spark plugs replace ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 373 of 947

Power Conversion (03.11)

Engine (03.00)

May 2007 Workshop Manual 3-11-1

Engine (03.00)

Power Conversion (03.11)

Maintenance

Connecting Rod Bearing-Renew (Engine

Set)

Removal

1. Remove engine oil sump (see Workshop Manual

procedure 03.02.BN Pan - Oil Sump - Remove and Re-

seal).

2. Remove spark plugs (see Workshop Manual procedure 03.07.DB Spark Plugs - Engine Set - Renew).

3. Remove bolts (x8) securing windage tray to engine bedplate, remove windage tray.

4. Mark bearing caps and connecting rods for correct installation.

5. Rotate crankshaft clockwise to access number 1 cylinder connecting rod bolts.

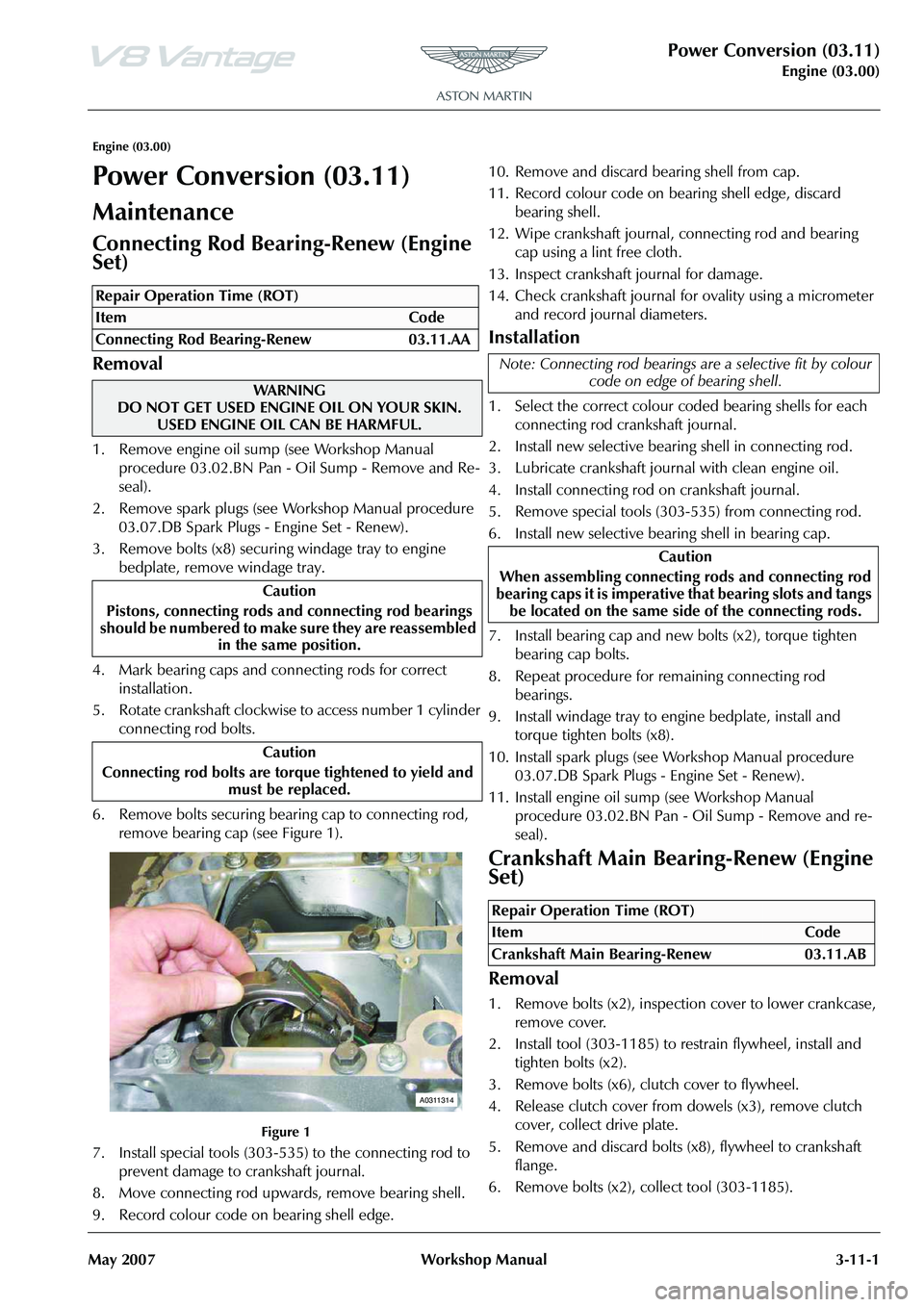

6. Remove bolts securing bearing cap to connecting rod, remove bearing cap (see Figure 1).

Figure 1

7. Install special tools (303-535) to the connecting rod to prevent damage to crankshaft journal.

8. Move connecting rod upwards, remove bearing shell.

9. Record colour code on bearing shell edge. 10. Remove and discard bearing shell from cap.

11. Record colour code on bearing shell edge, discard

bearing shell.

