O2 sensor ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 445 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-5

7. Remove nuts (x3 each side) from damper top mounting and remove engine cross brace support.

8. Remove nuts and bolts each side from damper lower mountings.

9. Remove spring and damper assembly.

10. Position spring compresso r to spring and compress

spring.

11. Hold damper shaft, and remove top mounting retaining nut.

12. Remove top mounting and spring assembly.

13. Remove dust shield from rebound bumper and spring seat flange.

Installation

1. Clean spring , spring seat flange, bumper, dust shield and top mounting .

2. Install spring seat flange, rebound bumper and dust shield onto damper.

3. Install spring and top mounting and install and tighten retaining nut.

4. Remove spring compressor.

5. Install spring and damper assembly and install engine cross brace support.

6. Install top mounting nuts (x3) each side (do not torque tighten).

7. Align damper to lower mounting and install bolts and nuts each side (do not torque tighten).

8. Position upper suspension arm and install bolts and nuts (x2) each side (do not torque tighten).

9. Connect ABS sensor multiplug and install harness clips in upper suspension arm and vertical link.

10. Install road wheel(s).

11. Lower vehicle on ramp.

12. Tighten upper arm nuts an d bolts to correct torque.

13. Torque tighten top mounting nuts (x3) and lower mounting nut and bolt.

14. Align engine cross brace, install Torx bolts (x2) and

tighten Torx bolts (x4) to correct torque.

Rear Spring and Damper Assembly-Pair-

Renew

Removal

1. Open fuel filler lid and remove fuel filler cap.

2. Raise vehicle on ramp.

3. Remove road wheel(s).

4. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew).

5. Remove RH wheel arch liner (see Workshop Manual procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

6. Remove bolt securing fuel filler pipe bracket to shock

absorber mounting bracket.

7. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside (see Fig. 1).

8. Disconnect ABS sensor multiplug (see Fig. 2).

If removed, place the engine

bay cross brace, complete with

mounts, in position.

Caution

Ensure that the brake flex hose is not over stretched.

Caution

Final tightening of suspension components must be

carried out with the suspensi on arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum upward travel.

Repair Operation Time (ROT)

Page 446 of 947

Shock Absorber System (04.03)

Suspension (04.00)4-3-6 Workshop Manual May 2007

9. Release sensor harness clips (x2) from toe control arm (see Fig. 3).

10. Remove bolts (x2) each side from handbrake calliper to rear hub and release calliper an d position aside (see Fig.

4)

.

11. Remove nuts and bolts both sides from toe control arms (see Fig. 5). 12. Remove nuts and bolts each side from lower damper

mountings (see Fig. 6).

13. Remove bolts (x4) each side from damper upper mounting (see Fig. 7).

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Page 447 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-7

