sensor ASTON MARTIN V8 VANTAGE 2010 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 279 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-5

8. Press out alternator mounting bushes (x2) from sump (refer to Figure 7).

9. Remove dowels (x4) from sump for oil pressure and scavenge pumps location (refer to Figure 8). 10. Remove Torx screws (x2) that attach the oil pump(s)

chain guide, remove chain gu ide (refer to Figure 9).

11. Remove oil plug from sump.

Installation

1. Clean chain guide, oil filter adaptor, filters (x2), sump plug , pump(s) dowels and crankshaft timing sensor.

2. Install alternator bushes.

3. Install oil filter adaptor.

4. Install filters (x2), install oil filter plates (x2), install and

torque tighten Torx screws (x4).

5. Install oil plug.

6. Install oil pump(s) dowels (x4).

7. Clean old sealant from sensor threads (x2).

8. Apply sealant to engine electric coolant temperature sensor threads, install and torque tighten sensor.

9. Apply sealant to oil pressure sensor threads, install and torque tighten sensor.

10. Install oil pump(s) chain guid e, Install and torque tighten

Torx screws (x2).

11. Install crankshaft timing sensor, install and torque tighten bolt.

12. Install oil sump (refer to Workshop Manual procedure 03.02.BN Pan - Oil Sump - Remove and Reseal).

Oil Sump Pan - Remove and Reseal

Removal

1. Remove oil pump(s) drive chain (refer to Workshop Manual procedure 03.02.AJ Chain - Oil Pump - Renew).

Figure 7

Figure 8

A030206C

A0302307

Figure 9

Repair Operation Time (ROT)

A0302307A

Page 280 of 947

Lubrication System (03.02)

