wheel torque ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 753 of 947

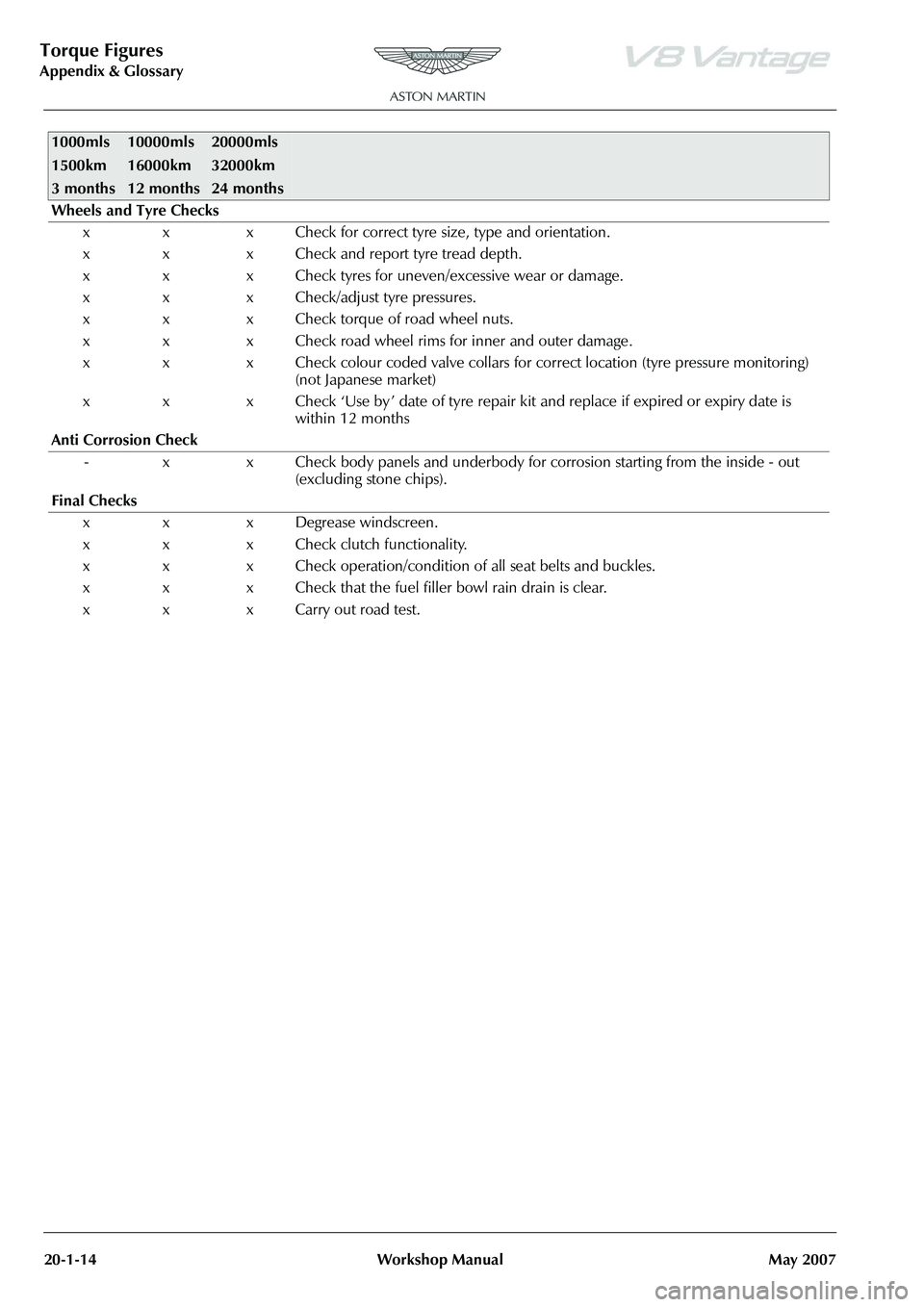

Torque Figures

Appendix & Glossary20-1-14 Workshop Manual May 2007

Wheels and Tyre Checks

x x x Check for correct tyre size, type and orientation.

x x x Check and report tyre tread depth.

x x x Check tyres for uneven/excessive wear or damage.

x x x Check/adjust tyre pressures.

x x x Check torque of road wheel nuts.

x x x Check road wheel rims for inner and outer damage.

x x x Check colour coded valve collars for co rrect location (tyre pressure monitoring)

(not Japanese market)

x x x Check ‘Use by ’ date of tyre repair kit and replace if expired or expiry date is

within 12 months

Anti Corrosion Check - x x Check body panels and underbody for corrosion starting from the inside - out

(excluding stone chips).