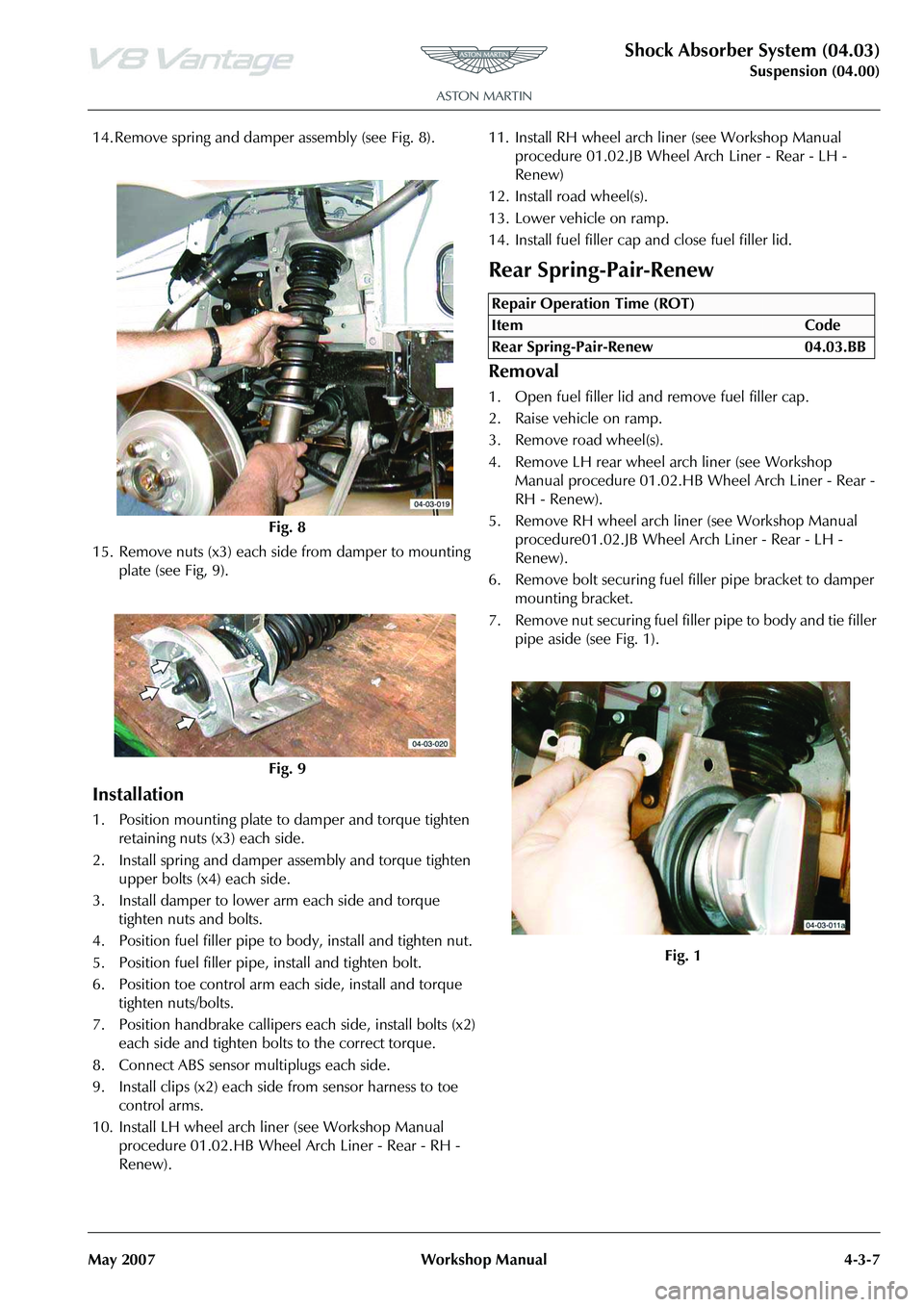

14. Remove spring and damper assembly (see Fig. 8).

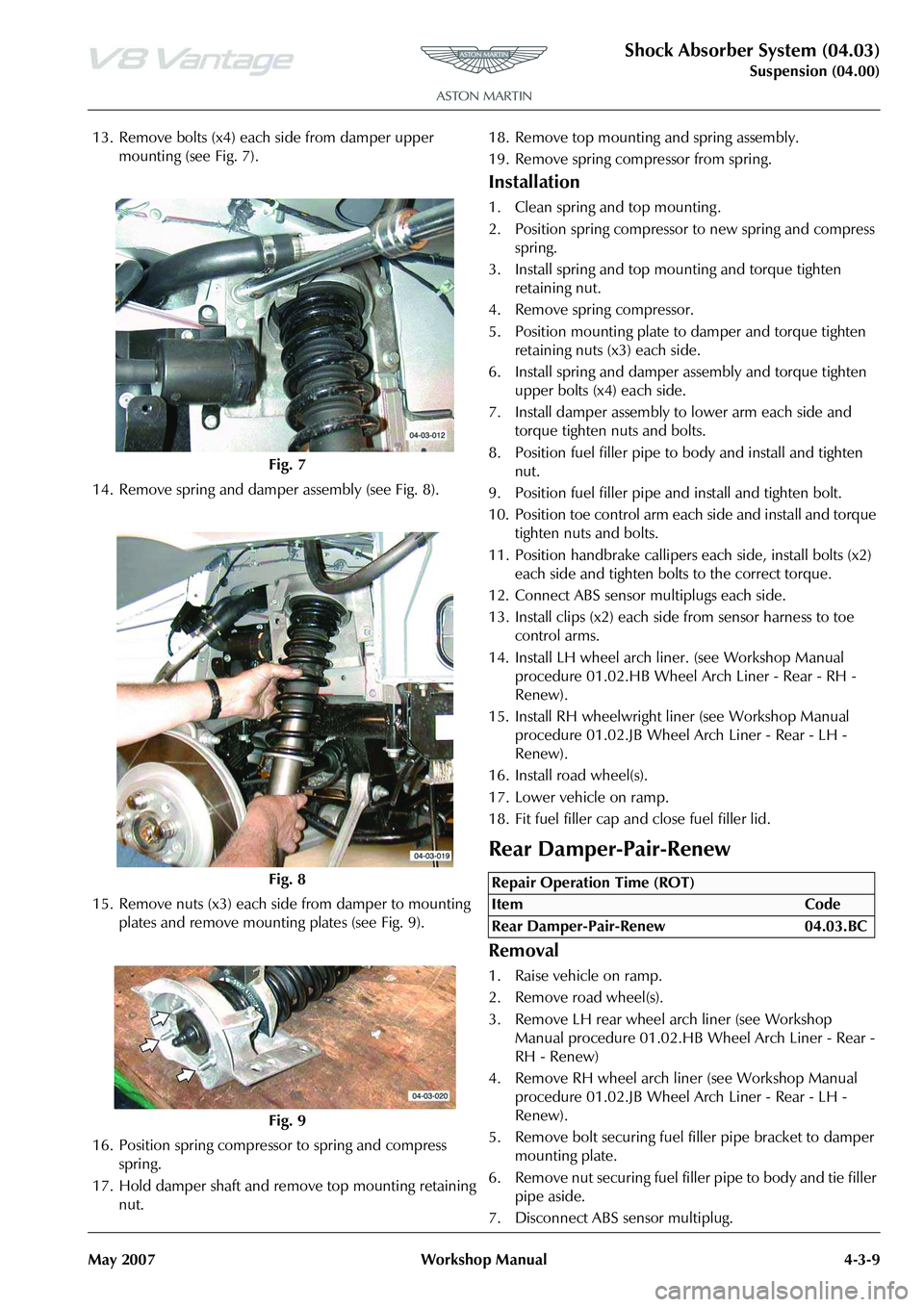

15. Remove nuts (x3) each side from damper to mounting plate (see Fig, 9).

Installation

1. Position mounting plate to damper and torque tighten retaining nuts (x3) each side.

2. Install spring and damper assembly and torque tighten upper bolts (x4) each side.

3. Install damper to lower arm each side and torque tighten nuts and bolts.

4. Position fuel filler pipe to body, install and tighten nut.

5. Position fuel filler pipe, install and tighten bolt.

6. Position toe control arm each side, install and torque tighten nuts/bolts.

7. Position handbrake callipers each side, install bolts (x2) each side and tighten bolts to the correct torque.

8. Connect ABS sensor multiplugs each side.

9. Install clips (x2) each side from sensor harness to toe control arms.

10. Install LH wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear - RH -

Renew). 11. Install RH wheel arch li

ner (see Workshop Manual

procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew)

12. Install road wheel(s).

13. Lower vehicle on ramp.

14. Install fuel filler cap and close fuel filler lid.

Rear Spring-Pair-Renew

Removal

1. Open fuel filler lid and remove fuel filler cap.

2. Raise vehicle on ramp.

3. Remove road wheel(s).

4. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew).

5. Remove RH wheel arch liner (see Workshop Manual procedure01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

6. Remove bolt securing fuel filler pipe bracket to damper

mounting bracket.

7. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside (see Fig. 1).

Fig. 8

Fig. 9

Repair Operation Time (ROT)

Page 448 of 947

Shock Absorber System (04.03)

Suspension (04.00)4-3-8 Workshop Manual May 2007

8. Disconnect ABS sensor multiplug (see Fig. 2).

9. Release sensor harness clips (x2) from toe control arm (see Fig. 3).

10. Remove bolts (x2) each side from handbrake calliper to rear hub and release calliper an d position aside (see Fig.

4)

.

11. Remove nuts and bolts both sides from toe control arms (see Fig. 5).

12. Remove nuts and bolts each side from lower damper mountings (see Fig. 6).

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Page 449 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-9

13. Remove bolts (x4) each side from damper upper mounting (see Fig. 7).

14. Remove spring and damper assembly (see Fig. 8).

15. Remove nuts (x3) each side from damper to mounting plates and remove mounting plates (see Fig. 9).

16. Position spring compresso r to spring and compress

spring.

