wiring ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 10 of 421

Electrics

Electrical Component Location and Wiring Information - Up to 97 MY

Component Index 6-19

Component Location Diagrams 6-23

Electronic Control Unit Location Diagram 6-38

Relay Panel, Fusebox and Earth Point Location Diagram 6-39

Loom Location Diagrams 6-40

Wiring Diagrams and Splice Lists 6-42

Electrical Component Location and Wiring Information - 97 MY

Component Index 6-43

Component Location Diagrams 6-47

Relay Location Diagrams 6-64

Wiring Diagrams and Splice Lists 6-68

Airbag System - Repair and Diagnostic Procedures 6-69

Seat Belt Pretensioner System - Repair and Diagnostic Procedures 6-101

Security System (Restricted Circulation) 6-111

PATS System (Restricted Circulation) 6-121

97.5 Model Year

6.6.03 Seat Removal (97.5 MY)

6.6.08 Seat Control Module (97.5 MY)

6-127

6-128

6-2 April! 997

Page 12 of 421

Electrics

Front Exterior Lamps - Removal Procedures E::M^=2?

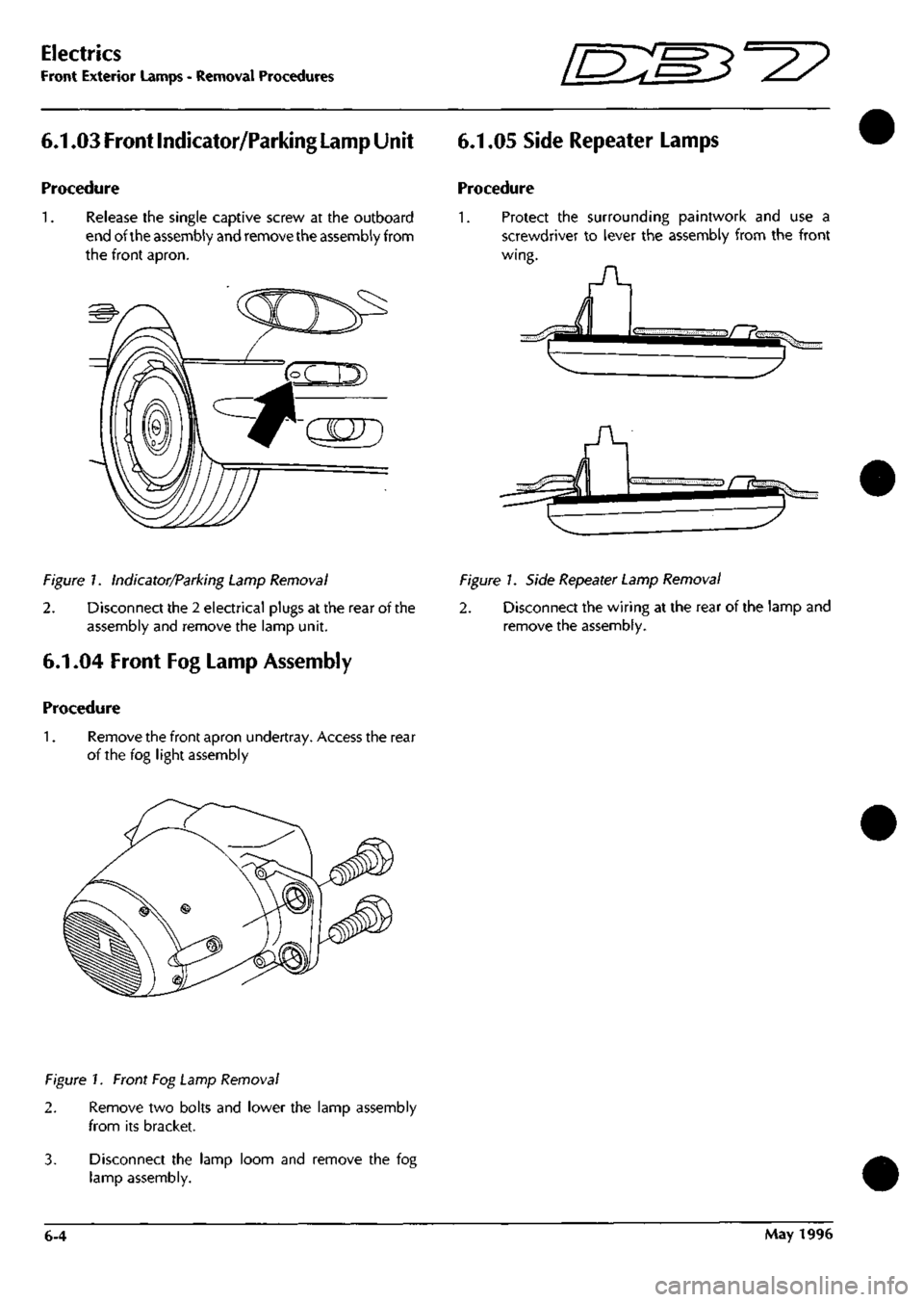

6.1.03 Front Indicator/Parking

Lamp

Unit 6.1.05 Side Repeater Lamps

Procedure

1.

Release the single captive screw at the outboard

end of the assembly and remove the assembly from

the front apron.

Procedure

1.

Protect the surrounding paintwork and use a

screwdriver to lever the assembly from the front

wing.

Figure 7. Indicator/Parking Lamp Removal

2. Disconnect the 2 electrical plugs at the rear of the

assembly and remove the lamp unit.

6.1.04 Front Fog Lamp Assembly

Figure /. Side Repeater Lamp Removal

2.

Disconnect the wiring at the rear of the lamp and

remove the assembly.

Procedure

1.

Remove the front apron undertray. Access the rear

of the fog light assembly

Figure 1. Front Fog Lamp Removal

2.

3.

