sensor ASTON MARTIN V8 VANTAGE 2010 Owners Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 417 of 947

Engine Management System (03.14)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-14-1

Engine (03.00)

Engine Management System (03.14)

Maintenance

LH Front Lower Heated Exhaust Gas

Oxygen (HEGO) Sensor - Renew

Removal

1. Raise vehicle on ramp.

2. Remove rear exhaust silencer (refer to Workshop Manual procedure 09.00.KA Silencer and Bypass Valve

Assembly - Remo ve for Access and Refit).

3. Disconnect multiplugs (x2), HEGO sensors.

4. Secure sufficient lengths of string to HEGO sensor multiplugs for assembly purposes.

5. Loosen LH and RH clamp nuts, catalysts to centre pipes.

6. With assistance, manoeuvre exhaust centre pipe assembly rearwards to release from catalysts.

7. Remove nuts (x3), catalyst to exhaust manifold.

8. Release and support weight of LH catalyst from exhaust

manifold.

9. Manoeuvre HEGO sensor leads and remove cable tie. Release HEGO sensor leads from behind heat shield.

Remove string from HEGO multiplugs.

10. Remove catalyst assembly.

11. Remove and discard gasket.

12. Remove HEGO sens ors from catalyst.

Installation

1. Clean catalyst, mating joint faces and HEGO sensors.

2. Install and tighten HEGO sensor to catalyst.

3. Apply proprietary exhaust se alant around clamp joints.

4. Install new gasket to exhaust manifold.

5. Position catalyst, secure string (x2) to HEGO multiplugs, feed sensor leads behind heat shield. Install catalyst to

exhaust manifold.

6. Instal land tighten nuts (x3), catalyst to exhaust manifold.

7. Align centre pipe assembly to catalyst, tighten clamp

nuts.

8. Remove string (x2), conne ct multiplugs (x2), HEGO

sensors.

9. Install rear exhaust silencer (refer to Workshop Manual procedure 09.00.KA Silencer and Bypass Valve

Assembly - Remo ve for Access and Refit).

10. Lower vehicle on ramp.

LH Front Upper Heated Exhaust Gas

Oxygen (HEGO) Sensor - Renew

Repair Operation Time (ROT)

Repair Operation Time (ROT)

WA R N I N G

THE EXHAUST SYSTEM WILL BE VERY HOT AFTER OPERATION. LET THE EXHAUST SYSTEM COOL

BEFORE YOU DO WORK. IF YOU DO NOT, SEVERE

INJURY CAN OCCUR.

Repair Operation Time (ROT)

Page 418 of 947

Engine Management System (03.14)

Engine (03.00)3-14-2 Workshop Manual Issue 5, Janauary 2010

Removal

1. Raise vehicle on ramp.

2. Remove rear exhaust silencer (refer to Workshop Manual procedure 09.00.KA Silencer and Bypass Valve

Assembly - Remove for Access and Refit).

3. Disconnect multiplugs (x2), HEGO sensors.

4. Secure sufficient lengths of string to HEGO sensor multiplugs for assembly purposes.

5. Loosen LH and RH clamp nuts, catalysts to centre pipes.

6. With assistance, manoeuvre exhaust centre pipe assembly rearwards to release from catalysts.

7. Remove nuts (x3), catalyst to exhaust manifold.

8. Release and support weight of LH catalyst from exhaust manifold.

9. Manoeuvre HEGO sensor leads and remove cable tie. Release HEGO sensor leads from behind heat shield.

Remove string from HEGO multiplugs.

10. Remove catalyst assembly.

11. Remove and discard gasket.

12. Remove HEGO sensors from catalyst.

Installation

1. Clean catalyst, mating joint faces and HEGO sensors.

2. Install and tighten HEGO sensor to catalyst.

3. Apply proprietary exhaust sealant around clamp joints.

4. Install new gasket to exhaust manifold.

5. Position catalyst, secure string (x2) to HEGO multiplugs, feed sensor leads behind heat shield. Install catalyst to

exhaust manifold.

6. Instal land tighten nuts (x3), catalyst to exhaust manifold.

7. Align centre pipe assembly to catalyst, tighten clamp nuts to.

8. Remove string (x2), connect multiplugs (x2), HEGO sensors.

9. Install rear exhaust silencer (refer to Workshop Manual

procedure 09.00.KA Silencer and Bypass Valve

Assembly - Remove for Access and Refit).