17. Hold damper shaft and remove top mounting retaining nut. 18. Remove top mounting and spring assembly.

19. Remove spring compressor from spring.

Installation

1. Clean spring and top mounting .

2. Position spring compressor to new spring and compress

spring.

3. Install spring and top mounting and torque tighten retaining nut.

4. Remove spring compressor.

5. Position mounting plate to damper and torque tighten

retaining nuts (x3) each side.

6. Install spring and damper assembly and torque tighten upper bolts (x4) each side.

7. Install damper assembly to lower arm each side and torque tighten nuts and bolts.

8. Position fuel filler pipe to body and install and tighten nut.

9. Position fuel filler pipe and install and tighten bolt.

10. Position toe control arm each side and install and torque tighten nuts and bolts.

11. Position handbrake callipers each side, install bolts (x2) each side and tighten bolts to the correct torque.

12. Connect ABS sensor multiplugs each side.

13. Install clips (x2) each side from sensor harness to toe control arms.

14. Install LH wheel arch li ner. (see Workshop Manual

procedure 01.02.HB Wheel Arch Liner - Rear - RH -

Renew).

15. Install RH wheelwright li ner (see Workshop Manual

procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

16. Install road wheel(s).

17. Lower vehicle on ramp.

18. Fit fuel filler cap and close fuel filler lid.

Rear Damper-Pair-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew)

4. Remove RH wheel arch liner (see Workshop Manual procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

5. Remove bolt securing fuel filler pipe bracket to damper

mounting plate.

6. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside.

7. Disconnect ABS sensor multiplug.

Fig. 7

Fig. 8

Fig. 9

Repair Operation Time (ROT)

Page 450 of 947

Shock Absorber System (04.03)

Suspension (04.00)4-3-10 Workshop Manual May 2007

8. Release sensor harness clips (x2) from toe control arm.

9. Remove bolts (x2) each side from handbrake calliper to rear hub.

10. Release calliper and position aside.

11. Remove nuts and bolts both sides from toe control arms.

12. Remove nuts and bolts each side from lower damper mountings.

13. Remove bolts (x4) each side from damper upper mounting.

14. Remove spring and damper assembly.

15. Remove nuts (x3) each side from damper to mounting plates and remove mounting plates.

16. Position spring compressor to spring and compress spring.

17. Hold damper shaft and remove top mounting retaining nut.

18. Remove top mounting and spring assembly.

19. Remove dust shield, rebound bumper and spring seat flange.

Installation

1. Clean spring, spring seat flange, rebound bumper, dust

shield and top mounting .