Engine (03.00)3-2-6 Workshop Manual Issue 5, Janauary 2010

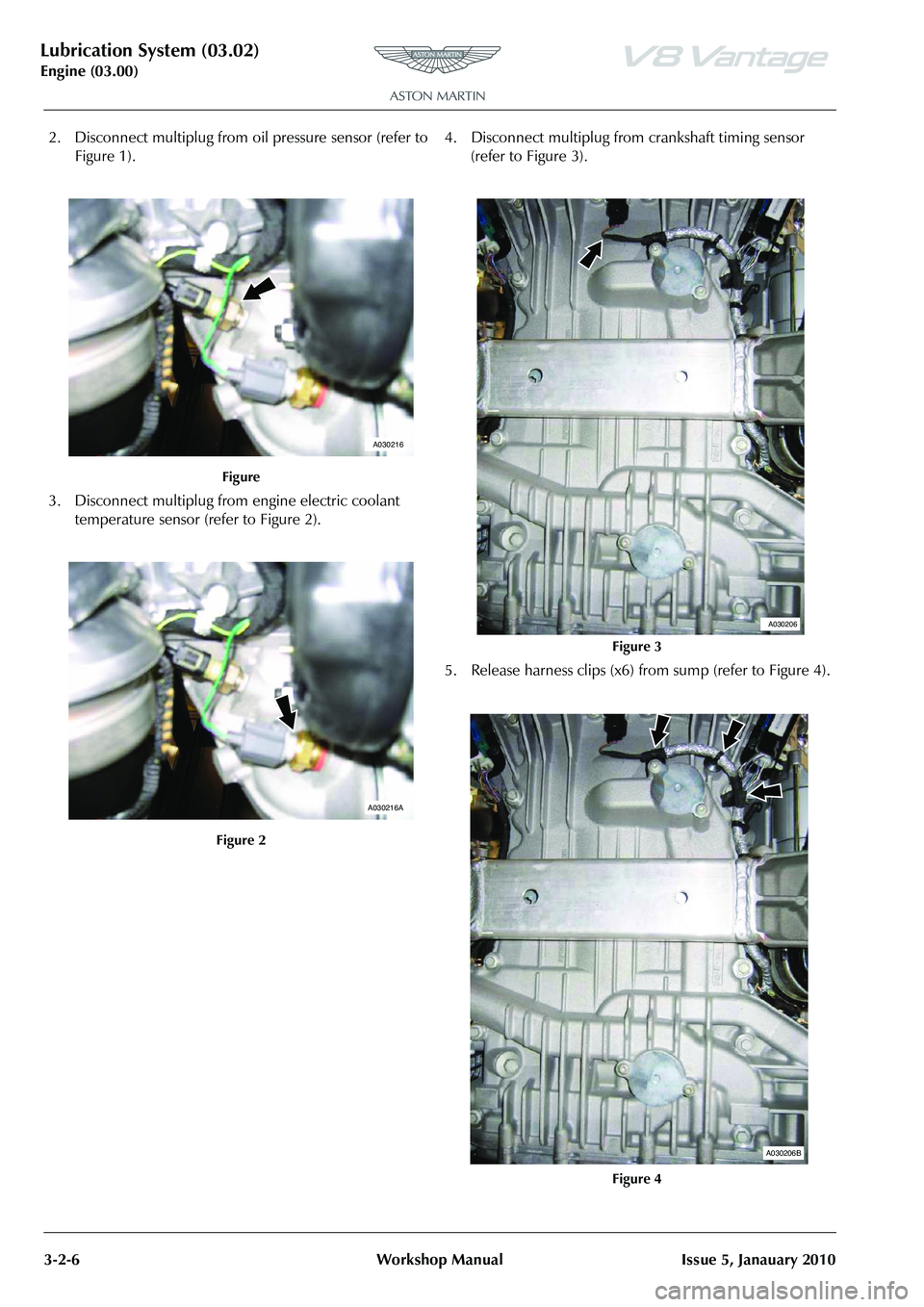

2. Disconnect multiplug from oi l pressure sensor (refer to

Figure 1).

3. Disconnect multiplug from engine electric coolant

temperature sensor (refer to Figure 2). 4. Disconnect multiplug from

crankshaft timing sensor

(refer to Figure 3).

5. Release harness clips (x6) from sump (refer to Figure 4).

Figure

Figure 2

A030216

A030216A

Figure 3

Figure 4

A030206

A030206B

Page 281 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-7