12. Wipe crankshaft journal, connecting rod and bearing cap using a lint free cloth.

13. Inspect crankshaft journal for damage.

14. Check crankshaft journal for ovality using a micrometer and record journal diameters.

Installation

1. Select the correct colour coded bearing shells for each connecting rod crankshaft journal.

2. Install new selective bearing shell in connecting rod.

3. Lubricate crankshaft journal with clean engine oil.

4. Install connecting rod on crankshaft journal.

5. Remove special tools (303-535) from connecting rod.

6. Install new selective bearing shell in bearing cap.

7. Install bearing cap and new bolts (x2), torque tighten bearing cap bolts.

8. Repeat procedure for remaining connecting rod bearings.

9. Install windage tray to engine bedplate, install and torque tighten bolts (x8).

10. Install spark plugs (see Workshop Manual procedure 03.07.DB Spark Plugs - Engine Set - Renew).

11. Install engine oil sump (see Workshop Manual

procedure 03.02.BN Pan - Oil Sump - Remove and re-

seal).

Crankshaft Main Bearing-Renew (Engine

Set)

Removal

1. Remove bolts (x2), inspection cover to lower crankcase, remove cover.

2. Install tool (303-1185) to restrain flywheel, install and tighten bolts (x2).

3. Remove bolts (x6), clutch cover to flywheel.

4. Release clutch cover from dowels (x3), remove clutch cover, collect drive plate.

5. Remove and discard bolts (x8), flywheel to crankshaft flange.

6. Remove bolts (x2), collect tool (303-1185).

Repair Operation Time (ROT)

WA R N I N G

DO NOT GET USED ENGINE OIL ON YOUR SKIN. USED ENGINE OIL CAN BE HARMFUL.

Caution

Pistons, connecting rods an d connecting rod bearings

should be numbered to make sure they are reassembled

in the same position.

Caution

Connecting rod bolts are tor qu

e tightened to yield and

mu st be replaced.

A0311314

Note: Connecting rod bearings ar e a selective fit by colour

code on edge of bearing shell.

Caution

When assembling connecting rods and connecting rod

bearing caps it is imperative that bearing slots and tangs

be located on the same side of the connecting rods.

Repair Operation Time (ROT)

