up to 97 MY in:m3'^?

Fig1.

1.

Harness, A.B.S RHD

Fig

2.

1.

Harness Bulkhead RHD/LHD

2.

Harness Door

3. Harness Door Mirror

Fig

3.

1.

Harness Cruise Control

2.

Harness Air Conditioning

3. Harness Boot Lid

4.

Harness Seat Beit

5. Earth Strap

Fig

4.

1.

Harness Left Forward

2.

Harness Auto Transmission

3. Harness Auto Transmission Link

4.

Harness Gear Selector Illumination

5. Harness Gearshift interlock

t

6-40 May 1996

Page 77 of 421

HO COLOUR J09 LCB 121

WR

131

YR

132

BK

154 GW 135 NS 136

US

138 RN 140 PB 144 WY I4S BG 149

P

170

BS

324

Y

530 YG 331

YU

376

BS

423

BS

478

B

495 OR 496 OU 548 RC 549 GR 590 BS 596 OU 597 OS 651

B

656 NK 669 OW 672

NO

676 P 687 NY 688 OG 690 OW 692 BK 694 BW 695 P 696 PW 699 NU 700

BP-

701 RN 702 8 703 RW 704

BP

705 V»K 706 BK 707 BK 708 BW 717

OU

719

LG

ARE*

85 83 B5 BS 85 B5 B5 B5 C5 C5 C5 C5 45 C2 C2 C2 A2-I34 A2-I34 C3-I35 C3-I38 C3-I37 C2 C2 A2-I34 02 02 B2 D2 D2 02 D2 B2 B2 02 02 C2 C2 02 C2 C2 C2 02 02 D2 D2 02 A5 C4 C3-I37 B5-I56

SPL

134 SPL 155

687 NY 651

B

DOOR HARNESS

SHEET

18

AREA

B6

NO COLOUF 688 OG 689 OU 690 OW 691 OR 692

BK

693 B 694 BW 695 P 696 PW 548 RG 549 GR

524

Y

697 LG 698 LG 699 NU 700 BP 701

RN

702

B

330 YG 331

YU

PIN 1 2 3 4 5 6 7 8 9 10 II 12 13 14 15 16 17 18 19 ?0 21

_J2.

AREA Bl C3-137 C3-140 03-138 Bl

A3-I3;

Bl Bl Bl Bl Bl

Al B3-13f B3-13( Bl Bl Bl Bl Al Al

12

22 n> T

D

0

D

D

D

D,

D

c=

D

D'

D

D

D

D

D

D|

0 o^ D

0

D

D

JD

D

11

II

1

13

DRIVERS SILL

HO COLOUf 656 NK

703 RW 676 P

672

NG

704 BP 705

WK

669 OW 597

OS

596 OU 706 BK

m 1 2 3 4 5 6 7 8 9 10 II 12 13 14 15

1?

mi Bl

Bl Bl

Bl Bl Bl Bl Bl Bl Bl

c

\L

1

15 1

DID]

fli

i

Qlt=l

Ul

Dl

(Dm

m m

Dicr

0)1

D)i 9

16

11

rp

p"

D D

I

D

Q k

0

1

D

D

D

M-

20

D

D

D

^

D D

—ij

mm

KICKDOWN SWITCH

NO COLOUR

PIN

AEHT

707

BK

1 CI

170

BS

2 A!

RIGHT FOWARO

NO COLOUR

PIN

134 GW 144 WY 135

NS

136 UB 138 RN 140 PB 151

YR

132

BK

121

WR

145 BG

109 LGB

149

P

107 BS

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

29

-SRfA

Al Al Al AJ Al Al Al Al Al Al

Al

Al A2-I34

SHEET

3

AREA

C6

NO COLOUR

PIN

AREA 708

BW

I CI i2iB 2 iiJlSl

RADIO TWEETER

"2? Wiring Diagram

Model

-

Aston Martin DB7 Coupe

Harness Title

-

Bulkhead RHD

7

Part No.-837-81309

Revision

- 0

Sheet 14 of 29

-

Up to 97 MY

Page 83 of 421

MICRO SWITCH

H4 coLduli

PIH 390 OU I 392

OR

2

I25JB

}

B?-|17I

B6

LOCK SWITCH

ffo-wroriiTr 760 B 1 761 RN 2 762

V

3 763

YG

4 764

YU

5

-imr A4-I5C

B4-M!

