oil ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 910 of 947

Aston Martin V8 Vantage2009MY OBDII Documentation 4.7L Aston Martin Confidential

Component P CodesMalfunction Strategy

Description Malfunction Criteria

(Fault) Fault condition

(Internal labels) Threshold Value

(Fault condition) Entry conditions Entry conditions values Filter Time to

log DTCPump relay P0947 Pump relay connected GNDPump relay Short circuit to GND The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output current > th3 during valve on phase th3= 3.7A

NOT (Cranking) 200ms

Clutch system P186D Clutch or actuator or valve damagedClutch not opening before gear

shifting Clutch not open in a timeout timeout = 500ms (Gear shifting in

progress) AND

(Clutch opening

Gear Box system P1734 Mechanical or hydraulic problemGear Box. Disengage failed

(mechanical causes) Gear not disengaged in a timeout timeout = 500ms (Gear shifting phase)

AND (disengage phase)

Gear Box system P1701 Mechanical or hydraulic problemGear Box. Wrong gear

engagement The gear which is going to be

engaged is not the requested one (Gear shifting phase)

Hydraulic circuit P0868 Hydraulic leakage Hydraulic circuit. Pressure low Comparison between sensor pressure signal and threshold = f(oil temperature)

pressure < th Th= 25 bar @ -30°C

Th= 40 bar @120°C linear interpolation (Engine ON) AND

NOT (cranking) 200ms

Power grounds P1710 Power grounds. Disconnection both ground pins Power grounds. Disconnection

both ground pins The diagnosis is based on the batter

y

voltage modification during the

activation of the clutch electrovalve. Ubatt < Ubatt0 - DltUbatt Ubatt0 = Ubatt before

starting the testDltUbatt = 2,5V Wake-up phase

ASM OBD

628/04/2008

Page 924 of 947

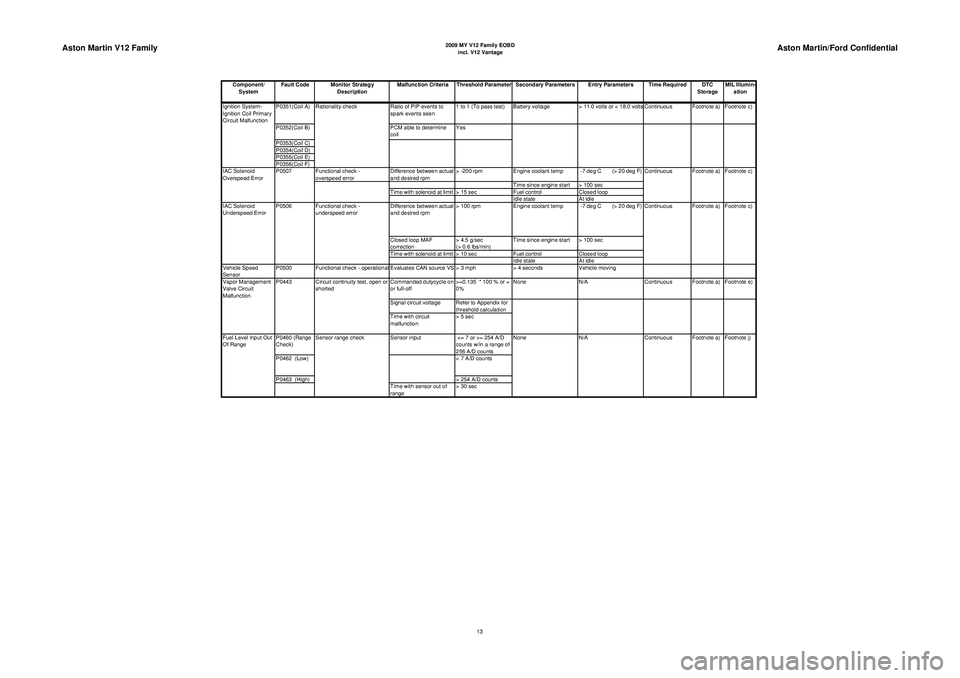

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

P0351(Coil A) Ratio of PIP events to

spark events seen 1 to 1 (To pass test) Battery voltage

> 11.0 volts or < 18.0 volts Continuous Footnote a) Footnote c)

P0352(Coil B) PCM able to determine

coil Yes

P0353(Coil C)

P0354(Coil D)

P0355(Coil E)

P0356(Coil F) Functional check -

overspeed error Difference between actual

and desired rpm> -200 rpm

Engine coolant temp -7 deg C (> 20 deg F)

