maintenance ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 278 of 421

in:!M3^^?

Air Conditioning

Contents

Contents

General Description 8-5

Specifications 8-5

Climate Control System 8-6

System Description 8-7

Special Servicing Tools and Equipment 8-7

Working Practices 8-8

General 8-8

Handling Refrigerant 8-8

Handling Lubricating Oil 8-8

System Maintenance 8-8

Temperature Distribution System 8-9

Fan Speed Control (Mode Switch) 8-10

Face Level Temperature Differential 8-10

Temperature Rotary Control 8-10

Refrigeration Cycle 8-11

System Protection 8-12

General System Procedures 8-12

Leak Test 8-12

Charge Recovery (System Depressurisation) 8-12

Evacuating the System 8-13

Adding Compressor Lubricating Oil 8-13

Adding Refrigerant 8-14

Functional Check 8-15

System Trouble Shooting 8-1 7

Electronic Control Module (ECM) 8-19

In Car Controls 8-21

Temperature Demand Switch 8-21

Face Level Differential Controller 8-21

Air Conditioning Function Switch 8-22

Fan Speed Control Switch (Mode Switch) 8-23

Temperature Sensors 8-23

Evaporator Sensor 8-24

Motorised In-Car Aspirated Sensor 8-24

Water Temperature Switch 8-25

Blower Motors 8-25

Potentiometers 8-26

Servo Motors 8-27

Vacuum System 8-28

Pressure-Temperature Graphs 8-29

May 1996 8-1

Page 285 of 421

Air Conditioning

Working Practices O" 15-^?

Working Practices

General

Be aware of, and comply

with,

all health and safety

requirements.

Before beginning any repair or service procedure,

disconnect the vehicle battery ground connection

and protect the vehicle from dirt or damage.

Work in a well ventilated, clean and tidy area.

Recovery and chargeequipment must comply

with,

or exceed the standard detailed in the General

Description.

Handling Refrigerant

Wear eye protection at all times.

Use gloves, keep skin that may come into contact

with refrigerant covered. If the refrigerant comes

into contactwith youreyesorskin wash the affected

area immediatelyw'ith cool water and seek medical

advice, do not attempt to treat yourself.

Avoid inhaling refrigerant vapour, it wil

your respiratory system.

irritate

Never use high pressure compressed air to flush out

a system. Under certain circumstances a

combination of HFC 134A and compressed air in

the presenceofa source ofcombustion (for instance,

welding or brazing equipment), results in an

explosion that releases toxic compounds into the

atmosphere.

The refrigerant and CFC 12 must never come into

contact with each other

as

they form an inseparable

mixture that can only be disposed of by incineration.

Do not vent refrigerant directly into the atmosphere,

always use approved recovery equipment.

Refrigerant is costly but it can be recycled. Clean

the refrigerant, using the recovery equipment and

reuse it.

Carry out LeakTestsonly with an electronic analyser

dedicated to Refrigerant El 34A.

Do not attemptto guess the amount of refrigerant in

a system, always recover it and recharge with the

correct charge weight. Do not depress the charge or

discharge port valves to check for the presence of

refrigerant.

Handling Lubricating Oil

Avoid breathinglubricantmist,itwillcauseirritation

to your respiratory system.

Always decant fresh oil from a sealed container. Do

not leave oil exposed to the atmosphere for any

reason other than to fill or empty a system; PAG oil

is hygroscopic (it absorbs water) and iscontaminated

rapidly by atmospheric moisture.

Following the recovery cycle do not reuse the oil

when it has been separated from the refrigerant;

dispose of the oil safely.

System Maintenance

Do not leave the system open to the atmosphere. If

a unit or part of the system is left open for more than

five minutes, it is advisable to renew the receiver-

dryer. There is not a safe period in which work is to

be carried out. Always plug pipes and units

immediately after disconnection and only remove

plugs when re-connecting.

If replacement parts are supplied without transit

plugs and seals do not use the parts. Return them to

your supplier.

Diagnostic equipment for pressure, mass and

volumeshouidbecalibrated regularly and certified

by a third party organisation.

Use extreme care when handling and securing

aluminium fittings, always use a backing spanner

and take special care when handlingtheevaporator.