Final Checks x x x Degrease windscreen.

x x x Check clutch functionality.

x x x Check operation/condition of all seat belts and buckles.

x x x Check that the fuel filler bowl rain drain is clear.

x x x Carry out road test.

1000mls

1500km

3 months10000mls

16000km

12 months20000mls

32000km

24 months

Page 792 of 947

Squeaks and Rattles Repair Manual

Page 8 of 21 Issue 3

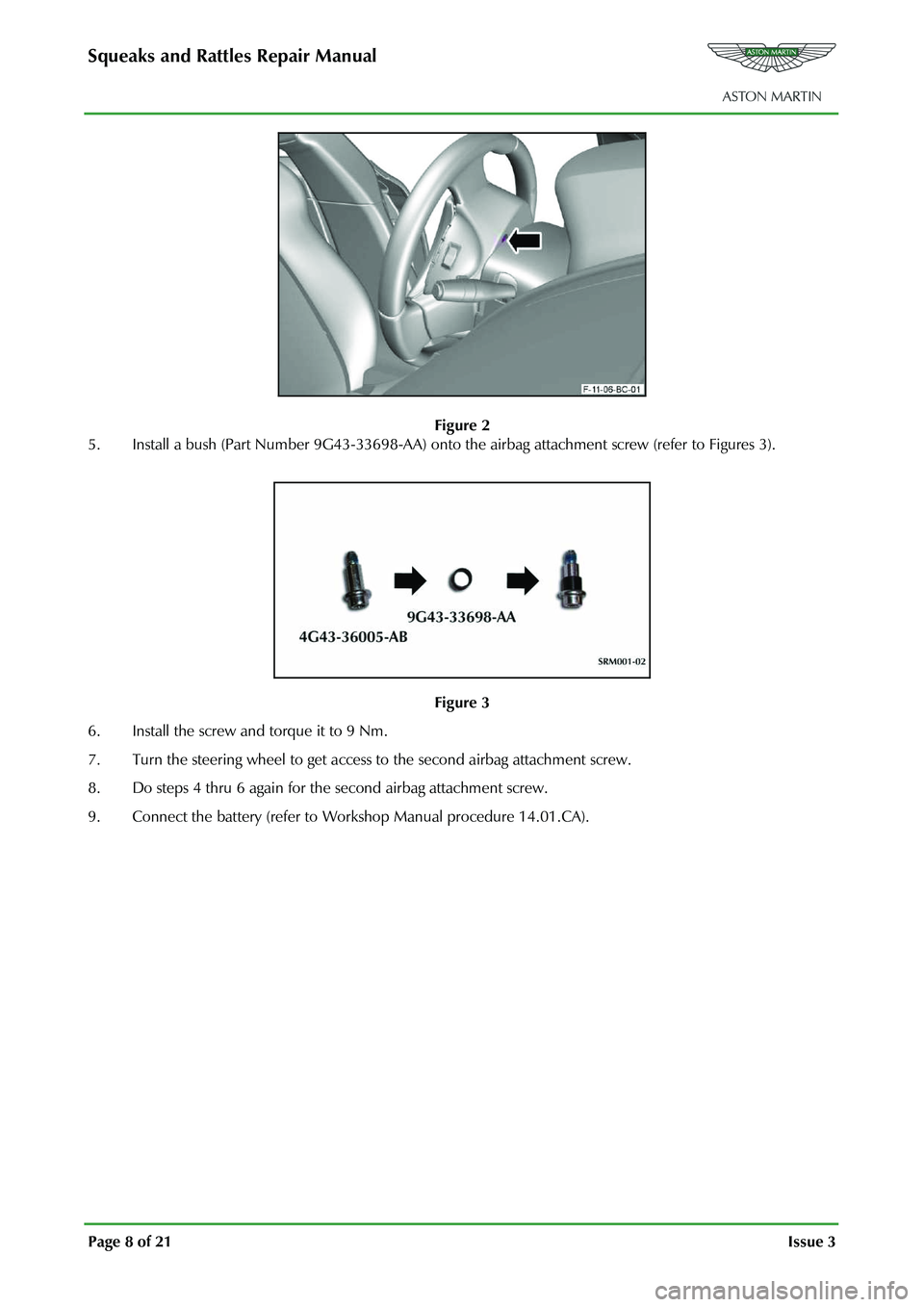

Figure 2

5. Install a bush (Part Number 9G43-33698-AA) onto th e airbag attachment screw (refer to Figures 3).

Figure 3

6. Install the screw and torque it to 9 Nm.

7. Turn the steering wheel to get access to the second airbag attachment screw.

8. Do steps 4 thru 6 again for the second airbag attachment screw.

9. Connect the battery (refer to Work shop Manual procedure 14.01.CA).

Page 883 of 947

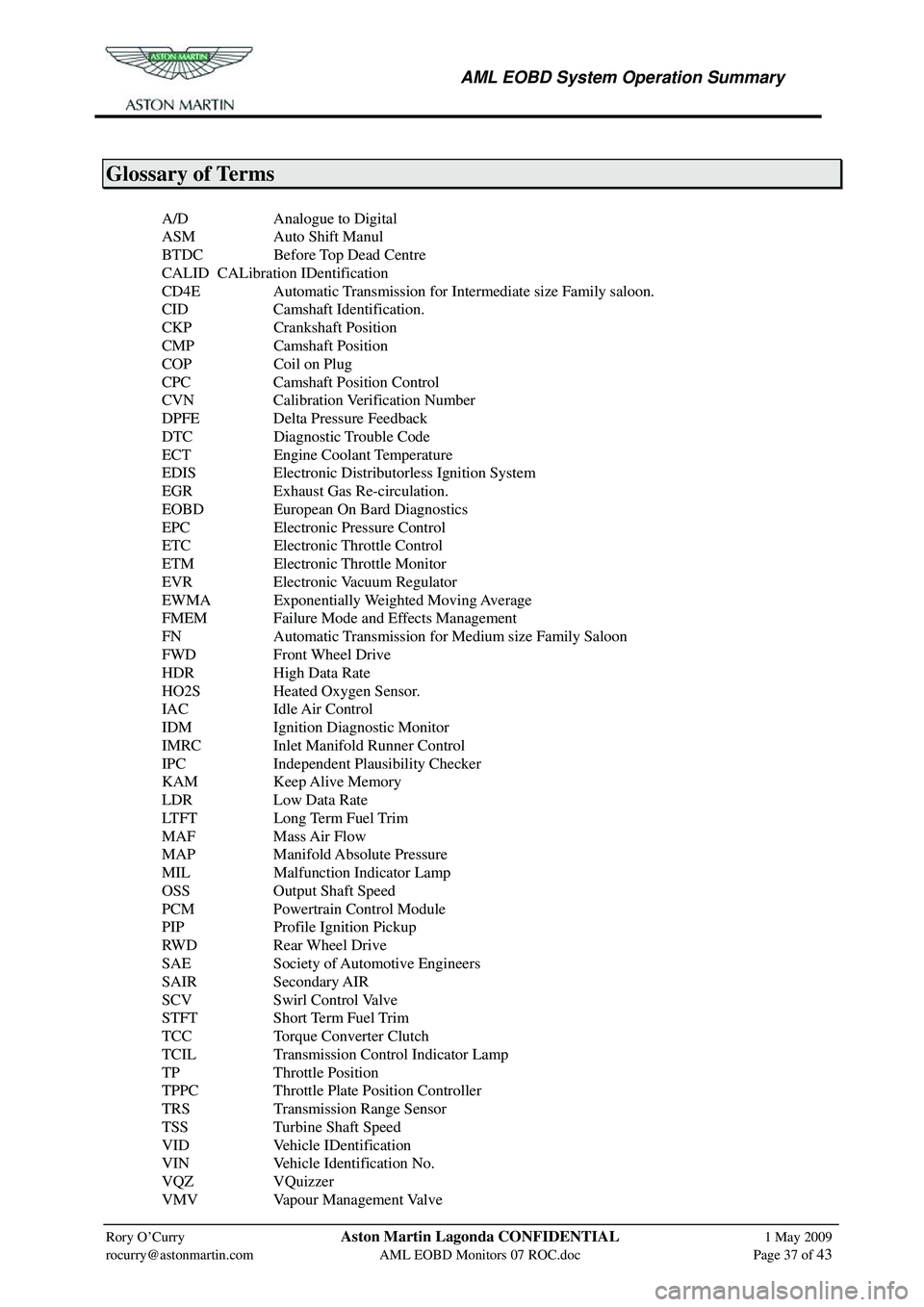