Time since engine start > 100 sec

Time with solenoid at limit > 15 sec Fuel controlClosed loop

Idle state At idle

Difference between actual

and desired rpm > 100 rpm

Engine coolant temp -7 deg C (> 20 deg F)

Closed loop MAF

correction > 4.5 g/sec

(> 0.6 lbs/min)Time since engine start > 100 sec

Time with solenoid at limit > 10 sec Fuel controlClosed loop

Idle state At idle

Vehicle Speed

Sensor P0500 Functional check - operational Evaluates CAN source VS > 3 mph

> 4 secondsVehicle moving

Commanded dutycycle on

or full-off >=0.135 * 100 % or =

0%None

N/A Continuous Footnote a) Footnote e)

Signal circuit voltage Refer to Appendix for threshold calculation

Time with circuit

malfunction > 5 sec

P0460 (Range

Check) Sensor input

<= 7 or >= 254 A/D

counts w/in a range of

256 A/D counts

P0462 (Low) < 7 A/D counts

P0463 (High) > 254 A/D counts

Time with sensor out of

range > 30 sec N/A

Continuous Footnote a) Footnote j)

Fuel Level Input Out

Of Range Sensor range check

None

Vapor Management

Valve Circuit

Malfunction

P0443 Circuit continuity test, open or

shorted Footnote a) Footnote c)

IAC Solenoid

Underspeed Error P0506 Functional check -

underspeed error Continuous

IAC Solenoid

Overspeed Error

P0507

Continuous Footnote a) Footnote c)

Ignition System-

Ignition Coil Primary

Circuit Malfunction

Rationality check

13

Page 935 of 947

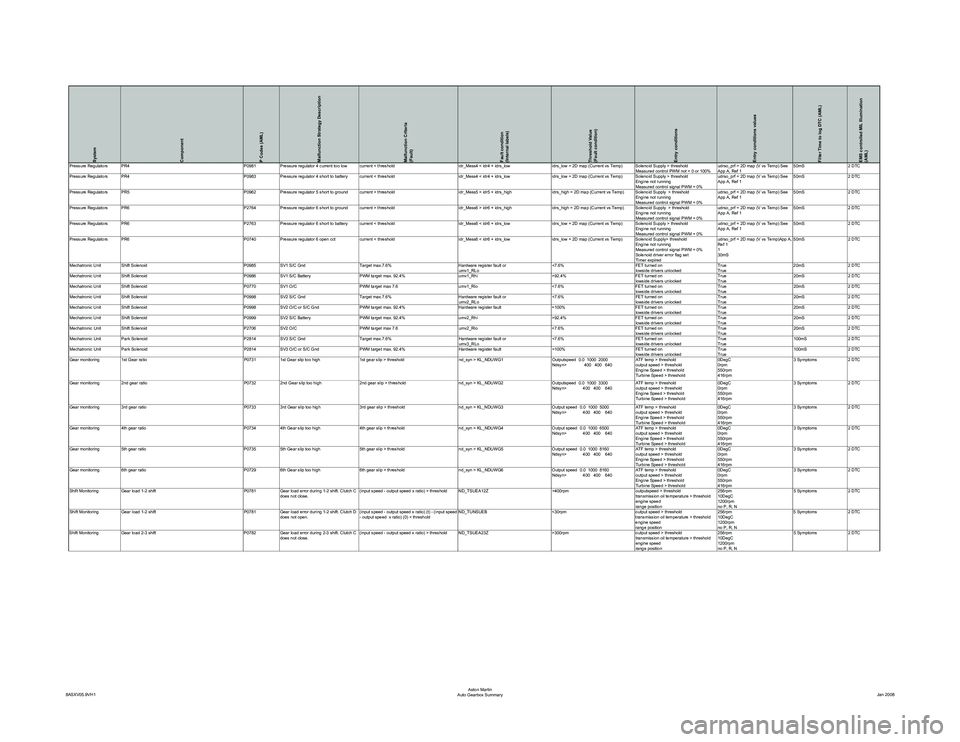

System

Component

P Codes (AML)

Malfunction Strategy Description

Malfunction Criteria

(Fault)

Fault condition

(Internal labels)

Threshold Value

(Fault condition)

Entry conditions

Entry conditions values

Filter Time to log DTC (AML)

EMS controlled MIL Illumination

(AML)