10. Lower vehicle on ramp.

RH Front Upper Heated Exhaust Gas

Oxygen (HEGO) Sensor - Renew

Removal

1. Raise vehicle on ramp.

2. Remove rear exhaust silencer (refer to Workshop Manual procedure 09.00.KA Silencer and Bypass Valve

Assembly - Remove for Access and Refit).

3. Disconnect multiplugs (x2), HEGO sensors.

4. Secure sufficient lengths of string to HEGO sensor

multiplugs for assembly purposes.

5. Loosen LH and RH clamp nuts, catalysts to centre pipes.

6. With assistance, manoeuvre exhaust centre pipe assembly rearwards to release from catalysts.

7. Remove nuts (x3), catalyst to exhaust manifold.

8. Release and support weight of LH catalyst from exhaust

manifold.

9. Manoeuvre HEGO sensor leads and remove cable tie. Release HEGO sensor leads from behind heat shield.

Remove string from HEGO multiplugs.

10. Remove catalyst assembly.

11. Remove and discard gasket.

12. Remove HEGO sensors from catalyst.

Installation

1. Clean catalyst, mating joint faces and HEGO sensors.

2. Install and tighten HEGO sensor to catalyst.

3. Apply proprietary exhaust sealant around clamp joints.

4. Install new gasket to exhaust manifold.

5. Position catalyst, secure string (x2) to HEGO multiplugs, feed sensor leads behind heat shield. Install catalyst to

exhaust manifold.

6. Instal land tighten nuts (x3), catalyst to exhaust manifold.

7. Align centre pipe assembly to catalyst, tighten clamp nuts to.

8. Remove string (x2), connect multiplugs (x2), HEGO sensors.

9. Install rear exhaust silencer (refer to Workshop Manual procedure 09.00.KA Silencer and Bypass Valve

Assembly - Remove for Access and Refit).

10. Lower vehicle on ramp.

RH Rear Lower Heated Exhaust Gas

Oxygen (HEGO) Sensor - Renew

WAR NI NG

THE EXHAUST SYSTEM WILL BE VERY HOT AFTER OPERATION. LET THE EXHAUST SYSTEM COOL

BEFORE YOU DO WORK. IF YOU DO NOT, SEVERE INJURY CAN OCCUR.

Repair Operation Time (ROT)

WAR NI NG

THE EXHAUST SYSTEM WILL BE VERY HOT AFTER OPERATION. LET THE EXHAUST SYSTEM COOL

BEFORE YOU DO WORK. IF YOU DO NOT, SEVERE INJURY CAN OCCUR

Repair Operation Time (ROT)

ItemCode

Rear Lower Heated Exhaust Gas

Oxygen (HEGO) Sensor - Renew 03.14.JB

Page 419 of 947

Engine Management System (03.14)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-14-3

Removal

1. Raise vehicle on ramp.

2. Remove rear exhaust silencer (refer to Workshop Manual procedure 09.00.KA Silencer and Bypass Valve

Assembly - Remove for Access and Refit).

3. Disconnect multiplugs (x2), HEGO sensors.

4. Secure sufficient lengths of string to HEGO sensor multiplugs for assembly purposes.

5. Loosen LH and RH clamp nuts, catalysts to centre pipes.

6. With assistance, manoeuvre exhaust centre pipe assembly rearwards to release from catalysts.

7. Remove nuts (x3), catalyst to exhaust manifold.

8. Release and support weight of LH catalyst from exhaust manifold.

9. Manoeuvre HEGO sensor leads and remove cable tie. Release HEGO sensor leads from behind heat shield.

Remove string from HEGO multiplugs.

10. Remove catalyst assembly.

11. Remove and discard gasket.

12. Remove HEGO sensors from catalyst.

Installation

1. Clean catalyst, mating joint faces and HEGO sensors.

2. Install and tighten HEGO sensor to catalyst.

3. Apply proprietary exhaust se alant around clamp joints.

4. Install new gasket to exhaust manifold.

5. Position catalyst, secure string (x2) to HEGO multiplugs, feed sensor leads behind heat shield. Install catalyst to

exhaust manifold.