2. Install spring seat flange, rebound bumper and dust shield onto damper.

3. Install spring and top mounting and fit and tighten retaining nut.

4. Remove spring compressor.

5. Position mounting plate to damper and torque tighten retaining nuts (x3).

6. Install spring and damper assembly and torque tighten upper bolts (x4) each side.

7. Install damper assembly to lower arm each side and torque tighten nuts and bolts.

8. Position fuel filler pipe to body and install and tighten nut.

9. Position fuel filler pipe and install and tighten bolt.

10. Position toe control arm each side and install and torque tighten nuts and bolts.

11. Position handbrake callipers each side, install bolts (x2) each side and tighten bolts to the correct torque.

12. Connect ABS sensor multiplugs each side.

13. Install clips (x2) each side from sensor harness to toe control arms.

14. Install LH wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear - RH -

Renew).

15. Install RH wheel arch liner (see Workshop Manual procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew)

16. Install road wheel(s).

17. Lower vehicle on ramp.

Page 460 of 947

Road Wheels and Tyres (04.04)

Suspension (04.00)4-4-10 Workshop Manual May 2007

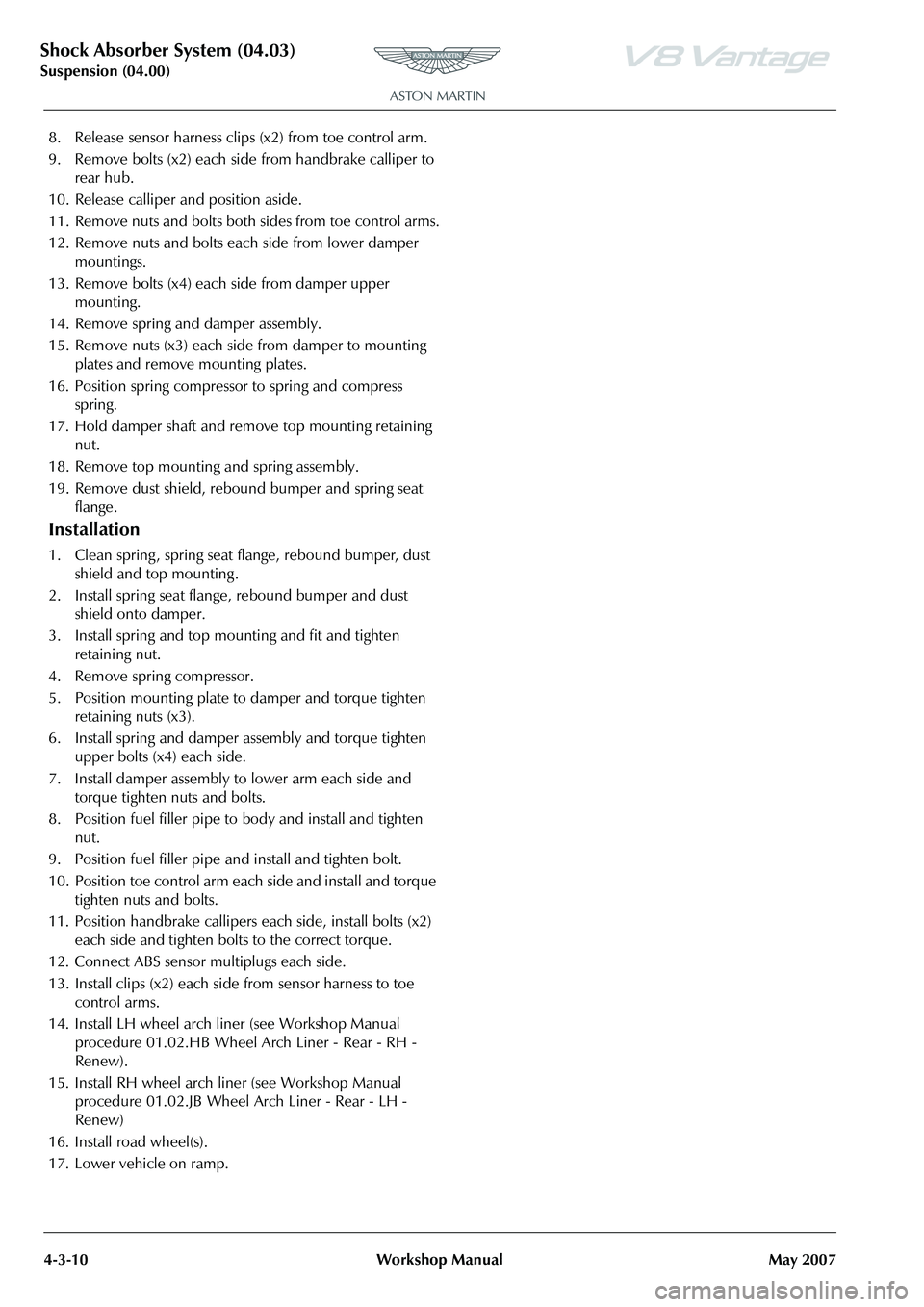

Display Unit

The display unit provides additional features when correctly

connected to a previously installed ‘Smartire’ system. The

display unit connects directly to the front of the basic

‘Smartire’ receiver and is powered from the vehicle circuits.

The display will be fully illu minated during use but will go

into ‘Energy Saver’ mode when no activity is detected.

Display Panel

Connection and Normal Operation

1. Remove the front bezel of the Pressure Sensor Receiver. Install the extension lead to the display unit and to the

receiver module. Turn on the ignition.