(V vs Temp

)App A,

Ref 1

1

30mS 50mS

2 DTC

Mechatronic Unit Shift Solenoid P0985SV1 S/C Gnd Target max.7.6% Hardware register fault or

umv1_RLo <7.6%

FET turned on

lowside drivers unlockedTrue

True20mS

2 DTC

Mechatronic Unit Shift Solenoid P0986SV1 S/C Battery PWM target max. 92.4% umv1_Rhi>92.4%FET turned on

lowside drivers unlocked True

True20mS

2 DTC

Mechatronic Unit Shift Solenoid P0770SV1 O/C PWM target max 7.6 umv1_Rlo<7.6%FET turned on

lowside drivers unlocked True

True20mS

2 DTC

Mechatronic Unit Shift Solenoid P0998SV2 S/C Gnd Target max.7.6% Hardware register fault or

umv2_RLo <7.6%

FET turned on

lowside drivers unlockedTrue

True20mS

2 DTC

Mechatronic Unit Shift Solenoid P0998SV2 O/C or S/C Gnd PWM target max. 92.4% Hardware register fault=100%FET turned on

lowside drivers unlocked True

True20mS

2 DTC

Mechatronic Unit Shift Solenoid P0999SV2 S/C Battery PWM target max. 92.4% umv2_Rhi>92.4%FET turned on

lowside drivers unlocked True

True20mS

2 DTC

Mechatronic Unit Shift Solenoid P2706SV2 O/C PWM target max 7.6 umv2_Rlo<7.6%FET turned on

lowside drivers unlocked True

True20mS

2 DTC

Mechatronic Unit Park Solenoid P2814SV3 S/C Gnd Target max.7.6% Hardware register fault or

umv3_RLo <7.6%

FET turned on

lowside drivers unlockedTrue

True100mS

2 DTC

Mechatronic Unit Park Solenoid P2814SV3 O/C or S/C Gnd PWM target max. 92.4% Hardware register fault=100%FET turned on

lowside drivers unlocked True

True100mS

2 DTC

Gear monitoring 1st Gear ratio P07311st Gear slip too high 1st gear slip > threshold nd_syn > KL_NDUWG1Outputspeed 0.0 1000 2000

Ndsyn> 400 400 640 ATF temp > threshold

output speed > threshold

Engine Speed > threshold

Turbine Speed > threshold0DegC

0rpm

550rpm

416rpm3 Symptoms

2 DTC

Gear monitoring 2nd gear ratio P07322nd Gear slip too high 2nd gear slip > threshold nd_syn > KL_NDUWG2Outputspeed 0.0 1000 3300

Ndsyn> 400 400 640 ATF temp > threshold

output speed > threshold

Engine Speed > threshold

Turbine Speed > threshold0DegC

0rpm

550rpm

416rpm3 Symptoms

2 DTC

Gear monitoring 3rd gear ratio P07333rd Gear slip too high 3rd gear slip > threshold nd_syn > KL_NDUWG3Output speed 0.0 1000 5000

Ndsyn> 400 400 640 ATF temp > threshold

output speed > threshold

Engine Speed > threshold

Turbine Speed > threshold0DegC

0rpm

550rpm

416rpm3 Symptoms

2 DTC

Gear monitoring 4th gear ratio P07344th Gear slip too high 4th gear slip > threshold nd_syn > KL_NDUWG4Output speed 0.0 1000 6500

Ndsyn> 400 400 640 ATF temp > threshold

output speed > threshold

Engine Speed > threshold

Turbine Speed > threshold0DegC

0rpm

550rpm

416rpm3 Symptoms

2 DTC

Gear monitoring 5th gear ratio P07355th Gear slip too high 5th gear slip > threshold nd_syn > KL_NDUWG5Output speed 0.0 1000 8160

Ndsyn> 400 400 640 ATF temp > threshold

output speed > threshold

Engine Speed > threshold

Turbine Speed > threshold0DegC

0rpm

550rpm

416rpm3 Symptoms

2 DTC

Gear monitoring 6th gear ratio P07296th Gear slip too high 6th gear slip > threshold nd_syn > KL_NDUWG6Output speed 0.0 1000 8160

Ndsyn> 400 400 640 ATF temp > threshold

output speed > threshold

Engine Speed > threshold

Turbine Speed > threshold0DegC

0rpm

550rpm

416rpm3 Symptoms

2 DTC

Shift Monitoring Gear load 1-2 shift P0781Gear load error during 1-2 shift. Clutch C

does not close. (input speed - output speed x ratio) > threshold ND_TSUEA12Z

>400rpmoutputspeed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

Shift Monitoring Gear load 1-2 shift P0781Gear load error during 1-2 shift. Clutch D

does not open.