Use only the correct or recommended tools for the

job and apply the manufacturer's torque

specifications.

Keep the working area, all components and tools

clean.

8-8 May 1996

Page 352 of 421

^?

The Aston Martin Lagonda Diagnostic System

Contents

Installation Instructions

Introduaion 9-2

The Aston Martin Diagnostic System 9-2

Diagnostic System Cables 9-5

Base Station Installation 9-8

Problem Solving 9-16

Service Centres 9-21

Service and Maintenance 9-22

Technical Specifications 9-24

Operating Instructions

The Aston Martin Lagonda Diagnostic System 9-27

Software 9-29

Cable Setup 9-31

Diagnostic Sockets - 97 MY 9-31

Establishing Communications 9-32

System Menu Selections 9-32

PDU Use 9-32

Engine Diagnostics - 97 MY 9-33

Transmission Diagnostics 9-40

Climate Control Diagnostics 9-43

Anti-Lock Brakes Diagnostics 9-43

Passive Anti-Theft (PATS) Diagnostics 9-44

Airbag System Diagnostics 9-45

Seat Belt Pretensioner Diagnostics 9-47

Print Facility 9-49

Digital Multimeter 9-50

Diagnostic Trouble Codes 9-53

Datalogger 9-55

Datalogger Example 9-63

Training 9-66

OBD II Scan Tool 9-66

System Self Test 9-69

The Asterisk (*) Menu 9-69

System Setup 9-70

May 1996 9-1

Page 353 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions E:MB^^?

Introduction The Aston Martin Diagnostic System

This guide contains instructions for the installation

of the Portable Diagnostic Unit hardware in Aston

Martin Dealer workshops. To achieve maxinnum

benefit from the system, please follow the

instructions carefully. The following System

Diagram shows the principal system components

and panel details.

This introduction briefly describes the system and

its capabilities. This is followed by the Installation

and Power-Up procedures which give detailed

instruaions on how to start the system and access

the self-contained Interactive

Training

Programme.

The subsequent sections detail the fault diagnosis

and maintenance procedures.

WARNING:

The equipment must

only

be used by

trained

personnel.

Care should

be taken to use the

equipment in accordance with the operating

procedures.

Observe

all safety

warnings

in this

guide.

If any part of

the system is damaged do not

use it. Call your local CenRad

Service

Centre

immediately

for a

substitute

part.

Refer to

'Parts

Ordering'.

The Aston Martin Diagnostic System is a new

generation diagnostic

tool

which fulfils

a

number of

functions in aiding the technician to quickly and

accurately locate faults. The heart of the system is

the Portable Diagnostic

Unit,

a

lightweight powerful

computer/measurement system providing a step-

by-step user friendly interface for the technician.

PDU functions include:

Data Logger - The ability to monitor and record

control module signals even whilst the vehicle is

being driven.

On-Line Help-Containing detailed descriptions in

the

operation

ofthevehicleselectroniccomponents.

Vehicle Setup - The ability to setup various

adjustable parameters to their optimum settings.

Diagnostic Trouble Codes - The ability to extract

recorded fault information from the DB7's control

modules.

Each of

these

funaions is described in detail in the

PDU Users Guide.

WARNING: If

the system is used to measure high

voltages,

these voltages can appear on the pins of

other

connectors in

the

system.

Ensure

that socket

covers

are

fitted

on

unused

sockets.

Ensure

that all

connections

are

made

prior to

applying the high

voltage to

the

probes.

Do not

leave the equipment

unattended

in

this

state.

The maximum

voltage

that may be applied

between the

test

probes is 150

volts

AC or DC.

Radio Interference Statements

This digital apparatus does not exceed the Class A

limits for radio noiseemissionsfromdigital apparatus

as set

out

in

the radio interference regulations of the

Canadian Department of Communications.

This equipment has been tested and found to

comply with the limits for Class A digital device

pursuant to part 15 of the Federal Communications

Commission (FCC) rules. However, operation in

close proximity to domestic communication

equipment may cause interference. It is the

responsibility of the user to avoid or correct this

condition.