Remove two bolts and lower the lamp assembly

from its bracket.

Disconnect the lamp loom and remove the fog

lamp assembly.

6-4 May 1996

Page 16 of 421

Electrics

Radio / Air-Con Switch Panel - Removal Procedures [D:m3^^2?

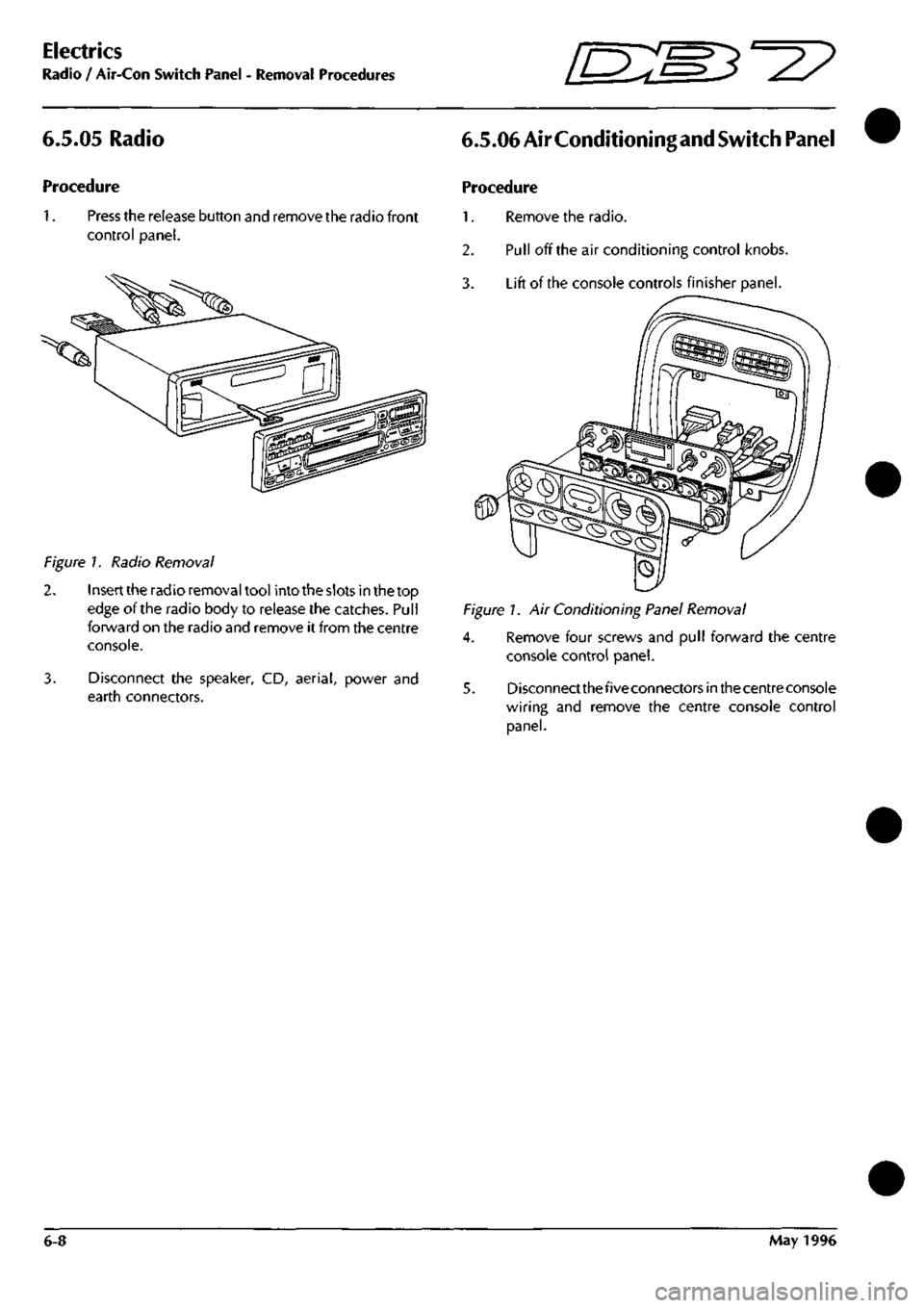

6.5.05 Radio

Procedure

1.

Press the release button and remove the radio front

control panel.

Figure

/. Radio Removal

2.

Insertthe radio removal tool intothe slots in thetop

edge of the radio body to release the catches. Pull

forward on the radio and remove it from the centre

console.

3. Disconnect the speaker, CD, aerial, power and

earth connectors.

6.5.06 AirConditioningand

Switch

Panel

Procedure

1.

Remove the radio.

2.

Pull off the air conditioning control knobs.

3. Lift of the console controls finisher panel.

Figure h Air Conditioning Panel Removal

4.

Remove four screws and pull forward the centre

console control panel.

5. Disconnectthefiveconnectorsinthecentreconsole

wiring and remove the centre console control

panel.

6-8 May 1996

Page 17 of 421

lEM^-^?