6. Instal land tighten nuts (x3), catalyst to exhaust manifold.

7. Align centre pipe assembly to catalyst, tighten clamp

nuts to.

8. Remove string (x2), conne ct multiplugs (x2), HEGO

sensors.

9. Install rear exhaust silencer (refer to Workshop Manual procedure 09.00.KA Silencer and Bypass Valve

Assembly - Remove for Access and Refit).

10. Lower vehicle on ramp.

Left Side Powertrain Control Module

(PCM) (Coupe Only) - Remove and

Install

Remove

1. Disconnect the ba ttery ground cable.

2. Remove the wheel and tyre. (refer to Workshop Manual procedure 04.04.EC - Wheel and Tyre)

3. Remove the six rear screws that attach the wheel-arch liner to the body.

4. Remove the rear screw that attaches the wheel-arch liner to the body.

5. Turn the steering fully to the right.

6. Move the wheel arch liner to get access to the Powertrain Control Module (PCM).

7. Disconnect the electrical connector from the direction

indicator.

8. Release the four fi r-tree clips that attach the wiring

harness for the direction indi cator and the screen wash

system.

9. Release the two fir tree clips that attach the wiring harness for the PCM.

10. Remove the three bolts that attach the PCM bottom bracket and PCM to the PCM top bracket.

11. Disconnect the three electrical connectors from the PCM.

12. Remove the PCM.

Install

1. Put the PCM in position.

2. Connect the three electrical connectors to the PCM.

3. Align the PCM to the top bracket.

4. Align the bottom bracket to the PCM.

5. Install and tighten the three bolts that attach the PCM bottom bracket and PCM to the PCM top bracket.

6. Install the two fir tree clips that attach the wiring harness for the PCM.

7. Attach the four fir-tree cl ips that attach the wiring

harness for the direction indi cator and the screen wash

system.

8. Connect the electrical connector to the direction indicator.

9. Put the wheel-arch liner into the correct position.

10. Install and tighten the rear screw that attaches the wheel-arch liner to the body.

11. Install and tighten the six rear screws that attach the wheel-arch liner to the body.

12. Move the steering to the centre position.

13. Connect the battery ground cable.

14. Install the wheel and tyre. (04.04.EC - Wheel and Tyre)

15. Connect AMDS.

16. Use AMDS to do a test of the PCM. (00.06.AD - AMDS Operation Check)

WA R N I N G

THE EXHAUST SYSTEM WILL BE VERY HOT AFTER OPERATION. LET THE EXHAUST SYSTEM COOL

BEFORE YOU DO WORK. IF YOU DO NOT, SEVERE

INJURY CAN OCCUR

Repair Operation Time (ROT)

Page 421 of 947

Throttle Control (03.16)

Engine (03.00)

May 2007 Workshop Manual 3-15-1

Engine (03.00)

Throttle Control (03.16)

Description

Motorised Throttles

The motorised throttle allows accurate control

of the inlet air.

A throttle position sensor (TPS) is incorporated

into the throttle unit. During normal engine

run, TPS signals are used by the PCM to

indicate power demand from the engine. If not

already at the desired position, the PCM will

drive the throttle motor to open or close the

throttle by the required amount.

At idle, the throttle butterfly is almost closed

and idle speed is controlled by small throttle

movements.

The throttle butterfly is spring loaded to fail in

the idle position. In the event of the throttle

butterfly spring failing, air flow will allow the

throttle butterflies to fail in the idle position.

No set-up procedure is required.

Page 425 of 947

Issue 6, May 2010 Workshop Manual 1-1-1

Suspension (04.00)

Contents

Road Wheel Alignment (04.00) ............................. 4-0-2Specifications ......................................................... 0-2

Maintenance ........................................................... 0-2All Wheel Alignment .............................................. 0-2

Front Suspension (04.01)....................................... 4-1-1 Description ............................................................. 1-1Suspension Arms .................................................... 1-1

Anti-roll Bar ........................................................... 1-1

Vertical link............................................................ 1-1

Specifications.......................................................... 1-1

Symptoms ............................................................... 1-2

Maintenance ........................................................... 1-3 RH/LH Front Hub and Bearing Assembly