9-2 May 1996

Page 366 of 421

r^ ' ^ ^ The Aston Martin Lagonda Diagnostic System

Installation Instructions

Finishing the Test

When data analysis is finished, switch off the PDU

and disconnect it from the vehicle. Store the PDU

and cables in the carrying case and refit the case to

the base station.

Connect the PDU to the base station using cable

0064.

The base station will keep the PDU batteries

fully charged at all times (Fig 15).

Figure 15. PDU connected for recharging

Care of the Equipment

CAUTION: With the exception of those parts

referred to in the Servicing and Maintenance

section, there are no user serviceable parts. All

servicing must be carried out by GenRad Service

Centres.

Switch offthe power before cleaningtheequipment.

The Aston Martin Diagnostic System should only

be cleaned using a non-abrasive, mild cleaning

agent. Dust and other particles should be lightly

brushed from the surface before

cleaning.

Cleaning

agent should be applied to a soft lint-free cleaning

cloth and never directly to the unit. Do not soak the

cleaning cloth and take care not to allow cleaning

fluid to enter connectors.

CAUTION: Ifany liquid is spilt on theequipment,

switch off immediately.

Ensure

that the equipment

has

dried out completely before operating it again,

especially in connectors where fluid can lodge.

May 1996 9-15

Page 367 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions ^7

Problem Solving

CAUTION: If any part of the

system

is damaged, do not use it. Call your local GenRad Service Centre immediately for

a substitute

part.

Refer to 'Parts Ordering'.

CAUTION: With the exception of

those

parts referred to in the Servicing and Maintenance section, there are no user

serviceable parts. All servicing must be carried out by GenRad Service Centres.

PDU Self-Test

The system self test routine should be run periodically even if there are no apparent problems with the system.

Running the system self-test will identify any problems before they impact on productivity.

If it is suspected that the system is operating incorrectly, run the PDU system self test option on the main menu).

If the system self test will not run, or the PDU will not switch on, the instructions in this section must be followed

carefully.

If one of the fol lowing test steps advises you to order or fit a new part, make a note of the test step, part number and

description. Then follow the parts ordering procedure later in this section.

Stepi

Connect the mains power to the base station. Is the green base station indicator illuminated?

YES - Go to step 4

NO - Go to step 2

Step 2

Check the mains supply, then check the mains

lead.

Is

the mains lead faulty?

YES - Renew the mains

lead.