Electrics

Control Switch - Removal Procedures

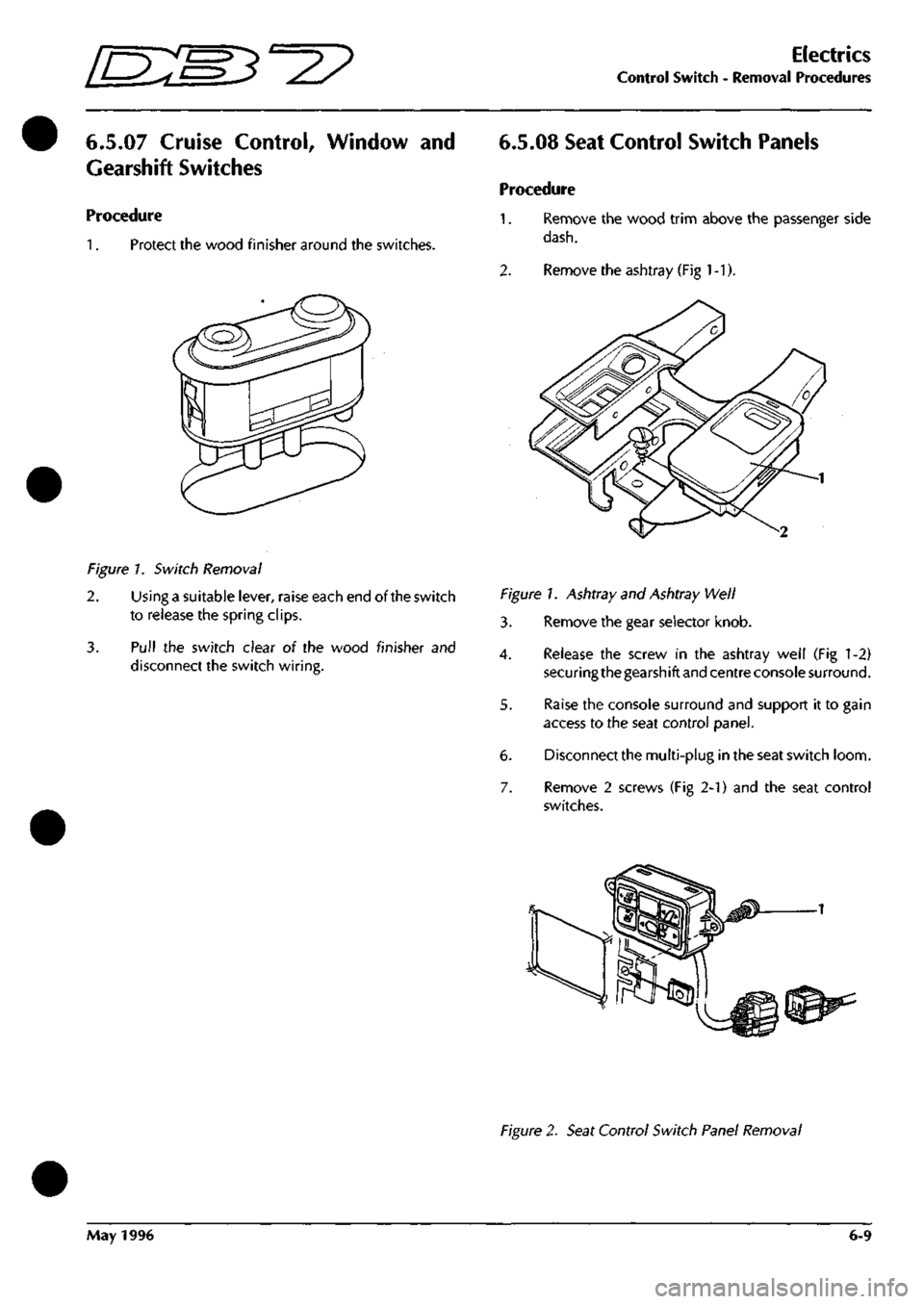

6.5.07 Cruise Control, Window and

Gearshift Switches

Procedure

1.

Protect the wood finisher around the switches.

6.5.08 Seat Control Switch Panels

Procedure

1.

Remove the wood trim above the passenger side

dash.

2.

Remove the ashtray (Fig

1

-1).

Figure 7. Switch Removal

2.

Using a suitable lever, raise each end of the switch

to release the spring clips.

3. Pull the switch clear oi the wood finisher and

disconnect the switch wiring.

Figure!. Ashtray and Ashtray Well

3. Remove the gear selector knob.

4.

Release the screw in the ashtray well (Fig 1-2)

securing the gearshift and centre console surround.

5. Raise the console surround and support it to gain

access to the seat control panel.

6. Disconnect the multi-plug in the seat switch loom.

7. Remove 2 screws (Fig 2-1) and the seat control

switches.