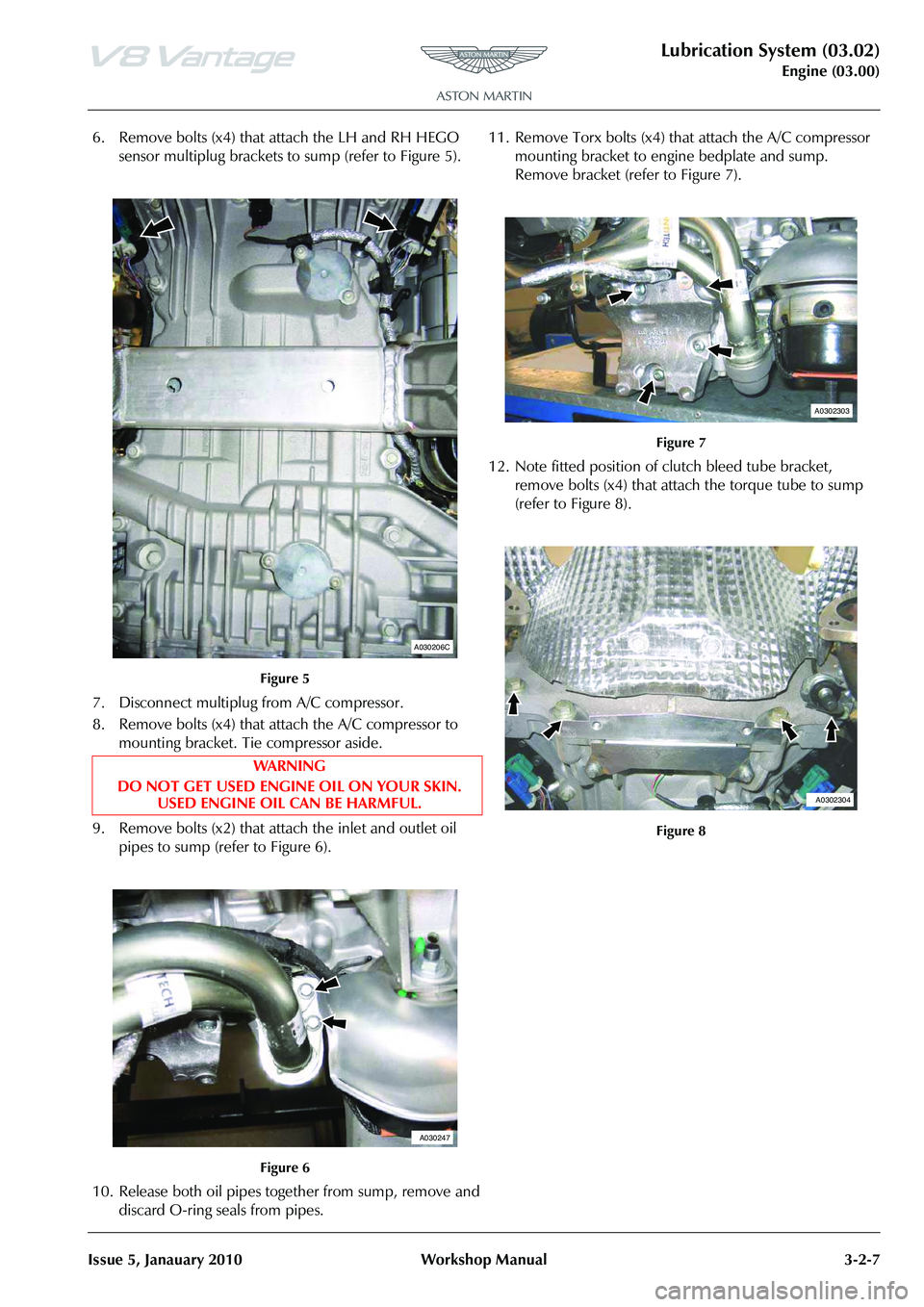

6. Remove bolts (x4) that attach the LH and RH HEGO sensor multiplug brackets to sump (refer to Figure 5).

7. Disconnect multiplug from A/C compressor.

8. Remove bolts (x4) that attach the A/C compressor to mounting bracket. Tie compressor aside.

9. Remove bolts (x2) that attach the inlet and outlet oil pipes to sump (refer to Figure 6).

10. Release both oil pipes toge ther from sump, remove and

discard O-ring seals from pipes. 11. Remove Torx bolts (x4) that attach the A/C compressor

mounting bracket to engine bedplate and sump.