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 37 of 43

Glossary of Terms

A/D Analogue to Digital

ASM Auto Shift Manul

BTDC Before Top Dead Centre

CALID CALibration IDentification

CD4E Automatic Transmission for Intermediate size Family saloon.

CID Camshaft Identification.

CKP Crankshaft Position

CMP Camshaft Position

COP Coil on Plug

CPC Camshaft Position Control

CVN Calibration Verification Number

DPFE Delta Pressure Feedback

DTC Diagnostic Trouble Code

ECT Engine Coolant Temperature

EDIS Electronic Distributorless Ignition System

EGR Exhaust Gas Re-circulation.

EOBD European On Bard Diagnostics

EPC Electronic Pressure Control

ETC Electronic Throttle Control

ETM Electronic Throttle Monitor

EVR Electronic Vacuum Regulator

EWMA Exponentially Weighted Moving Average

FMEM Failure Mode and Effects Management

FN Automatic Transmission for Medium size Family Saloon

FWD Front Wheel Drive

HDR High Data Rate

HO2S Heated Oxygen Sensor.

IAC Idle Air Control

IDM Ignition Diagnostic Monitor

IMRC Inlet Manifold Runner Control

IPC Independent Plausibility Checker

KAM Keep Alive Memory

LDR Low Data Rate

LTFT Long Term Fuel Trim

MAF Mass Air Flow

MAP Manifold Absolute Pressure

MIL Malfunction Indicator Lamp

OSS Output Shaft Speed

PCM Powertrain Control Module

PIP Profile Ignition Pickup

RWD Rear Wheel Drive

SAE Society of Automotive Engineers

SAIR Secondary AIR

SCV Swirl Control Valve

STFT Short Term Fuel Trim

TCC Torque Converter Clutch

TCIL Transmission Control Indicator Lamp

TP Throttle Position

TPPC Throttle Plate Position Controller

TRS Transmission Range Sensor

TSS Turbine Shaft Speed

VID Vehicle IDentification

VIN Vehicle Identification No.