All icons will illuminate briefly and then extinguish

leaving only the vehicle outline.

2. When tyre pressure data is received, (drive the vehicle

or spin the road wheels), all the road wheel icons will

appear. Press the Tyre icon to access the recorded data

for each of the four road wheels.

3. Press the Mode button to scroll through the pressure, temperature and pressure deviation readings for the

selected tyre. 4. If any tyre pressure sensor is defective, the display will

show three dashes to indicate the absence of data for

that tyre.

5. To return to normal mode, press the SET button.

System Programming

The system may be programmed by the user on three

different levels. Enter Progra mming Mode by pressing the

‘Set’ button:

• 2 seconds to enter level 1

• 5 seconds to enter level 2

• 10 seconds to enter level 3

The following parameters ma y be set in each level:

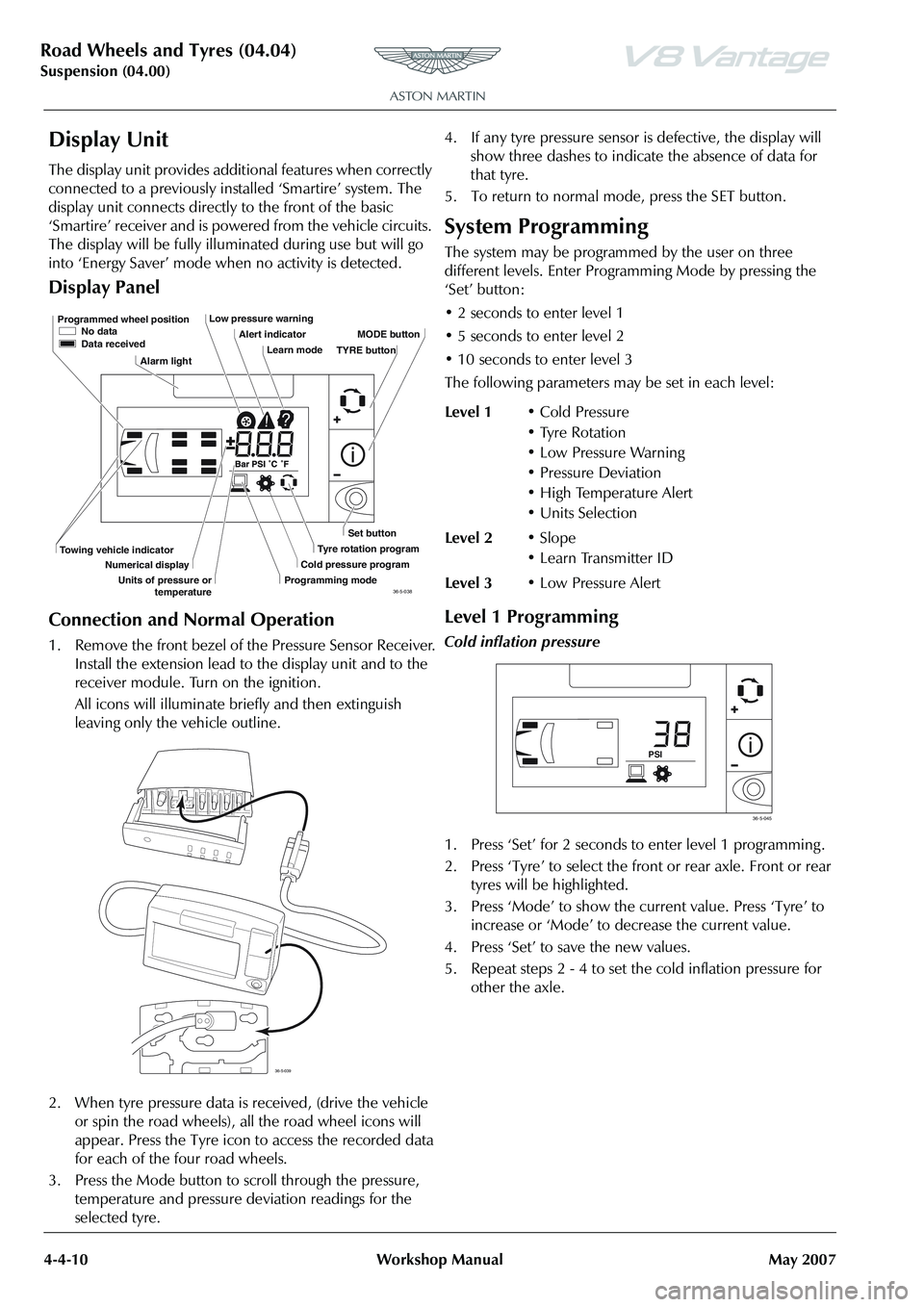

Level 1 Programming

Cold inflation pressure

1. Press ‘Set’ for 2 seconds to enter level 1 programming .

2. Press ‘Tyre’ to select the front or rear axle. Front or rear

tyres will be highlighted.