Figure 2. Seat Control Switch Panel Removal

May 1996 6-9

Page 18 of 421

Electrics

Interior Lamps and Front Seat - Removal Procedures EM^^^

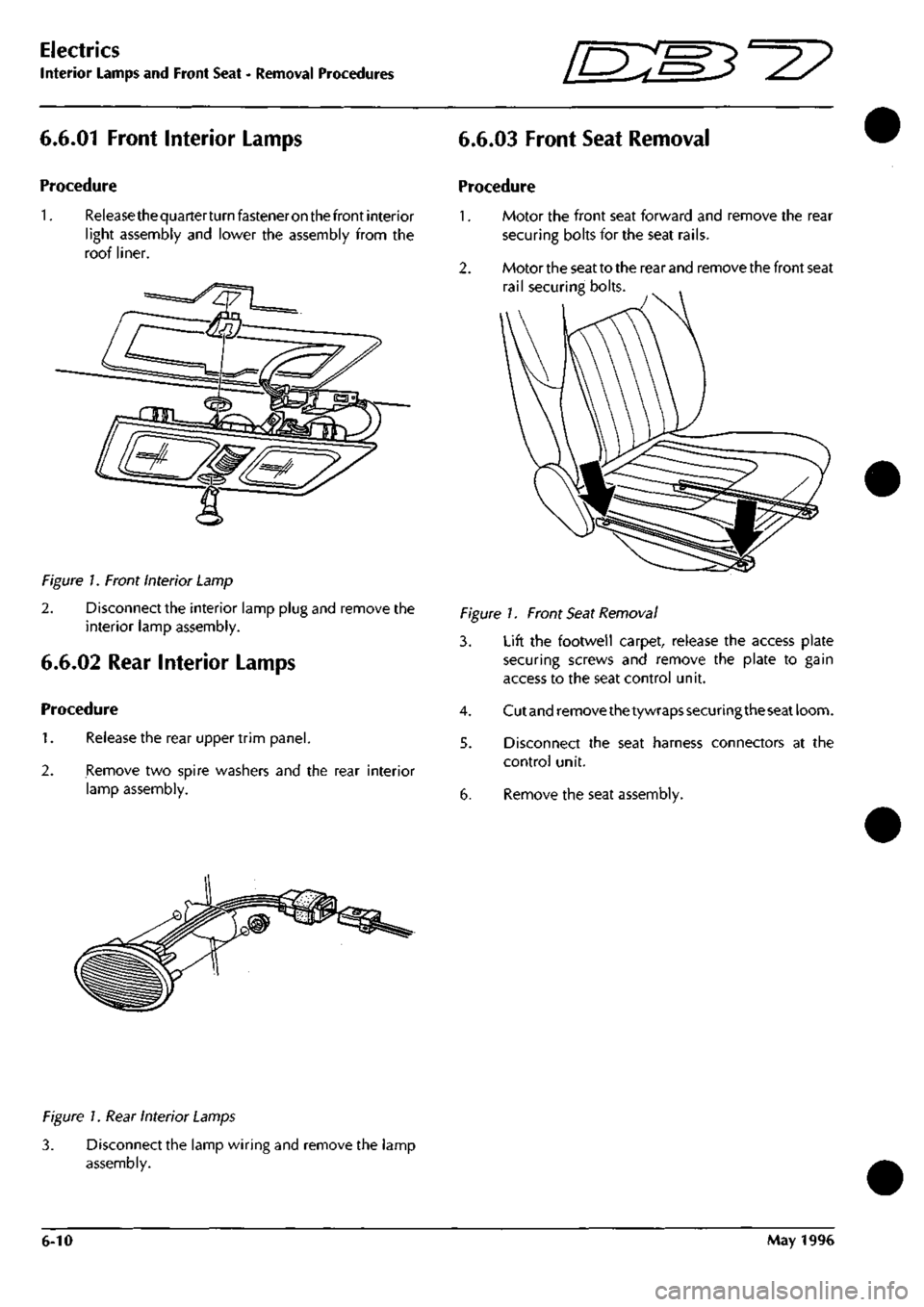

6.6.01 Front Interior Lamps

Procedure

1.

Releasethequarterturnfasteneronthefrontinterior

light assembly and lower the assembly from the

roof liner.

Figure 7. Front Interior Lamp

2. Disconnect the interior lamp plug and remove the

interior lamp assembly.

6.6.02 Rear Interior Lamps

Procedure

1.

Release the rear upper trim panel.

2.

Remove two spire washers and the rear interior

lamp assembly.

6.6.03 Front Seat Removal

Procedure

1.

2.

Motor the front seat forward and remove the rear

securing bolts for the seat rails.

Motor the seat to the rear and remove the front seat

rail securing bolts.

Figure 1. Front Seat Removal

3. Lift the footweil carpet, release the access plate

securing screws and remove the plate to gain

access to the seat control unit.

4.

Cutand remove thetywrapssecuringtheseat loom.

5. Disconnect the seat harness connectors at the

control unit.

6. Remove the seat assembly.

Figure 7. Rear Interior Lamps

3. Disconnect the lamp wiring and remove the lamp

assembly.