NO - Go to step 3

Step 3

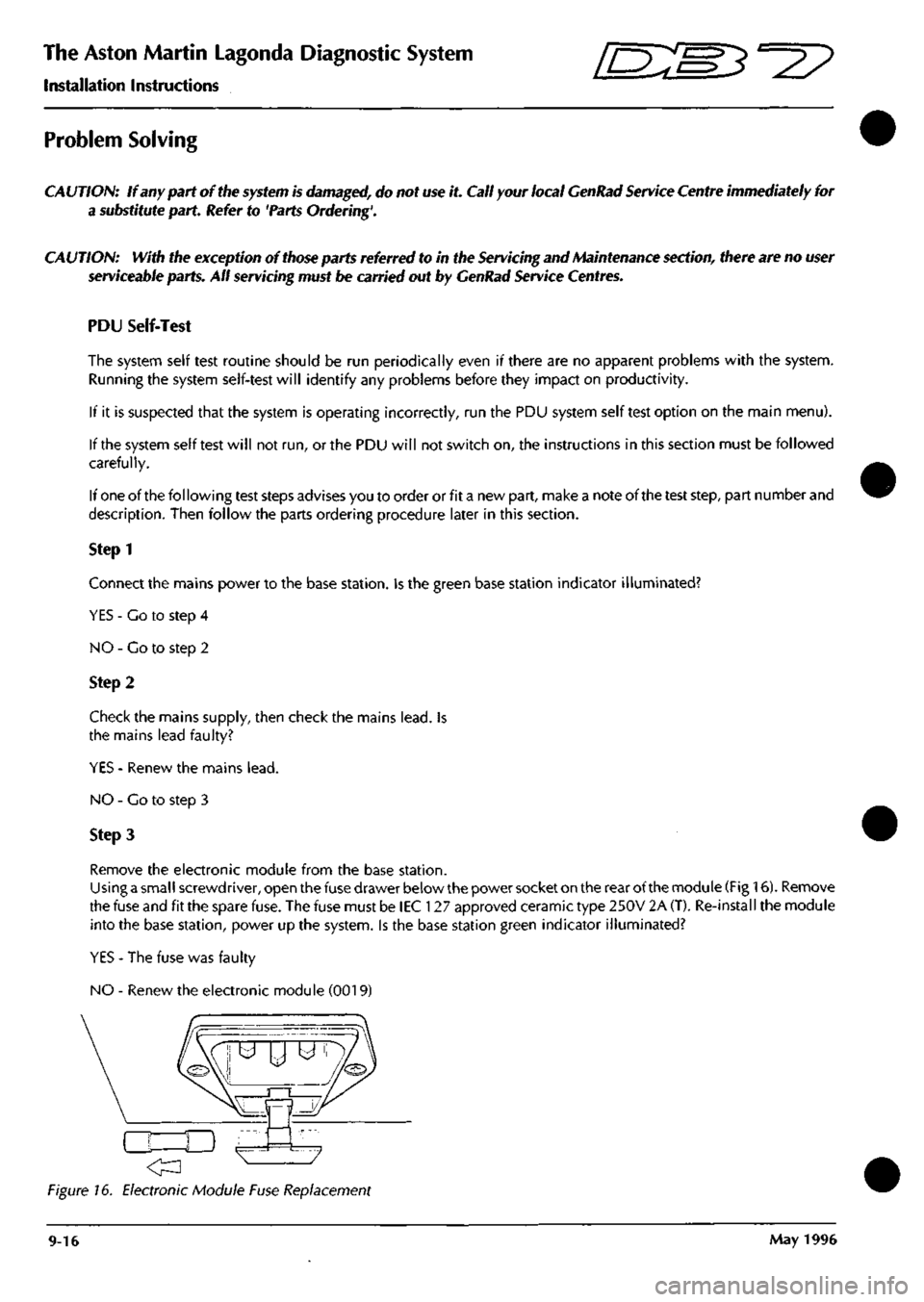

Remove the electronic module from the base station.

Using a small screwdriver, open the fuse drawer below the power socket on the rear of the module (Fig 16). Remove

the fuse and fit the spare fuse. The fuse must be lEC 127 approved ceramic type 250V 2A (T). Re-install the module

into the base station, power up the system. Is the base station green indicator illuminated?

YES - The fuse was faulty

NO - Renew the electronic module (0019)

Figure 16. Electronic Module Fuse Replacement

9-16 May 1996

Page 373 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions ^=2?

Warranty

The Aston Martin Diagnostic System is covered by a one year warranty. Should any of the electrical components

fail during the warranty period, contact your local GenRad Service Centre for a replacement part. Note that the

warranty does not include physical damage.

Spare Parts

Refer to the Aston Martin Diagnostic System Users Guide for a full parts list. All spare parts should be obtained from

your local GenRad Service Centre who can advise you on current prices.

Servicing and Maintenance

CA UTION: With the exception of those parts listed in this section, there are no user serviceable parts within the

system. All servicing must be carried out by GenRad Service Centres.

Battery Testing.

The NICAD batteries fitted in the PDU are designed to be rechargeable and should normally last through many

recharge cycles. Battery life of three to five years can be expected. The capacity of new batteries improves after

several charging cycles. After extended use, they may require renewing. The following procedure will assist you to

determine when renewal is required. Do not use this procedure with new batteries or with a new PDU.

Testing Procedure

1.

Remove all cables from the PDU.

2.

Switch the PDU on and leave it until it switches off (the power on indicator will extinguish)

3. Connect the PDU to the base station for at least 12 hours charging.

4.

Remove all cables from the PDU, switch on the PDU and start timing.