- Renew ................................................................. 1-3

RH/LH Lower Front Suspension Arm Assembly

- Renew ................................................................. 1-4

RH/LH Upper Front Suspension Arm Assembly

- Renew ................................................................. 1-4

Front Anti-Roll Bar - Renew ................................... 1-5

Front Pair Anti-Roll Bar Bushing - Renew................ 1-5

RH/LH Front Anti-Roll Bar Link - Renew ................ 1-5

RH/LH Front Hub Vertical Link - Renew ................ 1-6

Front Suspension Sensor Assembly-Renew ............. 1-7

Rear Suspension (04.02) ........................................ 4-2-1 Description ............................................................. 2-1Suspension Arms .................................................... 2-1

Anti-roll Bar ........................................................... 2-1

Vertical Link........................................................... 2-1

Specifications.......................................................... 2-2

Maintenance ........................................................... 2-2 RH/LH Rear Hub and Bearin g Assembly-Renew ..... 2-2

RH/LH Rear Lower Arm Assembly-Renew .............. 2-2

RH/LH Upper Rear Arm Assembly-Renew .............. 2-3

RH/LH Toe Control Rear Arm Assembly-Renew ..... 2-3

Rear Anti-Roll Bar-Renew ...................................... 2-3

Rear Pair-Anti-Roll Bar Bushing-Renew .................. 2-4

RH/LH Rear Anti-Roll Bar Link-Renew ................... 2-4

RH/LH Rear Hub Vertical Link-Renew.................... 2-4

Rear Suspension Sensor Assembly-Renew .............. 2-5

Shock Absorber System (04.03) ............................. 4-3-1 Description ............................................................. 3-1

Specifications.......................................................... 3-1

Maintenance ........................................................... 3-1Front Spring and Damper Assembly-Pair-Renew .... 3-1

Front Spring-Pair-Renew ........................................ 3-3

Front Damper-Pair-Renew ..................................... 3-4

Rear Spring and Damper Assembly-Pair-Renew...... 3-5

Rear Spring-Pair-Renew ......................................... 3-7

Rear Damper-Pair-Renew ...................................... 3-9

Road Wheels and Tyres (04.04)............................. 4-4-1 Specifications.......................................................... 4-1USA Tyre Gradings................................................. 4-2

Tread Wear ........................................................... 4-2

Traction ................................................................. 4-2 Temperature .......................................................... 4-2

Maintenance ........................................................... 4-3 Safety .................................................................... 4-3

Tyre Replacement and Wheel Interchanging ......... 4-3

Winter (Snow) tyres ................................................ 4-4 Recommended Winter Wheel and

Tyre Combination .................................................. 4-4

Inspection and Verification . ................................... 4-4

Tyre Wear ............................................................. 4-4

Tyre Damage ......................................................... 4-6

Repairs .................................................................. 4-7

Care of Alloy Road Wheels .................................... 4-7

Road Wheel Alignment .......................................... 4-7

Road Wheel and Tyre Balance ............................... 4-8

Torque Tightening of Road Wheel Nuts ................ 4-8

Tyre Pressure Sensing (Option).............................. 4-9 Pressure Sensing with Wint er Wheels and Tyres ..... 4-9

Warnings ............................................................... 4-9

Display Unit ........................................................ 4-10

System Programming ........................................... 4-10

Page 427 of 947

Front Suspension (04.01)

Suspension (04.00)

November 2008 Workshop Manual 4-1-1

Suspension (04.00)

Front Suspension (04.01)

Description

Suspension Arms

The upper suspension arm is attached to the body structure.

The lower suspension arm is attached to the front subframe.

Each upper suspension arm has a press-fit ball-joint, and two

interleaved rubber bushes. Two bolts attach the upper

suspension arm to the body structure.

Each lower suspension arm has a press fit ball-joint and

metal-to-rubber bonded bushes which are attached to the

front subframe by two eccentric cam bolts (Camber and

castor settings).

Anti-roll Bar

The anti-roll bar, is attached to the subframe in two positions

by rubber bushes and clamps. The outer ends of the anti-roll

bar are attached to the lower suspension arms by drop links.

The anti-roll bar provides the required stiffness to control

body roll.