6-10 May 1996

Page 20 of 421

Electrics

Lumbar Support, Recline Motor and Seat Control Unit - Removal Procedures

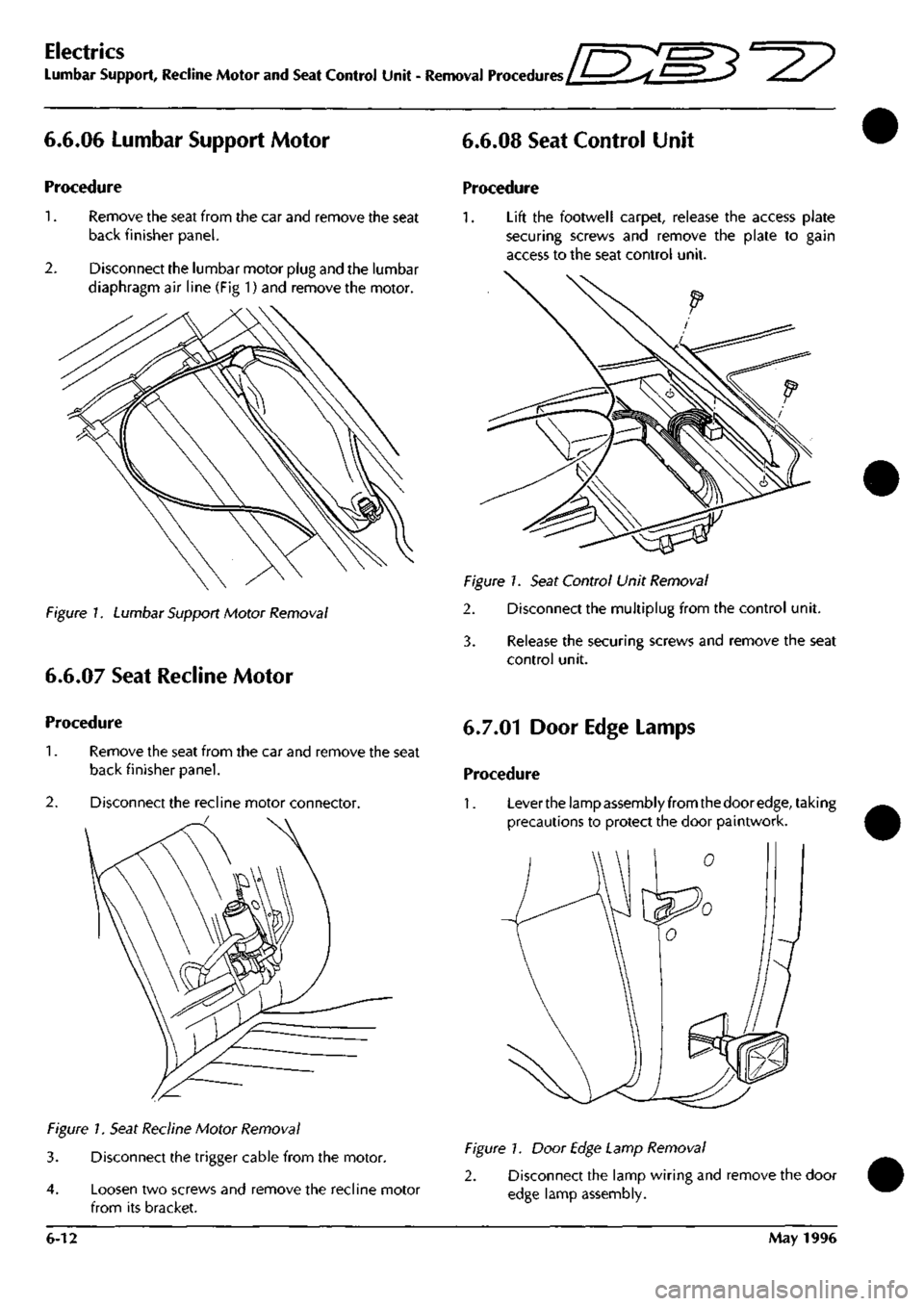

6.6.06 Lumbar Support Motor

Procedure

1.

Remove the seat from the car and remove the seat

back finisher panel.

2.

Disconnect the lumbar motor plug and the lumbar

diaphragm air line (Fig 1) and remove the motor.

Figure /. Lumbar Support Motor Removal

6.6.07 Seat Recline Motor

6.6.08 Seat Control Unit

Procedure

1.

Lift the footwell carpet, release the access plate

securing screws and remove the plate to gain

access to the seat control unit.

Figure 1. Seat Control Unit Removal

2. Disconnect the multiplug from the control unit.

3. Release the securing screws and remove the seat

control unit.

Procedure

1.

Remove the seat from the car and remove the seat

back finisher panel.

2.

Disconnect the recline motor connector.

Figure 1. Seat Recline Motor Removal

3. Disconnect the trigger cable from the motor.

4.

Loosen two screws and remove the recline motor

from its bracket.

6.7.01 Door Edge Lamps

Procedure

1.

Lever the lamp assembly from the door

edge,

taking

precautions to protect the door paintwork.

Figure 1. Door Edge Lamp Removal

2. Disconnect the lamp wiring and remove the door

edge lamp assembly.