Remove bracket (refer to Figure 7).

12. Note fitted position of clutch bleed tube bracket, remove bolts (x4) that attach the torque tube to sump

(refer to Figure 8).

Figure 5

WA R N I N G

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

Figure 6

A030206C

A030247

Figure 7

Figure 8

A0302303

A0302304

Page 282 of 947

Lubrication System (03.02)

Engine (03.00)3-2-8 Workshop Manual Issue 5, Janauary 2010

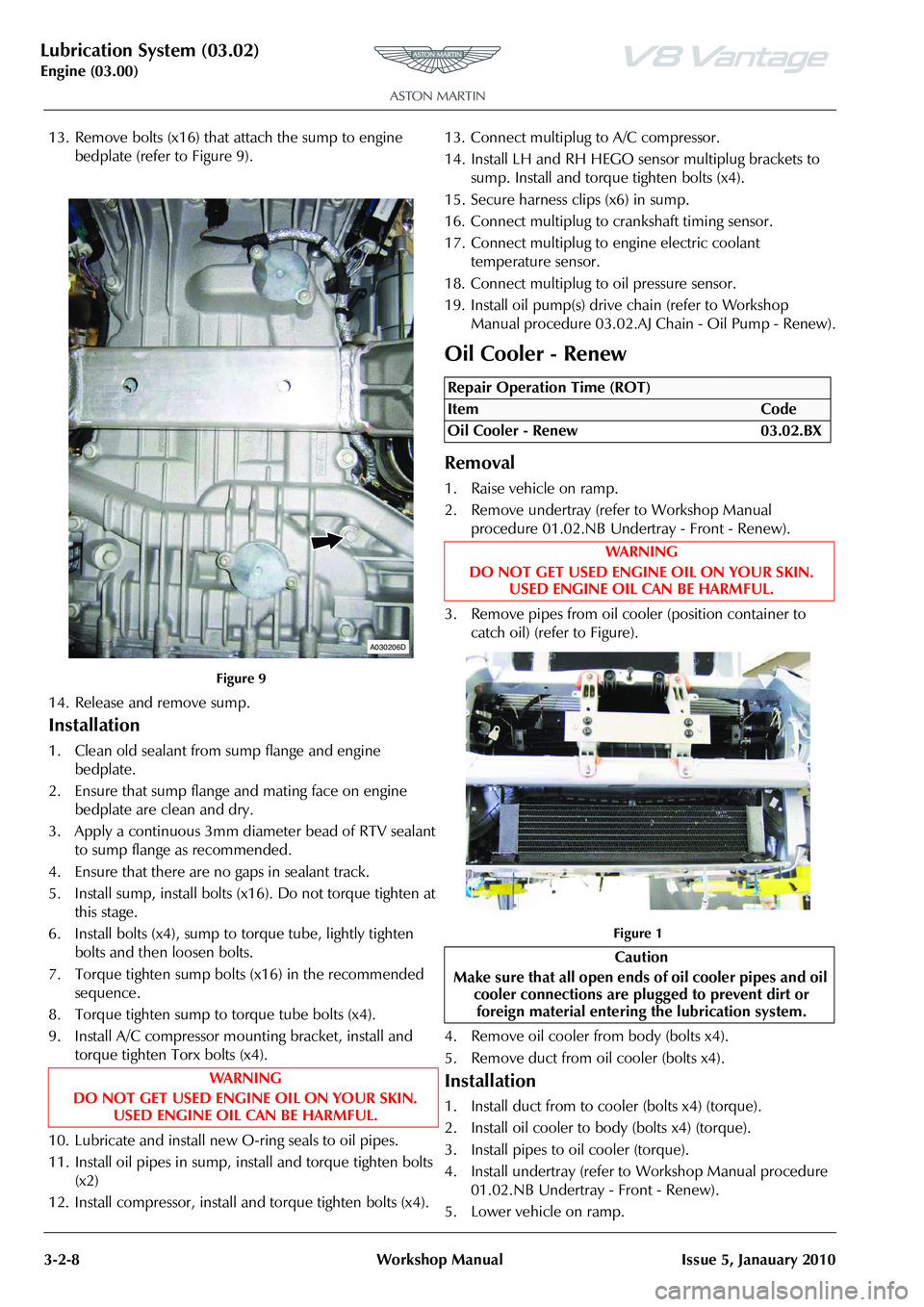

13. Remove bolts (x16) that attach the sump to engine bedplate (refer to Figure 9).

14. Release and remove sump.

Installation

1. Clean old sealant from sump flange and engine bedplate.

2. Ensure that sump flange and mating face on engine bedplate are clean and dry.

3. Apply a continuous 3mm diameter bead of RTV sealant to sump flange as recommended.

4. Ensure that there are no gaps in sealant track.

5. Install sump, install bolts (x16). Do not torque tighten at this stage.

6. Install bolts (x4), sump to torque tube, lightly tighten bolts and then loosen bolts.

7. Torque tighten sump bolts (x16) in the recommended sequence.

8. Torque tighten sump to torque tube bolts (x4).

9. Install A/C compressor mounting bracket, install and torque tighten Torx bolts (x4).

10. Lubricate and install new O-ring seals to oil pipes.

11. Install oil pipes in sump, install and torque tighten bolts (x2)

12. Install compressor, install and torque tighten bolts (x4). 13. Connect multiplug to A/C compressor.

14. Install LH and RH HEGO

sensor multiplug brackets to

sump. Install and torque tighten bolts (x4).

15. Secure harness clips (x6) in sump.

16. Connect multiplug to crankshaft timing sensor.

17. Connect multiplug to engine electric coolant temperature sensor.

18. Connect multiplug to oil pressure sensor.

19. Install oil pump(s) drive chain (refer to Workshop

Manual procedure 03.02.AJ Chain - Oil Pump - Renew).

Oil Cooler - Renew

Removal

1. Raise vehicle on ramp.

2. Remove undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

3. Remove pipes from oil cooler (position container to catch oil) (refer to Figure).

Figure 1

4. Remove oil cooler from body (bolts x4).

5. Remove duct from oil cooler (bolts x4).

Installation

1. Install duct from to cooler (bolts x4) (torque).

2. Install oil cooler to body (bolts x4) (torque).

3. Install pipes to oil cooler (torque).

4. Install undertray (refer to Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

5. Lower vehicle on ramp.

Figure 9

WAR NI NG

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

A030206D

Repair Operation Time (ROT)

ItemCode

Oil Cooler - Renew 03.02.BX

WAR NI NG

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

Caution

Make sure that all open ends of oil cooler pipes and oil cooler connections are plugged to prevent dirt or

foreign material entering the lubrication system.