Vertical link

The Vertical link (Knuckle Joint) swivels on the upper and

lower suspension arms via ball-joints, and carries the hub, a

unit 3 wheel bearing (including the ABS encoder ring), the

wheel speed sensor, the brake caliper, and the brake disc

and shield. The position of the Vertical link is determined by

the movement of the steering rack, which is connected to

the Vertical link by the steering track rod.

Specifications

Upper Arm Ball Joint

and Bushes

Ball Joint

and Bushes Verticle

Link

Bolts to Body

Lower Arm

Anti-roll Bar Drop Links

Eccentric

Cam Bolts

04-01-003

Torque Figures

DescriptionNmlb. / ft.

Brake dust shield. 9 7

Bearing Assembly to the Vertical

link. 55 41

Vertical Link to the Lower

Suspension Arm. 90 66.5

Vertical Link to the Upper

Suspension Arm. 90 66.5

Track-rod End Lock Nut. 70 52

Vehicle Ride Height Sensor. M8 M522.5

9 17

7

Anti-roll Bar Link Nuts 110 81.5

Anti-roll Bar Mounting Bolts

Torque bolt 1, then bolt 2, then

bolt 1 again (to allow for rubber

compression) 22.5 17

Torque the following suspensi on fixings with the vehicle

at normal ride height

Lower Suspension Arm front

bush to the Subframe M14 185 137

Lower Suspension Arm rear

bush to the Subframe. M12 115 85

Upper Suspension Arm to the

Front Structure 115 85

Spring and Damper Bolts Top Lower22.5

175 17

129.5

Normal ride height 2 x 37.5kg in front seats (37.5kg in

each seat) plus a full fuel tank.

Page 429 of 947

Front Suspension (04.01)

Suspension (04.00)