(input speed - output speed x ratio

) (t) - (input speed

- output speed x ratio) (0) < threshold ND_TUNSUEB

<30rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

Shift Monitoring Gear load 2-3 shift P0782Gear load error during 2-3 shift. Clutch C

does not close. (input speed - output speed x ratio) > threshold ND_TSUEA23Z

>300rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

8ASXV05.9VH1 Aston Martin

Auto Gearbox Summary Jan 2008

Page 936 of 947

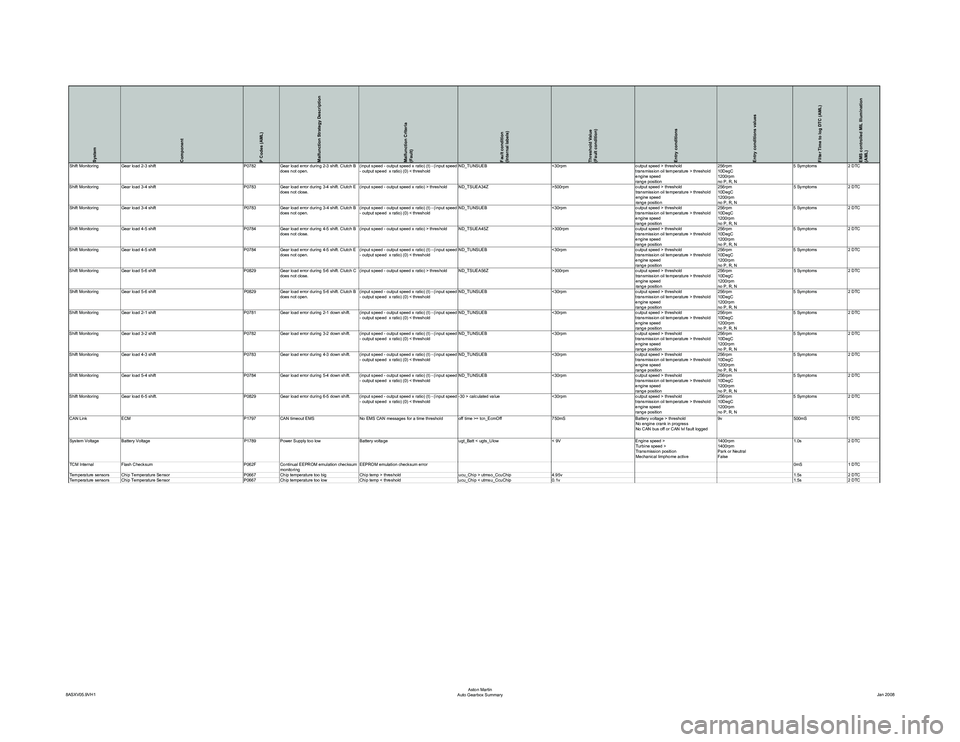

System

Component

P Codes (AML)

Malfunction Strategy Description

Malfunction Criteria

(Fault)

Fault condition

(Internal labels)

Threshold Value

(Fault condition)

Entry conditions

Entry conditions values

Filter Time to log DTC (AML)

EMS controlled MIL Illumination

(AML)

(input speed - output speed x ratio

) (t) - (input speed

- output speed x ratio) (0) < threshold ND_TUNSUEB

<30rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

Shift Monitoring Gear load 4-5 shift P0784Gear load error during 4-5 shift. Clutch B

does not close. (input speed - output speed x ratio) > threshold ND_TSUEA45Z

>300rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

Shift Monitoring Gear load 4-5 shift P0784Gear load error during 4-5 shift. Clutch E

does not open.

(input speed - output speed x ratio

) (t) - (input speed

- output speed x ratio) (0) < threshold ND_TUNSUEB

<30rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

Shift Monitoring Gear load 5-6 shift P0829Gear load error during 5-6 shift. Clutch C

does not close. (input speed - output speed x ratio) > threshold ND_TSUEA56Z

>300rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

Shift Monitoring Gear load 5-6 shift P0829Gear load error during 5-6 shift. Clutch B

does not open.

(input speed - output speed x ratio

) (t) - (input speed

- output speed x ratio) (0) < threshold ND_TUNSUEB

<30rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

Shift Monitoring Gear load 2-1 shift P0781Gear load error during 2-1 down shift.