Page 289 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-15

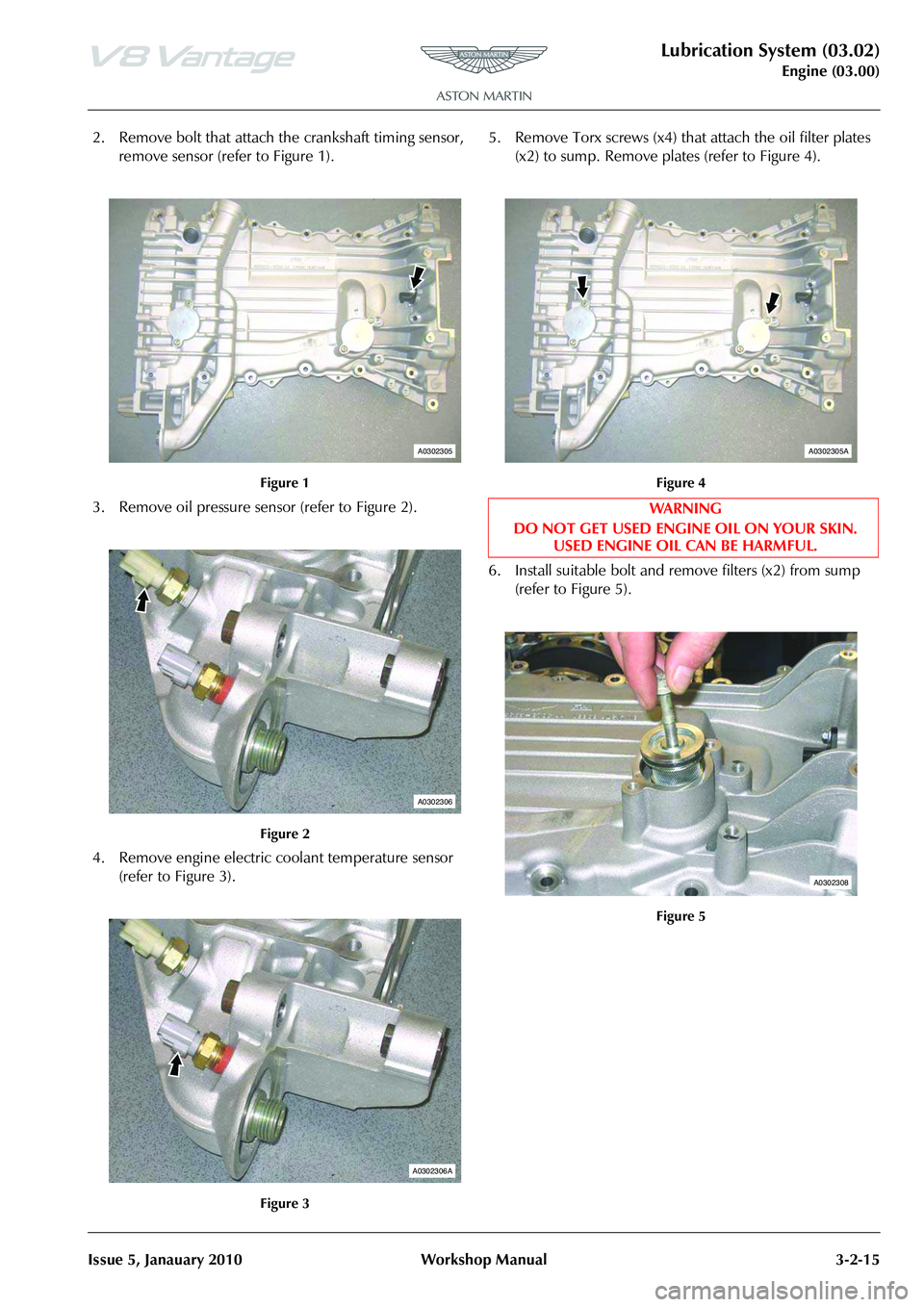

2. Remove bolt that attach the crankshaft timing sensor, remove sensor (refer to Figure 1).

3. Remove oil pressure sens or (refer to Figure 2).

4. Remove engine electric coolant temperature sensor (refer to Figure 3). 5. Remove Torx screws (x4) that

attach the oil filter plates

(x2) to sump. Remove plates (refer to Figure 4).

6. Install suitable bolt and re move filters (x2) from sump

(refer to Figure 5).

Figure 1

Figure 2

Figure 3

A0302305

A0302306

A0302306A

Figure 4

WA R N I N G

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

Figure 5

A0302305A

A0302308

Page 290 of 947

Lubrication System (03.02)