VQZ VQuizzer

VMV Vapour Management Valve

Page 933 of 947

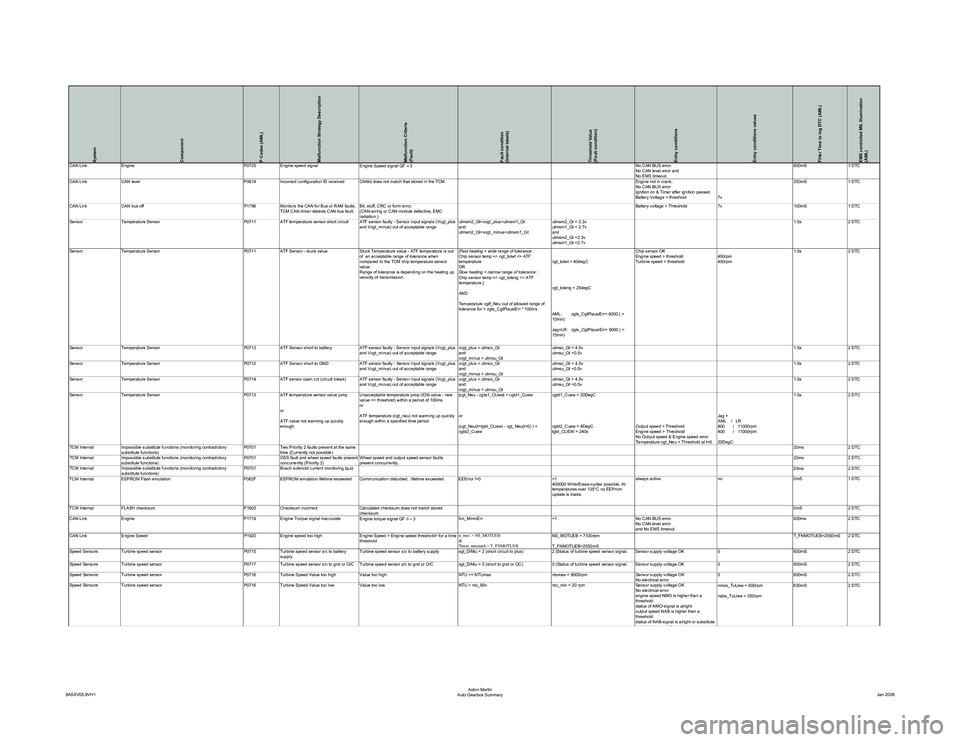

System

Component

P Codes (AML)

Malfunction Strategy Description

Malfunction Criteria

(Fault)

Fault condition

(Internal labels)

Threshold Value

(Fault condition)

Entry conditions

Entry conditions values

Filter Time to log DTC (AML)

EMS controlled MIL Illumination

(AML)

CAN LinkEngine P0725Engine speed signal

Engine Speed signal QF ≠ 3 No CAN BUS error.

No CAN level error and

No EMS timeout.600mS

1 DTC

CAN Link CAN level P0614Incorrect configuration ID received CANid does not match that stored in the TCM Engine not in crank.

No CAN BUS error

Ignition on & Timer after ignition passed.

Battery Voltage > threshold7v250mS

1 DTC

CAN Link CAN bus off P1796Monitors the CAN for Bus or RAM faults.

TCM CAN driver detects CAN bus fault. Bit, stuff, CRC or form error,

(CAN-wiring or CAN-module defective, EMC

radiation.) Battery voltage > Threshold

7v100mS1 DTC

Sensor Temperature Sensor P0711 ATF temperature sensor short circuit ATF sensor faulty - Sensor input signals (Vcgt_plus

and Vcgt_minus) out of acceptable range utmsm2_Gt

utmsm2_Gt

and

utmsm2_Gt =2.3v

utmsm1_Gt =2.7v 1.5s

2 DTC

Sensor Temperature Sensor P0711ATF Sensor - stuck value Stuck Temperature value - ATF temperature is out

of an acceptable range of tolerance when

compared to the TCM chip temperature sensor

value.

Range of tolerance is depending on the heating up

velocity of transmission . [

Fast heating = wide range of tolerance :

Chip sensor temp +/- cgt_tolwt <> ATF

temperature

OR

Slow heating = narrow range of tolerance :

Chip sensor temp +/- cgt_toleng <> ATF

temperature.]

AND

Temperature cgtf_Neu out of allowed range of

tolerance for > zgts_CgtPlausiErr * 100ms cgt_tolwt = 40degC

cgt_toleng = 25degC

AML: zgts_CgtPlausiErr= 6000 ( =

10min)

Jag+LR: zgts_CgtPlausiErr= 9000 ( =

15min)Chip sensor OK

Engine speed > threshold

Turbine speed > threshold

450rpm

450rpm1.5s

2 DTC

Sensor Temperature Sensor P0713ATF Sensor short to battery ATF sensor faulty - Sensor input signals (Vcgt_plus

and Vcgt_minus) out of acceptable range vcgt_plus > utmso_Gt

and

vcgt_minus > utmsu_Gtutmso_Gt = 4.5v

utmsu_Gt =0.5v

1.5s

2 DTC

Sensor Temperature Sensor P0712ATF Sensor short to GND ATF sensor faulty - Sensor input signals (Vcgt_plus

and Vcgt_minus) out of acceptable range vcgt_plus < utmso_Gt

and

vcgt_minus < utmsu_Gtutmso_Gt = 4.5v

utmsu_Gt =0.5v

1.5s

2 DTC

Sensor Temperature Sensor P0714ATF sensor open cct (circuit break) ATF sensor faulty - Sensor input signals (Vcgt_plus