(input speed - output speed x ratio

) (t) - (input speed

- output speed x ratio) (0) < threshold ND_TUNSUEB

<30rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

Shift Monitoring Gear load 3-2 shift P0782Gear load error during 3-2 down shift.

(input speed - output speed x ratio

) (t) - (input speed

- output speed x ratio) (0) < threshold ND_TUNSUEB

<30rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

Shift Monitoring Gear load 4-3 shift P0783Gear load error during 4-3 down shift.

(input speed - output speed x ratio

) (t) - (input speed

- output speed x ratio) (0) < threshold ND_TUNSUEB

<30rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

Shift Monitoring Gear load 5-4 shift P0784Gear load error during 5-4 down shift.

(input speed - output speed x ratio

) (t) - (input speed

- output speed x ratio) (0) < threshold ND_TUNSUEB

<30rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

Shift Monitoring Gear load 6-5 shift. P0829Gear load error during 6-5 down shift.

(input speed - output speed x ratio

) (t) - (input speed

- output speed x ratio) (0) < threshold -30 > calculated value

<30rpmoutput speed > threshold

transmission oil temperature > threshold

engine speed

range position 256rpm

10DegC

1200rpm

no P, R, N5 Symptoms

2 DTC

CAN Link ECM P1797CAN timeout EMS No EMS CAN messages for a time threshold off time >= tcn_EcmOff 750mSBattery voltage > threshold

No engine crank in progress

No CAN bus off or CAN lvl fault logged 9v

500mS1 DTC

System Voltage Battery Voltage P1789Power Supply too low Battery voltage ugt_Batt < ugts_Ulow< 9VEngine speed >

Turbine speed >

Transmission position

Mechanical limphome active 1400rpm

1400rpm

Park or Neutral

False1.0s

2 DTC

TCM Internal Flash Checksum P062FContinual EEPROM emulation checksum

monitoring EEPROM emulation checksum error

0mS1 DTC

Temperature sensors Chip Temperature Sensor P0667 Chip temperature too big Chip temp > threshold ucu_Chip > utmso_CcuChip4.95v 1.5s2 DTC

Temperature sensors Chip Temperature Sensor P0667 Chip temperature too low Chip temp < threshold ucu_Chip < utmsu_CcuChip0.1v 1.5s2 DTC