6-12 May 1996

Page 22 of 421

Electrics

Electric Windows - Fault Analysis / Window Motor Removal

[n:m3^^

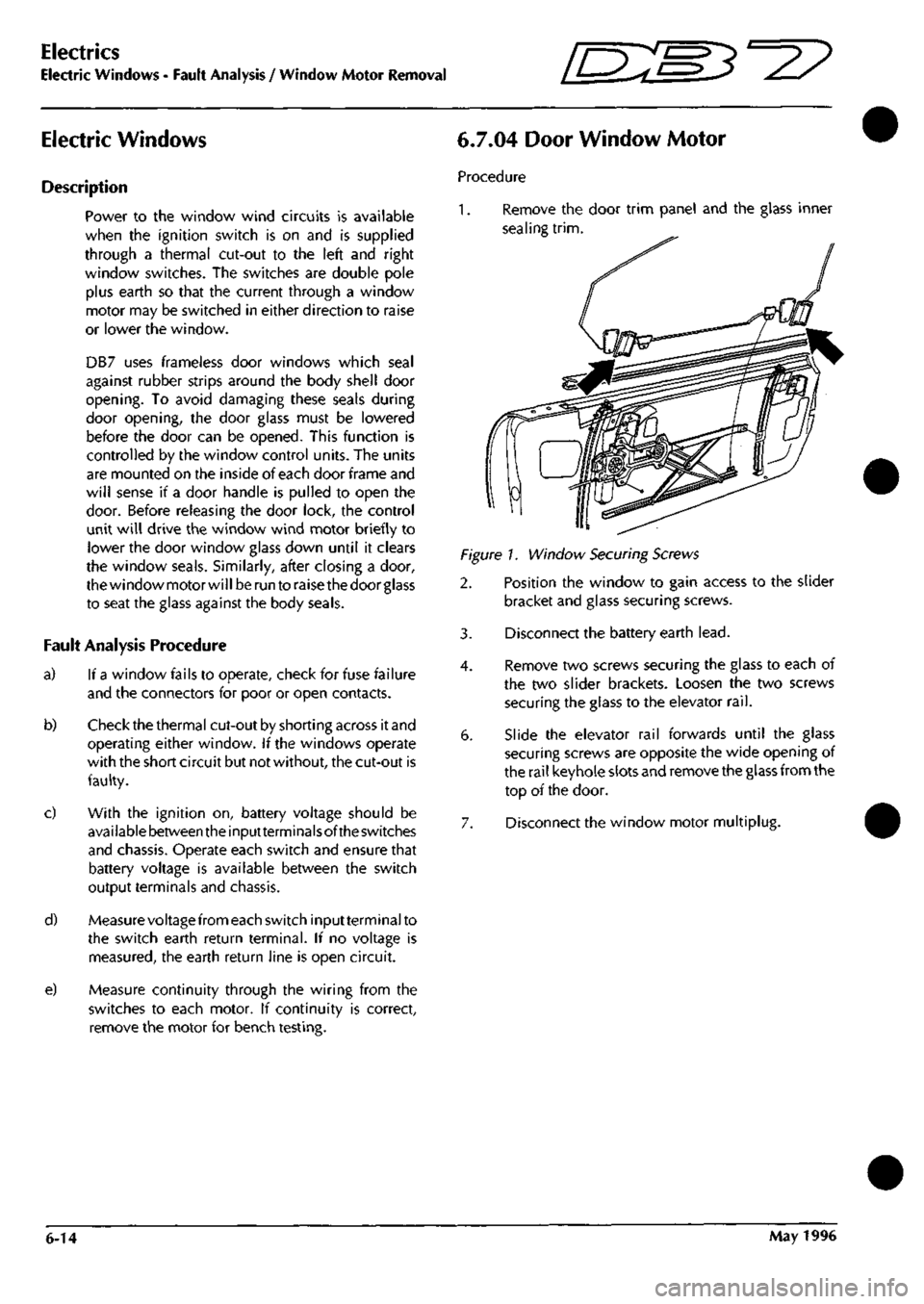

Electric Windows

Description

Power to the window wind circuits is available

when the ignition switch is on and is supplied

through a thermal cut-out to the left and right

window switches. The switches are double pole

plus earth so that the current through a window

motor may be switched in either direction to raise

or lower the window.

DB7 uses frameless door windows which seal

against rubber strips around the body shell door

opening.

To avoid damaging these seals during

door opening, the door glass must be lowered

before the door can be opened. This function is

controlled by the window control units. The units

are mounted on the inside of each door frame and

will sense if a door handle is pulled to open the

door. Before releasing the door lock, the control

unit will drive the window wind motor briefly to

lower the door window glass down until it clears

the window seals. Similarly, after closing a door,

the window motor will be run to raise the door glass

to seat the glass against the body seals.

Fault Analysis Procedure

a) If a window fails to operate, check for fuse failure

and the connectors for poor or open contacts.

b) Check the thermal cut-out by shorting across it and

operating either window. If the windows operate

with the short

ci rcu

it but not without, the cut-out is

faulty.

c) With the ignition on, battery voltage should be

available between the inputterminalsof the switches

and chassis. Operate each switch and ensure that

battery voltage is available between the switch

output terminals and chassis.

d) Measure voltagefrom each switch inputterminalto

the switch earth return terminal. If no voltage is

measured,

the earth return line is open circuit.

e) Measure continuity through the wiring from the

switches to each motor. If continuity is correct,

remove the motor for bench testing.

6.7.04 Door Window Motor

Procedure

1.

Remove the door trim panel and the glass inner

sealing

trim.

Figure!. Window Securing Screws

2. Position the window to gain access to the slider

bracket and glass securing screws.

3. Disconnect the battery earth

lead.

4.

Remove two screws securing the glass to each of

the two slider brackets. Loosen the two screws

securing the glass to the elevator

rail.

6. Slide the elevator rail forwards until the glass

securing screws are opposite the wide opening of

the rail keyhole slots and remove the glass from the

top of the door.