Engine (03.00)3-2-16 Workshop Manual Issue 5, Janauary 2010

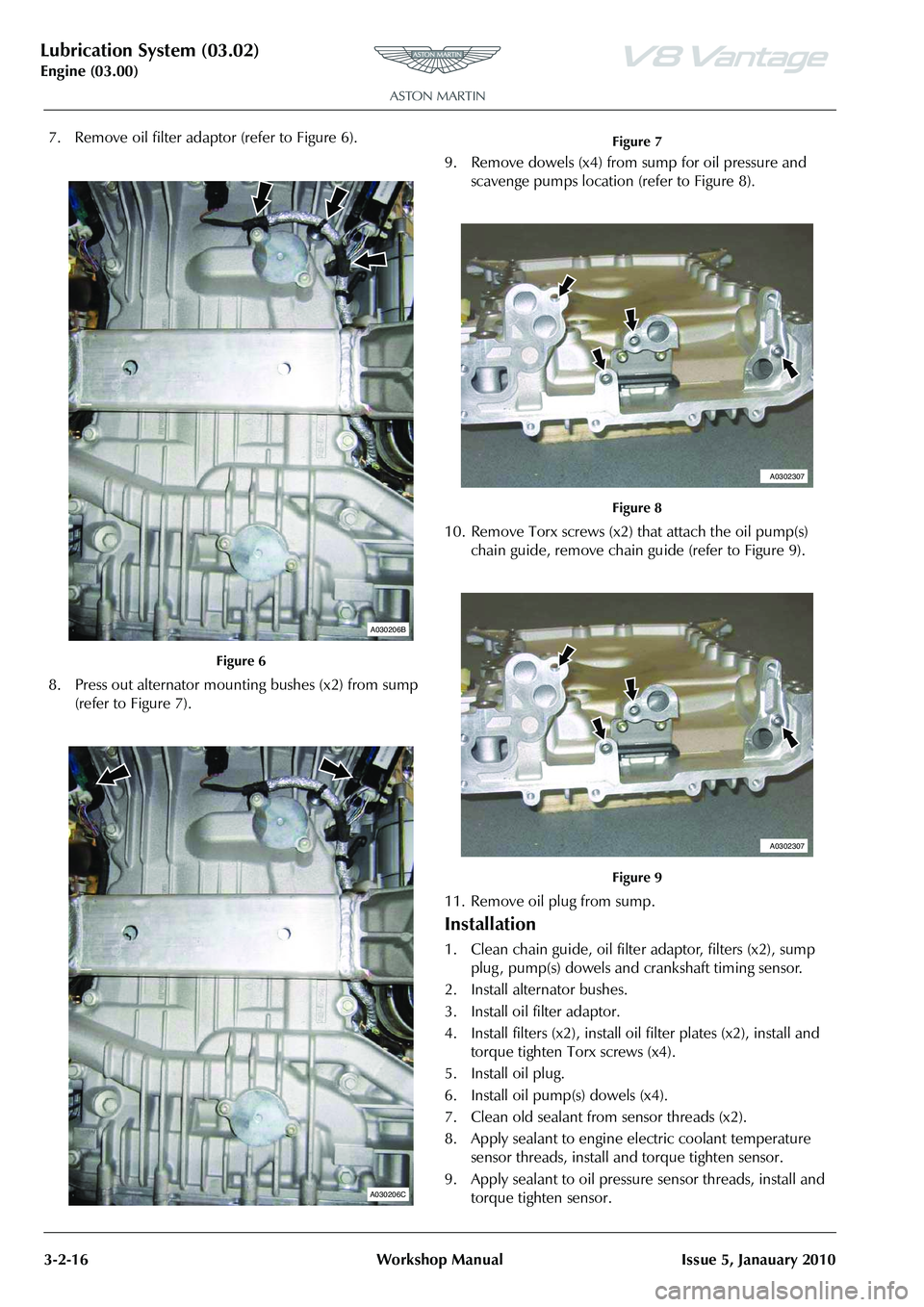

7. Remove oil filter adaptor (refer to Figure 6).

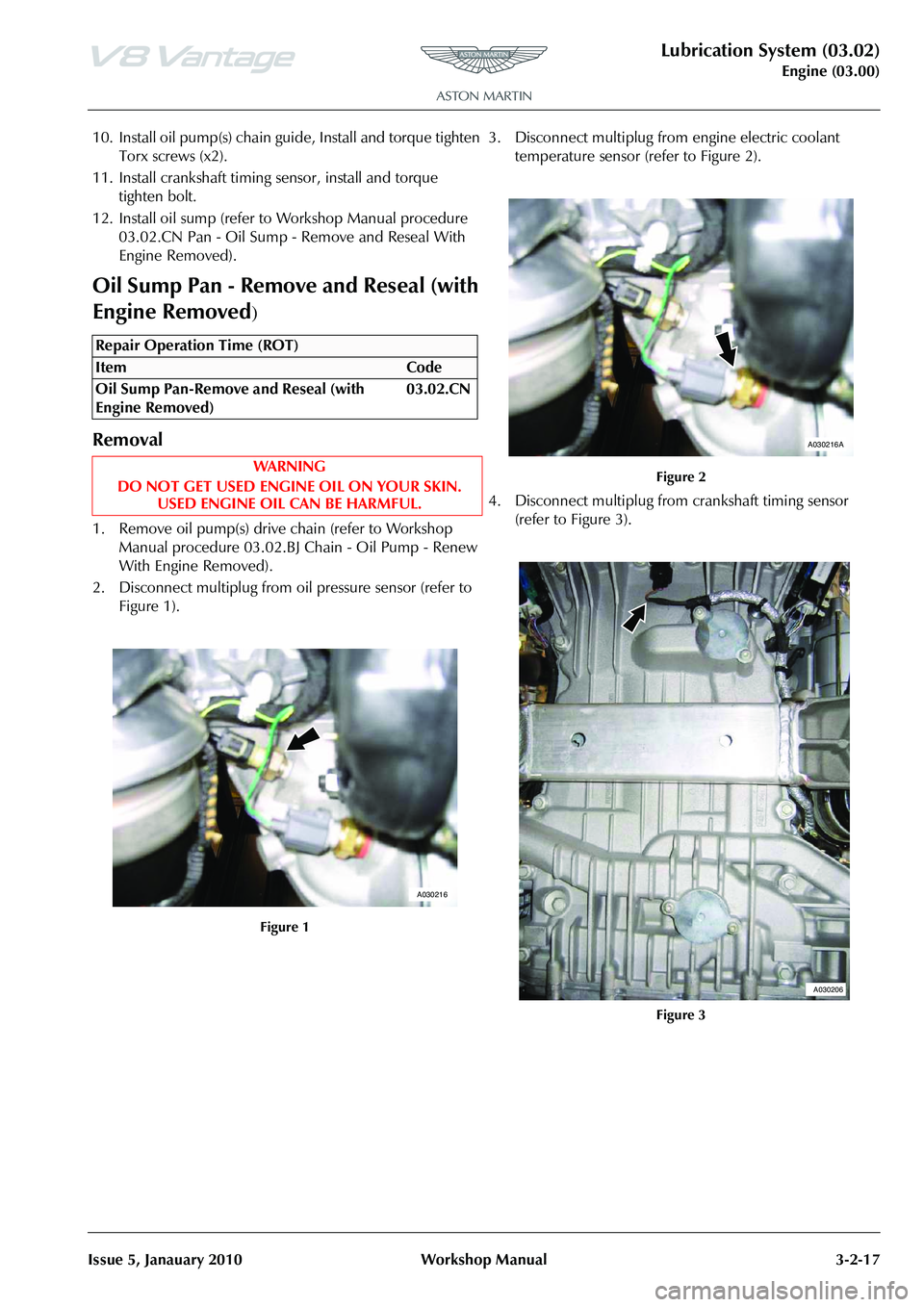

8. Press out alternator mounting bushes (x2) from sump (refer to Figure 7). 9. Remove dowels (x4) from

sump for oil pressure and

scavenge pumps location (refer to Figure 8).