8ASXV05.9VH1 Aston Martin

Auto Gearbox Summary Jan 2008

Page 939 of 947

Service Bulletin SB-17-0298

February 2009 Page 2 of 5

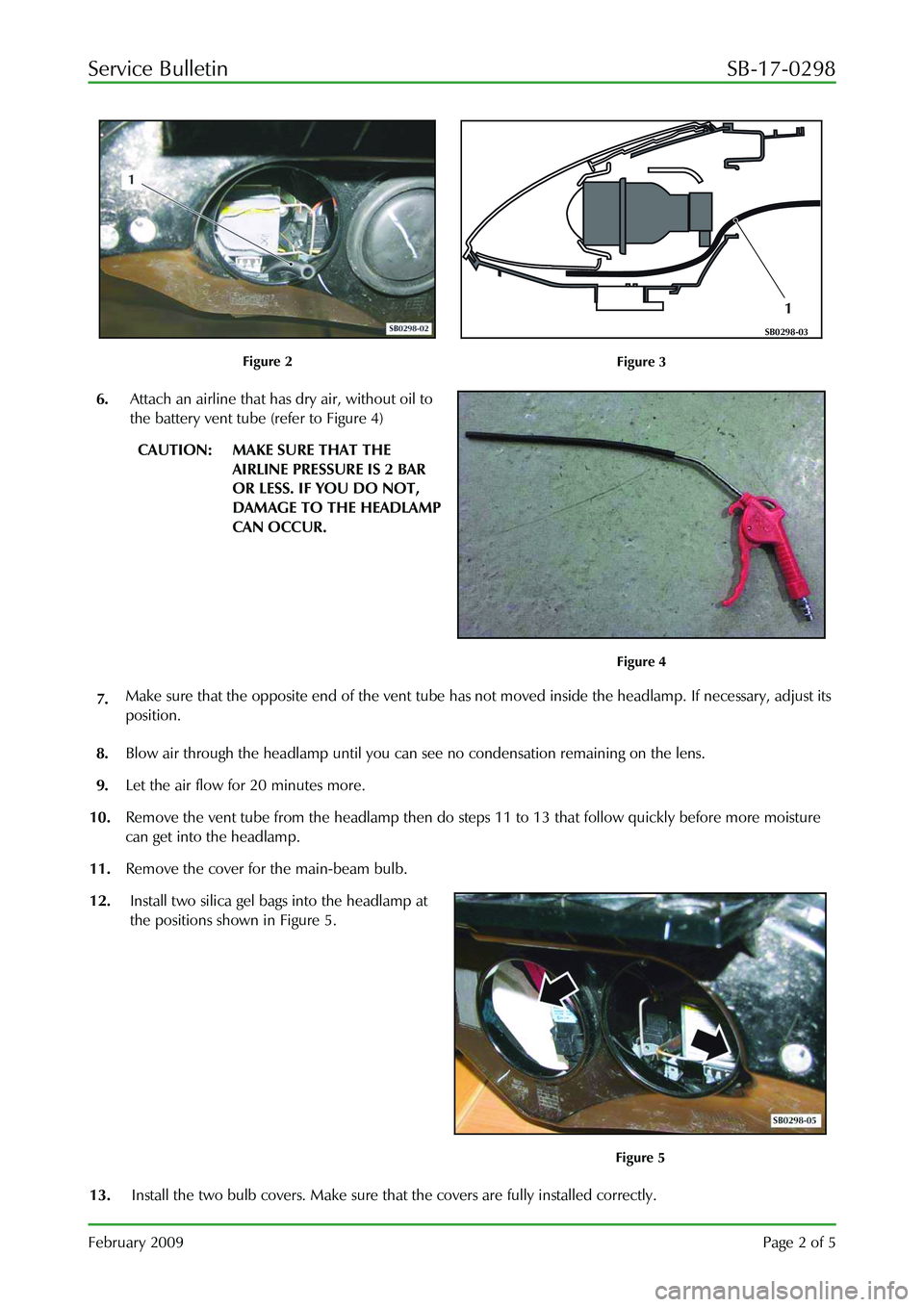

Figure 2

1

SB0298-03

Figure 3

6. Attach an airline that has dry air, without oil to

the battery vent tube (refer to Figure 4)

CAUTION: MAKE SURE THAT THE

AIRLINE PRESSURE IS 2 BAR

OR LESS. IF YOU DO NOT,

DAMAGE TO THE HEADLAMP

CAN OCCUR.

Figure 4

7. Make sure that the opposite end of the vent tube has

not moved inside the headlamp. If necessary, adjust its

position.

8. Blow air through the headlamp until you can see no condensation remaining on the lens.

9. Let the air flow for 20 minutes more.

10. Remove the vent tube from the headlamp then do st eps 11 to 13 that follow quickly before more moisture

can get into the headlamp.

11. Remove the cover for the main-beam bulb.

12. Install two silica gel bags into the headlamp at

the positions shown in Figure 5.