7. Disconnect the window motor multiplug.

6-14 May 1996

Page 23 of 421

in:s^^^

Electrics

Electric Door Mirrors

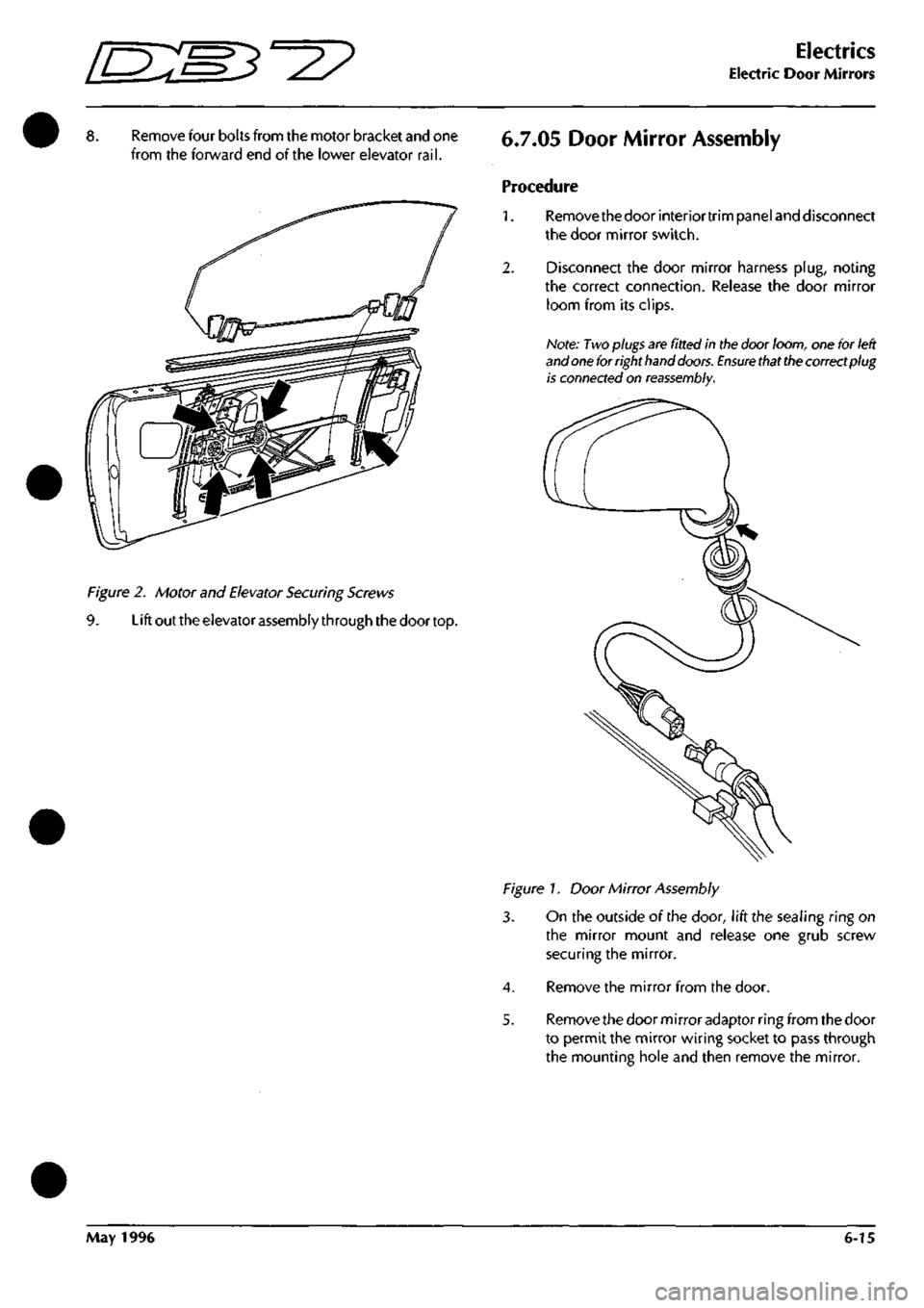

Remove four bolts from the motor bracket and one

from the forward end of the lower elevator

rail.

Figure 2. Motor and Elevator Securing Screws

9. Lift out the elevator assembly through the door top.

6.7.05 Door Mirror Assembly

Procedure

1.

2.

Removethe door interiortrim panel and disconnect

the door mirror switch.

Disconnect the door mirror harness

plug,

noting

the correct connection. Release the door mirror

loom from its clips.

Note:

Two

plugs are fitted in the door loom, one for left

and one for right hand

doors.

Ensure

that

the

correct plug

is connected on

reassembly.

Figure 7. Door Mirror Assembly

3. On the outside of the door, lift the sealing ring on

the mirror mount and release one grub screw

securing the mirror.

4.

Remove the mirror from the door.

5. Remove the door mirror adaptor ring from the door

to permit the mirror wiring socket to pass through

the mounting hole and then remove the mirror.

May 1996 6-15

Page 26 of 421

Electrics

Electrical Component Location and Wiring Information in::m3^?

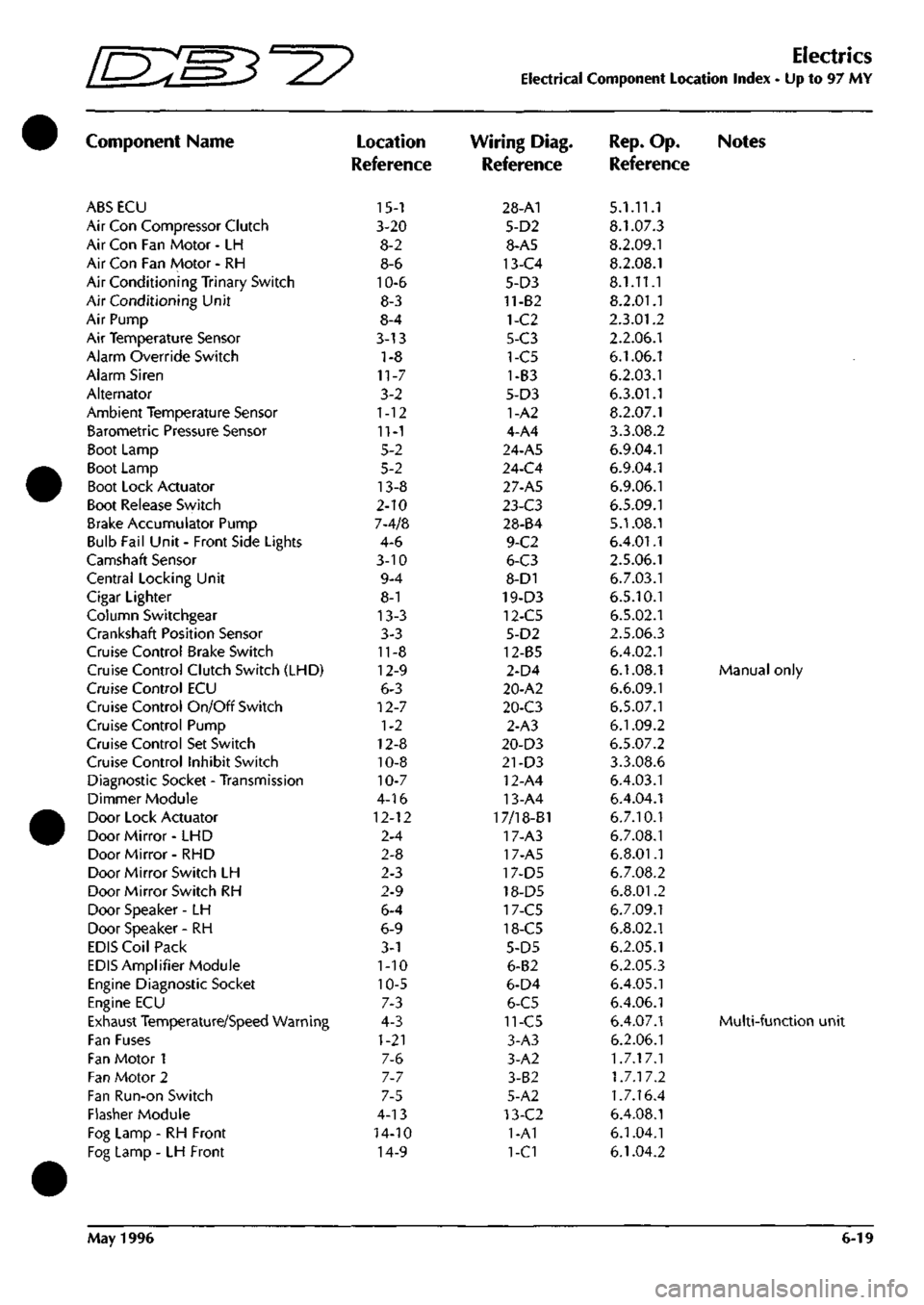

DB7 Electrical Component Location and

Wiring Information

Thefol lowing pages contains electrical component

location and electrical wiring diagrams.