3. Press ‘Mode’ to show the current value. Press ‘Tyre’ to increase or ‘Mode’ to decrease the current value.

4. Press ‘Set’ to save the new values.

5. Repeat steps 2 - 4 to set the cold inflation pressure for other the axle.

Programmed wheel position No data

Data received

Alarm light Low pressure warning

Alert indicatorLearn mode MODE button

Set button

Tyre rotation program

Cold pressure program

Programming mode

Towing vehicle indicator

Numerical display

Units of pressure or temperature TYRE button

36-5-038

36-5-039

Level 1

• Cold Pressure

• Tyre Rotation

• Low Pressure Warning

• Pressure Deviation

• High Temperature Alert

•Units Selection

Level 2 •Slope

• Learn Transmitter ID

Level 3 • Low Pressure Alert

PSI

36-5-045

Page 461 of 947

Road Wheels and Tyres (04.04)

Suspension (04.00)

May 2007 Workshop Manual 4-4-11

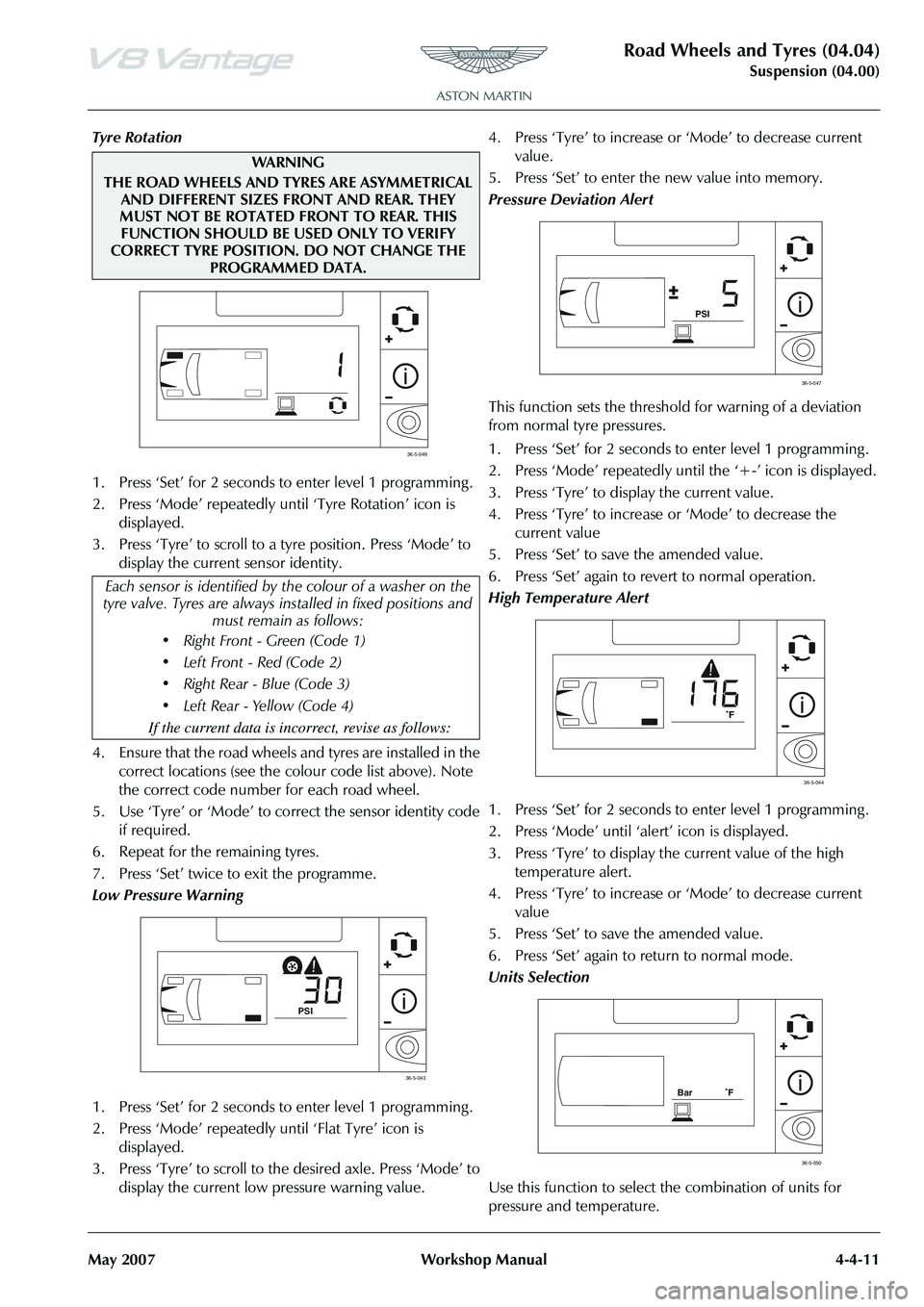

Tyre Rotation

1. Press ‘Set’ for 2 seconds to enter level 1 programming .

2. Press ‘Mode’ repeatedly until ‘Tyre Rotation’ icon is displayed.

3. Press ‘Tyre’ to scroll to a tyre position. Press ‘Mode’ to display the current sensor identity.

4. Ensure that the road wheels and tyres are installed in the correct locations (see the colour code list above). Note

the correct code number for each road wheel.

5. Use ‘Tyre’ or ‘Mode’ to co rrect the sensor identity code

if required.