Figure 5

13. Install the two bulb covers. Make sure that the covers are fully installed correctly.

Page 941 of 947

Service Bulletin SB-17-0298

February 2009 Page 4 of 5

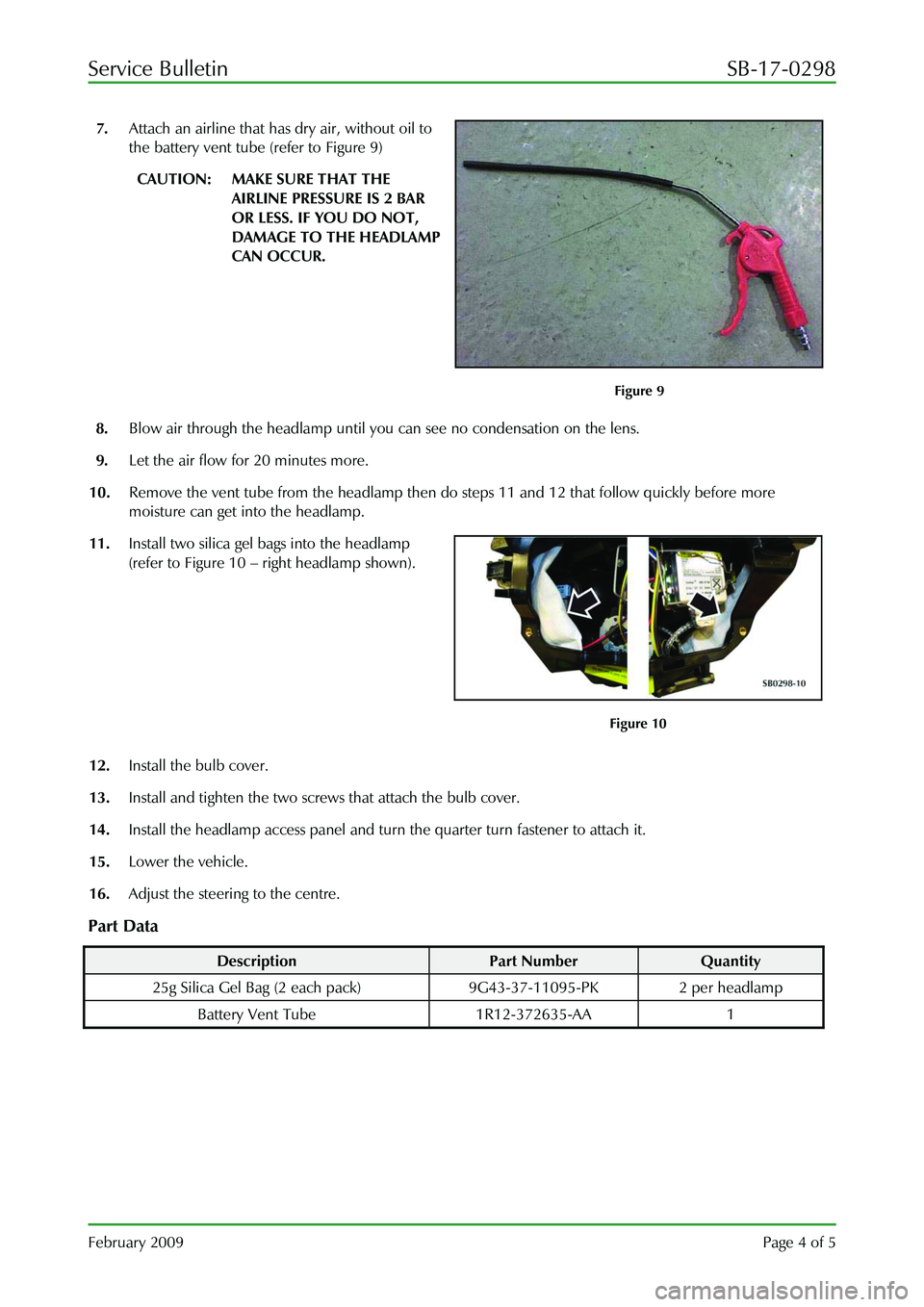

7. Attach an airline that has dry air, without oil to

the battery vent tube (refer to Figure 9)

CAUTION: MAKE SURE THAT THE

AIRLINE PRESSURE IS 2 BAR

OR LESS. IF YOU DO NOT,

DAMAGE TO THE HEADLAMP

CAN OCCUR.

Figure 9

8. Blow air through the headlamp until you can see no condensation on the lens.

9. Let the air flow for 20 minutes more.

10. Remove the vent tube from the headlamp then do steps 11 and 12 that follow quickly before more

moisture can get into the headlamp.