November 2008 Workshop Manual 4-1-3

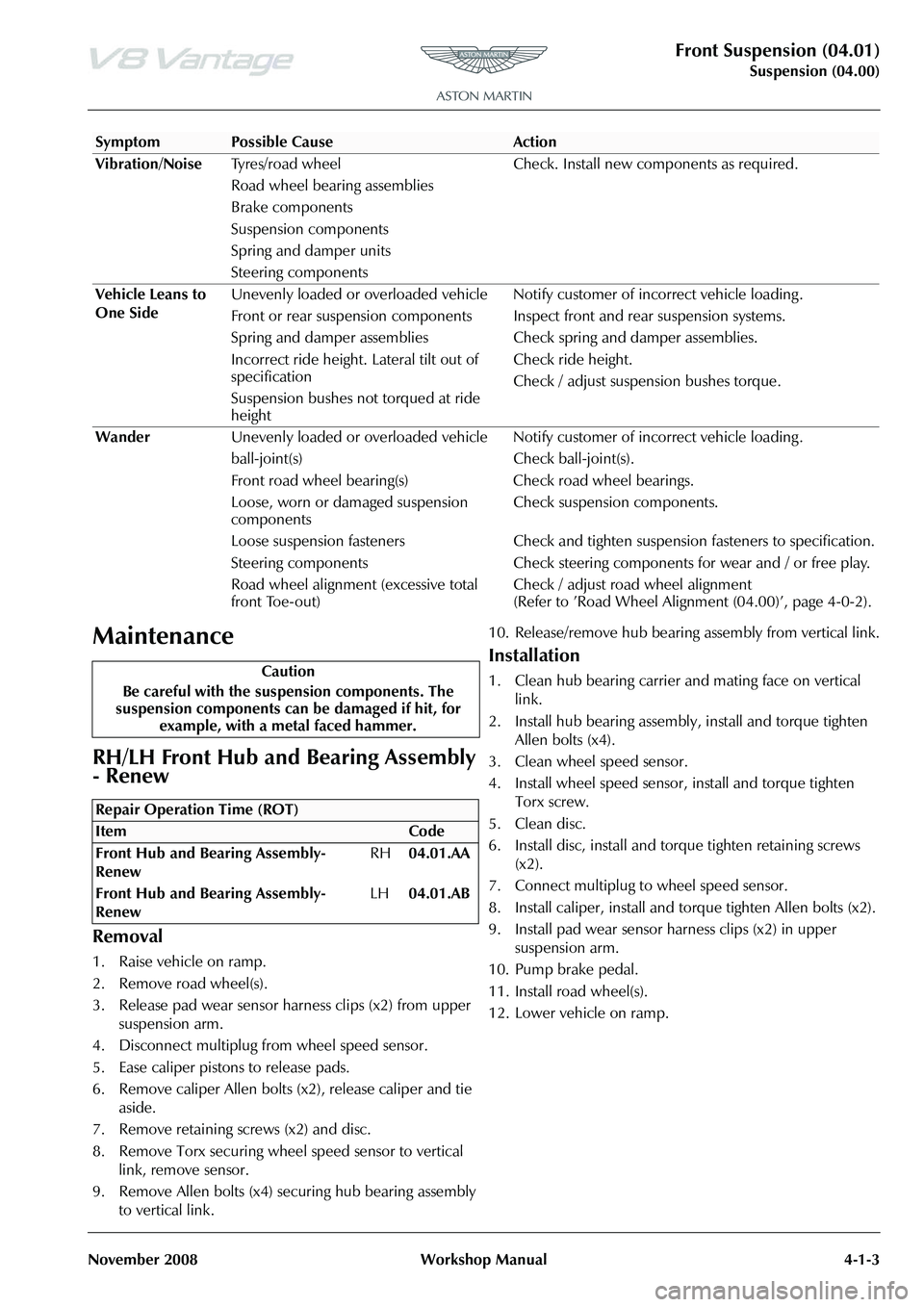

Maintenance

RH/LH Front Hub and Bearing Assembly

- Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Release pad wear sensor harness clips (x2) from upper suspension arm.

4. Disconnect multiplug from wheel speed sensor.

5. Ease caliper pistons to release pads.

6. Remove caliper Allen bolts (x2), release caliper and tie

aside.

7. Remove retaining screws (x2) and disc.

8. Remove Torx securing wheel speed sensor to vertical link, remove sensor.

9. Remove Allen bolts (x4) securing hub bearing assembly to vertical link. 10. Release/remove hub bearing assembly from vertical link.

Installation

1. Clean hub bearing carrier and mating face on vertical

link.

2. Install hub bearing assembly, install and torque tighten Allen bolts (x4).

3. Clean wheel speed sensor.

4. Install wheel speed sensor, install and torque tighten Torx screw.

5. Clean disc.

6. Install disc, install and torque tighten retaining screws (x2).

7. Connect multiplug to wheel speed sensor.

8. Install caliper, install and to rque tighten Allen bolts (x2).

9. Install pad wear sensor harness clips (x2) in upper suspension arm.

10. Pump brake pedal.

11. Install road wheel(s).

12. Lower vehicle on ramp.

Vibration/Noise

Tyres/road wheel

Road wheel bearing assemblies

Brake components

Suspension components

Spring and damper units

Steering components Check. Install new components as required.

Vehicle Leans to

One Side Unevenly loaded or overloaded vehicle Notif

y customer of incorrect vehicle loading .

Front or rear suspension components Inspect front and rear suspension systems.

Spring and damper assemblies Check spring and damper assemblies.

Incorrect ride height. Lateral tilt out of

specification

Suspension bushes not torqued at ride

height Check ride height.

Check / adjust suspension bushes torque.

Wander Unevenly loaded or overloaded vehicle Notif y customer of incorrect vehicle loading .

ball-joint(s) Check ball-joint(s).

Front road wheel bearing(s) Check road wheel bearings.

Loose, worn or damaged suspension

components Check suspension components.

Loose suspension fasteners Check and tighten suspension fasteners to specification.

Steering components Check steering components for wear and / or free play.

Road wheel alignment (excessive total

front Toe-out) Check / adjust road wheel alignment

(Refer to ’Road Wheel Alignment (04.00)’, page 4-0-2).

SymptomPossible CauseAction

Caution

Be careful with the suspension components. The

suspension components can be damaged if hit, for example, with a metal faced hammer.

Repair Operation Time (ROT)

Page 430 of 947

Front Suspension (04.01)

Suspension (04.00)4-1-4 Workshop Manual November 2008

RH/LH Lower Front Suspension Arm

Assembly - Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove nut/washer securing anti-roll bar link to lower suspension, release link from arm.