6. Repeat for the remaining tyres.

7. Press ‘Set’ twice to exit the programme.

Low Pressure Warning

1. Press ‘Set’ for 2 seconds to enter level 1 programming .

2. Press ‘Mode’ repeatedly until ‘Flat Tyre’ icon is displayed.

3. Press ‘Tyre’ to scroll to th e desired axle. Press ‘Mode’ to

display the current low pressure warning value. 4. Press ‘Tyre’ to increase or

‘Mode’ to decrease current

value.

5. Press ‘Set’ to enter the new value into memory.

Pressure Deviation Alert

This function sets the threshold for warning of a deviation

from normal tyre pressures.

1. Press ‘Set’ for 2 seconds to enter level 1 programming .

2. Press ‘Mode’ repeatedly until the ‘+-’ icon is displayed.

3. Press ‘Tyre’ to display the current value.

4. Press ‘Tyre’ to increase or ‘Mode’ to decrease the

current value

5. Press ‘Set’ to save the amended value.

6. Press ‘Set’ again to revert to normal operation.

High Temperature Alert

1. Press ‘Set’ for 2 seconds to enter level 1 programming .

2. Press ‘Mode’ until ‘ale rt’ icon is displayed.

3. Press ‘Tyre’ to display the current value of the high temperature alert.

4. Press ‘Tyre’ to increase or ‘Mode’ to decrease current

value

5. Press ‘Set’ to save the amended value.

6. Press ‘Set’ again to return to normal mode.

Units Selection

Use this function to select the combination of units for

pressure and temperature.

WAR NI N G

THE ROAD WHEELS AND TYRES ARE ASYMMETRICAL AND DIFFERENT SIZES FRONT AND REAR. THEY

MUST NOT BE ROTATED FRONT TO REAR. THIS FUNCTION SHOULD BE USED ONLY TO VERIFY

CORRECT TYRE POSITION. DO NOT CHANGE THE PROGRAMMED DATA.

Each sensor is identified by th e colour of a washer on the

tyre valve. Tyres are always in stalled in fixed positions and

must remain as follows:

• Right Front - Green (Code 1)

• Left Front - Red (Code 2)

Page 462 of 947

Road Wheels and Tyres (04.04)