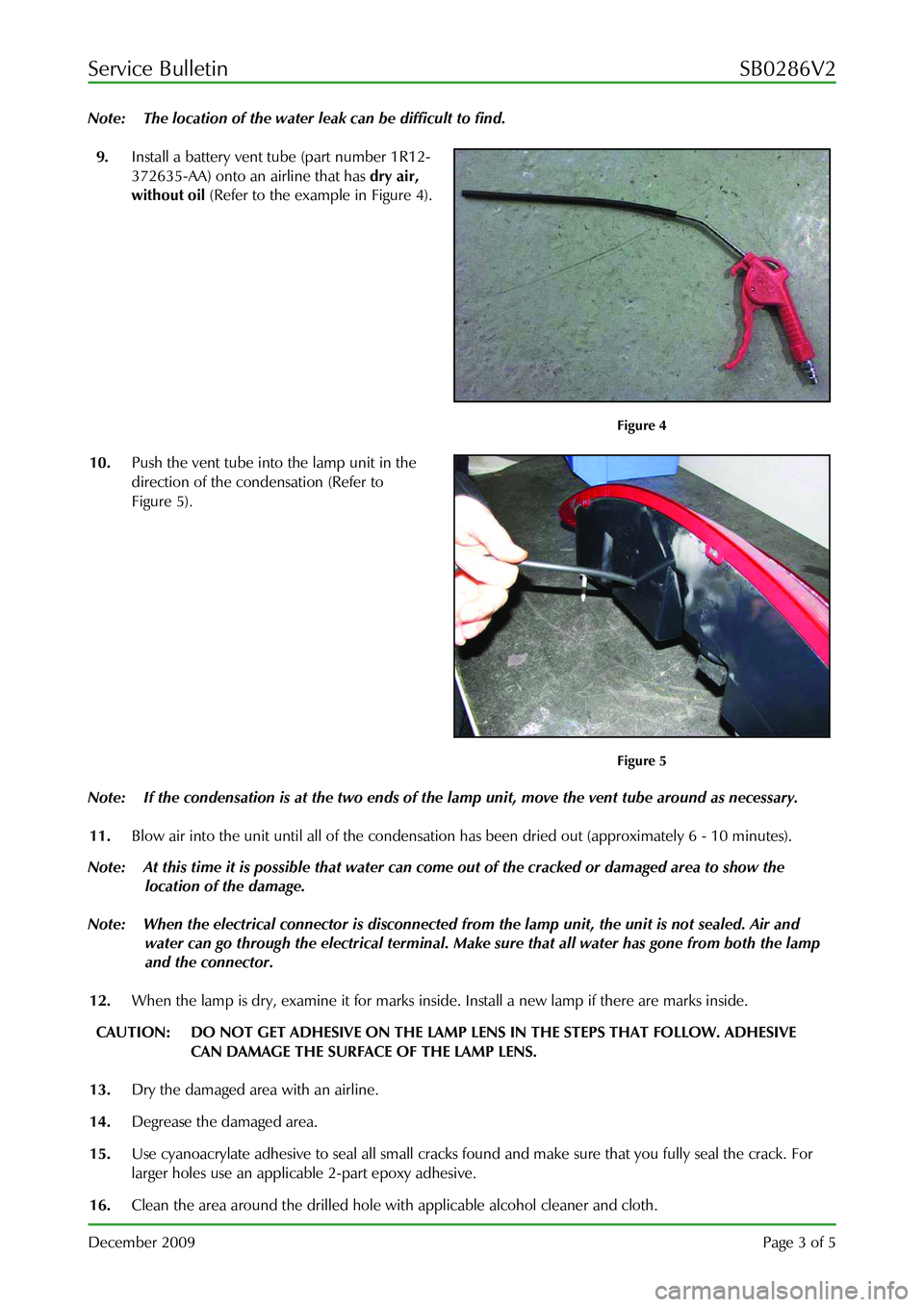

11. Install two silica gel bags into the headlamp

(refer to Figure 10 – right headlamp shown).

Figure 10

12. Install the bulb cover.

13. Install and tighten the two screws that attach the bulb cover.

14. Install the headlamp access panel and turn the quarter turn fastener to attach it.

15. Lower the vehicle.

16. Adjust the steering to the centre.

Part Data

Description Part Number Quantity

25g Silica Gel Bag (2 each pa ck) 9G43-37-11095-PK 2 per headlamp

Battery Vent Tube 1R12-372635-AA 1

Page 945 of 947

Service Bulletin SB0286V2

December 2009 Page 3 of 5

Note: The location of the water leak can be difficult to find.

9. Install a battery vent tube (part number 1R12-

372635-AA) onto an airline that has dry air,

without oil (Refer to the example in Figure 4).

Figure 4

10. Push the vent tube into the lamp unit in the

direction of the condensation (Refer to

Figure 5).

Figure 5

Note: If the condensation is at the two ends of the la mp unit, move the vent tube around as necessary.

11. Blow air into the unit until all of the condensati on has been dried out (approximately 6 - 10 minutes).

Note: At this time it is possible that water can come out of the cracked or damaged area to show the

location of the damage.

Note: When the electrical connector is disconnected from the lamp unit, the unit is not sealed. Air and

water can go through the electrical terminal. Make sure that all water has gone from both the lamp

and the connector.

12. When the lamp is dry, examine it for marks inside. Install a new lamp if there are marks inside.

CAUTION: DO NOT GET ADHESIVE ON THE LAMP LENS IN THE STEPS THAT FOLLOW. ADHESIVE

CAN DAMAGE THE SURFACE OF THE LAMP LENS.

13. Dry the damaged area with an airline.

14. Degrease the damaged area.

15. Use cyanoacrylate adhesive to seal all small cracks fo und and make sure that you fully seal the crack. For

larger holes use an applicab le 2-part epoxy adhesive.

16. Clean the area around the drilled hole with applicable alcohol cleaner and cloth.