Page 752 of 947

Torque Figures

Appendix & Glossary

May 2007 Workshop Manual 20-1-13

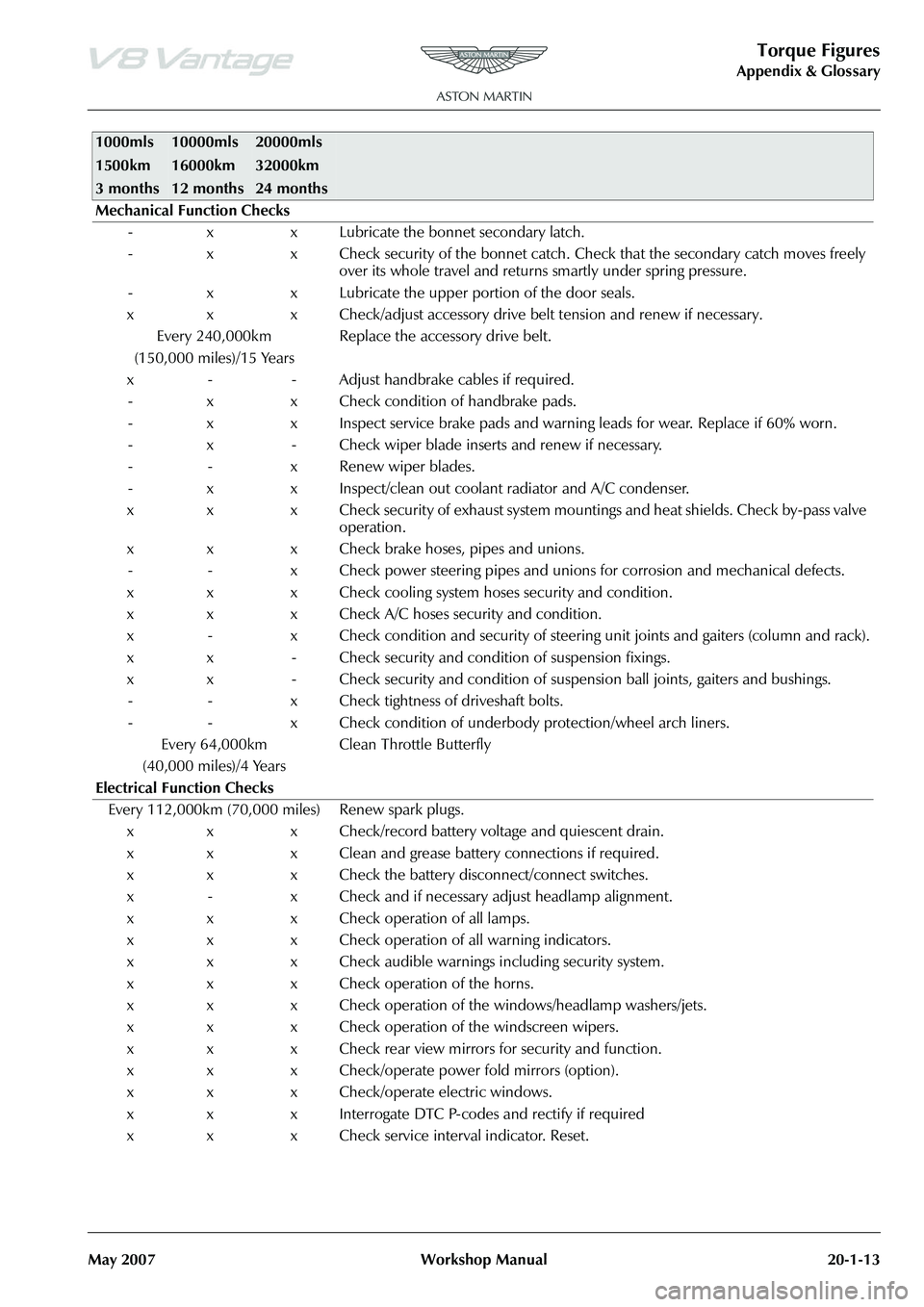

Mechanical Function Checks - x x Lubricate the bonnet secondary latch.

- x x Check security of the bonnet catch. Ch eck that the secondary catch moves freely

over its whole travel and returns smartly under spring pressure.

- x x Lubricate the upper portion of the door seals.

x x x Check/adjust accessory drive belt tension and renew if necessary. Every 240,000km

(150,000 miles)/15 Years Replace the accessory drive belt.

x - - Adjust handbrake cables if required. - x x Check condition of handbrake pads.

- x x Inspect service brake pads and warnin g leads for wear. Replace if 60% worn.

- x - Check wiper blade inserts and renew if necessary.

- - x Renew wiper blades.

- x x Inspect/clean out coolant radiator and A/C condenser.

x x x Check security of exhaust system mountings and heat shields. Check by-pass valve operation.

x x x Check brake hoses, pipes and unions. - - x Check power steering pipes and unions for corrosion and mechanical defects.

x x x Check cooling system hoses security and condition.

x x x Check A/C hoses security and condition.

x - x Check condition and security of steering unit joints and gaiters (column and rack).

x x - Check security and condition of suspension fixings.

x x - Check security and condition of susp ension ball joints, gaiters and bushings.

- - x Check tightness of driveshaft bolts.

- - x Check condition of underbody protection/wheel arch liners.

Every 64,000km

(40,000 miles)/4 Years Clean Throttle Butterfly

Electrical Function Checks Every 112,000km (70,000 miles) Renew spark plugs. x x x Check/record battery voltage and quiescent drain.

x x x Clean and grease battery connections if required.

x x x Check the battery disconnect/connect switches.

x - x Check and if necessary adjust headlamp alignment.

x x x Check operation of all lamps.

x x x Check operation of all warning indicators.

x x x Check audible warnings including security system.

x x x Check operation of the horns.

x x x Check operation of the windows/headlamp washers/jets.

x x x Check operation of the windscreen wipers.

x x x Check rear view mirrors for security and function.

x x x Check/operate power fold mirrors (option).

x x x Check/operate electric windows.

x x x Interrogate DTC P-codes and rectify if required

x x x Check service interval indicator. Reset.

1000mls

1500km

3 months10000mls

16000km

12 months20000mls

32000km

24 months