4. Remove nut/bolt securing damper to lower suspension arm, release damper from mounting.

5. Remove nut securing lower suspension arm ball-joint to vertical link.

6. Install tool (204 - 523) ba ll-joint remover and release

lower suspension ball-joi nt from vertical link.

7. Mark fitted positions of cam washers on lower suspension arm inner fixings to aid assembly purpose.

8. Remove nuts/bolts, cam washers (x2), securing lower suspension arm to subframe.

9. Release/remove lower suspension arm from subframe and vertical link.

Installation

1. Clean lower suspension arm and mating faces on vertical link and subframe

2. Install lower suspension arm in subframe.

3. Install cam washers, bolts/nuts (x2). Align cam washers to marks. Do not torque tighten at this stage.

4. Install lower suspension arm ball-joint in vertical link. Install and torque tighten nut.

5. Align damper to mounting, install bolt/nut. Do not torque tighten at this stage.

6. Install anti-roll bar link, install washer/nut. Do not torque tighten at this stage.

7. Final tightening of suspen sion components must be

carried out with the suspensi on arms at normal ride

height.

8. Install road wheel(s).

9. Lower vehicle on ramp.

10. Torque tighten suspension nuts/bolts.

11. 4 wheel alignment - check/adjust (see Workshop Manual procedure 04.00.AD 4 Wheel Alignment -

Check and Adjust).

RH/LH Upper Front Suspension Arm

Assembly - Renew

Removal

1. Raise the vehicle and make it safe.

2. Remove the road wheel for the applicable suspension arm.

3. Disconnect the electrical connector from the ABS sensor.

4. Release the three sensor harness clips from the upper suspension arm and the vertical link.

5. Remove the two Torx screws that attach the engine cross brace to the mounting.

6. Remove the two nuts and two bolts that attach the upper suspension arm to the body.

7. Release the suspension arm from the body.

8. Remove the three nuts that attach the damper top mounting.

9. Remove the mounting for the engine cross brace.

10. Remove the nut and bolt that attaches the damper to its lower mounting.

11. Remove spring/damper assembly.

12. Remove the nut that attaches the ball-joint for the upper suspension arm to the vertical link.

13. Install tool (204 - 523 - ball-joint remover) and release the ball-joint from vertical link.

14. Remove the upper suspension arm assembly.

Installation

1. Clean the upper suspension arm and the mating faces on the body and the vertical link.

2. Install the upper suspension arm to vertical link. Install the nut but do not torque tighten at this step.

3. Install spring/damper assembly.

4. Install the cross-brace support.

5. Install the three nuts but do not torque tighten at this step.

6. Align the damper to the lower mounting, install bolt/nut. Do not torque tighten at this step.

7. Put the upper suspension arm in positionon the body.

8. Install bolts and nuts but do not torque tighten at this step.

9. Connect the electrical connector to the ABS sensor.

Repair Operation Time (ROT)Repair Operation Time (ROT)

ItemCode

Upper Front Suspension Arm

Assembly-Renew RH

04.01.AE

Upper Front Suspension Arm

Assembly-Renew LH

04.01.AF

Caution

Be carefulthat you do not damage the ball-joint rubber

boot when you use the special tool.

Page 431 of 947

Front Suspension (04.01)

Suspension (04.00)

November 2008 Workshop Manual 4-1-5

10. Install the three sensor harness clips in the upper suspension and the vertical link.

11. Install the road wheel.

12. Lower the vehicle on ramp.

13. Do an all-wheel alignment procedure (Refer to ’All

Wheel Alignment’, page 4-0-2).

14. Torque tighten suspension nuts and bolts.

15. Align engine cross brace to support, install and torque tighten Torx bolts (x2).

Front Anti-Roll Bar - Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove front undertray (see Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

4. Remove nuts and washers (x2), anti-roll bar to drop links.

5. Remove bolts (x4), straps (x2).

6. Remove anti-roll bar.

7. Remove bushes (x2) from anti-roll bar.

Installation

1. Clean anti-roll bar, bushes and straps.

2. Install bushes (x2) on anti-roll bar.

3. Position anti-roll bar, align bushes (x2), install straps (x2), install bolts (x4). Do not torque tighten.

4. Install drop links to anti-roll bar, install nuts/washers (x2).

Do not torque tighten.