10. Remove Torx screws (x2) that attach the oil pump(s)

chain guide, remove chain gu ide (refer to Figure 9).

11. Remove oil plug from sump.

Installation

1. Clean chain guide, oil filter adaptor, filters (x2), sump plug , pump(s) dowels and crankshaft timing sensor.

2. Install alternator bushes.

3. Install oil filter adaptor.

4. Install filters (x2), install oil filter plates (x2), install and

torque tighten Torx screws (x4).

5. Install oil plug.

6. Install oil pump(s) dowels (x4).

7. Clean old sealant from sensor threads (x2).

8. Apply sealant to engine electric coolant temperature sensor threads, install and torque tighten sensor.

9. Apply sealant to oil pressure sensor threads, install and torque tighten sensor.

Figure 6

A030206B

A030206C

Figure 7

Figure 8

Figure 9

A0302307

A0302307

Page 291 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-17

10. Install oil pump(s) chain guid e, Install and torque tighten

Torx screws (x2).

11. Install crankshaft timing sensor, install and torque

tighten bolt.

12. Install oil sump (refer to Workshop Manual procedure

03.02.CN Pan - Oil Sump - Remove and Reseal With

Engine Removed).

Oil Sump Pan - Remove and Reseal (with

Engine Removed

)

Removal

1. Remove oil pump(s) drive chain (refer to Workshop Manual procedure 03.02.BJ Chain - Oil Pump - Renew

With Engine Removed).

2. Disconnect multiplug from oi l pressure sensor (refer to

Figure 1). 3. Disconnect multiplug from

engine electric coolant

temperature sensor (refer to Figure 2).

4. Disconnect multiplug from crankshaft timing sensor

(refer to Figure 3).

Repair Operation Time (ROT)

A030216

Figure 2

Figure 3

A030216A

A030206

Page 292 of 947

Lubrication System (03.02)

Engine (03.00)3-2-18 Workshop Manual Issue 5, Janauary 2010

5. Release harness clips (x6) from sump (refer to Figure 4). 6. Remove bolts (x4) that attach the LH and RH HEGO

sensor multiplug brackets to sump (refer to Figure 5).

7. Disconnect multiplug from A/C compressor.

8. Remove bolts (x4) that attach the A/C compressor to mounting bracket. Tie compressor aside.

9. Remove bolts (x2) that attach the inlet and outlet oil pipes to sump (refer to Figure 6).

10. Release both oil pipes together from sump, remove and discard O-ring seals from pipes.

Figure 4

A030206B

Figure 5

WAR NI NG

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

Figure 6

A030206C

A030247

Page 293 of 947

Lubrication System (03.02)

Engine (03.00)