Suspension (04.00)4-4-12 Workshop Manual May 2007

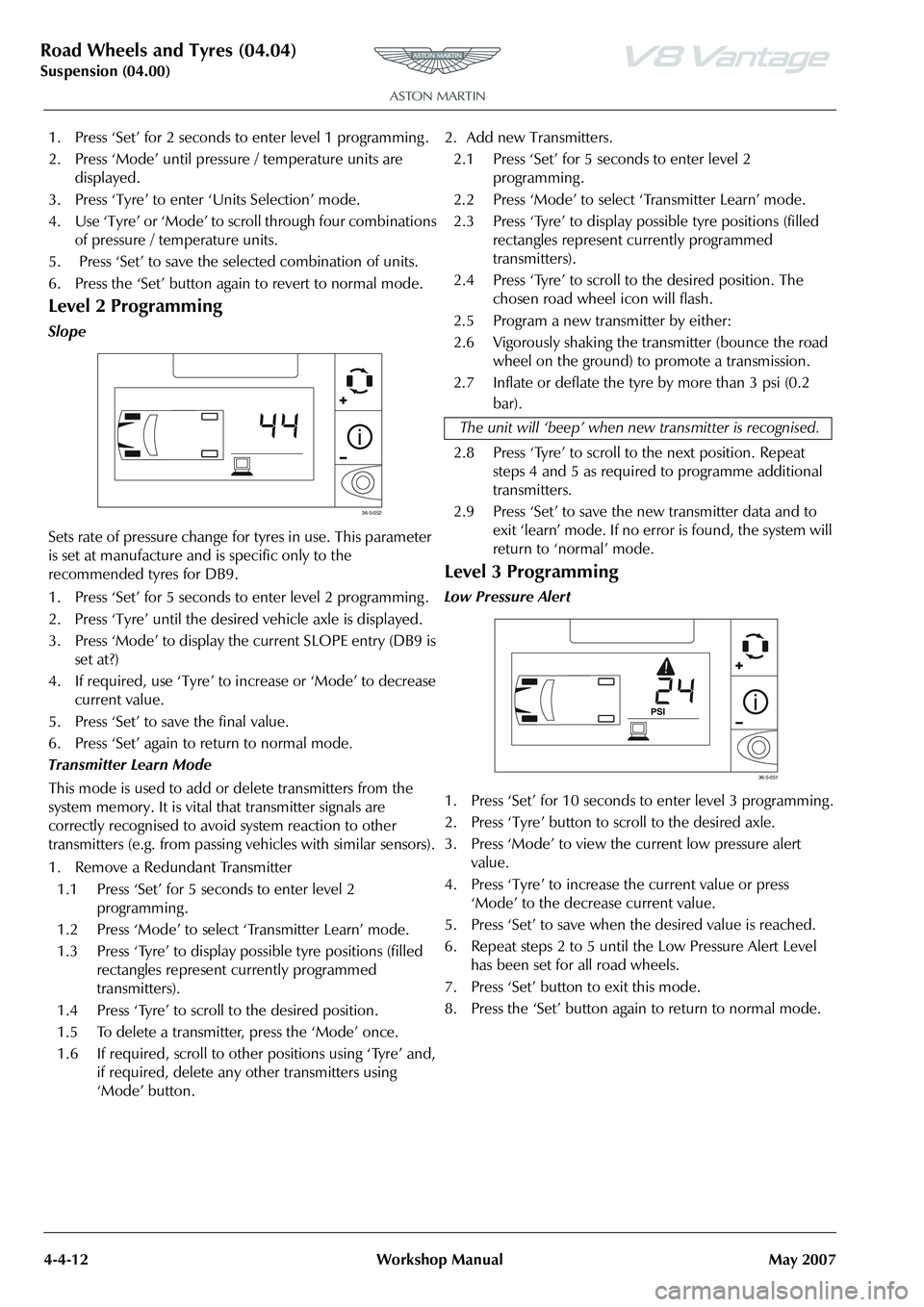

1. Press ‘Set’ for 2 seconds to enter level 1 programming .

2. Press ‘Mode’ until pressure / temperature units are displayed.

3. Press ‘Tyre’ to enter ‘Units Selection’ mode.

4. Use ‘Tyre’ or ‘Mode’ to scroll through four combinations of pressure / temperature units.

5. Press ‘Set’ to save the selected combination of units.

6. Press the ‘Set’ button again to revert to normal mode.

Level 2 Programming

Slope

Sets rate of pressure change for tyres in use. This parameter

is set at manufacture and is specific only to the

recommended tyres for DB9.

1. Press ‘Set’ for 5 seconds to enter level 2 programming .

2. Press ‘Tyre’ until the desired vehicle axle is displayed.

3. Press ‘Mode’ to display the current SLOPE entry (DB9 is set at?)

4. If required, use ‘Tyre’ to increase or ‘Mode’ to decrease current value.

5. Press ‘Set’ to save the final value.

6. Press ‘Set’ again to return to normal mode.

Transmitter Learn Mode

This mode is used to add or delete transmitters from the

system memory. It is vital that transmitter signals are

correctly recognised to avoid system reaction to other

transmitters (e.g. from passing vehicles with similar sensors).

1. Remove a Redundant Transmitter 1.1 Press ‘Set’ for 5 seconds to enter level 2 programming .

1.2 Press ‘Mode’ to select ‘Transmitter Learn’ mode.

1.3 Press ‘Tyre’ to display possible tyre positions (filled rectangles represent currently programmed

transmitters).

1.4 Press ‘Tyre’ to scroll to the desired position.

1.5 To delete a transmitter, press the ‘Mode’ once.

1.6 If required, scroll to other positions using ‘Tyre’ and, if required, delete any other transmitters using

‘Mode’ button. 2. Add new Transmitters.

2.1 Press ‘Set’ for 5 seconds to enter level 2 programming .

2.2 Press ‘Mode’ to select ‘Transmitter Learn’ mode.

2.3 Press ‘Tyre’ to display possible tyre positions (filled rectangles represent currently programmed

transmitters).

2.4 Press ‘Tyre’ to scroll to the desired position. The chosen road wheel icon will flash.

2.5 Program a new transmitter by either:

2.6 Vigorously shaking the transmitter (bounce the road wheel on the ground) to promote a transmission.

2.7 Inflate or deflate the tyre by more than 3 psi (0.2 bar).

2.8 Press ‘Tyre’ to scroll to the next position. Repeat steps 4 and 5 as required to programme additional

transmitters.

2.9 Press ‘Set’ to save the new transmitter data and to exit ‘learn’ mode. If no error is found, the system will

return to ‘normal’ mode.

Level 3 Programming

Low Pressure Alert

1. Press ‘Set’ for 10 seconds to enter level 3 programming .

2. Press ‘Tyre’ button to scroll to the desired axle.

3. Press ‘Mode’ to view the current low pressure alert value.

4. Press ‘Tyre’ to increase the current value or press ‘Mode’ to the decrease current value.

5. Press ‘Set’ to save when the desired value is reached.

6. Repeat steps 2 to 5 until the Low Pressure Alert Level has been set for all road wheels.

7. Press ‘Set’ button to exit this mode.

8. Press the ‘Set’ button again to return to normal mode.

36-5-052

The unit will ‘beep’ when ne w transmitter is recognised.

36-5-051

Page 463 of 947

May 2007 Workshop Manual 5-1-1

Driveline (05.00)

Contents

Driveshaft (05.01) .................................................. 5-1-2Description ............................................................. 1-2

Specifications.......................................................... 1-2

Maintenance ........................................................... 1-2 Propeller Shaft-Renew ........................................... 1-2

Propshaft Cam Sensor-Sportshift-Renew

-Sportshift Only...................................................... 1-2

Torque Tube-Renew .............................................. 1-3

Torque Tube & Prop Shaft Assembly-

Renew-Manual Vehicles Only ................................ 1-4

Torque Tube & Prop Shaft Assembly-

Renew-Sportshift Vehicles Only ............................. 1-4

Torque Tube-Remove for Access/Refit .................... 1-5

RH/LH Drive Shaft Assembly-Renew ...................... 1-7

Halfshafts (05.05) .................................................. 5-2-1 Specifications.......................................................... 2-1