5. Install front undertray (see Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

6. Lower vehicle in ramp.

7. Torque tighten link nuts (x4).

8. Torque tighten bush strap bolts (x4).

Front Pair Anti-Roll Bar Bushing - Renew

Removal

1. Raise vehicle on ramp.

2. Remove front undertray (see Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

3. Remove bolts (x4) securing anti-roll bar bush straps to subframe.

4. Release/remove bush straps.

5. Remove bushes (x2) from anti-roll bar.

Installation

1. Clean anti-roll bar and bush straps.

2. Install bushes on to anti-roll bar.

3. Install bush straps (x2), install bolts (x4). Do not torque tighten at this stage.

4. Install front undertray (see Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

5. Lower vehicle on ramp.

6. Torque tighten all suspension nuts/bolts.

RH/LH Front Anti-Roll Bar Link - Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove nut/bolt securing damper to lower suspension

arm.

4. Release damper from mounting sufficient to remove top anti-roll bar link.

5. Remove nuts and washers (x2) , link to lower suspension

arm and anti-roll bar.

6. Release and remove anti-roll bar link.

Installation

1. Clean anti-roll bar link and mating faces on lower suspension arm and anti-roll bar.

2. Install link to anti-roll bar and lower suspension arm.

3. Install washers (x2) and nuts (x2). Do not torque tighten.

Caution

Do not fully tighten the nuts and bolts on the suspension

components. Only tighten the nuts and bolts of the

suspension components when the suspension arms are

at their usual ride-height and you have adjusted the

geometry. If you do not do this, the suspension bushes

will have too much stress when the suspension is moved

to its maximum upward travel.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Page 432 of 947

Front Suspension (04.01)

Suspension (04.00)4-1-6 Workshop Manual November 2008

4. Align damper to lower mounting, install bolt/nut. Do not torque tighten at this stage.

5. Install road wheel(s).

6. Lower vehicle in ramp.

7. Torque tighten link nuts (x2).

8. Torque tighten lower damper bolt.RH/LH Front Hub Vertical Link - Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Install tool (204 - 524) on front hub, install and tighten wheel nuts.

4. Lower vehicle to raise suspension sufficient to install ball-joint removing tool (204 - 523).

5. Remove track rod end from vertical link (using tool 204- 523).

6. Remove pad wear sensors.

7. Remove ABS sensor multiplug.

8. Remove Torx screw securing ABS sensor, remove sensor.

9. Ease caliper pistons to release pads.

10. Remove caliper Allen bolts (x2), release caliper and tie caliper aside.

11. Remove brake disc Torx screws (x2), remove disc.

12. Release lower suspension arm from vertical link (using tool 204-523).

13. Release vertical link from upper suspension arm (using tool 204-523). Remove vertical link assembly.

14. Remove Allen bolts (x4) se curing hub bearing assembly

to vertical link.

15. Release/remove hub bearing a ssembly from vertical link.

16. Remove Torx screws (x4), di sc shield to vertical link.

Remove shield.

Installation

1. Clean vertical link, hub bearing carrier and disc shield.

2. Position disc shield to vertical link, install and torque tighten Torx screws (x4).

3. Install hub bearing assembly in vertical link, install Allen

bolts (x4) and tighten.

4. Install vertical link assembly to upper suspension arm. Install and torque tighten nut.

5. Install vertical link in lowe r suspension arm. Install and

torque tighten nut.

6. Clean brake disc.

7. Install brake disc. Install an d torque tighten Torx screws

(x2).

Caution

Do not fully tighten the nuts and bolts on the suspension

components. Only tighten th e nuts and bolts of the

suspension components when the suspension arms are

at their usual ride-height and you have adjusted the

geometry. If you do not do this, the suspension bushes

will have too much stress when the suspension is moved

to its maximum upward travel.

Repair Operation Time (ROT)

ItemCode

Front Hub Vertical Link-Renew RH04.01.CB

Front Hub Vertical Link-Renew LH04.01.DB

Caution

Do not fully tighten the nuts and bolts on the suspension

components. Only tighten the nuts and bolts of the

suspension components when the suspension arms are

at their usual ride-height and you have adjusted the

geometry. If you do not do this, the suspension bushes

will have too much stress when the suspension is moved

to its maximum upward travel.