Issue 5, Janauary 2010 Workshop Manual 3-2-19

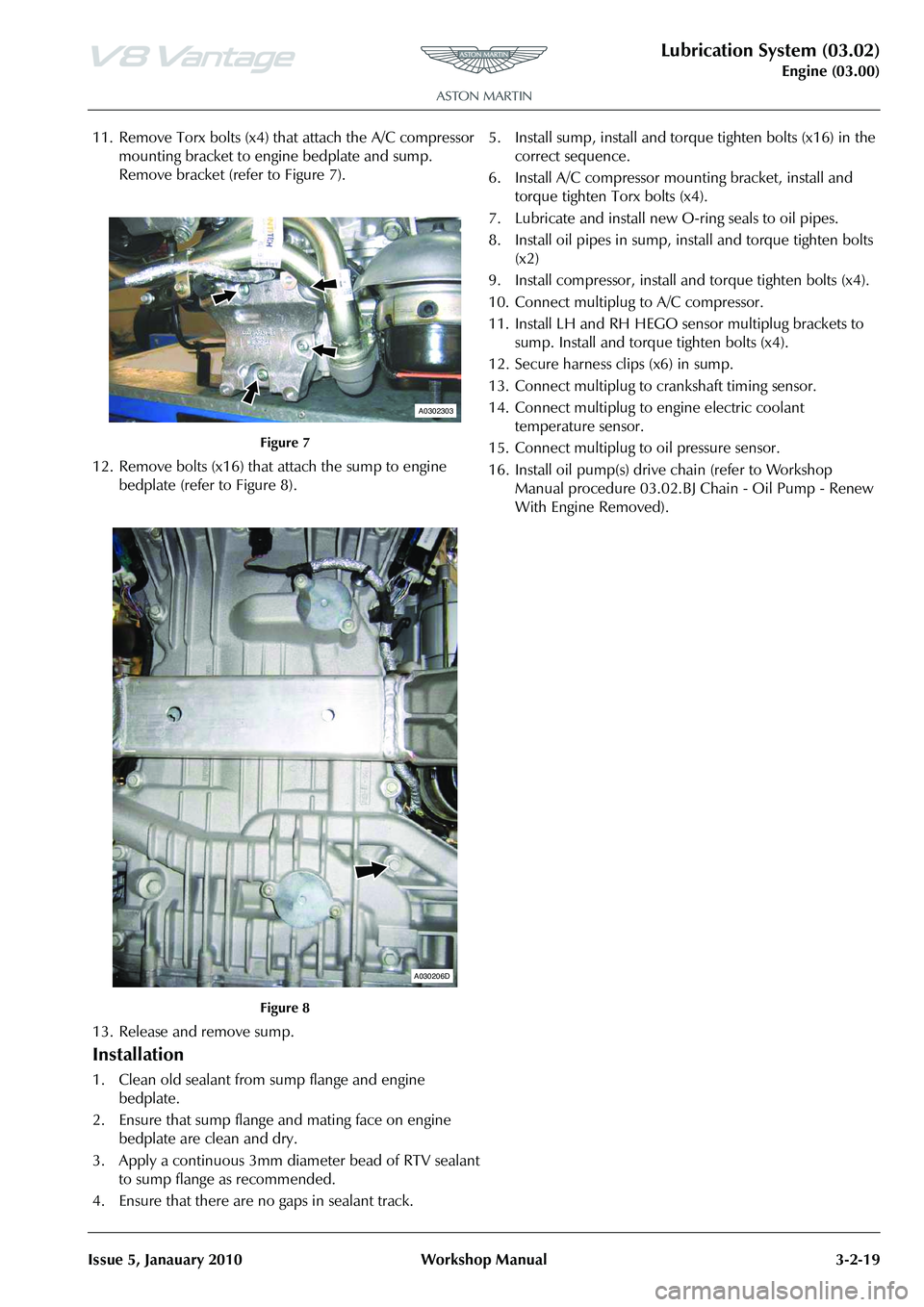

11. Remove Torx bolts (x4) that attach the A/C compressor mounting bracket to engine bedplate and sump.

Remove bracket (refer to Figure 7).

12. Remove bolts (x16) that attach the sump to engine bedplate (refer to Figure 8).

13. Release and remove sump.

Installation

1. Clean old sealant from sump flange and engine bedplate.

2. Ensure that sump flange and mating face on engine bedplate are clean and dry.

3. Apply a continuous 3mm diameter bead of RTV sealant to sump flange as recommended.

4. Ensure that there are no gaps in sealant track. 5. Install sump, install and torque tighten bolts (x16) in the

correct sequence.

6. Install A/C compressor mounting bracket, install and torque tighten Torx bolts (x4).

7. Lubricate and install new O-ring seals to oil pipes.

8. Install oil pipes in sump, install and torque tighten bolts (x2)

9. Install compressor, install and torque tighten bolts (x4).

10. Connect multiplug to A/C compressor.

11. Install LH and RH HEGO se nsor multiplug brackets to

sump. Install and torque tighten bolts (x4).

12. Secure harness clips (x6) in sump.

13. Connect multiplug to crankshaft timing sensor.

14. Connect multiplug to engine electric coolant temperature sensor.

15. Connect multiplug to oil pressure sensor.

16. Install oil pump(s) drive chain (refer to Workshop Manual procedure 03.02.BJ Chain - Oil Pump - Renew

With Engine Removed).

Figure 7

Figure 8

A0302303

A030206D

Page 304 of 947

Cooling System (03.03)

Engine (03.00)3-3-10 Workshop Manual Issue 5, Janauary 2010

12. Remove coolant manifold (bolts x4) (refer to Figure 9).

Figure 9

13. Remove old seals.

14. Remove bracket breather (bolt x1, nut x2).

Installation

1. Install bracket breather (bolt x1, nuts x2) (torque).

2. Clean gasket faces.

3. Install new seals.

4. Install coolant manifold (bolts x4) (torque).

5. Install 4th bolt of vacuum tank bracket fixing (torque).

6. Install harness clips (x2).

7. Connect coolant temp multiplug.

8. Connect separator hose (clip x1).

9. Connect breather hose (quickfit).

10. Connect heater return hose (clip x1).

11. Connect heater feed hose (clip x1).

12. Connect expansion tank feed hose (quickfit).

13. Disconnect top hose (clip x1).

14. Connect bottom hose (clip x1).

15. Install reservoir bracket asse mbly - vacuum system (refer

to Workshop Manual procedu re 03.08.AE Reservoir and

Bracket Assembly - Vacuum System - Renew).

Engine Electric Co olant Temperature

Sensor - Renew

Removal

1. Drain Cooling system (refer to Workshop Manual procedure 03.03.AD Coolant - Drain and Refill).

2. Disconnect breather pipe qu ickfits (x2) from air cleaner

duct.

3. Remove throttle body duct for access. (clips x3). 4. Remove pump pulley bolts (x3) (refer to Figure 1).

Figure 1

5. Release tensioner and slip belt from idler (refer to Figure

2).

Figure 2

6. Remove pump pulley.

7. Disconnect throttle body coolant hose (refer to Figure 3).

Figure 3

Repair Operation Time (ROT)

A030368A030350

A030553

A030364