5. If the PDU switches off in less than 30 minutes, the batteries should be renewed.

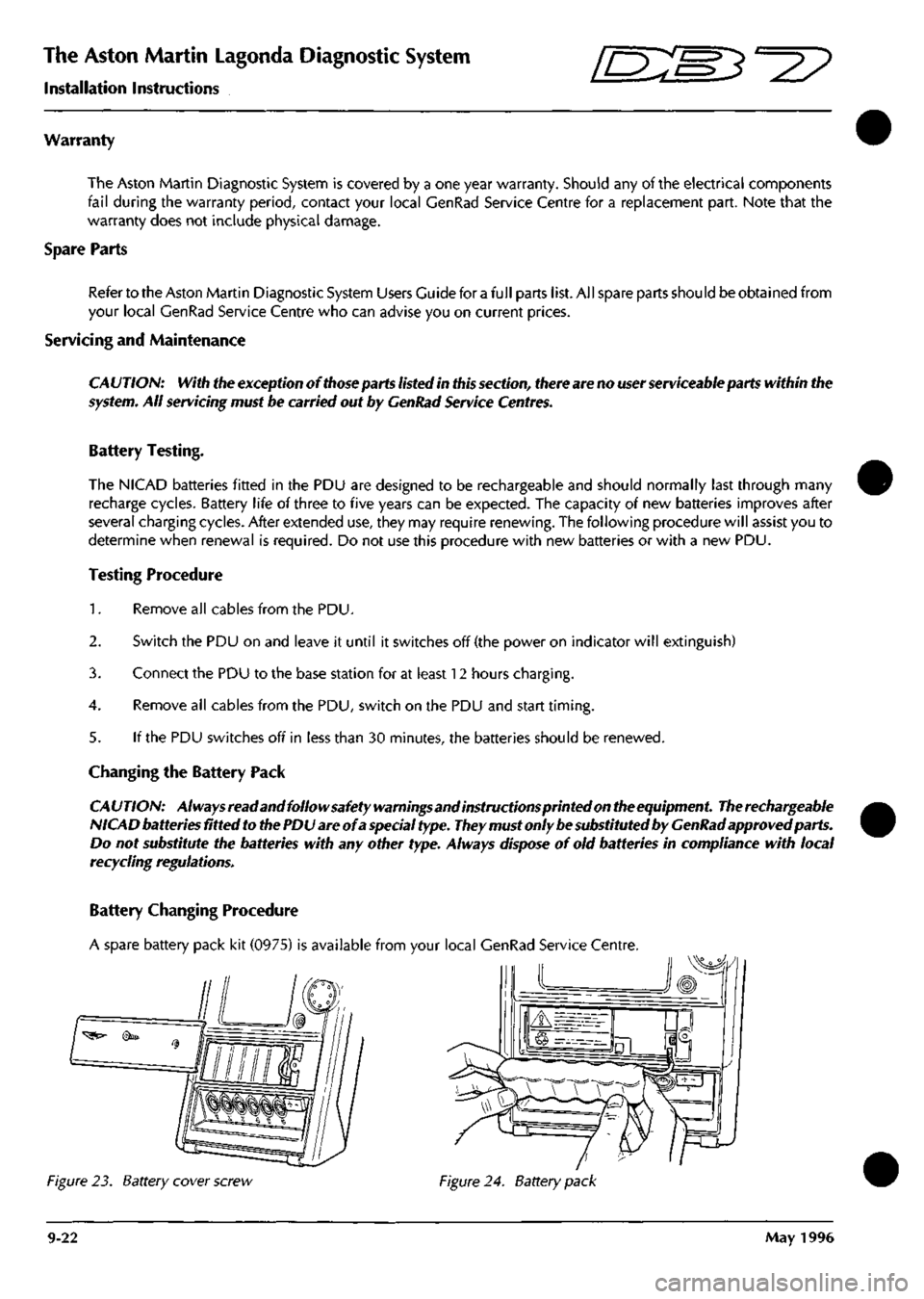

Changing the Battery Pack

CAUTION: Always read and follow safety warnings and instructions printed on the equipment. The rechargeable

NICAD batteries fitted to the PDU are of a special type. They must only be substituted by GenRad approved parts.

Do not substitute the batteries with any other type. Always dispose of old batteries in compliance with local

recycling regulations.

Battery Changing Procedure

A spare battery pack kit (0975) is available from your local GenRad Service Centre.

Figure 23. Battery cover screw Figure 24. Battery pack

9-22 May 1996