and Vcgt_minus) out of acceptable range vcgt_plus > utmso_Gt

and

vcgt_minus < utmsu_Gtutmso_Gt = 4.5v

utmsu_Gt =0.5v

1.5s

2 DTC

Sensor Temperature Sensor P0713 ATF temperature sensor value jump

or

ATF value not warming up quickly

enough Unacceptable temperature jump (lOld value - new

value <> threshold) within a period of 100ms

or

ATF temperature (cgt_neu) not warming up quickly

enough within a specified time period

|cgt_Neu - cgta1_CUew| > cgtd1_Cuew

or

(cgt_Neu(t=tgtd_CUew) - cgt_Neu(t=0) ) <

cgtd2_Cuewcgtd1_Cuew = 20DegC

cgtd2_Cuew = 4DegC

tgtd_CUEW = 240s

Output speed > Threshold

Engine speed > Threshold

No Output speed & Engine speed error

Temperature cgt_Neu < Threshold at t=0Jag +

AML / LR

800 / 11000rpm

400 / 11000rpm

20DegC1.5s

2 DTC

TCM Internal Impossible substitute functions (monitoring contradictory

substitute functions) P0701

Two Priority 2 faults present at the same

time (Currently not possible) 20ms

2 DTC

TCM Internal Impossible substitute functions (monitoring contradictory

substitute functions) P0701

OSS fault and wheel speed faults present

concurrently (Priority 3) Wheel speed and output speed sensor faults

present concurrently. 20ms

2 DTC

TCM Internal Impossible substitute functions (monitoring contradictory

substitute functions) P0701

Bosch solenoid current monitorin

g fault 20ms 2 DTC

TCM Internal EEPROM Flash emulation P062FEEPROM emulation lifetime exceeded Communication disturbed, lifetime exceeded EEError !=0 =1

400000 Write/Erase-cycles possible. At

temperatures over 135°C no EEProm

update is made.always active

no0mS1 DTC

TCM Internal FLASH checksum P1603Checksum incorrect Calculated checksum does not match stored

checksum 0mS

2 DTC

CAN Link Engine P1719Engine Torque signal inaccurate

Engine torque signal QF 0 = 3 fcn_MmmErr

=1No CAN BUS error.

No CAN level error

and No EMS timeout. 600ms

2 DTC

CAN Link Engine Speed P1920Engine speed too high Engine Speed > Engine speed threshold> for a time

threshold n_mot > NS_MOTUEB

&

Timer_nmotueb > T_FNMOTUEBNS_MOTUEB = 7100rpm

T_FNMOTUEB=2550mS T_FNMOTUEB=2550mS 2 DTC

Speed Sensors Turbine speed sensor P0715Turbine speed sensor s/c to battery

supply Turbine speed sensor s/c to battery supply sgt_DiNtu = 2 (short circuit to plus)

2 (Status of turbine speed sensor signal. Sensor supply voltage OK0600mS2 DTC

Speed Sensors Turbine speed sensor P0717Turbine speed sensor s/c to gnd or O/C Turbine speed sensor s/c to gnd or O/C sgt_DiNtu = 0 (short to gnd or OC)0 (Status of turbine speed sensor signal. Sensor supply voltage OK 0600mS2 DTC

Speed Sensors Turbine speed sensor P0716Turbine Speed Value too high Value too high NTU >= NTUmaxntumax = 8000rpmSensor supply voltage OK

No electrical error 0

600mS2 DTC

Speed Sensors Turbine speed sensor P0716Turbine Speed Value too low Value too low NTU < ntu_Minntu_min = 20 rpmSensor supply voltage OK

No electrical error

engine speed NMO is higher than a

threshold:

status of NMO-signal is alright

output speed NAB is higher than a

threshold:

status of NAB-signal is alright or substitute

fltfl fb Ei t t

nmos_TuUew = 600rpm

nabs_TuUew = 250rpm 600mS

2 DTC

8ASXV05.9VH1 Aston Martin

Auto Gearbox Summary Jan 2008