B5-I4! C5-I44 BS-I4S

L.H DOOR MIRROR

NO COLOUR PIN 391 OW I 389 OG 2__ B6

LOCK MOTOR

NO COLOUR PIN 755

B

1 756

RN

2 757

Y

3 758

YR

4 759

YB

5

AREA A4-I5C B4-I4! B5-I4; C5-I46 B4-I4f

tooT

SPL 151 0Q

R.H DOOR MIRROR

NO COLOUR 765

B

AREA A4-I5C B5-I47

SPL 147 SPL 145 SPL 143

1

. I .. 1

SPL 148 SPL 146 SPL 144

[amtTI'

1 13

•laD

("

c

• 0 D 0 DOZ^ D 0 D D Q 0 D 0

on:

0 D 0 D 0 Q

NO COLOUR PIN IRfF 394B I B6 395 BW 2 B6

REAR GUARD LAMP

NO COLOUR PIN 325

LG

A 768

BP

B 322

R

C 323

G

0

767

B

328

NU

AREA C6 C4-I5I

Be

B5-I47

DOOR MIRROR SWITCH

NO COLOUR 769

YR

770

YG

771 Y 752

LG

773 YU 772 B 774 YB

PIN 1 2 3 4 5 6 7

?

AREA C5-M6 C5-I44 B5-I4! C6 B5-I4! A4-I5C C4-I4f

NO COLOUR PIN 320 P 1 321 PW 2 5

AREA B6 86

NO COLOUR PIN 389 OS 390 OU 391 OW 392

OR

394 B 395 BW 320

P

321 PW 322

R

323

G

750

YG

751 YU 324

Y

752 LG 325

LG

326

NU

327

BP

328

RN

329 8 330 YR 331 YB

1 2 3 4 5 6 7 8 9 10 II 12 13 14 15 16 17 18 19 20 21 22

MS 81 A2 61 A2

C5 C5 D2 02 03 03 C5-I44 B5-I4: B5-I4; DS 03 03 C4-I5I C4-I4S B5-I4; C5-I46 C4-I4(

SHEET

8

AREA

C3

lD:m^'=2? Wiring Diagram

Model - Aston Martin DB7 Coupe

Harness Title - Passengers Door

PartNo.-B37-81312

Revision - 0 Sheet 17 of 29 - Up to 97 MY

Page 85 of 421

HO COLOUR

PIH

&RE7

776

BP I

04-160

777

B

2 M-159 2

MICRO SWITCH

LOCK SWITCH

HO C6L6illl 760 B 761

RN

762

r 765 rc

764

YU

I^IN

1 2 3 4

}

,.

AREA A4-I5S B4-I5( 85-152 C5-I55 BS-154

L.H

DOOR MIRROR NO COLOUR 755

B

756

RH

757

1

758

VR

'59

YB

r-

1

AREA A4-I59 B4-I58 B5-I52 C5-I55

B1-I5]

SPL 160

-

HO COLOUR

PIH

690 OW

I

688 OG

2

AREA B6 86

OCD

R.H

DOOR MIRROR

NO COLOUR AREA 765

B

A4-I59 766

B

B5-I56

SPL

156 SPL 154 SPL 152

1.1.1

SPL

157 SPL 155 SPL 153

-[iBQlllDs

1

15

^0

D

l»

c

a

D

D

0

ooz^

0

0

Q

Q

0

D

0

D

onzr'

Q

0

Q

0

0

Q

NO MI.6UA ^IM JRfT

693 B

1 B6

694 BW

2 B£_

REAR GUARD LAMP

NO COLOUR 698 LG 768

BP

548 R 549 6

767

B

699 HU

Pita

A B C D E F

?

AREA C6 C4-I60 B6 66

B5-I56 C6

DOOR MIRROR SWITCH

HO COLOUR 769

VR

770

YG

771

Y

697 LG 773 YU 772

B

774 YB

PIN 1 2 3 4 5 6 7

8

AREA C5-I55 05-153 85-152 06 B5-I5< A4-I5S 04-157

HO COLOUR

PIN

695 P

I 696

PW

2

3

AREA

86 86

NO COLOUR

PIH

688 OG 689 OU 690 OW 691

OR

695 B 694 BW 695 P 696 PW 548 R 549 G 753

YG

754

YU

324

Y

697 LG 698 LG 699 NU 700 BP 701

RN

702

B

330 YR 331

YB

1 2 3 4 5 6 7 8 9 10 II 12 13 14 15 16 17 18 19 20 21

22-

•/SREr

Bl A2 Bl Bl

A2 05 D2 02 02 D3 03-153 C5-I54 B5-152 D5 03 03 C4-16( C4-158 B5-156 05-155 04-157

Wiring Diagram

Model

-

Aston Martin

DB7

Coupe

Harness Title

-

Drivers Door

PartNo.-B37-81313

Revision

- 0

Sheet

18 of 29 - Up to 97 MY