Component Index

The following list details all of the functional

electrical components of the DB7. The list is given

in alphabetical order with component location and

wiring diagram references for each component.

Component Location on the vehicle

To locate a component on the veh

icie,

find its name

in the component index and note the component

location reference.

The component location reference gives the figure

number and item number for each component so

that you can find the component on the following

location diagrams and in the car.

Component Location on the Wiring Diagrams

The wiring diagram reference gives the wiring

diagram number and the location coordinates so

that you can locate the component and its wiring

on the wiring diagrams.

Wiring Diagrams

Each diagram covers a complete loom or section of

a major loom.

Continuations of a loom on another sheet and

connections to other looms are indicated by the

continuation arrow »* and the Sheet Number and

Co-Ordinateswherethecontinuation or connection

is located.

Each connector is illustrated with an end view of

the mating face of the connector. A table beside

each connector gives the pin number, wire colour

and destination of each wire.

Wire Colours

The following key is used to denote wire colours in

the connector wiring tables

B = Black P = Purple G = Green

K = Pink S = Slate LG = Light Green

N = Brown W = White O = Orange

R = Red U = Blue Y = Yellow

Wire Splices

Many wire runs are spliced within the loom

wrapping and additional information is required to

aid in fault analysis. All splices are noted on the

wiring diagrams (e.g. SPL1 = Splice 1). On the

facing page for each wiring diagram, a splice list

gives the splice number and the wire colours and

destinations for each wire coming from the splice.

6-18 May 1996

Page 27 of 421

Electrics

Electrical Component Location Index - Up to 97 MY

Component Name

ABS ECU

Air Con Compressor Clutch

Air Con Fan Motor - LH

Air Con Fan Motor - RH

Air Conditioning Trinary Switch

Air Conditioning Unit

Air Pump

Air Temperature Sensor

Alarm Override Switch

Alarm Siren

Alternator

Ambient Temperature Sensor

Barometric Pressure Sensor

Boot Lamp

Boot Lamp

Boot Lock Actuator

Boot Release Switch

Brake Accumulator Pump

Bulb Fail Unit - Front Side Lights

Camshaft Sensor

Central Locking Unit

Cigar Lighter

Column Switchgear

Crankshaft Position Sensor

Cruise Control Brake Switch

Cruise Control Clutch Switch (LHD)

Cruise Control ECU

Cruise Control On/Off Switch

Cruise Control Pump

Cruise Control Set Switch

Cruise Control Inhibit Switch

Diagnostic Socket - Transmission

Dimmer Module

Door Lock Actuator

Door Mirror- LHD

Door Mirror- RHD

Door Mirror Switch LH

Door Mirror Switch RH

Door Speaker -LH

Door Speaker - RH

EDIS Coil Pack

EDIS Amplifier Module

Engine Diagnostic Socket

Engine ECU

Exhaust Temperature/Speed Warning

Fan Fuses

Fan Motor 1

Fan Motor 2

Fan Run-on Switch

Flasher Module

Fog Lamp - RH Front

Fog Lamp - LH Front

Location

Reference

15-1

3-20

8-2

8-6

10-6

8-3

8-4

3-13

1-8

11-7

3-2

1-12

11-1

5-2

5-2

13-8

2-10

7-4/8

4-6

3-10

9-4

8-1

13-3

3-3

11-8

12-9

6-3

12-7

1-2

12-8

10-8

10-7

4-16

12-12

2-4

2-8

2-3

2-9

6-4

6-9

3-1

1-10

10-5

7-3

4-3

1-21

7-6

7-7

7-5

4-13

14-10

14-9

Wiring Diag.

Reference

28-A1

5-D2

8-A5

13-C4

5-D3

11-82

1-C2

5-C3

1-C5

1-B3

5-D3

1-A2

4-A4

24-A5

24-C4

27-A5

l-i-C3

28-84

9-C2

6-C3

8-D1

19-D3

12-C5

5-D2

12-85

2-D4

20-A2

20-C3

2-A3

20-D3

21-D3

12-A4

13-A4

17/18-B1

17-A3

17-A5

17-D5

18-D5

17-C5

18-C5

5-D5

6-B2

6-D4

6-C5

11-C5

3-A3

3-A2

3-B2

5-A2

13-C2

1-A1

1-C1

Rep.

Op. Notes

Reference

5.1.11.1

8.1.07.3

8.2.09.1

8.2.08.1

8.1.11.1

8.2.01.1

2.3.01.2

2.2.06.1

6.1.06.1

6.2.03.1

6.3.01.1

8.2.07.1

3.3.08.2

6.9.04.1

6.9.04.1

6.9.06.1

6.5.09.1

5.1.08.1

6.4.01.1

2.5.06.1

6.7.03.1

6.5.10.1

6.5.02.1

2.5.06.3

6.4.02.1

6.1.08.1 Manual only

6.6.09.1

6.5.07.1

6.1.09.2

6.5.07.2

3.3.08.6

6.4.03.1

6.4.04.1

6.7.10.1

6.7.08.1

6.8.01.1

6.7.08.2

6.8.01.2

6.7.09.1

6.8.02.1

6.2.05.1

6.2.05.3

6.4.05.1

6.4.06.1

6.4.07.1 Multi-functio

6.2.06.1

1.7.17.1

1.7.17.2

1.7.16.4

6.4.08.1

6.1.04.1

6.1.04.2

May 1996 6-19